Professional Documents

Culture Documents

Data Point Summary For Building Management System

Data Point Summary For Building Management System

Uploaded by

Basil OguakaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Point Summary For Building Management System

Data Point Summary For Building Management System

Uploaded by

Basil OguakaCopyright:

Available Formats

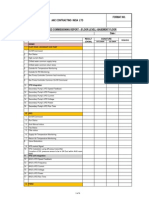

DPS- 1

DATA POINT SUMMARY FOR BUILDING MANAGEMENT SYSTEM

Sr. No.

Description

DI

AO

DO

By IBMS Contractor

By 3rd Party Contractors

HVAC Vendor to provide RS 485

MODBUS / Bacnet interface in each

chiller. HVAC Vendor to show the

parameters on the MODSCAN

Bacnet / Modbus Interface License /Bacstack/Cimetrics software

before integrating to IBMS. All

mapping details & the Master/slave

ID setting in the Chillers to be done

by the HVAC Contractor

Chiller (2 Nos.)

Chillers - ON / OFF

Chiller run status

Chiller Auto / Manual switch

Chillers Trip / Fault

CHW supply / return temp.

Common Header CHW supply / return temp.

Ambient Temperature & Humidity

Chiller isolation Mortised

command & status.

Differential pressure sensor and transmitter across

chilled water header

10

Chilled Water Flow Status

Primary Chilled Water Pumps

Pump ON / OFF

Pump run status

Pump Auto / Manual switch status

CHW pump trip status.

Condenser Water Pumps

Condenser Water pump ON / OFF Command.

Condenser Water pump ON / OFF status.

Differential pressure switch across Suitable Insertion Provision in Water

the CHW pumps for ON/OFF status. Line

Condenser Water pump Auto / Manual status.

Signal from A/M switch.

Condenser Water pump trip status.

Signal from potential free contact.

Cooling Tower

Cooling Tower sump outlet temperature.

Cooling Tower fan ON/OFF command.

Cooling Tower fan trip status.

Signal from potential free contact.

Potential Free Contact in CT Panel

Cooling Tower fan Auto/ Manual status.

Signal from potential free contact.

Potential Free Contact in CT Panel

Sump level monitoring low

Signal from level switch

Make up water tank

Signal from level switch

Sub Total (A+B+C+D+E)

Data Point Summary

AI

2

4

valves

2

8

ON/OFF

BMS Acceptance of Potential Free

Output in Chiller Panel

BMS Potential Free Contact in Chiller

Panel

BMS Potential Free Contact in Chiller

Panel

BMS Potential Free Contact in Chiller

Panel

Suitable Insertion Provision in Water

Immersion temperature sensor

Line

Suitable Insertion Provision in Water

Immersion temperature sensor

Line

Ambient temp/Humidity sensor

2

2

2

2

16

Potential Free Contact from

to Chiller MCC panel

Potential Free Contact to

from Chiller MCC panel

Potential Free Contact to

from Chiller MCC panel

Potential Free Contact to

from Chiller MCC panel

31

10

Potential Free Contact from BMS to Butterfly Valves

motorised butter fly valve with limit

switch for position status.

Suitable Insertion Provision in Water

Differential Pressure Sensor

Line

Suitable Insertion Provision in Water

Suitable insertion provision

Line

Potential Free Contact from BMS Acceptance of Potential Free

to Pump Starter panel

Output in Pump Panel

Suitable Insertion Provision in Water

Differential Switch across Pumps

Line

Potential

Free

Contact

at Potential Free Contact in Pump

Auto/Manual Switch

Panel

Potential Free Contact in Pump

Signal from potential free contact.

Panel

Potential Free Contact from BMS Acceptance of Potential

to Pump Starter panel

Output in Pump Panel

Free

Potential Free Contact in Pump

Panel

Potential Free Contact in Pump

Panel

Imm type temp sensor.

Potential Free Contact from BMS Acceptance of Potential

to CT Starter panel

Output in CT Panel

Suitable Insertion

Cooling Tower

Suitable Insertion

Cooling Tower

Free

Provision

in

Provision

in

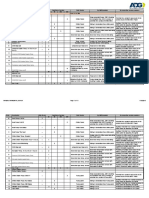

DPS- 2

DATA POINT SUMMARY FOR BUILDING MANAGEMENT SYSTEM

Sr. No.

Description

DI

Air Handling Units - (20 Nos.)

