Professional Documents

Culture Documents

Ball Data Sheet

Ball Data Sheet

Uploaded by

shashikanth79Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ball Data Sheet

Ball Data Sheet

Uploaded by

shashikanth79Copyright:

Available Formats

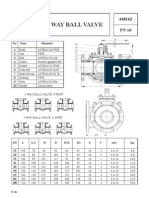

Torque Value & Cv Value

Floating Ball Valve Design Torque

Size

(inch)

1/2

3/4

1

1-1/2

2

2-1/2

3

4

5

6

8

10

Class 150

12

14

27

55

75

125

162

234

546

804

1410

2600

Class 300

17

23

48

89

100

141

216

476

910

1338

3100

5400

Design Torque (N.m)

Class 600

30

38

66

120

160

233

308

635

--1944

-----

Class 900

38

56

98

189

240

390

610

-----------

Class 1500

51

71

130

238

350

550

980

-----------

Notes:

1. For FC, FR & FF series valves, torque is the same.

2. All valves are in normal temperature, with PTFE seat for Class 150~300 and Nylon seat for Class 600~1500.

3. For cryogenic ball valve, torque will be 2~2.5 times the above torque.

4. Torque shown in this table is to be used as a guide for actuator selection. A safety factor of 1.5 is recommended for actuator sizing.

5. Torque may be changed according to different medium and trim material.

Ball Valve Flow Coefficient (Cv)

Size

(inch)

1/2

3/4

1

1-1/2

2

3

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

40

Cv

Class 150

24

53

92

211

381

845

1523

3381

6031

9442

13614

16621

21920

28076

34995

42676

51117

59012

68872

79493

89268

101307

112306

139982

Class 300

24

53

92

211

381

845

1523

3381

6031

9442

13614

16621

21920

28076

34995

42676

51117

59012

68872

79493

89268

101307

112306

139982

Class 600

24

53

92

211

381

845

1523

3381

6031

9442

13614

16621

21920

28076

34995

42676

51117

59012

68872

79493

89268

101307

112306

139982

Class 900

24

53

92

211

381

845

1523

3381

6031

9442

13614

15363

20581

26435

32743

40184

47884

56076

65110

74610

84977

96020

107487

---

Class 1500

24

53

92

211

381

845

1523

3120

5508

8500

12223

14800

19178

24243

30565

35860

41733

---------------

Class 2500

24

53

92

211

283

600

1160

2590

4795

7410

10433

---------------------------

Note:

1. The flow coefficiency "Cv" of a valve is the flow rate in Gallons /minute of 60F water through a fully opened valve, at a pressure drop of 1 psi

across the vavle.

2. All the ball valves are in full bore.

47

Torque Value & Mounting Flange Dimensions

A

B

C

G

n- d

2- P

Key KxK

Size

inch

2*1-1/2

Class

150

300

600

900

1500

2500

150

300

600

900

1500

2500

150

300

600

900

1500

2500

150

300

600

900

1500

2500

Torque

N.m

42

66

102

142

241

423

76

91

143

231

349

798

121

159

269

524

887

1583

179

355

670

875

1351

2111

A

90

90

90

90

90

125

90

90

90

125

125

150

125

125

125

150

150

175

125

125

150

175

210

210

B

70

70

70

70

70

102

70

70

70

102

102

125

102

102

102

125

125

140

102

102

125

140

165

165

Flange Dimensions

mm

C

f

t

n-d

55

3 12

4-9

55

3 12

4-9

55

3 12

4-9

55

3 12

4-9

55

4-9

3 12

70

3 15 4-11

55

4-9

3 12

55

4-9

3 12

55

4-9

3 12

70

3 15 4-11

70

3 15 4-11

85

3 18 4-13

70

3 15 4-11

70

3 15 4-11

70

3 15 4-11

85

3 18 4-13

85

3 18 4-13

100 4 20 4-18

70

3 15 4-11

70

3 15 4-11

85

3 18 4-13

100 4 20 4-18

130 5 22 4-22

130 5 22 4-22

P

6

6

6

6

6

8

6

6

6

8

8

10

8

8

8

10

10

10

8

8

10

10

12

12

ISO5211 Key Size

Flange

KxK

No.

