Professional Documents

Culture Documents

1-A Hybrid MF Process Based On Flotation PDF

1-A Hybrid MF Process Based On Flotation PDF

Uploaded by

Alvaroll Javier Valderramones ZentenoCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 27 How To Make Water in Oil EmulsionsDocument1 page27 How To Make Water in Oil EmulsionsEmontevideo100% (2)

- Branches of Architectural AcousticsDocument26 pagesBranches of Architectural AcousticsGanie MhooreNo ratings yet

- B.E. EceDocument2 pagesB.E. EceJesintha CharlesNo ratings yet

- Soldering and Brazing: MENG16000: Design & Manufacture 1 Manufacturing ProcessesDocument10 pagesSoldering and Brazing: MENG16000: Design & Manufacture 1 Manufacturing ProcessesChen Zhi ShenNo ratings yet

- CMB - Mains - 16-07-2022 - After Corrections at 15.58 On 12-07-22Document5 pagesCMB - Mains - 16-07-2022 - After Corrections at 15.58 On 12-07-22Tanush AgarwalNo ratings yet

- Akkurt 2002 PDFDocument12 pagesAkkurt 2002 PDFDavid ThangaduraiNo ratings yet

- AP Chapter 3b - StoichiometryDocument3 pagesAP Chapter 3b - StoichiometryCacaNo ratings yet

- Uop Parex Process: Scott E. CommissarisDocument8 pagesUop Parex Process: Scott E. CommissarisBharavi K SNo ratings yet

- A Textbook Of: Hemical Ngineering HermodynamicsDocument11 pagesA Textbook Of: Hemical Ngineering HermodynamicsAiswarya RaviNo ratings yet

- Written ReportDocument16 pagesWritten ReportJamel Cayabyab50% (2)

- KU SeriesDocument1 pageKU SeriesRoger Pozo AriasNo ratings yet

- Lurgi 2001 Methanol Casale Experience With A Russian Methanol Project FIMDocument14 pagesLurgi 2001 Methanol Casale Experience With A Russian Methanol Project FIMFer MugrabiNo ratings yet

- PT Chapter 1Document13 pagesPT Chapter 1shubhamNo ratings yet

- Document WPS OfficeDocument5 pagesDocument WPS Officecollins chinsungweNo ratings yet

- Module 1 SiliconDocument4 pagesModule 1 SiliconTriveni M KNo ratings yet

- Lab Experiments - Grade 9 - 2023Document11 pagesLab Experiments - Grade 9 - 2023Steve AntonyNo ratings yet

- Applied Hydraulic Engineering NotesDocument128 pagesApplied Hydraulic Engineering NotesShane RodriguezNo ratings yet

- 125 Amazing Facts About SpaceDocument8 pages125 Amazing Facts About SpaceSolehah Mohammad RodzeNo ratings yet

- BSBF2 - LIGa - US4101317Document20 pagesBSBF2 - LIGa - US4101317Fred Duarte CaldeiraNo ratings yet

- Physical ChemistryDocument43 pagesPhysical Chemistrydrami94No ratings yet

- CSWIP 3.2 Multiple ChoiceDocument10 pagesCSWIP 3.2 Multiple Choicerandhir kumar jha0% (1)

- JBES Vol 14 No 2 P 138 148Document12 pagesJBES Vol 14 No 2 P 138 148Bouaicha FouedNo ratings yet

- Enggzc232 Sep29 FNDocument2 pagesEnggzc232 Sep29 FNkasimNo ratings yet

- Engineering Mechanics QuestionsDocument9 pagesEngineering Mechanics QuestionsHarshil PatelNo ratings yet

- Bphy101l Engineering-Physics TH 10 67 Bphy101l - 221027 211852Document3 pagesBphy101l Engineering-Physics TH 10 67 Bphy101l - 221027 211852Atreya KamatNo ratings yet

- 414CC3 Excel Template Prelim Shell and Tube Heat Exchanger Design Si UnitsDocument3 pages414CC3 Excel Template Prelim Shell and Tube Heat Exchanger Design Si UnitsGuruh Mehra MulyanaNo ratings yet

- Trilogy Connector Design Contact FinishesDocument3 pagesTrilogy Connector Design Contact FinisheschopanalvarezNo ratings yet

- Review On CarbotaniumDocument20 pagesReview On CarbotaniumSahil DalalNo ratings yet

