Professional Documents

Culture Documents

Us 20120037510

Us 20120037510

Uploaded by

Thusith WijayawardenaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us 20120037510

Us 20120037510

Uploaded by

Thusith WijayawardenaCopyright:

Available Formats

US 20120037510A1

(19) United States

(12) Patent Application Publication (10) Pub. N0.: US 2012/0037510 A1

BETHUREM

(54)

PROCESS AND APPARATUS FOR THE

(52)

PREPARATION OF COMBUSTIBLE FLUID

(57)

(75) Inventor:

_

(73)

(43) Pub. Date:

Feb. 16, 2012

US. Cl. .................................... .. 205/462; 204/275.1

ABSTRACT

GARY J_ BETHUREM, Simi

A fuel and hydrogen generator includes electrolysis in a ?rst

Valley CA (Us)

closed yess'el containing a bath of Water, electrolyte and suf

?cient l1qu1d hydrocarbon fuel to serve as an oxygen barrier.

The hydrogen produced in the ?rst closed Vessel is introduced

Asslgnee'

ADVANCED COMBUSTION

TECHNOLOGIESINC

(21) Appl. No.:

12/855,617

into a second closed Vessel having a bath of Water, electrolyte

and liquid hydrocarbon fuel in an amount Volumetrically

equal to the Water. Electrodes extend through the liquid

hydrocarbon fuel to the Water to conduct electrolysis.

Makeup Water and liquid hydrocarbon fuel is supplied to both

(22) Filed.

Aug 12, 2010

closed Vessels as needed. The bath in the second closed vessel

is recirculated to entrain all constituents Within the bath and to

Pubhcatlon Classl?catlon

(51)

cool the bath to ambient temperature. Gas is draWn off of the

bath in the second closed Vessel though Vacuum With con

Int, Cl,

C101, 1/04

(200601)

stituents then fractionally lique?ed to create a reformed liquid

hydrocarbon fuel and to separate the fuel from the gaseous

C25B 9/00

(2006.01)

hydrogen.

Patent Application Publication

14

Feb. 16, 2012

US 2012/0037510 A1

Feb. 16, 2012

US 2012/0037510 A1

PROCESS AND APPARATUS FOR THE

PREPARATION OF COMBUSTIBLE FLUID

BACKGROUND OF THE INVENTION

[0001]

The ?eld of the present invention is hydrocarbon

re?ning.

[0002]

Electrolysis of Water to generate hydrogen and oxy

gen is Well knoWn. Also knoWn are HHO generators Which

use electrolysis to transform Water into its component parts

but not to separate the hydrogen and oxygen once released.

Such devices have been employed to directly feed internal

combustion engines to improve combustion. In modern

engines, oxygen sensors are used to control air fuel mixture as

they sense variations in oxygen. Even though the oxygen

introduced from an HHO generator is in a stoichiometric ratio

With the hydrogen also introduced, the oxygen sensor does

not account for the added combustible hydrogen and senses

an excess of oxygen. As a result, the tuning of the engine must

be amended to account for the introduction of hydrogen With

the additional oxygen from such a generator. Further, as a

stoichiometric mixture of oxygen and hydrogen is explosive

With a threshold input of energy, such generators are typically

employed to immediately feed combustion so that the explo

sive mixture is not accumulated. The HHO supplied to the

intake of internal combustion engines for boosting the opera

tion of liquid hydrocarbon fuels is intended to operate in

various Ways to increase performance, increase e?iciency

and/or reduce exhaust pollutants. Mixed results have led to

further study Without yet establishing a compelling need to

Both regulation of the voltage across the electrodes and the

recirculation may be used to maintain ambient temperatures

in the bath. Neutral electrodes may additionally be used to

match impedance With the poWer source to gain e?iciency.

[0007] In a third separate aspect of the present invention, a

plurality of baths consisting essentially of Water, electrolyte

and liquid hydrocarbons are arranged serially With different

ratios of liquid hydrocarbon fuel to Water. Serial association

of the baths are understood to impact the ratio of products

derived.

[0008] In a fourth separate aspect of the present invention,

a fuel generator employs a closed vessel, Water, liquid hydro

carbon fuel, electrolyte and electrodes of opposite polarity

extending into the hydrocarbons and Water in the vessel. The

electrolysis causes the transformation of Water and liquid

hydrocarbon fuel into hydrogen and reformulated fuel. A

vacuum pump in communication With the gas space in the

closed vessel removes products Which can be volatiliZed

Without signi?cantly volatiliZing the original liquid hydrocar

bon fuel.