mm

F07

F07

F07

F07

F07

F10

F07

F07

F07

F10

F10

F12

F10

F10

F10

F12

F12

F14

F10

F10

F12

F14

F16

F16

6x6

6x6

6x6

6x6

6x6

8x8

6x6

6x6

6x6

8x8

8x8

10x10

8x8

8x8

8x8

10x10

10x10

12x12

8x8

8x8

10x10

12x12

14x14

14x14

G

mm

D

mm

h

mm

H

mm

25

25

25

25

25

32

25

25

25

32

32

41

32

32

32

41

41

51

32

32

41

51

57

62

22

22

22

22

22

28

22

22

22

28

28

36

28

28

28

36

36

45

28

28

36

45

50

55

25

25

25

25

25

30

25

25

25

30

30

55

30

30

30

55

55

65

30

30

55

65

75

80

100

100

100

100

100

115

103

103

103

117

117

135

130

130

132

142

147

165

150

150

160

172

185

205

48

Torque Value & Mounting Flange Dimensions

Size

inch

10

12

14

16

18

20

24

49

Class

Torque

N.m

150

300

600

900

1500

2500

150

300

600

900

1500

2500

150

300

600

900

1500

2500

150

300

600

900

1500

2500

150

300

600

900

1500

150

300

600

900

1500

150

300

600

900

1500

150

300

600

900

1500

150

300

600

900

1500

631

854

1609

1927

3512

5454

987

1562

2501

4012

6513

8495

1321

2304

3450

5017

7996

13148

1650

3041

4507

6512

10078

18007

2415

4019

6578

9489

14860

3314

5350

9025

12877

21857

5148

8375

13493

18975

29032

6425

10987

18502

26048

40907

12379

19384

29546

42379

65223

Flange Dimensions

mm

A

150

150

175

210

210

300

210

210

210

210

300

300

210

210

210

300

300

300

210

210

300

300

300

300

300

300

300

300

300

300

300

300

300

350

300

300

300

350

350

300

300

350

350

415

300

350

350

415

475

B

125

125

140

165

165

254

165

165

165

165

254

254

165

165

165

254

254

254

165

165

254

254

254

254

254

254

254

254

254

254

254

254

254

298

254

254

254

298

298

254

254

298

298

356

254

298

298

356

406

C

85

85

100

130

130

200

130

130

130

130

200

200

130

130

130

200

200

200

130

130

200

200

200

200

200

200

200

200

200

200

200

200

200

230

200

200

200

230

230

200

200

230

230

260

200

230

230

260

300

f

3

3

4

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

8

t

18

18

20

22

24

26

20

20

22

22

25

28

22

22

24

25

28

28

24

24

25

28

28

30

26

26

28

28

30

28

28

28

30

32

28

28

30

32

38

30

30

32

38

42

32

32

38

42

48

n-d

4-13

4-13

4-18

4-22

4-22

8-18

4-22

4-22

4-22

4-22

8-18

8-18

4-22

4-22

4-22

8-18

8-18

8-18

4-22

4-22

8-18

8-18

8-18

8-18

8-18

8-18

8-18

8-18

8-18

8-18

8-18

8-18

8-18

8-22

8-18

8-18

8-18

8-22

8-22

8-18

8-18

8-22

8-22

8-33

8-18

8-22

8-22

8-33

8-39

P

10

10

10

12

14

16

10

10

12

14

16

16

12

12

14

16

16

16

14

14

16

16

16

16

16

16

16

16

16

16

16

16

16

20

16

16

16

20

20

16

16

20

20

28

16

20

20

28

28

ISO5211 Key Size

Flange

KxK

No.