- Reduction Agents Organic ChemistryDocument55 pagesReduction Agents Organic ChemistryvgvijuNo ratings yet

1-A Hybrid MF Process Based On Flotation PDF

1-A Hybrid MF Process Based On Flotation PDF

Uploaded by

Alvaroll Javier Valderramones ZentenoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1-A Hybrid MF Process Based On Flotation PDF

1-A Hybrid MF Process Based On Flotation PDF

Uploaded by

Alvaroll Javier Valderramones ZentenoCopyright:

Available Formats

Journal of Membrane Science 228 (2004) 8388

A hybrid MF process based on flotation

N.K. Lazaridis a , C. Blcher b , J. Dorda b , K.A. Matis a,

a

Section of Chemical Technology & Industrial Chemistry, School of Chemistry, Aristotle University, Box 116, Thessaloniki, Hellas GR-54124, Greece

b Institute for Environmentally Compatible Process Technology (upt) Ltd., Im Stadtwald Geb. 47, D-66123 Saarbrcken, Germany

Received 13 February 2003; accepted 15 July 2003

Abstract

In the present work, a two-stage process was used for zinc ions removal from aqueous solutions. The first stage consists of the sorption of

metal ions onto zeolite and the second one the separation of the metal-loaded sorbent in a hybrid cell. The later combines dispersed-air flotation

and micro-filtration in one unit. The main parameters investigated were zeolite concentration, solution pH, collector type and concentration as

well as the submerged membranes backflush. The higher the zeolite dose the higher the transmembrane pressure and the lower the permeability

was observed. Backflush found to have a small effect on hybrid cell operation, under the studied conditions, while the collector type was

a crucial parameter. Zinc ion removal was almost complete. A 90% zeolite recovery by flotation, which was the foreseen aim, reached

successfully.

2003 Elsevier B.V. All rights reserved.

Keywords: Membranes; Dispersed air; Zeolites; Metal ions; Industrial wastewater

1. Introduction

Integrated membrane filtration processes have been recently developed, usually combined in a bioreactor with

immersed membranes [1,2]. Compared with traditional

wastewater treatment processes, this type of membrane

bioreactors offers several advantages. Fouling control in

these is usually done by air bubbling, creating an upward

air/liquid flown and thus turbulence inside the modules [3].

Air injection has been also used to improve filtration performance (flux, energy consumption) in crossflow filtration

[4,5], in which it was also applied to a ceramic flat sheet

membrane [6]. In the latter, the membrane orientation was

evaluated. For given conditions of aeration, periodic backwashing (15 s every 5 min) gave an additional efficiency

by decreasing internal fouling. Bubbles have been found to

be efficient for limiting particle deposition and polarization

phenomena.

Fouling problems, very low membrane permeability

and low water yield (up to 75%) are the main problems

encountered with conventional membrane processes (i.e.

electrodialysis, nanofiltration and reverse osmosis) applied

Corresponding author. Tel.: +30-2310-997743;

fax: +30-2310-997759.

E-mail address: kamatis@chem.auth.gr (K.A. Matis).

0376-7388/$ see front matter 2003 Elsevier B.V. All rights reserved.

doi:10.1016/j.memsci.2003.07.024

for metal ions removal. High investment costs and periodical membrane cleaning are entailed, while high quantities

of wastewater are generated. On the other hand, selective

adsorbents with fast reaction kinetics for binding the toxic

metals (like zinc) have been practiced for long time [7].

Scope of this paper constitutes the introduction of flotation in the same unit of operation with MF/UF separation,

the impact of this hybrid cell being a new separation technology [8]. In this way, the air bubbles being the necessary

transport medium of particulate matter for flotation would

be also and together used to the vacuum-driven membranes

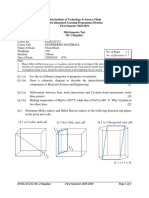

in their cleaning. Fig. 1 gives an idea of the integration of

the process investigated into the overall process for heavy

metals removal from wastewater.

For this reason, the dispersed-air flotation technique was

applied for fine pore diffusion [9]. Flotation is a well-known

separation method both in minerals processing as froth

flotation, where it was originated, and nowadays in water and wastewater treatment [10]. Further, a pilot study

suggested that dissolved-air flotation (DAF) pretreatment

helped reduce membrane fouling in hollow-fiber microfiltration [11]. Membrane fouling by the DAF-pretreated water was characterized by reduced pore blockage and lower

cake compressibility.

