Professional Documents

Culture Documents

Quality Docuemnts - PWHF

Quality Docuemnts - PWHF

Uploaded by

Haneefa ChCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Docuemnts - PWHF

Quality Docuemnts - PWHF

Uploaded by

Haneefa ChCopyright:

Available Formats

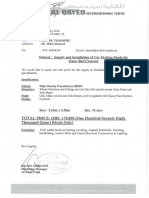

COMPANY:

CONTRACTOR:

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY(PWHF)EXPANSION

QUALITYASSURANCE/CONTROLSYSTEM

The Quality Management System of Target Engineering is based on ISO 9001:2008 role model which

ensures that adequate controls are established and implemented during construction and the final

productisfullycomplyingwiththecontract/COMPANYrequirements.TargetiscertifiedtoIntegrated

ManagementSystem(IMS)byGermanischerLloydsCertificationandtheQualityManagementSystem

isbasedonISO9001:2008,certifiedsince1995.

Quality of works is ensured through implementation of project specific quality plan and procedures,

which ensures that the Company requirements / deliverables for fabrication, construction engineering,

installation, procurement, and precommissioning activities have been clearly identified, systematically

andcorrectlycarriedouttotherequiredstandardandprovidesevidencethathastakenplace,personnel

areawareoftheirresponsibilities;verifyingdocumentsareidentifiedandarecompletedintime.

The quality plan is being prepared considering the Project Quality Assurance requirements Quality

Requirements such as Project Management, Planning, Document / Drawing Control, Change Control,

Purchasing, Material Control, Construction Management, QA/QC and Precommissioning &

Commissioning Plans, Engineering, Records and Test Certificate are addressed in the Project Quality

Plan, Contractors Quality Management Procedure and will be more specifically addressed in various

projectspecificprocedureswhichwillbesubmittedduringexecution.

Theinspectionandtestplans,andqualitychecksheetsdetailthecontrolofallactivitiesandmethodof

verification and recording. Applicable materials / equipments will be inspected by qualified personnel.

Precommissioning and commissioning activities will be covered by Precommissioning and

commissioning procedure. The procedure will be submitted and implemented on Company approval.

The procedure will cover how the various testing will be conducted and formats for recording the test

results.

MaterialtestingrequirementsoftheProjectwillbecompliedwith.TheproposedTestingLaboratorywill

comply with the requirements in terms of accreditation, qualification, quality system, procedures,

personnelandequipment.

Further detail regarding how the various activities on site comply with ISO 9001 requirements and the

controlsappliedaredescribedintheProvisionalProjectQualityPlanT2368PSP401andingeneralinthe

IMS Manual. CONTRACTOR will fully coordinate with Company on establishing and implementing a

project specific ISO 9001:2008 compliant quality management system on site, as detailed by our project

qualityplan.

Attachments:

ContractorsCompanyQualityPolicy

ISO9001:2008Certificate

ProjectSpecificQualityPlan

ContractorsCompany IntegratedManagementSystem(IMS)Manual

COMPANY:

CONTARCTOR:

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY(PWHF)EXPANSION

ContractorsCompanyQualityPolicy

COMPANY:

CONTARCTOR:

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY(PWHF)EXPANSION

ISO9001:2008Certificate

COMPANY:

CONTARCTOR:

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY(PWHF)EXPANSION

ProjectSpecificQualityPlan

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

2of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

Contents

Number

PageNumber

RevisionHistory,ApprovalsandDistributionList

IndexofContents

Description

1

2

1.0

1.1

1.2

1.3

1.4

INTRODUCTIONANDPURPOSE

ScopeofApplication

ReferenceDocumentsandPrecedenceLevel

COMPANY/CONTRACTORCoordination

34

Issue/RevisionControl&Distribution

DEFINITIONS

QUALITYPOLICY,OBJECTIVESANDCOMMITMENT

67

4.0

QUALITYMANAGEMENTSYSTEM

Documentation/CoordinationRequirements

812

5.0

MANAGEMENTRESPONSIBILITY

ManagementCommitment

Responsibility,AuthorityandCommunication

InternalCommunication

ManagementReview

1314

6.0

RESOURCEMANAGEMENT

ProvisionofResources

HumanResources

Infrastructure

WorkEnvironment

15

7.0

PRODUCTREALIZATION

PlanningofProductRealization

CustomerRelatedProcess

DesignandDevelopment

PurchasingandSubcontracting

ProductionandServiceProvision

ControlofMonitoringandMeasuringDevices

1623

8.0

MEASUREMENT,ANALYSISANDIMPROVEMENT

Monitoring&Measurement

CustomerSatisfaction

InternalAudit

Monitoring&MeasurementofProcesses

Monitoring&MeasurementofProduct(InspectionandTesting)

SiteLaboratory/Testing

FieldInspectionCoordinationProcedure

ReceivingInspection

InprocessInspectionandTesting

FinalInspectionandTesting

ControlofNonConformingProduct

AnalysisofData

ImprovementCorrectiveandPreventiveActions

2431

LISTOFATTCHMENT

9.0

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

3of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

1.0

INTRODUCTIONANDPURPOSE

This quality plan describes Target Engineering Construction Companys (hereafter referred as

CONTRACTOR)proposedQualityManagementSystemasapplicabletotheprojecttitled,

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY(PWHF)EXPANSION

As part of CONTRACTOR commitment to quality, this project is covered by a Project Specific

Quality Plan I n compliance with the relevant elements of ISO 9001:2008 as applicable to the

project.

This quality plan ensures that CONTRACTOR has specified the policies, the objectives,

establishedasystemofprocedurestoaccomplishthem,assignedduties,delegatedauthorityand

set up suitable inspection, testing, examination and audit programs to verify that the requisite

standardsofperformanceandcustomer(COMPANY)satisfactionareachieved.

Thisqualityplanisdesignedtoaccomplishanddemonstrateachievement/complianceof/toall

contractual material, equipment and services quality, performance and workmanship

requirementsspecifiedbyTender/ContractandtheCOMPANY.

HSEmanagementsystemisaddressedseparatelybyHSEPlan,Ref.DocumentT2368PSP501.

1.1

ScopeofApplication

Thisqualityplanisoverallapplicableforthecaptionedproject.Thescopeoftheprojectconsistsof

engineering, site surveys, detailed design, procurement, transportation, site preparation, civil

works,fabrication,installation,erection,construction,tiein,precommissioning,andassistancein

commissioningof thefollowingProducedWaterHandlingFacility(PWHF)ExpansiononHalul

Island.

The scope of work is more specifically mentioned in the company provided tender documents

(ExhibitA)andspecifications.

1.2

ReferenceDocumentsandPrecedenceLevels

Thefollowingmatrixshowstheinterrelationshipandtheprecedencelevelsofthevariousquality

relateddocumentstobeimplementedinthisproject.

ReferenceDocuments

1. ContractAgreement

2. SpecificationandDrawings

3. COMPANYProjectCoordinationProcedure

4. COMPANYQualityManagement,Quality

AssuranceandProjectQualityPlan

5. COMPANYQualityManagement

Requirements

PrecedenceLevel

Agreement/Contract,Drawings&Specs

ProjectQualityPlan,ISO9001:2008,Project

Procedures,Inspection&testPlans

ApprovedInspectionandTestPlans

ApprovedMethodStatements

TargetCorporateProcedures

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

4of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

1.3

Company&ContractorCoordination

Where applicable and instructed coordination will be done by using CONTRACTOR provided

procedure&formats,insteadofSUBCONTRACTORprocedure&formats.

1.4

Issue/RevisionControl&Distribution

This quality plan is prepared by CONTRACTOR and it is a provisional copy meant to be

submitted along with the bid. It will be resubmitted for approval during mobilization phase on

contractawardandshallbeapprovedbytheCOMPANYforimplementationonsite.Atthetime

ofContractawarditwillbeacontrolleddocumentandtheSiteQA/QCManagerwillcontrolits

issueanddistribution.Alistofcontrolledcopyholderswillbemaintainedonsite.RefDocument

DistributionMatrix.FormNo.T2368FM40114,

Revisions may be necessary to incorporate COMPANY Instructions or as a result of site

requirements/correctiveactionsagreedduringinternalaudits.Allrevisionsareconductedbythe

QualityManager(delegatedtotheSiteQA/QCManagerasrequired)andallholdersofcontrolled

copies will be issued latest revised copies whenever revisions are effected and approved by

COMPANY.