[0009] In a ?fth separate aspect of the present invention,

any of the foregoing aspects may be combined to greater

result.

[0010] Accordingly, it is an object of the present invention

to provide a novel process for the generation of reformulated

hydrocarbon fuel. Other and further objects and advantages

Will appear hereinafter.

BRIEF DESCRIPTION OF THE DRAWING

commercialiZe such devices.

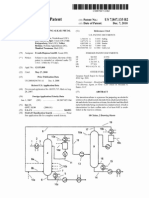

[0011]

[0003] Hydrocarbon liquid fuels employed in internal com

bustion engines range broadly With the most conventional

fuels being gasoline, diesel and kerosene. These liquids are

ratus of one embodiment of the present invention.

blended hydrocarbons of various molecular Weight and con

?guration. The siZe and con?guration of such molecules can

affect burn rate and exhaust products. Additives have been

employed to modify those effects.

SUMMARY OF THE INVENTION

[0004] The present invention is directed to the creation of

reformed fuel from liquid hydrocarbon fuel such as gasoline,

diesel and kerosene that appears to burn cleaner and provide

The draWing is a schematic of the process and appa

DETAILED DESCRIPTION OF THE PREFERRED

EMBODIMENT

[0012] Turning to the schematic, a ?rst closed vessel 10

includes an arrangement of anodes and cathodes 12 in a cavity

14. Neutral electrodes may also be used to match the imped

ance With the poWer source to maximiZe ef?ciency as may be

empirically determined. The electrodes employed in the pre

ferred embodiment are plates 12 of alternating polarity

extending across the cavity 14. Stainless steel has been used

but more exotic metals are knoWn to increase plate longevity.

substantial energy for combustion in an internal combustion

Electrical feeds 16 conventionally communicate With the

engine With a lighter blend of hydrocarbons.

electrodes 12. This ?rst closed vessel 10 contains a bath in the

[0005] In a ?rst separate aspect of the present invention, a

process for the preparation of combustible ?uid includes con

cavity 14 consisting essentially of Water, electrolyte, and a

thin layer of liquid hydrocarbon fuel. The electrolyte may be

ducting electrolysis in a bath consisting essentially of Water,

electrolyte and liquid hydrocarbons With removal of the gas

from the bath during electrolysis and adding makeup Water

introduced as potassium hydroxide. The fuel may be any

combustible hydrocarbon Which Would be liquid in the envi

ronment of the bath, most typically gasoline, diesel fuel or

and liquid hydrocarbons to effect a continuous process. In

kerosene. The layer of liquid hydrocarbon fuel is su?icient to

implementing this process, the volumetric ratio of hydrocar

bon fuel to Water may range from about 6:1 doWn to a very

form an oxygen barrier above the Water. Less than one quarter

inch is su?icient in most cases. The electrodes 12 extend

small ratio With only a small amount of hydrocarbon fuel to

through the hydrocarbon layer to the Water.

de?ne an oxygen barrier above the Water. Different ratios can

[0013]

impact the ?nal blend of resulting hydrocarbon constituents.

may be a battery, 110 AC or other voltage source Which is

recti?ed as needed. The system operates Well at 19 volts,

[0006]

In a second separate aspect of the present invention,

a process for the preparation of combustible ?uid includes

conducting electrolysis in a bath consisting essentially of

Water, electrolyte and liquid hydrocarbons. The process fur

The electrolysis is driven by a poWer source Which

draWing about 3 amps for the closed vessel 10. The poWer is

subjected to the voltage being pulsed on and off to reduce the

generation of heat in the bath.

ther includes the circulation of the liquid phase to maintain

[0014]

intermediate products in suspension for further processing.

The electrolysis contemplates electrodes of opposite polarity

a port 18 and liquid hydrocarbon fuel is made up through a

port 20. Gas generated Within the closed vessel 10 is draWn

off through a port 22 located above the level of liquid.

extending into the hydrocarbons and to the Water in the bath.

