Professional Documents

Culture Documents

Lecture 3

Lecture 3

Uploaded by

Siswand BIn Mohd AliCopyright:

Available Formats

You might also like

- Ellen Fein - The RulesDocument184 pagesEllen Fein - The Rulesanna.wangeitNo ratings yet

- Full Revised Chapter 7Document55 pagesFull Revised Chapter 7Diovinyl Kartil67% (3)

- Modeling A Triple-Effect Evaporator in Aspen Plus: An ExampleDocument5 pagesModeling A Triple-Effect Evaporator in Aspen Plus: An ExampleSalsabila Masitah HakimNo ratings yet

- Class 23 Washing and LeachingDocument30 pagesClass 23 Washing and LeachingFernando AlvarezNo ratings yet

- 1165r05320801 Mass Transfer Operations IIDocument9 pages1165r05320801 Mass Transfer Operations IIsobichemNo ratings yet

- CL 303-Assignment No.1Document2 pagesCL 303-Assignment No.1Vineeth Dasaraju0% (1)

- Chapter 4Document77 pagesChapter 4S S S REDDYNo ratings yet

- MDocument3 pagesMbamban bam100% (1)

- Maulid Simtudduror & English Translated: Page 1 of 76Document76 pagesMaulid Simtudduror & English Translated: Page 1 of 76Siswand BIn Mohd AliNo ratings yet

- Accidental Intravenous Infusion of Air: A Concise ReviewDocument5 pagesAccidental Intravenous Infusion of Air: A Concise ReviewSiswand BIn Mohd AliNo ratings yet

- Acupressure ChartDocument1 pageAcupressure Chartapi-3838398100% (9)

- Dr. Mohammad Siraj Alam: Curriculum VitaeDocument7 pagesDr. Mohammad Siraj Alam: Curriculum VitaeShreyank Deepali GoelNo ratings yet

- Exercise6 Stripper SolutionDocument8 pagesExercise6 Stripper SolutionHoney AlarconNo ratings yet

- Milieux Poreux Et Dispersés-FiltrationDocument2 pagesMilieux Poreux Et Dispersés-FiltrationKhezazna SeifNo ratings yet

- Low Chain Esters of Stearic Acid As Phase Change Materials For Thermal Energy Storage in BuildingsDocument12 pagesLow Chain Esters of Stearic Acid As Phase Change Materials For Thermal Energy Storage in Buildingsfabio1199No ratings yet

- موازنة الطاقة الثالثةDocument32 pagesموازنة الطاقة الثالثةكرار عبدالحسين قاسم100% (1)

- Imene Djedid Coagulation-FloculationDocument3 pagesImene Djedid Coagulation-Floculationmanel KaddourNo ratings yet

- 12 B Tech - ECE PDFDocument248 pages12 B Tech - ECE PDFFarhaan BudalyNo ratings yet

- W3V21 Gas Treatment V2016 HandoutDocument7 pagesW3V21 Gas Treatment V2016 HandoutJessica King100% (1)

- Raffinage Des Huiles Et Des Corps Gras Et Élimination Des ContaminantsDocument14 pagesRaffinage Des Huiles Et Des Corps Gras Et Élimination Des ContaminantsBoussebha NoureddineNo ratings yet

- Chapter 3 - Thermal Processing-Exercises-Student-PrintDocument11 pagesChapter 3 - Thermal Processing-Exercises-Student-PrintNguyễn Thị NinhNo ratings yet

- SAND Study For Orifice PDFDocument48 pagesSAND Study For Orifice PDFAnoop GeorgeNo ratings yet

- ArticleDocument14 pagesArticlejaime100% (1)

- الاستخلاصDocument40 pagesالاستخلاصAli AliNo ratings yet

- The Diels-Alder Reaction: PROBLEM 22.10Document8 pagesThe Diels-Alder Reaction: PROBLEM 22.10Sandipan Saha100% (1)

- Chapter 1 DistillationDocument73 pagesChapter 1 DistillationNUR HIDAYAHNo ratings yet

- Chapter 04 Absorption and Stripping of Dilute MixturesDocument31 pagesChapter 04 Absorption and Stripping of Dilute MixturesJonny Yana CruzNo ratings yet

- Exercise Z Matrix CH4Document18 pagesExercise Z Matrix CH4Manjeet BhatiaNo ratings yet

- R-723 - An Azeotrope On The Basis of AmmoniaDocument6 pagesR-723 - An Azeotrope On The Basis of AmmoniaevrimkNo ratings yet

- Toxicophores: Groups and Metabolic Routes Associated With Increased Safety RiskDocument13 pagesToxicophores: Groups and Metabolic Routes Associated With Increased Safety RiskMercedes ArmijosNo ratings yet

- Phénomène de Surface - TD - Exercices Corrigés 6612Document16 pagesPhénomène de Surface - TD - Exercices Corrigés 6612Fatma Benamer100% (1)

- Tutorial 3 Electrochemistry - AnswersDocument10 pagesTutorial 3 Electrochemistry - AnswerssgarrabNo ratings yet

- 3MS - First Term Examination - Tom Memories 2017-2018 by Teacher Nad RoseDocument3 pages3MS - First Term Examination - Tom Memories 2017-2018 by Teacher Nad RoseLahcen Aoun0% (1)

- (NATO ASI Series 110) Alirio Rodrigues, Carlos Costa, Rosa Ferreira (Auth.), Hugo I. de Lasa (Eds.)-Chemical Reactor Design and Technology_ Overview of the New Developments of Energy and PetrochemicalDocument838 pages(NATO ASI Series 110) Alirio Rodrigues, Carlos Costa, Rosa Ferreira (Auth.), Hugo I. de Lasa (Eds.)-Chemical Reactor Design and Technology_ Overview of the New Developments of Energy and PetrochemicalAzharuddin_kfupmNo ratings yet

