Professional Documents

Culture Documents

Working Manual Complete Version 2014

Working Manual Complete Version 2014

Uploaded by

Siti Nor FazilahwatiCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Iata CRM TemDocument184 pagesIata CRM TemPILCOMOV10No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Kamishibai Intro PDFDocument27 pagesKamishibai Intro PDFGanesh Nagaraj100% (1)

- Dell & Eureka Forbes' Channel StrategyDocument17 pagesDell & Eureka Forbes' Channel StrategySaHil GuptaNo ratings yet

- Telekom Malaysia DC System Test Rectifier Test PlanDocument59 pagesTelekom Malaysia DC System Test Rectifier Test Planzamricepu0% (1)

- A Proposal To Replace Aging Fire Extinguishers in Healthcare Facilities in SarawakDocument3 pagesA Proposal To Replace Aging Fire Extinguishers in Healthcare Facilities in SarawakSiti Nor FazilahwatiNo ratings yet

- KNH 5073 Lecture Notes - Updated 21072016Document58 pagesKNH 5073 Lecture Notes - Updated 21072016Siti Nor FazilahwatiNo ratings yet

- Report CEM Hospital Bahiyah 10 Oct 18 HSB (v1)Document48 pagesReport CEM Hospital Bahiyah 10 Oct 18 HSB (v1)Siti Nor Fazilahwati0% (1)

- Research Title: Nocturnal Cooling of Water For Radiant Cooling in Malaysian BuildingDocument24 pagesResearch Title: Nocturnal Cooling of Water For Radiant Cooling in Malaysian BuildingSiti Nor FazilahwatiNo ratings yet

- Printout: Wednesday, 29 October 2014 7:02 AMDocument1 pagePrintout: Wednesday, 29 October 2014 7:02 AMSiti Nor FazilahwatiNo ratings yet

- Water Boar Dock 2014Document1 pageWater Boar Dock 2014Siti Nor FazilahwatiNo ratings yet

- Memo Energy PolicyDocument2 pagesMemo Energy PolicySiti Nor FazilahwatiNo ratings yet

- Sesco Oct2014Document1 pageSesco Oct2014Siti Nor FazilahwatiNo ratings yet

- Domestic Home Structure Drawing 3d With RoofDocument1 pageDomestic Home Structure Drawing 3d With RoofSiti Nor FazilahwatiNo ratings yet

- Water Level and TempDocument24 pagesWater Level and TempSiti Nor FazilahwatiNo ratings yet

- No, 4606 Taman Sumber Alam Santuary, Jalan Sultan Tengah 93050, PETRA JAYA, KUCHING, Malaysia Mobile: 0172000959Document3 pagesNo, 4606 Taman Sumber Alam Santuary, Jalan Sultan Tengah 93050, PETRA JAYA, KUCHING, Malaysia Mobile: 0172000959Siti Nor FazilahwatiNo ratings yet

- QCWFKXDocument4 pagesQCWFKXSiti Nor FazilahwatiNo ratings yet

- Masjid Muttaqin ASGMNTDocument21 pagesMasjid Muttaqin ASGMNTSiti Nor FazilahwatiNo ratings yet

- Is 2090 Specification For High Tensile Steel Bars Used in PRDocument12 pagesIs 2090 Specification For High Tensile Steel Bars Used in PRFrank StephensNo ratings yet

- Commission On Installment BasisDocument2 pagesCommission On Installment BasisDevorah Mae CubeloNo ratings yet

- Autodesk Feature CodesDocument14 pagesAutodesk Feature Codessplaw9484No ratings yet

- 3d Printing InternshipDocument2 pages3d Printing InternshipDharshan SNo ratings yet

- D ReportDocument26 pagesD ReportSandeep KumarNo ratings yet

- Carrier 42 Cet FCUDocument21 pagesCarrier 42 Cet FCUcantorband8234100% (2)

- Scan Doc2346Document1 pageScan Doc2346Marcelo PellizzaNo ratings yet

- Busway (Low Voltage) Aftermarket Solutions - CA - EN - 6 - 2012Document16 pagesBusway (Low Voltage) Aftermarket Solutions - CA - EN - 6 - 2012Jonatan Lopez RodriguezNo ratings yet

- Healthy House SpecsDocument27 pagesHealthy House SpecswhsprzNo ratings yet

- Bread Maker SBB 850 EDS A1: Kitchen ToolsDocument183 pagesBread Maker SBB 850 EDS A1: Kitchen ToolsOtylyia RaluNo ratings yet

- Adopting Building Information Modeling (Bim) As Collaboration Platform in The Design IndustryDocument10 pagesAdopting Building Information Modeling (Bim) As Collaboration Platform in The Design IndustryPuneet AroraNo ratings yet