For feedstock, makeup Water is introduced through

Feb. 16, 2012

US 2012/0037510 A1

[0015] A second closed vessel 24 is coupled With the closed

vessel 10 through the port 22 by Which the closed vessel 24

receives gas generated from the ?rst vessel 1 0 at a port 26. The

closed vessel 24 includes a cavity 28 With electrodes 30 of

alternating polarity extending through the hydrocarbon fuel

and to the Water in a bath consisting essentially of Water,

electrolyte and liquid hydrocarbon fuel. The electrodes 30 in

this embodiment are stainless steel plates extend through the

hydrocarbon fuel and to the Water in the bath. More exotic

metals Will likely improve longevity as noted above. The port

26 is located beloW the bath in the closed vessel 24 to intro

duce the hydrogen into the electrolysis process. The same

electrolyte may be employed in the second bath but the liquid

hydrocarbon fuel is at a much higher volumetric ratio With the

Water than in the ?rst bath. E?iciency in the preferred

embodiment appears to be maximiZed With a ratio of about 6

to 1. Again, poWer to the electrolysis process is as described

not occur, as discussed above. The hydrogen passes through

the port 22 above the liquid level and from the vessel 10.

Because of the thin layer of liquid hydrocarbon fuel on the

surface of the Water in the closed vessel 10, oxygen is pre

vented by this barrier from escaping from the bath.

[0020] The hydrogen from the closed vessel 10 is fed to the

second closed vessel 24 into the port 26. The second vessel 24

conducts electrolysis in an environment With the bath con

taining much larger ratios of liquid hydrocarbon fuel to Water

With an electrolyte and With the hydrogen gas delivered from

the closed vessel 10. The electrolysis is accomplished by the

electrodes 30 of alternating opposite polarity Which extend

through the hydrocarbon fuel to the Water. The electrolysis

process is run on a cycle of about 50% on and 50% off.

E?iciency appears to be maximiZed at around this 50% poWer

supply cycle and the controls keep temperature Within the

bath doWn. It has been found that cycling the poWer such that

above for the ?rst closed vessel 10 With 19 volts draWing

about 3 amps in the closed vessel 24 With the poWer pulsed.

the electrodes 30 are charged about 50% of the time creates a

Each of these parameters is subject to empirical tuning to

[0021] To further maintain temperature and to retain all

components of the process entrained in the bath, the constitu

maximiZe ef?ciency in the environment of each reactor ves

sel.

[0016]

During the electrolysis process in the second closed

greater ef?ciency of operation.

ents of the bath are recirculated through the pump 34 and tank

36. Cooling is included in this recirculating ?oW by the heat

vessel 24, the liquid contained therein is recirculated from a

exchanger 38. It is advantageous to maintain the bath at

port 32 through a recirculation pump 34 to a tank 36. The tank

ambient temperature. The intermediate hydrocarbon material

36 has the ingredients of the second bath including some

intermediate hydrocarbon material Which is to be circulated

With the Water back into the bath. From the tank 36, recircu

lation continues through a heat exchanger 38 and back into

the bath of the second closed vessel 24 through a port 40.

[0017] As feedstock, a Water tank 42 feeds makeup Water to

the tank 36 as electrolysis loWers the quantity of Water in the

system. A hydrocarbon fuel tank 44 also makes up liquid fuel

ingredients as needed. Solenoids 46 and 48 control the Water

tank 42 and fuel tank 44, respectively. The same sources may

be used to provide feedstock to the ?rst closed vessel, as

shoWn in the schematic.

[0018] A further port 50 located above the liquid level

Within the second closed vessel 24 draWs gas into a safety

bubbler 52 and then to a vacuum pump/compressor assembly

54. The vacuum pump/ compressor assembly 54 draWs a

vacuum on the closed vessel 24 and compresses a fraction of

the gasi?ed product into liquid delivered to a tank 56. The

vacuum draWn is moderated. At start-up, foaming is an issue

and operation of the vacuum pump/compres sor 54 is delayed.

Once the bath has been operating for a While, foaming

decreases and a vacuum can be draWn. As the bath is a blend

of liquid hydrocarbons, the level of vacuum Will impact the

constituents volatiliZed. A maximum of l 0 pounds per square

inch beloW atmospheric has been used. This avoids volatiliZ

ing any of the feedstock Water at the bottom of the bath or

?ashing off the feedstock liquid hydrocarbon fuel before it

has been subjected to a time of residence in the bath. The

degree of vacuum can be used to vary the residence time of the

volatile hydrocarbons in the second bath, Which is understood

is circulated With the Water back into the bath as this appears

to ultimately convert dark hydrocarbon material, intermedi

ate in the conversion process, into the desired volatile hydro

carbons.

