Professional Documents

Culture Documents

Ethanol Amines

Ethanol Amines

Uploaded by

Ganesh GanyCopyright:

Available Formats

You might also like

- Mist PDFDocument28 pagesMist PDFGanesh GanyNo ratings yet

- BASF Glyoxal As An H2S ScavengerDocument8 pagesBASF Glyoxal As An H2S ScavengerMo OsNo ratings yet

- Alkyl Polyglycosides-Properties and Applications of A New Class of SurfactantsDocument18 pagesAlkyl Polyglycosides-Properties and Applications of A New Class of Surfactantsmjs9170100% (1)

- Coatings Solutions GuideDocument88 pagesCoatings Solutions Guidekhiemnguyen8668No ratings yet

- Ion Exchange Resins and Adsorbents in Chemical Processing: Second EditionFrom EverandIon Exchange Resins and Adsorbents in Chemical Processing: Second EditionRating: 5 out of 5 stars5/5 (1)

- AGITAN Defoamer Technologies PDFDocument15 pagesAGITAN Defoamer Technologies PDFMarco Lopez100% (1)

- Alketerge EDocument4 pagesAlketerge EYohanes OktavianusNo ratings yet

- Titrimetric Determination of ZirconiumDocument28 pagesTitrimetric Determination of Zirconiumalvarinjo9681100% (1)

- Katalog - Polyester Distribution Boxes BARTECDocument4 pagesKatalog - Polyester Distribution Boxes BARTECPedjaNo ratings yet

- Esterquats-The Novel Class of Cationic Fabric Softeners - S Mishra PDFDocument8 pagesEsterquats-The Novel Class of Cationic Fabric Softeners - S Mishra PDFPedskaNo ratings yet

- Highly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesFrom EverandHighly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesNo ratings yet

- Fatty Amine Ethoxylates and ItDocument3 pagesFatty Amine Ethoxylates and ItRizki RamadhanNo ratings yet

- CSNL An Environment Friendly Alternative PDFDocument15 pagesCSNL An Environment Friendly Alternative PDFDonald_12No ratings yet

- ImidazolineDocument8 pagesImidazolineamirarsham1365No ratings yet

- Brochure Antifoams Defoamers Tego AntifoamDocument8 pagesBrochure Antifoams Defoamers Tego AntifoamJuan CubasNo ratings yet

- Ethanolamines: Product InformationDocument48 pagesEthanolamines: Product InformationElias0% (1)

- Alkaline Cleaning GuideDocument3 pagesAlkaline Cleaning Guide同道文档中心100% (3)

- Sorbitan Esters PlantDocument9 pagesSorbitan Esters PlantHolman SanabriaNo ratings yet

- Maxfloc - TDocument3 pagesMaxfloc - TChoice OrganoNo ratings yet

- Preparation of Sorbitan StearateDocument5 pagesPreparation of Sorbitan StearatevannesaNo ratings yet

- Improved Technology For Production of Palm-Based Esterquats: By: Haliza Abdul Aziz and Zainab IdrisDocument4 pagesImproved Technology For Production of Palm-Based Esterquats: By: Haliza Abdul Aziz and Zainab IdrisMehmet Aydin100% (1)

- Product BrochureDocument20 pagesProduct BrochureSiddhan100% (1)

- AkzoNobel Narrow Range Ethoxylates - 2015Document4 pagesAkzoNobel Narrow Range Ethoxylates - 2015Vilas DhakappaNo ratings yet

- Cationic SurfactantsDocument4 pagesCationic SurfactantsAlfonso PeñarandaNo ratings yet

- Ester Alkoxylation TehnologyDocument9 pagesEster Alkoxylation TehnologySanjayka100% (1)

- Dow Chelating AgentsDocument12 pagesDow Chelating Agentsfshirani7619100% (1)

- Anti Migrasi ReaktifDocument12 pagesAnti Migrasi ReaktifharlanNo ratings yet

- Antifoam Solutions Brochure InddDocument0 pagesAntifoam Solutions Brochure Inddhisham_00No ratings yet

- Technical Brochure: Dissolvine GLDocument16 pagesTechnical Brochure: Dissolvine GLChemist Technologist100% (1)

- Cellosize BrochureDocument28 pagesCellosize BrochureDiana NguyenNo ratings yet

- Propylene Glycol Usp-EpDocument4 pagesPropylene Glycol Usp-Epvanhung68No ratings yet

- Water Soluble PolymersDocument57 pagesWater Soluble PolymersVimal GirnaraNo ratings yet

- Silicon Wax Emulsion For Polyurethane Water Release AgentDocument3 pagesSilicon Wax Emulsion For Polyurethane Water Release Agentmyosi laboratoriumNo ratings yet

- Introductory Brochures - Dequest Water AdditivesDocument9 pagesIntroductory Brochures - Dequest Water Additives中西文香No ratings yet

- Phenolic Resins by P MaheshwarDocument50 pagesPhenolic Resins by P MaheshwarArjun Satheesh Kumar100% (1)

- BBI Webinar Lutropur MSA-XP For DistributionDocument18 pagesBBI Webinar Lutropur MSA-XP For DistributionSeptian Wahyu PriyonoNo ratings yet

- Metalworkingfluidsneatcuttingoils1600658984320 PDFDocument46 pagesMetalworkingfluidsneatcuttingoils1600658984320 PDFShaara NeyNo ratings yet

- Akypo Lm-40 Leaflet Eng - KAO - AKYPO-LM-40Document3 pagesAkypo Lm-40 Leaflet Eng - KAO - AKYPO-LM-40bexigaobrotherNo ratings yet

- Dow Glycol Ethers PDFDocument27 pagesDow Glycol Ethers PDFMatt100% (1)

- Dimethyl TerephthalateDocument9 pagesDimethyl Terephthalatehung_metalNo ratings yet

- EODocument26 pagesEOdieego001100% (1)

- Imidazoline-Théorie Ferm1954Document21 pagesImidazoline-Théorie Ferm1954Belkhadem FatimaNo ratings yet

- Dover Chemicals - AdditivesDocument20 pagesDover Chemicals - AdditivesHovoFunnyNo ratings yet

- Brochure MosselmanDocument12 pagesBrochure Mosselmanvcoranm100% (1)

- Organo ClayDocument4 pagesOrgano ClayRaoni Batista Dos AnjosNo ratings yet

- Sokalan CP Types TI EN PDFDocument7 pagesSokalan CP Types TI EN PDFAhmedNo ratings yet

- Ethoxylates & Surfactants Pat Impex Manufacturer & Suppliers in IndiaDocument16 pagesEthoxylates & Surfactants Pat Impex Manufacturer & Suppliers in IndiaPat ImpexNo ratings yet

- Biocide FormulDocument3 pagesBiocide FormulIsmael RocaNo ratings yet

- Dispersing Agents PDFDocument14 pagesDispersing Agents PDFalmasNo ratings yet

- Lieferprogramm Phosphate EstersDocument12 pagesLieferprogramm Phosphate Estersjangri1098100% (1)

- Batch Emulsion PolymerizationDocument166 pagesBatch Emulsion PolymerizationShubham CholeNo ratings yet

