Professional Documents

Culture Documents

1762 Ob16

1762 Ob16

Uploaded by

SANKPLYOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1762 Ob16

1762 Ob16

Uploaded by

SANKPLYCopyright:

Available Formats

Installation Instructions

MicroLogix 1762-OB16 Solid State

24V dc Source Output Module

Inside

Description ................................................................................................3

Installation ................................................................................................4

Mounting...................................................................................................5

System Assembly......................................................................................7

Field Wiring Connections..........................................................................7

I/O Memory Mapping .............................................................................10

Specifications .........................................................................................11

Hazardous Location Considerations .......................................................13

Environnements dangereux ....................................................................14

Publication 1762-IN011A-EN-P

MicroLogix 1762-OB16 Solid State 24V dc Source Output Module

For More Information

For

Refer to this Document

Information on installing, wiring, and

operating a MicroLogix 1200

Programmable Controller

MicroLogix 1200 Programmable 1762-UM001A-US-P

Controllers User Manual

(Bulletin 1762 Controllers and

Expansion I/O)

Installation guide for the MicroLogix

1200 Programmable Controller.

MicroLogix 1200 Programmable 1762-IN006B-ML-P

Controllers Installation

Instructions

More information on proper wiring and Industrial Automation Wiring

grounding techniques.

and Grounding Guidelines

Pub. No.

1770-4.1

If you would like a manual, you can:

download a free electronic version from the internet:

www.ab.com/micrologix or www.theautomationbookstore.com

purchase a printed manual by:

contacting your local distributor or Rockwell Automation representative

visiting www.theautomationbookstore.com and placing your order

calling 1.800.963.9548 (USA/Canada)

or 001.330.725.1574 (Outside USA/Canada)

Publication 1762-IN011A-EN-P

MicroLogix 1762-OB16 Solid State 24V dc Source Output Module

Description

9

1a

Item Description

7

1a

upper panel mounting tab

1b

lower panel mounting tab

I/O diagnostic LEDs

module door with terminal

identification label

bus connector

with male pins

bus connector cover

flat ribbon cable with bus

connector (female pins)

terminal block

DIN rail latch

pull loop

1b

4

1a

6

2

1b

Publication 1762-IN011A-EN-P

MicroLogix 1762-OB16 Solid State 24V dc Source Output Module

Installation

1762 I/O is suitable for use in an industrial environment when installed in

accordance with these instructions. Specifically, this equipment is intended for use in

clean, dry environments (Pollution degree 2 (1)) and to circuits not exceeding Over

Voltage Category II(2) (IEC 60664-1).(3)

Prevent Electrostatic Discharge

ATTENTION Electrostatic discharge can damage integrated circuits or

semiconductors if you touch bus connector pins. Follow these

guidelines when you handle the module:

Touch a grounded object to discharge static potential.

Wear an approved wrist-strap grounding device.

Do not touch the bus connector or connector pins.

Do not touch circuit components inside the module.

If available, use a static-safe work station.

When not in use, keep the module in its static-shield box.

Remove Power

ATTENTION Remove power before removing or installing this module. When

you remove or install a module with power applied, an electrical

arc may occur. An electrical arc can cause personal injury or

property damage by:

sending an erroneous signal to your systems field devices,

causing unintended machine motion

causing an explosion in a hazardous environment

causing permanent damage to the modules circuitry

Electrical arcing causes excessive wear to contacts on both the

module and its mating connector. Worn contacts may create

electrical resistance.

(1) Pollution Degree 2 is an environment where, normally, only non-conductive pollution occurs except that

occasionally a temporary conductivity caused by condensation shall be expected.

(2) Over Voltage Category II is the load level section of the electrical distribution system. At this level transient

voltages are controlled and do not exceed the impulse voltage capability of the products insulation.

(3) Pollution Degree 2 and Over Voltage Category II are International Electrotechnical Commission (IEC)

designations.

Publication 1762-IN011A-EN-P

MicroLogix 1762-OB16 Solid State 24V dc Source Output Module

Mounting

Minimum Spacing

Top

Side

MicroLogix

1200

1762 I/O

Maintain spacing from

enclosure walls, wireways,

adjacent equipment, etc.