The use of a synthetic zeolite (of NaY type) for zinc ion

removal from dilute aqueous solution was published [12], in

84

N.K. Lazaridis et al. / Journal of Membrane Science 228 (2004) 8388

bonding and recycling stage

bonding agents

higher contaminated

water with

toxic metal ions

selective

bondage

of metal ions

separation stage

vacuum-driven hybrid process:

flotation combined with

submerged membranes

membrane

filtration

purified water

for re-use or

discharge

recycled

bonding agent

regenerator/

separator

metal ions

concentrates or

solid metal for re-use

Fig. 1. The two-stage flow scheme for high concentrated (up to 500 mg l1 ) metal ion removal [8].

a combined process later termed as sorptive flotation. Certainly, what is worth noting, in this case it significant to pay

attention to chemical speciation [13]. For a number of years,

zeolite A (4A) has been used in extensive tonnages throughout the world as a builder in detergents to replace phosphates;

lately, the maximum aluminum p-type zeolite (MAP) was

introduced, which has a more flexible structure [14].

2. Experimental

Zinc, used as a mere example of pollutant to be removed,

was the metal ion under investigation. Its initial concentration in the feed solution was 50 mg l1 . The solution

was kept agitated in a feed tank, of around 20 l content,

in a continuous flow rig. Chemical analysis of the metal

in the collected effluent samples was conducted by atomic

absorption spectrometry (AAS), in the standard manner. In

the tank, with the help of mixing the zinc removal by ion

exchange and precipitation was accomplished.

The zinc-bonding agent (adsorbent) used in the present,

as a suitable model system for the separation, was a zeolite of type 4A with chemical structure Na2 O2SiO2

Al2 O3 nH2 Okindly supplied by Ineos Silicas. This zeolite (designated as CA 150), according to the company

information, has an ion exchange capacity of 6 meq. g1

and particle size (sedigraph) 3 m.

The suspension was fed by a peristaltic pump to the constructed cell, at a superficial velocity of 7.4 105 m s1

(liquid flowrate 0.58 106 m3 s1 ), as imposed by the

available membranes area. The duration of each experimental cycle was 550 min, noting that the residence time in the

cell was about 108 min; the respective flotation time was

only 1015 min [12]. The cell was a perspex column with

height 0.48 m and inside diameter 0.10 m. The feed water

was provided to the cell with or without the simultaneous

air supply from the base, through a blower at around one

atmosphere excess pressure. The air superficial velocity

was 8.5 105 m s1 (air flowrate 6.7 106 m3 s1 ).

The arrangement was similar to the type used for

dispersed-air flotation experiments, as normally [15]. The

diaphragm used for air bubbles generation, was from fritted glass (D4 type), with mean pore diameter 1016 m.

Ethanol was applied, if required (at pH 6) as frother, meanwhile reducing the bubbles size.

Hexadecyl or cetyl trimethyl-ammonium bromide (denoted as HDTMA) was the cationic collector applied in natural pH, usually at the concentration of 10 mg l1 and with

conditioning time of 10 min. At pH 6, the anionic collector sodium dodecyl-sulphate was used (60 mg l1 SDS, plus

0.15% v/v ethanol), as found appropriate. Recovery of zeolites, denoted as Rzeo (%), was calculated with turbidity

measurements often coupled by gravimetric measurements

to close the material balance.

The membranes were coming from Hermsdorfer Institut fr Technische Keramik (Thuringia, Germany) and the

module was prepared in upt Ltd., Saarbrcken. The latter,

with two vertical membranes was used here. These membranes were patented ceramic membranes with flat-sheet

multi-channel geometry and hydrophilic surface properties.

The mean pore size was 0.3 m, the pure water flux about

2 m3 m2 h1 bar1 . The membranes surface area was

0.021 m2 . The module was placed at around the one-sixth

of the column height from the bottom, over the air diffuser.