AHU ON/OFF

AHU blower status

20

AHU Auto / Manual status

20

AHU filter status

20

Return Air Temperature

Motorised Valve Cooling

Sub Total (F)

Pressurization Fans

Fan ON/OFF

Fan Air Flow status

Fan Auto / Manual status

Sub Total (I)

AO

DO

20

20

4

8

Duct Temperature Sensor

Suitable Insertion Provision in AHU

0-10 V DC Signal

2 / 3 Way Control Valve by HVAC,

with acceptance of 0-10 V DC

Signal

Potential Free Contact from BMS Acceptance of Potential

to fan Starter panel

Output in AHU Panel

Suitable Insertion Provision in AHU

Potential

Free

Contact

Auto/Manual Switch

at Potential Free Contact in AHU

Panel

Ventillation Fans

Fan ON/OFF

Fan Air Flow status

Fan Auto / Manual status

CO Level Monitoring in Parking Areas

Sub Total (J)

Fire Fighting System

Hydrant pressure monitroing

Pressure Sensor

Sprinkler pressure monitroing

Pressure Sensor

2

3

4

5

6

7

10

Suitable Insertion Provision in AHU

10

Potential

Free

Contact

Auto/Manual Switch

at Potential Free Contact in AHU

Panel

CO Sensors

20

Sprinkler Pump run status

Fire Pump Run Status (Electrically driven)

Sub Total (L)

Free

Differential Switch across Fans

Fire Pump Run Status (Diesel driven)

Potential Free Contact from BMS Acceptance of Potential

to fan Starter panel

Output in AHU Panel

10

Jockey Pump run status

Sprinkler / Hydrant header flow status

Free

Differential Switch across Fans

Free

Suitable Insertion Provision in AHU

20

Potential Free Contact from BMS Acceptance of Potential

to fan Starter panel

Output in AHU Panel

Potential

Free

Contact

at Potential Free Contact in AHU

Auto/Manual Switch

Panel

Differential Pressure Switch across

Suitable Insertion Provision in AHU

filter

20

60

By 3rd Party Contractors

Differential Switch across Fans

20

20

By IBMS Contractor

Data Point Summary

AI

10

Potential Free Contact water DP

switch

Potential Free Contact water DP

switch

Potential Free Contact water DP

switch

Suitable insertion provision

Potential Free Contact water DP

switch

Suitable

Line

Suitable

Line

Suitable

Line

Suitable

Line

Suitable

Line

Suitable

Line

Suitable

Line

Insertion Provision in Water

Insertion Provision in Water

Insertion Provision in Water

Insertion Provision in Water

Insertion Provision in Water

Insertion Provision in Water

Insertion Provision in Water

DPS- 3

DATA POINT SUMMARY FOR BUILDING MANAGEMENT SYSTEM

Sr. No.

Description

DI

AO

DO

By IBMS Contractor

By 3rd Party Contractors

Water Supply System

Fire Water Tank High / Low Level

Level Switch

Suitable Insertion Provision

Raw Water Tank High / Low Level

Level Switch

Suitable Insertion Provision

Treated Water Tank High / Low Level

Level Switch

Suitable Insertion Provision

Soft Water Tank High / Low Level

Level Switch

Suitable Insertion Provision

Fire Pump Auto/Manual Status

Fire Pump run status

Raw Water Pump Auto/Manual Status

Raw Water Pump run status

Soft Water Pump Auto/Manual Status

10

Soft Water Pump run status

Potential Free Contact to BMS

from fan Starter panel

Differential pressure switch across

the pumps

Potential Free Contact to BMS

from fan Starter panel

Differential pressure switch across

the pumps

Potential Free Contact to BMS

from fan Starter panel

Differential pressure switch across

the pumps

Potential Free Contact in

Panel

Suitable Insertion Provision in

Line

Potential Free Contact in

Panel

Suitable Insertion Provision in

Line

Potential Free Contact in

Panel

Suitable Insertion Provision in

Line

Sub Total (M)

N

Electrical System - HT Panels , LT Panels

HT / LT Panel Phase Voltage Monitoring

HT / LT Panel Phase Current Monitoring

HT / LT Panel Frequency Monitoring

HT / LT Panel KW Monitoring

HT / LT Panel KWH Monitoring

6

7

8

HT / LT Breaker On/Off status

Bus Coupler On/Off Status

HT / LT Panel Trip Status

Sub Total (N)

28

10

10

10

0

30

DG Start/Stop Stauts

DG AMF Breaker Status

3

4

Bulk Storage Tank level Monitoring

DG Oil Day Tank Level

Sub Total (O)

Lifts / Escalators

UPS Nos on Modbus RTU / Bacnet

Fire Alarm System

1

2

3

through

0

Integration of Lifts through Modbus

Protocol.