Allow 50.8 mm (2 in.) of

space on all sides for

adequate ventilation, as

shown:

1762 I/O

Do not remove protective debris strip until after the module and

all other equipment near the module is mounted and wiring is

complete. Once wiring is complete and the module is free of

debris, carefully remove protective debris strip. Failure to remove

strip before operating can cause overheating.

1762 I/O

ATTENTION

Side

Bottom

NOTE

ATTENTION

1762 expansion I/O may be mounted horizontally only.

During panel or DIN rail mounting of all devices, be sure that all

debris (metal chips, wire strands, etc.) is kept from falling into

the module. Debris that falls into the module could cause

damage when power is applied to the module.

Publication 1762-IN011A-EN-P

MicroLogix 1762-OB16 Solid State 24V dc Source Output Module

DIN Rail Mounting

The module can be mounted using the following DIN rails: 35 x 7.5 mm

(EN 50 022 - 35 x 7.5) or 35 x 15 mm (EN 50 022 - 35 x 15).

Before mounting the module on a DIN rail, close the DIN rail latch. Press the DIN

rail mounting area of the module against the DIN rail. The latch will momentarily

open and lock into place.

Use DIN rail end anchors (Allen-Bradley part number 1492-EA35 or

1492-EAH35) for vibration or shock environments.

End Anchor

End Anchor

NOTE

For environments with greater vibration and shock concerns, use

the panel mounting method described below, instead of DIN rail

mounting.

Panel Mounting

Use the dimensional template shown below to mount the module. The preferred

mounting method is to use two M4 or #8 panhead screws per module. M3.5 or #6

panhead screws may also be used, but a washer may be needed to ensure a good

mechanical contact. Mounting screws are required on every module.

For more than 2 modules: (number of modules - 1) x 40 mm (1.58 in.)

14.5

(0.57)

40.4

(1.59)

NOTE: All

dimensions are in

mm (inches). Hole

spacing tolerance:

0.4 mm

(0.016 in.).

100 90

(3.94) (3.54)

40.4

(1.59)

Publication 1762-IN011A-EN-P

MicroLogix 1762-OB16 Solid State 24V dc Source Output Module

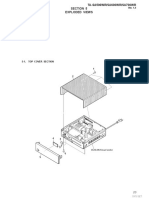

System Assembly

The expansion I/O module is attached to the controller or another I/O module by

means of a flat ribbon cable after mounting as shown below.

NOTE

ATTENTION

Use the pull loop on the connector to disconnect modules. Do

not pull on the ribbon cable.

EXPLOSION HAZARD

In Class I, Division 2 applications, the bus connector must be

fully seated and the bus connector cover must be snapped in

place.

In Class I, Division 2 applications, all modules must be

mounted in direct contact with each other as shown on

Page 6. If DIN rail mounting is used, an end stop must be

installed ahead of the controller and after the last 1762 I/O

module.

Field Wiring Connections

Grounding the Module

This product is intended to be mounted to a well-grounded mounting surface such

as a metal panel. Refer to Industrial Automation Wiring and Grounding Guidelines,

Allen-Bradley publication 1770-4.1, for additional information.

Publication 1762-IN011A-EN-P

MicroLogix 1762-OB16 Solid State 24V dc Source Output Module

Output Wiring

Basic wiring(1) of the 1762-OB16 is shown below.

+DC

VDC+

CR

CR

OUT 0

OUT 1

CR

OUT 3

CR

OUT 2

OUT 4

OUT 5

CR

OUT 6

CR

OUT 7

CR

OUT 8

CR

OUT 9

CR

OUT 11

24V dc (source)

OUT 10

OUT 12

CR

OUT 13

OUT 14

OUT 15

DC COM

-DC

A write-on label is provided with the module. Mark the identification of each

terminal with permanent ink, and slide the label back into the door.

ATTENTION

Be careful when stripping wires. Wire fragments that fall into a

module could cause damage when power is applied. Once wiring

is complete, ensure the module is free of all metal fragments.