mm

F12

F12

F14

F16

F16

F25

F16

F16

F16

F16

F25

F25

F16

F16

F16

F25

F25

F25

F16

F16

F25

F25

F25

F25

F25

F25

F25

F25

F25

F25

F25

F25

F25

F30

F25

F25

F25

F30

F30

F25

F25

F30

F30

F35

F25

F30

F30

F35

F40

10x10

10x10

12x12

14x14

16x16

16x16

12x12

12x12

14x14

16x16

18x18

18x18

14x14

14x14

16x16

18x18

18x18

20x20

16x16

16x16

18x18

18x18

20x20

24x24

16x16

16x16

18x18

20x20

24x24

18x18

18x18

20x20

24x24

28x28

18x18

20x20

24x24

28x28

32x32

20x20

24x24

28x28

32x32

36x36

24x24

28x28

32x32

36x36

40x40

G

mm

D

mm

h

mm

H

mm

41

41

51

62

68

73

51

51

62

68

79

84

62

62

68

79

84

95

68

68

79

84

95

107

73

73

84

95

107

84

84

95

107

119

84

95

107

119

136

90

107

119

136

158

102

124

136

158

180

36

36

45

55

60

65

45

45

55

60

70

75

55

55

60

70

75

85

60

60

70

75

85

95

65

65

75

85

95

75

75

85

95

105

75

85

95

105

120

80

95

105

120

140

90

110

120

140

160

55

55

65

80

90

95

60

60

80

90

105

110

80

80

90

105

110

125

90

90

105

110

125

140

95

95

110

125

140

110

110

125

140

165

110

125

140

165

180

120

140

165

180

210

135

165

180

210

240

186

186

208

215

255

305

233

233

250

260

280

360

280

280

290

305

345

390

315

315

345

360

405

465

353

353

370

390

435

393

400

420

440

485

435

440

462

500

545

485

490

515

530

580

562

570

610

630

730

Notes:

1. The above table is for TF,TW&TT series valves, which are with ISO 5211 mounting flange and adaptablity for all types actuators mounting.

2. The torque is for valves with PTFE seat or Molon seat as per different size/class selection.

3. The torque value showed in above table is the valve torque at normal temperature. For customer's sizing actuator:

a. If medium temperature is -10~40, the output torque of actuator should be 1.5 times the valve torque;

b. If medium temperature is less than -10, the output torque of actuator should be 2 or 2.5 times the valve torque.

Soft Materials Data

Specifications for Seat Materials

PTFE

24.8

35

250

56

<0.01

2.2

-300~400

150~600

Chemical &

Service Application

Cryogenic

Nylon 1010

Tensile Strength (MPa)

55

Compressive Strength (MPa)

70

Elongation (%)

150

Hardness(SH.A)

70

Water Absorption (%)

0.3

Specific Gravity (G/cm3)

1.04

Temperature Range (F)

-40~200

Pressure Rating (Class)

600~1500

High Pressure &

Service Application

Low Temperature

Tensile Strength (MPa)

Compressive Strength (MPa)

Elongation (%)

Hardness(SH.A)

Water Absorption (%)

Specific Gravity (G/cm3)

Temperature Range (F)

Pressure Rating (Class)

RPTFE

25.4

52

120

60

<0.01

2.2

-150~425

150~600

Chemical &

Cryogenic

Nylon 12

60

79

200

75

0.2

1.01

-58~250

600~1500

High Pressure &

Low Temperature

Molon(Nylon+MoS 2 )

75~100

100~140

10~30

78

0.7

1.2

-40~300

150~1500

High Pressure &

Low Temperature

Devlon V

80

140

5.37

78

0.1

1.14

-150~300

150~1500

High Pressure &

Low Temperature

PEEK

91

137

50

82

0.12

1.35

-150~500

150~2500

High Pressure &

High Temperature

Delrin

68

110

220

78

0.2

1.41

-58~230

150~1500

High Pressure &

Low Temperature

Specifications for Seal Materials

Temperature range (F)

Hardness (SH.A)

Specific Gravity (G/cm3)

Service Application

Viton A

-20~400

70

1.85

NBR

-50~250

70

1.2

Viton B

-20~400

70

1.85

Petroleum Oils,

Gasoline,

Transmission Fluid

Petroleum Oils,

Water,

Hydraulic Oils

Mineral Acid,

Steam,

MTBE

HNBR (HSN)

-40~320

80

1.33

Petroleum Oils,

H2S & CO2

Anti-Explosive

Decompression

Viton AED

-20~480

90

1.9

Petroleum Oils,

H2S & CO2

Anti-Explosive

Decompression

Specifications for Gasket Materials

Temperature Range F

PH

-300~900

0~14

Spiral Wound

316+Graphite

-300~900

0~14

Service Application

Fire-safe

Fire-safe

Flexible Graphite

PTFE

-300~400

0~14

Cryogenic,

High Corrosive

Spiral Wound

Monel + PTFE

-300~400

0~14

High Corrosive

*Due to quick develop, we reserve the right to institute changes in material, design and specifications

for all VIZA designed valves without prior notice.