- Mobil Eal ArcticDocument1 pageMobil Eal ArcticFERNANDONo ratings yet

- ECFanGrid Installation and Operation Guide PDFDocument79 pagesECFanGrid Installation and Operation Guide PDFMarceloNo ratings yet

- General Work Permit S3-F7: Start Date: End Date: Start Time: End TimeDocument1 pageGeneral Work Permit S3-F7: Start Date: End Date: Start Time: End TimeHareekirishnan LrkNo ratings yet

- EASA-TCDS-E.052 (IM) Rolls - Royce Model 250 Series II Engines-01-22062011Document12 pagesEASA-TCDS-E.052 (IM) Rolls - Royce Model 250 Series II Engines-01-22062011starsalingsoul80000% (1)

- Public FinanceDocument3 pagesPublic FinanceAndhika Pres'Lee Bintang10% (10)

- MIS Assignment 4Document5 pagesMIS Assignment 4Ah Vee60% (5)

- Rise and Fall of Air IndiaDocument39 pagesRise and Fall of Air IndianARAYANNo ratings yet

- Data Management SolutionsDocument11 pagesData Management SolutionsrkNo ratings yet

- Honda BikeDocument43 pagesHonda Bikehariom sharmaNo ratings yet

- Sizing, Specifying and Selecting Centrifugal Pumps (CE) PDFDocument5 pagesSizing, Specifying and Selecting Centrifugal Pumps (CE) PDFjdgh1986100% (1)

- Lessons Learned From Launch Vehicle Avionics SystemsDocument10 pagesLessons Learned From Launch Vehicle Avionics Systemsdovesnest_inNo ratings yet

- Wind Power PDFDocument13 pagesWind Power PDF3319826No ratings yet

- Hydraulic & Mechanical PullersDocument9 pagesHydraulic & Mechanical PullersMeilvy Rahmadani PaneNo ratings yet

- Lubricants: Unoba EPDocument2 pagesLubricants: Unoba EPQC RegianNo ratings yet

- PR01301 Eurol Product CatalogueDocument57 pagesPR01301 Eurol Product CatalogueMarco LizanaNo ratings yet

Working Manual Complete Version 2014

Working Manual Complete Version 2014

Uploaded by

Siti Nor FazilahwatiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Working Manual Complete Version 2014

Working Manual Complete Version 2014

Uploaded by

Siti Nor FazilahwatiCopyright:

Available Formats

WORKING MANUALS AND TOOLS

For

JABATAN KESIHATAN NEGERI SARAWAK

ENERGY MANAGEMENT SYSTEM

Doc num: JKNSSEMS/WM 1

Effective date: 1st July 2014

Review date:

Revision num: 00

Page 2

Content

1. Operational guide

1.1 Objectives

1.2 Scope of guide

1.3 Standard and reference document

1.4 Normal working procedures to control energy consumption

Page

3

3

4

5

2. Specific Energy Conservation Measures: For future implementation

3. Leading Techniques For Energy Savings in Commercial Office Buildings

8

10

4. Process Mapping, work instruction and log sheet

4.1 Objectives

4.2 Development of PM

4.3 Work Instruction (WI) and Log Sheet (LS)

13

13

13

5. Revision Record

6. Lampiran

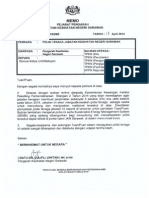

a. Memo Perlantikan Sebagai Ahli Jawatankuasa Tenaga (Energy

Committee)

b. Memo Polisi Tenaga Jabatan Kesihatan Negeri Sarawak

21

WORKING MANUALS AND TOOLS

For

JABATAN KESIHATAN NEGERI SARAWAK

ENERGY MANAGEMENT SYSTEM

Doc num: JKNSSEMS/WM 1

1. Operational guide

1.1 Objectives

Effective date: 1st July 2014

Review date:

Revision num: 00

Page 3

To set up energy conservation practices for Energy Accounting Centres.

To set up a firm base for the preparation of energy conservation targets and plans for each

EAC.

