Professional Documents

Culture Documents

Section I: Material Safety Data Sheet Date of Preparation: 02/11/11 6010000

Section I: Material Safety Data Sheet Date of Preparation: 02/11/11 6010000

Uploaded by

sebaversaCopyright:

Available Formats

You might also like

- Aerosol Paint MsdsDocument6 pagesAerosol Paint MsdsParviz Nasirov50% (4)

- Material Safety Data Sheet Date of Preparation: 2/11/11 6393000Document2 pagesMaterial Safety Data Sheet Date of Preparation: 2/11/11 6393000sebaversaNo ratings yet

- MSDS TBBS Nouvel AccélérantDocument6 pagesMSDS TBBS Nouvel AccélérantJean GrégoireNo ratings yet

- MSDS 15W40Document4 pagesMSDS 15W40Sukhjeet SinghNo ratings yet

- Material Safety Data Sheet: Section 1: Product IdentificationDocument7 pagesMaterial Safety Data Sheet: Section 1: Product Identificationcvolkan1No ratings yet

- Msds of Spraytech OilDocument4 pagesMsds of Spraytech OilNesscel Ann Piquero DonkDonkNo ratings yet

- MSD Eg 20Document5 pagesMSD Eg 20Julio MendezNo ratings yet

- Muriatic Acid MSDSDocument8 pagesMuriatic Acid MSDSKim MalangNo ratings yet

- Dr. P. Clean MSDSDocument6 pagesDr. P. Clean MSDSjayand_netNo ratings yet

- Msds - Hfo Heavy Fuel OilDocument9 pagesMsds - Hfo Heavy Fuel OilKrishnan RajappanNo ratings yet

- Msds H2so4Document5 pagesMsds H2so4Rahasia Tahu RahasiaNo ratings yet

- MSDS AlumDocument5 pagesMSDS Alumdhinda clariestaNo ratings yet

- Material Safety Data Sheet: Tolylene 2,4-DiisocyanateDocument4 pagesMaterial Safety Data Sheet: Tolylene 2,4-DiisocyanateKaka BabaNo ratings yet

- Bitzer BSE 170 EngDocument7 pagesBitzer BSE 170 EngJoão RodrigoNo ratings yet

- All Purpose Thinner Sep11Document4 pagesAll Purpose Thinner Sep11Paul De ChaufepieNo ratings yet

- MSDS SurfactantDocument8 pagesMSDS SurfactantTrue StoryNo ratings yet

- CLR Bath Kitchen Cleaner 740319-3-19 PDFDocument7 pagesCLR Bath Kitchen Cleaner 740319-3-19 PDFYoutube For EducationNo ratings yet

- Material Safety Data Sheet: Section 1 - Chemical Product / Company InformationDocument6 pagesMaterial Safety Data Sheet: Section 1 - Chemical Product / Company Informationceemore300No ratings yet

- Material Safety Data Sheet: 1. Chemical Product and Company IdentificationDocument5 pagesMaterial Safety Data Sheet: 1. Chemical Product and Company IdentificationEdgar Julio Sara TairoNo ratings yet

- 1107 Solvent No 1 1314174041Document8 pages1107 Solvent No 1 1314174041Renato AsNo ratings yet

- Sodium HydroxideDocument16 pagesSodium Hydroxidehitm357No ratings yet

- Used Oil MsdsDocument7 pagesUsed Oil Msdspequenita34No ratings yet

- Oleum EnglishDocument10 pagesOleum Englishhyde2520015754No ratings yet

- MSDSDocument9 pagesMSDSshishir4870No ratings yet

- Elkon Products - Silica Fume MSDS, April 2013Document11 pagesElkon Products - Silica Fume MSDS, April 2013Sigit PurwandiNo ratings yet

- Material Safety Data Sheet: I - Product IdentificationDocument8 pagesMaterial Safety Data Sheet: I - Product IdentificationHaris OktaviantoNo ratings yet

- Material Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationDocument7 pagesMaterial Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationTeresa SilvaNo ratings yet

- Carboline 890 Part ADocument6 pagesCarboline 890 Part AclintonNo ratings yet

- MSDS Kaigo Fuel Injection CleanerDocument6 pagesMSDS Kaigo Fuel Injection CleanerJhonAceMalauNo ratings yet

- Nalco Tri Act 1820Document13 pagesNalco Tri Act 1820anon_336536469No ratings yet

- Methanol MSDS PDFDocument10 pagesMethanol MSDS PDFPutriErvinaNo ratings yet

- MSDSDocument8 pagesMSDSsyamthemarinerNo ratings yet

- MSDSDocument6 pagesMSDSMuhammad Iqbal NiyaziNo ratings yet

- Msds - of - Bitumen 115-15Document7 pagesMsds - of - Bitumen 115-15digitalmarketingNo ratings yet

- Data Sheet - HFO Heavy Fuel OilDocument9 pagesData Sheet - HFO Heavy Fuel OilPierluigiBusettoNo ratings yet

- Safety Data Sheet Paint Master Aluminium: June 2011Document3 pagesSafety Data Sheet Paint Master Aluminium: June 2011Michael JoudalNo ratings yet

