Professional Documents

Culture Documents

Elasticities and Strengths

Elasticities and Strengths

Uploaded by

Ricky LuznyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Elasticities and Strengths

Elasticities and Strengths

Uploaded by

Ricky LuznyCopyright:

Available Formats

Elasticities and strengths 2.2.

1 of 7

http://www.kayelaby.npl.co.uk/general_physics/2_2/2_2_2.html

Home | About | Table of Contents | Advanced Search | Copyright | Feedback | Privacy

You are here: Chapter: 2 General physics

Section: 2.2 Mechanical properties of materials

SubSection: 2.2.2 Elasticities and strengths

Previous Subsection

Next Subsection

Unless otherwise stated this page contains Version 1.0 content (Read more about versions)

2.2.2 Elasticities and strengths

Elastic properties isotropic materials

Listed below are the elastic constants in common use, any two of which are sufficient to define the elastic properties of a

homogeneous isotropic solid. The two fundamental constants are those which relate change of volume and change of shape to

applied stress. They are respectively, the bulk modulus K (as in p =

K . V/V) and the shear modulus G.

For many practical purposes, the following constants are commonly used:

Youngs Modulus, or longitudinal elasticity, E.

Poissons ratio, = lateral contraction per unit breadth divided by the longitudinal extension per unit length under an applied

longitudinal stress.

Compressibility, = 1/K.

Longitudinal modulus, M, which is the longitudinal modulus for zero lateral strain and determines the velocity of ultrasonic stress

pulses in solids.

For a homogeneous isotropic solid, the following relations exist between the constants.

(a) G =

(c) K=

E

2(1 + )

1

EG

3 3(3G

E)

(b)

K=

(d)

M=K+

3 (1

2 )

4

3

The value of Poissons ratio is usually positive and lies between 0 and

, but in some cases it may be negative.

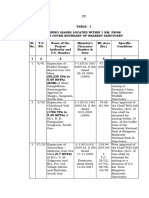

Elasticities of metals and alloys

Material

20 C

Aluminium . . . . .

Bismuth . . . . . .

Cadmium

. . . . .

Chromium

. . . . .

Copper . . . . . .

Gold . . . . . . .

Iron (soft)

. . . . .

Iron (cast) . . . . .

Lead

. . . . . .

Magnesium . . . . .

Nickel (unmag., soft) . .

,,

,,

hard) . .

Niobium

. . . . .

Platinum

. . . . .

Silver

. . . . . .

Tantalum

. . . . .

Tin

. . . . . . .

Titanium

. . . . .

Tungsten

. . . . .

Vanadium . . . . .

Zinc . . . . . . .

Brass (70 Zn, 30 Cu) .

Constantan . . . . .

GPa

GPa

GPa

70.3

31.9

49.9

279.1

129.8

78.0

211.4

152.3

16.1

44.7

199.5

219.2

104.9

168.0

82.7

185.7

49.9

115.7

411.0

127.6

108.4

100.6

162.4

26.1

12.0

19.2

115.4

48.3

27.0

81.6

60.0

5.59

17.3

76.0

83.9

37.5

61.0

30.3

69.2

18.4

43.8

160.6

46.7

43.4

37.3

61.2

0.345

0.330

0.300

0.210

0.343

0.44

0.293

0.27

0.44

0.291

0.312

0.306

0.397

0.377

0.367

0.342

0.357

0.321

0.280

0.365

0.249

0.350

0.327

75.5

31.3

41.6

160.1

137.8

217.0

169.8

109.5

45.8

35.6

177.3

187.6

170.3

228.0

103.6

196.3

58.2

107.7

311.0

158.0

72.0

111.8

156.4

19/01/2015 11:19 AM

Elasticities and strengths 2.2.2

2 of 7

http://www.kayelaby.npl.co.uk/general_physics/2_2/2_2_2.html

Hidurax Special . . .

Invar (36 Ni, 63.8 Fe, 0.2 C)

Nickel Silver . . . .

Steel (Mild)

. . . .

,, (

C) . . . .

,, (

C hardened) .

,, Tool|| . . . . .

,, Tool (hardened)|| .

,, Stainless . . .

Tungsten Carbide

. .