ATTENTION

Miswiring of the module to an AC power source will damage the

module.

(1) Surge Suppression Connecting surge suppressors across your external inductive load will extend the

life of the relay contacts. For additional details, refer to Industrial Automation Wiring and Grounding

Guidelines, Allen-Bradley publication 1770-4.1.

Publication 1762-IN011A-EN-P

MicroLogix 1762-OB16 Solid State 24V dc Source Output Module

NOTE

Finger-safe cover not shown for clarity.

Wiring the Finger-Safe Terminal Block

When wiring the terminal block, keep the finger-safe cover in place.

1. Route the wire under the terminal pressure plate. You can use the stripped end of

the wire or a spade lug. The terminals will accept a 6.35 mm (0.25 in.) spade lug.

2. Tighten the terminal screw making sure the pressure plate secures the wire.

Recommended torque when tightening terminal screws is 0.90 Nm

(8 in-lbs).

NOTE

If you need to remove the finger-safe cover, insert a screw driver

into one of the square wiring holes and gently pry the cover off.

If you wire the terminal block with the finger-safe cover removed,

you will not be able to put it back on the terminal block because

the wires will be in the way.

Wire Size and Terminal Screw Torque

Each terminal accepts up to two wires with the following restrictions:

Wire Type

Wire Size

Terminal Screw Torque

Solid

Cu-90C (194F)

#14 to #22 AWG

0.90 Nm (8 in-lbs)

Stranded

Cu-90C (194F)

#16 to #22 AWG

0.90 Nm (8 in-lbs)

Publication 1762-IN011A-EN-P

10

MicroLogix 1762-OB16 Solid State 24V dc Source Output Module

I/O Memory Mapping

Output Data File

Word

For each output module, the output data file contains the controller-directed state of

the discrete output points. Bit positions 0 through 15 correspond to output

terminals 0 through 15.

Bit Position

15

14

13

12

11

10

w = write only

Addressing

The addressing scheme for 1762 Expansion I/O is shown below.

Slot Number(1)

Data File

Output

Word (always zero for this module)

O0:x.0/0

Slot Delimiter

Bit (0 to 15)

Bit Delimiter

Word Delimiter

(1) I/O located on the controller (embedded I/O) is slot 0. I/O added to the controller (expansion I/O) begins with

slot 1.

Publication 1762-IN011A-EN-P

MicroLogix 1762-OB16 Solid State 24V dc Source Output Module

11

Specifications

General Specifications

Specification

Value

Dimensions

90 mm (height) x 87 mm (depth) x 40.4 mm (width)

height including mounting tabs is 110 mm

3.54 in. (height) x 3.43 in. (depth) x 1.59 in. (width)

height including mounting tabs is 4.33 in.

Approximate Shipping Weight

(with carton)

235g (0.52 lbs.)

Storage Temperature

-40C to +85C (-40F to +185F)

Operating Temperature

0C to +55C (+32F to +131F)

Operating Humidity

5% to 95% non-condensing

Operating Altitude

2000 meters (6561 feet)

Vibration

Operating: 10 to 500 Hz, 5G, 0.030 in. max. peak-to-peak,

2 hours per axis

Shock

Operating: 30G panel mounted, 3 pulses per axis

Non-Operating: 50G panel mounted, 3 pulses per axis

(40G DIN Rail mounted)

Agency Certification

C-UL certified (under CSA C22.2 No. 142)

UL 508 listed

CE compliant for all applicable directives

Hazardous Environment Class

Class I, Division 2, Hazardous Location, Groups A, B, C, D

(UL 1604, C-UL under CSA C22.2 No. 213)

Radiated and Conducted Emissions

EN50081-2 Class A

Electrical /EMC:

ESD Immunity (IEC1000-4-2)

The module has passed testing at the following levels:

4 kV contact, 8 kV air, 4 kV indirect

Radiated Immunity (IEC1000-4-3)

10 V/m, 80 to 1000 MHz, 80% amplitude modulation, +900

MHz keyed carrier

Fast Transient Burst (IEC1000-4-4)