- Clariant Wetting-AgentsDocument7 pagesClariant Wetting-AgentsAPEX SON100% (1)

- Exxon Exxal Alcohols For Ethoxylates - Huntsman - Feb 2017 PDFDocument28 pagesExxon Exxal Alcohols For Ethoxylates - Huntsman - Feb 2017 PDFMattNo ratings yet

- Products For Unsaturated PolyestersDocument8 pagesProducts For Unsaturated PolyestersNgan100% (1)

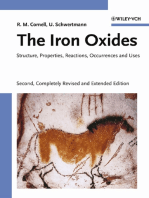

- The Iron Oxides: Structure, Properties, Reactions, Occurrences and UsesFrom EverandThe Iron Oxides: Structure, Properties, Reactions, Occurrences and UsesRating: 5 out of 5 stars5/5 (1)

- Handbook of Vinyl FormulatingFrom EverandHandbook of Vinyl FormulatingRichard F GrossmanRating: 3 out of 5 stars3/5 (1)

- Chemistry and Technology of SurfactantsFrom EverandChemistry and Technology of SurfactantsRichard J. FarnNo ratings yet

- Biobased Lubricants and Greases: Technology and ProductsFrom EverandBiobased Lubricants and Greases: Technology and ProductsRating: 5 out of 5 stars5/5 (1)

- Lignin and Lignans as Renewable Raw Materials: Chemistry, Technology and ApplicationsFrom EverandLignin and Lignans as Renewable Raw Materials: Chemistry, Technology and ApplicationsNo ratings yet

- Maros Training Handout PDFDocument29 pagesMaros Training Handout PDFGanesh GanyNo ratings yet

- Helideck Emergency Response Team Member Hertm Training Standard Available From 1st Jan 2018Document54 pagesHelideck Emergency Response Team Member Hertm Training Standard Available From 1st Jan 2018Ganesh GanyNo ratings yet

- THERMINOL 55 MSDS FEB2017.pdf2018-12-11 - 20 - 08 - 31 - SyP - Sga - enDocument8 pagesTHERMINOL 55 MSDS FEB2017.pdf2018-12-11 - 20 - 08 - 31 - SyP - Sga - enGanesh GanyNo ratings yet

- Radiation: Facts, Risks and RealitiesDocument17 pagesRadiation: Facts, Risks and RealitiesGanesh Gany100% (1)

- Pulsation Dampner SizingDocument3 pagesPulsation Dampner SizingGanesh GanyNo ratings yet

- Offshore Emergency Response Team Member Valid From 1st of March 2017Document48 pagesOffshore Emergency Response Team Member Valid From 1st of March 2017Ganesh GanyNo ratings yet

- Offshore Emergency Response Team LeaderDocument40 pagesOffshore Emergency Response Team LeaderGanesh Gany100% (1)

- Internal Verifier Training StandardDocument22 pagesInternal Verifier Training StandardGanesh GanyNo ratings yet

- Aga Transmission Measurement Committee Report No 8 - Google SearchDocument2 pagesAga Transmission Measurement Committee Report No 8 - Google SearchGanesh GanyNo ratings yet

- Asme MFC 6MDocument4 pagesAsme MFC 6MGanesh GanyNo ratings yet

- Fundamentals of Process Control Theory ThirdEd - Murrill - Unit2Document10 pagesFundamentals of Process Control Theory ThirdEd - Murrill - Unit2Ganesh Gany100% (1)

- Orifi Ce Plate and Orifi Ce FlangeDocument39 pagesOrifi Ce Plate and Orifi Ce FlangeGanesh GanyNo ratings yet

- Heat TraceDocument9 pagesHeat TraceGanesh GanyNo ratings yet

- Presentation - Pragati MaidanDocument22 pagesPresentation - Pragati MaidanMohamed Anas100% (4)

- Jyotish - Hindu Panchangam & MuhurtasDocument40 pagesJyotish - Hindu Panchangam & MuhurtasSamir Kadiya100% (1)

- BNVD Eaufrance Metadonnees Vente 20230130Document16 pagesBNVD Eaufrance Metadonnees Vente 20230130moussaouiNo ratings yet

- Safety Manual (B-80687EN 10)Document35 pagesSafety Manual (B-80687EN 10)Jander Luiz TomaziNo ratings yet

- LC1D32M7: Product Data SheetDocument7 pagesLC1D32M7: Product Data SheetCHAHRHLHOHSNo ratings yet

- Revisit of Harriott's Method For Process ControlDocument3 pagesRevisit of Harriott's Method For Process ControlkiddhoNo ratings yet

- The Body Productive Rethinking Capitalism Work and The Body Steffan Blayney Full ChapterDocument67 pagesThe Body Productive Rethinking Capitalism Work and The Body Steffan Blayney Full Chaptersharon.tuttle380100% (6)

- Protocols For Public-Key CryptosystemsDocument13 pagesProtocols For Public-Key CryptosystemsIvo LemosNo ratings yet

- Onco, TSG & CancerDocument8 pagesOnco, TSG & Cancersumera120488No ratings yet

- WhatsApp v. Union of India Filing VersionDocument224 pagesWhatsApp v. Union of India Filing VersionVinayNo ratings yet

- HCI 2008 Promo W SolutionDocument12 pagesHCI 2008 Promo W SolutionMichael CheeNo ratings yet

- Person To PersonDocument126 pagesPerson To PersonYalmi AdiNo ratings yet

- Explosion Protection - E PDFDocument7 pagesExplosion Protection - E PDFAPCANo ratings yet

- Tranzen1A Income TaxDocument46 pagesTranzen1A Income TaxMonica SorianoNo ratings yet

- Lienard EquationDocument9 pagesLienard EquationmenguemengueNo ratings yet

- Testing ChecklistDocument3 pagesTesting ChecklistAnurag YadavNo ratings yet

- Turbine-Less Ducted Fan Jet Engine: Subsonic PropulsionDocument25 pagesTurbine-Less Ducted Fan Jet Engine: Subsonic PropulsionزهديابوانسNo ratings yet

- Mapeh GR9 First Quarter ReviewerDocument8 pagesMapeh GR9 First Quarter ReviewerRalph Emerson SantillanNo ratings yet

- Aquamaster 4 Few4 and Fet4: Electromagnetic FlowmeterDocument48 pagesAquamaster 4 Few4 and Fet4: Electromagnetic FlowmeterAmol BorikarNo ratings yet

- Testbank: Applying Ifrs Standards 4eDocument11 pagesTestbank: Applying Ifrs Standards 4eSyed Bilal AliNo ratings yet

- Cell Theory Refers To The Idea That: MicrographiaDocument5 pagesCell Theory Refers To The Idea That: MicrographiadeltasixNo ratings yet

- 5054 s16 Ms 41 PDFDocument3 pages5054 s16 Ms 41 PDFKritish RamnauthNo ratings yet

- Cuadernillo de Trabajo: InglésDocument20 pagesCuadernillo de Trabajo: InglésFátima Castellano AlcedoNo ratings yet

- Vision PT 365 Culture 2021 (WWW - Upscpdf.com)Document51 pagesVision PT 365 Culture 2021 (WWW - Upscpdf.com)Swati YadavNo ratings yet