- Absorption II. Abstrip-Packed - ColumnsDocument58 pagesAbsorption II. Abstrip-Packed - ColumnsAnonymous wCDPbgMLJNo ratings yet

- Aplication Fat Extraction FoodDocument6 pagesAplication Fat Extraction FoodKu BonNo ratings yet

- 6-Absorption Stripping Pt1Document18 pages6-Absorption Stripping Pt1Naufal FasaNo ratings yet

- AbsorptionDocument16 pagesAbsorptionGloria BailonNo ratings yet

- Distillation, Ponchon Savarit, ShahzadDocument30 pagesDistillation, Ponchon Savarit, ShahzadMahad ZahidNo ratings yet

- TF06 Convection 03Document2 pagesTF06 Convection 03thekrumpNo ratings yet

- Saponification: Esters, Soapless and Soapy DetergentsDocument17 pagesSaponification: Esters, Soapless and Soapy Detergentsp bergerNo ratings yet

- Chemistry of Chromium Detecting Chromium Triple Ion (CR)Document29 pagesChemistry of Chromium Detecting Chromium Triple Ion (CR)Abambagade AberaNo ratings yet

- Raffinage Du BrutDocument68 pagesRaffinage Du BrutfahimNo ratings yet

- Bowen Full Flow Reverse Circulation Junk Baskets: Instruction ManualDocument11 pagesBowen Full Flow Reverse Circulation Junk Baskets: Instruction ManualHadjer zitNo ratings yet

- Dme Simulation With DwsimDocument4 pagesDme Simulation With Dwsimingegnere1234No ratings yet

- Pressure-Driven Cavitating Flow of Water Through A Sharp-Edged OrificeDocument13 pagesPressure-Driven Cavitating Flow of Water Through A Sharp-Edged OrificeKaushika Rajapaksha PereraNo ratings yet

- Kelompok 7 Chap 18Document6 pagesKelompok 7 Chap 18Katharina AjengNo ratings yet

- Membrane Separation: ProcessesDocument8 pagesMembrane Separation: ProcessesSaptarshi BhattacharjeeNo ratings yet

- Ex03 PDFDocument10 pagesEx03 PDFafendiNo ratings yet

- ASTM Distillation (ASTM)Document2 pagesASTM Distillation (ASTM)ahmadreza bayemaniNo ratings yet

- Aspen Hysys Studie Kite-1Document10 pagesAspen Hysys Studie Kite-1AnavheobaNo ratings yet

- Exercise 1 Structure of MatterDocument2 pagesExercise 1 Structure of MatterSelwah Hj Akip100% (1)

- TF06 Convection 07Document2 pagesTF06 Convection 07SABANo ratings yet

- 2.7 Exercise 2 - Extraction of Aluminium and TitaniumDocument4 pages2.7 Exercise 2 - Extraction of Aluminium and TitaniumHo Yong WaiNo ratings yet

- Tute Sheet-8Document2 pagesTute Sheet-8s barmanNo ratings yet

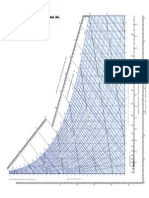

- Psychrometric Chart: Enthalpy - Btu Per Pound of Dry AirDocument1 pagePsychrometric Chart: Enthalpy - Btu Per Pound of Dry AirJavier MendozaNo ratings yet

- TD Physique NuageDocument3 pagesTD Physique Nuageelsa olive ze100% (1)

- Visbreaking ModelDocument13 pagesVisbreaking ModelMaileen Julissa Hoyos CastellanosNo ratings yet

- Liquid LiquidExtractionDocument57 pagesLiquid LiquidExtractionYasir MukhtarNo ratings yet

- Tutorial C5 AnswerDocument7 pagesTutorial C5 AnswerAustin Phua Yun HockNo ratings yet

- MBBR Product Information MaterialsDocument2 pagesMBBR Product Information MaterialsAvinash kandhareNo ratings yet

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Modified Checklist For Autism in Toddlers, Revised (M-CHAT-R)Document3 pagesModified Checklist For Autism in Toddlers, Revised (M-CHAT-R)Siswand BIn Mohd AliNo ratings yet

- ImamNawawiProject Brief PDFDocument6 pagesImamNawawiProject Brief PDFSiswand BIn Mohd AliNo ratings yet

- A Star Organisation Chart: Chairman DirectorDocument1 pageA Star Organisation Chart: Chairman DirectorSiswand BIn Mohd AliNo ratings yet

- Ramadan For The Pregnant, Nursing and Elderly: Nuruddinzangi March 1, 2019Document3 pagesRamadan For The Pregnant, Nursing and Elderly: Nuruddinzangi March 1, 2019Siswand BIn Mohd AliNo ratings yet

- Wisdom in Friday Suras: Nuruddinzangi June 3, 2019Document1 pageWisdom in Friday Suras: Nuruddinzangi June 3, 2019Siswand BIn Mohd AliNo ratings yet

- JRDPHL Payment Details: FlightDocument2 pagesJRDPHL Payment Details: FlightSiswand BIn Mohd AliNo ratings yet

- .Sg-3 Month Old BabyDocument4 pages.Sg-3 Month Old BabySiswand BIn Mohd AliNo ratings yet

- Onal Paper SeriesDocument48 pagesOnal Paper SeriesSiswand BIn Mohd AliNo ratings yet

- Ramadan Engl. Werb. p.3 11Document9 pagesRamadan Engl. Werb. p.3 11Siswand BIn Mohd AliNo ratings yet

- The Refinement of Character: Tahdhib Al-AkhlaqDocument2 pagesThe Refinement of Character: Tahdhib Al-AkhlaqSiswand BIn Mohd AliNo ratings yet