- Polyken 2019 PrimerDocument5 pagesPolyken 2019 Primernrd9771No ratings yet

- Paint Master Universal Undercoat - SDSDocument3 pagesPaint Master Universal Undercoat - SDSMichael JoudalNo ratings yet

- Material Safety Data Sheet: SECTION I. Chemical Product and Company IdentificationDocument6 pagesMaterial Safety Data Sheet: SECTION I. Chemical Product and Company IdentificationGhufran SaeedNo ratings yet

- Lubricant Oil and Grease List, MSDS For ChemicalsDocument19 pagesLubricant Oil and Grease List, MSDS For ChemicalsMuhammadPurnamaSugiriNo ratings yet

- Material Safety Data Sheet: Coupling GreaseDocument6 pagesMaterial Safety Data Sheet: Coupling GreaserefeiNo ratings yet

- Usa Safety Data Sheet: LORD Corporation 111 LORD Drive Cary, NC 27511-7923 USADocument6 pagesUsa Safety Data Sheet: LORD Corporation 111 LORD Drive Cary, NC 27511-7923 USALaura RodríguezNo ratings yet

- 1240 EnglishDocument8 pages1240 EnglishNikos StamopoulosNo ratings yet

- MSDS SolarguardDocument5 pagesMSDS SolarguardKeyleen LinaresNo ratings yet

- 302 1006 003 Make Up750ml MEK United StatesDocument8 pages302 1006 003 Make Up750ml MEK United StatesLeonor Virginia GalindezNo ratings yet

- MSDS Petropath LimeDocument8 pagesMSDS Petropath LimeAlok SinghNo ratings yet

- MSDS Reach Potassium Silico FluorideDocument6 pagesMSDS Reach Potassium Silico Fluoridesamir5yNo ratings yet

- 10 Tenths Race Coolant Inhibitor Rev 7.02 0515Document9 pages10 Tenths Race Coolant Inhibitor Rev 7.02 0515ᮛᮥᮞ᮪ᮓᮤ ᮎᮦᮎᮦᮕ᮪No ratings yet

- Stihl BioPlus Chain and Bar Oil Rev 0-0-0713Document10 pagesStihl BioPlus Chain and Bar Oil Rev 0-0-0713MolokoNo ratings yet

- Potassium HydroxideDocument10 pagesPotassium HydroxideSyahrul MtiNo ratings yet

- Msds Am 2cDocument5 pagesMsds Am 2cTony KhouryNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument14 pagesSafety Data Sheet: 1. IdentificationJivendra KumarNo ratings yet

- Material Safety Data Sheet: F-29, Liquid SanitizerDocument4 pagesMaterial Safety Data Sheet: F-29, Liquid SanitizerNiraNo ratings yet

- MSDS Kyoso Cutting OilDocument4 pagesMSDS Kyoso Cutting Oilachwan febriantoNo ratings yet

- Product Name: Sodium Hydroxide 10-50% Liquid-Rayon Grade: Material Safety Data SheetDocument6 pagesProduct Name: Sodium Hydroxide 10-50% Liquid-Rayon Grade: Material Safety Data SheetLiliana ComeriorensiNo ratings yet

- Section 1 Product Identification: Material Safety Data SheetDocument4 pagesSection 1 Product Identification: Material Safety Data SheetJery Setiadi maulanaNo ratings yet

- MSDS LBLA Glue SuperheroDocument7 pagesMSDS LBLA Glue SuperherotiffyoloNo ratings yet

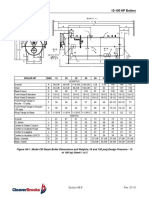

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)Document5 pagesModel CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)sebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDocument5 pagesModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDocument5 pagesModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Sound LevelDocument5 pagesModel CB 15-100 HP Boilers: Sound LevelsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: LightsDocument5 pagesModel CB 15-100 HP Boilers: LightssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocument5 pagesModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaNo ratings yet

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Engineering DataDocument5 pagesModel CBL 900-1800 HP Boilers: Engineering DatasebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Document6 pagesModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaNo ratings yet

- Section A5: Model CBL 900-1800 HP BoilersDocument5 pagesSection A5: Model CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizeDocument5 pagesModel CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizesebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDocument5 pagesModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaNo ratings yet

- Features and Benefits: Model CB 15-100 HP BoilersDocument5 pagesFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP BoilersDocument5 pagesModel CBR 125-800 HP BoilerssebaversaNo ratings yet

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocument5 pagesModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaNo ratings yet

- Model ICB 100-800 HP Boilers: Table A4-14. Model ICB Steam Boiler Safety Valve Outlet SizeDocument4 pagesModel ICB 100-800 HP Boilers: Table A4-14. Model ICB Steam Boiler Safety Valve Outlet SizesebaversaNo ratings yet

- Model CBL: 900 - 1800 HP Steam Wet-Back Package BurnerDocument5 pagesModel CBL: 900 - 1800 HP Steam Wet-Back Package BurnersebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 pagesModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaNo ratings yet