Integration of UPS through Modbus

Protocol / Bacnet

Integration of FAS through

Modbus/Bacnet/OPC Protocols of

all devices/detectors

44

155

20

Pump

Water

in

in

in

in

in

DG Panel vendor to provide RS 485

MODBUS RTU. The electrical vendor

to show the parameters on the

Modbus MODSCAN

software

before

integrating to IBMS. All mapping

details & the Master/slave ID

setting in the meter to be done by

the DG vendor

Potential Free Contact from BMS

to DG Starter panel

Potential Free Contact from BMS

to DG Starter panel

Flame Proof Level Transmitter

Flame Proof Level Transmitter

0

Pump

Water

Integration

Protocol

Diesel Generator

Pump

Water

Provision of suitable rating PT

Panel

Provision of suitable rating CT

Panel

Provision of suitable rating CT/PT

Panel

Provision of suitable rating CT/PT

Panel

Provision of suitable rating CT/PT

Panel

Potential Free Contact in Panel

Potential Free Contact in Panel

Potential Free Contact in Panel

Through Modbus Output of Multi

data meters

Grand Total (A to R)

Data Point Summary

AI

44

You might also like

- QAQC Electrical Inspection: A Beginner's GuideFrom EverandQAQC Electrical Inspection: A Beginner's GuideRating: 4 out of 5 stars4/5 (1)

- Calefaccion de GasDocument208 pagesCalefaccion de Gasjuan vital80% (5)

- BMS Sample IO Point ScheduleDocument31 pagesBMS Sample IO Point ScheduleIshan Ranganath100% (2)

- BMS Single Line Diagram & Schedule of PointsDocument11 pagesBMS Single Line Diagram & Schedule of PointsChim Con86% (7)

- I O Summary For BMSDocument2 pagesI O Summary For BMSN Faathimaa Shabrina67% (3)

- 07 BMS CheckListDocument13 pages07 BMS CheckListamhosny6486% (7)

- BMS Dependancy ListDocument6 pagesBMS Dependancy ListHemantSharmaNo ratings yet

- Appendix J - Qq01 Bms Io Points ListDocument19 pagesAppendix J - Qq01 Bms Io Points Listkkppkk1100% (4)

- IO Summary For BMSDocument2 pagesIO Summary For BMSAmol Bengiri75% (8)

- Direct Digital Controls and Commissioning - Shadpour PDFDocument30 pagesDirect Digital Controls and Commissioning - Shadpour PDFalexander alvaradoNo ratings yet

- BMS Point Schedule - ExhaustiveDocument2 pagesBMS Point Schedule - Exhaustiveabdullah sahibNo ratings yet

- JCI BMS ArchitectureDocument2 pagesJCI BMS ArchitectureGopal KrishnaNo ratings yet

- DDC System Test Procedure-0831Document20 pagesDDC System Test Procedure-0831Abdul Mohid SheikhNo ratings yet

- BMS Point ScheduleDocument14 pagesBMS Point Schedulesajeevi piumikaNo ratings yet

- BMSDocument44 pagesBMSHari Krishna100% (5)

- 2018 Recommended Reading ListDocument10 pages2018 Recommended Reading ListBasil OguakaNo ratings yet

- York Indoor Split UnitDocument40 pagesYork Indoor Split UnitAugustine Dharmaraj50% (4)

- BMT Check List - XLSXDocument6 pagesBMT Check List - XLSXNedunuri.Madhav MurthyNo ratings yet

- 2727 Input Output SummaryDocument4 pages2727 Input Output SummaryMinh Nhut LuuNo ratings yet

- Estimate - BmsDocument12 pagesEstimate - BmsSaurabh Kumar SharmaNo ratings yet

- BMS IO Summary For QC2 R1 20.02.2013Document9 pagesBMS IO Summary For QC2 R1 20.02.2013Nedunuri.Madhav Murthy100% (2)

- Itcc Bms Io HvacDocument40 pagesItcc Bms Io Hvacuddinnadeem0% (1)