- Selawat TextsDocument2 pagesSelawat TextsSiswand BIn Mohd AliNo ratings yet

- Hamza Yusuf On Gay MuslimsDocument4 pagesHamza Yusuf On Gay MuslimsSiswand BIn Mohd Ali100% (1)

- Dragon Warrior Monsters 2 Magic KeyDocument7 pagesDragon Warrior Monsters 2 Magic KeySiswand BIn Mohd AliNo ratings yet

- Master of Arts in Arabic Linguistic StudiesDocument2 pagesMaster of Arts in Arabic Linguistic StudiesSiswand BIn Mohd AliNo ratings yet

- Orlando Gunman Omar MateenDocument7 pagesOrlando Gunman Omar MateenSiswand BIn Mohd AliNo ratings yet

- Powerful Dua To Remove Afflictions and CalamitiesDocument2 pagesPowerful Dua To Remove Afflictions and CalamitiesSiswand BIn Mohd Ali100% (1)

- Palestinian Christians: "We Say Allahu Akbar (Too) ": by Nadezhda Kevorkova - Posted inDocument8 pagesPalestinian Christians: "We Say Allahu Akbar (Too) ": by Nadezhda Kevorkova - Posted inSiswand BIn Mohd AliNo ratings yet

- Dragon Warrior Monsters 2 Magic KeyDocument7 pagesDragon Warrior Monsters 2 Magic KeySiswand BIn Mohd AliNo ratings yet

- 14-Ramadan-560 Hijri: Avempace Ibn BâjjaDocument3 pages14-Ramadan-560 Hijri: Avempace Ibn BâjjaSiswand BIn Mohd AliNo ratings yet

- Fyp ReferencesDocument1 pageFyp ReferencesSiswand BIn Mohd AliNo ratings yet

- Chemistry Project PDFDocument30 pagesChemistry Project PDFyash hiraniNo ratings yet

- 2003 Corkscrew Bike Trail StudyDocument25 pages2003 Corkscrew Bike Trail StudyJoey KulkinNo ratings yet

- Lo2012 TPFDocument114 pagesLo2012 TPFramjoceNo ratings yet

- Deering 2020Document4 pagesDeering 2020KevinNo ratings yet

- Blazevideo HDTV Player V6.0R User'S ManualDocument17 pagesBlazevideo HDTV Player V6.0R User'S ManualGianfranco CruzattiNo ratings yet

- Journal of CO2 Utilization: Changsoo Kim, Chun-Jae Yoo, Hyung-Suk Oh, Byoung Koun Min, Ung LeeDocument22 pagesJournal of CO2 Utilization: Changsoo Kim, Chun-Jae Yoo, Hyung-Suk Oh, Byoung Koun Min, Ung Leeayemyattheint kyawNo ratings yet

- 100 Watts Power Amplifier Design PDFDocument47 pages100 Watts Power Amplifier Design PDFMark Kenneth ValerioNo ratings yet

- Wastewater Surveillance of Pathogens Can Inform Public Health ResponsesDocument4 pagesWastewater Surveillance of Pathogens Can Inform Public Health ResponsesMiriam LeiNo ratings yet

- Wire Nails Manufacturing Business. How To Start Nail Factory. Profitable Small Business Ideas in India-887813Document63 pagesWire Nails Manufacturing Business. How To Start Nail Factory. Profitable Small Business Ideas in India-887813MuazNo ratings yet

- Central Academy SyllabusDocument3 pagesCentral Academy Syllabuski5814601No ratings yet

- SprinklersDocument2 pagesSprinklersMohamed El MorsyNo ratings yet

- ISCDL - Problem Statements For State Level HackthonDocument6 pagesISCDL - Problem Statements For State Level HackthonSarvesh DubeyNo ratings yet

- Unit 1 Chapter 3: Quadratic FunctionsDocument18 pagesUnit 1 Chapter 3: Quadratic FunctionsZlata OsypovaNo ratings yet

- August 24, 2021 - OCW Song Line-Up - Shell VibalDocument9 pagesAugust 24, 2021 - OCW Song Line-Up - Shell VibalDennis GiananNo ratings yet

- Clean RoomDocument9 pagesClean Roomxyzscribd1988No ratings yet

- Stewart Revofalg ExercisesDocument12 pagesStewart Revofalg Exercisesapi-261282952No ratings yet

- KW 18KWH Canada Interim Letters - KWUSDocument2 pagesKW 18KWH Canada Interim Letters - KWUSMecano PadNo ratings yet

- Sony KV 13TR27 Chasis.P 3BDocument29 pagesSony KV 13TR27 Chasis.P 3BTereza Yamileth Coto ENo ratings yet

- Introducing MPLS Traffic Engineering Components-L01Document35 pagesIntroducing MPLS Traffic Engineering Components-L01Cuong HaNo ratings yet

- Sistemas de Refrigeracion Industrial en AmoniacoDocument102 pagesSistemas de Refrigeracion Industrial en AmoniacoDiego Trinidad100% (8)

- Lightolier Lytespan Track Lighting Systems Catalog 1984Document94 pagesLightolier Lytespan Track Lighting Systems Catalog 1984Alan Masters100% (1)

- Turbine Cat SolarDocument2 pagesTurbine Cat SolarAbid Lakhani100% (1)

- Led Music Controller InsructionsDocument2 pagesLed Music Controller InsructionsArnaldoloNo ratings yet

- Ar Prda 2018 - FinalDocument37 pagesAr Prda 2018 - FinalucokNo ratings yet

- Remedies For VenusDocument2 pagesRemedies For VenusAnonymous 4Iu6iiNo ratings yet

- Flint Manual 2013Document69 pagesFlint Manual 2013Syafara Salsa Bila Wahyudin0% (1)

- Abe 424 Farm Structures and Environmental ControlDocument42 pagesAbe 424 Farm Structures and Environmental ControlAmabi SilasNo ratings yet

- Assignment 2 Inorganic ChemistryDocument2 pagesAssignment 2 Inorganic Chemistryinam ullahNo ratings yet

Lecture 3

Lecture 3

Uploaded by

Siswand BIn Mohd AliOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture 3

Lecture 3

Uploaded by

Siswand BIn Mohd AliCopyright:

Available Formats

Lecture 3

Flash distillation

Multicomponent flash distillation design

Example problem

Sizing of a flash drum

Compulsory reading: Chapter 2 (sections 2.6 and 2.8) from the text book

Farooq/CN3132/Flash Distillation-3-1

1

Multicompoment flash distillation

Graphical solution limited to binary separation.