- General: Model ICB 100-800 HP BoilersDocument4 pagesGeneral: Model ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EDocument5 pagesModel CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EsebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimDocument4 pagesModel ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimsebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- Research ArticleDocument9 pagesResearch ArticlesebaversaNo ratings yet

- Word Find: Search Up, Down, Forward, Backward, and On The: Diagonal To Find The Hidden Words Related To Food IndustryDocument22 pagesWord Find: Search Up, Down, Forward, Backward, and On The: Diagonal To Find The Hidden Words Related To Food IndustryMaridelMujarNo ratings yet

- Laboratory Facilities, Quality Control, and Data Handling 3.1 Laboratory OrganizationDocument11 pagesLaboratory Facilities, Quality Control, and Data Handling 3.1 Laboratory OrganizationkhajeeNo ratings yet

- MSDS Rhodiamine 865 SLDocument7 pagesMSDS Rhodiamine 865 SLTirta MaulanaNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingDocument14 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingMark tettehNo ratings yet

- Specification of PPEDocument4 pagesSpecification of PPErjagdale79No ratings yet

- Operation SOP 47Document4 pagesOperation SOP 47pothanNo ratings yet

- Msds Thinner 91-83Document8 pagesMsds Thinner 91-83Omer ChaudhryNo ratings yet

- TR Agricultural Machinery Operation NC IIDocument97 pagesTR Agricultural Machinery Operation NC IIAljon BalanagNo ratings yet

- Kosto Lens Cleaning ToweletteDocument9 pagesKosto Lens Cleaning TowelettePubcrawlNo ratings yet

- PV System Operations and Maintenance Fundamentals: Solar America Board For Codes and StandardsDocument46 pagesPV System Operations and Maintenance Fundamentals: Solar America Board For Codes and StandardsEdmund YoongNo ratings yet

- RMI - RMAP ESG Standard For Mineral Supply Chains - June32021 - FINALDocument31 pagesRMI - RMAP ESG Standard For Mineral Supply Chains - June32021 - FINALHilman DarojatNo ratings yet

- 1Document16 pages1Saurabh PatelNo ratings yet

- 3-Part Spray Silver Reducer Concentrate SDS C2195Document9 pages3-Part Spray Silver Reducer Concentrate SDS C2195Niko BellikNo ratings yet

- How To Clean Mechanical PpeDocument2 pagesHow To Clean Mechanical PpeDetti FahmiasyariNo ratings yet

- Hse Requirement: Specification FORDocument28 pagesHse Requirement: Specification FORNizar EnnettaNo ratings yet

- Safety Data Sheet: 1 Identification of The Substance and of The CompanyDocument7 pagesSafety Data Sheet: 1 Identification of The Substance and of The CompanyGianpieroNo ratings yet

- WSH Council - Technical Advisory For DemolitionDocument16 pagesWSH Council - Technical Advisory For Demolitionlwin_oo2435No ratings yet

- HX130LCRDocument612 pagesHX130LCRГригорий ГригорянNo ratings yet

- SWIFS Firearms and Toolmarks Training Manual v1.1 (01.15.08) 271 PagesDocument271 pagesSWIFS Firearms and Toolmarks Training Manual v1.1 (01.15.08) 271 Pagesjac_blake100% (3)

- Safety Data Sheet: According To EC Directive 91/155/EECDocument6 pagesSafety Data Sheet: According To EC Directive 91/155/EECdalton2004No ratings yet

- Shipping Container PreservationDocument16 pagesShipping Container PreservationMohamed Sahnoun100% (1)

- 006R5-WMS-JI-MI-MAU-ACS-II-23 Working Method - Pile CapDocument20 pages006R5-WMS-JI-MI-MAU-ACS-II-23 Working Method - Pile CapEko Budi HartantoNo ratings yet

- Imd 100 Integration Manual 4189360015 UkDocument243 pagesImd 100 Integration Manual 4189360015 UkLUATNo ratings yet

- Expamet ConstructionDocument95 pagesExpamet Constructionanele_amisNo ratings yet

- JetBlack User Document V5 (115) Issue 7Document16 pagesJetBlack User Document V5 (115) Issue 7NSK SupportNo ratings yet

- Operating Jig SawDocument2 pagesOperating Jig SawgrantNo ratings yet

- Industrial Safety OutlineDocument16 pagesIndustrial Safety Outlinermallik1972No ratings yet

- Building Construction 1-4Document47 pagesBuilding Construction 1-4Beltran, Andrea Nicole E.No ratings yet

- RA Routing Fueling ProcessesDocument1 pageRA Routing Fueling Processesmohamed atefNo ratings yet

- MC-PH01-P04-06A03-SAB-MTS-CIV-000003 Method Statement For Blinding Concr...Document16 pagesMC-PH01-P04-06A03-SAB-MTS-CIV-000003 Method Statement For Blinding Concr...ehteshamNo ratings yet

Section I: Material Safety Data Sheet Date of Preparation: 02/11/11 6010000

Section I: Material Safety Data Sheet Date of Preparation: 02/11/11 6010000

Uploaded by

sebaversaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section I: Material Safety Data Sheet Date of Preparation: 02/11/11 6010000

Section I: Material Safety Data Sheet Date of Preparation: 02/11/11 6010000

Uploaded by

sebaversaCopyright:

Available Formats

*** MATERIAL SAFETY DATA SHEET ***

Date of preparation: 02/11/11

Page 1

6010000

SECTION I

Manufacturer

Address

: W. R. MEADOWS, INC.