- Tata Projects Limited: Doc. No: Operation & Control PhilosophyDocument10 pagesTata Projects Limited: Doc. No: Operation & Control Philosophyvenkatraman JNo ratings yet

- Construction Issue: Qty. (Nos) AI DI AO DO Hvac System I Water Chilling Units 3Document11 pagesConstruction Issue: Qty. (Nos) AI DI AO DO Hvac System I Water Chilling Units 3Al Amin Hossain Srabon100% (1)

- BMS I-O ListDocument5 pagesBMS I-O ListCulve Yon100% (1)

- A554 D A2110 DWG A05 510Document1 pageA554 D A2110 DWG A05 510Non Etabas Gadnatam100% (1)

- BMS Point ScheduleDocument5 pagesBMS Point ScheduleNguyen Tran QuynhNo ratings yet

- Bms Design Guide PDFDocument95 pagesBms Design Guide PDFalmig200100% (3)

- Building Management System: CharacteristicsDocument14 pagesBuilding Management System: Characteristicsshaikamirulhasan100% (1)

- BMS Io Datapoint ScheduleDocument2 pagesBMS Io Datapoint Scheduleabdullah sahibNo ratings yet

- BMS Design - Interface RequirementsDocument4 pagesBMS Design - Interface RequirementsJoanne Castro Agustin75% (4)

- ETA SummeryDocument1 pageETA SummeryNedunuri.Madhav Murthy100% (1)

- IO Summary For IBMS Service PDFDocument348 pagesIO Summary For IBMS Service PDFpratimNo ratings yet

- SCADA Point List 6 7 11Document1 pageSCADA Point List 6 7 11puru55980No ratings yet

- BMS SpecificationDocument10 pagesBMS SpecificationsharafanyNo ratings yet

- BMS Control Cable SpecificationDocument3 pagesBMS Control Cable SpecificationAddis Tesfaye67% (3)

- Sequence of Operation For Constant Air Volume Air Conditioning SystemDocument7 pagesSequence of Operation For Constant Air Volume Air Conditioning SystemDong VanraNo ratings yet

- Sequence of OperationsDocument12 pagesSequence of Operationseyad100% (3)

- Direct Digital ControlDocument60 pagesDirect Digital ControlAkaka32150% (2)

- BMS Device Instllation DetailsDocument52 pagesBMS Device Instllation Detailsdharman_s100% (2)

- ABB I-Bus KNX System DescriptionDocument24 pagesABB I-Bus KNX System DescriptionSivabalan MarimuthuNo ratings yet

- Ibms Design Based ReportDocument67 pagesIbms Design Based ReportShameel PtNo ratings yet

- Lonix IBMS SpecificationDocument23 pagesLonix IBMS Specificationkakyo29433100% (1)

- BMS-Concept IO Schedule For MEPDocument8 pagesBMS-Concept IO Schedule For MEPSINTO THOMASNo ratings yet

- Ahu Performance 2Document29 pagesAhu Performance 2maddy1667100% (1)

- Fan Coil Units PDFDocument4 pagesFan Coil Units PDFAnonymous hxj75CHM5No ratings yet

- Section 15900 - Building Management System and Hvac EquipmentDocument18 pagesSection 15900 - Building Management System and Hvac EquipmentBudi MarelanNo ratings yet

- Saiver AHUDocument12 pagesSaiver AHUNorsyafiqah Rozi100% (1)

- 23 05 93 HVAC - TAB Guide Specification 8-28-2014Document9 pages23 05 93 HVAC - TAB Guide Specification 8-28-2014Naeem KhanNo ratings yet

- BMS I-O List - XocopxxyDocument3 pagesBMS I-O List - XocopxxyCulve YonNo ratings yet

- BMS UbcDocument94 pagesBMS Ubcamhosny64No ratings yet

- Standard Technical Requirements For Sub-Metering System: T D H B I A FDocument25 pagesStandard Technical Requirements For Sub-Metering System: T D H B I A Fshadi sabikNo ratings yet

- Access Control Terminal Installation GuideDocument2 pagesAccess Control Terminal Installation GuideRoss FloresNo ratings yet

- IO SummaryDocument8 pagesIO SummaryVineeth VKNo ratings yet

- SECTION 15180 BMS and Automatic ControlsDocument32 pagesSECTION 15180 BMS and Automatic ControlskdpmansiNo ratings yet