Manually solve by trial and error

Computer solution using nonlinear equation

solver

We can write the following equations:

y

(1)

Equilibrium: K i = i

xi

K i = f (Pdrum,Tdrum, xi ) (non-ideal)

= f (Pdrum,Tdrum ) (ideal)

Ki xFi

K

x

y

=

=

xi i= i1.0 i 1 +(2)

( Ki 1) f

yi = 1.0;

i=1

i =1

Combining eqs (1), (3) and (4):

Fzi

zi

zi

xi =

=

=

F V + VK i 1 + K 1 V 1 + (K i 1) f

( i )

F

(5)

Add all components:

C

C

z

(6)

xi = 1 + (K i 1) f = 1

i

1

1

Multiply eq (5) with K i :

K i zi

K i xi = yi =

(10) 1 + (K i 1) f

Add all components:

C

K i xi = yi =

Mass balances around Loop 1:

(7)

K i zi

=1

1 + (K i 1) f

(8)

Loop 1

V, y, HV

F, z

TF, PF, hF

IDEAL

STAGE

L, x, hL

Overall: F = L + V

(3)

Component: Fzi = Lxi + Vyi

(4)

Subtract eq (8) from eq (6):

C

(K i 1) zi = 0

1 + (K 1) f

i

1

(9)

Eqs (6), (8) and (9) are the design equations.

Eq (9) has good convergence property.

Farooq/CN3132/Flash Distillation-3-2

2

Test your understanding

Feed composition, zi , is usually known. For an ideal system K i = (Pdrum ,Tdrum )

Consider the following two scenarios:

Scenario 1

Pdrum,Tdrum are known.

What is the unknown in eq (6), (8) or (9)?

Scenario 2

Pdrum and f are known.

Can you determine Tdrum ?

If you are able to solve the unknown,

can you calculate compositions of the

vapor (V) and liquid (L) streams

leaving the flash drum?

Farooq/CN3132/Flash Distillation-3-3

3

Example problem on multicomponent flash

A flash chamber operating at 50 C and 200 kPa is separating 1000 kg moles/hr of a feed that is 30 mole %

propane, 10 mole % n-butane, 15 mole % n-pentane and 45 mole % n-hexane. Find the product compositions

and flow rates.

Design equations

V, y1, y2, y3, y4

F = 1000 kg moles/hr

z1= 0.30

z2= 0.10

z3= 0.15

z4= 0.45

zi

1 + (K i 1) f

yi = K i xi

Tdrum = 50 o C

xi =

Pdrum = 200 kPA

L, x1, x2, x3, x4

(K i 1) zi

1 + (K 1) f

i

i =1

4

=0

(1)

(2)

(3)

zi given

Tdrum and Pdrum given - Ki can be

calculated

V

f = is the only unknown in eq (1)

F

Solution procedure

Eq (1) is nonlinear in f

Solve by trial and error or use EXCEL

Use the f in eq (2) to calculate xi

Use xi in eq (3) to calculate yi

V = (F)(f)

L = F-V

Farooq/CN3132/Flash Distillation-3-4

4

Solution by trial and error

1. Get Ki from given Tdrum and Pdrum

2. Guess a value for f (between 0 and 1)

4

(K i 1) zi

3. Check the value of

i =1 1 + (K i 1) f

4. If , where is tolerance limit, accept guessed f

5. If not then go back to step 2

Sample result

Components

zi

Ki

0.3

0.1

0.15

0.45

1.0

7.4

2.55

0.76

0.29

LHS of eq (1)

f = 0.4 f = 0.6

f =0.5

xi

yi

0.071

0.056

0.170

0.698

0.995

0.525

0.143

0.129

0.202

0.999

(kg moles/hr)

1000

Propane

n-butane

n-pentane

n-hexane

0.149

-0.122

0.008

500 500

Test your understanding

How would you proceed if

V

( = f ) is known and you are required to calculate Tdrum or Pdrum ?

F

Demonstration of solution using EXCEL

http://courses.nus.edu.sg/course/chesf/cn3132/Notes/Multicomponent%20Flash.xls

Farooq/CN3132/Flash Distillation-3-5

5

Water-Hydrocarbon Systems

Hydrocarbon and water may be assumed to be completely immiscible for the purposes of flash calculations. Each

of the two phases (immiscible) exerts its own vapor pressure and the total pressure is the sum of the individual

vapor pressures.