The first revision is 0 followed by 1, 2 and 3 on subsequent revisions. The revision number is

indicated on every page as can be seen in the header. Wherever practical, the changes /

modificationsoramendmentsareindicatedbyaverticallineintheleftmargin.

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

5of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

2.

Definitions

COMPANY

QatarPetroleum

CONTRACTOR

TECHNIP&TargetEngineeringConstructionCompany(TARGET)

Consortium

PROJECT

EPCI Halul Island Produced WaterHandling Facility (PWHF)

Expansion

DOCUMENT

Any form, letter, facsimile, contract, subcontract specification,

drawing,orrecordofanykindrequiredtotransmitinformationfrom

onepartytoanother.Italsoincludescomputergenerateddrawings,

lists, charts, etc. andother datausedtoforma permanent recordof

theProjectProgressandAsBuiltcondition.

SUBCONTRACTOR

Any person, firm, or company employed by CONTRACTOR to

performanyworkordutyonCONTRACTORsbehalf.

VARIATION

Any and all changes in or relative services and amendments to the

agreement.

VENDOR

Anyperson,firmorcompanycontractedtosupplyanymaterialor

serviceinconnectionwiththisproject.

IMS

IntegratedManagementSystem(CompliancetoISO9001,ISO14001

andBSOHSAS18001ManagementSystems)

ITP

InspectionandTestPlan

RFI

RequestForInspection

TQ

TechnicalQuery

HSE

Health,Safety&Environment

NCR/CAR

NonConformanceReport/CorrectiveActionRequest

MAR

MaterialApprovalRequest

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

6of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

3.

QUALITYPOLICY,OBJECTIVEANDCOMMITMENT

3.1

The Contractor Quality Policy Statement declared in IMS Manual, extract of our quality policy is

reproducedbelow.ThesignedcopyisattachedasExhibit2.

Target engineering Construction Company provides construction engineering solutions: design,

engineering,Procurement,ConstructionandCommissioningofOnshoreandOffshoreCivil,Mechanical,

Electrical and Instrumentation Projects, Piping Systems & Vessels / Tanks Fabrication and Installation,

MarineConstructionProjectsandmarineTransportOperations.

It is the Companys Policy to ensure that the all projects are executed in accordance with contract

specifications and drawings, within the contractual time frame, and the compliance with all legal

requirementsthusprovidinggoodvalueandsatisfactorytoourClient.

This quality policy will be abasis of ourQuality Management System and shallprovidea frameworkfor

settingandreviewingqualityobjectivesandtargets.

Thequalitymanagementsystemadoptedwillcomplywithalltheapplicablerequirementsoflatesteditionof

ISO9001QualityManagementSystemsRequirements.

The Company Management is committed to continuously improve the effectiveness of the quality

managementsystembyanalyzingcustomerfeedback,conductinginternalaudits,importingtrainingwhere

necessaryandreviewoftheQualityManagementSystem.

We believe that our clients, employees, suppliers/subcontractors and the society in general are important

contributorsinourbusiness.Thisfactwillbeevenlyconsidersinouroverallbusinessdealingsvisvisthe

interestsofCompanyShareholders.

Thepolicyisapplicabletoallbranches,divisions,sitesandsubcontractors.Itwillbedisplayedinofficesand

allsites,anditistheresponsibilityofboththemanagementandemployeestobeawareofthisqualitypolicy

andapplicablecompanysystemsrelevanttoonesareofworks.

Thispolicywillbereviewedforadequacyandeffectivenessduringthebiannualmanagementreviews.

Date:16thApril2014

SignedChaouciYassine,ChiefExecutiveOfficer

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

7of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

3.2

QualityObjective

The Quality objectives are set in order to achieve, maintain a performance level to achieve

customer(COMPANY)satisfaction.

Theobjectivesforthisprojectarelistedbelow:

Objectivesforthisproject

1Quality

CompliancetoProjectSpecifications,Requirements&Drawings.

CustomerSatisfactionLevelMinimumLevel2.

(Satisfiedtominimum80%)

Customer Satisfaction Survey midway during execution and towards end

ofproject

Auditsconductedasperschedulewithin5%ofProjectProgress.

Non Conformances Issued by COMPANY to be replied within 3 working

daysandclosedwithinanaveragetimeof4weeks.

2HSE

Fatalities

: 0

FrequencyRate

: 0LTA/MillionManHour

SeverityRate

: 0DayLost/MillionManHour

FireIncident

: 0

NearMissReporting

: AsManyasPossible

VehicleIncident

: 0

PropertyDamage

: 0

EnergyConsumption

: AsMinimumasPossible

Analysis and update on Quarterly

Aspects/Impact

:

Basis

Compliance to all applicable legal

PollutionControl

:

requirements

Note:DetailHSEObjectivewillbeavailableinProjectHSEPlan

3Design

Compliancewithalldesignrequirements.

CompletionofDesignwithintheapprovedschedule.

AimforCOMPANYapprovalofalldesigndeliverableswithinmaximum3

submissions.

4Procurement Identificationandlistoflongleaditemswithfourweeksofaward.

Compliancetoallspecification,drawings,codesandstandard.

Compliancetoapprovedschedulefordelivery.

Compliancetoallinspectionrequirements,intervention,scheduleandon

timenotification.

5Construction Completionofallworksasperapprovedscheduleofworksandwithinthe

/Progress

earlylatedates.

CompletionwithinMilestones.

ProgressReportssubmittedwithinstipulatedtime;WeeklyProgressReport

byMonday,MonthlyReportwithin5thdayinthe1stweekofeverymonth.

6CostControl Actualcostswithinbudget.

CostcontrolreportstoCorporateOfficeonamonthlybasis.

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

8of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

4.

QUALITYMANAGEMENTSYSTEM

4.1

General

CONTRACTORwillimplementandmaintainthequalitymanagementsystemforthisprojectas

detailedinthisqualityplantogetherwithallapplicablecontractualdocumentsreferredinsection

1.2.

CONTRACTOR is committed to continually improve the effectiveness of the IMS by religious

implementation and planned internal audits. Ongoing improvements / suggestions and

recommendationsfromCOMPANYwillbeimplemented.

The following five sections describe how CONTRACTOR will execute the project whilst

complyingwithISO9001:2008requirements.

4.1.1

InteractionandApplicationoftheProcesses

Thekeyprocessesaregroupedintothreemainprocessgroups

KeyProcessGroup1)Management,ResourcesandAdministration(sections56)

KeyProcessGroup2)Project/ConstructionOperations(Section7)

KeyProcessGroup3)Measurement,AnalysisandImprovement(section8)

These process groups satisfy the ISO 9001:2008 requirement for processes in that they include

Management Responsibility (ISO 9001:2008, #5),Provision of Resources(#6),ProductRealization

(#7)andMeasurement,AnalysisandImprovement(#8).

Process1)Management,ResourcesandAdministrationcoversallthemanagementactivitiesof

planning, implementing and managing the system and determining and providing those

resourcesneededtooperatethesystemeffectivelyandassureproduct/serviceconformity.

Process1)enablesProcess2)Project/ConstructionOperationstotakeplaceinaplannedand

systematicwayinordertocomplywithcontract/projectrequirementsandeventualCOMPANY

satisfaction and realization of payments. Process 2) covers all those elements of product and

servicerealization,thoseactivitiespertinenttothequalitymanagementsystemwhichtakeplace

duringtheplanning,purchasing,design,installationoftheproductorserviceandrelatedtesting

andcommissioningworks.

Process3)Measurement,AnalysisandImprovementmeasuresandmonitorstheeffectiveness

ofProcess1)andProcess2)andprovidesfeedbacktothoseprocessesforimprovement.