2 kV, 5 kHz

Surge Immunity (IEC1000-4-5)

2 kV common mode, 1 kV differential mode

Conducted Immunity (IEC1000-4-6)

10V, 0.15 to 80 MHz(1)

(1) Conducted Immunity frequency range may be 150 kHz to 30 MHz if the Radiated Immunity frequency range is

30 MHz to 1000 MHz.

Publication 1762-IN011A-EN-P

12

MicroLogix 1762-OB16 Solid State 24V dc Source Output Module

Output Specifications

Specification

1762-OB16

Voltage Category

24V dc

Operating Voltage Range

20.4V dc to 26.4V dc

Number of Outputs

16

Bus Current Draw (max.)

175 mA at 5V dc (0.88W)

Heat Dissipation (max.)

2.9 total Watts at 30C (86F)

2.1 total Watts at 55C (131F)

Signal Delay (max.) resistive

load

turn-on = 0.1 ms

Off-State Leakage (max.)

1.0 mA

turn-off = 1.0 ms

On-State Current (min.)

1.0 mA

On-State Voltage Drop (max.)

1.0V dc

Continuous Current per Point

(max.)

0.5A at 55C (131F)

Continuous Current per Module

(max.)

4.0A at 55C (131F)

Surge Current (max.)

2.0A (Repeatability is once every 2 seconds at 55C (131F),

once every second at 30C (86F) for a duration of 10 msec.)

Power Supply Distance Rating

6 (The module may not be more than 6 modules away from the

power supply.)

Isolated Groups

Group 1: Outputs 0 to 15

Output Group to Backplane

Isolation

Verified by one of the following dielectric tests: 1200V ac for 1

sec. or 1697V dc for 1 sec.

Vendor I.D. Code

Product Type Code

Product Code

103

1.0A at 30C (86F)

8.0A at 30C (86F)

75V dc working voltage (IEC Class 2 reinforced insulation)

Publication 1762-IN011A-EN-P

MicroLogix 1762-OB16 Solid State 24V dc Source Output Module

13

Sourcing Output - Source describes the current flow between the I/O module and

the field device. Sourcing output circuits supply (source) current to sinking field

devices. Field devices connected to the negative side (DC Common) of the field

power supply are sinking field devices. Field devices connected to the positive side

(+V) of the field supply are sourcing field devices.

Typical Loading Resistor - To limit the effects of leakage current through

solid-state outputs, a loading resistor can be connected in parallel with your load.

Use a 5.6k ohm, 1/4W resistor for transistor outputs, 24V dc operation.

Recommended Surge Suppression - Use a 1N4004 diode reverse-wired across the

load for transistor outputs switching 24V dc inductive loads. For additional

information, refer to Industrial Automation Wiring and Grounding Guidelines,

Allen-Bradley publication 1770-4.1.

Hazardous Location Considerations

This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D or

non-hazardous locations only. The following WARNING statement applies to use

in hazardous locations.

WARNING

EXPLOSION HAZARD

Substitution of components may impair suitability for Class I,

Division 2.

Do not replace components or disconnect equipment unless

power has been switched off.

Do not connect or disconnect components unless power has

been switched off.

This product must be installed in an enclosure.

In Class I, Division 2 applications, the bus connector must be

fully seated and the bus connector cover must be snapped in

place.

In Class I, Division 2 applications, all modules must be

mounted in direct contact with each other as shown on

Page 6. If DIN rail mounting is used, an end stop must be

installed ahead of the controller and after the last 1762 I/O

module.

Publication 1762-IN011A-EN-P

14

MicroLogix 1762-OB16 Solid State 24V dc Source Output Module

Environnements dangereux

Cet quipement est conu pour tre utilis dans des environnements de Classe I,

Division 2, Groupes A, B, C, D ou non dangereux. La mise en garde suivante

sapplique une utilisation dans des environnements dangereux.

MIS EN GARDE

DANGER DEXPLOSION

La substitution de composants peut rendre cet quipement

impropre une utilisation en environnement de Classe I,

Division 2.