: 300 Industrial Drive

: Hampshire, Illinois 60140

Telephone #

Emergency #

: (847) 683-4500

: 1-800-424-9300 Chemtrec

Product Class

Mfg. code I.D.

Trade Name

: DIVISION 7

: 6010000

: CATALYTIC BONDING ASPHALT

-HMIS|Health

|Flammability

|Reactivity

|Personal Protection

|1

|2

|0

|

|

|

|

|

(Hazard Rating: 0=Least,1=Slight,2=Moderate,3=High,4=Extreme,*=Chronic)

SECTION II-A

HAZARDOUS COMPONENTS

% by

SARA

VAPOR PRESSURE

LEL

No. Component

CAS#

Weight

313

(mm Hg @ 20 C)

(@ 25 C)

1.

Petroleum Asphalt

8052-42-4

80-85

NO

N/A

N/A

#2 Fuel Oil

64741-44-2

15-20

NO

5.00

0.70

2.

None of the components of this product are recognized as carcinogenic.

N/A = Not Applicable

Under the reporting requirements of Section 313 of Title III of the Superfund Amendments and Reauthorization Act of 1986 (SARA)

and 40 CFR Part 372, chemicals listed on the 313 List (40 CFR Part 373.65) are identified under the heading "SARA 313".

SECTION II-B

OCCUPATIONAL EXPOSURE LIMITS

OSHA

ACGIH

No. PEL/TWA

PEL/CEILING PEL/STEL SKIN

TLV/TWA

TLV/CEILING TLV/STEL

SKIN

1.

5 mg/m+

N/E

N/E

N/E

5 mg/m+

N/E

N/E

N/E

2.

5 mg/m*

N/E

N/E

N/E

5 mg/m*

N/E

10 mg/m*

N/E

Skin absorption may contribute to the overall exposure to this material. Take appropriate measures to prevent skin contact.

N/E = Not established

* = Mineral Oil mist in air

+ = Asphalt Fumes

SECTION III

Boiling Point

Evaporation Rate

Vapor Density

pH Level

SECTION IV

PHYSICAL DATA

: Not established

: < 1 (ether = 1)

: > 1 (air = 1)

: Not applicable

% Volatile by volume

% Volatile by weight

Weight per gallon

Product Appearance

: 22.23 (Theoretical)

: 18.75 (Theoretical)

: 8.04 (Theoretical)

: Black semi-solid

HEALTH INFORMATION

EYE CONTACT: Based on the presence of component 2 this product may cause eye irritation. Corneal injury is unlikely.

SKIN CONTACT: Exposure may cause mild skin irritation. Prolonged or repeated contact may cause redness, burning, drying, and cracking of the

skin. Persons with pre -existing skin disorders may be more susceptible to the effects of this material. Based on the presence of components 1 and 2

prolonged or repeated contact may result in defatting and drying of the skin which may result in dermatitis.

INHALATION: Based on the presence of component 1 prolonged inhalation of vapors should be avoided because of potential chronic effects. Based

on the presence of component 2 exposure to excessive vapor concentrations may cause signs of transient central nervous system depression

(e.g., headache, drowsiness, loss of coordination, and fatigue).

INGESTION: Ingestion may cause irritation of the gastrointestinal tract and/or ulceration/burns in the throat and mouth. Based on the presence of

component 2 ingestion may result in nausea, vomiting, diarr hea, and restlessness. Aspiration of vomitus into the lungs must be avoided as even small

quantities in the lungs can produce chemical pneumonitis and pulmonary edema/hemorrhage.

SIGNS AND SYMPTOMS: Symptoms of eye irritation include pain, tearing, reddeni ng, and swelling. Symptoms of skin irritation include reddening,

swelling, rash, and redness. Symptoms of respiratory irritation include runny nose, sore throat, coughing, chest discomfort, shortness of breath, and

reduced lung function. Symptoms of gastrointestinal irritation include sore throat, abdominal pain, nausea, vomiting, and diarrhea.

AGGRAVATED MEDICAL CONDITIONS: Pre-existing skin, eye, and respiratory disorders may be aggravated by exposure to this product.

OTHER HEALTH EFFECTS: From skin -painting studies in laboratory animals, it has been concluded that some asphalts may possess weak

carcinogenic activity. This means that workers who practice poor personal hygiene, and who are repeatedly exposed by direct skin contact

with

petroleum asphalt over many years, may potentially be at risk of developing skin cancer. Intermittent or occasional skin contact with petroleum asphalt

is not expected to have serious health effects as long as good personal hygiene measures, such as those outlined in this mate rial safety data sheet,

are followed. In addition, asphalt vapors may contain polycyclic aromatic hydrocarbons, some of which are known to be carcinogenic.