4.2

DocumentationRequirements

The project quality management is documented by this quality plan and associated project

procedures as may be developed, together with the corporate IMS Manual and procedures and

projectspecificmethodstatementsthatwillbedevelopedfortheproject.

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

9of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

4.2.1

DocumentationStructure

The following three levels of documentation will be utilized and maintained to satisfy the

requirementsoftheProjectandISO9001:2008andtoensureadequatecontroloftheprocesses.

LevelI

QualityPlan

ContractDocumentstakeprecedence(Agreement,Specs,and

Drawings)

LevelII

Design,DetailEngineering,ResidualEngineeringand

ProjectSpecificProceduresasrequired,QualityControl

Plans/InspectionandTestPlanMethodStatements

LevelIII

QualityRecords

TheabovewillbecomplementedbytheCONTRACTORsCorporateIMSManualandtheQuality

ManagementProcedures,acopyofwhichisavailableonsite.

4.2.2

Document&DataControl

Document control will ensure that valid issues of documents related to the project are available

andusedintheexecutionofthework,andthatobsoletedocumentsarepromptlyremovedfrom

all points of use. Timely Distribution is controlled and is detailed in the Document Distribution

Matrix,Ref.DocumentT2368FM40114

WhereapplicableandinstructedspecificCOMPANYreportingformatswillbeimplementedand

utilized instead of CONTRACTORs formats. A valid document register indicating contract

documentsasreceivedfromCOMPANYwillbemaintained.

Any obsolete document is either destroyed or if need to be retained these are clearly marked

SUPERSEDED.

All documents will be uniquely numbered as explained in 4.2.3. Forms within a procedure are

numbered with a prefix FM after the project code. For example T2368PQP401 is the Project

Quality Plan and a form belonging to this procedure / plan is numbered as T2368FM40114

DocumentDistributionMatrix.

4.2.3

DocumentNumberingSystem

CONTRACTORproposednumberingsystemforqualityrelateddocumentsareexplainedbelow.

However,CONTRACTORmayadoptanynumberingsystempreferredbyCOMPANY.

a) Allprojectdocumentshavebeencategorizedwithabbreviationsasunder.

Table1CategoryofDocumentsandProjectCode

No

1

2

3

4

5

6

TargetEngineeringConstructionCo.

DescriptionofDocument

ProjectSpecificProcedures

MethodStatement

InspectionTestPlans

QualityChecksheets

Forms

ProjectCode

Abbreviation

PSP

MS

ITP

QC

FM

T2368

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

10of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

b) Uniqueserieshasbeenallocatedforvariousprojectmanagement/controlactivities.Theseare

reproducedasunder:

Table2ProjectActivitySeries(tobedevelopedasrequired)

SeriesNo

0100

0200

0300

0400

0500

1000

2000

3000

4000

ProjectActivities

ProjectManagement

EngineeringandDesignControl

Material,ProcurementandSubcontracting

QualityManagement

Health,SafetyandEnvironmentManagement

Civil/StructuralMethodStatements&ITPs

MechanicalMethodStatements&ITPs

ElectricalMethodStatements&ITPs

AnyOthersMethodStatements&ITPs

The numbering system for all documents described above is a simple alphanumeric system

giving the category of the document, the project reference, the serial number (3 digits for

Procedures and an extended digit for related Forms and Quality Checksheets) within the

Procedure/ActivitySeries.

Table3NumberingSystemBlockDiagram.Eachblockbeingseparatedbyahyphen

1

ProjectReference

T2368

2

Category

of

the

Document

PSP = Project Specific

Procedure

MS=MethodStatement

ITP = Inspection and

TestPlan

F=Form

QC

=

Quality

Checksheet

3

Three/Four Digits Serial Number for

Procedures, Method Statements, ITPs as in

Table 2 with extended digits for forms and

QualityChecksheets

E.g.ProcedureSeries

101,102,2368,201,202401,402,.etc.

1001,1002,2001,2002.,etc

Forms&Checksheetswithinagivenprocedure

followthesame3digitnumberfollowedby1,2,

3andseparatedbyahyphen

E.g.FormswithinProcedure

T2368PSP101willhavenumbers

T2368FM1011,T2368FM1012etc.

c) All documents will have full reference to the Project / Agreement Number and will have the

documentnumber,revisionnumberanddateonwhichthedocumentwasmade.

d) The first submission will have a Revision

submissionswillhaverevisionnumbers1,2,3andsoon.

Number

and

subsequent

f) Status of submission and approval will be updated every time a submission is made and

COMPANYcommentsarereceived.

g) Monthly status reports on submissions / approval will be issued by the Document Controller.

FollowuponsubmissionswillbedonebyCONTRACTORProjectManager.

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

11of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

h) Approval category legends for documents as specified in Tender by CONTRACTOR will be

complied with. The status code for drawings and other documents shall be as shown in the

followingtable:

Table4ApprovalLegendsforDrawingsandOtherDocuments

CONTRACTORProposedCOMPANYApprovalLegends

Approval

Code

A

Explanation

Accepted,proceedwithwork

(NoAdversecommentsonthesubmittal,Workmaybecarriedout.NoRe

submittalrequired)

Acceptedwithcommentsincorporate/takeintoaccountcommentsand

proceedwithworks

(Revise and Resubmit as applicable. Work may start taking into account

Company`scomments)

Revise and resubmit for approval incorporating comments by

COMPANY,norelatedworktostart

(ReviseandResubmitasapplicable)

NotAccepted,reviseandresubmitforapproval,norelatedworktostart.

(Resubmissionwillbeconsideredasfirstsubmission)

4.2.4

Letters/FaxesandDocumentTransmittalsNumbering

The letters and fax numbering system will be as agreed with the COMPANY. The

CONTRACTORs Project Manager together with the Site Secretary / Document Controller is

responsibleforcontrolofalldocumentsandinformingallaffecteddepartments/personnel.

Incoming/OutgoingMail

Allincomingmail/correspondence,documenttransmittalsarestampedtoindicatedateofreceipt.

The CONTRACTORs Project Manager then reviews and indicates further distribution (to

CONTRACTORsHOandrelevantsubcontractors)andactionbyothers.

ProjectSpecificCorrespondenceisloggedinIncomingMailRegister.

Thesecretary/documentcontrollerwilltrackandensurethatCONTRACTORsProjectManager

respondstoCOMPANYcorrespondence.

4.2.5

Drawings

All project design and shop drawings shall be uniquely numbered with indication of latest

revisions as per the agreed drawing numbering system. COMPANY Engineering Document

Numbering will be complied with. Wherever practical, the changes themselves are indicated by

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

12of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

clouding and placing the revision number in a triangle beside the cloud. All drawing submittal

andapprovalstatusistrackedusingtheDrawingSubmittalandApprovalLog.

AsBuiltDrawings

As built mark ups are continuously marked during execution by the Surveyor / Site Engineer.

After incorporation of these as built mark ups in the drawings, the AS BUILT drawings are

submittedforapprovalfromCOMPANY.CommentsbyCOMPANYwillbefurtherincorporated

until the As Built Drawings are approved. Submission requirements for As Built Drawings as

indicatedinthecontractwillbefollowed.

4.2.6

ControlofQualityRecords

Thefollowingqualityrecordswillbemaintainedonsite:

a)

b)

c)

d)

e)

f)

g)

h)

i)

j)

k)

l)

m)

n)

o)

p)

q)

r)

s)

t)

u)

v)

w)

ProjectProgress

QA/QCPersonnelonSite

ConstructionQualityPlanStatus

UpdatedStatusofQualityDocumentationSubmittalsandapprovalstatuswithHighlights

ofChangesduringthemonth

StatusofRequestforInspectionandTesting

Rejectionsduringreceivinginspections

DetailsofanyTestfailure

FrequencyTestConductedfortheMaterial(Forthecurrentmonth)

Concretecompressivestrengthtestsconducted

Fielddensitytestsconducted

UpdatedStatusofTechnicalQueryincludingsummary

SummarystatusofCOMPANY/InternalAuditsandcorrectiveactionrequests

NonConformanceStatus

OngoingCorrectiveandPreventiveActions

WeldJointStatus(Ifapplicable)

StatusofWaivers

Customersatisfactionsurveydetails

Commissioningdetailsforthesystem(Asapplicable)

Instrumentcalibrationrecords

Summaryofmeetingsandoutstandingissuesdetails

Punchliststatus(Asapplicable)

Detailsoftrainingconducted

Anyotherissues

Generally these records are filed in sequence so as to make the final hand over a convenient

exercise.ThehandoverdossieriscompiledbasedontheMasterIndex(tobesubmittedlaterand

willbeagreedwithCOMPANY)asrequired&approvedbytheCOMPANY.