144.5

144.0

132.5

211.9

210.0

201.4

211.6

203.2

215.3

534.4

54.4

57.2

49.7

82.2

81.1

77.8

82.2

78.5

83.9

219.0

0.333

0.259

0.333

0.291

0.293

0.296

0.287

0.295

0.293

0.22

144.1

99.4

132.0

169.2

168.7

165.0

165.3

165.2

166.0

319.0

Approx. value or values for materials of variable composition.

Cu-Ni alloy with Al, Fe and Mn additions.

Approx. % composition: Cu 55, Ni 8, Zn 27.

|| Oil hardening non-deforming tool steel of approx. % composition: C 0.98, Mn 1.03, Cr 0.65, W 1.01, V 0.1, remainder Fe.

Approx. % composition: C 0.02, Si 0.5, Mn 0.7, Ni 2, Cr 18, remainder Fe.

Elasticities of glasses

Material

20 C

Glass (Heavy Flint)

Glass (Crown)

.

Quartz (fused)

.

.

.

.

.

.

.

.

.

.

GPa

GPa

GPa

80.1

71.3

73.1

31.5

29.2

31.2

0.27

0.22

0.17

57.6

41.2

36.9

Several values in these tables are taken from Bradfield (1964).

Bulk moduli of elements

K

Element

Element

GPa

Aluminium

Antimony .

Arsenic

.

Bismuth

.

Bromine

.

Cadmium .

Caesium .

Calcium

.

Carbon .

(diamond)

Carbon

(graphite)

. .

.

.

.

.

.

.

.

.

.

75.5

42.0

22.0

31.3

1.9

41.6

1.6

17.2

542.0

33.0

Element

GPa

Chlorine

(liq) . .

Chromium

Copper .

Gold . .

Iodine . .

Iron . .

Lead . .

Lithium

.

Magnesium

Manganese

Mercury .

.

.

.

.

.

.

.

.

.

.

.

1.1

160.1

137.8

217.0

7.7

169.8

45.8

11.1

44.7

118.0

25.0

Element

GPa

Molybdenum

Nickel

(soft) . .

(hard) . .

Palladium .

Phosphorus .

(red)

.

Phosphorus

(white) .

Platinum .

Potassium .

Rubidium .

231.0

177.3

187.6

182.0

10.9

GPa

Selenium

Silicon .

Silver .

Sodium

Sulphur

Thallium

Tin . .

Zinc

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

8.3

100.0

103.6

6.3

7.7

43.0

58.2

72.0

4.9

228.0

3.1

2.5

Bradfield (1964).

Markham (1968).

Bulk moduli of liquids

As the pressure increases, K increases. In general a rise in temperature decreases the bulk modulus of a liquid; water, however,

shows a maximum value of K at about 50 C (see J. H. Poynting and J. J. Thomson (1920) Properties of Matter, London, Charles

Griffin; Bridgman (1949)).

Liquid

Acetic acid, 116 atm

Amyl alcohol, 8 atm

.

Benzene, 8 atm

.

.

Butyl alcohol, 8 atm

.

Butyl alcohol, iso-, 8 atm

Carbon bisulphide, 837 atm

Carbon tetrachloride .

.

Chloroform, 100-200 atm .

Ether:

150 atm .

.

.

9001000 atm

.

.

9001000 atm

.

.

Temp.

GPa

20

17.7

17.9

17.4

17.9

15.6

20

20

1.45

1.12

1.10

1.13

1.03

1.16

1.12

1.1

0

0

198

0.689

1.56

0.703

Liquid

Mercury:

837 atm .

.

.

100200 atm .

.

Methyl acetate, 837 atm

Methyl alcohol, 37 atm .

Olive oil .

.

.

.

Paraffin oil

.

.

.

Pentane

.

.

.

.

Petroleum .

.

.

.

Propyl alcohol, 8 atm

.

Propyl alcohol, iso-, 8 atm

Turpentine

.

.

.

Temp.

GPa

20

15

14.3

14.7

20.5

14.8

20

16.5

17.7

17.8

19.7

26.2

30.0

1.04

0.97

1.60

1.62

0.318

1.46

1.04

0.983

1.280

19/01/2015 11:19 AM

Elasticities and strengths 2.2.2

3 of 7

http://www.kayelaby.npl.co.uk/general_physics/2_2/2_2_2.html

Ethyl acetate, 837 atm

Ethyl alcohol:

1500 atm

.

150200 atm

.

Ethyl bromide, 837 atm

Ethyl chloride, 837 atm

Glycerine

.

.

.

13.3

0.974

.

.

.