Bubble point calculation (liquid mixture being heated)

o

For a binary water-hydrocarbon system: Total pressure, P = PHC

+ PHo2O

(1)

For a multi-component water-hydrocarbon system: P = PHC + PHo2O

(2)

Partial pressure of hydrocarbons in the mixture: PHC = P PHo2O

(3)

Criteria:

yi = Ki ( T,PHC ) xi = 1

i

(where y and x indicate water-free basis)

(4)

Example

Calculate the bubble point at 25 psia for the hydrocarbon water mixture whose feed composition is shown below:

n-C5

n-C6

n-C7

H2O

0.225

0.450

0.225

0.100

1.000

x'

(water

free)

0.250

0.500

0.250

1.000

T = 160 F

PHo2O = 4.7; PHC = 20.3

Kx

T = 163.4 F

PHo2O = 5.2;PHC = 19.8

K

Kx

1.94

0.77

0.30

0.485

0.385

0.075

2.05

0.815

0.324

0.511

0.408

0.081

0.945

1.000

Farooq/CN3132/Flash Distillation-3-6

6

Dew point calculation (vapor mixture being cooled)

PHC = P yHCi

i

Criteria:

(5)

xi = K ( T,Pi ) = 1

i

HC

i

i

(6)

Example

Calculate the bubble point at 25 psia for the hydrocarbon water mixture whose feed composition is shown below:

n-C5

n-C6

n-C7

H2O

0.225

0.450

0.225

0.100

1.000

y'

(water

free)

0.250

0.500

0.250

1.000

K

2.5

1.08

0.46

T = 190 F

PHC = 22.5

y/K

0.100

0.463

0.543

1.106

T = 195 F

PHC = 22.5

y/K

2.71

1.17

0.515

0.092

0.423

0.485

1.000

Farooq/CN3132/Flash Distillation-3-7

7

Drum Size Calculation

Drum sizing is an empirical procedure. Vertical falsh drum design is discussed here.

Step1. Calculate the permissible vapor velocity, uperm

L v

(1)

v

uperm is the maximum permissible vapor velocity (in ft/s at maximum cross-section)

uperm = K drum

L liquid density

v vapor density

Must be in the same unit

K drum = exp[A + BlnFlv + C(lnFlv )2 + D(lnFlv )3 + E(lnFlv )4 ] 1

W v

Flv = L

Wv L

WL liquid mass flow rate

Wv vapor mass flow rate

Must be in the same unit

(2)

The constants

(Blackwell, 1984):

A = -1.877478097

B = -0.8145804597

C = -0.1870744085

D = -0.0145228667

E = -0.0010148518

Kdrum is an empirical constant whose value has been correlated graphically by Watkins (1967) for 85% of flood with no demister.

Approximately 5% liquid will be entrained with the vapor. Use of the same design with a demister will reduce entrainment to less

than 1%. The demister traps small liquid droplets on fine wires and prevents them from exiting. The droplets then coalesce into

larger droplets, which fall off the wire and through the rising vapor into the liquid pool at the bottom of the flash chamber. Blackwell

(1984) fit Watkins correlation to equation (2).

Farooq/CN3132/Flash Distillation-3-8

8

Step 2.

( )

ft 3600s

lbm

uperm

A c ft 2 v 3

lb moles

s hr

ft

V

=

hr

lbm

MWvapour

lb mole

V (MWv )

(3)

Ac =

uperm ( 3600 ) v

For a vertical drum: Diameter, D =

4A c

(4)

Usually, the diameter is increased to the next largest 6-in. increment.

Step 3.

L hV + hf + hL

=

(3<L/D<5)

D

D

(5)

hv = 36 in + 0.5d with a minimum requirement of 46 in.

hf = 12 in + 0.5d with a minimum requirement of 18 in.

hL =

Vsurge

D2 / 4

Vsurge is the desired surge volume

d is the diameter of the feed nozzle

(6)

L/D < 3, choose larger Vsurge

L/D > 5, use horizontal drum (Dhorizontal 2D vertical)

See Example 2.4 from the text book

Farooq/CN3132/Flash Distillation-3-9

9

Homework 1 (CN 3132)

1. The outlet air from the paint formulation chamber of a paint industry shown in the figure is saturated with solvent hexane. The

outlet air stream is at atmospheric pressure and 25 oC. A consultant has been hired to design a flash separator that will

remove at least 90% of hexane from the outlet air before discharging the air steam to atmosphere. Available in the store is a

cooling system that can cool the outlet air stream up to -5 oC. Also available is a compressor that can compress the air

stream up to 600 kPa. The consultant has recommended that the flash separator be operated at 0 oC and 200 kPa. K values

of hexane at 2 different conditions are also included in the figure below.

Fresh air

Hexane saturated

outlet air

10 moles/hr

Paint

formulation

chamber

Maximum 10% of hexane in

Nearly pure

K values of hexane.

Pressure Temp

K

o

1 atm

25 C

0.2

200 kPa 0 oC 0.035

(i) Find the flow rate of the hexane stream leaving the bottom of the flash unit assuming 90% removal.

(ii) Do you agree with the recommendation of the consultant? Show the calculations in support of your answer.

Farooq/CN3132/Flash Distillation-3-10

10

180

2. The T-x-y data for toluene-phenol system at 1 atm pressure

is given in Figure 2. It has been decided that a 35:65 mixture

of toluene and phenol will be flash distilled at a feed rate of

1000 kmol/hr in a flash drum at 1 atm pressure and 140 oC.

o

T ( C)

a. Find toluene mole fractions in the vapor and liquid

streams leaving the flash unit. Show your drawings in

Figure 2.

b. Calculate the vapor flow rate leaving the flash unit

c. Calculate the diameter of the drum if the permissible

vapor velocity is 2 m/s. Average molecular weight of

the vapor is 92.5. Molar density of the vapor is 0.0295

kmol/m3.

Vapor

160

140

120

Liquid

100

0.2

0.4

0.6

0.8

xT or yT

Figure: 2

3. A flash drum operating at 300 kPa is separating a mixture that is fed in as 40 mole % isobutane, 25 % n-pentane, and 35% nhexane. We wish a 90% recovery of n-hexane in the liquid. F= 1000 kg moles/hr. Find Tdrum, xi, yi, V/F.