Ne pas remplacer de composants ou dconnecter

l'quipement sans s'tre assur que l'alimentation est coupe.

Ne pas connecter ou dconnecter des composants sans s'tre

assur que l'alimentation est coupe.

Ce produit doit tre install dans une armoire.

Pour les applications de Classe I, Division 2, le connecteur de

bus doit tre correctement install et son couvercle enclench.

Pour les applications de Classe I, Division 2, tous les modules

doivent tre installs en contact direct les uns avec les autres,

comme indiqu Page 6. Si on utilise le montage sur rail DIN,

une bute doit tre place l'avant de l'automate et aprs la

dernire unit d'E/S 1762.

Publication 1762-IN011A-EN-P

MicroLogix 1762-OB16 Solid State 24V dc Source Output Module

15

Publication 1762-IN011A-EN-P

MicroLogix is a trademark of Rockwell Automation.

Publication 1762-IN011A-EN-P - July 2000

PN 40071-115-01(A)

2000 Rockwell International Corporation. Printed in MALAYSIA.

H'+/!AZ

You might also like

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- Samsung Sync Master 940N LCD Service ManualDocument63 pagesSamsung Sync Master 940N LCD Service ManualFelix SemenNo ratings yet

- BFT LIBRA Control PanelDocument10 pagesBFT LIBRA Control PanelAADAFFAFASASNo ratings yet

- Abc of Power Modules: Functionality, Structure and Handling of a Power ModuleFrom EverandAbc of Power Modules: Functionality, Structure and Handling of a Power ModuleNo ratings yet

- T 2000 Wiring Diagram StandardDocument1 pageT 2000 Wiring Diagram StandardKilo D la VegaNo ratings yet

- KIRK Scheme BookDocument38 pagesKIRK Scheme BookvivaldomendesNo ratings yet

- Micrologix™ Analog Input/Output: Installation InstructionsDocument24 pagesMicrologix™ Analog Input/Output: Installation InstructionsDavid LucioNo ratings yet

- Compact 32-Point Solid-State 24V DC Source Output Module: Installation InstructionsDocument24 pagesCompact 32-Point Solid-State 24V DC Source Output Module: Installation InstructionsThanh BaronNo ratings yet

- Micrologix™ Analog Input/Output: Installation InstructionsDocument24 pagesMicrologix™ Analog Input/Output: Installation Instructionscamus1125No ratings yet

- Micrologix 1200 Thermocouple/Mv Input Module: Installation InstructionsDocument24 pagesMicrologix 1200 Thermocouple/Mv Input Module: Installation InstructionsRexNo ratings yet

- Redundancy Module Quint-Diode/40: 1. Short DescriptionDocument6 pagesRedundancy Module Quint-Diode/40: 1. Short Description54045114No ratings yet

- 1769 Ob32tDocument24 pages1769 Ob32tHilder Ramirez PuellesNo ratings yet

- 1769 Iq32tDocument20 pages1769 Iq32tHilder Ramirez PuellesNo ratings yet

- 3ADW000193R0601 DCS800 Firmware Manual e FDocument466 pages3ADW000193R0601 DCS800 Firmware Manual e Fdat_nguyen_2100% (1)

- MANUAL PARTES DS - Ipm - 2 - 14 - 1393854595Document56 pagesMANUAL PARTES DS - Ipm - 2 - 14 - 1393854595marlon diazNo ratings yet

- 3ADW000194R0601 DCS800 Hardware Manual e FDocument128 pages3ADW000194R0601 DCS800 Hardware Manual e FDeepak JainNo ratings yet

- Controllogix Voltage/Current Input Module: Installation InstructionsDocument20 pagesControllogix Voltage/Current Input Module: Installation InstructionsMarco RojasNo ratings yet

- Mini Mcr-Sl-I-I: Standard Signal - 3-Way Isolating AmplifierDocument7 pagesMini Mcr-Sl-I-I: Standard Signal - 3-Way Isolating AmplifieremersonalessandroNo ratings yet