- Hayden Esterak Resume 1Document1 pageHayden Esterak Resume 1api-666885986No ratings yet

- Alere G1 Glucose Meter ManualDocument55 pagesAlere G1 Glucose Meter ManualSundar Rajan33% (6)

- Consumer Behavior, Market Research, and AdvertisementDocument37 pagesConsumer Behavior, Market Research, and AdvertisementMohamed AbdelazizNo ratings yet

- ANSWERS - PhyLabS6 EX02 Water TowerDocument8 pagesANSWERS - PhyLabS6 EX02 Water TowerGuacNo ratings yet

- 3I Grading Rubric For Output PresentationDocument2 pages3I Grading Rubric For Output PresentationBinibining Michelle CenizaNo ratings yet

Ethanol Amines

Ethanol Amines

Uploaded by

Ganesh GanyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ethanol Amines

Ethanol Amines

Uploaded by

Ganesh GanyCopyright:

Available Formats

DSA9781.

qxd

1/31/03

10:21 AM

Page 1

ETHANOLAMINES

Monoethanolamine

Diethanolamine

Triethanolamine

DSA9781.qxd

1/31/03

10:21 AM

Page 2

CONTENTS

Introduction ...............................................................................................................................2

Ethanolamine Applications.........................................................................................................3

Gas Sweetening ..................................................................................................................3

Detergents, Specialty Cleaners, Personal Care Products.......................................................4

Textiles.................................................................................................................................4

Metalworking ......................................................................................................................5

Other Applications...............................................................................................................5

Ethanolamine Physical Properties ...............................................................................................6

Typical Physical Properties ....................................................................................................6

Vapor Pressure of Ethanolamines (Figure 1).........................................................................7

Heat of Vaporization of Ethanolamines (Figure 2)................................................................7

Specific Heats of Ethanolamines (Figure 3) ..........................................................................8

Comparative Hygroscopicities of Diethanolamine and Triethanolamine (Figure 4) ...............8

Weight Percent Ethanolamine in Aqueous Solutions vs Normality of Solution (Figure 5).....9

pH of Ethanolamine Solutions (Figure 6) .............................................................................9

Partial Pressure of Ethanolamines in Aqueous Solutions at Various Temperatures

(Figure 7, 9, 11) ........................................................................................................10-12

Vapor-Liquid Equilibria of Aqueous Solutions at 760 mm Hg Absolute

(Figure 8, 10, 12) ......................................................................................................10-12

Absolute Viscosities of Aqueous Solutions (Figures 13-15) ................................................13

Freezing Points of Aqueous Ethanolamine Solutions (Figure 16)........................................14

Specific Gravity of Aqueous Ethanolamine Solutions (Figure 17) .......................................14

Weight per Gallon of Aqueous Solutions at Various Temperatures (Figures 18-20)......15-16

Specific Heats of Aqueous Solutions (Figures 21-23) .........................................................17

Storage and Handling ..............................................................................................................18

Shipping Information ...............................................................................................................19

Specifications ...........................................................................................................................19

Product Safety..........................................................................................................................19

DSA9781.qxd

1/31/03

10:21 AM

Page 3

ETHANOLAMINES

Dows versatile family of ethanolamines including monoethanolamine (MEA),

diethanolamine (DEA), and triethanolamine (TEA) offers a broad spectrum of application

opportunities. Triethanolamine is available as TEA, 99% and TEA, Commercial (which contains

nominally 15% diethanolamine). Because ethanolamines combine the properties of amines

and alcohols, they exhibit the unique capability of undergoing reactions common to both

groups. As amines, they are mildly alkaline and react with acids to form salts or soaps. As

alcohols, they are hygroscopic and can be esterified. The chemical structures of the

ethanolamines are:

MEA H NCH CH OH

DEA HN(CH CH OH)

TEA N(CH CH OH)

2

Monoethanolamine

Ethanolamines find uses in such diverse areas as gas sweetening, where they serve as lubricants and scouring agents; detergent and specialty cleaner formulations, in which they are

used to form various amine salts and to control pH; and in a host of other applications

including concrete admixtures, flexible urethane foam catalysts, pharmaceuticals, personal

care products, agricultural chemicals, photographic emulsions, and more.

Diethanolamine

Triethanolamine

TECHNOLOGY LEADERSHIP

Ethanolamines from Dow are backed by approximately 80 years of innovative scientific

research. Since their introduction in the late 1920s, MEA, DEA, and TEA have undergone

extensive commercial development in our laboratories at South Charleston, WV.

WORLD SCALE PRODUCTION CAPACITY

Backed by the worlds largest ethylene oxide capacity, Dows efficient ethanolamines

facilities, located at Seadrift, TX, are the worlds largest. Designed for flexibility, this plant is

capable of producing ethanolamines to meet the most demanding specifications of the

marketplace.

Additional worldscale ethanolamines facilities were added in 1997 at Taft, LA, and in 2002,

at the Optimal joint venture between Dow and Petronas at Kertih, Malaysia. Additional

plants will be added to meet other developing worldwide markets.

Dows position as the leading producer of basic ethylene oxide and ethanolamines translates

into dependability, not only as a source of supply, but in quality of product as well. The purity

and consistency of Dows ethanolamines are unsurpassed.

BROADEST DISTRIBUTION NETWORK

The Dow network of sales personnel, technical service experts, bulk storage terminals, and

distributors has been carefully constructed to reach all of Dows customers worldwide. Problem

solving assistance is virtually a phone call away, and Dows vast distribution system assures

fast delivery of tanker, barge, tank truck, tank car, or drum quantities from strategically

located bulk terminals and warehouses.

Whatever your needs in ethanolamines MEA, DEA, or TEA Dow has the technical,

production, and distribution resources to serve you best. This booklet has been designed to

provide the answers to most questions about Dows ethanolamine products. For further

information contact your Dow representative.

DSA9781.qxd

1/31/03

10:21 AM

Page 4

Ethanolamine Applications

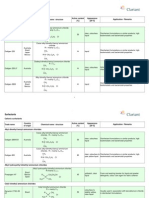

Typical Applications

MEA

Adhesives

Agricultural Chemicals

DEA

TEA,

Commercial

Cement Grinding Aids

Concrete Additives

TEA, 99%

Detergents, Specialty Cleaners

Personal Care Products

Gas Treating

Metalworking

Oil Well Chemicals

Packaging & Printing Inks

Photographic Chemicals

Rubber

Textile Finishing

Urethane Foams

ETHANOLAMINES FOR GAS SWEETENING

Aqueous solutions of monoethanolamine and diethanolamine react with carbon

dioxide and hydrogen sulfide at ambient temperature to form compounds that,

when exposed to elevated temperatures, release the acid gas and regenerate the

amine for reuse.

Monoethanolamine is commonly used for treating synthesis gas streams formed

in ammonia, hydrogen, carbon monoxide, and flue gas facilities. Carbon dioxide

is the principal contaminant that is removed.

Diethanolamine is primarily used for treating natural and refinery gas and for

liquid streams. Carbon dioxide and hydrogen sulfide are the principal contaminants removed.

Engineering companies can provide individually designed plants or standard packaged units

that can be installed wherever it is necessary to remove carbon dioxide and/or hydrogen

sulfide from gas streams.

