Professional Documents

Culture Documents

2013 Year in Review Art

2013 Year in Review Art

Uploaded by

brandonloganCopyright:

Available Formats

You might also like

- Africa and Its Global Diaspora (2017) PDFDocument380 pagesAfrica and Its Global Diaspora (2017) PDFdanamilicNo ratings yet

- Internship Report On AKRSPDocument83 pagesInternship Report On AKRSPhaikel jan67% (3)

- Cecd, Edfp: Professional ExperienceDocument4 pagesCecd, Edfp: Professional ExperienceIsland Packet and Beaufort GazetteNo ratings yet

- Open For Business Magazine April / May 15Document15 pagesOpen For Business Magazine April / May 15Eugene Area Chamber of Commerce CommunicationsNo ratings yet

- The Setx Times: EconomicDocument4 pagesThe Setx Times: EconomicCharlie FoxworthNo ratings yet

- Section I: Organizational Overview: Raison D'êtreDocument20 pagesSection I: Organizational Overview: Raison D'êtreShan KhingNo ratings yet

- Open For Business Magazine - August/September 12 IssueDocument13 pagesOpen For Business Magazine - August/September 12 IssueEugene Area Chamber of Commerce CommunicationsNo ratings yet

- Top 10 Companies in The Philippines JaysonDocument4 pagesTop 10 Companies in The Philippines JaysonJayson Lopez FloresNo ratings yet

- Manufacturing Operations Improvement President in FT Wayne IN Resume Kevin EarlyDocument3 pagesManufacturing Operations Improvement President in FT Wayne IN Resume Kevin EarlyKevinEarlyNo ratings yet

- GLIInvestorReport 2011Document38 pagesGLIInvestorReport 2011Chris OttsNo ratings yet

- Environmental & Social Report : Kanto Auto Works, LTDDocument39 pagesEnvironmental & Social Report : Kanto Auto Works, LTDdist2235No ratings yet

- Vice President Supply Chain in NYC New Jersey Resume Jeffrey WallingDocument4 pagesVice President Supply Chain in NYC New Jersey Resume Jeffrey WallingJeffreyWallingNo ratings yet

- VP Finance Consumer Goods in New York City Resume Edward HoulihanDocument2 pagesVP Finance Consumer Goods in New York City Resume Edward HoulihanEdwardHoulihanNo ratings yet

- Ge Investor Communications Brochure 2q2007Document6 pagesGe Investor Communications Brochure 2q2007cvan65No ratings yet

- 2012 Progress B SectionDocument8 pages2012 Progress B SectionThe Delphos HeraldNo ratings yet

- Business Support Panel ReportDocument179 pagesBusiness Support Panel ReportPostmediaNo ratings yet

- Peter Laybourn - Industrial Symbiosis in ActionDocument14 pagesPeter Laybourn - Industrial Symbiosis in ActionMauricio CastroNo ratings yet

- Executive SummaryDocument17 pagesExecutive SummaryCayla HarrisNo ratings yet

- Monica Soileau Relevant Community Leader AccomplishmentsDocument11 pagesMonica Soileau Relevant Community Leader AccomplishmentsMonica SoileauNo ratings yet

- Ramores, Kaith Marjorie T. BSA51 Ayala Corporation'S Sustainability Report (2008) : A Review I. Brief Company OverviewDocument2 pagesRamores, Kaith Marjorie T. BSA51 Ayala Corporation'S Sustainability Report (2008) : A Review I. Brief Company OverviewNevan NovaNo ratings yet

- CIT Annual Report 2011 - FINALDocument16 pagesCIT Annual Report 2011 - FINALstephaniebouchNo ratings yet

- 2010 Community Report: Opportunities RealizedDocument16 pages2010 Community Report: Opportunities RealizedAnonymous Feglbx5No ratings yet

- ROI Overview Feb10Document9 pagesROI Overview Feb10teampaNo ratings yet

- About AyalaDocument6 pagesAbout AyalaRia BagoNo ratings yet

- Annual ReportDocument24 pagesAnnual ReportAnonymous Feglbx5No ratings yet

- General ElectricDocument8 pagesGeneral ElectricAnjali Daisy100% (1)

- Veolia Environmental Services North AmericaDocument4 pagesVeolia Environmental Services North AmericajohnribarNo ratings yet

- Full ReportDocument66 pagesFull ReportshanzarapunzleNo ratings yet

- Mare-Producator-Auto-Transformat-Intr-Colos-Picioare-Lut - HTM Creation: 1897-1909Document4 pagesMare-Producator-Auto-Transformat-Intr-Colos-Picioare-Lut - HTM Creation: 1897-1909Ionel GNo ratings yet

- Overall Equipment Effectiveness:: Guidelines For The CPG Industry and Its SuppliersDocument21 pagesOverall Equipment Effectiveness:: Guidelines For The CPG Industry and Its Suppliers18085012No ratings yet

- CSE Fellows Application - Matias SolariDocument2 pagesCSE Fellows Application - Matias Solarimsolari2006No ratings yet