- L196WTQ-S, BFQ eDocument30 pagesL196WTQ-S, BFQ eadisistemsNo ratings yet

- SLC 500™ 32-Channel Digital I/O Modules: (Catalog Numbers 1746-IB32, - IV32, - OB32, - OB32E and - OV32)Document20 pagesSLC 500™ 32-Channel Digital I/O Modules: (Catalog Numbers 1746-IB32, - IV32, - OB32, - OB32E and - OV32)Rim GrissaNo ratings yet

- 1756 Ib32Document16 pages1756 Ib32Daniel BacicNo ratings yet

- Instructions AND Parts Manual: Modular Drive SystemDocument55 pagesInstructions AND Parts Manual: Modular Drive SystemMarcos Ribeiro100% (1)

- Ult REL Output Analog Modules 1734-In002 enDocument24 pagesUlt REL Output Analog Modules 1734-In002 enGabriel Constantin NastaseNo ratings yet

- 3adw000379r0501 Dcs550 Manual e eDocument316 pages3adw000379r0501 Dcs550 Manual e eMr.K chNo ratings yet

- IDU Online Kit ManualDocument21 pagesIDU Online Kit ManualAhmed SeragNo ratings yet

- A1SD75P 1 2 3 S3 UserManual Hardware IB 66732 EDocument16 pagesA1SD75P 1 2 3 S3 UserManual Hardware IB 66732 EJuliana BertonNo ratings yet

- 1764-24AWA - 24BWA - 28BXB Install (1764-In001A-MU-P Mar 2000) - SuperseededDocument122 pages1764-24AWA - 24BWA - 28BXB Install (1764-In001A-MU-P Mar 2000) - SuperseededjishyNo ratings yet

- Devicenet 1732 Armorblock I/O, Series A: Installation InstructionsDocument16 pagesDevicenet 1732 Armorblock I/O, Series A: Installation InstructionsMariano DavicoNo ratings yet

- DCS800ServiceManual RevADocument96 pagesDCS800ServiceManual RevAElinplastNo ratings yet

- 1762 Ob8 PDFDocument16 pages1762 Ob8 PDFRodríguez EdwardNo ratings yet

- Manual Armoblock ABDocument24 pagesManual Armoblock ABJermy Abraham CarrascoNo ratings yet

- SLC 500™ Analog Input Modules: Installation InstructionsDocument20 pagesSLC 500™ Analog Input Modules: Installation InstructionsneoflashNo ratings yet

- MPD-1000 Bug-ODocument59 pagesMPD-1000 Bug-OROMERJOSENo ratings yet

- SCXI-1326 High-Voltage-Terminal-Block-Installation-Guide-And-SpecificationsDocument8 pagesSCXI-1326 High-Voltage-Terminal-Block-Installation-Guide-And-SpecificationsTrung Lung TungNo ratings yet

- MDS Ipm Bugo MDS 1002Document57 pagesMDS Ipm Bugo MDS 1002Taz Juan GNo ratings yet

- GuardPLC Digital Input Output Module PDFDocument20 pagesGuardPLC Digital Input Output Module PDFTarun BharadwajNo ratings yet

- Abb Rdcu 12cDocument14 pagesAbb Rdcu 12cMarco MedinaNo ratings yet

- Mla Mini User GuideDocument48 pagesMla Mini User Guidepmacs10No ratings yet

- Instalation ManualDocument9 pagesInstalation Manualjoseluisrosglz1678No ratings yet

- C264 en o C80Document828 pagesC264 en o C80Natarajan SubramanyanNo ratings yet

- AB ControlLogixOutputModule 1756 OF8Document20 pagesAB ControlLogixOutputModule 1756 OF8QuynhtnNo ratings yet

- Deye Inverter ManualDocument46 pagesDeye Inverter ManualVicente II DeocarezaNo ratings yet

- LG L194WTDocument29 pagesLG L194WTqxbgwhvuNo ratings yet

- IOLC1Document13 pagesIOLC1Adithya A RNo ratings yet

- LG M1921A Service ManualDocument33 pagesLG M1921A Service Manualvalerus17100% (1)