For natural gas systems and refinery-treating systems in sulfur service, diethanolamine solutions

have performed satisfactorily for years in units where carbon steel has been the major material of

construction. In improperly designed or improperly operated units, however, corrosion will occur

in carbon steel exchangers, condensers, and reboiler-type bundles. In special situations, therefore,

alloy materials of construction may be required. In addition, improved design and operating

criteria may be specified, including activated carbon filtration and good inlet separation.

DSA9781.qxd

1/31/03

10:21 AM

Page 5

ETHANOLAMINES FOR DETERGENTS,

SPECIALTY CLEANERS, AND

PERSONAL CARE PRODUCTS

Ethanolamines are used in heavy-duty liquid laundry detergents because they

provide a unique combination of beneficial property and performance qualities.

These ethanolamines impart a reserve alkalinity to the laundry bath, which is

essential to efficient cleaning. They neutralize the fatty acids present in the oily

soil components and, through this neutralization, convert them to amine soaps.

These soaps, in turn, aid in the overall cleaning process. The effect is readily

observed when standard industrial oily soils are used.

These same ethanolamines are also effective soil anti-redeposition agents. They help to keep soil

in the laundry bath from redepositing onto the fabric during the cleaning process. The effect is

evident in the performance of nonionic, anionic, and mixed nonionic/anionic surfactant-based

products on cotton, blended cotton/polyester, and polyester fabrics.

Diethanolamine is used to prepare fatty acid amides, which may be used in various personal

care products.

Triethanolamine may be reacted with lauryl sulfate to form the foaming base surfactant used

in hair shampoos.

Fatty acids neutralized with ethanolamines, particularly triethanolamine, are excellent emulsifiers

for oil-in-water emulsions. Gel-type industrial hand cleaners, aerosol shave creams, and hand and

body lotions are only a few of the consumer products commonly formulated with such soaps.

Triethanolamine is also used as the base component in the production of certain mild bar soaps.

ETHANOLAMINES FOR TEXTILES

Ethanolamines are used in textile processing as reaction intermediates for the

preparation of durable press fabric finishes and softeners.

Amine soaps are used as scouring agents for wool and silk because of their

low alkalinity.

Ethanolamines are also used as dye auxiliaries. Because of their hygroscopicity,

ethanolamines find application in the preparation of vat printing pastes.

Diethanolamine and triethanolamine are used in making acetate rayon dyes.

Textile lubricants often incorporate salts of ethanolamines to benefit from their

anticorrosion and antistatic properties. Ethanolamine salts of mono- or di-phosphates,

sulfonates, and sulfates are typical components of staple finishes.

DSA9781.qxd

1/31/03

10:21 AM

Page 6

ETHANOLAMINES FOR METALWORKING

Acidic additives and/or acidic decomposition products are the prime contributors

to corrosion of metal surfaces, particularly in the presence of moisture.

Ethanolamines are often used as neutralizers of acid components in lubricants

and are a time-tested means of preventing corrosion.

In water-soluble cutting and grinding fluids, ethanolamines are used to provide

the alkalinity needed to protect against rusting (ferrous metals do not oxidize

under alkaline conditions). Ethanolamines are also used as intermediates in the

preparation of water-soluble lubricants, emulsifiers, proprietary corrosion

inhibitors, and biocides.

OTHER ETHANOLAMINE APPLICATIONS

In addition to supplying ethanolamines for the four major applications already

discussed, Dow provides these versatile materials for a variety of other uses

(See Applications Chart, page 3).

Diethanolamine and triethanolamine are used as catalysts that promote

stability during the reaction process in the manufacture of flexible and rigid

urethane foams. In the photographic chemical industry, these ethanolamines

find application in complex modern developing systems. Diethanolamine and

triethanolamine are used in the agricultural chemical field as intermediates in a

number of applications, most notably the manufacture of herbicides.

Triethanolamine finds use as an intermediate for additives that control the rate at which water

evaporates from drying concrete. In another application, triethanolamine is used as a component in the formulation of cement grinding media during the manufacture of cement. In still

another important use, triethanolamine is utilized down hole in oil wells to prevent corrosion

of drilling equipment.

Triethanolamine also functions as an intermediate for adhesive and rubber chemicals. Monoethanolamine is used as a pH control agent in the formulation of packaging and printing inks.

Triethanolamine (Trolamine 99% NF Grade) meets the requirements of the applicable National

Formulary monograph.

DSA9781.qxd

1/31/03

10:21 AM

Page 7

Typical Physical Properties

The properties of Dows family of ethanolamines enable these versatile materials to be

utilized in a broad range of applications. Typical properties of the ethanolamines are shown

in the table below and in Figures 1-23.

Table 1 Typical Properties of DOW Ethanolamines

Monoethanolamine Diethanolamine

Formula

Molecular Weight

Triethanolamine

H2NCH2CH2OH

61.08

HN(CH2CH2OH)2

105.14

N(CH2CH2OH)3

149.19

1.017

0.00080

1.092(a)

0.00065(b)

1.126(f)

0.00059

Boiling Point at 760 mm Hg, C

at 50mm Hg, C

at 10mm Hg, C

170.4

101

71

268(c)

182

150

335(c)

245(c)

205

Vapor Pressure at 20C, mm Hg

<1

<0.01

<0.001

Freezing Point, C(F)

Absolute Viscosity at 20C, cP

at 30C, cP

10.5 (50.9)

24.1

16.2

28.0 (82.4)

380

21.6 (70.9)(e)

921(f)

404

Solubility at 20C, % by wt

In Water

Water In

Complete

Complete

Complete(f)

Complete(f)

Complete(f)

Solubility in Organic Liquids

at 25C, % by wt

Acetone

Benzene

Carbon Tetrachloride

Ethyl Ether

Heptane

Methanol

Complete

0.6

0.1

0.7

0.1

Complete

Complete(f)

0.03

0.01

0.5

0.03

Complete(f)

Complete

2

Complete

2

<0.03

Complete

Surface Tension, dynes/cm

Refractive Index, nD20

ND/t at 20 to 40C per C

48.3(d)

1.4539

0.00034

48.5(g)

1.4747(g)

0.00027(b)

48.9(d)

1.4852(f)

0.00020

Flash Point, C (F)

96 (205)(h)

191 (375)(h)

208 (407)(h)

Apparent Sp. Gr. at 20/20C

Sp. Gr./t at 10 to 80C

(a) At 30/20C

(b) At 35 to 65C

(c) Extrapolated (decomposes)

(d) At 25C

(e) Supercools easily

(f) Supercooled liquid

(g) At 30C

(h) Determined by ASTM Method D 93,

using the Pensky-Martens Closed Cup

NOTE

This table sets forth typical properties of Monoethanolamine, Diethanolamine, and

Triethanolamine based upon analysis(ses) of commercial product or purified sample, etc.;

however, Dow does not analyze each shipment of product for all of these properties. Dow

warrants only that, at the time of delivery, product will conform to Dows standard specifications as then in effect.

DSA9781.qxd

1/31/03

10:21 AM

Page 8

Figure 1

Vapor Pressure of Ethanolamines

Temperature, F

70

1000

600

400

90

120

160

200

240

320

400

480

800

500

300

Note: Ethanolamines begin

decomposing at temperatures

above about 200C and can

undergo self-sustained

decomposition at temperatures

above 250C.