.

.

0

310

99.3

15.2

20.5

1.32

0.024

0.343

0.662

4.03

Water:

125 atm .

9001000 atm

9001000 atm

25003000 atm

Water (sea)

.

.

.

.

.

.

.

.

.

.

.

15

15

198

14.2

2.05

2.75

1.81

3.88

2.32

Elasticities of plastics

All plastics are visco-elastic and consequently the elasticity varies considerably with temperature and strain rate. The table below

gives approximate values at 20 C for slow rates of strain.

Material

Material

GPa

ABS . . . .

Epoxy

. . .

Nylon 6 (cast)

.

Nylon 6 (moulded)

Nylon 66

. .

Polybenzoxazole .

Polycarbonate

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

GPa

1.43.1

~3.2

2.43.1

0.83.1

1.22.9

~3.5

2.4

Polyethylene (high density) . .

Polyimide

. . . . . . .

Polymethylmethacrylate (PMMA)

Polypropylene . . . . . .

Polystyrene

. . . . . .

Polytetrafluoroethylene (PTFE)

Polyvinylchloride (PVC)

. .

(unplasticised)

0.41.3

~3.1

2.43.4

1.11.6

2.74.2

0.4

2.44.1

Temperature coefficient of elastic constants for a range of materials

Temperature coefficient

Et = E15{1 - (t

15)}

Gt = G15{1 - '(t

15)}

At 15C

10

Aluminium

.

Brass

. .

Copper

. .

German silver

Gold

. .

Iron

. . .

Phosphor-bronze

Platinum . .

Quartz fibre .

Silver . . .

Steel . . .

Tin

. . .

.

.

.

.

.

.

.

.

.

.

.

in

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

for E

4.8

3.7

3.0

4.8

2.3

0.98

1.5

7.5

2.4

'

10

for G

5.2

4.6

3.1

6.5

3.3

2.8

3.0

1.0

1.1

4.5

2.6

5.9

Elastic properties anisotropic materials

Anisotropic materials can be either naturally occurring (e.g. wood) or manufactured (e.g. fibre reinforced composites). In general

they are characterised by twenty-one independent constants, but this is reduced to nine for orthotropic materials and five for

transversely isotropic materials. They are frequently planar in form.

The main engineering constants in use for orthotropic composites are:

longitudinal modulus of elasticity, E11

transverse modulus of elasticity, E22

through-thickness modulus of elasticity, E33

longitudinal in-plane shear modulus, G12

longitudinal through-thickness shear modulus, G13

transverse through-thickness shear modulus, G23

major Poissons ratio, 12

minor Poissons ratio, 13

19/01/2015 11:19 AM

Elasticities and strengths 2.2.2

4 of 7

http://www.kayelaby.npl.co.uk/general_physics/2_2/2_2_2.html

transverse Poissons ratio, 23

For unidirectionally reinforced composites, 1 = fibre direction in-plane, 2 = transverse to fibre in-plane and 3 = transverse

through-thickness (i.e. perpendicular to plane). For other materials, the directions would be defined by other features, such as the

production length-wise direction. Poissons ratio can be greater than 0.5 for angle-ply or multidirectionally reinforced materials.

Composites with fully unidirectional reinforcement are approximately transversely isotropic materials (i.e. 2 and 3 directions are

equal). The following relations exist in this case:

E33 = E22, G13 = G12,

13

= 12,

and

E22 = 2(1 + 23)G23

For orthotropic symmetry the following relations exist:

12

E11

21

E22

23

E22

13

32

31

=

,

E33 E11

E33

Elasticities of woods

All woods are elastically anisotropic and in general there are nine independent elastic constants. The values in the table below are

for some common woods and give the three principal values of Youngs modulus measured along the grain EL, in a radial direction

ER and tangential direction ET (Hearmon, 1948).

Wood

Ash . .

Balsa

.

Beech

.

Birch

.

Mahogany

Oak . .

Walnut .

Teak . .

Douglas Fir

Scots Pine

Spruce .

. . . . . .

. . . . . .

. . . . . .

. . . . . .

. . . . . .

. . . . . .

. . . . . .

. . . . . .

. . . . . .

. . . . . .

. . . . . .