- COO VP Operations Consultant in UT Resume Cynthia Pressley-SheltonDocument7 pagesCOO VP Operations Consultant in UT Resume Cynthia Pressley-SheltonCynthiaPressleySheltNo ratings yet

- EcDev JournalDocument4 pagesEcDev JournalAishah ImranNo ratings yet

- Gov. Cuomo Office - Economic Development FundingDocument22 pagesGov. Cuomo Office - Economic Development FundingerikvsorensenNo ratings yet

- Human Resources Director in Phoenix AZ Resume Eileen LileDocument2 pagesHuman Resources Director in Phoenix AZ Resume Eileen LileEileenLileNo ratings yet

- A Study On Labour Welfare Services With Reference To Wheels India LimitedDocument37 pagesA Study On Labour Welfare Services With Reference To Wheels India LimitedumajayakarthickNo ratings yet

- Chevron Announces L .4 Billion Pascagoula Base Oil ProjectDocument8 pagesChevron Announces L .4 Billion Pascagoula Base Oil ProjectHoang NamNo ratings yet

- Progressive Waste SolutionsDocument4 pagesProgressive Waste SolutionsjohnribarNo ratings yet

- CSR As A Business Strategy: BSR Identifies Five Key Trends in CSRDocument4 pagesCSR As A Business Strategy: BSR Identifies Five Key Trends in CSRfrancistsyNo ratings yet

- Dec 2012 NewsletterpdfDocument4 pagesDec 2012 NewsletterpdfRich PirrottaNo ratings yet

- Veolia Water North America Case Study: The SituationDocument9 pagesVeolia Water North America Case Study: The SituationMARSNo ratings yet

- AECOM Case Study ReportDocument21 pagesAECOM Case Study ReportjohnNo ratings yet

- Washington Innovation Partnership Zones - 2012 CSG Innovations Award WinnerDocument4 pagesWashington Innovation Partnership Zones - 2012 CSG Innovations Award Winnerbvoit1895No ratings yet

- HITO 2005 Annual ReportDocument20 pagesHITO 2005 Annual ReportHITONo ratings yet

- New Instructor Brings Big Changes To CAVC Food Service ProgramDocument2 pagesNew Instructor Brings Big Changes To CAVC Food Service ProgramAnonymous tqFrRpQvTHNo ratings yet

- The Michigan Banner December 16, 2011 EditionDocument32 pagesThe Michigan Banner December 16, 2011 EditiontangramtechNo ratings yet

- Applied MaterialsDocument5 pagesApplied MaterialsAryan PandeyNo ratings yet

- 2009 2010 Business Nonprofit CriteriaDocument88 pages2009 2010 Business Nonprofit CriteriabearbearkhooNo ratings yet

- Employee Welfare Management - Basha PDFDocument44 pagesEmployee Welfare Management - Basha PDFL. V B ReddyNo ratings yet

- Ayala 2013 Annual ReportDocument265 pagesAyala 2013 Annual ReportWynmar Kevyn MarquezNo ratings yet

- Math 12 BESR ABM Q2-Week 5Document14 pagesMath 12 BESR ABM Q2-Week 5SHEENA MAE DALGUNTAS100% (2)

- BSC Oxford Brookes Acca Thesis SampleDocument5 pagesBSC Oxford Brookes Acca Thesis Samplef6a5mww8100% (2)

- Project ProposalDocument3 pagesProject ProposalPam ExquisitesNo ratings yet

- Business Journal March 2012 A SectionDocument8 pagesBusiness Journal March 2012 A SectionThe Delphos HeraldNo ratings yet

- PTC Final ProjectDocument40 pagesPTC Final ProjectRehan Yousaf60% (5)

- ZForce NovDec 2015 ENGDocument13 pagesZForce NovDec 2015 ENGwesleitigerNo ratings yet

- CSV WebinarDocument22 pagesCSV WebinarNeusa RavarotoNo ratings yet

- An Executive's Guide to Fundraising Operations: Principles, Tools, and TrendsFrom EverandAn Executive's Guide to Fundraising Operations: Principles, Tools, and TrendsNo ratings yet

- Boosting Gender Equality Through ADB Trade Finance PartnershipsFrom EverandBoosting Gender Equality Through ADB Trade Finance PartnershipsNo ratings yet

- Talent Keepers: How Top Leaders Engage and Retain Their Best PerformersFrom EverandTalent Keepers: How Top Leaders Engage and Retain Their Best PerformersNo ratings yet

- Enhancing Energy-Based Livelihoods for Women Micro-Entrepreneurs: India Gender Equality Results Case StudyFrom EverandEnhancing Energy-Based Livelihoods for Women Micro-Entrepreneurs: India Gender Equality Results Case StudyNo ratings yet

- The Role of State of SingaporeDocument31 pagesThe Role of State of SingaporeWannor AdilahNo ratings yet

- Fourth National PlanDocument266 pagesFourth National PlanRamesh PokharelNo ratings yet