Vapor Pressure, mm Hg

200

100

60

40

80

50

30

20

MEA

10

6

4

DEA

TEA

8

5

3

2

1

20

40

60

80

120

Temperature, C

160

200

240

Figure 2

Heat of Vaporization of Ethanolamines

Temperature, F

150

250

350

450

550

650

440

410

Heat of Vaporization, Btu/lb*

MEA

380

350

320

DEA

290

260

*1 Btu/lb = 0.56 cal/g

TEA

230

200

50

100

150

200

250

Temperature, C

300

350

DSA9781.qxd

1/31/03

10:21 AM

Page 9

Figure 3

Specific Heat of Ethanolamines

40

80

Temperature, F

120 160 200 240 280 320 360

0.84

0.82

0.80

0.78

Specific Heat, Cal/g-C

0.76

MEA

0.74

DEA

0.72

0.70

TEA

0.68

0.66

0.64

0.62

0.60

0.58

0.56

0.54

0

20

40

60

80 100 120 140 160 180 200

Temperature, C

Figure 4

Comparative Hygroscopicities of Diethanolamine and Triethanolamine from 75 to 80F

100

80

Percent Gain in Weight at Equilibrium

60

DEA

40

TEA

20

10

8

6

4

1

10

20

30

40

50

60

Relative Humidity, %

70

80

DSA9781.qxd

1/31/03

10:21 AM

Page 10

Figure 5

Weight Percent Ethanolamine in Aqueous Solutions vs Normality of Solution

70

TEA

DEA

Amine, Percent by Weight in Solution

60

MEA

50

40

30

20

10

0

0

6

9

12

Normality of Amine Solution

15

Figure 6

pH of Ethanolamine Solutions

40

20

TEA, 99%

Amine, Percent by Weight

10

TEA,

Commercial

4

2

1

DEA

MEA

.4

.2

.1

.04

.02

.01

8

10

11

pH at 20C

12

13

DSA9781.qxd

1/31/03

10:21 AM

Page 11

Figure 7

Partial Pressure of Monoethanolamine in Aqueous Solutions at Various Temperatures

Temperature, F

40

Partial Pressure of Monoethanolamine, mm Hg

10

60

80

100

120

MEA

% by wt

100

95

90

80

60

40

30

20

0.1

0.01

10

5

10 -3

10 -4

0

10

20

30

Temperature, C

40

50

Figure 8

Vapor-Liquid Equilibria (T-x-y) of Aqueous Monoethanolamine Solutions at 760 mm Hg Absolute

180

170

340

160

320

300

140

280

130

260

120

240

110

220

100

Liquid Phase

90

180

80

0

10

200

10

20 30 40 50 60 70 80 90 100

Monoethanolamine, Percent by Weight

Temperature, F

Temperature, C

Vapor Phase

150

DSA9781.qxd

1/31/03

10:21 AM

Page 12

Figure 9

Partial Pressure of Diethanolamine in Aqueous Solutions at Various Temperatures

Temperature, F

60

80

Partial Pressure of Diethanolamine, mm Hg

0.1

100

120

140

DEA

% by wt

0.01

100

95

10-3

80

60

40

10-4

20

10

10

-5

10-6

15 20 25

30 35 40 45 50 55

Temperature, C

60 65

70

Figure 10

Vapor-Liquid Equilibria (T-x-y) of Aqueous Diethanolamine Solutions at 760 mm Hg Absolute

275

495

Vapor Phase

235

455

215

415

195

375

175

335

155

295

135

255

115

Note: Ethanolamines can

undergo decomposition

at temperatures above

approximately 200C

Liquid Phase

215

95

175

75

0

11

10

20 30 40 50 60 70 80 90 100

Diethanolamine, Percent by Weight

Temperature, F

Temperature, C

255

DSA9781.qxd

1/31/03

10:21 AM

Page 13

Figure 11

Partial Pressure of Triethanolamine in Aqueous Solutions at Various Temperatures

Temperature, F

120

140

Partial Pressure of Triethanolamine, mm Hg

0.1

160

180

200

TEA

% by wt

0.01

100

95

1 0 -3

80

60

1 0 -4

40

10

20

10

-5

5

1 0 -6

1 0 -7

45 50 55 60

65 70 75 80 85

Temperature, C

90 95 100

Figure 12

Vapor-Liquid Equilibria (T-x-y) of Aqueous Triethanolamine Solutions at 760 mm Hg Absolute

380

360

680

340

640

320

600

Note: Ethanolamines can

undergo decomposition

at temperatures above

approximately 200C

560

Vapor Phase

280

520

260

480

240

440

220

200

400

180

360

160

320

140

280

120

240

100

Liquid Phase

80

0

12

10

20 30 40 50 60 70 80 90 100

Triethanolamine, Percent by Weight

200

Temperature, F

Temperature, C

300

DSA9781.qxd

1/31/03

10:21 AM

Page 14

Figure 13

Absolute Viscosity, Centipoise

Absolute Viscosity of Aqueous Monoethanolamine Solutions

1 30C (86F)

2 50C (122F)

3 75C (167F)

4 100C (212F)

100

60

40

20

10

6

4

2

1

0.6

0.4

0.2

0.1

1

2

3

4

0 10 20 30 40 50 60 70 80 90 100

Monoethanolamine, Percent by Weight

Figure 14

Absolute Viscosity, Centipoise

Absolute Viscosity of Aqueous Diethanolamine Solutions

1 30C (86F)

2 50C (122F)

3 75C (167F)

4 100C (212F)

1000

400

200

100

40

20

10

4

2

1

0.4

0.2

0.1

1

2

3

4

10 20 30 40 50 60 70 80 90 100

Diethanolamine, Percent by Weight

Figure 15

Absolute Viscosity, Centipoise

Absolute Viscosity of Aqueous Triethanolamine Solutions

1 30C (86F)

2 50C (122F)

3 75C (167F)

4 100C (212F)