Relative

density

EL

ER

ET

GPa

GPa

GPa

0.7

0.2

0.7

0.6

0.5

0.7

0.6

0.6

0.5

0.5

0.40.5

16

6

14

16

12

11

11

13

16

16

1016

1.6

0.3

2.2

1.1

1.1

1.2

1.1

1.1

0.40.9

0.9

0.1

1.1

0.6

0.6

0.6

0.8

0.6

0.40.6

Elasticities of fibre-reinforced plastics full set

Material

v12

v21

v23

2.5

0.30

0.01

0.55

3.9

0.36

0.02

0.48

E11

E22

E33

G12

G13

G23

GPa

GPa

GPa

GPa

GPa

GPa

High Modulus Carbon Fibre/Epoxy

unidirectionally reinforced

specimen

287

7.80

7.75

6.7

6.7

High Strength Carbon Fibre/Epoxy

unidirectionally reinforced

specimen

172

7.8

7.8

11.6

11.6

Elastic Constants measured at NPL by the Ultrasonic Technique (Read and Dean, 1978).

Elasticities of fibre-reinforced plastics in-plane properties

Material

23 C

Injection moulded, discontinuous (long) fibre thermoplastic: glass-fibre/nylon

(30% fibre by volume)

E11

E22

GPa

GPa

10.6

7.9

v12

v21

0.34

0.22

19/01/2015 11:19 AM

Elasticities and strengths 2.2.2

5 of 7

http://www.kayelaby.npl.co.uk/general_physics/2_2/2_2_2.html

Hot compression moulded, sheet moulding (thermoset) compond (SMC): glass

fibre strands/filler/polyester resin (62% fibre + filler by volume)

Thermoformed (press) moulded, mat + unidirectional fibres/thermoplastic

glass-fibre/polypropylene (18% fibre by volume)

Autoclaved, unidirectional continuous fibre/thermoset resin: glass-fibre/epoxy

(59% fibre by volume)

Autoclaved, unidirectional continuous fibre/thermoset resin: carbo-fibre/epoxy

(61% fibre by volume)

10.0

9.8

0.30

0.31

9.2

4.4

0.41

0.22

47.0

16.4

0.28

0.08

9.9

0.30

0.02

146

Typical values measured at NPL using mechanical test methods (Sims et al., 1993) actual values depend on fibre type,

orientation and distribution, also on resin properties and process route.

Strength properties isotropic materials

The strength properties of many materials are dependent on the rate of loading and the test temperature. This particularly applies

to plastics and glass-fibre reinforced plastics. Generally materials will reach their elastic limit prior to failure.

Substance

Tensile

strength

MPa

Metals

Aluminium (cast)

(rolled)

Brass (66% Cu, 34% Zn) (cast)

"

(rolled)

90100

90150

150190

230270

Calcium

4260

Cobalt

260750

Copper (cast)

,,

(rolled)

120170

200400

Gun metal (90% Cu, 10% Sn)

190260

Iron (cast)

100230

,, (wrought)

Lead (cast)

1217

Magnesium (cast)

,,

290450

6080

(extruded)

170190

Phosphor-bronze (cast)

180280

Steel (castings).

400600

Steel (mild) (0.2% C)

430490

High-carbon spring steel:

(annealed

(tempered)

(nickel) (5% Ni)

(nickel-chromium)

700770

9301080

8001000

10001500

Soft solder

5575

Tin (cast)

2035

Zinc (rolled)

110150

Plastics

Nylon 6

7697

Nylon 66

6283

Polyacetal

~69

Polybenzoxazole

82117

Polycarbonate

5565

Polyethylene

2135

Polyimide

69-104

Polymethylmethacrylate

50-76

Polypropylene

30-40

Polystyrene

34-52

Miscellaneous

19/01/2015 11:19 AM

Elasticities and strengths 2.2.2

6 of 7

http://www.kayelaby.npl.co.uk/general_physics/2_2/2_2_2.html

Catgut

420

Glass

3090

Hemp rope

60100

Leather belt

3050

Silk fibre

260

Spider thread

180

Woods:

Ash, beech, oak, teak, mahogany

60110

Fir, pitch-pine

4080

Red or white deal

3070

White or yellow pine

2050

Quartz fibre (fused)

~1000

Wires

Aluminium

200-450

Brass

350-550

Copper (hard-drawn)

,,

400460

(annealed)

280-310

Duralumin

400-550

German Silver

460

Gold

200250

Iron (charcoal, hard-drawn

,,

540-620

(annealed)

460

Molybdenum

11003000

Nickel

500-900

Palladium

350450

Phosphor-bronze (hard-drawn)

6901080

Platinum

330370

Pt + 10% Rh

630

Silver

290

Steel (ordinary)

~1100

,,

(tempered)

1550

,,

(pianoforte, hard-drawn) .