The permeate flux (provided by another peristaltic pump

at the exit) was 2.78 105 m3 m2 s1 . Pressure was

N.K. Lazaridis et al. / Journal of Membrane Science 228 (2004) 8388

It is known that zeolite 4A exchanges its sodium ions by

calcium and magnesium ions in hard waters. In order to elucidate the mechanism of zinc ions uptake by zeolite batch

wise sorption experiments were performed, for 20 min contact time. At the end of sorption the bulk, after filtration, was

analyzed for sodium and zinc content. The following results

were deduced: (i) employing 0.5 g l1 zeolite, at pH = 6,

ion exchange was responsible for 43% of zinc ions removal;

and (ii) employing 2 g l1 zeolite, at pH = 6, ion exchange

was responsible for 99% of zinc ions removal. However,

the latter became about 83% in the presence of 50 mg l1

of calcium ions; hence, a non-selective removal. Generally,

the removal of the metal(s) was a matter of the amount of

bonding agent (zeolites) added.

To shed more light on zinc ion removal mechanism blank

tests were performed versus pH. The following results were

obtained: (i) at pH = 6, zinc precipitation was almost nil;

(ii) at pH 7 it was 51.4%; (iii) at pH 8 it was 94%; and (iv) at

pH 9 it was 99.7% [13]. The natural pH of zeolite was found

around 10.5. From the pH value of about 4.5 and towards the

acidic region, it is noted that the zeolites were dissolving.

The two most common systems with dispersed air are subsurface and mechanical; in the former, air is introduced in

the form of very small bubbles by diffusers or other devices

submerged in the wastewater. Fine bubble aeration results in

more bubble surface area per unit volume, also greater number of bubbles for the same air volume, but lower rise rate

[15]. The size of bubbles that are released is a function of

the pore diameter of the opening, liquid density and surface

tension. The specific role of bubbles size in flotation has

been examined; bubble coalescence was discussed too [16].

Three methods of bubble generation in terms of average bubble diameter, bubble size distribution and power consumed,

during production, were elsewhere published [17].

Table 1 presents some selected results of batch flotation.

The necessity of applying different flotation collector (either

Table 1

Batch flotation results: [Zn] 50 mg l1

[Zeolite] (g l1 )

pH

[Collector] (mg l1 )

Rzeo (%)a

2

2

2

2

6

6

10.5

10.5

[SDS] = 20

[SDS] = 40

[HDTMA] = 10

[HDTMA] = 20

97

>99

71

>96

Batch flotation.

0

-100

Ptm (mbar)

3.1. Metal sorption and loaded zeolites flotation

-200

-300

without air

without flotation

with flotation

-400

-500

0

120

(a)

240

360

480

600

time (min)

1400

3. Results and discussion

SDS or HDTMA) depending on the solution pH was noticed.

It was also observed, from the chemical analysis of surfactants, that as flotation time was increased, the remaining in

the solution collector was decreasing, being transferred by

the air bubbles towards the liquid surface.

Another finding had to do with the influence of zeolite

aging in solution or wetting. At pH 6, a drop of flotation

recovery with time was observed. Zeolites contain large

amounts of water, at ambient conditions; upon dehydration, they undergo considerable structural changes, such as

pore shrinkage, cation migration, and even total collapse

[18]. In this pH case, as a possible counteract, the advantageous use of a polyelectrolyte (2 mg l1 Zetag 87) was

found.

In this observation, a further assistance was given by an

electrokinetic insight, in the laboratory. The measurements

showed an immediate iso-electric point (i.e.p.) of pH 8;

which, however, was moved to about 5.75 when the zeolites were well wet. At acidic pH values under the i.e.p.,

the solid had a positive surface charge, being changed to

a negative charge when overpassing that value, moving towards basicity. This study also helped in the decision of

the suitable flotation collector, according to the conditions.

The -potential was shifting towards the basic or acidic region, when respectively the cationic or anionic surfactant

permeability [L/m hbar]

measured by a transducer installed in the permeate line, for

the calculation of transmembrane pressure, Ptm . The applied backflushing was normally every 30 min for 0.5 min,

as found suitable.

85

without air

without flotation

with flotation

1200

1000

800

600

400

200

0

0

(b)

120

240

360

480

600

time (min)

Fig. 2. Influence of air and flotation on the time variation of (a)

transmembrane pressure and (b) permeability. Experimental conditions:

[Zn] = 50 mg l1 , [zeolite] = 5 g l1 , [HDTMA] = 10 mg l1 , pH = 10.5.

86

N.K. Lazaridis et al. / Journal of Membrane Science 228 (2004) 8388

was added. It is also known that flotation should be working

at optimum conditions [10,15].