- Land Tenure Security and Agricultural InvestmentDocument7 pagesLand Tenure Security and Agricultural InvestmentLemi TayeNo ratings yet

- Quality Control and Quality Assurance in Building ConstructionDocument9 pagesQuality Control and Quality Assurance in Building ConstructionAbdul JabbarNo ratings yet

- DBM Calculation ExcelDocument3 pagesDBM Calculation ExcelmaneeshkNo ratings yet

- Human Resource ManagementDocument39 pagesHuman Resource ManagementKIPNGENO EMMANUEL100% (1)

- B Plan Syllabus Copy SPA - JNAFAUDocument43 pagesB Plan Syllabus Copy SPA - JNAFAUJagadeesh PrakashNo ratings yet

- Gerald M. Meier - Biography of A Subject - An Evolution of Development Economics-Oxford University Press (2004)Document261 pagesGerald M. Meier - Biography of A Subject - An Evolution of Development Economics-Oxford University Press (2004)Artur AlvarengaNo ratings yet

- HMDA Act-2008Document90 pagesHMDA Act-2008vhkprasadNo ratings yet

- Personal Resume (H)Document2 pagesPersonal Resume (H)majidradaei5973No ratings yet

- Economic Development Strategic PlanningDocument8 pagesEconomic Development Strategic PlanningArsdy NovalentioNo ratings yet

- China As A New Coloniser Kısmına BakDocument87 pagesChina As A New Coloniser Kısmına BakEda GezmekNo ratings yet

- EconomicsDocument10 pagesEconomicsCalvinNo ratings yet

- Brgy. Zamora SBDGR 2017Document67 pagesBrgy. Zamora SBDGR 2017Yuri Villanueva100% (1)

- CDP ProjBrief Template Form 3bDocument2 pagesCDP ProjBrief Template Form 3bWendel AbejoNo ratings yet

- Korea Indonesia Port StudyDocument65 pagesKorea Indonesia Port StudySaid BasalimNo ratings yet

- Elias HailemeskelDocument71 pagesElias HailemeskelMekuriaw MezgebuNo ratings yet

- Science and Technology System in Jamaica - UNESCODocument14 pagesScience and Technology System in Jamaica - UNESCOAspirin A. BayerNo ratings yet

- The Peoples Agenda For Change (June 2016)Document176 pagesThe Peoples Agenda For Change (June 2016)Imperator FuriosaNo ratings yet

- Sacramento Community Center Theater White PaperDocument18 pagesSacramento Community Center Theater White PaperCapital Public RadioNo ratings yet

- Impact of Education in Poverty Allevation Satish Kumar SrivastavaDocument9 pagesImpact of Education in Poverty Allevation Satish Kumar SrivastavasalmanNo ratings yet

- Mazra Integrated Project For Empowerment of Women and ChildrenDocument18 pagesMazra Integrated Project For Empowerment of Women and Childrenmuhammed aliNo ratings yet

- Thesis Proposal v-6Document19 pagesThesis Proposal v-6William ThomsonNo ratings yet

- Introduction To Business & BCK PDFDocument28 pagesIntroduction To Business & BCK PDFPrabhakar DashNo ratings yet

- Ecs4867 - Study Guide - 2019 - FinalDocument60 pagesEcs4867 - Study Guide - 2019 - FinalaubreyNo ratings yet

- 316 Special Issue No. 7 Vol. XVIII (2013) METALURGIA INTERNATIONALDocument6 pages316 Special Issue No. 7 Vol. XVIII (2013) METALURGIA INTERNATIONALykaNo ratings yet

- API Is - Air.good - mt.k1 Ds2 en Excel v2 5997834Document68 pagesAPI Is - Air.good - mt.k1 Ds2 en Excel v2 5997834alireza.shadanpoorNo ratings yet

2013 Year in Review Art

2013 Year in Review Art

Uploaded by

brandonloganOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2013 Year in Review Art

2013 Year in Review Art

Uploaded by

brandonloganCopyright:

Available Formats

2013 R EVIEW

Appalachian Partnership for Economic Growth

Ohios Newest Economic Development

Region Delivers for Appalachia

The newest of JobsOhios six economic development partners, the

Appalachian Partnership completed

its first full year of operation in 2013.

President and CEO John Molinaro was

hired in July, 2012, and began to staff

the fledging operation, headquartered

in Nelsonville.

Today, APEGs

experienced

economic development professionals

and support staff

are establishing

working relationships with existing business and

John Molinaro,

industry leaders

President and CEO,

in the 28-county

APEG

Appalachian region.

Project managers are located in the

part of the region they serve.

In addition, the Appalachian Partnership offers its businesses access

to tailored training and consulting

expertise though a unique collaboration with the Manufacturing Extension

Partnership.

Our effort on behalf of Ohios

Appalachian people is to accelerate

business growth and job creation to

build enduring, widely-shared prosperity, said Molinaro. We want our

Appalachian communities to thrive so

they will be there for the generations

of families to come.