18602330

Tantalum

8001100

Tungsten

15003500

Zirconium (annealed)

,,

260390

(hard-drawn)

1000

Along the grain

Strength properties anisotropic materials

The strength properties of anisotropic materials measured in different directions may differ considerably. Differences in strengths

can be higher than those in elastic properties.

Ultimate tensile strength properties of fibre-reinforced plastics in-plane properties. (Sims et al., 1993). Typical values;

actual values depend on fibre type, orientation and distribution; resin properties and process route (NB. 11 = longitudinal

ultimate tensile strength and 22 = transverse ultimate tensile strength).

Material

23 C

Injection moulded discontinuous (long) glass-fibre/nylon (30% fibre by volume)

Hot comperssion moulded, sheet moulding material (SMC) glass fibre strands/filler/polyester

resin (62% fibre + filler by volume)

Thermoformed (press) moulded, mat + unidirectional/thermoplastic glass-fibre/

polypropylene (18% fibre by volume )

Autoclaved, unidirectional glass-fibre/epoxy (59% fibre by volume)

11

22

MPa

MPa

148

113

60

59

143

38

1139

63

19/01/2015 11:19 AM

Elasticities and strengths 2.2.2

7 of 7

http://www.kayelaby.npl.co.uk/general_physics/2_2/2_2_2.html

Autoclaved, unidirectional carbon-fibre/epoxy (61% fibre by volume)

2386

76

References

G. Bradfield (1964) Notes on Applied Science No. 30, Use in Industry of Elasticity with the Help of Mechanical Vibrations, HMSO.

P. W. Bridgman (1949) The Physics of High Pressure, Bell.

J. A. Ewing (1899) Strength of Material, Cambridge University Press.

R. F. S. Hearmon (1948). See also R. F. S. Hearmon, Elasticity of Wood and Plywood, Forest Products Research Special Report No.

7, HMSO.

M. F. Markham (1968) Measurements made at the NPL.

B. E. Read and G. D. Dean (1978) The determination of dynamic properties of polymers and composites, Adam Hilger.

G. D. Sims, W. Nimmo and W. R. Broughton (1993) Data measured at the NPL.

Others sources of data include,

W. Bolton (1989) Engineering Materials Pocket Book, Newnes.

Handbook of Industrial Materials (1992) Elsevier Adv. Tech.

N. A. Waterman and M. F. Ashby (1992) Elsevier Materials Selector, Elsevier Applied Science.

G.Sims

Home

About

Table of Contents

Advanced Search

Copyright

Feedback

Privacy

^ Top of Page ^

This site is hosted and maintained by the National Physical Laboratory 2015.

19/01/2015 11:19 AM

You might also like

- 2318-RA 18.03.2023-REV 0A Cutting The Leg Bracing - RIG Rig LovansingDocument9 pages2318-RA 18.03.2023-REV 0A Cutting The Leg Bracing - RIG Rig LovansingHafeez AliNo ratings yet

- Adventurers' Guild - SwordtagDocument12 pagesAdventurers' Guild - Swordtagtruly epicNo ratings yet

- Creep and Failure of Lead-Free Solder AlloysDocument77 pagesCreep and Failure of Lead-Free Solder AlloysTamara KhasimaNo ratings yet

- ME 2140 Mechanics of Materials Lab: Lab 1B: Uniaxial Compression Test Jacob StiebDocument8 pagesME 2140 Mechanics of Materials Lab: Lab 1B: Uniaxial Compression Test Jacob StiebCH FurqanNo ratings yet

- Blah Blah StoryDocument2 pagesBlah Blah StoryRicky LuznyNo ratings yet

- CrystalMaker TutorialDocument38 pagesCrystalMaker TutorialCatPapperNo ratings yet

- Teori Lamina BKHDocument21 pagesTeori Lamina BKHA RopikNo ratings yet

- Class #10, 11, 12 - Material Characterization TechniquesDocument66 pagesClass #10, 11, 12 - Material Characterization TechniquesAnshuman SinghNo ratings yet