So, in the continuous flow experiments (of around 9 h

operation), given in details in the next chapter, with 1 g l1

zeolites in the feed, the zinc removal was 95% at natural

pH and only 85% at pH 6. While, with 3 g l1 zeolites, zinc

removal was 97% at natural pH and 90% at pH 6.

Ptm (mbar)

-100

-200

-300

without air

without flotation

with flotation

3.2. The hybrid flotation-MF cell

-400

0

Ptm (mbar)

-100

-200

-300

without air

without flotation

with flotation

-400

-500

0

120

(a)

240

360

480

600

480

600

time (min)

1400

360

480

600

time (min)

1400

1200

1000

800

600

400

without air

without flotation

with flotation

200

0

120

240

360

480

600

time (min)

Fig. 4. Effect of air and flotation on the time variation of (a) transmembrane

pressure and (b) permeability. Experimental conditions: [Zn] = 50 mg l1 ,

[zeolite] = 1 g l1 , [HDTMA] = 10 mg l1 , pH = 10.5.

permeability [L/m hbar]

240

(b)

1200

1000

800

600

400

without air

without flotation

with flotation

200

0

0

(b)

120

(a)

permeability [L/m hbar]

It was earlier found that the more fine were the air bubbles applied, experienced by inserting in the solution a

frother (ethanol) or changing the mean pore diameter of

the air diffuser used (D2 instead of D4), the lower was the

pressure drop through the membranes. So, this led to the

use of the said sparger, and also the addition of a surfactant

that anyway is required to undergo flotation. The likely explanation to this finding is that the flow with finer bubbles

is more uniform, which means that the small bubbles are

more likely to be effective at the surface of the membrane.

With bigger bubbles, at the same flow rate, it is possible that the main bubble flow passes in a greater distance

from the membrane; thus, creating lower effective shear

rate.

120

240

360

time (min)

Fig. 3. Influence of air and flotation on the time variation of (a)

transmembrane pressure and (b) permeability. Experimental conditions:

[Zn] = 50 mg l1 , [zeolite] = 3 g l1 , [HDTMA] = 10 mg l1 , pH = 10.5.

The air presence, in other words, improved the membranes

operation. Figs. 24 present some of the obtained results

with the operation cell, giving good behavior. Lower transmembrane pressures and higher permeabilities were found

with air flow; at the greater solids concentration this effect

was more apparent and particularly, during flotation. In any

case, there were no zeolites passing through the membranes.

Similar results were found for the other solids concentration tested: for example, with 4 g l1 zeolites, the Ptm

was 120 mbar for the hybrid operation, 250 mbar for air

and 0.1% ethanol present (no flotation), 280 mbar for air

sparging alone, and 350 mbar for only microfiltration. The

respective permeability figures were 800, 400, 363.6 and

285.7 l m2 h1 bar1 .

From the figures, it can be concluded that membrane

performance is to a higher extent influenced by the concentration of zeolites in the bulk solution (related to flotation

efficiency) than by the presence of air. The relative increase

in membrane permeability by introducing air is about 20%,

whereas, if this air is used for flotation, permeability is

nearly doubled.

Then, the effect of the collector was investigated at natural pH (Fig. 5). With 10 mg l1 HDTMA, the Ptm was

140 mbar and the permeability 714.3 l m2 h1 bar1 .

The respective values at the adding of 20 mg l1 HDTMA

were 120 mbar and 800 l m2 h1 bar1 in other words,

N.K. Lazaridis et al. / Journal of Membrane Science 228 (2004) 8388

0

87

0

with

without

-100

800

-100

600

400

-150

-150

-200

-1

-200

0

120

240

(a)

360

480

100

200

300

400

500

0

600

time (min)

600

time (min)

Fig. 6. Effect of backflushing on the time variation of transmembrane

pressure and permeability. Experimental conditions: [Zn] = 50 mg l1 ,

[zeolite] = 4 g l1 , pH = 10.5, [HDTMA] = 10 mg l1 .

1400

200

with backflushing

without backflushing

-1

20 mg L HDTMA

5 mg L HDTMA

permeability [L/m hbar]

Ptm (mbar)

Ptm (mbar)

1000

-50

-50

permeability [L/m hbar]

1200

1200

1000

plain the results. For a batch experiment the zeolites that

are not floated to the surface within the 1015 min flotation

time are not recovered in the froth but remain in the bulk solution. In contrast, in membrane flotation these zeolites are

retained by the membranes and are thus likely to be trapped

by the bubbles or other particles later on and thus finally

also transferred to the froth.