Shale Play

Driven by the Marcellus and Utica

shale boom, the Appalachian region

reported the largest total of capital

investment among JobsOhios six

regional economic development

partners in 2013. At a whopping $986

million, the Appalachian Partnership

for Economic Growth led the state

which tallied over $2.58 billion in

capital investment last year.

The area is very fortunate to have

the shale resources that have led to

this enormous investment. As the drilling and pipeline construction continue

to grow and expand, one of APEGs

key strategies for the future is to

develop mid- and end-stream processes that will capture jobs utilizing the

natural gas and oil being produced,

said Molinaro.

Kraton Polymers

But shale isnt the only game in the

region. The Appalachian Partnership

helped Kraton, a world-class polymer

manufacturer located in Washington

County, with a decision to make major

investments to install new natural gas

red boilers and electrical cogeneration equipment.

APEG aided their research process

by helping the company assess the

potential for increased use of barge

shipping on the Ohio River and researching the regulations about utility

installations. The result was 428 jobs

retained and an $80 million capital

investment in the Belpre plant.

Miba Sinter

APEGs strong advocacy for Miba

Sinter USA helped attract corporate

investment in a major expansion,

developing a Sinter operation as a

companion to the McConnelsville

bearings operation of this Austrianowned company. MIBA Sinter

and MIBA Bearings also received

extensive assistance through APEGs

Manufacturing Extension Partnership.

The Miba Sinter project yielded 110

new jobs and retained 88 jobs plus a

capital investment of $34 million in

Morgan County.

GKN Sinter

GKN Sinter Metals expansion was

accomplished with APEGs strong

involvement in the project. APEG

worked with the City of Gallipolis,

Gallia County and JobsOhio to

secure the growth project resulting

in 50 new jobs, 163 retained jobs

and a $10 million capital investment

in Gallia County.

Ohio gained this commitment and

came out on top among several nonOhio locations being considered. The

Gallipolis plant manufactures clutches

and gears; GKN group headquarters is

located in the United Kingdom.

Business Retention &

Expansion

Last year APEG staff made more than

139 Business Retention and Expansion calls and hundreds of Manufacturing Extension Partnership visits to help

companies overcome barriers in their

operations and identify and capitalize

on opportunities for growth.

The Appalachian Partnership

continues to focus on supporting and

expanding existing industries; diversity

is our best strategy and the best way

to use the rich experiences and assets

available in the region, said Molinaro.

APEGs 2014

PRIORITIES

Inventory and develop

high-value sites along the

Ohio River.

Help existing manufacturers

retain and build jobs by

linking Manufacturing

Extension Partnership

and JobsOhio incentive

programs.

With American Electric

Power investment,

heighten skills among local

and regional economic

development professionals.

Apply Make It in America

Challenge grant resources

to strengthen manufacturers

and capture re-shored

manufacturing from foreign

locations.

Promote mid-stream

development linked to the

regions Utica and Marcellus

shale gas resources.

MEP Goal: Increase top-line, reduce bottom-line

As part of the vision for establishing the Appalachian Partnership for Economic Growth,

John Molinaro, president and CEO, felt it critical for area business and industry to have

access to the kinds of high level expertise and training that help companies improve

their processes and productivity to sustain and grow. He accomplished that by incorporating the regional Manufacturing Extension Partnership (MEP) outreach into APEG.

MEP provides proven solutions and expertise for manufacturing companies to

achieve market growth, increase sales, implement operational savings and build skills

at all levels of the organization. This on-site assistance and training is specific to each

companys unique challenges and requirements to increase top-line growth and reduce

bottom-line cost.

Of the 44 companies using MEP services in 2013 six of the industry

groupings were represented; the majority of the companies were from advanced

manufacturing.

MEP is the manufacturing parallel to the agricultural extension programs that helped

create Americas highly competitive agribusiness industry. Closely aligning access to

improvement tactics and economic development strategies gives our business and

industry leadership the tools to stay competitive and to grow, said Molinaro.

In 2013 the MEP staff worked with 44 Appalachian companies providing training and

expert guidance in: Lean/Process Improvement; Leadership; Quality Systems; Safety;

Human Resources; Technical Skills and Growth Services.

The majority of the training focused on continuous improvement and workforce

development. Among the most popular training areas were Lean topics, process

improvement, supervisor leadership, and process mapping.

Continuous improvement (Lean, process mapping, supply chain development)

and workforce-related training (safety, supervision/leadership development, specific

skills training) were the most utilized MEP service areas in 2013.

First-time collaboration delivers $2.1 million grant

Collaboration and partnership were front

and center in November 2013 when a

$2.1 million Make It in America Challenge

grant was awarded to a group of Appalachian Ohio development organizations in

a tough competition.

The Appalachian Partnership for

Economic Growth (APEG) brought together the regions three Local Development

Districts in their first-ever combined effort

for federal grant resources and created a

winning proposal.

Together we were able to create

a very complex application, said John

Molinaro, president and CEO of the Appalachian Partnership. We wove funding

streams from three federal agencies into

a single unified project with a different

applicant for each agency. It was the

combination of all of our resources that

brought us success.