50

You might also like

- SS2 Agv200 0300 01Document12 pagesSS2 Agv200 0300 01RaymondIlyasNo ratings yet

- Hindle 4.2.2 Torque Characteristics PDFDocument6 pagesHindle 4.2.2 Torque Characteristics PDFpandit1010No ratings yet

- Valvulas de Bola - JAMESBURYDocument4 pagesValvulas de Bola - JAMESBURYcasv9No ratings yet

- 2WS21ENDocument8 pages2WS21ENcibocrisNo ratings yet

- Butterfly ValveDocument20 pagesButterfly Valvenazar750No ratings yet

- 3105 B 26Document3 pages3105 B 26ParIs MoRanNo ratings yet

- PRV Catlogue-Samson (09!06!09)Document6 pagesPRV Catlogue-Samson (09!06!09)pkrishna984No ratings yet

- ASCO SolenoidDocument10 pagesASCO Solenoidsharib26No ratings yet

- Swagelok HoseDocument28 pagesSwagelok HoseRashi Akmal0% (1)

- Product Data SheetsDocument12 pagesProduct Data SheetsTreeNo ratings yet

- 2500-249 Series Level-Trol Pneumatic Liquid Level Controllers and TransmittersDocument6 pages2500-249 Series Level-Trol Pneumatic Liquid Level Controllers and TransmittersmoisesNo ratings yet

- Fisher Globe ValveDocument16 pagesFisher Globe ValvePhornlert WanaNo ratings yet

- Bulletin 1301Document8 pagesBulletin 1301Syed Haris Bin AkhterNo ratings yet

- A005 AtosDocument4 pagesA005 AtosramabhplNo ratings yet

- Mark 50 Series: Self-Operated Back Pressure RegulatorsDocument16 pagesMark 50 Series: Self-Operated Back Pressure RegulatorsDarren JohnstonNo ratings yet

- Bomba Rexroth A4SGCDocument32 pagesBomba Rexroth A4SGCEdgarRetuertoNo ratings yet

- Aerzen TurboDocument3 pagesAerzen Turbocarlangas77No ratings yet

- Grundfos MTS Screw Spindle PumpDocument68 pagesGrundfos MTS Screw Spindle PumpAnonymous lswzqlo100% (1)

- EZR RegulatorDocument40 pagesEZR RegulatorBranko BabicNo ratings yet

- Autoclave AccessoriesDocument20 pagesAutoclave Accessoriescmct0819No ratings yet

- TORQUES Actuator For Ball Valve PDFDocument12 pagesTORQUES Actuator For Ball Valve PDFChaerul AnwarNo ratings yet

- 電動式SS2 AGV200 0300Document16 pages電動式SS2 AGV200 0300terrybook1968No ratings yet

- T-Series Thermowells Model TF Flanged Wells, Model TT Threaded Wells, Model TW Weld-In Wells, and Model TS Sanitary WellsDocument12 pagesT-Series Thermowells Model TF Flanged Wells, Model TT Threaded Wells, Model TW Weld-In Wells, and Model TS Sanitary Wellssalmo83:18No ratings yet

- 41000Document36 pages41000tetiospamNo ratings yet

- Válvula DurcoDocument12 pagesVálvula DurcoJames Henrry López EspejoNo ratings yet

- AE AccessoriesDocument16 pagesAE AccessoriesmisaelzaNo ratings yet

- EZR Installation ManualDocument40 pagesEZR Installation ManualRoberto Aldayuz HerediaNo ratings yet

- K TRON Loss in Weight Single Screw Feeder K ML S500 10DDocument2 pagesK TRON Loss in Weight Single Screw Feeder K ML S500 10Ddeus_7No ratings yet

- Diesel GensetDocument4 pagesDiesel GensetErwin GunawanNo ratings yet

- Parker 3349112014 PGP511 Series, Pgp511a0140ab1h2vf5f3b1b1Document21 pagesParker 3349112014 PGP511 Series, Pgp511a0140ab1h2vf5f3b1b1Anonymous srN69mFE100% (2)

- 480Document12 pages480Sergio Figueroa MuñozNo ratings yet

- fp50 fp100 fp200Document10 pagesfp50 fp100 fp200ducmanh83No ratings yet

- Eaton Overcenter Valve 1CPBD300 - PCT - 274201Document2 pagesEaton Overcenter Valve 1CPBD300 - PCT - 274201snsnagarajanNo ratings yet