Farooq/CN3132/Flash Distillation-3-11

11

You might also like

- Ellen Fein - The RulesDocument184 pagesEllen Fein - The Rulesanna.wangeitNo ratings yet

- Full Revised Chapter 7Document55 pagesFull Revised Chapter 7Diovinyl Kartil67% (3)

- Modeling A Triple-Effect Evaporator in Aspen Plus: An ExampleDocument5 pagesModeling A Triple-Effect Evaporator in Aspen Plus: An ExampleSalsabila Masitah HakimNo ratings yet

- Class 23 Washing and LeachingDocument30 pagesClass 23 Washing and LeachingFernando AlvarezNo ratings yet

- 1165r05320801 Mass Transfer Operations IIDocument9 pages1165r05320801 Mass Transfer Operations IIsobichemNo ratings yet

- CL 303-Assignment No.1Document2 pagesCL 303-Assignment No.1Vineeth Dasaraju0% (1)

- Chapter 4Document77 pagesChapter 4S S S REDDYNo ratings yet

- MDocument3 pagesMbamban bam100% (1)

- Maulid Simtudduror & English Translated: Page 1 of 76Document76 pagesMaulid Simtudduror & English Translated: Page 1 of 76Siswand BIn Mohd AliNo ratings yet

- Accidental Intravenous Infusion of Air: A Concise ReviewDocument5 pagesAccidental Intravenous Infusion of Air: A Concise ReviewSiswand BIn Mohd AliNo ratings yet

- Acupressure ChartDocument1 pageAcupressure Chartapi-3838398100% (9)

- Dr. Mohammad Siraj Alam: Curriculum VitaeDocument7 pagesDr. Mohammad Siraj Alam: Curriculum VitaeShreyank Deepali GoelNo ratings yet

- Exercise6 Stripper SolutionDocument8 pagesExercise6 Stripper SolutionHoney AlarconNo ratings yet

- Milieux Poreux Et Dispersés-FiltrationDocument2 pagesMilieux Poreux Et Dispersés-FiltrationKhezazna SeifNo ratings yet

- Low Chain Esters of Stearic Acid As Phase Change Materials For Thermal Energy Storage in BuildingsDocument12 pagesLow Chain Esters of Stearic Acid As Phase Change Materials For Thermal Energy Storage in Buildingsfabio1199No ratings yet

- موازنة الطاقة الثالثةDocument32 pagesموازنة الطاقة الثالثةكرار عبدالحسين قاسم100% (1)

- Imene Djedid Coagulation-FloculationDocument3 pagesImene Djedid Coagulation-Floculationmanel KaddourNo ratings yet

- 12 B Tech - ECE PDFDocument248 pages12 B Tech - ECE PDFFarhaan BudalyNo ratings yet

- W3V21 Gas Treatment V2016 HandoutDocument7 pagesW3V21 Gas Treatment V2016 HandoutJessica King100% (1)

- Raffinage Des Huiles Et Des Corps Gras Et Élimination Des ContaminantsDocument14 pagesRaffinage Des Huiles Et Des Corps Gras Et Élimination Des ContaminantsBoussebha NoureddineNo ratings yet

- Chapter 3 - Thermal Processing-Exercises-Student-PrintDocument11 pagesChapter 3 - Thermal Processing-Exercises-Student-PrintNguyễn Thị NinhNo ratings yet

- SAND Study For Orifice PDFDocument48 pagesSAND Study For Orifice PDFAnoop GeorgeNo ratings yet

- ArticleDocument14 pagesArticlejaime100% (1)

- الاستخلاصDocument40 pagesالاستخلاصAli AliNo ratings yet

- The Diels-Alder Reaction: PROBLEM 22.10Document8 pagesThe Diels-Alder Reaction: PROBLEM 22.10Sandipan Saha100% (1)

- Chapter 1 DistillationDocument73 pagesChapter 1 DistillationNUR HIDAYAHNo ratings yet

- Chapter 04 Absorption and Stripping of Dilute MixturesDocument31 pagesChapter 04 Absorption and Stripping of Dilute MixturesJonny Yana CruzNo ratings yet

- Exercise Z Matrix CH4Document18 pagesExercise Z Matrix CH4Manjeet BhatiaNo ratings yet

- R-723 - An Azeotrope On The Basis of AmmoniaDocument6 pagesR-723 - An Azeotrope On The Basis of AmmoniaevrimkNo ratings yet

- Toxicophores: Groups and Metabolic Routes Associated With Increased Safety RiskDocument13 pagesToxicophores: Groups and Metabolic Routes Associated With Increased Safety RiskMercedes ArmijosNo ratings yet

- Phénomène de Surface - TD - Exercices Corrigés 6612Document16 pagesPhénomène de Surface - TD - Exercices Corrigés 6612Fatma Benamer100% (1)

- Tutorial 3 Electrochemistry - AnswersDocument10 pagesTutorial 3 Electrochemistry - AnswerssgarrabNo ratings yet

- 3MS - First Term Examination - Tom Memories 2017-2018 by Teacher Nad RoseDocument3 pages3MS - First Term Examination - Tom Memories 2017-2018 by Teacher Nad RoseLahcen Aoun0% (1)

- (NATO ASI Series 110) Alirio Rodrigues, Carlos Costa, Rosa Ferreira (Auth.), Hugo I. de Lasa (Eds.)-Chemical Reactor Design and Technology_ Overview of the New Developments of Energy and PetrochemicalDocument838 pages(NATO ASI Series 110) Alirio Rodrigues, Carlos Costa, Rosa Ferreira (Auth.), Hugo I. de Lasa (Eds.)-Chemical Reactor Design and Technology_ Overview of the New Developments of Energy and PetrochemicalAzharuddin_kfupmNo ratings yet