Therefore,

prolonged breathing of vapors should be avoided. From skin painting studies o f petroleum distillates similar to component 2, it has been shown that

these types of materials may demonstrate weak carcinogenic activity in laboratory animals. Therefore, there may be a potential risk of skin cancer

from prolonged/repeated contact in the absence of good personal hygiene pra ctices. During laboratory testing, the material was not washed off

between applications. Personal hygiene measures taken to prevent skin irritation are expected to be adequate to prevent the risk of cancer.

Date of preparation: 02/11/11

CATALYTIC BONDING ASPHALT

6010000

Page 1

*** MATERIAL SAFETY DATA SHEET ***

Date of preparation: 02/11/11

SECTION V

Page 2

6010000

EMERGENCY AND FIRST AID PROCEDURES

EYE CONTACT: If irritation or redness develops, move victim away from exposure source and into fresh air. Flush eyes with water for fifteen (15)

minutes. If symptoms persist, seek medical attention.

SKIN CONTACT: Wash with mild soap and water to remove condensed oil film. Do not use petroleum solvents to remove solid.

INHALATION: If respiratory symptoms develop, move victim away from exposure source and into fresh air. If symptoms persist, seek medical

attention. If victim is not breat hing, immediately begin artificial respiration. If breathing difficulties develop, oxygen should be administered by qualified

personnel. Seek immediate medical attention.

INGESTION: Do not induce vomiting. Vomiting will cause further damage to the throat. Dilute by giving water or milk to drink if the victim is conscious.

Consult a physician, hospital, or poison control center and/or transport to an emergency facility immediately.

SECTION VI

FLAMMABILITY CLASSIFICATION

FIRE AND EXPLOSION HAZARDS

- NFPA: Combustible Liquid Class IIIA

- DOT : Bulk Shipments Only; Combustible Liquid, N.O.S. (#2 Fuel Oil) NA 1993, III

FLASH POINT: 150 degrees F

EXTINGUISHING MEDIA: Use water fog, foam, dry chemical, or Carbon Dioxide.

SPECIAL FIRE FIGHTING PROCEDURES AND PRECAUTIONS: WARNING : COMBUSTIBLE. Clear area of unprotected personnel. Do no t enter

confined fire space without helmet, face shield, bunker coat, gloves, rubber boots, and a positive pressure NIOSH approved self -contained breathing

apparatus.

UNUSUAL FIRE AND EXPLOSION HAZARDS: Containers exposed to intense heat from fires should be cooled with water to prevent vapor pressure

buildup which could result in container rupture . Container area exposed to direct flame contact should be cooled with large quantities of water as

needed to prevent weakening of container structure.

SECTION VII

REACTIVITY

STABILITY: Stable

HAZARDOUS POLYMERIZATION: Will not occur

CONDITIONS AND MATERIALS TO AVOID: Avoid oxidizing materials.

HAZARDOUS DECOMPOSITION PRODUCTS: Oxides and compounds of Nitrogen, Oxides and compounds of Sulfur. Combustion may yield Carbon

Dioxide, Carbon Monoxide, and/or incomplete combustion products. Do not breathe smoke or fumes. Wear appropriate protective equipment.

SECTION VIII

EMPLOYEE PROTECTION

RESPIRATORY PROTECTION: Use ventilation as required to control vapor concentrations - at least 10 air changes per hour are recommended for

good general room ventilation. If exposure exceeds the PEL/TLV, use the appropriate NIOSH approved respirator.

PROTECTIVE CLOTHING: Wear safety glasses, goggles, or a splash shield to prevent eye contact. Contact lenses should not be worn. Wear

appropriate gloves and protective clothing to prevent contact with skin and clothing.

ADDITIONAL PROTECTIVE MEASURES: Eye wash fountains and safety showers should be available for use in an emergency.

SECTION IX

ENVIRONMENTAL PROTECTION

SPILL OR LEAK PROCEDURES: LARGE SPILLS>> Evacuate the hazard area of unprotected personnel. Wear appropriate respirator and protective

clothing. Shut off source of leak only if safe to do so. Dike and contain. Remove/extinguish ignition sources. If vapor cloud forms, water fog may be

used to suppress; contain run-off. Remove with vacuum trucks or pump to storage/salvage vessels. Soak up residue with an absorbent such as

clay, sand, or other suitable material; place in non-leaking containers for proper disposal. Flush area with water to remove trace residue; dispose of

flush solutions as above. SMALL SPILLS>> Take up with an absorbent material and place in non-leaking containers; seal tightly for proper disposal.

WASTE DISPOSAL: Observe all Federal, State and local regulations regarding proper disposal.

SECTION X

ADDITIONAL PRECAUTIONS

Keep liquid and vapor away from heat, sparks, and flame. Extinguish pilot lights, cigarettes, and turn off other possible sources of ignition prior to use

and until vapors are gone. Surfaces that are sufficiently hot may ignite product in the absence of sparks or flame. Vapors may accumulate and travel

to ignition sources distant from the handling site. Keep containers closed when not in use. Use with adequate ventilation. Containers, even if empty,

can contain explosive vapors. Do not cut, drill, grind or weld near containers. Containers can contain hazardous product residues even when empty.