- Rolling Contact Fatigue Wear of Nitriding Austempered Ductile Iron (Adi) - Adi DiscsDocument8 pagesRolling Contact Fatigue Wear of Nitriding Austempered Ductile Iron (Adi) - Adi DiscslucianoNo ratings yet

- Assignment #2 2018Document2 pagesAssignment #2 2018Rima ChinnasamyNo ratings yet

- 04-MB-11 (Version Anglaise) - Mai 2012Document6 pages04-MB-11 (Version Anglaise) - Mai 2012LuisAranaNo ratings yet

- The Effect of Square Hole On Thermal Stresses in An Aluminum Metal-Matrix Cross-Ply Laminated CompositesDocument9 pagesThe Effect of Square Hole On Thermal Stresses in An Aluminum Metal-Matrix Cross-Ply Laminated Compositessamir deghboudjNo ratings yet

- Question Paper CodeDocument3 pagesQuestion Paper Codeeugin cebertNo ratings yet

- Metals Non MetalsDocument17 pagesMetals Non MetalsJacqueseNo ratings yet

- II Biaxial LoadDocument7 pagesII Biaxial LoadNandit JadvaniNo ratings yet

- Mmax PL: P 200 N, L 100 MM, and X 2Document3 pagesMmax PL: P 200 N, L 100 MM, and X 2ebsanNo ratings yet

- 3 Semiconductors and Insulators 1Document35 pages3 Semiconductors and Insulators 1Dam SonNo ratings yet

- Mechanics-Based Scaling Laws For The Durability of Thermal Barrier CoatingsDocument23 pagesMechanics-Based Scaling Laws For The Durability of Thermal Barrier CoatingsAmir.h FartashNo ratings yet

- Torsional Testing of Various Common MetalsDocument31 pagesTorsional Testing of Various Common Metalsnashb96No ratings yet

- 1 PBDocument10 pages1 PBChristina Christina ChristinaNo ratings yet

- Strain in OtrsionDocument45 pagesStrain in OtrsionrenebbNo ratings yet

- Ing Sismica Pentamode 2016Document10 pagesIng Sismica Pentamode 2016ponjoveNo ratings yet

- 신소재과학 시험문제모음Document9 pages신소재과학 시험문제모음Hanjin SeoNo ratings yet

- De Faoite - 2013 - Regression Analysis of Temperature-Dependent Mechanical and Thermal PropertiesDocument14 pagesDe Faoite - 2013 - Regression Analysis of Temperature-Dependent Mechanical and Thermal PropertiesAlaa SaadNo ratings yet

- 98materials Crystal DefectDocument28 pages98materials Crystal DefectmedazNo ratings yet

- Development of A Composite Pressure Vessel For High Pressure ApplicationsDocument12 pagesDevelopment of A Composite Pressure Vessel For High Pressure ApplicationsfsNo ratings yet

- 155 Report 4Document11 pages155 Report 4Joyson D SouzaNo ratings yet

- Love Is Sweet NB:!Verify Solutions From HandoutsDocument8 pagesLove Is Sweet NB:!Verify Solutions From HandoutsFrancis OpokuNo ratings yet

- 20110926HW1Document2 pages20110926HW1David SimonNo ratings yet

- Optical Properties of Gese, Gese Te and Gese Te Thin FilmsDocument6 pagesOptical Properties of Gese, Gese Te and Gese Te Thin FilmsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Effect of Heat Exchange During Vulcanization On Possible Fabrication of Rubberized Entities by Methods of Plastic DeformationDocument8 pagesEffect of Heat Exchange During Vulcanization On Possible Fabrication of Rubberized Entities by Methods of Plastic DeformationAldi IgnielNo ratings yet

- ° Technical University of LodzDocument22 pages° Technical University of LodzLTE002No ratings yet

- Biomaterials 2009 Fall Home Work No4Document2 pagesBiomaterials 2009 Fall Home Work No4_Ariane_Enaira_5613No ratings yet

- Piazzoni AntonioSebastianoDocument87 pagesPiazzoni AntonioSebastianoAntonio PiazzoniNo ratings yet

- Input Data For Test Cases Used in Triaxial Failure Theories PDFDocument18 pagesInput Data For Test Cases Used in Triaxial Failure Theories PDFRohitMadkeNo ratings yet

- Archive of SID: Stress Concentrations of Symmetrically Laminated Composite Plates Containing Circular HolesDocument14 pagesArchive of SID: Stress Concentrations of Symmetrically Laminated Composite Plates Containing Circular HolesAugusto Tinoco PadauiNo ratings yet