One of only 11 awards made, the

monies will be invested in incumbent

worker training for the regions metal

fabrication, polymers and chemicals

industries, and in the creation of an online

inventory of regional facilities and land

available for new or expanding industry

development.

A well-trained workforce in combination with available job sites that

are accessible to our world-class highway-rail-river infrastructure, proximity

to locally sourced fuel and feed stocks,

and manufacturing strength in the target

industries will make Appalachian Ohio attractive as production returns to the U.S.,

said Molinaro.

The third component of the Make It

In America Grant is supply chain development for the regions wood furniture

manufacturing industry.

Appalachian Ohio currently hosts

about 400 high-quality wood furniture

making firms. This is likely the largest

remaining concentration of these firms in

America and includes many very small

Amish and family-owned enterprises.

The grant will support a supply chain

development position to help these

firms join together to design products,

market their capabilities and fill orders

that exceed the capacity of the individual

firms. It will also connect furniture

manufacturers with sustainable forestry

initiatives, allowing the firms to market

a sustainably certified product line and

further increase sales opportunities and

profit margins.

The projects were designed to attract

the re-shoring of manufacturing from Europe, Asia, the Middle East, and Russia.

The grant partners included Local

Development Districts: OMEGA, Buckeye

Hills-Hocking Valley Regional Development District, Ohio Valley Regional Development Commission and the Ohio Valley

Employment Resources. A grant from the

Appalachian Regional Commission supported the application expenses.

The funding is a collaborative effort by

the U.S. Department of Labors Employment and Training Administration and the

Department of Commerce. In addition,

funding is supplied by the Economic

Development Administration (through the

National Institute of Standards and Technology Manufacturing Extension Partnership) and the Delta Regional Authority.

The Make It in America Challenge is

designed to help distressed regions build

on existing assets, promote a competitive environment for foreign-owned and

domestic firms to establish and grow their

U.S. operations, create jobs and develop

a skilled workforce for specific industries.

When the Local Development

Districts asked us to facilitate this

application we knew it wouldnt be

easy, said Molinaro, but forming a

unified Appalachian Ohio to compete for

economic development is what will make

us successful. We demonstrated our

first big success and I couldnt be more

pleased or appreciative of everyones

efforts.

APEG and partners pursue Ohio River development strategy

Infra-Metals Co. unloads steel at its Ohio River barge dock

in New Boston, Scioto County.

APEG, in cooperation with JobsOhio, AEP, and the

regions Local Development Districts, is working to

develop a strategy and plan focused on the Ohio

River as an economic development asset.

Among the unique benefits the river provides is

a second barge route to the Gulf of Mexico via the

Tennessee River and the Port of Mobile. Using the

Ohio River, shippers can avoid disruptions caused

by low or high water conditions on the Mississippi.

The anticipated expansion of the Panama Canal

will triple the canals tonnage capacity, making it

easier and less expensive to move export goods by

Gulf ports, enhancing the Ohio River asset.

Barge transport offers substantial costsavings compared to rail or truck, especially when

connecting to international markets. Goods moved

by barge are about 40 percent cheaper per ton than

by rail.Transport by barge uses 28 percent less

energy per ton than rail, and 73 percent less than

truck.

With nine ports on Lake Erie and several Ohio

River terminals, Ohio is the fourth largest state by

tonnage, with more trafc than the Panama Canal.

To improve overall transportation and infrastructure, both Norfolk Southern and CSX have invested

in high-volume rail lines linking Ohio with Mid Atlantic seaports.

The Heartland Corridor (Norfolk Southern) and

National Gateway (CSX) will help the region drive

economic growth resulting from the Panama Canal

expansion, which is expected to bring more trafc

through east coast ports.

APEG and JobsOhio collaboration means broad support for the region

The economic development strategy in

Ohio is designed to use the unique assets

and strengths of the states six regions

deep ties to local businesses. Networked

with the power of a statewide entity that

can support the regions plus market the

entire state, the vision becomes a reality

through JobsOhio.

This private, non-profit corporation

was created to expand existing business

and industry and bring new enterprises

and investments to Ohio.

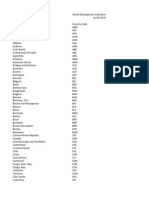

GKN Sinter Metals, LLC

McWane, Inc.

Miba Sinter USA LLC

Southeastern Ohio Port Authority

Blue Racer Midstream

C.A. Joseph Company

Commercial Vehicle Group - Shadyside

Diagnostic Hybrids, A Quidel Company

Echo Environmental LLC

Electronic Design for Industry, Inc.

Gad Dairy

GE Aviation

Kraton Polymers U.S. LLC

Ludowici Roof Tile, Inc.

MarkWest Energy Partners, LP

Ohio Precious Metals LLC

Ohio Stoneware, LLC

PVR Partners, L.P.

Somerset Regional Water Resources

Spectra Energy

Yutzy Woodworking, Ltd.

The state/regional, client-focused

approach delivers all of Ohios resources

to proactively meet with companies and

their management teams, listen to their

business needs, and assess alternative

ways to assist them.