Wash with soap and water before eating, drinking, smoking or using toilet facilities.

The information contained herein is based on the data available to us and is believed to be correct.

However, we make no warranty, expressed or implied regarding the accuracy of this data or the results to

be obtained from the use thereof. We assume no responsibility for injury from the use of the product

described herein.

Date of preparation: 02/11/11

CATALYTIC BONDING ASPHALT

6010000

Page 2

You might also like

- Aerosol Paint MsdsDocument6 pagesAerosol Paint MsdsParviz Nasirov50% (4)

- Material Safety Data Sheet Date of Preparation: 2/11/11 6393000Document2 pagesMaterial Safety Data Sheet Date of Preparation: 2/11/11 6393000sebaversaNo ratings yet

- MSDS TBBS Nouvel AccélérantDocument6 pagesMSDS TBBS Nouvel AccélérantJean GrégoireNo ratings yet

- MSDS 15W40Document4 pagesMSDS 15W40Sukhjeet SinghNo ratings yet

- Material Safety Data Sheet: Section 1: Product IdentificationDocument7 pagesMaterial Safety Data Sheet: Section 1: Product Identificationcvolkan1No ratings yet

- Msds of Spraytech OilDocument4 pagesMsds of Spraytech OilNesscel Ann Piquero DonkDonkNo ratings yet

- MSD Eg 20Document5 pagesMSD Eg 20Julio MendezNo ratings yet

- Muriatic Acid MSDSDocument8 pagesMuriatic Acid MSDSKim MalangNo ratings yet

- Dr. P. Clean MSDSDocument6 pagesDr. P. Clean MSDSjayand_netNo ratings yet

- Msds - Hfo Heavy Fuel OilDocument9 pagesMsds - Hfo Heavy Fuel OilKrishnan RajappanNo ratings yet

- Msds H2so4Document5 pagesMsds H2so4Rahasia Tahu RahasiaNo ratings yet

- MSDS AlumDocument5 pagesMSDS Alumdhinda clariestaNo ratings yet

- Material Safety Data Sheet: Tolylene 2,4-DiisocyanateDocument4 pagesMaterial Safety Data Sheet: Tolylene 2,4-DiisocyanateKaka BabaNo ratings yet

- Bitzer BSE 170 EngDocument7 pagesBitzer BSE 170 EngJoão RodrigoNo ratings yet

- All Purpose Thinner Sep11Document4 pagesAll Purpose Thinner Sep11Paul De ChaufepieNo ratings yet

- MSDS SurfactantDocument8 pagesMSDS SurfactantTrue StoryNo ratings yet

- CLR Bath Kitchen Cleaner 740319-3-19 PDFDocument7 pagesCLR Bath Kitchen Cleaner 740319-3-19 PDFYoutube For EducationNo ratings yet

- Material Safety Data Sheet: Section 1 - Chemical Product / Company InformationDocument6 pagesMaterial Safety Data Sheet: Section 1 - Chemical Product / Company Informationceemore300No ratings yet

- Material Safety Data Sheet: 1. Chemical Product and Company IdentificationDocument5 pagesMaterial Safety Data Sheet: 1. Chemical Product and Company IdentificationEdgar Julio Sara TairoNo ratings yet

- 1107 Solvent No 1 1314174041Document8 pages1107 Solvent No 1 1314174041Renato AsNo ratings yet

- Sodium HydroxideDocument16 pagesSodium Hydroxidehitm357No ratings yet

- Used Oil MsdsDocument7 pagesUsed Oil Msdspequenita34No ratings yet

- Oleum EnglishDocument10 pagesOleum Englishhyde2520015754No ratings yet

- MSDSDocument9 pagesMSDSshishir4870No ratings yet

- Elkon Products - Silica Fume MSDS, April 2013Document11 pagesElkon Products - Silica Fume MSDS, April 2013Sigit PurwandiNo ratings yet

- Material Safety Data Sheet: I - Product IdentificationDocument8 pagesMaterial Safety Data Sheet: I - Product IdentificationHaris OktaviantoNo ratings yet

- Material Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationDocument7 pagesMaterial Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationTeresa SilvaNo ratings yet

- Carboline 890 Part ADocument6 pagesCarboline 890 Part AclintonNo ratings yet

- MSDS Kaigo Fuel Injection CleanerDocument6 pagesMSDS Kaigo Fuel Injection CleanerJhonAceMalauNo ratings yet

- Nalco Tri Act 1820Document13 pagesNalco Tri Act 1820anon_336536469No ratings yet

- Methanol MSDS PDFDocument10 pagesMethanol MSDS PDFPutriErvinaNo ratings yet

- MSDSDocument8 pagesMSDSsyamthemarinerNo ratings yet

- MSDSDocument6 pagesMSDSMuhammad Iqbal NiyaziNo ratings yet

- Msds - of - Bitumen 115-15Document7 pagesMsds - of - Bitumen 115-15digitalmarketingNo ratings yet