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

13of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

5.

MANAGEMENTRESPONSIBILITY

CONTRACTORs Management is committed to implement an effective quality management

system on site. Communication of this commitment will be done by periodic reminders of the

needandimportancetomeetingCOMPANYandregulatoryrequirements.

CONTRACTOR will also ensure regular interactions with COMPANY and comply with

specificationrequirementsandapproveddrawings.Commitmentsmadeduringmeetingswillbe

implemented.

CONTRACTOR quality policy has already been detailed in section 3 and is the basis of

CONTRACTORsQualityManagementSystem.Specificprojectobjectiveshavebeenindicatedin

section3.2.Thesewillbeverifiedduringinspectionsandaudits.

5.1

Responsibility,AuthorityandCommunication

Theprojectwillbemanagedwithadequateresourcesonsiteforexecutingcontractrequirements.

The siteorganizationis detailedby theProjectOrganizationChart, copyofProject Organization

Chartcanbefoundinattachmentsforreference.Updatedorganizationchartmaybefoundatsite

andismaintainedcurrentbytheProjectManager.UpdateswillbesubmittedtoCOMPANY.

CONTRACTOR site team will be fully complemented by the CONTRACTORs corporate Head

OfficesupportintermsofEngineeringdrawings,Procurement&Expediting,QualityAssurance,

HSEManagementandcontractadministration.

Thekeypersonnelreporting&interactionisshownontheorganizationchart.Theresponsibilities

ofthekeypersonnelcanbefoundinattachmentstothisplan.Theformalpointofcontactwillbe

the Project Manager. The Project Manager reports directly to the Division Manager / Chief

Operations Manager, who represents Sr. Management of CONTRACTOR and is, authorized to

dealwithtechnocommercialissuesoftheproject.

TheQualityManagertogetherwithhisSiteQA/QCManagerisresponsibleforallqualityissues.

The quality personnel and the HSE personnel on site are independent and haveaccess to senior

managementforallissuesonqualityandsafety.

5.2

InternalCommunication

CONTRACTORwillensurethatallinternalcommunicationsareeffectiveeitherverbalorwritten

format (memos). Copies of Company / internal correspondence will be copied to relevant

personnel.Sitemeetingsforcoordinationandprogresswillbeheldinternally.

Priortothecommencementofmajorworkactivities,aninitialqualitysysteminductiontraining

session will be conducted by the Site QA/QC Manager. This training induction will include

persons who will conduct or be involved with a quality function. The training will include the

proper use of this Project Quality Plan, the use of the project specific procedures, the

implementation of the inspection and test plans and maintenance of quality records. Routine

RefreshertrainingwillbedoneonthejobbytheQA/QCEngineer.

Project related scope of works and highlights will be addressed by Division Manager and the

ContractorsProjectManager.

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

14of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

The Corporate Quality Manager and the Site QA/QC Manager are organizationally independent

andassuchhavethenecessaryfreedomandauthoritytocarryouttheQualityRelatedActivities/

dutiesrequiredforthesuccessfulexecutionoftheproject.

5.3

ManagementReview

Formal Management Reviews of the overall CONTRACTORs Quality System are done at least

twice a year to ensure continuing suitability and effectiveness in satisfying the requirements of

contracts and the ISO 9001 standard. Statistics for the captioned Project for the applicable areas

willalsobeconsideredforoverallCONTRACTOR`sManagementReviewThisreviewbySenior

ManagementconsiderstheresultsoftheinternalqualityandHSEaudits,theCOMPANYaudits,

Nonconformancesandthecorrective/preventiveandimprovementactions,trainings,customer

satisfactionsurveyresponse/feedback,customercomplaintsandHSEstatisticsfortheProjects.

Evaluationsduringthesereviewsformthebasisofanychangesintheprojectqualitysystem.This

managementreviewwillberecordedeitherasareportorasminutesandcirculated/maintained

bytheQualityManager.Allrecommendationsandactionpointsarisingoutofthisreviewwillbe

acteduponwithinagreedtimes.

The review participants will include the CONTRACTORs Senior Management, Division

ManagersandCorporateQualityandHSEManagersasrequired.

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

15of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

6.

RESOURCEMANAGEMENT

6.1

ProvisionofResources

CONTRACTORwillensurethatallresourcesrequiredforthesuccessfulexecutionareprovided

within time. These resources include manpower, equipments, site facilities, computers, lifting

toolsandtackles,storagespace,personalprotectiveequipment,instruments,andmachinery.

Details of these as made in technical submissions during tender / and those committed by

programme / and required to successfully complete the project will be mobilized to site in

accordance with the programme requirements. All necessary resources for implementing the

quality management system on site will be provided for Sufficient personnel, document

controlleranddocumentcontrolsystemsincludingtrainedauditors.

6.2

HumanResources

6.2.1

General

CONTRACTOR will ensure that only competent personnel with sufficient qualifications /

experience and / or training will be utilized on the project site. CONTRACTOR believes that all

proposedkeypersonnel/seniorpositionsarecompetenttoleadthisprojectandgenerallycomply

withtherequirementsofCOMPANY.WenoteandunderstandCOMPANYrighttointerviewand

approvethesekeypersonnelbeforeutilizationonsite.

6.2.2

AwarenessandTraining

Regulartrainingsessionsfollowingtheinitialinductiontrainingwillbeconductedonsitetokeep

and update the personnel, contract and technical requirements. Training needs on site will be

identifiedbytheSiteEngineer/SiteQA/QCManager/LeadHSEEngineer.HSEtrainingwillbe

conductedinaccordancewith theHSE Training Matrix attachedwith HSE Plan T2368PSP501.

Necessarytrainingforanyspecializedactivityshallbeprovidedtopersonnelasapplicable.Any

othertrainingforspecialistoperationsonsitewillbeprovided.

6.3

Infrastructure

All equipment deployed on site will be fit for use on site. Authority requirements / Legal

requirements and COMPANY requirements for vehicles, lifting equipment and tackles will be

compliedwith.

6.4

WorkEnvironment

Proper infrastructure, Safety Tools and Tackles, necessary rest / ablution facilities and other

requirement to provide a safe conducive work environment will be provided. This will help to

ensureprovisionofconstructionservicesinconformitywithCOMPANYrequirements.Necessary

safetyproceduresandrelevantcontractrequirementswillbepostedatpertinentlocations.

All COMPANY and CONTRACTORs Corporate Safety requirements will be proactively

implemented onsite to ensure safe working environment and to ensure project is successfully

executedwithoutfatalities,losttimeaccidentsandlosttimeincidents.

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

16of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

7.

PRODUCTREALIZATION

7.1

PlanningofProductRealization

Theprojectwillbeexecutedstrictlyinaccordancewiththecontractspecificationsanddrawings,

approvedproceduresandprogrammes.CONTRACTORsPlanningPackage/Programmewillbe

submitted separately. COMPANY applicable reporting formats will be utilized. Only approved

materialswillbeutilizedintheproject.SubcontractorsasapprovedbyCOMPANYwillbeutilized

onsite.

ThewholeprocessofProject/Constructionoperationscanbesplitas:

Contract review which is done at tender stage and again will be done immediately after

award

DesignControldetailengineeringandshopdrawingswillbesubmittedtoCOMPANYfor

approval,e.g.workingdrawingsandshopdrawings

PurchasingControluseofapprovedmaterialsandsubcontractorsandstorecontrol.