1.2 Scope of guide

This operational guide is applicable for working areas of the following EACs:

List of EACs and controlled equipment or system of EACs:

Controlled

Equipment ref

EACs

equipment or

Quantity

Unit

no.

system

EAC 1

AHU

4

Unit

Lighting system

1

System

CWFCU

9

Unit

ACSU

23

Unit

Exhaust fan

30

Unit

Photocopier

9

Unit

EAC 2

AHU

9

Unit

Lighting system

1

System

CWFCU

1

Unit

ACSU

14

Unit

Exhaust fan

26

Unit

Photocopier

11

Unit

EAC 3

AHU

6

Unit

Lighting system

1

System

CWFCU

2

Unit

ACSU

16

Unit

Exhaust fan

22

Unit

Photocopier

9

Unit

EAC 4

Chiller

2

Unit

Lighting system

1

System

Electrical system

1

System

Exhaust fan

7

Unit

EAC 5

Lighting system

1

System

WORKING MANUALS AND TOOLS

For

JABATAN KESIHATAN NEGERI SARAWAK

ENERGY MANAGEMENT SYSTEM

Doc num: JKNSSEMS/WM 1

Effective date: 1st July 2014

Review date:

Revision num: 00

Page 4

Figure 1: Layout of EACs

1.3 Standard and reference document

Surat Pekeliling Am Bil 2 Tahun 2014, Jabatan Perdana Menteri

Pekeliling Perbendaharaan Bil 2 Tahun 2014, Kementerian Kewangan

Memo dalaman Jabatan Kesihatan Negeri Sarawak 3 Mac 2014, Langkah-langkah

Penjimatan Utiliti Jabatan, Pejabat Pengarah Kesihatan Negeri Sarawak

Memo dalaman Seksyen Kejuruteraan JKN Sarawak, 20 Mac 2014, Kawalan

Chiller Plant

Malaysian Industrial Energy Audit Guidelines, 2003, KETTHA

Energy Efficiency And Conservation Guidelines for Malaysian Industries, 2007,

KETTHA

MS 1525:2007

WORKING MANUALS AND TOOLS

For

JABATAN KESIHATAN NEGERI SARAWAK

ENERGY MANAGEMENT SYSTEM

Doc num: JKNSSEMS/WM 1

Effective date: 1st July 2014

Review date:

Revision num: 00

Page 5

1.4 Normal working procedures to control energy consumption

1.4.1 Lighting

a. Switch off lighting during break hours

b. Switch off entirely or partially lighting in rooms or area that has sufficient daylighting

c. Switch on lighting in areas or rooms that is in use only

d. Switch off light in store rooms, pantries, filing rooms, meeting rooms, discussion rooms ect

when not in use.

e. Switch off lighting in toilet when enough daylighting is available.

1.4.2 Air conditioning

a. Shut off Air Conditioning (WCFCU/ACSU) after meeting

List of meeting rooms as follows

- Bilik mesyuarat Utama

- Bilik Mesyuarat Bahagian Perubatan

- Bilik Mesyuarat Bahagian Pergigian

- BIlik Mesyaurat Bahagian Kesihatan Awam

- Bilik Mesyuarat Pengurusan

- Bilik Mesyuarat

b. Shut of Air Conditioning in store room when not occupied by anybody.

c. Shut off exhaust fan in store room/document room ect. when not occupied by anybody.

d. Chiller shall be operated according to set time as follows; Flow chart I following page shows

the operation procedure of the chillers and AHUs.

Morning : 8am-1pm

Afternoon : 2.30pm 4.30pm

e. Air conditioning should be set to 24 -25C to avoid overcooling.

f. Ensure all doors and windows are properly shut to prevent warm and humid air from

entering the room.

g. Utilise normal standing fan provided to increase thermal comfort.

h. Normal air flow from AHU should be between 200-350CFM.

WORKING MANUALS AND TOOLS

For

JABATAN KESIHATAN NEGERI SARAWAK

ENERGY MANAGEMENT SYSTEM

Doc num: JKNSSEMS/WM 1

Effective date: 1st July 2014

Review date:

Revision num: 00

Page 6

Operation procedure for chiller

AUTOMATIC CHILLER

START ON 8.00 AM.

AHU SHALL START AT

LEAST 15 MINUTES

EARLY.

CHILLER RUN

YES

BREAKDOWN / TRIP /

EMERGENCY SHUTDOWN

/ ANY UNFAMILLIAR

VIBRATION OR SOUND

NO

12.45 PM CHILLER STOP (TOUCH

SCREEN ONLY) CHANGE THE

CHILLER SELECTOR TO 0

SEVERE

REFER TO

MANUFACTURER

ENGINEERING

ASSESS SEVERITY

OF PROBLEM

NOT SEVERE

2.30 PM CHILLER START (TOUCH

SCREEN ONLY) CHANGE THE

SELECTOR TO 1/2

AUTOMATIC CHILLER

STOP ON 4.30 PM.

AHU SHALL STOP AT

LEAST 15 MINUTES

AFTER CHILLER.

WORKING MANUALS AND TOOLS

For

JABATAN KESIHATAN NEGERI SARAWAK

ENERGY MANAGEMENT SYSTEM

Doc num: JKNSSEMS/WM 1

1.4.3 Lift

Effective date: 1st July 2014

Review date:

Revision num: 00

Page 7

a. If possible choose the stair case instead of lift to go to upper floor.