- Data Sheet - HFO Heavy Fuel OilDocument9 pagesData Sheet - HFO Heavy Fuel OilPierluigiBusettoNo ratings yet

- Safety Data Sheet Paint Master Aluminium: June 2011Document3 pagesSafety Data Sheet Paint Master Aluminium: June 2011Michael JoudalNo ratings yet

- Polyken 2019 PrimerDocument5 pagesPolyken 2019 Primernrd9771No ratings yet

- Paint Master Universal Undercoat - SDSDocument3 pagesPaint Master Universal Undercoat - SDSMichael JoudalNo ratings yet

- Material Safety Data Sheet: SECTION I. Chemical Product and Company IdentificationDocument6 pagesMaterial Safety Data Sheet: SECTION I. Chemical Product and Company IdentificationGhufran SaeedNo ratings yet

- Lubricant Oil and Grease List, MSDS For ChemicalsDocument19 pagesLubricant Oil and Grease List, MSDS For ChemicalsMuhammadPurnamaSugiriNo ratings yet

- Material Safety Data Sheet: Coupling GreaseDocument6 pagesMaterial Safety Data Sheet: Coupling GreaserefeiNo ratings yet

- Usa Safety Data Sheet: LORD Corporation 111 LORD Drive Cary, NC 27511-7923 USADocument6 pagesUsa Safety Data Sheet: LORD Corporation 111 LORD Drive Cary, NC 27511-7923 USALaura RodríguezNo ratings yet

- 1240 EnglishDocument8 pages1240 EnglishNikos StamopoulosNo ratings yet

- MSDS SolarguardDocument5 pagesMSDS SolarguardKeyleen LinaresNo ratings yet

- 302 1006 003 Make Up750ml MEK United StatesDocument8 pages302 1006 003 Make Up750ml MEK United StatesLeonor Virginia GalindezNo ratings yet

- MSDS Petropath LimeDocument8 pagesMSDS Petropath LimeAlok SinghNo ratings yet

- MSDS Reach Potassium Silico FluorideDocument6 pagesMSDS Reach Potassium Silico Fluoridesamir5yNo ratings yet

- 10 Tenths Race Coolant Inhibitor Rev 7.02 0515Document9 pages10 Tenths Race Coolant Inhibitor Rev 7.02 0515ᮛᮥᮞ᮪ᮓᮤ ᮎᮦᮎᮦᮕ᮪No ratings yet

- Stihl BioPlus Chain and Bar Oil Rev 0-0-0713Document10 pagesStihl BioPlus Chain and Bar Oil Rev 0-0-0713MolokoNo ratings yet

- Potassium HydroxideDocument10 pagesPotassium HydroxideSyahrul MtiNo ratings yet

- Msds Am 2cDocument5 pagesMsds Am 2cTony KhouryNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument14 pagesSafety Data Sheet: 1. IdentificationJivendra KumarNo ratings yet

- Material Safety Data Sheet: F-29, Liquid SanitizerDocument4 pagesMaterial Safety Data Sheet: F-29, Liquid SanitizerNiraNo ratings yet

- MSDS Kyoso Cutting OilDocument4 pagesMSDS Kyoso Cutting Oilachwan febriantoNo ratings yet

- Product Name: Sodium Hydroxide 10-50% Liquid-Rayon Grade: Material Safety Data SheetDocument6 pagesProduct Name: Sodium Hydroxide 10-50% Liquid-Rayon Grade: Material Safety Data SheetLiliana ComeriorensiNo ratings yet

- Section 1 Product Identification: Material Safety Data SheetDocument4 pagesSection 1 Product Identification: Material Safety Data SheetJery Setiadi maulanaNo ratings yet

- MSDS LBLA Glue SuperheroDocument7 pagesMSDS LBLA Glue SuperherotiffyoloNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)Document5 pagesModel CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)sebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDocument5 pagesModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDocument5 pagesModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Sound LevelDocument5 pagesModel CB 15-100 HP Boilers: Sound LevelsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: LightsDocument5 pagesModel CB 15-100 HP Boilers: LightssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocument5 pagesModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaNo ratings yet

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Engineering DataDocument5 pagesModel CBL 900-1800 HP Boilers: Engineering DatasebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Document6 pagesModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaNo ratings yet

- Section A5: Model CBL 900-1800 HP BoilersDocument5 pagesSection A5: Model CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizeDocument5 pagesModel CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizesebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDocument5 pagesModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaNo ratings yet

- Features and Benefits: Model CB 15-100 HP BoilersDocument5 pagesFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP BoilersDocument5 pagesModel CBR 125-800 HP BoilerssebaversaNo ratings yet

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocument5 pagesModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaNo ratings yet

- Model ICB 100-800 HP Boilers: Table A4-14. Model ICB Steam Boiler Safety Valve Outlet SizeDocument4 pagesModel ICB 100-800 HP Boilers: Table A4-14. Model ICB Steam Boiler Safety Valve Outlet SizesebaversaNo ratings yet