- DDC ControllerDocument14 pagesDDC ControllerharishupretiNo ratings yet

- BMS Submittal SampleDocument66 pagesBMS Submittal Sampleaads1984No ratings yet

- BMS-Day 01 PDFDocument23 pagesBMS-Day 01 PDFdevakaNo ratings yet

- BMS Spec'sDocument80 pagesBMS Spec'sShaik Bepari Jakeer100% (1)

- Method Statement Submittal FOR Start-Up Commissioning of Air Cooled ChillersDocument14 pagesMethod Statement Submittal FOR Start-Up Commissioning of Air Cooled ChillersSamboy Dionisio100% (1)

- DDC ControlsDocument85 pagesDDC Controlssui1981100% (1)

- Data Point Summary For Building Management SystemDocument3 pagesData Point Summary For Building Management SystemawadalmekawyNo ratings yet

- Preventing Legionellosis: by Janet Stout, PH.D., Associate Member ASHRAEDocument5 pagesPreventing Legionellosis: by Janet Stout, PH.D., Associate Member ASHRAEBasil OguakaNo ratings yet

- Singapore Fire Safety Engineering Guidelines 2015 - 0Document88 pagesSingapore Fire Safety Engineering Guidelines 2015 - 0DONGTA123100% (2)

- IPP Guideline Template Non-Res BLDGDocument11 pagesIPP Guideline Template Non-Res BLDGBasil OguakaNo ratings yet

- Fiberglass Tank InstaalationDocument12 pagesFiberglass Tank InstaalationBasil OguakaNo ratings yet

- Hrs Funke Storage CalorifierDocument12 pagesHrs Funke Storage CalorifierBasil Oguaka100% (1)

- Panasonic Air Conditioning Uk 030309Document83 pagesPanasonic Air Conditioning Uk 030309Basil OguakaNo ratings yet

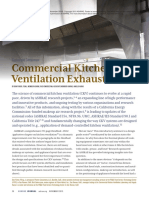

- Commercial Kitchen Ventilation Exhaust Hoods: Technical FeatureDocument14 pagesCommercial Kitchen Ventilation Exhaust Hoods: Technical FeatureBasil OguakaNo ratings yet

- WAHX Selection: Project Title: Design City: Name: Company: Email: Phone: NotesDocument1 pageWAHX Selection: Project Title: Design City: Name: Company: Email: Phone: NotesBasil OguakaNo ratings yet

- MGM Grand Fire and Fire Safety Then, Now: Technical FeatureDocument10 pagesMGM Grand Fire and Fire Safety Then, Now: Technical FeatureBasil OguakaNo ratings yet

- Financial Performance Impacts Compensation Options: Technical FeatureDocument8 pagesFinancial Performance Impacts Compensation Options: Technical FeatureBasil OguakaNo ratings yet

- Appendix - 33A Requirements For Underground Water Tank and Fire PumpsDocument1 pageAppendix - 33A Requirements For Underground Water Tank and Fire PumpsBasil OguakaNo ratings yet

- Dear Elijah,: Comments For Shopping Mall, Mushin Mechanical Designs 17-05-2016Document4 pagesDear Elijah,: Comments For Shopping Mall, Mushin Mechanical Designs 17-05-2016Basil OguakaNo ratings yet

- Fire Dynamics II: Lecture # 1 Introduction / Enclosure PhenomenaDocument23 pagesFire Dynamics II: Lecture # 1 Introduction / Enclosure PhenomenaBasil OguakaNo ratings yet

- Above Ground Storage TankDocument6 pagesAbove Ground Storage TankBasil OguakaNo ratings yet

- Fire Dynamics II - Chemistry of Room Fire Combustion Lecture - 5Document28 pagesFire Dynamics II - Chemistry of Room Fire Combustion Lecture - 5Basil OguakaNo ratings yet

- A Case Study On How Performance Based Design Became A New Approach To Determine Fire Protection StrategiesDocument2 pagesA Case Study On How Performance Based Design Became A New Approach To Determine Fire Protection StrategiesBasil OguakaNo ratings yet

- Safety Matters - Performance Based Design Using Computer Fire ModelsDocument4 pagesSafety Matters - Performance Based Design Using Computer Fire ModelsBasil OguakaNo ratings yet