Inspection and Testing including receiving inspection, in process inspections and testing,

inspectionsatvendorpremises,testingandcommissioning

Handover

MorespecificallytheQA/QCactivitieswillbegovernedtoensurethefollowing:

IncorporationofCOMPANYrequirementsduringCONTRACTORsdetailedengineering(see

Para7.3.1to7.3.7).

Ensuring quality of material / equipment by reviewing materials data sheets, FAT for

equipmentsandsecuringpreapprovalandreceivinginspection.

Ensuring quality of installation by checks during and after installation. Refer list of Method

StatementandInspectionTestPlaninattachment9.3.

Finally closing out of all snags / nonconformances raised by COMPANY or internal by

CONTRACTOR.

All the above processes forming the Project / Construction operations are covered by corporate

procedures and / or project specific procedures (See attachment 9.3: Document Submission

Schedule). Records required to demonstrate compliance are indicated in each of the procedures,

whichwillbeverifiedduringinternalaudits.

Method Statements for critical activities will be submitted to ensure planning of the detailed

constructionactivitiesincludingspecificationrequirements,equipment,andpossiblehazardsand

controlmeasureswhichneedtobeinplaceforasafeoperation.

7.2

CustomerRelatedProcesses

CONTRACTOR will review the contractual requirements in detail at the time of tender, post

tender negotiations and on award of contract. All addenda and bulletins issued during tender

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

17of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

period, post tender clarifications and other queries are all will be retained as contractual

documents.

Where requirements are not clear, the COMPANY will be contacted and clarifications will be

soughtusingtheTechnicalQueryformat,see7.2.1below.Recordsarekeptofallreviewsandany

exchanges of correspondence on contractual requirements and are filed as evidence of contract

review.ExampleMinutesofMeeting

The post award contract review will be done in CONTRACTORs Head Office and will be

attended by the CONTRACTORs Division Manager, the Quality Manager and the Project

Managerand/orhisdeputy.

7.2.1

ClarificationsonSite

Anyclarificationsondrawings,scopeofworks,contractualrequirementsareassessedbymeansof

aTechnicalQuery.AllTechnicalqueriesaretreatedascontractualdocumentsandwillformpart

of the final hand over documentation. COMPANY responses will be copied to relevant

departments/personnel.

7.2.2

Variations/SiteMeasurements

TheVariationProcedureaswillbeagreedbyCOMPANY.Allinstructionsconstitutingvariations

willbeproperlydocumentedandprocessed.

7.3

DesignandDevelopment

7.3.1.1

The design works as applicable for the Project will be undertaken by CONTRACTORor by any

COMPANY approved engineering design subcontractor. Coordination meetings and site visits

willbeconductedtoknowandunderstandCOMPANYrequirementsindepthanddetail,which

willbeincorporatedindesign.

7.3.1.2

NecessarymeetingswillbeconductedwithCOMPANY,andrelevantpartners(ifany)toagreeon

thereviewstages,deliverablesandsubmissionschedule.Responsibilitiesofeachofthemembers

ofthedesignteamwillbeestablished.Ingeneraltheseresponsibilitiesaresummarizedbelow:

No. Member

COMPANY

CONTRACTOR

SubContractor

TargetEngineeringConstructionCo.

Responsibilities

ApprovalofDeliverables,DesignComputations&

RespondingtoClarifications

/ CompileDesignDeliverables

Reviewforcompletenessalldesigndocuments

Reviewforcontractualcompliance

SubmitdocumentstoCOMPANYforapproval

Participate as applicable in Design Review / Verification / Validation

Meetings

Submitdesignengineeringprocedure

SubmitListofdeliverables

SubmitDesignComputations

SubmitDesignDocumentsSpecificationsandDrawings

SubmitDesignEngineeringFormats

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

18of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

7.3.1.5

TheDesignProcesswillbeauditedbytheContractorasindicatedintheInternalAuditSchedule,

i.e.Attachment4:ProjectQualityAuditSchedule

7.3.1.6

DesignManagementStrategy

COMPANY has in contract document specified scope of works including general requirements

andspecificdesignandperformancecriteriaforvariousportionsofthework.

Contractorwillinputrequirementwithotherinformationfromsite,proprietaryinformationand

specificationsandapplyapplicable/relevantcodesandstandardstocompleteadetaileddesign

which will be delivered in the form of drawings and specifications including computations

whereverrequired.

Detaileddesignwillbecarriedoutasperapplicablecodesandstandards,especiallyconsidering

ease of construction, availability of materials locally, ease of maintenance, economics, reliability

andsustainability.

Regularmeetingsareenvisagedwheredesignreviewandtechnicaldiscussionswillbecarriedout

/informationexchangedtoensurethedesignprogrammedisexecutedinaccordancewithagreed

milestonesfordeliverables.

Alldesigndocumentswillbechecked/reviewedbyauthorizedpersonnelwithintheContractor

organizationandsubmittedforapprovalbyCOMPANY.Alldesignchangeswillberecordedand

allnecessaryrecords/changes/instructionswillbemaintained.Designwillbevalidatedagainst

userrequirementsbymeansoftestsandcommissioning/handover.

7.3.2

DesignandDevelopmentInputs

7.3.2.1

Thedesigninputsforthisprojectcouldbegroupedasunder:

a) ConceptdrawingsasreceivedfromCOMPANY

b) ContractSpecifications

c)

ContractAgreement/ContractConditionsGeneralandParticular

d) Proprietaryinformationofotherrelevantservices,protectionofexistingfacilities

e) ExitingSoilConditions,LoadInformation

f)

Authority/COMPANYRequirements

g) ChangesrequestedbyCOMPANY

7.3.2.2

The above design inputs shall be reviewed for adequacy and any unclear, ambiguity will be

clarifiedwithCOMPANY.

7.3.3

DesignandDevelopmentOutputs

7.3.3.1

Design Outputs will bein the form of the drawings, sketches, details, design computations, and

specifications.Basicallyalistofdeliverableswillbeagreedwhichwillbethebasisforcomparing

theprogressofdesignworks.

7.3.3.2

Necessary formats agreed with COMPANY and the output documents will be submitted to the

COMPANYforapproval.

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

19of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

7.3.3.3

Contractor will ensure that the design output documents will satisfy the input requirements,

provide adequate specifications for purchasing, installation and servicing, provide acceptance

criteriaandspecifysafetyrequirementsasappropriate.

7.3.4

DesignandDevelopmentReview

7.3.4.1

Reviews may take the form of meetings, or submittals and all design review meetings will be

recorded. It is understood that design activities / process status will be discussed during the

weekly/monthlyprogressmeetings.

7.3.4.2

Review will also identify any bottlenecks in the design process, identify solutions and will also

evaluatetheabilityofthedesignprocesstomeetrequirements.

7.3.5

DesignandDevelopmentVerification

7.3.5.1

DesignVerificationwilltaketheformofapprovalsfromtheCOMPANYandanymeetingsheld

forthepurposeasin7.3.4above.

7.3.5.2

Methodsusedforverificationinclude1)performingalternativecalculations,2)reviewofdesign

outputdocumentsasdiscussedin7.3.3and3)comparingdesignspecificationwithsimilarproven

designspecification.

7.3.5.3

All design verification documents will be recorded / maintained, including results for any tests

anddemonstrations.

7.3.5.4

Resultsofanyverificationthatnecessitateschangesinotheralreadyreviewed/approved/issued

documents will be highlighted and subject documents will be reissued / resubmitted for

COMPANYapproval.

7.3.6

DesignandDevelopmentValidation

7.3.6.1

DesignValidationverifiesthatusersneedsaremet.Thiswillbeachievedbyensuringcompleted

works are checked, tested, commissioned and COMPANY user departments / authorities have

acceptedtheworks.

7.3.6.2

For the nature of the construction industry the design validation documents will be final

inspection reports, snag lists if any, testing and commissioning reports; and the provisional and

finalacceptancecertificates.

7.3.7

DesignChanges

7.3.7.1

All design changes necessitated either as a result of design review, verification, validation,

COMPANY instructions, changes in law / regulations, etc will be recorded. Affected documents

willbemodifiedappropriatelyanddocumented,reviewedandapprovedinaccordancewith7.3.1

7.3.6.Alldesignchangeswillberecordedandmaintained.