[0022] Gas is draWn off above the bath in the second closed

vessel 24 by the vacuum pump/compressor 54 through the

safety bubbler 52, compressed and then cooled again if nec

essary to create a stable liquid at atmospheric pressure. The

hydrogen gas is naturally fractionated from the hydrocarbon

fuel thus derived. As noted above, the vacuum is regulated to

not gasify the feedstock Water and alloW residence time for

the liquid hydrocarbon fuel. The operation of electrolysis in

the second vessel 24 reduces the hydrocarbons to a lighter

blend of constituents in the resulting liquid fuel. By control

ling residence time in the second bath, the resulting blend of

hydrocarbon constituents volatiZed is understood to vary in

Weight.

[0023]

Thus, a gas and fuel generator and the process of

using same to generate reconstituted liquid hydrocarbon fuel

has been disclosed. While embodiments and applications of

this invention have been shoWn and described, it Would be

apparent to those skilled in the art that many more modi?ca

tions are possible Without departing from the inventive con

cepts herein. The invention, therefore is not to be restricted

except in the spirit of the appended claims.

What is claimed is:

1. A process for the preparation of combustible ?uid, com

prising

conducting electrolysis in a bath consisting essentially of

Water, electrolyte and liquid hydrocarbon fuel;

side is unable to liquefy the hydrogen generated during this

removing gas from above the bath during electrolysis;

providing makeup Water and liquid hydrocarbon fuel dur

process, Which is separately conveyed to a second tank 58. Of

course, each of these fractionated products may be directed to

2. The process of claim 1, removing gas including draWing

can impact the ?nal mix as may be desired. The compressor

ing the electrolysis.

other devices for processing or use.

gas With a vacuum pump, the vacuum being loW enough to

[0019]

separate volatile components from the feedstock Water.

Looking to the process directly, the bath in the ?rst

closed vessel 10 is subjected to electrolysis and, being prin

cipally Water, generates hydrogen and oxygen. PoWer is

3. The process of claim 1, conducting electrolysis being

betWeen electrodes of opposite polarity extending into the

directed to the electrolysis process such that overheating does

hydrocarbon fuel and to the Water.

Feb. 16, 2012

US 2012/0037510 A1

4. The process of claim 1 further comprising

fractionally liquefying gas removed from above the bath;

conducting electrolysis in a second bath consisting essen

tially of Water, electrolyte and a second amount of liquid

hydrocarbons betWeen electrodes of opposite polarity

and

separating hydrogen there from.

5. The process of claim 1 further comprising

maintaining the bath at ambient temperature.

6. The process of claim 5, maintaining the bath at ambient

temperature including recirculating liquid from the bath and

cooling the recirculating liquid to ambient temperature.

7. The process of claim 6, maintaining the bath at ambient

extending into the hydrocarbons and to the Water;

introducing the gas removed from the ?rst bath during

electrolysis to the Water in the second bath;

removing gas from above the second bath during electroly

s1s;

providing makeup Water and liquid hydrocarbon to the

second bath during the electrolysis.

temperature further including pulsing the voltage for the elec

12. The process of claim 11, removing gas from the second

trolysis on and off to maintain temperature.

8. A process for the preparation of combustible ?uid, com

bath including draWing the gas With a vacuum pump, the

prising

conducting electrolysis in a bath consisting essentially of

Water, electrolyte and liquid hydrocarbon fuel using

electrodes of opposite polarity extending into the hydro

carbon fuel and to the Water;

draWing gas from above the bath during electrolysis under

vacuum;

fractionally liquefying gas removed from above the bath;

and

providing makeup Water and liquid hydrocarbon fuel dur

ing the electrolysis.

9. The process of claim 8 further comprising

recirculating liquid from the bath.

10. The process of claim 1, conducting the electrolysis

vacuum being loW enough to separate volatile components

from the feedstock Water, the process further comprising

cooling and compressing the gas from the second bath to

fractionally liquefy the gas.

13. The process of claim 11 further comprising

maintaining the second bath at ambient temperature.

14. The process of claim 13, maintaining the second bath at

ambient temperature including recirculating liquid from the

bath and cooling the recirculating liquid to ambient tempera

ture.