The 21 APEG region companies listed

below received economic development

support from the Appalachian Partnership

and JobsOhio in 2013. The matrix shows

the resulting economic development

outcomes from the partnerships.

County

Gallia

Coshocton

Morgan

Washington

Monroe

Jefferson

Belmont

Athens

Pike

Washington

Holmes

Adams

Washington

Perry

Harrison

Jackson

Perry

Jefferson

Harrison

Jefferson

Holmes

City

Gallipolis

Coshocton

McConnelsville

Marietta

Shadyside

Athens

Waverly

Belpre

Millersburg

Peebles

Belpre

Pike Township

Cadiz

Jackson

Crooksville

Cadiz

Toronto

Millersburg

Totals

2013 results

APEG

JobsOhio

New jobs

1,051

17,857

Retained jobs

2,122

70,449

$968 million

$3.6 billion

Capital investment

Jobs Created

50

25

110

131

10

20

97

350

25

20

20

25

12

20

40

80

16

1,051

Jobs retained

163

374

88

181

152

60

300

428

135

40

3

198

2,122

Capital investments

$10,000,000

$7,000,000

$34,200,000

$15,300,000

$100,000,000

$847,000

$5,000,000

$550,000.00

$90,000,000

$80,000,000

$500,000,000

$125,000,000

$500,000

$968,397,000

Appalachian Partnership for Economic Growth

35 Public Square PO Box 456 Nelsonville, OH 45764

740.753.5359 www.apeg.com

You might also like

- Africa and Its Global Diaspora (2017) PDFDocument380 pagesAfrica and Its Global Diaspora (2017) PDFdanamilicNo ratings yet

- Internship Report On AKRSPDocument83 pagesInternship Report On AKRSPhaikel jan67% (3)

- Cecd, Edfp: Professional ExperienceDocument4 pagesCecd, Edfp: Professional ExperienceIsland Packet and Beaufort GazetteNo ratings yet

- Open For Business Magazine April / May 15Document15 pagesOpen For Business Magazine April / May 15Eugene Area Chamber of Commerce CommunicationsNo ratings yet

- The Setx Times: EconomicDocument4 pagesThe Setx Times: EconomicCharlie FoxworthNo ratings yet

- Section I: Organizational Overview: Raison D'êtreDocument20 pagesSection I: Organizational Overview: Raison D'êtreShan KhingNo ratings yet

- Open For Business Magazine - August/September 12 IssueDocument13 pagesOpen For Business Magazine - August/September 12 IssueEugene Area Chamber of Commerce CommunicationsNo ratings yet

- Top 10 Companies in The Philippines JaysonDocument4 pagesTop 10 Companies in The Philippines JaysonJayson Lopez FloresNo ratings yet

- Manufacturing Operations Improvement President in FT Wayne IN Resume Kevin EarlyDocument3 pagesManufacturing Operations Improvement President in FT Wayne IN Resume Kevin EarlyKevinEarlyNo ratings yet

- GLIInvestorReport 2011Document38 pagesGLIInvestorReport 2011Chris OttsNo ratings yet

- Environmental & Social Report : Kanto Auto Works, LTDDocument39 pagesEnvironmental & Social Report : Kanto Auto Works, LTDdist2235No ratings yet

- Vice President Supply Chain in NYC New Jersey Resume Jeffrey WallingDocument4 pagesVice President Supply Chain in NYC New Jersey Resume Jeffrey WallingJeffreyWallingNo ratings yet

- VP Finance Consumer Goods in New York City Resume Edward HoulihanDocument2 pagesVP Finance Consumer Goods in New York City Resume Edward HoulihanEdwardHoulihanNo ratings yet

- Ge Investor Communications Brochure 2q2007Document6 pagesGe Investor Communications Brochure 2q2007cvan65No ratings yet

- 2012 Progress B SectionDocument8 pages2012 Progress B SectionThe Delphos HeraldNo ratings yet

- Business Support Panel ReportDocument179 pagesBusiness Support Panel ReportPostmediaNo ratings yet

- Peter Laybourn - Industrial Symbiosis in ActionDocument14 pagesPeter Laybourn - Industrial Symbiosis in ActionMauricio CastroNo ratings yet

- Executive SummaryDocument17 pagesExecutive SummaryCayla HarrisNo ratings yet

- Monica Soileau Relevant Community Leader AccomplishmentsDocument11 pagesMonica Soileau Relevant Community Leader AccomplishmentsMonica SoileauNo ratings yet

- Ramores, Kaith Marjorie T. BSA51 Ayala Corporation'S Sustainability Report (2008) : A Review I. Brief Company OverviewDocument2 pagesRamores, Kaith Marjorie T. BSA51 Ayala Corporation'S Sustainability Report (2008) : A Review I. Brief Company OverviewNevan NovaNo ratings yet

- CIT Annual Report 2011 - FINALDocument16 pagesCIT Annual Report 2011 - FINALstephaniebouchNo ratings yet