7.4

PurchasingandSubcontracting

MaterialsandanysubcontractorstobeusedintheworksshallbefirstsubmittedforCOMPANY

approval. Consideration will be given on quality, price, delivery, reliability and service. Criteria

for selection of subcontractors and suppliers / vendors besides complying with Specifications,

legal/localauthorityregistrationsareorganizationalstructure,priorexperience,QualityandHSE

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

20of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

systems,pastperformance,previousexperiencewithCOMPANY,currentworkloadandadequate

experience/experienceintheparticularserviceshallbeconsideredandcompliedwith.Contractor

will endeavor to procure local material considering the above criteria and the extent of

availability. Where there are proprietary items and the above criteria cannot be adhered to,

COMPANYwouldbeplacedontheactualpicturewithdetailsduringsubmissionforapprovals.

CriticalmilestonesonprocurementofLongLeadItemsandnecessaryfollowupwillbedoneto

meet the milestone deadlines. Material Approval & Delivery will be tracked and reported in

progressreports.Materialispurchasedonlyfromtheapprovedsources.Materialrequisitionsare

sentfromsite,detailingtherequirements.

Allmaterialstobepermanentlyincorporatedintotheprojectwillbesubjectedtoreceivingchecks

SiteQA/QCManager/ProjectManager/SiteEngineerandStorekeeper.See8.2.7

All subcontractors used in the project are subjected to the same project quality assurance

requirements as applicable to Contractor. Subcontract agreements are made on a backtoback

basis,thusmakingallsubcontractorsboundtothemaincontractrequirements.

7.5

ProductionandServiceProvision

CONTRACTOR understands the critical operations involved during the construction works. As

such, coordination, use of dated and approved drawings, and strict compliance to safety

requirements and approved method statement will be ensured. The Work Permit System for the

individualareas (as applicable) and will be complied with. Reference, Project HSE Plan: T2368

PSP501.

7.5.1A ControlofProductionandService

The construction activities shall be controlled by the use of this Quality Plan, HSE Plan, Master

ConstructionSchedule/Program,theMobilizationPlan,InspectionandTestPlans,ProjectSpecific

Procedures / Method Statements, Check Sheets together with the contract drawings and

specifications.

Familiarityandknowledgeofcontractspecifications/drawingsandstrictadherencetogetherwith

the regular interaction / monitoring / inprocess inspections will ensure that work is executed to

contractrequirements.

The CONTRACTORs Project Manager together with his site team will ensure that the work is

executed in line with the relevant procedures / method statements, suitable equipment are used

and the work is monitored at various stages as required by specifications and identified in the

Inspection&TestPlansandrelevantprocedures.

Inspection will be done using calibrated instruments at predefined inspection times as per the

InspectionandTestPlans.

Contract Requirements on planning and construction management will be as agreed in contract.

WorkProgressismonitoredonadaily/weeklybasisandprogressreportingisdoneaspercontract

requirements. Suitable actions are taken to accelerate progress to take care of slippages. Where

required,thescheduleswillbemodifiedasagreedwiththeCOMPANY.

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

21of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

7.5.1B ServiceProvision

CONTRACTOR will provide Servicing / Maintenance as agreed in the contract. The mandatory

maintenance period after receipt of provisional acceptance (and before Final Acceptance) is an

example of servicing. All subcontract arrangements for executing works reflect the maintenance

clause so as to ensure servicing / product warranty is guaranteed for the COMPANY. Records of

thecorrespondencewithrelevantsubcontractorsduringthisstagearemaintainedandretainedin

theCONTRACTORsHeadOffice.

All Operational and Maintenance Manuals and Spare Parts List, Spares and Special Tools as

required like for the electrical / electro mechanical equipments installed will be submitted to

COMPANY for approval sufficiently in advance of completion and hand over stage. COMPANY

comments will be incorporated and all submissions will be done accordingly. Training of

COMPANY Personnel shall be provided as per contract requirements as may be required and as

applicable.

7.5.2

ValidationofProcess

Specialized / critical work activities will be covered by procedures / method statements duly

approved by COMPANY and work will be done accordingly. Project Specific Procedures will be

developedforworkactivitywhereabsencewouldaffectqualityofwork.Thiswillbecoordinated

withtheCOMPANY.Specialprocesswillbevalidatedforensuringdesiredoutcomepriortouse.

List/examplesofsuchprocesseswiththeircontrolplansareindicatedbelow:

7.5.3

Sr.No.

Process

ControlPlans

1.0

MockupSamples

Preparation mockup samples as per

CONTRACTORs Planning Package /

Programme and subsequent approval of

COMPANY.

2.0

ConcreteMixDesignTrial

Mix calculations, review of previous

performance / data, ingredient tests, mix

designtrialandrequiredtestingpriortouse.

3.0

Material testing / results Material testing, submission of previous test

duringMaterialApproval

results / conformity certificate during material

approval.

4.0

Testing&PreCommissioning

Integrity of process equipments thru shop

pressure testing, piping thru field pressure

testing and rotary equipments thru test runs

during construction phase and pre

commissioning.

ProductIdentificationandTraceability

Theproductinthiscasethebuildingsandotherstructures,etc.arevisuallyidentifiableastothe

status of work and the numbering as indicatedin the drawings. COMPANY specified system of

numberingtheindividualbuildingandotherstructureswillbefollowed.

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

22of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

Incoming materials are correctly identified and stored. Most of the construction materials are

identifiablebymeansoflabelsandpackagingbythemanufacturer/supplier.Wherenotavailable,

materialswillbesuitablyidentifiedbyusingcoloredmarkersandortags.Allmaterialscomingout

ofstoreshallbeeithertraceablebymarking/labels,storerecords,testcertificate,etc.

CONTRACTOR also understands the confidentiality of drawings and the property contained

thereinandwillonlyexchangeinformationasnecessaryforexecutionoftheproject.

7.5.4

CustomerProperty

There are no free issue materials issued by COMPANY for this project, if any then it will be

properly identified, checked, stored and handled in full compliance to requirements. These items

will be checked for correctness before accepting to be used on site. Any missing items will be

indicated to COMPANY. Any surplus material at the end of construction will be returned to

COMPANY. The surplus material shall be stored in a separate area pending a decision on their

disposal.

Materialobtainedfromdismantling/demolition(asapplicable)willbeconsideredasCOMPANY

property and will be returned / disposed off as per COMPANY instructions and contract

agreement.

CarewillbetakenofCOMPANYpropertybycomplyingwithallsafetyandsecurityrequirements.

CONTRACTOR also understands the confidentiality of drawings and the property contained

thereinandwillonlyexchangeinformationasnecessaryforexecutionoftheproject.

7.5.5

PreservationofProduct

Suitable actions are initiated on site to ensure material to be used in the project are handled and

stored in accordance with manufacturers instructions / good engineering practice, so as to avoid

damage to materials. Any other specific contract requirements on storage and handling are

followed.

Materials received on site for permanent incorporation on the sites are subject to Receiving

Inspection by QA/QC Engineer / Site Engineer and Storekeeper. Presence of COMPANY

Representative will be as per contract requirements and as indicated in the ITPs. Acceptable

materials are listed on the Site Receipts and logged in to the database. Store data is continuously

updatedonreceiptandissuetosite.Inventorywillbedoneonasixmonthlybasisfortheproject.

Handling / Storage will be done as recommended by Manufacturers / Suppliers or as per good

engineeringpracticessoastoavoidandminimizedamagetomaterial.RelevantMSDSMaterial

Safety Data Sheet will be maintained and specified storage requirements will be complied with.

Necessary preservation activities will be done, such as storage under controlled conditions of

temperatureforsensitivematerialsandshaded/ventilatedareasforvolatilematerials.

Deliveriestositesofconstructionmaterialslikessteelstructures,pipes,etc.areunloadedascloseto

thepointofuseaspossible.Thisisdonetopreventdamageandavoiddoublehandling.