1.4.4 Electrical appliances

a. Switch off computers power source when not in use for long period etc. an hour or more.

b. Set electrical appliance and computers in standby/sleep mode if not using for couple of

minutes

c. Switch off all appliances when leaving the office.

d. Promote use of LCD monitor and laptop where these utilise much less energy than CRT

monitor.

e. Switch off all photocopier and printer after working hours.

f. Set all photocopier and printer to save mode or off to minimise use of energy.

g. Only print after print preview to save and optimize paper.

WORKING MANUALS AND TOOLS

For

JABATAN KESIHATAN NEGERI SARAWAK

ENERGY MANAGEMENT SYSTEM

Effective date: 1st July 2014

Revision num: 00

Review date:

Page 8

2. Specific Energy Conservation Measures: For future implementation

Doc num: JKNSSEMS/WM 1

Building Envelope

Install Replacement Windows

Install Window Sun Shades

Install/Increase Attic Insulation

Install Roof Insulation

Install Wall Insulation

Control Air Leakage

Space Cooling

Condenser water temperature reset

Chilled water temperature reset

Appication of Variable Speed Drive

Improve chiller efficiency through regular maintenance

More efficient fan/blower/ cooling tower

More efficient pump

Eliminate flow control valve and bypass control

Start stop control of pump

Impeller trimming

Lighting

Replace Incandescent Lighting with Compact Fluorescent Lamps in Dwelling Units

Replace Incandescent Lighting with Fluorescent Lighting in Common Areas

Replace Standard Fluorescent Lamps with Energy-Saving Lamps and Install Electronic Ballasts in

Common Areas

Install Lighting Controls in Common Areas

Convert Exterior Lighting Fixtures

Install Photo-Controls for Exterior Lighting

Doc num: JKNSSEMS/WM 1

WORKING MANUALS AND TOOLS

For

JABATAN KESIHATAN NEGERI

SARAWAK

ENERGY MANAGEMENT SYSTEM

Effective date: 1st July 2014

Review date:

Revision num: 00

Page 9

Miscellaneous ECMs

Replace Older Refrigerators with High-Efficiency Units

Convert Water Supply Pumps

Install Checkmetering or Individual Metering

Install Water-Saving Toilets

Ref:

http://portal.hud.gov/hudportal/HUD?src=/program_offices/public_indian_housing/programs/ph/ph

ecc/strat_list

WORKING MANUALS AND TOOLS

For

JABATAN KESIHATAN NEGERI SARAWAK

ENERGY MANAGEMENT SYSTEM

Effective date: 1st July 2014

Revision num: 00

Review date:

Page 10

3. LEADING TECHNIQUES FOR ENERGY SAVINGS IN COMMERCIAL OFFICE BUILDINGS

Fundamental Control Applications

This is the starting point for the building owner who wants to move beyond programmable

thermostats or sensor-activated lighting controls. Techniques for fundamental control include:

Doc num: JKNSSEMS/WM 1

Zone Scheduling

Permits defined sections of a building to have HVAC and lighting reduced or shut down on a

schedule. Zone scheduling means that a whole building does not need to run at a 100% comfort

setting if on only a few occupants are in the facility.

Night/Unoccupied Setback

Changes the comfort settings (setpoints) of HVAC so that space temperature decreases in

winter and increases in summer, thereby reducing demand for heating and cooling during

unoccupied hours. This feature can also be done using a programmable thermostat, but with only a

few schedules and no flexibility to more aggressively change setback temperatures.

After-Hours Override

Allows temporary changes to comfort settings after-hours. This eliminates the need to modify

schedules, which can sometimes become permanent by accident. This also avoids having the entire

building run in occupied mode to meet the needs of a small group.

Occupancy Sensors

Detect motion or infrared signatures in the space, and trigger lights or HVAC accordingly. The BAS

also enables scheduled overrides or triggers based on card access to an area of the building.

Holiday Scheduling

A calendar defines HVAC and lighting control for an entire calendar year, saving staff time

implementing special schedules and ensuring holiday weekdays do not run in occupied mode

WORKING MANUALS AND TOOLS

For

JABATAN KESIHATAN NEGERI SARAWAK

ENERGY MANAGEMENT SYSTEM

Effective date: 1st July 2014

Revision num: 00

Review date:

Page 11

Advanced Control Applications

In most cases, the same BAS put in place for fundamental controls is also capable of more advanced

control applications, often with only software changes. Techniques for advanced control include:

Doc num: JKNSSEMS/WM 1

Follow Sunrise & Sunset

Permits lighting schedules (such as parking lots, signs, and outdoor access lighting) to vary

throughout the year as the length of daylight changes. This prevents lights from being on during the

daytime. The BAS automatically computes sunrise and sunset based on the latitude and longitude of

the buildings location.