- Actuator Torque Calc PDFDocument12 pagesActuator Torque Calc PDFNishith0% (1)

- Fluid Components Full CatalogDocument464 pagesFluid Components Full Catalognegg 348No ratings yet

- Slurry Pumps Parastaltic PumpsDocument9 pagesSlurry Pumps Parastaltic Pumpsmtl40No ratings yet

- Vane Pumps PFE-31, PFE-41, PFE-51: Fixed DisplacementDocument4 pagesVane Pumps PFE-31, PFE-41, PFE-51: Fixed DisplacementLibinNo ratings yet

- FNW Fig.340Document4 pagesFNW Fig.340Imtinan MohsinNo ratings yet

- CPDocument12 pagesCPthehammer2No ratings yet

- 3E AND 110H/210H SERIES Canned Motor Pumps: R S P W C I MDocument16 pages3E AND 110H/210H SERIES Canned Motor Pumps: R S P W C I Mari_prasNo ratings yet

- 31 SRC enDocument6 pages31 SRC enlggomezupbNo ratings yet

- ValvulaDocument8 pagesValvulaJosé Gasset Del ValleNo ratings yet

- Mustang Series M115 (Globe), M1115 (Angle) Specification SheetDocument7 pagesMustang Series M115 (Globe), M1115 (Angle) Specification SheetWattsNo ratings yet

- Astma 269Document4 pagesAstma 269Raúl TinocoNo ratings yet

- EJ Series Butterfly ValvesDocument12 pagesEJ Series Butterfly ValvesGia Minh Tieu TuNo ratings yet

- Unique Single Seat Valve-Simply UniqueDocument8 pagesUnique Single Seat Valve-Simply UniquelggomezupbNo ratings yet

- Walvoil Cartridge Ventielen HICDocument20 pagesWalvoil Cartridge Ventielen HICddNo ratings yet

- Case 595 P100 GBDocument5 pagesCase 595 P100 GBLAZARO GARCIANo ratings yet

- Fisher 8580 Rotary Valve PDFDocument24 pagesFisher 8580 Rotary Valve PDFARMANDONo ratings yet

- Valvula ASCO Falcon SB2500Document2 pagesValvula ASCO Falcon SB2500Elmer HuashuayoNo ratings yet

- Self-Operated Pressure Regulators Type 41-73 Universal Excess Pressure ValveDocument8 pagesSelf-Operated Pressure Regulators Type 41-73 Universal Excess Pressure ValvecartarNo ratings yet

- Case 595 Sle LSPDocument6 pagesCase 595 Sle LSPyeferson mora guerreroNo ratings yet

- T 80120 CaDocument16 pagesT 80120 CaVinod KumarNo ratings yet

- 1013Document4 pages1013Ph03n1x-No ratings yet

- Model BFV-300/BFV-300C Butterfly Valve Grooved End General DescriptionDocument8 pagesModel BFV-300/BFV-300C Butterfly Valve Grooved End General DescriptionMERCURE GARINDOLPGNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Gate Valve: No Material 1 2 3 4 5 6 7 8 9 10 11 12Document1 pageGate Valve: No Material 1 2 3 4 5 6 7 8 9 10 11 12shashikanth79No ratings yet

- Resilient Seated Gate Valve: 620302 620301 PN 16 PN 10Document1 pageResilient Seated Gate Valve: 620302 620301 PN 16 PN 10shashikanth79No ratings yet

- Globe Valve: No Material 1 2 3 4 6 7 8 9 10 11 12Document1 pageGlobe Valve: No Material 1 2 3 4 6 7 8 9 10 11 12shashikanth79No ratings yet

- Ball Valve Full Bore - Flanged End: 1 No MaterialDocument1 pageBall Valve Full Bore - Flanged End: 1 No Materialshashikanth79No ratings yet

- Globe Valve: No Material 1 2 4 5 6 7 8 9 10 11 12Document1 pageGlobe Valve: No Material 1 2 4 5 6 7 8 9 10 11 12shashikanth79No ratings yet

- Ball Check Valve: 4740 47401 PN 16 PN 10Document1 pageBall Check Valve: 4740 47401 PN 16 PN 10shashikanth79No ratings yet