7.6

ControlofMonitoringandMeasuringDevices

Allinstruments/equipmentaffectingquality(surveyingequipment)andtobeusedonsitewillbe

listedandidentifiedwithuniqueCONTRACTORidentificationnumber.TheCalibrationStatusis

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

23of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

identifiedbyavailabilityofcalibrationcertificates.Calibrationisdoneonceayearorexpirydatesas

indicated in calibration certificate or earlier if an error is reported. However calibration checks /

accuracy checks will be done before actual measurement of any characteristic. Any instrument

showingerrorswillbesentbacktoCONTRACTORsHOforcalibration.Anymeasurementsdone

withsuchinstrumentswillbevalidatedonceagainusingcalibratedinstrument.

Theinstrumentsandmeasuringequipmentsarestoredinsuchawayastoavoiddamageandalter

the calibrated status. Users of all instruments and equipment are responsible to check that the

instrumentstheyareusingarecalibratedandaccurate.InitialChecksaregenerallydonetoensure

accuracy. Instruments / Equipment used by Subcontractors on site will also be subjected to the

samecontrol.

Copies of the Calibration Certificates will be available on site; Originals are filed with the

CONTRACTORsHOQADepartment.

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

24of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

8.

MEASUREMENT,ANALYSISANDIMPROVEMENT

8.1

General

CONTRACTORwillplanandimplementthemonitoring,measurement,analysisandimprovement

processes to demonstrate conformity with the contract requirements, process performance

objectives, conformity of the planned quality management system, and for the continuous

improvementofthequalitymanagementsystem.

Themonitoring,measurement,andtheanalysisareindicatedbelow

Customer Satisfaction use of the Customer Satisfaction Survey Questionnaire twice during

theprojectduration.

InternalAudittocheckcomplianceandeffectivenessofthequalitymanagementsystemand

processes

MonitoringandMeasurementoftheProcesses(CONTRACTORsCompanylevel)

MonitoringandMeasurementoftheProduct(InspectionandTesting)useofInspectionand

TestPlans

ControlofNonConformancesandNonconformingproduct

Analysisofdata

Whiletheimprovementprocessesinclude

CorrectiveAction

PreventiveAction

ContinualImprovement

Alltheaboveprocessesaredescribedingreaterdetailbelow.

8.2

MonitoringandMeasurement

8.2.1

CustomerSatisfaction

CONTRACTORwillseekCOMPANYresponseontheperformanceandsatisfactionsachievedand

checkwhetherrequirements/expectationshavebeensatisfied.Aquestionnairewillbecirculated,

andCOMPANYresponsewillbeanalyzedandweakareasindicatedwillbehighlightedtosenior

management and site management. Necessary actions will be taken to improve upon the weak

areas indicated. Customer satisfaction survey (frequency) will be conducted at least two in the

project, one at the mid of project and one just before handover. Customer satisfaction survey

questionnaireisattached.(Ref.Attachment9.6.7)

8.2.2

InternalAudit

AsapartofthecontinuousmonitoringoftheeffectivenessoftheQualitySystem,periodicinternal

auditswillbecarriedoutbytrainedinternalauditorsfromCONTRACTOR.TheCOMPANYwill

be notified 14 days prior to the audit for participation. The findings will be reported to the

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

25of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

CONTRACTOR Senior Management and all improvement actions and follow up will be done by

theCONTRACTORsProjectManager.(Ref.Attachment9.4:ProjectQualityAuditSchedule).

8.2.3

MonitoringandMeasurementofProcesses

Effectivenessofprocesseswillbecheckedagainstthepreplannedperformanceobjectivessetforthe

processesduringinternalaudits.Theperformanceobjectivesforprocesseshavebeendocumented

on corporate level and achievement or otherwise will be used to check effectiveness of the

processes.

8.2.4

MonitoringandMeasurementofProduct(Inspection&Testing)

The inspection and testing activities are conducted as indicated in the Inspection and Test Plan

(ITP) (ref. list of ITP attachment: 9.3). Necessary coordination will be done with COMPANY

representative.

TheMaterials/Equipmentswhicharerequiredtobeinspectedatmanufacturerpointoforiginwill

beinspected/witnessedbyqualifiedpersonnelorbytheapprovedthirdpartyinspectorsasagreed

and required by the contract. Sufficient notice time will be given to COMPANY in writing for

inspection/testingwitnessofreferencematerials/equipmentatsource.

8.2.5

SiteLaboratory/NDTTesting

An independent Third Party Testing Laboratory will be established on site and specialized NDT

subcontractorwillbeutilized.TheproposedIndependentTestingLaboratory,NDTagencyandits

personnelwillbeasapprovedbyCOMPANY.SoilandConcretetestswillbecarriedoutinthesite

laboratory while other tests as required will be conducted off site in approved laboratories /

agenciesvisviseconomicsandtheavailabilityoftestingequipment.

The QA/QC Engineer together with Project Manager and Construction Manager will ensure

necessary coordination with the Independent Testing Laboratory. They will ensure adequate

quantities of representative samples of materials (as applicable) are secured and delivered other

materials required controls are provided and notify laboratory sufficiently in advance of

operations.

8.2.6

FieldInspectionCoordinationProcedure

8.2.6.1InspectionActivitiesandAttendance

CONTRACTOR will provide Project Specific Procedure (PSP) / Quality Control Procedure (QCP)

andsetofInspectionandTestPlans(ITP),togetherwithChecksheetsforrecording/conductingthe

inspection.EachoftheseITPindicatethevariousinspectionandtestingactivityforagivenactivity

/installation,therelevantspecification/acceptancecriteriaandtheQualityChecksheet(verifying

document) required for the inspection documentation. The Inspection and Test Plans specify a

symbolforeachcontrol/inspectionrequiredlevelandthepartiesinvolved.

TheSiteQA/QCManagerwillraisetheRFIforallHOLD/WITNESSactivities.Additionallyitis

understoodthattheCOMPANYhavetherighttowitnessatanymomenttheongoingconstruction

activities,aspercontractagreement.

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

26of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

8.2.6.2 DefinitionofSymbols

H=HoldPoint

CONTRACTOR is obliged to perform the inspection / test and to verify that the results are

acceptableaccordingtorequiredspecifications,therelevantinspection/testreport/qualitycontrol

Check Sheet will be signed off. Further works cannot be processed until the hold point stage is

executedandclearancereceivedfromCOMPANY(see8.2.6.3).

COMPANYisobligedtowitnessonrequestbyRFI,theinspection/testthatwillbeperformedby

othersandtoascertainthattheinspection/testiscorrectlyexecutedandtheresultsareacceptable

according to contractual specifications, relevant inspection / test report / quality control form /

checksheettobesignedoff.

W=WitnessPoint

COMPANY is requested in writing but not obliged to witness the inspection / test that will be

performed by others; in case of attendance, the party will be sign the relevant inspection / test

report/QCformiftheresultsareacceptable.

R=RecordReview/ReviewPoint

The COMPANY is requested by Contractor to review documents issued such as inspection

reports,millcertificates,etc.

S=Surveillance

COMPANY may perform daily random inspections, monitoring the relevant results, on

constructionactivities/processesasindicatedinthedescriptionofitemtobeinspected.

I=Inspection

DailyInspectionsbyContractorsQA/QCEngineerasworkprogresses.

A=Approval

Thepartyinvolvedisrequestedtogiveapprovalontherelevantitem.

All the controls and tests that involve COMPANY are intended to be performed jointly with the

CONTRACTORQA/QCEngineer.Thetest/inspectionreportwillbeissuedbytheCONTRACTOR

whichwillbereviewed/approvedbytheCOMPANYasapplicable.

8.2.6.3 RequestforInspectionandTesting(RFI)

Onlythoseactivitiesrelatedtoanyinspection/test/reportandclassifiedasHold(H)/Witness(W)

willbecarriedoutthroughthreeessentialstepswhichare

Callforinspection

Inspection

ResultofInspection(TestReport/QCChecksheet)

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

27of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

CallingforinspectionwillbedonebytheuseofRFIRequestforInspectionandTesting,which

is a written request for approval of work activities that classified as HOLD and / or WITNESS

pointsintheInspectionandTestPlan.ThesearesubmittedtotheCONTRACTOR,interactionwith

COMPANY(ifrequired)forrelatedinspectionwillbecoordinatedbytheCONTRACTOR.