- Absorption II. Abstrip-Packed - ColumnsDocument58 pagesAbsorption II. Abstrip-Packed - ColumnsAnonymous wCDPbgMLJNo ratings yet

- Aplication Fat Extraction FoodDocument6 pagesAplication Fat Extraction FoodKu BonNo ratings yet

- 6-Absorption Stripping Pt1Document18 pages6-Absorption Stripping Pt1Naufal FasaNo ratings yet

- AbsorptionDocument16 pagesAbsorptionGloria BailonNo ratings yet

- Distillation, Ponchon Savarit, ShahzadDocument30 pagesDistillation, Ponchon Savarit, ShahzadMahad ZahidNo ratings yet

- TF06 Convection 03Document2 pagesTF06 Convection 03thekrumpNo ratings yet

- Saponification: Esters, Soapless and Soapy DetergentsDocument17 pagesSaponification: Esters, Soapless and Soapy Detergentsp bergerNo ratings yet

- Chemistry of Chromium Detecting Chromium Triple Ion (CR)Document29 pagesChemistry of Chromium Detecting Chromium Triple Ion (CR)Abambagade AberaNo ratings yet

- Raffinage Du BrutDocument68 pagesRaffinage Du BrutfahimNo ratings yet

- Bowen Full Flow Reverse Circulation Junk Baskets: Instruction ManualDocument11 pagesBowen Full Flow Reverse Circulation Junk Baskets: Instruction ManualHadjer zitNo ratings yet

- Dme Simulation With DwsimDocument4 pagesDme Simulation With Dwsimingegnere1234No ratings yet

- Pressure-Driven Cavitating Flow of Water Through A Sharp-Edged OrificeDocument13 pagesPressure-Driven Cavitating Flow of Water Through A Sharp-Edged OrificeKaushika Rajapaksha PereraNo ratings yet

- Kelompok 7 Chap 18Document6 pagesKelompok 7 Chap 18Katharina AjengNo ratings yet

- Membrane Separation: ProcessesDocument8 pagesMembrane Separation: ProcessesSaptarshi BhattacharjeeNo ratings yet

- Ex03 PDFDocument10 pagesEx03 PDFafendiNo ratings yet

- ASTM Distillation (ASTM)Document2 pagesASTM Distillation (ASTM)ahmadreza bayemaniNo ratings yet

- Aspen Hysys Studie Kite-1Document10 pagesAspen Hysys Studie Kite-1AnavheobaNo ratings yet

- Exercise 1 Structure of MatterDocument2 pagesExercise 1 Structure of MatterSelwah Hj Akip100% (1)

- TF06 Convection 07Document2 pagesTF06 Convection 07SABANo ratings yet

- 2.7 Exercise 2 - Extraction of Aluminium and TitaniumDocument4 pages2.7 Exercise 2 - Extraction of Aluminium and TitaniumHo Yong WaiNo ratings yet

- Tute Sheet-8Document2 pagesTute Sheet-8s barmanNo ratings yet

- Psychrometric Chart: Enthalpy - Btu Per Pound of Dry AirDocument1 pagePsychrometric Chart: Enthalpy - Btu Per Pound of Dry AirJavier MendozaNo ratings yet

- TD Physique NuageDocument3 pagesTD Physique Nuageelsa olive ze100% (1)

- Visbreaking ModelDocument13 pagesVisbreaking ModelMaileen Julissa Hoyos CastellanosNo ratings yet

- Liquid LiquidExtractionDocument57 pagesLiquid LiquidExtractionYasir MukhtarNo ratings yet

- Tutorial C5 AnswerDocument7 pagesTutorial C5 AnswerAustin Phua Yun HockNo ratings yet

- MBBR Product Information MaterialsDocument2 pagesMBBR Product Information MaterialsAvinash kandhareNo ratings yet

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Modified Checklist For Autism in Toddlers, Revised (M-CHAT-R)Document3 pagesModified Checklist For Autism in Toddlers, Revised (M-CHAT-R)Siswand BIn Mohd AliNo ratings yet

- ImamNawawiProject Brief PDFDocument6 pagesImamNawawiProject Brief PDFSiswand BIn Mohd AliNo ratings yet

- A Star Organisation Chart: Chairman DirectorDocument1 pageA Star Organisation Chart: Chairman DirectorSiswand BIn Mohd AliNo ratings yet

- Ramadan For The Pregnant, Nursing and Elderly: Nuruddinzangi March 1, 2019Document3 pagesRamadan For The Pregnant, Nursing and Elderly: Nuruddinzangi March 1, 2019Siswand BIn Mohd AliNo ratings yet

- Wisdom in Friday Suras: Nuruddinzangi June 3, 2019Document1 pageWisdom in Friday Suras: Nuruddinzangi June 3, 2019Siswand BIn Mohd AliNo ratings yet

- JRDPHL Payment Details: FlightDocument2 pagesJRDPHL Payment Details: FlightSiswand BIn Mohd AliNo ratings yet

- .Sg-3 Month Old BabyDocument4 pages.Sg-3 Month Old BabySiswand BIn Mohd AliNo ratings yet

- Onal Paper SeriesDocument48 pagesOnal Paper SeriesSiswand BIn Mohd AliNo ratings yet

- Ramadan Engl. Werb. p.3 11Document9 pagesRamadan Engl. Werb. p.3 11Siswand BIn Mohd AliNo ratings yet

- The Refinement of Character: Tahdhib Al-AkhlaqDocument2 pagesThe Refinement of Character: Tahdhib Al-AkhlaqSiswand BIn Mohd AliNo ratings yet

- Selawat TextsDocument2 pagesSelawat TextsSiswand BIn Mohd AliNo ratings yet

- Hamza Yusuf On Gay MuslimsDocument4 pagesHamza Yusuf On Gay MuslimsSiswand BIn Mohd Ali100% (1)