- 2010 Community Report: Opportunities RealizedDocument16 pages2010 Community Report: Opportunities RealizedAnonymous Feglbx5No ratings yet

- ROI Overview Feb10Document9 pagesROI Overview Feb10teampaNo ratings yet

- About AyalaDocument6 pagesAbout AyalaRia BagoNo ratings yet

- Annual ReportDocument24 pagesAnnual ReportAnonymous Feglbx5No ratings yet

- General ElectricDocument8 pagesGeneral ElectricAnjali Daisy100% (1)

- Veolia Environmental Services North AmericaDocument4 pagesVeolia Environmental Services North AmericajohnribarNo ratings yet

- Full ReportDocument66 pagesFull ReportshanzarapunzleNo ratings yet

- Mare-Producator-Auto-Transformat-Intr-Colos-Picioare-Lut - HTM Creation: 1897-1909Document4 pagesMare-Producator-Auto-Transformat-Intr-Colos-Picioare-Lut - HTM Creation: 1897-1909Ionel GNo ratings yet

- Overall Equipment Effectiveness:: Guidelines For The CPG Industry and Its SuppliersDocument21 pagesOverall Equipment Effectiveness:: Guidelines For The CPG Industry and Its Suppliers18085012No ratings yet

- CSE Fellows Application - Matias SolariDocument2 pagesCSE Fellows Application - Matias Solarimsolari2006No ratings yet

- COO VP Operations Consultant in UT Resume Cynthia Pressley-SheltonDocument7 pagesCOO VP Operations Consultant in UT Resume Cynthia Pressley-SheltonCynthiaPressleySheltNo ratings yet

- EcDev JournalDocument4 pagesEcDev JournalAishah ImranNo ratings yet

- Gov. Cuomo Office - Economic Development FundingDocument22 pagesGov. Cuomo Office - Economic Development FundingerikvsorensenNo ratings yet

- Human Resources Director in Phoenix AZ Resume Eileen LileDocument2 pagesHuman Resources Director in Phoenix AZ Resume Eileen LileEileenLileNo ratings yet

- A Study On Labour Welfare Services With Reference To Wheels India LimitedDocument37 pagesA Study On Labour Welfare Services With Reference To Wheels India LimitedumajayakarthickNo ratings yet

- Chevron Announces L .4 Billion Pascagoula Base Oil ProjectDocument8 pagesChevron Announces L .4 Billion Pascagoula Base Oil ProjectHoang NamNo ratings yet

- Progressive Waste SolutionsDocument4 pagesProgressive Waste SolutionsjohnribarNo ratings yet

- CSR As A Business Strategy: BSR Identifies Five Key Trends in CSRDocument4 pagesCSR As A Business Strategy: BSR Identifies Five Key Trends in CSRfrancistsyNo ratings yet

- Dec 2012 NewsletterpdfDocument4 pagesDec 2012 NewsletterpdfRich PirrottaNo ratings yet

- Veolia Water North America Case Study: The SituationDocument9 pagesVeolia Water North America Case Study: The SituationMARSNo ratings yet

- AECOM Case Study ReportDocument21 pagesAECOM Case Study ReportjohnNo ratings yet

- Washington Innovation Partnership Zones - 2012 CSG Innovations Award WinnerDocument4 pagesWashington Innovation Partnership Zones - 2012 CSG Innovations Award Winnerbvoit1895No ratings yet

- HITO 2005 Annual ReportDocument20 pagesHITO 2005 Annual ReportHITONo ratings yet

- New Instructor Brings Big Changes To CAVC Food Service ProgramDocument2 pagesNew Instructor Brings Big Changes To CAVC Food Service ProgramAnonymous tqFrRpQvTHNo ratings yet

- The Michigan Banner December 16, 2011 EditionDocument32 pagesThe Michigan Banner December 16, 2011 EditiontangramtechNo ratings yet

- Applied MaterialsDocument5 pagesApplied MaterialsAryan PandeyNo ratings yet

- 2009 2010 Business Nonprofit CriteriaDocument88 pages2009 2010 Business Nonprofit CriteriabearbearkhooNo ratings yet

- Employee Welfare Management - Basha PDFDocument44 pagesEmployee Welfare Management - Basha PDFL. V B ReddyNo ratings yet

- Ayala 2013 Annual ReportDocument265 pagesAyala 2013 Annual ReportWynmar Kevyn MarquezNo ratings yet

- Math 12 BESR ABM Q2-Week 5Document14 pagesMath 12 BESR ABM Q2-Week 5SHEENA MAE DALGUNTAS100% (2)

- BSC Oxford Brookes Acca Thesis SampleDocument5 pagesBSC Oxford Brookes Acca Thesis Samplef6a5mww8100% (2)

- Project ProposalDocument3 pagesProject ProposalPam ExquisitesNo ratings yet

- Business Journal March 2012 A SectionDocument8 pagesBusiness Journal March 2012 A SectionThe Delphos HeraldNo ratings yet

- PTC Final ProjectDocument40 pagesPTC Final ProjectRehan Yousaf60% (5)