- Graphene and Boron Nitride Single Layers: October 23, 2018Document54 pagesGraphene and Boron Nitride Single Layers: October 23, 2018samirayasmin1117No ratings yet

- Quantum and Nonlinear OpticsDocument45 pagesQuantum and Nonlinear OpticsNick NardelliNo ratings yet

- Properties of Materials PDFDocument42 pagesProperties of Materials PDFpika pikaNo ratings yet

- 01 DoDocument9 pages01 DoSrihari DNo ratings yet

- Hall EffektDocument15 pagesHall EffektputeluNo ratings yet

- 2 - Material PropertiesDocument67 pages2 - Material PropertiesAzooNo ratings yet

- MDF Creep StudyDocument10 pagesMDF Creep StudySharath P CNo ratings yet

- Thermal Properties of Polymeric Composites Reinforced by Nanoceramic MaterialsDocument8 pagesThermal Properties of Polymeric Composites Reinforced by Nanoceramic MaterialsTJPRC PublicationsNo ratings yet

- Surface Science of Tin Oxide PDFDocument108 pagesSurface Science of Tin Oxide PDFJorge Alexis RamosNo ratings yet

- Lecture On NanocompositesDocument44 pagesLecture On Nanocompositeskire14pffNo ratings yet

- Chapter 6 - Cylindrical VEDDocument32 pagesChapter 6 - Cylindrical VEDJoaquim TchamoNo ratings yet

- Mechanical Properties For Polyester Resin Reinforce With Fe Weave WireDocument5 pagesMechanical Properties For Polyester Resin Reinforce With Fe Weave WireInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Elasticity of Composite MaterialsDocument78 pagesElasticity of Composite MaterialsRobby GunadiNo ratings yet

- Matprop HYPERMESH 1DDocument12 pagesMatprop HYPERMESH 1DSaurabh MistryNo ratings yet

- PHYS 3203 - Lab PDFDocument55 pagesPHYS 3203 - Lab PDFTaukeer KhanNo ratings yet

- In Situ SEM-EBSD Analysis of Plastic Deformation Mechanisms in Neutron-Irradiated Austenitic SteelDocument27 pagesIn Situ SEM-EBSD Analysis of Plastic Deformation Mechanisms in Neutron-Irradiated Austenitic SteelChin-Min YangNo ratings yet

- Slides Chapter 4 Material Behavior-Linear Elastic SolidsDocument11 pagesSlides Chapter 4 Material Behavior-Linear Elastic SolidskkhemmoNo ratings yet

- Modulus of Elasticity - Young Modulus For Some Common MaterialsDocument2 pagesModulus of Elasticity - Young Modulus For Some Common Materialsozlatan1100% (1)

- Tensile and Flexural Properties of Single Carbon FibresDocument10 pagesTensile and Flexural Properties of Single Carbon FibrestrebeardNo ratings yet

- 2017+Module+1+Term+Test+ SolutionsDocument13 pages2017+Module+1+Term+Test+ Solutionszubair ahmedNo ratings yet

- CH 6: Mechanical Properties: Students Should Know This TerminologyDocument13 pagesCH 6: Mechanical Properties: Students Should Know This TerminologyLeonardo Aji NugrahaNo ratings yet

- Grain+Size+Effect+on+the+Martensite+Formation+in+a+High Manganese+TWIP+Steel+by+the+Rietveld+MethodDocument6 pagesGrain+Size+Effect+on+the+Martensite+Formation+in+a+High Manganese+TWIP+Steel+by+the+Rietveld+MethodLeonidas GilapaNo ratings yet

- 2Document2 pages2faizrummanNo ratings yet

- Studying The Effect of Tramp Elements inDocument7 pagesStudying The Effect of Tramp Elements inmohit madaviNo ratings yet

- Assignment IIDocument2 pagesAssignment IISaurav KumarNo ratings yet

- Magnetism: Molecules to Materials VFrom EverandMagnetism: Molecules to Materials VJoel S. MillerNo ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- Glaunach: Surface TreatmentDocument5 pagesGlaunach: Surface TreatmentRicky LuznyNo ratings yet

- A Novel Equation For Isothermal Pipe Flow - Kim 2012Document9 pagesA Novel Equation For Isothermal Pipe Flow - Kim 2012Ricky LuznyNo ratings yet

