Professional Documents

Culture Documents

Design and Implementation of Wireless Energy Meter System For Monitoring The Single Phase Supply

Design and Implementation of Wireless Energy Meter System For Monitoring The Single Phase Supply

Uploaded by

Reeta DuttaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Implementation of Wireless Energy Meter System For Monitoring The Single Phase Supply

Design and Implementation of Wireless Energy Meter System For Monitoring The Single Phase Supply

Uploaded by

Reeta DuttaCopyright:

Available Formats

International Journal of Computer Applications (0975 8887)

Volume 41 No.2, March 2012

Design and Implementation of Wireless Energy Meter

System for Monitoring the Single Phase Supply

Prashanth B.U.V

Instrumentation Engineer

Dept. of Science & Technology (DST)

Promotion of University Research & Scientific Excellence (PURSE)

Sri Venkateswara University, Tirupati-517502.

ABSTRACT

Wireless energy meter is a system developed to serve as a

basic single-phase energy meter with advanced functionalities

such as Peak hour setting, Peak load setting Wireless reading

transmission; further the system eliminates the role of a Meter

Reader.

Keywords: - Single phase supply, WEM, Microcontroller

In this design of wireless energy meter the ADE7752 used as

energy metering IC. Inputs to the IC are the stepped down

voltage & current of the utility supply using CT & PT. The IC

generates pulses as output proportional to power consumed.

Micro reads the number of pulses as 3200=1 unit of energy.

The circuit shown in figure1 is the circuit of energy metering

IC ADE7752. Below circuit shows the power supply circuit

using the regulator IC LM7805.

1. INTRODUCTION

In the present scenario, there is no option for the electricity

board to regulate the load distribution during peak hours. As a

result, even today, a number of customers are suffering due to

Low Voltage during peak hours. Power is saved at the mercy

of customers only during peak hours. A large amount is spend

for obtaining the meter readings every month. Meter readers

find it difficult to collect the readings from remote areas. The

wireless energy meter product specification is the energy

meter with increased functionality of a single phase handheld

module monitoring system.

Figure 2 Power Supply Circuit.

2. PRINCIPLE

WEM monitors the energy consumption for a single phase

supply. There will be a preset value for the Peak hour &

permissible load at peak hour. Bimonthly readings will be sent

to the control station on the second day [1]. At the base

station, the total bill amount is prepared. Further at the base

station, NCU & ECU are extracted. The energy meter module

consists of the basic functions of standard energy meter, It

consists of a Single phase supply, It is having the capability of

Unit & Time setting ,Further it has a detachable Keypad

facility along with GSM facility and LCD display[1].

3. DESIGN OF WEM

Figure 1. Circuit Diagram of energy metering

IC ADE7751

26

International Journal of Computer Applications (0975 8887)

Volume 41 No.2, March 2012

As shown in the figure3 the microcontroller circuit is

interfaced to a 16x2 LCD and a resistor pack connected to

Vcc of +5V. Further a MAX232 IC is interfaced to the

microcontroller for the interface to the serial to the P.C with

baud rate of 9600 bps. This circuit is as shown in the next

figure4.Here the MAX232 is interfaced to the port 3 of the

microcontroller AT89C52.

Figure 3 Microcontroller Circuit

Further the MAX232 circuit is used to interface with the

external devices such as P.C with hyper terminal software as

the interfacing software with the baud rate of 9600kbps

[5].This circuit is as shown in figure 4.

Further the entire module is interfaced to the real time clock

DS1307 as shown in the below figure.

Figure 5 Real Time Clock circuit

Figure 4 MAX232 Circuit

Energy meter Consists of Atmel micro controller which has a

long period life cycle. RTC IC (DS 1307) connected with a 3.3V

Battery which will last for a minimum period of 10 years unless

any short circuit occurs. So the circuit is more reliable.

27

International Journal of Computer Applications (0975 8887)

Volume 41 No.2, March 2012

reader, also it has the features of Wireless Data logging with

previous data base search option.

6. OPERATION OF WEM

Energy Meter tested at different voltage conditions using an

Auto transformer. Supply voltage varied from 150 VAC to

240 VAC. During this testing process meter consistently

works with accuracy. Different load devices are connected to

test the current handling capability of the meter (10W to

1000W).

7. RESULTS

The hardware design of the energy meter has been completed

and implemented. The code at meter side completed and

tested. The front end is designed using Visual basic [2].

Mobile phones are used instead of GSM modules. The test

results using Visual basic screen shots are as follows.

Figure 6 PCB Module of the entire circuit.

4. COMMUNICATION PROTOCOL.

Wireless communication with the control station is made

possible by means of the GSM modem. It supports the AT

command sets. Using Serial communication protocol

(USART) we communicate with the GSM Modem. RTC and

EEPROM [8]. The meter reading are stored in each change in

values to a permanent memory. This is made possible by

2

means of I C protocol. Its a 3 wire synchronous

communication protocol. A scanning method is used to

interface with the keyboard.

Steps to Interface with MODEM

Step 1:-GSM modem supports the AT command set AT +

(0x0d, 0x0a) is send to the modem. Modem returned with an

OK signal in the same baud rate.