The influence of backflushing was also examined. The cell

was working better than the simple system (without backflushing), as shown in Fig. 6. Again this can be explained by

the membrane operation, as with backflushing the zeolites

that form a cake layer on the membrane surface, are forced

back into the liquid and can be transferred to the froth, thus,

increasing recovery.

Nevertheless, the process at pH 6, even with varied collector, was seen quite problematic (Fig. 7), the possible reasons

were explained in the aforementioned. Table 2 presents further comparisons, being in favor at the natural pH (i.e. giving higher recoveries, greater feed solids concentration, less

of collector). The obtained recovery of 97% is noteworthy.

In wastewater treatment processes, generally, aeration introduces air into a liquid providing an aerobic medium for

microbial degradation of organic matter [9]. In the present,

it may be said that a different application of bubble aera-

800

600

400

200

-1

20 mg L HDTMA

-1

5 mg L HDTMA

0

0

120

(b)

240

360

480

600

time (min)

Fig. 5. Effect of collector concentration on the time variation of (a)

transmembrane pressure and (b) permeability. Experimental conditions:

[Zn] = 50 mg l1 , [zeolite] = 1 g l1 , pH = 10.5.

improved. However, in the latter case difficulties were experienced to control frothing; hence, the used collector concentration was excessive. With 5 mg l1 HDTMA, the Ptm

and the permeability were a little lowered in comparison to

20 mg l1 .

Table 2 shows the comparison with the batch flotation results alone, presenting may be a surprise; which is rather

usual, steady state flotation results to improvement. The

membranes forming a 100% barrier for the zeolites can exTable 2

Comparison between continuous flotation and hybrid system

[Zeolite] (g l1 )

1

2

3

4

5

1

1

1

3

pH

10.5

10.5

10.5

10.5

10.5

10.5

10.5

6

6

a

BF: backflushing.

[Collector] (mg l1 )

[HDTA] = 10

[HDTA] = 10

[HDTA] = 10

[HDTA] = 10

[HDTA] = 10

[HDTA] = 5

[HDTA] = 20

[SDS] = 40

[SDS] = 60

Rzeo (%)

Continuous flotation

Hybrid without BFa

Hybrid with BFa

85

85

78

82

80

89

93

90

93

94

82

89

66

74

97

97

77

88

N.K. Lazaridis et al. / Journal of Membrane Science 228 (2004) 8388

0

1000

-50

Ptm (mbar)

1200

permeability [L/m hbar]

with

without

800

-100

600

400

-150

200

with backflushing

without backflushing

-200

0

100

200

300

400

500

0

600

time (min)

Fig. 7. Effect of backflushing on the time variation of transmembrane

pressure and permeability. Experimental conditions: [Zn] = 50 mg l1 ,

[zeolite] = 3 g l1 , [SDS] = 40 mg l1 , pH = 6.

tion has been investigated. Certain limitations were further

imposed on the parameters examined, like the air flow,

bubbles size and apparatus design. It is necessary to use

the generated bubbles in flotation and membranes cleaning

simultaneously.

4. Conclusions

The hybrid cell is now a reality. The main conclusions of

this work are the following

(a) There was an influence of solids concentration, as expected.

(b) Frothing, with the appropriate dosage of surfactant

and/or frother, should be controlled. Backflushing (gentle) contribution had no important influence and rather

improved the operation.

(c) The results were better at natural pH, where flotation

should be operated. The cells efficiency, expressed as

flotation recovery, was found better than the respective

batch flotation results.

The hybrid cell was observed in the laboratory to work

well: the combination of flotationmembranes filtration

was proved satisfying (recovery of 90%). This means automatically that, in a hypothetical case, if has to separate

a feed with 4 g l1 solid particles (here, the metal bonding

agent), following flotation the actual system, treated by the

membranes will only have the concentration 0.4 g l1 ; with

all its fouling effects onto membranes. It is needless to add

the apparent advantage of having a compact volume of the

hybrid cell and that no energy was necessary for the fouling

control, in addition to that needed anyway for the flotation

separation.