Daylight Harvesting

In zones of the building near exterior walls and windows, lighting can be dimmed or shut off based

on specified minimum lighting levels detected by photocells. Controlled use of motorized shades can

also optimize the availability of natural light without compromising energy efficiency.

Optimum Start

Starts HVAC equipment only as early as required to bring the building setpoints to comfort levels

for occupancy. Control routines take into account outside air temperature and inside space

temperatures when initiating the morning warm-up or cool-down cycles. Optimum start takes the

guess-work out of scheduled startup

Optimum Stop

Determines the earliest possible time to initiate setback temperatures before unoccupied periods

while still maintaining occupant comfort. Also known as coasting. Space temperature drifts

gradually beyond comfort levels in anticipation of the unoccupied period.

Ventilation On Demand

CO2levels in the occupied space are used as an indicator of the number of occupants in a room.

Calculations are then performed that relate the CO2level to the fresh air intake damper, indicating

when more outdoor air is needed. CO2levels also assist heating and cooling anticipation in

thermostatic control to optimize comfort and air circulation.

Variable Air Volume (VAV) Supply Air Temperature Reset

The supply air temperature (SAT) of variable volume air handlers can be reset upwards when full

cooling is not required. The SAT setpoint is increased on cooler days based upon the actual building

load. Then when terminal boxes reach 100% open, the SAT is decreased. This minimizes the need for

mechanical cooling, optimizes the use of economizers, and improves tenant comfort by reducing

drafts due to the movement of excessively cold air.

WORKING MANUALS AND TOOLS

For

JABATAN KESIHATAN NEGERI SARAWAK

ENERGY MANAGEMENT SYSTEM

Effective date: 1st July 2014

Revision num: 00

Review date:

Page 12

Demand Limiting or Load Shedding

Monitors electric meters and current draw on high-demand equipment, then relaxes setpoints to

immediately reduce demand. This technique can, for example, prevent a chiller from further loading,

but can also globally change setpoints throughout the building to shed electric load to avoid peak

utility charges. Non-critical equipment and lighting loads can also be shut off. Discussion and

planning usually occur with the customer in advance so the right strategies are implemented that fit

the business.

Doc num: JKNSSEMS/WM 1

Chiller Optimization

The chilled water loop temperature can be raised as the cooling requirements for the building are

reduced, increasing chiller efficiency. A technique known as load reset raises the chilled water

temperature setpoint until one of the chilled water valves is 100% open.

Cooling Tower Optimization

The condenser water supply to the chiller can be decreased to a minimum setpoint, as defined by

the manufacturer. Then an optimal water supply setpoint can be calculated using a combination of

the outside air wet-bulb temperature and the cooling tower approach temperature. The reduced

water temperature improves the chillers partial load efficiency and also optimizes the cooling

towers operation.

Hot Water Reset

Hot water system temperatures can be reset based on outside air temperature, decreasing heat

losses in supply piping. This saves energy and also makes the office space more comfortable because

it reduces localized heating caused by excessively hot pipes.

Ref:

http://www.schneiderelectric.com.my/documents/buildings/office_building_energy_efficiency.pdf

WORKING MANUALS AND TOOLS

For

JABATAN KESIHATAN NEGERI SARAWAK

ENERGY MANAGEMENT SYSTEM

Doc num: JKNSSEMS/WM 1

Effective date: 1st July 2014

Review date:

Revision num: 00

Page 13

4. Process Mapping (PM) for Energy

4.1 Objectives

To identify the type of energy that has been use in EAC

To identify how energy has been used in EAC

To specify critical parameters related to product quality and energy

consumption for each EAC

To identify documents needed for controlling of energy consumption in each

EAC

4.2 Development of PM

Process Mapping sheet below is customized for use in every EAC. Since there is no sub

metering was provided for each EAC, therefore energy input cannot be objectively

determined for each EAC. As such a cumulative energy consumption and EEI status shall

be provided in Energy Report to Top Management. However sub metering will be

proposed in Energy Committee for approval as part of Energy Conservative Measures.

4.3 Work Instruction (WI) and Log Sheet (LS)

Work Instruction in the following page shows the inspection process to be conducted on

all the process listed and monitoring of the controlling value. The data will be collected

using a range of equipment such as flow meter, temperature meter, lux meter as well as

other means of data collection that is available. Log sheet is also provided for the

inspectors to fill in actual data of all control parameters based on the frequency stated

in work instruction. Inspectors shall be appointed by Energy Committee.