- Model CBL: 900 - 1800 HP Steam Wet-Back Package BurnerDocument5 pagesModel CBL: 900 - 1800 HP Steam Wet-Back Package BurnersebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 pagesModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaNo ratings yet

- General: Model ICB 100-800 HP BoilersDocument4 pagesGeneral: Model ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EDocument5 pagesModel CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EsebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimDocument4 pagesModel ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimsebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- Research ArticleDocument9 pagesResearch ArticlesebaversaNo ratings yet

- Word Find: Search Up, Down, Forward, Backward, and On The: Diagonal To Find The Hidden Words Related To Food IndustryDocument22 pagesWord Find: Search Up, Down, Forward, Backward, and On The: Diagonal To Find The Hidden Words Related To Food IndustryMaridelMujarNo ratings yet

- Laboratory Facilities, Quality Control, and Data Handling 3.1 Laboratory OrganizationDocument11 pagesLaboratory Facilities, Quality Control, and Data Handling 3.1 Laboratory OrganizationkhajeeNo ratings yet

- MSDS Rhodiamine 865 SLDocument7 pagesMSDS Rhodiamine 865 SLTirta MaulanaNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingDocument14 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingMark tettehNo ratings yet

- Specification of PPEDocument4 pagesSpecification of PPErjagdale79No ratings yet

- Operation SOP 47Document4 pagesOperation SOP 47pothanNo ratings yet

- Msds Thinner 91-83Document8 pagesMsds Thinner 91-83Omer ChaudhryNo ratings yet

- TR Agricultural Machinery Operation NC IIDocument97 pagesTR Agricultural Machinery Operation NC IIAljon BalanagNo ratings yet

- Kosto Lens Cleaning ToweletteDocument9 pagesKosto Lens Cleaning TowelettePubcrawlNo ratings yet

- PV System Operations and Maintenance Fundamentals: Solar America Board For Codes and StandardsDocument46 pagesPV System Operations and Maintenance Fundamentals: Solar America Board For Codes and StandardsEdmund YoongNo ratings yet

- RMI - RMAP ESG Standard For Mineral Supply Chains - June32021 - FINALDocument31 pagesRMI - RMAP ESG Standard For Mineral Supply Chains - June32021 - FINALHilman DarojatNo ratings yet

- 1Document16 pages1Saurabh PatelNo ratings yet

- 3-Part Spray Silver Reducer Concentrate SDS C2195Document9 pages3-Part Spray Silver Reducer Concentrate SDS C2195Niko BellikNo ratings yet

- How To Clean Mechanical PpeDocument2 pagesHow To Clean Mechanical PpeDetti FahmiasyariNo ratings yet

- Hse Requirement: Specification FORDocument28 pagesHse Requirement: Specification FORNizar EnnettaNo ratings yet

- Safety Data Sheet: 1 Identification of The Substance and of The CompanyDocument7 pagesSafety Data Sheet: 1 Identification of The Substance and of The CompanyGianpieroNo ratings yet

- WSH Council - Technical Advisory For DemolitionDocument16 pagesWSH Council - Technical Advisory For Demolitionlwin_oo2435No ratings yet

- HX130LCRDocument612 pagesHX130LCRГригорий ГригорянNo ratings yet

- SWIFS Firearms and Toolmarks Training Manual v1.1 (01.15.08) 271 PagesDocument271 pagesSWIFS Firearms and Toolmarks Training Manual v1.1 (01.15.08) 271 Pagesjac_blake100% (3)

- Safety Data Sheet: According To EC Directive 91/155/EECDocument6 pagesSafety Data Sheet: According To EC Directive 91/155/EECdalton2004No ratings yet

- Shipping Container PreservationDocument16 pagesShipping Container PreservationMohamed Sahnoun100% (1)

- 006R5-WMS-JI-MI-MAU-ACS-II-23 Working Method - Pile CapDocument20 pages006R5-WMS-JI-MI-MAU-ACS-II-23 Working Method - Pile CapEko Budi HartantoNo ratings yet

- Imd 100 Integration Manual 4189360015 UkDocument243 pagesImd 100 Integration Manual 4189360015 UkLUATNo ratings yet

- Expamet ConstructionDocument95 pagesExpamet Constructionanele_amisNo ratings yet

- JetBlack User Document V5 (115) Issue 7Document16 pagesJetBlack User Document V5 (115) Issue 7NSK SupportNo ratings yet

- Operating Jig SawDocument2 pagesOperating Jig SawgrantNo ratings yet

- Industrial Safety OutlineDocument16 pagesIndustrial Safety Outlinermallik1972No ratings yet

- Building Construction 1-4Document47 pagesBuilding Construction 1-4Beltran, Andrea Nicole E.No ratings yet

- RA Routing Fueling ProcessesDocument1 pageRA Routing Fueling Processesmohamed atefNo ratings yet

- MC-PH01-P04-06A03-SAB-MTS-CIV-000003 Method Statement For Blinding Concr...Document16 pagesMC-PH01-P04-06A03-SAB-MTS-CIV-000003 Method Statement For Blinding Concr...ehteshamNo ratings yet