Acknowledgements

This research comprises part from a program funded by

EU, with contract no. EVK1-CT-2000-00083. Many thanks

are due to the coordinator Dr. V. Mavrov (Saarland University) for his help; also, to Dr. M. Webb (ex-Crosfield) for

the zeolites sample and relative information, Ms. E. Peleka

(AUTh) for experimental collaboration and Prof. M. Dohnal

(TU Brno) for useful discussion.

References

[1] C. Blcher, M. Noronha, L. Fnfrocken, J. Dorda, V. Mavrov, H.D.

Janke, H. Chmiel, Recycling of spent process water in the food

industry by an integrated process of biological treatment and membrane separation, Desalination 144 (2002) 143.

[2] E.L.H. Bouhabila, R. Ben Am, H. Buisson, Fouling characterization

in membrane bioreactors, Sep. Purif. Tech. 2223 (2001) 123.

[3] T. Ueda, K. Hata, Y. Kikuoka, O. Seino, Effects of aeration on the

suction pressure in a submerged membrane bioreactor, Water Res.

313 (1997) 489.

[4] C. Cabassud, S. Laborie, L. Durand-Bourtier, J.M. Lain, Air sparging in ultrafiltration hollow fibers: relationship between flux enhancement, cake characteristic and hydrodynamic parameters, J. Membr.

Sci. 181 (2001) 57.

[5] G. Ducom, H. Matamoros, C. Cabassud, Air sparging for flux enhancement in nanofiltration membranes: application to O/W stabilised

and non-stabilised emulsions, J. Membr. Sci. 204 (2002) 221.

[6] M. Mercier-Bonin, C. Lagane, C. Fonade, Influence of a gas/liquid

two-phase flow on the ultrafiltration and microfiltration performances:

case of a ceramic flat sheet membrane, J. Membr. Sci. 180 (2000) 93.

[7] V. Mavrov, T. Erwe, H. Chmiel, Selective separation of heavy metals from industrial wastewater streams, in: A.G. Kungolos, A.B.

Liakopoulos (Eds.), Proceedings of the International Conference on

Protection and Restoration of the Environment, vol. VI, Skiathos

Island, Greece, 2002, pp. 707714.

[8] Internet site, http://www.eurice.de/metasep.

[9] Environmental Protection Agency, Wastewater Technology Fact

Sheet: Fine Bubble Aeration, EPA 832-F-99-065, September 1999.

[10] (a) K.A. Matis, P. Mavros, Recovery of metals by ion flotation from

dilute aqueous solutions, Sep. Purif. Methods 20 (1991) 1, 163;

(b) K.A. Matis, P. Mavros, Foam/froth flotation. Part II. Removal of

particulate matter, Sep. Purif. Methods 20 (1991) 1, 163.

[11] A. Braghetta, J.G. Jacangelo, S. Chellam, M.L. Hotaling, B.A. Utne,

DAF pre-treatment: its effect on MF performance, J. AWWA 89

(1997) 1090.

[12] A.I. Zouboulis, D. Zamboulis, K.A. Matis, Foam flotation of zeolites:

application on zinc ion removal, Sep. Sci. Tech. 26 (1991) 355.

[13] K.A. Matis, A.I. Zouboulis, Flotation techniques in water technology

for metals recovery: the impact of speciation, Sep. Sci. Tech. 36

(2001) 3777.

[14] L.V.C. Rees, Ion exhange in zeolites: detergency and catalytic systems, in: A. Dyer, M.J. Hudson, P.A. Williams (Eds.), Progress in

Ion ExchangeAdvances and Applications, RSC, London, 1997,

pp. 393402.

[15] K.A. Matis (Ed.), Flotation Science and Engineering, Marcel Dekker,

New York, 1995.

[16] Y.S. Cho, J.S. Laskowski, Effect of flotation frothers on bubble size

and foam stability, Int. J. Miner. Process. 64 (2002) 69.

[17] S.E. Burns, S. Yiakoumi, C. Tsouris, Microbubble generation for

environmental and industrial separations, Sep. Purif. Tech. 11 (1997)

221.