1000

400

200

100

40

20

10

4

2

1

0.4

0.2

0.1

1

2

3

4

0 10 20 30 40 50 60 70 80 90 100

Triethanolamine, Percent by Weight

13

DSA9781.qxd

1/31/03

10:21 AM

Page 15

Figure 16

Freezing Points of Aqueous Ethanolamine Solutions

140

60

120

40

100

20

Diethanolamine

60

40

20

0

-20

-20

Note: Freezing point data

for 70% to 90%

Diethanolamine in water are

extrapolated

-40

-40

-60

Monoethanolamine

-60

0

20

40

60

80

Ethanolamine, Percent by Weight

100

Figure 17

Specific Gravity of Aqueous Ethanolamine Solutions at 20/20C

1.13

1.12

1.11

Triethanolamine

Specific Gravity, 20/20C

1.10

1.09

Freezing

Point

1.08

1.07

1.06

Diethanolamine

1.05

1.04

1.03

Monoethanolamine

1.02

1.01

1.00

0

14

10

20 30 40 50 60 70 80

Ethanolamine, Percent by Weight

90 100

Freezing Point, F

Freezing Point, C

80

Triethanolamine

1/31/03

10:21 AM

Page 16

Figure 18

Weight per Gallon of Aqueous Monoethanolamine Solutions at Various Temperatures

9.2

Freezing Point Curve

9.0

0F

Pounds per Gallon

8.8

30F

60F

8.6

90F

120F

8.4

150F

180F

8.2

210F

8.0

7.8

0

20

40

60

80

Monoethanolamine, Percent by Weight

100

Figure 19

Weight per Gallon of Aqueous Diethanolamine Solutions at Various Temperatures

9.4

Freezing Point Curve

-20 F

9.2

30F

60F

90F

0 F

9.0

Pounds per Gallon

DSA9781.qxd

120F

150F

8.8

180F

210F

8.6

240F

8.4

Boiling Point

8.2

8.0

0

15

20

40

60

80

Diethanolamine, Percent by Weight

100

1/31/03

10:21 AM

Page 17

Figure 20

Weight per Gallon of Aqueous Triethanolamine Solutions at Various Temperatures

9.6

Freezing Point Curve

9.4

30F

60F

90F

120F

150F

180F

210F

240F

0F

9.2

Pounds per Gallon

DSA9781.qxd

9.0

8.8

8.6

8.4

Boiling Point

8.2

8.0

7.8

0

16

20

40

60

80

Triethanolamine, Percent by Weight

100

DSA9781.qxd

1/31/03

10:21 AM

Page 18

Figure 21

Specific Heats of Aqueous Monoethanolamine Solutions Temperature, F

40

1.1

80

120

160

200

240

Cal/g-C

MEA % by Wt

1.0

0.9

25

0.8

50

75

0.7

100

0.6

0

20

40

60

80

Temperature, C

100

120

Figure 22

Specific Heats of Aqueous Diethanolamine Solutions

1.1

40

Temperature, F

120

160

200

240

DEA % by Wt

1.0

Cal/g-C

80

0.9

25

0.8

50

0.7

75

100

0.6

0

20

40

60

80

Temperature, C

100

120

Figure 23

Specific Heats of Aqueous Triethanolamine Solutions

1.1

40

Temperature, F

120

160

200

240

TEA % by Wt

1.0

Cal/g-C

80

0

0.9

25

0.8

50

0.7

75

0.6

100

0.5

0

17

20

40

60

80

Temperature, C

100

120

DSA9781.qxd

1/31/03

10:21 AM

Page 19

Storage and Handling

Proper storage and handling will help maintain the quality of ethanolamine products. Under

normal conditions ethanolamines are considered to be thermally stable molecules and are

not corrosive to the proper containers. However, they are sufficiently reactive that upon

exposure to adventitious carbon dioxide, nitrogen oxides, and oxygen, trace levels of

byproducts can form and increased color often results.

For storage and handling information contact your Dow representative.

SAFETY NOTE MONOETHANOLAMINE

Monoethanolamine in contact with iron can form a crystalline complex called

tris(ethanolamino)-iron. This compound can ignite when heated to 130-160F (54-71C) in

the presence of air. A fire is known to have occurred in a storage tank equipped with a

carbon steel heating coil using 150 psig steam. For internal steam applications, stainless steel

heating coils should be used; low-pressure steam is preferred for safety and product quality.

STORAGE TEMPERATURES

Ethanolamines require heated and insulated storage and transfer facilities. Ethanolamines

darken, however, at temperatures above 140F (60C).

Table 2 Storage Temperatures for Ethanolamines

Freezing

Point, C (F)

Storage

Temperature, F

Approximate

Viscosity, cP,

30C (86F)

Monoethanolamine

10.5 (50.9)

65-95

15

Diethanolamine

28.0 (82.4)

95-120

380

Triethanolamine, Commercial

15.8 (60.4)

75-110

400

Triethanolamine, 99%

21.6 (70.9)

85-110

400

(a) Supercools easily

18

(a)

DSA9781.qxd

1/31/03

10:21 AM

Page 20

Shipping Information

For your convenience in ordering, Dow markets ethanolamines both direct and through an

effective network of distributors. Less than full tank car or tank truck quantities can be

delivered most rapidly through a Dow distributor. Consult your Dow representative for the

name of the distributor nearest you.

For delivery of large volume orders, ethanolamines are stocked in terminals throughout the

world.

Table 3 Shipping Data for Ethanolamines

Monoethanolamine Diethanolamine

Pounds per Gallon at 20C

Kilograms per liter at 20C

Triethanolamine, Triethanolamine,

Commercial

99%

8.47

1.015

9.10 (30C)

1.088 (30C)

9.37

1.123

9.38

1.124

Coefficient of Expansion

at 55C, per C

0.00081

0.00060

0.00049

0.00053

Flash Point, C (F)(a)

96 (205)

191 (375)

194 (382)

208 (407)

(a) Determined by ASTM Method D 93, using the Pensky-Martens Closed Cup

Specifications

Specifications for DOW Ethanolamines are available on request from your Dow sales

representative.

Product Safety

When considering the use of any Dow products in a particular application, you should

review Dows latest Material Safety Data Sheets and ensure that the use you intend can be

accomplished safely. For Material Safety Data Sheets and other product safety information,

please contact us using the numbers on the back cover of this brochure. Before handling

any other products mentioned in the text, you should obtain available product safety information and take necessary steps to ensure safety of use.

No chemical should be used as or in a food, drug, medical device, or cosmetic, until the

user has determined the suitability and legality of the use. Since government regulations

and use conditions are subject to change, it is the users responsibility to determine that this

information is appropriate and suitable under current, applicable laws and regulations.

Dow requests that the customer read, understand, and comply with the information

contained in this publication and the current Material Safety Data Sheet(s). The customer

should furnish the information in this publication to its employees, contractors, and

customers, or any other users of the product(s), and request that they do the same.

19

1/31/03

10:21 AM

Page 21

The Dow Chemical Company

Midland, Michigan 48674 U.S.A.

In the United States and Canada: call 1-800-447-4369 fax 1-989-832-1465

In Europe: call toll-free +800 3 694 6367 +32 3 450 2240 fax +32 3 450 2815

In the Pacific: call +852 2879 7260 fax +852 2827 5881

In Other Global Areas: call 1-989-832-1560 fax 1-989-832-1465

Or visit us at www.dow.com

NOTICE: No freedom from any patent owned by Seller or others is to be inferred. Because use conditions and applicable laws may differ from one location to

another and may change with time, Customer is responsible for determining whether products and the information in this document are appropriate for

Customers use and for ensuring that Customers workplace and disposal practices are in compliance with applicable laws and other governmental enactment.