- Dragon Warrior Monsters 2 Magic KeyDocument7 pagesDragon Warrior Monsters 2 Magic KeySiswand BIn Mohd AliNo ratings yet

- Master of Arts in Arabic Linguistic StudiesDocument2 pagesMaster of Arts in Arabic Linguistic StudiesSiswand BIn Mohd AliNo ratings yet

- Orlando Gunman Omar MateenDocument7 pagesOrlando Gunman Omar MateenSiswand BIn Mohd AliNo ratings yet

- Powerful Dua To Remove Afflictions and CalamitiesDocument2 pagesPowerful Dua To Remove Afflictions and CalamitiesSiswand BIn Mohd Ali100% (1)

- Palestinian Christians: "We Say Allahu Akbar (Too) ": by Nadezhda Kevorkova - Posted inDocument8 pagesPalestinian Christians: "We Say Allahu Akbar (Too) ": by Nadezhda Kevorkova - Posted inSiswand BIn Mohd AliNo ratings yet

- Dragon Warrior Monsters 2 Magic KeyDocument7 pagesDragon Warrior Monsters 2 Magic KeySiswand BIn Mohd AliNo ratings yet

- 14-Ramadan-560 Hijri: Avempace Ibn BâjjaDocument3 pages14-Ramadan-560 Hijri: Avempace Ibn BâjjaSiswand BIn Mohd AliNo ratings yet

- Fyp ReferencesDocument1 pageFyp ReferencesSiswand BIn Mohd AliNo ratings yet

- Chemistry Project PDFDocument30 pagesChemistry Project PDFyash hiraniNo ratings yet

- 2003 Corkscrew Bike Trail StudyDocument25 pages2003 Corkscrew Bike Trail StudyJoey KulkinNo ratings yet

- Lo2012 TPFDocument114 pagesLo2012 TPFramjoceNo ratings yet

- Deering 2020Document4 pagesDeering 2020KevinNo ratings yet

- Blazevideo HDTV Player V6.0R User'S ManualDocument17 pagesBlazevideo HDTV Player V6.0R User'S ManualGianfranco CruzattiNo ratings yet

- Journal of CO2 Utilization: Changsoo Kim, Chun-Jae Yoo, Hyung-Suk Oh, Byoung Koun Min, Ung LeeDocument22 pagesJournal of CO2 Utilization: Changsoo Kim, Chun-Jae Yoo, Hyung-Suk Oh, Byoung Koun Min, Ung Leeayemyattheint kyawNo ratings yet

- 100 Watts Power Amplifier Design PDFDocument47 pages100 Watts Power Amplifier Design PDFMark Kenneth ValerioNo ratings yet

- Wastewater Surveillance of Pathogens Can Inform Public Health ResponsesDocument4 pagesWastewater Surveillance of Pathogens Can Inform Public Health ResponsesMiriam LeiNo ratings yet

- Wire Nails Manufacturing Business. How To Start Nail Factory. Profitable Small Business Ideas in India-887813Document63 pagesWire Nails Manufacturing Business. How To Start Nail Factory. Profitable Small Business Ideas in India-887813MuazNo ratings yet

- Central Academy SyllabusDocument3 pagesCentral Academy Syllabuski5814601No ratings yet

- SprinklersDocument2 pagesSprinklersMohamed El MorsyNo ratings yet

- ISCDL - Problem Statements For State Level HackthonDocument6 pagesISCDL - Problem Statements For State Level HackthonSarvesh DubeyNo ratings yet

- Unit 1 Chapter 3: Quadratic FunctionsDocument18 pagesUnit 1 Chapter 3: Quadratic FunctionsZlata OsypovaNo ratings yet

- August 24, 2021 - OCW Song Line-Up - Shell VibalDocument9 pagesAugust 24, 2021 - OCW Song Line-Up - Shell VibalDennis GiananNo ratings yet

- Clean RoomDocument9 pagesClean Roomxyzscribd1988No ratings yet

- Stewart Revofalg ExercisesDocument12 pagesStewart Revofalg Exercisesapi-261282952No ratings yet

- KW 18KWH Canada Interim Letters - KWUSDocument2 pagesKW 18KWH Canada Interim Letters - KWUSMecano PadNo ratings yet

- Sony KV 13TR27 Chasis.P 3BDocument29 pagesSony KV 13TR27 Chasis.P 3BTereza Yamileth Coto ENo ratings yet

- Introducing MPLS Traffic Engineering Components-L01Document35 pagesIntroducing MPLS Traffic Engineering Components-L01Cuong HaNo ratings yet

- Sistemas de Refrigeracion Industrial en AmoniacoDocument102 pagesSistemas de Refrigeracion Industrial en AmoniacoDiego Trinidad100% (8)

- Lightolier Lytespan Track Lighting Systems Catalog 1984Document94 pagesLightolier Lytespan Track Lighting Systems Catalog 1984Alan Masters100% (1)

- Turbine Cat SolarDocument2 pagesTurbine Cat SolarAbid Lakhani100% (1)

- Led Music Controller InsructionsDocument2 pagesLed Music Controller InsructionsArnaldoloNo ratings yet

- Ar Prda 2018 - FinalDocument37 pagesAr Prda 2018 - FinalucokNo ratings yet

- Remedies For VenusDocument2 pagesRemedies For VenusAnonymous 4Iu6iiNo ratings yet

- Flint Manual 2013Document69 pagesFlint Manual 2013Syafara Salsa Bila Wahyudin0% (1)

- Abe 424 Farm Structures and Environmental ControlDocument42 pagesAbe 424 Farm Structures and Environmental ControlAmabi SilasNo ratings yet

- Assignment 2 Inorganic ChemistryDocument2 pagesAssignment 2 Inorganic Chemistryinam ullahNo ratings yet