15. The process of claim 14, maintaining the second bath at

ambient temperatures further including pulsing the voltage

for the electrolysis on and off to maintain temperature.

16. A fuel generator comprising

a closed vessel;

including pulsing the voltage on and off to reduce heat to the

bath.

11. A process for the preparation of combustible ?uid,

Water, liquid hydrocarbons, electrolyte and electrodes of

opposite polarity extending into the hydrocarbons and

comprising

a vacuum pump in communication With gas space in the

conducting electrolysis in a ?rst bath consisting essentially

Water in the closed vessel;

of Water, electrolyte and a ?rst amount of liquid hydro

closed vessel above the Water and hydrocarbons.

17. The fuel generator of claim 16 further comprising

carbon fuel su?icient to form an oxygen barrier above

a radiator in communication With the vacuum pump.

the Water in the ?rst bath;

removing gas from above the ?rst bath during electrolysis;

providing makeup Water and liquid hydrocarbon to the ?rst

bath during the electrolysis;

18. The fuel generator of claim 16 further comprising

a source of hydrogen coupled With the closed vessel.

*

You might also like

- En Nissan Ge13 EngineDocument614 pagesEn Nissan Ge13 EngineDan92% (51)

- Calibration Training SIEMENS VDODocument118 pagesCalibration Training SIEMENS VDOkermanpur.mghNo ratings yet

- DelphiDocument10 pagesDelphileearoza100% (1)

- Dt466-Dt570-Torque de Cabaza ValvuasDocument22 pagesDt466-Dt570-Torque de Cabaza ValvuasWero vences Alpargatas80% (5)

- Br0917bioluminescent Reporter Assaysoverview 00a PDFDocument84 pagesBr0917bioluminescent Reporter Assaysoverview 00a PDFThusith WijayawardenaNo ratings yet

- Manual de Servicio Chery QQDocument55 pagesManual de Servicio Chery QQJose Rengel100% (2)

- 3784A KXX K4J K4M Clio Motor ManualDocument32 pages3784A KXX K4J K4M Clio Motor ManualDavid NebainNo ratings yet

- MetoxidoDocument8 pagesMetoxidocessavelinoNo ratings yet

- PetroleumDocument13 pagesPetroleumPrashantNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2009/0206007 A1Document13 pagesPatent Application Publication (10) Pub. No.: US 2009/0206007 A1Tree SilviaNo ratings yet

- Comparison of Alternative Molten Electrolytes For Water Splitting To Generate Hydrogen FuelDocument8 pagesComparison of Alternative Molten Electrolytes For Water Splitting To Generate Hydrogen FuelOgie CabNo ratings yet

- SMeyer-CA1231872A1-Hydrogen Injection System V3Document38 pagesSMeyer-CA1231872A1-Hydrogen Injection System V3Bryan RodríguezNo ratings yet

- 1 s2.0 S0360319912007094 MainDocument10 pages1 s2.0 S0360319912007094 MainAntoni GuilhermeNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 7,935,254 B2Document6 pagesUlllted States Patent (10) Patent N0.: US 7,935,254 B2Dejan CekovskiNo ratings yet

- Experimental Hydrogen Booster ModelDocument4 pagesExperimental Hydrogen Booster ModelMaiman LatoNo ratings yet

- Hydrogen Energy SystemsDocument9 pagesHydrogen Energy SystemsDIPTA DUTTA 1702122No ratings yet

- Fuel Lab ManualDocument23 pagesFuel Lab ManualANOOP KUMAR100% (4)

- HHO Gas Generation in Hydrogen Generator Using EleDocument9 pagesHHO Gas Generation in Hydrogen Generator Using EleNishanNo ratings yet

- Hydrogen Fuel CellDocument5 pagesHydrogen Fuel Cellabeer fatimaNo ratings yet

- Python Project SynopsisDocument30 pagesPython Project SynopsisAshish RoshanNo ratings yet

- A Novel Route For Converting Aromatics Into Hydrogen Via Steam ReformingDocument8 pagesA Novel Route For Converting Aromatics Into Hydrogen Via Steam ReformingMarcelo Varejão CasarinNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. N0.: US 2005/0224338 A1Document6 pagesUnited States: (12) Patent Application Publication (10) Pub. N0.: US 2005/0224338 A1Yesid Tapiero MartínezNo ratings yet

- US20150107990A1Document7 pagesUS20150107990A1Taufiq Fahlifi YfzerobrrNo ratings yet