- Ubom Ahc 3 - 21Document36 pagesUbom Ahc 3 - 21Victor PATIÑONo ratings yet

- Hybrid Inverter: User ManualDocument43 pagesHybrid Inverter: User ManualZaw Myo HtetNo ratings yet

- Kewo AD1000 Ac Drive Manual No LogoDocument121 pagesKewo AD1000 Ac Drive Manual No Logoquân nguyễnNo ratings yet

- DC (1030V) Input Module Cat. No. 1771IBD Series B: Installation InstructionsDocument9 pagesDC (1030V) Input Module Cat. No. 1771IBD Series B: Installation InstructionsSikandar Zeb BachaNo ratings yet

- IO-RO16, IO-RO16-L: I/O Expansion Modules 16 Relay OutputsDocument8 pagesIO-RO16, IO-RO16-L: I/O Expansion Modules 16 Relay OutputsAliNo ratings yet

- Q Amp CX UserguideDocument102 pagesQ Amp CX UserguideGOLDEN MUSIC DISCO MOVILNo ratings yet

- Relay Block PDFDocument5 pagesRelay Block PDFJapheth K. KiptooNo ratings yet

- Lac m8410 GCSCDocument52 pagesLac m8410 GCSCRenatoMaiaNo ratings yet

- 22-60VDC Grid Tie Microinverter: User ManualDocument15 pages22-60VDC Grid Tie Microinverter: User ManualLeandro Gomes100% (1)

- 3ADW000196R0101 DCS800 12-Pulse Manual e ADocument96 pages3ADW000196R0101 DCS800 12-Pulse Manual e ADeepak Jain100% (1)

- Installation SupportDocument22 pagesInstallation Supportsydneyaus2005No ratings yet

- Renesola Installation ManualDocument8 pagesRenesola Installation ManualTarun BharadwajNo ratings yet

- VFD MDocument134 pagesVFD MBố Táo100% (1)

- Analog Dialogue Volume 46, Number 1: Analog Dialogue, #5From EverandAnalog Dialogue Volume 46, Number 1: Analog Dialogue, #5Rating: 5 out of 5 stars5/5 (1)

- En StandardsDocument1 pageEn StandardsSANKPLYNo ratings yet

- Pharmaceutical Catalog 2014 Tray SizesDocument6 pagesPharmaceutical Catalog 2014 Tray SizesSANKPLYNo ratings yet

- Comodo HIPS and Firewall Leak Test SuiteDocument1 pageComodo HIPS and Firewall Leak Test SuiteSANKPLYNo ratings yet

- Halcon 11 Brochure EnglishDocument20 pagesHalcon 11 Brochure EnglishSANKPLYNo ratings yet

- BOA Installation Manual V11aDocument29 pagesBOA Installation Manual V11aSANKPLYNo ratings yet

- Guppy PRO DataSheet F-031 V3.0.2 enDocument4 pagesGuppy PRO DataSheet F-031 V3.0.2 enSANKPLYNo ratings yet

- 1762 of 4 Data FormatDocument2 pages1762 of 4 Data FormatSANKPLYNo ratings yet

- Screen-Reader Users, Click Here To Turn Off Google Instant.: +satheesanDocument3 pagesScreen-Reader Users, Click Here To Turn Off Google Instant.: +satheesanSANKPLYNo ratings yet

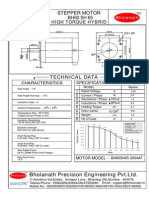

- Stepper Motor: Bholanath High Torque HybridDocument1 pageStepper Motor: Bholanath High Torque HybridSANKPLYNo ratings yet

- Shimpo Gearbox 2 Stage1Document1 pageShimpo Gearbox 2 Stage1SANKPLYNo ratings yet

- CAT IF30 E - Signal SplitteeDocument1 pageCAT IF30 E - Signal SplitteeSANKPLYNo ratings yet

- ATEX Direktiva 94 9 ECDocument31 pagesATEX Direktiva 94 9 ECspahicdaniloNo ratings yet

- Encoder Signal Splitter ManualDocument10 pagesEncoder Signal Splitter ManualSANKPLYNo ratings yet