Seller assumes no obligation or liability for the information in this document. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

Published January 2003

DSA9781.qxd

*Trademark of The Dow Chemical Company

Form No. 111-01375-0103 AMS

You might also like

- Mist PDFDocument28 pagesMist PDFGanesh GanyNo ratings yet

- BASF Glyoxal As An H2S ScavengerDocument8 pagesBASF Glyoxal As An H2S ScavengerMo OsNo ratings yet

- Alkyl Polyglycosides-Properties and Applications of A New Class of SurfactantsDocument18 pagesAlkyl Polyglycosides-Properties and Applications of A New Class of Surfactantsmjs9170100% (1)

- Coatings Solutions GuideDocument88 pagesCoatings Solutions Guidekhiemnguyen8668No ratings yet

- Ion Exchange Resins and Adsorbents in Chemical Processing: Second EditionFrom EverandIon Exchange Resins and Adsorbents in Chemical Processing: Second EditionRating: 5 out of 5 stars5/5 (1)

- AGITAN Defoamer Technologies PDFDocument15 pagesAGITAN Defoamer Technologies PDFMarco Lopez100% (1)

- Alketerge EDocument4 pagesAlketerge EYohanes OktavianusNo ratings yet

- Titrimetric Determination of ZirconiumDocument28 pagesTitrimetric Determination of Zirconiumalvarinjo9681100% (1)

- Katalog - Polyester Distribution Boxes BARTECDocument4 pagesKatalog - Polyester Distribution Boxes BARTECPedjaNo ratings yet

- Esterquats-The Novel Class of Cationic Fabric Softeners - S Mishra PDFDocument8 pagesEsterquats-The Novel Class of Cationic Fabric Softeners - S Mishra PDFPedskaNo ratings yet

- Highly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesFrom EverandHighly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesNo ratings yet

- Fatty Amine Ethoxylates and ItDocument3 pagesFatty Amine Ethoxylates and ItRizki RamadhanNo ratings yet

- CSNL An Environment Friendly Alternative PDFDocument15 pagesCSNL An Environment Friendly Alternative PDFDonald_12No ratings yet

- ImidazolineDocument8 pagesImidazolineamirarsham1365No ratings yet

- Brochure Antifoams Defoamers Tego AntifoamDocument8 pagesBrochure Antifoams Defoamers Tego AntifoamJuan CubasNo ratings yet

- Ethanolamines: Product InformationDocument48 pagesEthanolamines: Product InformationElias0% (1)

- Alkaline Cleaning GuideDocument3 pagesAlkaline Cleaning Guide同道文档中心100% (3)

- Sorbitan Esters PlantDocument9 pagesSorbitan Esters PlantHolman SanabriaNo ratings yet

- Maxfloc - TDocument3 pagesMaxfloc - TChoice OrganoNo ratings yet

- Preparation of Sorbitan StearateDocument5 pagesPreparation of Sorbitan StearatevannesaNo ratings yet

- Improved Technology For Production of Palm-Based Esterquats: By: Haliza Abdul Aziz and Zainab IdrisDocument4 pagesImproved Technology For Production of Palm-Based Esterquats: By: Haliza Abdul Aziz and Zainab IdrisMehmet Aydin100% (1)

- Product BrochureDocument20 pagesProduct BrochureSiddhan100% (1)

- AkzoNobel Narrow Range Ethoxylates - 2015Document4 pagesAkzoNobel Narrow Range Ethoxylates - 2015Vilas DhakappaNo ratings yet

- Cationic SurfactantsDocument4 pagesCationic SurfactantsAlfonso PeñarandaNo ratings yet

- Ester Alkoxylation TehnologyDocument9 pagesEster Alkoxylation TehnologySanjayka100% (1)

- Dow Chelating AgentsDocument12 pagesDow Chelating Agentsfshirani7619100% (1)

- Anti Migrasi ReaktifDocument12 pagesAnti Migrasi ReaktifharlanNo ratings yet

- Antifoam Solutions Brochure InddDocument0 pagesAntifoam Solutions Brochure Inddhisham_00No ratings yet

- Technical Brochure: Dissolvine GLDocument16 pagesTechnical Brochure: Dissolvine GLChemist Technologist100% (1)

- Cellosize BrochureDocument28 pagesCellosize BrochureDiana NguyenNo ratings yet

- Propylene Glycol Usp-EpDocument4 pagesPropylene Glycol Usp-Epvanhung68No ratings yet

- Water Soluble PolymersDocument57 pagesWater Soluble PolymersVimal GirnaraNo ratings yet

- Silicon Wax Emulsion For Polyurethane Water Release AgentDocument3 pagesSilicon Wax Emulsion For Polyurethane Water Release Agentmyosi laboratoriumNo ratings yet

- Introductory Brochures - Dequest Water AdditivesDocument9 pagesIntroductory Brochures - Dequest Water Additives中西文香No ratings yet

- Phenolic Resins by P MaheshwarDocument50 pagesPhenolic Resins by P MaheshwarArjun Satheesh Kumar100% (1)

- BBI Webinar Lutropur MSA-XP For DistributionDocument18 pagesBBI Webinar Lutropur MSA-XP For DistributionSeptian Wahyu PriyonoNo ratings yet

- Metalworkingfluidsneatcuttingoils1600658984320 PDFDocument46 pagesMetalworkingfluidsneatcuttingoils1600658984320 PDFShaara NeyNo ratings yet

- Akypo Lm-40 Leaflet Eng - KAO - AKYPO-LM-40Document3 pagesAkypo Lm-40 Leaflet Eng - KAO - AKYPO-LM-40bexigaobrotherNo ratings yet

- Dow Glycol Ethers PDFDocument27 pagesDow Glycol Ethers PDFMatt100% (1)

- Dimethyl TerephthalateDocument9 pagesDimethyl Terephthalatehung_metalNo ratings yet

- EODocument26 pagesEOdieego001100% (1)

- Imidazoline-Théorie Ferm1954Document21 pagesImidazoline-Théorie Ferm1954Belkhadem FatimaNo ratings yet

- Dover Chemicals - AdditivesDocument20 pagesDover Chemicals - AdditivesHovoFunnyNo ratings yet

- Brochure MosselmanDocument12 pagesBrochure Mosselmanvcoranm100% (1)

- Organo ClayDocument4 pagesOrgano ClayRaoni Batista Dos AnjosNo ratings yet

- Sokalan CP Types TI EN PDFDocument7 pagesSokalan CP Types TI EN PDFAhmedNo ratings yet

- Ethoxylates & Surfactants Pat Impex Manufacturer & Suppliers in IndiaDocument16 pagesEthoxylates & Surfactants Pat Impex Manufacturer & Suppliers in IndiaPat ImpexNo ratings yet

- Biocide FormulDocument3 pagesBiocide FormulIsmael RocaNo ratings yet

- Dispersing Agents PDFDocument14 pagesDispersing Agents PDFalmasNo ratings yet

- Lieferprogramm Phosphate EstersDocument12 pagesLieferprogramm Phosphate Estersjangri1098100% (1)

- Batch Emulsion PolymerizationDocument166 pagesBatch Emulsion PolymerizationShubham CholeNo ratings yet

- Clariant Wetting-AgentsDocument7 pagesClariant Wetting-AgentsAPEX SON100% (1)

- Exxon Exxal Alcohols For Ethoxylates - Huntsman - Feb 2017 PDFDocument28 pagesExxon Exxal Alcohols For Ethoxylates - Huntsman - Feb 2017 PDFMattNo ratings yet

- Products For Unsaturated PolyestersDocument8 pagesProducts For Unsaturated PolyestersNgan100% (1)

- The Iron Oxides: Structure, Properties, Reactions, Occurrences and UsesFrom EverandThe Iron Oxides: Structure, Properties, Reactions, Occurrences and UsesRating: 5 out of 5 stars5/5 (1)