- Ball Valve Full Bore - Compact: No MaterialDocument1 pageBall Valve Full Bore - Compact: No Materialshashikanth79No ratings yet

- Ball Valve Full Bore - Flanged End: 1 Body No MaterialDocument1 pageBall Valve Full Bore - Flanged End: 1 Body No Materialshashikanth79No ratings yet

- Globe Valve: No Material 1 2 3 5 6 7 8 9 10 11 12Document1 pageGlobe Valve: No Material 1 2 3 5 6 7 8 9 10 11 12shashikanth79No ratings yet

- 3-Way Ball Valve Full Bore - Screwed End: No MaterialDocument1 page3-Way Ball Valve Full Bore - Screwed End: No Materialshashikanth79No ratings yet

- Ball Valve Full Bore - Flanged End: 1 No MaterialDocument1 pageBall Valve Full Bore - Flanged End: 1 No Materialshashikanth79No ratings yet

- Ball Valve Full Bore - Screwed End: 442013 PN 30 PN 20Document1 pageBall Valve Full Bore - Screwed End: 442013 PN 30 PN 20shashikanth79No ratings yet

- Ball Check Valve: 472452 472451 PN 16 PN 10Document1 pageBall Check Valve: 472452 472451 PN 16 PN 10shashikanth79No ratings yet

- Ball Valve Full Bore - Screwed End: 1 No MaterialDocument1 pageBall Valve Full Bore - Screwed End: 1 No Materialshashikanth79No ratings yet

- Ball Valve Screwed or Welded End Fire SafeDocument1 pageBall Valve Screwed or Welded End Fire Safeshashikanth79No ratings yet

- 3-Way Gland Cock: 1 No MaterialDocument1 page3-Way Gland Cock: 1 No Materialshashikanth79No ratings yet

- Ball Valve Full Bore - Flanged End: No MaterialDocument1 pageBall Valve Full Bore - Flanged End: No Materialshashikanth79No ratings yet

- Ball Valve Full Bore - Butt Weld End: No MaterialDocument1 pageBall Valve Full Bore - Butt Weld End: No Materialshashikanth79No ratings yet

- Ball Valve Full Bore - Screwed End: No MaterialDocument1 pageBall Valve Full Bore - Screwed End: No Materialshashikanth79No ratings yet

- Ball Valve Full Bore - Screwed End: 1 No MaterialDocument1 pageBall Valve Full Bore - Screwed End: 1 No Materialshashikanth79No ratings yet

- Ball Valve Full Bore - Flanged End: 1 No MaterialDocument1 pageBall Valve Full Bore - Flanged End: 1 No Materialshashikanth79No ratings yet

- Ball Valve Full Bore - Butt Weld End: 1 No MaterialDocument1 pageBall Valve Full Bore - Butt Weld End: 1 No Materialshashikanth79No ratings yet

- 3-Way Gland Cock: No Material 1Document1 page3-Way Gland Cock: No Material 1shashikanth79No ratings yet

- 3-Way Gland Cock: 1 No MaterialDocument1 page3-Way Gland Cock: 1 No Materialshashikanth79No ratings yet

- 3 Way Ball Valve With Gear: No Part Material 1 2 3 4 5 6 7 8 9 10Document1 page3 Way Ball Valve With Gear: No Part Material 1 2 3 4 5 6 7 8 9 10shashikanth79No ratings yet

- 3-Way Ball Valve Full Bore - Flanged End: 1 No MaterialDocument1 page3-Way Ball Valve Full Bore - Flanged End: 1 No Materialshashikanth79No ratings yet

- 3 Way Ball Valve: No Part Material 1 2 3 4 5 6 7 8 9 10Document1 page3 Way Ball Valve: No Part Material 1 2 3 4 5 6 7 8 9 10shashikanth79No ratings yet

- Strainer: 483492 483491 PN 16 PN 10Document1 pageStrainer: 483492 483491 PN 16 PN 10shashikanth79No ratings yet

- 3-Way Ball Valve Screwed End: No MaterialDocument1 page3-Way Ball Valve Screwed End: No Materialshashikanth79No ratings yet

- Strainer: 483422 483421 PN 16 PN 10Document1 pageStrainer: 483422 483421 PN 16 PN 10shashikanth79No ratings yet

- Makalah LiteratureDocument19 pagesMakalah LiteratureDenny Permana100% (1)