[18] A.R. Ruiz-Salvador, A. Gmez, N. Almora-Barrios, M. Mistry,

T. Gibbs, D.W. Lewis, The role of water in determining zeolite

structureinsights from computer modelling, in: P. Misaelilides

(Ed.), Proceedings of the Zeolite02, the 6th International Conference on Occurrence, Properties and Utilization of Natural Zeolites,

Book of Abstracts, AU Thessaloniki, 2002, p. 321.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 27 How To Make Water in Oil EmulsionsDocument1 page27 How To Make Water in Oil EmulsionsEmontevideo100% (2)

- Branches of Architectural AcousticsDocument26 pagesBranches of Architectural AcousticsGanie MhooreNo ratings yet

- B.E. EceDocument2 pagesB.E. EceJesintha CharlesNo ratings yet

- Soldering and Brazing: MENG16000: Design & Manufacture 1 Manufacturing ProcessesDocument10 pagesSoldering and Brazing: MENG16000: Design & Manufacture 1 Manufacturing ProcessesChen Zhi ShenNo ratings yet

- CMB - Mains - 16-07-2022 - After Corrections at 15.58 On 12-07-22Document5 pagesCMB - Mains - 16-07-2022 - After Corrections at 15.58 On 12-07-22Tanush AgarwalNo ratings yet

- Akkurt 2002 PDFDocument12 pagesAkkurt 2002 PDFDavid ThangaduraiNo ratings yet

- AP Chapter 3b - StoichiometryDocument3 pagesAP Chapter 3b - StoichiometryCacaNo ratings yet

- Uop Parex Process: Scott E. CommissarisDocument8 pagesUop Parex Process: Scott E. CommissarisBharavi K SNo ratings yet

- A Textbook Of: Hemical Ngineering HermodynamicsDocument11 pagesA Textbook Of: Hemical Ngineering HermodynamicsAiswarya RaviNo ratings yet

- Written ReportDocument16 pagesWritten ReportJamel Cayabyab50% (2)

- KU SeriesDocument1 pageKU SeriesRoger Pozo AriasNo ratings yet

- Lurgi 2001 Methanol Casale Experience With A Russian Methanol Project FIMDocument14 pagesLurgi 2001 Methanol Casale Experience With A Russian Methanol Project FIMFer MugrabiNo ratings yet

- PT Chapter 1Document13 pagesPT Chapter 1shubhamNo ratings yet

- Document WPS OfficeDocument5 pagesDocument WPS Officecollins chinsungweNo ratings yet

- Module 1 SiliconDocument4 pagesModule 1 SiliconTriveni M KNo ratings yet

- Lab Experiments - Grade 9 - 2023Document11 pagesLab Experiments - Grade 9 - 2023Steve AntonyNo ratings yet

- Applied Hydraulic Engineering NotesDocument128 pagesApplied Hydraulic Engineering NotesShane RodriguezNo ratings yet

- 125 Amazing Facts About SpaceDocument8 pages125 Amazing Facts About SpaceSolehah Mohammad RodzeNo ratings yet

- BSBF2 - LIGa - US4101317Document20 pagesBSBF2 - LIGa - US4101317Fred Duarte CaldeiraNo ratings yet

- Physical ChemistryDocument43 pagesPhysical Chemistrydrami94No ratings yet

- CSWIP 3.2 Multiple ChoiceDocument10 pagesCSWIP 3.2 Multiple Choicerandhir kumar jha0% (1)

- JBES Vol 14 No 2 P 138 148Document12 pagesJBES Vol 14 No 2 P 138 148Bouaicha FouedNo ratings yet

- Enggzc232 Sep29 FNDocument2 pagesEnggzc232 Sep29 FNkasimNo ratings yet

- Engineering Mechanics QuestionsDocument9 pagesEngineering Mechanics QuestionsHarshil PatelNo ratings yet

- Bphy101l Engineering-Physics TH 10 67 Bphy101l - 221027 211852Document3 pagesBphy101l Engineering-Physics TH 10 67 Bphy101l - 221027 211852Atreya KamatNo ratings yet

- 414CC3 Excel Template Prelim Shell and Tube Heat Exchanger Design Si UnitsDocument3 pages414CC3 Excel Template Prelim Shell and Tube Heat Exchanger Design Si UnitsGuruh Mehra MulyanaNo ratings yet

- Trilogy Connector Design Contact FinishesDocument3 pagesTrilogy Connector Design Contact FinisheschopanalvarezNo ratings yet

- Review On CarbotaniumDocument20 pagesReview On CarbotaniumSahil DalalNo ratings yet

- Reduction Agents Organic ChemistryDocument55 pagesReduction Agents Organic ChemistryvgvijuNo ratings yet