- H Ho System High ProductionDocument8 pagesH Ho System High Productionmr.XNo ratings yet

- Actividad en InglésDocument2 pagesActividad en InglésEvelin Zuñiga barreraNo ratings yet

- Mitigation of Caustic Stress Corrosion C PDFDocument9 pagesMitigation of Caustic Stress Corrosion C PDFJean YureNo ratings yet

- US3093691Document2 pagesUS3093691Ayu GirlsNo ratings yet

- Light Monoolefins From Methanol And/or Dimethyl Ether: BonifazDocument12 pagesLight Monoolefins From Methanol And/or Dimethyl Ether: BonifazSp4rkZ87No ratings yet

- HYDROGENDocument23 pagesHYDROGENMAHESH CHANDNo ratings yet

- Hydrocarbons From Sustainable SourcesDocument6 pagesHydrocarbons From Sustainable Sourcesravi kansagaraNo ratings yet

- Springer - 2001 - J. - Electrochem. - Soc. - 148 - A11Document14 pagesSpringer - 2001 - J. - Electrochem. - Soc. - 148 - A11Faseeh KKNo ratings yet

- Zero Fuel Cost and EmissionDocument25 pagesZero Fuel Cost and EmissionD-pacNo ratings yet

- A Desalination BatteryDocument5 pagesA Desalination BatteryMarco Villegas BermúdezNo ratings yet

- Hydrogen Oxygen Steam Generator Integrating With Renewable Energy Resource For Electricity GenerationDocument9 pagesHydrogen Oxygen Steam Generator Integrating With Renewable Energy Resource For Electricity GenerationKean PascualNo ratings yet

- Us 2807656Document9 pagesUs 2807656Suzu SuzuNo ratings yet

- United States Patent 1191: Tu (45) Sep. 7, 1982Document4 pagesUnited States Patent 1191: Tu (45) Sep. 7, 1982AdyNo ratings yet

- Renewable HydrogenDocument10 pagesRenewable HydrogenVedavathi ReddyNo ratings yet

- Jan-27, 1959 ' - G. Baecklund 2,870,866: Method of Obtaining Acetaldehyde ' Filed June 14, 1952Document3 pagesJan-27, 1959 ' - G. Baecklund 2,870,866: Method of Obtaining Acetaldehyde ' Filed June 14, 1952MuhlisaApriliaNo ratings yet

- US20090008268A1Document17 pagesUS20090008268A1hankyb14No ratings yet

- Us20110065939a1 PDFDocument17 pagesUs20110065939a1 PDFniralNo ratings yet

- Flowchart For AcetaldehydeDocument2 pagesFlowchart For Acetaldehydeyigitilgaz0% (1)

- A Practical Guide To Free Energy DevicesDocument10 pagesA Practical Guide To Free Energy DevicesRahul ChelaniNo ratings yet

- Ref 3 Lu2012Document9 pagesRef 3 Lu2012erlan rosyadiNo ratings yet

- Hho 2Document5 pagesHho 2Prittam Kumar JenaNo ratings yet

- 2002-KLOUZ-Ethanol Reforming For Hydrogen Production in A Hybrid Electric VehicleDocument9 pages2002-KLOUZ-Ethanol Reforming For Hydrogen Production in A Hybrid Electric VehicleMarioNo ratings yet

- H2O and Co2 ConversionDocument5 pagesH2O and Co2 ConversionHoangNo ratings yet

- Us2901407 PDFDocument4 pagesUs2901407 PDFMufita RamadhinaNo ratings yet

- Us 4899000Document5 pagesUs 4899000Karen Vanessa GonzalezNo ratings yet

- Hybrid Combined Cycle Power Plant: Károly VeszelyDocument8 pagesHybrid Combined Cycle Power Plant: Károly Veszelyankit407No ratings yet

- Pem 1Document10 pagesPem 1RandomV D.ENo ratings yet

- CiclohexanoDocument6 pagesCiclohexanoSebastian BelloNo ratings yet

- Lecture 21: Alternative Energy Resources - The Fuel CellDocument6 pagesLecture 21: Alternative Energy Resources - The Fuel CellIjazzzAliNo ratings yet

- Recovering Hydrogen Sulfide From Sulfurous Waters With PEM Fuel Cells 2016 Energy ProcediaDocument6 pagesRecovering Hydrogen Sulfide From Sulfurous Waters With PEM Fuel Cells 2016 Energy ProcediathaightNo ratings yet