- Part A: ProbabilitiesDocument10 pagesPart A: ProbabilitiesRicky LuznyNo ratings yet

- PS4Document8 pagesPS4Ricky LuznyNo ratings yet

- Lec 8 - Compressible Duct Flow With FrictionDocument23 pagesLec 8 - Compressible Duct Flow With FrictionRicky LuznyNo ratings yet

- Michigan Wing Encampment - 2008Document16 pagesMichigan Wing Encampment - 2008CAP History LibraryNo ratings yet

- Thunder Cake StoryDocument5 pagesThunder Cake Storyapi-21226401No ratings yet

- Victims From GazaDocument29 pagesVictims From Gazamoa baraNo ratings yet

- Conduction Power Loss in MOSFET Synchronous Rectifier With Parallel-Connected Schottky Barrier DiodeDocument7 pagesConduction Power Loss in MOSFET Synchronous Rectifier With Parallel-Connected Schottky Barrier DiodeMuhammad Saqib AliNo ratings yet

- SSR HmiDocument16 pagesSSR HmiAnandharaj .KNo ratings yet

- Changes From Rev AK To Rev AL Skyview Installation GuideDocument608 pagesChanges From Rev AK To Rev AL Skyview Installation GuideF BakımNo ratings yet

- Biological ClasifficationDocument6 pagesBiological Clasifficationchannel of dhyanaNo ratings yet

- Dowden, B Logical Reasoning Cap 3 y 6Document80 pagesDowden, B Logical Reasoning Cap 3 y 6vladimir mendozaNo ratings yet

- TurbineDocument8 pagesTurbineJay Patel100% (1)

- Piping Vent & DrainsDocument8 pagesPiping Vent & Drainsswati2584100% (2)

- Overall Analyses Character Analysis KinoDocument5 pagesOverall Analyses Character Analysis KinoGodfrey MuchaiNo ratings yet

- Midterm Examination: Ce 322 - Building Systems DesignDocument5 pagesMidterm Examination: Ce 322 - Building Systems DesignJEAN KATHLEEN SORIANONo ratings yet

- MCQ's of Industrial Hydraulics & Pneumatics Laboratory: B. One DirectionDocument3 pagesMCQ's of Industrial Hydraulics & Pneumatics Laboratory: B. One Directionyuvarajballal100% (4)

- AKG-2 Gate 4 Review Package Rev 0Document19 pagesAKG-2 Gate 4 Review Package Rev 0pvpallasigui3126100% (1)

- FeasibDocument57 pagesFeasibCPAREVIEWNo ratings yet

- Important Intial McqsDocument34 pagesImportant Intial Mcqslover boyNo ratings yet

- Aqualisa Quartz Simply A Better ShowerDocument12 pagesAqualisa Quartz Simply A Better ShowerPranjal SinghNo ratings yet

- Workmanship Standard For Crimping, Interconnecting Cables, Harnesses, and WiringDocument101 pagesWorkmanship Standard For Crimping, Interconnecting Cables, Harnesses, and WiringCemy IraclyNo ratings yet

- Private Cloud Appliance x9 DatasheetDocument3 pagesPrivate Cloud Appliance x9 DatasheetKesava ReddyNo ratings yet

- Operational Amplifi Ers: ExperimentDocument4 pagesOperational Amplifi Ers: Experimentampalacios1991No ratings yet

- An Epistle of JeremiahDocument3 pagesAn Epistle of JeremiahBenson MuimiNo ratings yet

- T50e Replace DriveDocument24 pagesT50e Replace DrivevcalderonvNo ratings yet

- All Tables - Chapter 2 - WL - 77 To 188Document112 pagesAll Tables - Chapter 2 - WL - 77 To 188sdasorisaNo ratings yet

- 1986 GT CatalogDocument16 pages1986 GT CatalogtspinnerNo ratings yet

- Aquaculture Asia Jan 08Document60 pagesAquaculture Asia Jan 08Nilamdeen Mohamed ZamilNo ratings yet

- 1kd 2kd Ect PDFDocument4 pages1kd 2kd Ect PDFÓscar Pereira100% (3)

- THESIS Evaluation of CO2 Supermarket Refrigeration Systems. Field Measurements in Three SupermarketsDocument83 pagesTHESIS Evaluation of CO2 Supermarket Refrigeration Systems. Field Measurements in Three SupermarketsP. ReobNo ratings yet