Surveillance inspections of ongoing supporting activities like surveying, excavations, will not be

coveredbyanRFI.TheseactivitiesareindicatedintheDailySiteReport/DailyScheduleofWorks.

InspectionandWorkactivitieswillnotproceedfurtherforHOLDpointinspection,eveniffailto

attend due to any reason, unless COMPANY have allowed to proceed. Rescheduling is expected

within 24 hours so as not have a schedule impact. However for all WITNESS point inspections,

work activities will not be stopped even if the COMPANY fails to attend witness inspections for

anyreasons.

AllRFIs will be numberedas T2368C001,T2368M001, etc.indicating the discipline and

sequentialserialnumbers.NoticetimewillbegivenincompliancewithQualityRequirementsand

aswillbemutuallyagreedonsite.

Following inspection, the result of the inspection will be recorded on the related Quality Control

checksheet,whicheventuallybecomestheQCinspectionreport. TheQCreports/checksheetcan

bereplacedbyLaboratoryReports/TestCertificatesforagivenactivity.TheQCchecksheetswill

besuitablycrossreferredwithRFInumberandthelocationofstructure/activitybeeninspected.

ItisexpectedthattheRFIwillbereturnedtotheCONTRACTORwithsummaryresultsmarkedfor

the various inspection activities requested. Where the result of inspection is not satisfactory, and

positiveresultshavenotbeenachieved,afreshRFIwillbeputinafterrectification.

The Site QA/QC Manager will log all RFIs, and maintain the status of RFIs and report in the

WeeklyQualityReport.

8.2.7

ReceivingInspection

All construction material (to be permanently incorporated in the project), received on site will be

subjected to receiving checks on site by the QA/QC Engineer / Site Engineer and Storekeeper to

ensure these are as approved and specified. Such receiving checks will be recorded on the Site

Receipt Notes. Expiration dates, identification, physical compliance, traceability and review of

certificatesofconformity/millcertificatesaretheparametersthatwillbechecked.Whererequired

andasindicatedintheITP,theCOMPANYwillbenotifiedforreceivinginspectionthosethatare

classifiedasHOLD/WITNESSpointsintheInspectionandTestPlans.

8.2.8

InProcessInspection&Testing

ForallHold&WitnessPointsidentifiedontheITPCOMPANYColumn,theRequestforTesting

&InspectionSystemisfollowed.SeedescriptionunderFieldInspection&CoordinationProcedure

8.2.6above.NecessarycoordinationwiththeTestingLaboratorywillbeensured.

8.2.9

FinalInspection&Testing

TheCONTRACTORsProjectManageralongwithSiteQA/QCManager/SiteEngineerwillensure

all final inspection and testing are carried out as outlined in the Inspection and Test Plans. The

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

28of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

PunchListsofalloutstandingworkswhicharetoberectified,providedbyCOMPANYwillbe

attendedtoandclosedoutwithinagreedtimetablewithCOMPANY.

Aftercompletionofallfunctionalchecksoneachelementofwork/equipment,precommissioning

checkswillbedonetoensurecomplianceandproperfunctioningofallsystems.FinalTestingand

commissioning (as applicable) will then be done as per agreed time / schedule with witnessing

fromCOMPANYaspermutuallyagreedandapprovedprocedure.

8.3

ControlofNonConformingProduct

The CONTRACTOR ensures that any nonconformance or nonconformity is controlled, acted

uponanddocumentedasnecessaryandresolved.AllCONTRACTORsemployeesareencouraged

tohighlightanynonconformingactivityorproducttohisimmediateSupervisor.

Nonconformance might be identified and initiated by the COMPANY and / or CONTRACTOR

during

a)

b)

c)

d)

e)

Material/equipmentinspectionatvendor/supplierpremisesormaterialreceivinginspection

Siteworksinspectionordaily/routinesurveillance&testing/commissioning

QualityAuditbyCOMPANY

InternalQualityAuditbyCONTRACTORand

ExternalThirdPartyQualityAudit(asmaybeapplicable)

Depending upon the nature of non conformance, any nonconforming work identified on site

(eitherparty)isrectifiedasperagreedcorrectiveaction.Actionsinclude:

A. Repair/reworktodrawings&specifications.

B. Rejectifnonconformingproductisbeyondrepair.

C. Acceptasiswhenfurtherrectificationmayresultinseriousfunctionalproblems.

a)NonConformancerelatedtoMaterial/Equipment

Material/equipmentnonconformancefoundduringtheinspectionatvendor/supplierpremises

are not delivered to site until the corrections / corrective actions as agreed are completed and

verified.

Material / equipment nonconformance found during the incoming material receiving inspection

stage are kept isolated from use or in quarantined area, labeling the item if necessary. The

concernedSupplierorthePurchasingdepartmentisthenintimatedtoresolvethenonconformance

and propose necessary corrections / corrective actions. For major materials these corrections /

corrective actions shall be discussed and agreed with COMPANY. Generally immediate

replacements/rectifications,resolutionsareprovided.

Nonconformingmaterialsarenotused/incorporatedtheprojectsite,unlessallowed/agreedwith

andapprovedbytheCOMPANYwithfulltraceabilityforapositiverecallifneeded.

TargetEngineeringConstructionCo.

COMPANY:

CONTRACTOR:

DocumentCategory:

QualityManagementProcedure

DocumentNo.

T2368PSP401

RevisionNo.

Date:

12.10.2014

Page:

29of31

ProjectTitle:

EPCIHALULISLANDPRODUCEDWATERHANDLINGFACILITY

(PWHF)EXPANSION

DocumentTitle:

ProjectQualityPlan

b) NonConformance identified during site works inspection or daily / routine

surveillanceandduringTestingandCommissioning

NonConformanceissuedbyCONTRACTOR:

Once the corrective and preventive actions are agreed and coordinated with CONTRACTORs

Project Manager / the Site QA/QC Manager, they will be implemented at site. Corrective actions

shallbecompletedsoonestbutnotlaterthanfourweeksunlessotherwisejustified.Assoonasthe

agreedcorrectiveandpreventiveactionsarecompletedandverified,theNonconformancewillbe

closed.

NonConformanceissuedByCOMPANY:

NonconformancereportmaybereceivedfromtheCOMPANYasaresultofanauditorduetonon

conformancedetectedduringsiteworksinspectionordaily/routinesurveillanceorduringTesting

andCommissioning.AfterreceivingaNonConformanceReport(NCR),CONTRACTORsProject

Manager together with Site QA/QC Manager will review the Non Conformance, discuss with

COMPANYand agreeon the immediatecorrectiveaction to rectify the Non Conformanceand a

preventiveactiontopreventrecurrence.

CONTRACTORwillwritetheCorrective/PreventiveActionontheNCRandmeettheCOMPANY

andforwardacopyoftheNCRwithproposedcorrectiveandpreventiveactions.

On review and approval by COMPANY, the corrective actions will be completed and offered for

reinspectionandthenclosedasapplicable.ThenonconformingworkshallbeputonHOLDuntil

thecorrectiveactionisacceptedbytheCOMPANY.

Records of rectification necessary to close out a Non Conformance are kept. Actions taken are

recorded on the Non Conformance Report. After disposition of NCR, the COMPANY will be

requestedtoverifythesame.

AllNCRsshallberegisteredintheNCRLog/Register.

cde)NonConformanceidentifiedduringQualityAudit

NonconformanceidentifiedduringInternal,SecondPartyandExternalThirdPartyQualityAudits

will be reviewed and appropriate corrective / preventive actions will be proposed. Once the

corrective / preventive actions are agreed by the Auditor, these actions will be implemented and

Auditors will be requested to close the NCRs after submission of appropriate evidence of

completion.

8.4

AnalysisofData

8.4.1

MonthlyQualityReport

TheQA/QCEngineerincoordinationwiththeDocumentControllerwillprepareandsubmitona

monthlybasisareporttotheCONTRACTORCorporateOffice,indicatingissuesdetailedbelow.If