- McQuay BrochureDocument24 pagesMcQuay BrochureAna Gil Pinto BrásNo ratings yet

- Si34-803B - Service Manual VRVIII RXYQ5-54PAY1 - PAYL - PTL R-410A Heat Pump 50Hz - 60Hz - Service Manuals - EnglishDocument452 pagesSi34-803B - Service Manual VRVIII RXYQ5-54PAY1 - PAYL - PTL R-410A Heat Pump 50Hz - 60Hz - Service Manuals - Englishghencea100% (1)

- Boiler Soot-Blowing in Power Plants - Compressed Air Best PracticesDocument8 pagesBoiler Soot-Blowing in Power Plants - Compressed Air Best PracticesRoland NicolasNo ratings yet

- Guia ServiceDocument60 pagesGuia ServiceselvamejiaNo ratings yet

- (Doi 10.1115/gt2015-42449) Corsini, Alessandro Delibra, Giovanni Minotti, Stefano Rossin - (ASME ASME Turbo Expo 2015 - Turbine Technical Conference and Exposition - Montreal, Quebec, Canada (MonDocument10 pages(Doi 10.1115/gt2015-42449) Corsini, Alessandro Delibra, Giovanni Minotti, Stefano Rossin - (ASME ASME Turbo Expo 2015 - Turbine Technical Conference and Exposition - Montreal, Quebec, Canada (MonAngga FirmansyahNo ratings yet

- 3406 400kva STANDBY PDFDocument6 pages3406 400kva STANDBY PDFPablo Gaspar D'Agostini AmengualNo ratings yet

- York Predator XP Heat PumpDocument54 pagesYork Predator XP Heat Pumpjack-bc100% (1)

- Exhausto - Solutii VentilatiiDocument12 pagesExhausto - Solutii VentilatiialanatoraNo ratings yet

- TTM Gen Fam 21Document146 pagesTTM Gen Fam 21aerologik100% (2)

- Catalogo Servomotors HDPDocument24 pagesCatalogo Servomotors HDPkantorunoNo ratings yet

- Hvac Equipment Boq-EpcDocument15 pagesHvac Equipment Boq-EpcJami MnNo ratings yet

- Electrical Maintenance ManualDocument326 pagesElectrical Maintenance ManualTiti Sariyati100% (4)

- Cs Pw9gke Phaag0701008c2Document65 pagesCs Pw9gke Phaag0701008c2Ferenc Schmidt100% (1)

- 55 MaintenanceDocument39 pages55 MaintenanceJefry Somarribas HerreraNo ratings yet

- Confined SpaceDocument6 pagesConfined SpaceAnonymous LpCD3hNo ratings yet

- IM S-MMS - en - # - #99Document176 pagesIM S-MMS - en - # - #99thoalevanNo ratings yet

- Ventsim ManualDocument232 pagesVentsim ManualMendoza Castillo JulioNo ratings yet

- Duplex 1500 8000 Mutli-N Rooftop en 2014 06Document8 pagesDuplex 1500 8000 Mutli-N Rooftop en 2014 06chaesar1No ratings yet

- Interlock & Protection HandbookDocument67 pagesInterlock & Protection Handbookgaurav tiwari100% (7)

- VAV BrochureDocument28 pagesVAV BrochureMuralidharan SudhakarNo ratings yet

- Inverter Pair FTK (X) J RK (X) J Service ManualDocument162 pagesInverter Pair FTK (X) J RK (X) J Service ManualБорис Борян100% (1)

- LG Therma V MonoblocDocument47 pagesLG Therma V MonoblocMuhidin KozicaNo ratings yet

- C1574 (Q432118) User Manual Emerson IMHC1210 ItalGruuDocument39 pagesC1574 (Q432118) User Manual Emerson IMHC1210 ItalGruumliugongNo ratings yet

- Smoke Control TraneDocument156 pagesSmoke Control Traneeselcosac100% (1)

- Catalogo LG Inverter Fan Coil Piso Techo Cassete y Multy Split PDFDocument28 pagesCatalogo LG Inverter Fan Coil Piso Techo Cassete y Multy Split PDFMaxiaires Refrigeracion100% (3)

- Aer Conditionat Multisplit LG Unitati Externe Pliant Date Tehnice PDFDocument9 pagesAer Conditionat Multisplit LG Unitati Externe Pliant Date Tehnice PDFClau HerleaNo ratings yet

- Tray Drying Report PDFDocument10 pagesTray Drying Report PDF杜振维No ratings yet