- Handbook of Vinyl FormulatingFrom EverandHandbook of Vinyl FormulatingRichard F GrossmanRating: 3 out of 5 stars3/5 (1)

- Chemistry and Technology of SurfactantsFrom EverandChemistry and Technology of SurfactantsRichard J. FarnNo ratings yet

- Biobased Lubricants and Greases: Technology and ProductsFrom EverandBiobased Lubricants and Greases: Technology and ProductsRating: 5 out of 5 stars5/5 (1)

- Lignin and Lignans as Renewable Raw Materials: Chemistry, Technology and ApplicationsFrom EverandLignin and Lignans as Renewable Raw Materials: Chemistry, Technology and ApplicationsNo ratings yet

- Maros Training Handout PDFDocument29 pagesMaros Training Handout PDFGanesh GanyNo ratings yet

- Helideck Emergency Response Team Member Hertm Training Standard Available From 1st Jan 2018Document54 pagesHelideck Emergency Response Team Member Hertm Training Standard Available From 1st Jan 2018Ganesh GanyNo ratings yet

- THERMINOL 55 MSDS FEB2017.pdf2018-12-11 - 20 - 08 - 31 - SyP - Sga - enDocument8 pagesTHERMINOL 55 MSDS FEB2017.pdf2018-12-11 - 20 - 08 - 31 - SyP - Sga - enGanesh GanyNo ratings yet

- Radiation: Facts, Risks and RealitiesDocument17 pagesRadiation: Facts, Risks and RealitiesGanesh Gany100% (1)

- Pulsation Dampner SizingDocument3 pagesPulsation Dampner SizingGanesh GanyNo ratings yet

- Offshore Emergency Response Team Member Valid From 1st of March 2017Document48 pagesOffshore Emergency Response Team Member Valid From 1st of March 2017Ganesh GanyNo ratings yet

- Offshore Emergency Response Team LeaderDocument40 pagesOffshore Emergency Response Team LeaderGanesh Gany100% (1)

- Internal Verifier Training StandardDocument22 pagesInternal Verifier Training StandardGanesh GanyNo ratings yet

- Aga Transmission Measurement Committee Report No 8 - Google SearchDocument2 pagesAga Transmission Measurement Committee Report No 8 - Google SearchGanesh GanyNo ratings yet

- Asme MFC 6MDocument4 pagesAsme MFC 6MGanesh GanyNo ratings yet

- Fundamentals of Process Control Theory ThirdEd - Murrill - Unit2Document10 pagesFundamentals of Process Control Theory ThirdEd - Murrill - Unit2Ganesh Gany100% (1)

- Orifi Ce Plate and Orifi Ce FlangeDocument39 pagesOrifi Ce Plate and Orifi Ce FlangeGanesh GanyNo ratings yet

- Heat TraceDocument9 pagesHeat TraceGanesh GanyNo ratings yet

- Presentation - Pragati MaidanDocument22 pagesPresentation - Pragati MaidanMohamed Anas100% (4)

- Jyotish - Hindu Panchangam & MuhurtasDocument40 pagesJyotish - Hindu Panchangam & MuhurtasSamir Kadiya100% (1)

- BNVD Eaufrance Metadonnees Vente 20230130Document16 pagesBNVD Eaufrance Metadonnees Vente 20230130moussaouiNo ratings yet

- Safety Manual (B-80687EN 10)Document35 pagesSafety Manual (B-80687EN 10)Jander Luiz TomaziNo ratings yet

- LC1D32M7: Product Data SheetDocument7 pagesLC1D32M7: Product Data SheetCHAHRHLHOHSNo ratings yet

- Revisit of Harriott's Method For Process ControlDocument3 pagesRevisit of Harriott's Method For Process ControlkiddhoNo ratings yet

- The Body Productive Rethinking Capitalism Work and The Body Steffan Blayney Full ChapterDocument67 pagesThe Body Productive Rethinking Capitalism Work and The Body Steffan Blayney Full Chaptersharon.tuttle380100% (6)

- Protocols For Public-Key CryptosystemsDocument13 pagesProtocols For Public-Key CryptosystemsIvo LemosNo ratings yet

- Onco, TSG & CancerDocument8 pagesOnco, TSG & Cancersumera120488No ratings yet

- WhatsApp v. Union of India Filing VersionDocument224 pagesWhatsApp v. Union of India Filing VersionVinayNo ratings yet

- HCI 2008 Promo W SolutionDocument12 pagesHCI 2008 Promo W SolutionMichael CheeNo ratings yet

- Person To PersonDocument126 pagesPerson To PersonYalmi AdiNo ratings yet

- Explosion Protection - E PDFDocument7 pagesExplosion Protection - E PDFAPCANo ratings yet

- Tranzen1A Income TaxDocument46 pagesTranzen1A Income TaxMonica SorianoNo ratings yet

- Lienard EquationDocument9 pagesLienard EquationmenguemengueNo ratings yet

- Testing ChecklistDocument3 pagesTesting ChecklistAnurag YadavNo ratings yet

- Turbine-Less Ducted Fan Jet Engine: Subsonic PropulsionDocument25 pagesTurbine-Less Ducted Fan Jet Engine: Subsonic PropulsionزهديابوانسNo ratings yet

- Mapeh GR9 First Quarter ReviewerDocument8 pagesMapeh GR9 First Quarter ReviewerRalph Emerson SantillanNo ratings yet

- Aquamaster 4 Few4 and Fet4: Electromagnetic FlowmeterDocument48 pagesAquamaster 4 Few4 and Fet4: Electromagnetic FlowmeterAmol BorikarNo ratings yet

- Testbank: Applying Ifrs Standards 4eDocument11 pagesTestbank: Applying Ifrs Standards 4eSyed Bilal AliNo ratings yet

- Cell Theory Refers To The Idea That: MicrographiaDocument5 pagesCell Theory Refers To The Idea That: MicrographiadeltasixNo ratings yet

- 5054 s16 Ms 41 PDFDocument3 pages5054 s16 Ms 41 PDFKritish RamnauthNo ratings yet

- Cuadernillo de Trabajo: InglésDocument20 pagesCuadernillo de Trabajo: InglésFátima Castellano AlcedoNo ratings yet

- Vision PT 365 Culture 2021 (WWW - Upscpdf.com)Document51 pagesVision PT 365 Culture 2021 (WWW - Upscpdf.com)Swati YadavNo ratings yet

- Hayden Esterak Resume 1Document1 pageHayden Esterak Resume 1api-666885986No ratings yet

- Alere G1 Glucose Meter ManualDocument55 pagesAlere G1 Glucose Meter ManualSundar Rajan33% (6)

- Consumer Behavior, Market Research, and AdvertisementDocument37 pagesConsumer Behavior, Market Research, and AdvertisementMohamed AbdelazizNo ratings yet

- ANSWERS - PhyLabS6 EX02 Water TowerDocument8 pagesANSWERS - PhyLabS6 EX02 Water TowerGuacNo ratings yet

- 3I Grading Rubric For Output PresentationDocument2 pages3I Grading Rubric For Output PresentationBinibining Michelle CenizaNo ratings yet