WORKING MANUALS AND TOOLS

For

JABATAN KESIHATAN NEGERI SARAWAK

ENERGY MANAGEMENT SYSTEM

Doc num: JKNSSEMS/WM 1

Effective date: 1st July 2014

Review date:

Revision num: 00

Page 14

Process Mapping Sheet

EAC: EAC 1, EAC 2, EAC 3

Baseline EEI :

4749 kWh/working days

Sub EEI :

No Energy Input

Process Detail

Output

kWh

%

Diagram

1

Cooling (AHU)

Cooling indoor to

low temperature

Operating hours

2

Power (socket)

Lighting

100

Powering appliances

and compliance to

item 1.4 .4

Lighting set to right

brightness and

compliance to item

1.4.1

Total energy consumption

Specify name of EAC

Specify number, unit

Specify number, unit

Control

Log sheet

Parameter/standard/ref

(ref)

Set to 24-26C

Start 7.45am

Stop 4.15pm

8.00am-5.00pm

300 lux

WORKING MANUALS AND TOOLS

For

JABATAN KESIHATAN NEGERI SARAWAK

ENERGY MANAGEMENT SYSTEM

Doc num: JKNSSEMS/WM 1

Effective date: 1st July 2014

Review date:

Revision num: 00

Page 15

Process Mapping Sheet

EAC: EAC 4

Baseline EEI :

Sub EEI :

No Energy Input

kWh

%

1

kWh/working days

Process Detail

Diagram

Chiller

Output

Cold water

Operating hours

100

Total energy consumption

Specify name of EAC

Specify number, unit

Specify number, unit

Control

Log sheet

Parameter/standard/ref

(ref)

4-6 C

Start 8am

Stop 12.45noon

Start 2.30pm

Stop 4.30pm

WORKING MANUALS AND TOOLS

For

JABATAN KESIHATAN NEGERI SARAWAK

ENERGY MANAGEMENT SYSTEM

Doc num: JKNSSEMS/WM 1

Effective date: 1st July 2014

Review date:

Revision num: 00

Page 16

Process Mapping Sheet

EAC: EAC 5

Baseline EEI :

Sub EEI :

No Energy Input

kWh

%

1

100

kWh/working days

Process Detail

Diagram

Common area

lighting

Output

Lighting set to right

brightness and

compliance to item

1.4

Total energy consumption

Specify name of EAC

Specify number, unit

Specify number, unit

Control

Log sheet

Parameter/standard/ref

(ref)

300 lux

WORKING MANUALS AND TOOLS

For

JABATAN KESIHATAN NEGERI SARAWAK

ENERGY MANAGEMENT SYSTEM

Doc num: JKNSSEMS/WM 1

Work Instruction

Item

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Effective date: 1st July 2014

Review date:

Process or

Machine/Equipment

Cooling-AHU/CWFCU/ACSU

Lighting

Control

Value

24-26C

300 lux

Inspection

Frequency

Monthly

Monthly

Monthly

Inspector

EAC 1

EAC 1

EAC 1

Inspection

Items

Refer 1.4 .2

Refer 1.4 .1

Refer 1.4 .4

Ir Imran

Engr Asmee

Engr Lailatul

spot-checks

EAC 2

EAC 2

EAC 2

Refer 1.4 .2

Refer 1.4 .1

Refer 1.4 .4

24-26C

300 lux

Monthly

Monthly

Monthly

Engr Khairul

Engr Azhar

A.Engr Sani

spot-checks

Refer 1.4 .2

Refer 1.4 .1

Refer 1.4 .4

24-26C

300 lux

Power for electrical appliances

EAC 3

EAC 3

EAC 3

Monthly

Monthly

Monthly

Engr Yusuf

A.Engr Zulhairi

Engr James

spot-checks

Cooling -Chiller

Lighting

Lift

EAC 4

EAC 5

EAC 2

Refer 1.4 .2

Refer 1.4 .1

Refer 1.4.3

4-6 C

300 lux

Monthly

Monthly

Monthly

Engr Khairrul

A.Engr Zulhairi

Engr Yusuf

spot-checks

Power for electrical appliances

Cooling-AHU/CWFCU/ACSU

Lighting

Power for electrical appliances

Cooling-AHU/CWFCU/ACSU

Lighting

Location

Revision num: 00

Page 17

Recommendation Remark

WORKING MANUALS AND TOOLS

For

JABATAN KESIHATAN NEGERI SARAWAK

ENERGY MANAGEMENT SYSTEM

Doc num: JKNSSEMS/WM 1

Log Sheet

Effective date: 1st July 2014

Review date:

Revision num: 00

Page 18

ref:

EAC:

Item

Process

Machine/Equipment

Inspection Items

Inspector: .