- An Integrated Catalytic Approach For The Production of Hydrogen by GlycerolDocument6 pagesAn Integrated Catalytic Approach For The Production of Hydrogen by GlycerolMahdy HajienayatiNo ratings yet

- Us 20120035390Document18 pagesUs 20120035390sariNo ratings yet

- Steiu S. Separation of Ammonia Water Sodium Hydroxide Mixtures Using Reverse Osmosis Membranes For Low Temperature Driven Absorption Chillers 2008Document7 pagesSteiu S. Separation of Ammonia Water Sodium Hydroxide Mixtures Using Reverse Osmosis Membranes For Low Temperature Driven Absorption Chillers 2008Federico MontoyaNo ratings yet

- Hydrogen Production From Water Under UV RadiationDocument10 pagesHydrogen Production From Water Under UV Radiationbjarne9800No ratings yet

- Ablative Flash Pyrolysis of Straw and Wood Bench-Scale ResultsDocument9 pagesAblative Flash Pyrolysis of Straw and Wood Bench-Scale ResultsGiriraj JoshiNo ratings yet

- The Hydrogen Economy PDFDocument15 pagesThe Hydrogen Economy PDFAbhinav GuptaNo ratings yet

- Public A Tiew Ur Co 2 EnergyDocument5 pagesPublic A Tiew Ur Co 2 EnergyEnergiemediaNo ratings yet

- Aquafuel, An Example of The Emerging New Energies and The New Methods For Their Scientific StudyDocument21 pagesAquafuel, An Example of The Emerging New Energies and The New Methods For Their Scientific Studymaadobe27No ratings yet

- Characterization of A Multi-Electrode Common-Ducted HHO Dry CellDocument5 pagesCharacterization of A Multi-Electrode Common-Ducted HHO Dry CellNam stareNo ratings yet

- Sinterizacion Del Cu en WGSRDocument5 pagesSinterizacion Del Cu en WGSRsayonara_3No ratings yet

- CatalDocument16 pagesCatalSoumyadeep PaulNo ratings yet

- 1 s2.0 S001346862101999X MainDocument13 pages1 s2.0 S001346862101999X MainROBSON CardosoNo ratings yet

- Sustainable and Green Electrochemical Science and TechnologyFrom EverandSustainable and Green Electrochemical Science and TechnologyNo ratings yet

- GME SAMPLE Contract - 21Document5 pagesGME SAMPLE Contract - 21Thusith WijayawardenaNo ratings yet

- Pecan and Macadamia Samples 11.15.2022Document1 pagePecan and Macadamia Samples 11.15.2022Thusith WijayawardenaNo ratings yet

- Current Research Track ResidentsDocument5 pagesCurrent Research Track ResidentsThusith WijayawardenaNo ratings yet

- WO2019045261A1Document35 pagesWO2019045261A1Thusith WijayawardenaNo ratings yet

- BehaviouralDocument402 pagesBehaviouralThusith WijayawardenaNo ratings yet

- Ni Hms 898083Document18 pagesNi Hms 898083Thusith WijayawardenaNo ratings yet

- Molybdenum and Its Compounds: 1 Characterization of The SubstanceDocument21 pagesMolybdenum and Its Compounds: 1 Characterization of The SubstanceThusith WijayawardenaNo ratings yet

- Ni Hms 898083Document18 pagesNi Hms 898083Thusith WijayawardenaNo ratings yet

- Investigation of Molybdate Melts As An Alternative Method of Reprocessing Used Nuclear FuelDocument28 pagesInvestigation of Molybdate Melts As An Alternative Method of Reprocessing Used Nuclear FuelThusith WijayawardenaNo ratings yet

- Treatment and Prevention of Childhood Obesity: Sponsored byDocument4 pagesTreatment and Prevention of Childhood Obesity: Sponsored byThusith WijayawardenaNo ratings yet

- Department of XXXXX University of California, Los AngelesDocument5 pagesDepartment of XXXXX University of California, Los AngelesThusith WijayawardenaNo ratings yet

- Material Safety Data Sheet: 1. Chemical Product and Company IdentificationDocument6 pagesMaterial Safety Data Sheet: 1. Chemical Product and Company IdentificationThusith WijayawardenaNo ratings yet