- ZForce NovDec 2015 ENGDocument13 pagesZForce NovDec 2015 ENGwesleitigerNo ratings yet

- CSV WebinarDocument22 pagesCSV WebinarNeusa RavarotoNo ratings yet

- An Executive's Guide to Fundraising Operations: Principles, Tools, and TrendsFrom EverandAn Executive's Guide to Fundraising Operations: Principles, Tools, and TrendsNo ratings yet

- Boosting Gender Equality Through ADB Trade Finance PartnershipsFrom EverandBoosting Gender Equality Through ADB Trade Finance PartnershipsNo ratings yet

- Talent Keepers: How Top Leaders Engage and Retain Their Best PerformersFrom EverandTalent Keepers: How Top Leaders Engage and Retain Their Best PerformersNo ratings yet

- Enhancing Energy-Based Livelihoods for Women Micro-Entrepreneurs: India Gender Equality Results Case StudyFrom EverandEnhancing Energy-Based Livelihoods for Women Micro-Entrepreneurs: India Gender Equality Results Case StudyNo ratings yet

- The Role of State of SingaporeDocument31 pagesThe Role of State of SingaporeWannor AdilahNo ratings yet

- Fourth National PlanDocument266 pagesFourth National PlanRamesh PokharelNo ratings yet

- Land Tenure Security and Agricultural InvestmentDocument7 pagesLand Tenure Security and Agricultural InvestmentLemi TayeNo ratings yet

- Quality Control and Quality Assurance in Building ConstructionDocument9 pagesQuality Control and Quality Assurance in Building ConstructionAbdul JabbarNo ratings yet

- DBM Calculation ExcelDocument3 pagesDBM Calculation ExcelmaneeshkNo ratings yet

- Human Resource ManagementDocument39 pagesHuman Resource ManagementKIPNGENO EMMANUEL100% (1)

- B Plan Syllabus Copy SPA - JNAFAUDocument43 pagesB Plan Syllabus Copy SPA - JNAFAUJagadeesh PrakashNo ratings yet

- Gerald M. Meier - Biography of A Subject - An Evolution of Development Economics-Oxford University Press (2004)Document261 pagesGerald M. Meier - Biography of A Subject - An Evolution of Development Economics-Oxford University Press (2004)Artur AlvarengaNo ratings yet

- HMDA Act-2008Document90 pagesHMDA Act-2008vhkprasadNo ratings yet

- Personal Resume (H)Document2 pagesPersonal Resume (H)majidradaei5973No ratings yet

- Economic Development Strategic PlanningDocument8 pagesEconomic Development Strategic PlanningArsdy NovalentioNo ratings yet

- China As A New Coloniser Kısmına BakDocument87 pagesChina As A New Coloniser Kısmına BakEda GezmekNo ratings yet

- EconomicsDocument10 pagesEconomicsCalvinNo ratings yet

- Brgy. Zamora SBDGR 2017Document67 pagesBrgy. Zamora SBDGR 2017Yuri Villanueva100% (1)

- CDP ProjBrief Template Form 3bDocument2 pagesCDP ProjBrief Template Form 3bWendel AbejoNo ratings yet

- Korea Indonesia Port StudyDocument65 pagesKorea Indonesia Port StudySaid BasalimNo ratings yet

- Elias HailemeskelDocument71 pagesElias HailemeskelMekuriaw MezgebuNo ratings yet

- Science and Technology System in Jamaica - UNESCODocument14 pagesScience and Technology System in Jamaica - UNESCOAspirin A. BayerNo ratings yet

- The Peoples Agenda For Change (June 2016)Document176 pagesThe Peoples Agenda For Change (June 2016)Imperator FuriosaNo ratings yet

- Sacramento Community Center Theater White PaperDocument18 pagesSacramento Community Center Theater White PaperCapital Public RadioNo ratings yet

- Impact of Education in Poverty Allevation Satish Kumar SrivastavaDocument9 pagesImpact of Education in Poverty Allevation Satish Kumar SrivastavasalmanNo ratings yet

- Mazra Integrated Project For Empowerment of Women and ChildrenDocument18 pagesMazra Integrated Project For Empowerment of Women and Childrenmuhammed aliNo ratings yet

- Thesis Proposal v-6Document19 pagesThesis Proposal v-6William ThomsonNo ratings yet

- Introduction To Business & BCK PDFDocument28 pagesIntroduction To Business & BCK PDFPrabhakar DashNo ratings yet

- Ecs4867 - Study Guide - 2019 - FinalDocument60 pagesEcs4867 - Study Guide - 2019 - FinalaubreyNo ratings yet

- 316 Special Issue No. 7 Vol. XVIII (2013) METALURGIA INTERNATIONALDocument6 pages316 Special Issue No. 7 Vol. XVIII (2013) METALURGIA INTERNATIONALykaNo ratings yet

- API Is - Air.good - mt.k1 Ds2 en Excel v2 5997834Document68 pagesAPI Is - Air.good - mt.k1 Ds2 en Excel v2 5997834alireza.shadanpoorNo ratings yet