- The SpectaclesDocument37 pagesThe SpectacleslooneypersoneyNo ratings yet

- Certificate of Eligibility FinalDocument9 pagesCertificate of Eligibility Finalgena sanchez BernardinoNo ratings yet

- Bonding CompositeDocument210 pagesBonding CompositeDinesh KumarNo ratings yet

- Method Statement For Marble Flooring and Marble Wall CladdingDocument10 pagesMethod Statement For Marble Flooring and Marble Wall Claddingumit100% (1)

- Excel Basics RoadmapDocument3 pagesExcel Basics RoadmapLalatenduNo ratings yet

- Mio Amore Registration Form (1) - 1Document4 pagesMio Amore Registration Form (1) - 1Anish ChakrabortyNo ratings yet

- 0173NF2016 Fo2c PDFDocument26 pages0173NF2016 Fo2c PDFRadhakrishna MadabhushiNo ratings yet

- A Simulation-Based Optimization Methodology For FaDocument11 pagesA Simulation-Based Optimization Methodology For FahenokzewduNo ratings yet

- Classification of Cyber Attacks Using Support Vector MachineDocument4 pagesClassification of Cyber Attacks Using Support Vector MachineBindhu100% (1)

- Prashant Pandey Roll No 57 FinalDocument87 pagesPrashant Pandey Roll No 57 FinalSMF022VANSH JAINNo ratings yet

- Al Qudra LakeDocument2 pagesAl Qudra Lakeواجد چوھدریNo ratings yet

- COT 1 Lesson PlanDocument2 pagesCOT 1 Lesson PlanShiny Natividad86% (7)

- ZnetworkDocument368 pagesZnetworkSaurabh SinghNo ratings yet

- 9 1 Cathode Ray OscilloscopeDocument14 pages9 1 Cathode Ray Oscilloscopesuemozac100% (6)

- Reding Gapped TextDocument18 pagesReding Gapped TextChi Nguyen0% (2)

- Aurora 3800 Especificaciones PDFDocument8 pagesAurora 3800 Especificaciones PDFCarlos PalmaNo ratings yet

- Apostolic ConstitutionsDocument2 pagesApostolic ConstitutionsMarcel100% (1)

- Analisis Fungsi Kepemimpinan Camat Kubu Kabupaten Rokan HilirDocument14 pagesAnalisis Fungsi Kepemimpinan Camat Kubu Kabupaten Rokan Hilirtoto saepul anwarNo ratings yet

- BBI2421 SCL WORKSHEET 1 (WEEK 2-3) - SENTENCE STRUCTURE, SENTENCE ERRORS & TENSES SEM 2 2017-18-1Document12 pagesBBI2421 SCL WORKSHEET 1 (WEEK 2-3) - SENTENCE STRUCTURE, SENTENCE ERRORS & TENSES SEM 2 2017-18-1Aina NadhirahNo ratings yet

- Medieval PhilosophyDocument39 pagesMedieval PhilosophyJorhen PanisNo ratings yet

- ByteBlaster InstructionsDocument11 pagesByteBlaster InstructionsildevanNo ratings yet

- Simulink Exercise: Prepared by Jayakrishna Gundavelli and Hite NAME: - DATEDocument12 pagesSimulink Exercise: Prepared by Jayakrishna Gundavelli and Hite NAME: - DATEKarthikeyan SubbiyanNo ratings yet

- Book Abstracts CORMVDocument171 pagesBook Abstracts CORMVthamizh555No ratings yet

- Analysis: Is Science Killing Sport?Document3 pagesAnalysis: Is Science Killing Sport?Raunak Chakraborty (Rio)No ratings yet

- MG Motor Success Story - Case Study - FN PDFDocument4 pagesMG Motor Success Story - Case Study - FN PDFsevakendra palyaNo ratings yet

- I. Objectives: PE10PF-Ia-h-39Document3 pagesI. Objectives: PE10PF-Ia-h-39Ken Genece LlanesNo ratings yet

- Citra Log - Txt.oldDocument57 pagesCitra Log - Txt.oldEmmanuel PeraltaNo ratings yet

- Arindam Chaudhuri - The TruthDocument8 pagesArindam Chaudhuri - The TruthCatalyticGirlNo ratings yet

- Faculty of Business ManagementDocument4 pagesFaculty of Business Managementmalik234everNo ratings yet