Control

Value

Inspection

Date

Normal

X

Abnormal

Problem

Correction

Remark

WORKING MANUALS AND TOOLS

For

JABATAN KESIHATAN NEGERI SARAWAK

ENERGY MANAGEMENT SYSTEM

Doc num: JKNSSEMS/WM 1

Effective date: 1st July 2014

Review date:

Revision num: 00

Page 19

ref:

LS/JKNS/EAC

2/2014

Imran

Inspector: .

Log Sheet (example)

EAC 2

EAC:

Item

1

2

3

Process

Machine/Equipment

Example:

AHU BII/G1

AHU BII/G2

AHU BII/F1

4

5

6

7

8

9

10

11

AHU BII/F2

AHU BII/S1

AHU BII/S2

AHU BII/S3

AHU BII/T1

AHU BII/T2

Lighting BII/G

Lighting BII/F

Inspection Items

Control

Value

Inspection

Date

Normal

24-26C

24-26C

24-26C

9/4/2014

9/4/2014

9/4/2014

24-26C

24-26C

24-26C

24-26C

24-26C

24-26C

300 lux

300 lux

9/4/2014

9/4/2014

9/4/2014

9/4/2014

9/4/2014

9/4/2014

9/4/2014

9/4/2014

X

Abnormal

20C

Problem

Correction

nil

nil

overcooling

nil

nil

Thermostat

damage

nil

nil

nil

nil

nil

nil

nil

nil

nil

nil

nil

nil

nil

nil

nil

nil

Remark

Further Inspection

and repair by

others

WORKING MANUALS AND TOOLS

For

JABATAN KESIHATAN NEGERI SARAWAK

ENERGY MANAGEMENT SYSTEM

Doc num: JKNSSEMS/WM 1

Effective date: 1st July 2014

Review date:

Revision num: 00

Page 20

12

Lighting BII/S

300 lux

9/4/2014

900

13

Lighting BII/T

300 lux

9/4/2014

700

14

Power for electrical

appliances

9/4/2014

Curtain

completely

closed with all

lamps switch on

Curtain

completely

closed with all

lamps switch on

Photocopier not

on save mode

lamps partially

switched on

and slide open

curtain

lamps partially

switched on

and slide open

curtain

Set to save

mode/off

Copy log sheet

given to ketua

unit for action

Copy log sheet

given to ketua

unit for action

Copy log sheet

given to ketua

unit for action

WORKING MANUALS AND TOOLS

For

JABATAN KESIHATAN NEGERI SARAWAK

ENERGY MANAGEMENT SYSTEM

Doc num: JKNSSEMS/WM 1

Revision No

Effective date: 1st July 2014

Review date:

Page

Revision num: 00

Page 21

Detail

Revision Record

Effective Date

Note

LAMPIRAN

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Iata CRM TemDocument184 pagesIata CRM TemPILCOMOV10No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Kamishibai Intro PDFDocument27 pagesKamishibai Intro PDFGanesh Nagaraj100% (1)

- Dell & Eureka Forbes' Channel StrategyDocument17 pagesDell & Eureka Forbes' Channel StrategySaHil GuptaNo ratings yet

- Telekom Malaysia DC System Test Rectifier Test PlanDocument59 pagesTelekom Malaysia DC System Test Rectifier Test Planzamricepu0% (1)

- A Proposal To Replace Aging Fire Extinguishers in Healthcare Facilities in SarawakDocument3 pagesA Proposal To Replace Aging Fire Extinguishers in Healthcare Facilities in SarawakSiti Nor FazilahwatiNo ratings yet

- KNH 5073 Lecture Notes - Updated 21072016Document58 pagesKNH 5073 Lecture Notes - Updated 21072016Siti Nor FazilahwatiNo ratings yet

- Report CEM Hospital Bahiyah 10 Oct 18 HSB (v1)Document48 pagesReport CEM Hospital Bahiyah 10 Oct 18 HSB (v1)Siti Nor Fazilahwati0% (1)

- Research Title: Nocturnal Cooling of Water For Radiant Cooling in Malaysian BuildingDocument24 pagesResearch Title: Nocturnal Cooling of Water For Radiant Cooling in Malaysian BuildingSiti Nor FazilahwatiNo ratings yet

- Printout: Wednesday, 29 October 2014 7:02 AMDocument1 pagePrintout: Wednesday, 29 October 2014 7:02 AMSiti Nor FazilahwatiNo ratings yet

- Water Boar Dock 2014Document1 pageWater Boar Dock 2014Siti Nor FazilahwatiNo ratings yet

- Memo Energy PolicyDocument2 pagesMemo Energy PolicySiti Nor FazilahwatiNo ratings yet