- Clinical Research Coordinator (CRC) Certificate Course: Ucla CtsiDocument9 pagesClinical Research Coordinator (CRC) Certificate Course: Ucla CtsiThusith WijayawardenaNo ratings yet

- QAM - Lancaster Labs PDFDocument279 pagesQAM - Lancaster Labs PDFThusith WijayawardenaNo ratings yet

- Acs Analchem 7b02612Document7 pagesAcs Analchem 7b02612Thusith WijayawardenaNo ratings yet

- Colorsorb XFP21 PDFDocument2 pagesColorsorb XFP21 PDFThusith WijayawardenaNo ratings yet

- Research & Development Report No. RD 2076Document9 pagesResearch & Development Report No. RD 2076Thusith WijayawardenaNo ratings yet

- Smoke in Diesel Engines and CausesDocument3 pagesSmoke in Diesel Engines and Causesgoldy456No ratings yet

- Basic Codes: Location On VehicleDocument7 pagesBasic Codes: Location On Vehicledaniel_jorge_10No ratings yet

- Volvo D16 PDFDocument2 pagesVolvo D16 PDFirwanbahrudin117134No ratings yet

- Shell Helix Ultra ECT C2/C3 0W-30: Performance, Features & BenefitsDocument2 pagesShell Helix Ultra ECT C2/C3 0W-30: Performance, Features & Benefitsteps ongNo ratings yet

- K20 Engine Control Module X2 (LGX) Document ID# 4739091Document3 pagesK20 Engine Control Module X2 (LGX) Document ID# 4739091Data TécnicaNo ratings yet

- 6148 Datasheet 4CHLDocument1 page6148 Datasheet 4CHLLwin PhyoNo ratings yet

- 400 Series 403F-07Document5 pages400 Series 403F-07zohirNo ratings yet

- Analisa GMT John Deere PDFDocument8 pagesAnalisa GMT John Deere PDFHidayatNo ratings yet

- Advance Workshop PumpsDocument24 pagesAdvance Workshop PumpsSachin YadavNo ratings yet

- Yanmar Crawler Carrier C30R-3 Parts Catalog CP663ENMA00101Document194 pagesYanmar Crawler Carrier C30R-3 Parts Catalog CP663ENMA00101gmpmorisNo ratings yet

- Concrete PumpDocument2 pagesConcrete Pumpajeet ranaNo ratings yet

- RT-flex 1Document48 pagesRT-flex 1rafaelNo ratings yet

- Data & Specifications: 3299N030 4-Stroke EnginesDocument9 pagesData & Specifications: 3299N030 4-Stroke EnginesShadi MuhammedNo ratings yet

- Robin Engine EH650 EH650DA JapanDocument29 pagesRobin Engine EH650 EH650DA JapanyewlimNo ratings yet

- 4-Cyl - TDI Engine, 2.0 Ltr. 4-Valve Common Rail (EA 288 Gen. I)Document158 pages4-Cyl - TDI Engine, 2.0 Ltr. 4-Valve Common Rail (EA 288 Gen. I)Valy PadNo ratings yet

- Catalogo de Pecas Comet GT-250Document76 pagesCatalogo de Pecas Comet GT-250André BuenoNo ratings yet

- Werkstatthandbuch Linhai 310 420 600Document514 pagesWerkstatthandbuch Linhai 310 420 600Felix Leone Enache100% (1)

- MAN ME Engine OperationDocument28 pagesMAN ME Engine Operationironmanz316No ratings yet

- Wd10g220e23 (G0311) Engine Parts CatalogDocument99 pagesWd10g220e23 (G0311) Engine Parts CatalogSok Bunnarang0% (1)

- Gol/Parati/Saveiro No. 140 / 1Document17 pagesGol/Parati/Saveiro No. 140 / 1Igmar Franco NegreteNo ratings yet

- Arnes Motor MBE900 EPA 04 PDFDocument1 pageArnes Motor MBE900 EPA 04 PDFDagar GR0% (1)

- Modulo de Ignicion UltimaDocument5 pagesModulo de Ignicion UltimaNelson VargasNo ratings yet

- 645 PM Prior To SN 2032-2Document310 pages645 PM Prior To SN 2032-2crcenginesNo ratings yet

- DATA - Mercruiser 3Document12 pagesDATA - Mercruiser 3Bakri danoNo ratings yet