- Polycab Cable Price List 1 2011Document10 pagesPolycab Cable Price List 1 2011SANKPLYNo ratings yet

- Magnetic Speed Pensor - 6732Document1 pageMagnetic Speed Pensor - 6732Jezrell JaravataNo ratings yet

- G8V-RH: High Current Micro 280 Terminal LayoutDocument3 pagesG8V-RH: High Current Micro 280 Terminal Layoutchrdue1No ratings yet

- Switch Gears 134-149Document16 pagesSwitch Gears 134-149Vijaya Kumar100% (1)

- Simha 214Document76 pagesSimha 214Vamsi SakhamuriNo ratings yet

- Siemon Tera E6 Cable Spec SheetDocument2 pagesSiemon Tera E6 Cable Spec SheetAdrian Gamboa MarcellanaNo ratings yet

- Lab 3Document4 pagesLab 3mlj8753No ratings yet

- FM Transmitter PDFDocument5 pagesFM Transmitter PDFAndrés HoyteNo ratings yet

- KA393Document7 pagesKA393Tri NguyenstNo ratings yet

- OVR T1-T2 3N 12.5-275s P QSDocument1 pageOVR T1-T2 3N 12.5-275s P QSDiego PeñaNo ratings yet

- Bts 442 eDocument13 pagesBts 442 eiqdam94No ratings yet

- Watt Transducer (전력 변환기)Document3 pagesWatt Transducer (전력 변환기)blackhandNo ratings yet

- RelaysDocument30 pagesRelaysujjwalNo ratings yet

- CAT-5006 FA-1025T Five Zone Fire Alarm Control Panel PDFDocument2 pagesCAT-5006 FA-1025T Five Zone Fire Alarm Control Panel PDFJosue Serrano ChenNo ratings yet

- AccuSine Selection ToolDocument34 pagesAccuSine Selection ToolMohamed SamyNo ratings yet

- Work - Instruction 66-33KV TRANSFORMERDocument5 pagesWork - Instruction 66-33KV TRANSFORMERTAHIR HUSAINNo ratings yet

- Touch Sensor PSRDocument8 pagesTouch Sensor PSRDurai SinghNo ratings yet

- Dinel UHC-01 Convertidor Hart A USBDocument4 pagesDinel UHC-01 Convertidor Hart A USBJhon Sanchez ChNo ratings yet

- TA-SA500WR ConsumerDocument2 pagesTA-SA500WR ConsumerJulien Bertinchant0% (1)

- PH 2104 Tutorial Set 1Document3 pagesPH 2104 Tutorial Set 1Zuhura RamadhaniNo ratings yet

- Internship Report 500 KV Grid StationDocument24 pagesInternship Report 500 KV Grid StationAhmadinijad50% (4)

- Price List Veloce LBS, COS & ATS (Email) - 1Document4 pagesPrice List Veloce LBS, COS & ATS (Email) - 1Rengga PrasetyoNo ratings yet

- Ignition PDFDocument16 pagesIgnition PDFDoDuyBacNo ratings yet

- LV Live Feeder and Phase Identifier FC3000Document12 pagesLV Live Feeder and Phase Identifier FC3000abbotNo ratings yet

- EW - 1 Calculation of Short Circuit Current For Equipment Evaluation EW-1.1 Generating Plant Single Line DiagramDocument11 pagesEW - 1 Calculation of Short Circuit Current For Equipment Evaluation EW-1.1 Generating Plant Single Line DiagramCatrina FedericoNo ratings yet

- Eti Datasheet 002620011 En-GbDocument6 pagesEti Datasheet 002620011 En-GbAbc ThoiNo ratings yet

- Chapter Fifteen EarthingDocument26 pagesChapter Fifteen Earthingmuaz_aminu1422No ratings yet

- Fcgen h2pm One Rack - 10kw Data SheetDocument2 pagesFcgen h2pm One Rack - 10kw Data SheetULLAS VAGHRINo ratings yet

- XCMN2102L5: Product Data SheetDocument6 pagesXCMN2102L5: Product Data SheetMário BassoliNo ratings yet