- Sesco Oct2014Document1 pageSesco Oct2014Siti Nor FazilahwatiNo ratings yet

- Domestic Home Structure Drawing 3d With RoofDocument1 pageDomestic Home Structure Drawing 3d With RoofSiti Nor FazilahwatiNo ratings yet

- Water Level and TempDocument24 pagesWater Level and TempSiti Nor FazilahwatiNo ratings yet

- No, 4606 Taman Sumber Alam Santuary, Jalan Sultan Tengah 93050, PETRA JAYA, KUCHING, Malaysia Mobile: 0172000959Document3 pagesNo, 4606 Taman Sumber Alam Santuary, Jalan Sultan Tengah 93050, PETRA JAYA, KUCHING, Malaysia Mobile: 0172000959Siti Nor FazilahwatiNo ratings yet

- QCWFKXDocument4 pagesQCWFKXSiti Nor FazilahwatiNo ratings yet

- Masjid Muttaqin ASGMNTDocument21 pagesMasjid Muttaqin ASGMNTSiti Nor FazilahwatiNo ratings yet

- Is 2090 Specification For High Tensile Steel Bars Used in PRDocument12 pagesIs 2090 Specification For High Tensile Steel Bars Used in PRFrank StephensNo ratings yet

- Commission On Installment BasisDocument2 pagesCommission On Installment BasisDevorah Mae CubeloNo ratings yet

- Autodesk Feature CodesDocument14 pagesAutodesk Feature Codessplaw9484No ratings yet

- 3d Printing InternshipDocument2 pages3d Printing InternshipDharshan SNo ratings yet

- D ReportDocument26 pagesD ReportSandeep KumarNo ratings yet

- Carrier 42 Cet FCUDocument21 pagesCarrier 42 Cet FCUcantorband8234100% (2)

- Scan Doc2346Document1 pageScan Doc2346Marcelo PellizzaNo ratings yet

- Busway (Low Voltage) Aftermarket Solutions - CA - EN - 6 - 2012Document16 pagesBusway (Low Voltage) Aftermarket Solutions - CA - EN - 6 - 2012Jonatan Lopez RodriguezNo ratings yet

- Healthy House SpecsDocument27 pagesHealthy House SpecswhsprzNo ratings yet

- Bread Maker SBB 850 EDS A1: Kitchen ToolsDocument183 pagesBread Maker SBB 850 EDS A1: Kitchen ToolsOtylyia RaluNo ratings yet

- Adopting Building Information Modeling (Bim) As Collaboration Platform in The Design IndustryDocument10 pagesAdopting Building Information Modeling (Bim) As Collaboration Platform in The Design IndustryPuneet AroraNo ratings yet

- Mobil Eal ArcticDocument1 pageMobil Eal ArcticFERNANDONo ratings yet

- ECFanGrid Installation and Operation Guide PDFDocument79 pagesECFanGrid Installation and Operation Guide PDFMarceloNo ratings yet

- General Work Permit S3-F7: Start Date: End Date: Start Time: End TimeDocument1 pageGeneral Work Permit S3-F7: Start Date: End Date: Start Time: End TimeHareekirishnan LrkNo ratings yet

- EASA-TCDS-E.052 (IM) Rolls - Royce Model 250 Series II Engines-01-22062011Document12 pagesEASA-TCDS-E.052 (IM) Rolls - Royce Model 250 Series II Engines-01-22062011starsalingsoul80000% (1)

- Public FinanceDocument3 pagesPublic FinanceAndhika Pres'Lee Bintang10% (10)

- MIS Assignment 4Document5 pagesMIS Assignment 4Ah Vee60% (5)

- Rise and Fall of Air IndiaDocument39 pagesRise and Fall of Air IndianARAYANNo ratings yet

- Data Management SolutionsDocument11 pagesData Management SolutionsrkNo ratings yet

- Honda BikeDocument43 pagesHonda Bikehariom sharmaNo ratings yet

- Sizing, Specifying and Selecting Centrifugal Pumps (CE) PDFDocument5 pagesSizing, Specifying and Selecting Centrifugal Pumps (CE) PDFjdgh1986100% (1)

- Lessons Learned From Launch Vehicle Avionics SystemsDocument10 pagesLessons Learned From Launch Vehicle Avionics Systemsdovesnest_inNo ratings yet

- Wind Power PDFDocument13 pagesWind Power PDF3319826No ratings yet

- Hydraulic & Mechanical PullersDocument9 pagesHydraulic & Mechanical PullersMeilvy Rahmadani PaneNo ratings yet

- Lubricants: Unoba EPDocument2 pagesLubricants: Unoba EPQC RegianNo ratings yet

- PR01301 Eurol Product CatalogueDocument57 pagesPR01301 Eurol Product CatalogueMarco LizanaNo ratings yet