Figure 7 software front end

Step 2: Send ATE0 + (0x0d, 0x0a) to the modem to Turn the

Echo off Modem returned with an OK signal in the same baud

rate.

Step3: Send command AT+CMGF=1 + (0x0d, 0x0a) to Select

text mode in the GSM Modem returned with an OK signal in

the same baud rate.

Step 4: To send the Message use the following format

AT+CMGS=+919xxxxxxxxx, after getting a confirmation

(on receiving > from modem) s end the Meter reading and

meter ID.

5. ADVANTAGES OF WEM

Even though a number of Energy meters are available, WEM

has following unique features such as Peak Hour-Load setting

capability, further it completely avoids the role of meter

Figure 8 Invalid Entry screen.

28

International Journal of Computer Applications (0975 8887)

Volume 41 No.2, March 2012

E.

a.

b.

c.

d.

Once the pass word is entered

There will be options to edit through keypad

That is as follows

ID

Fixed unit value

Mobile Number

Exit

8. CONCLUSIONS

Figure9 Front End Without extra unit.

The past few decades have been marked by the onslaught of

devices that are intelligent and interactive. The present day

scenario the embedded systems are designed as hardwaresoftware co-design, that is software is design is ported on the

standalone board that contains a microcontroller with the

other peripheral devices interfaced to it. The other peripheral

devices interfaced are Real Time Clock (RTC), MAX232

circuit, Power supply circuit, along with LCD and other glue

logic circuit. And finally taking all the above points into

consideration a wireless energy meter (WEM) system is

developed to serve as a basic single-phase energy meter. This

meter is equipped with the advanced functionalities such as

Peak hour setting, Peak load setting Wireless reading

transmission. Further the system eliminates the role of a

Meter Reader.

9. FUTURE SCOPE

The wireless energy meter system can modified to a 3-phase

supply. In this system the printing mechanism can be

embedded at the meter side so that a hardcopy of the bill may

be obtained. A GSM module can be embedded in the same

PCB as different layers [6] .The overall size can be reduced if

multilayer PCB is used.

10. REFERENCES

[1] Muhammad Ali Mazidi, Janice Gillispie Mazidi and Rolin

D McKinlay, The 8051 Microcontroller and Embedded

Systems, Prentice Hall, Edition 2, 2006.

[2] Evangelos Petroutsos, Mastering Microsoft Visual

Basic2008, Wiley India, Edition 1, 2008.

[3] Silberschatz, Korth and Sudarsan, Database System

Concepts, McGraw-Hill International, Edition4.

Figure 10 Front End with extra unit.

The operating conditions of WEM are as follows, the energy

meter tested at different voltage conditions using an Auto

transformer. Supply voltage varied from 150 VAC to 240

VAC. During this testing process meter consistently works

with accuracy. Different load devices are connected to test the

current handling capability of the meter (10W to 1000W).

The output results can be described as follows

A. When wireless energy meter is switched ON, the

minute value is set to 1.

Initializations take place

B. When minute=2, a message is sent, hourly.

For each hour, 5-8 minutes

taken as

peak hours.

C. Total reading displayed in the LCD and gets

updated.

#$12345$00.00$00.00$* is the format for transmission ie;#$

meter id $ (total-extra) $ (extra) $*

D. Default password is 1234

[4] M. Barr, Anthony Massa, Programming Embedded

Systems, second edition, O'Reilly, 2006.

[5] Athulya.A Design and Development of a user friendly

embedded product for testing serial communication

interfaces, IJCA Proceedings on International

conference on VLSI, Communication and

Instrumentation(ICVCI)(10)35-37,2011

[6] S. E. Derenzo, Practical Interfacing in the Laboratory:

Using a PC for Instrumentation, Data Analysis and

Control, Cambridge, 2003.

[7] A.Jantsch, Modeling Embedded Systems and SoCs Concurrency and Time in Models of Computation:

Morgan Kaufmann, 2003.

[8] The I2C- bus Specification, Philips Semiconductors,2000.

[9] J. Banks, J. S. Carson II, B. L. Nelson, and D. M. Nicol,

Discrete-Event System Simulation by, Prentice-Hall,

2001.

29

You might also like

- ME 2304 Two MarksDocument21 pagesME 2304 Two Markssanthanam102100% (1)

- Digital Signal Processing - S. Salivahanan, A. Vallavaraj and C. GnanapriyaDocument68 pagesDigital Signal Processing - S. Salivahanan, A. Vallavaraj and C. GnanapriyaMallik KglNo ratings yet

- TroubleshootingDocument39 pagesTroubleshootingTrí NguyễnNo ratings yet

- CTRL Sys Lab ManualDocument46 pagesCTRL Sys Lab Manualabixek100% (2)

- Doc-Automatic Light ControlDocument71 pagesDoc-Automatic Light ControlBenazir BegamNo ratings yet

- Frequency RelayDocument2 pagesFrequency RelayAkhilesh JindalNo ratings yet

- Project Report: Water Temperature ControllerDocument13 pagesProject Report: Water Temperature ControllerMuhammad OmerNo ratings yet

- Program For Symmetrical Fault AnalysisDocument12 pagesProgram For Symmetrical Fault AnalysisBarathNo ratings yet

- ICL8038 Linear Sweep Function Generator CCTDocument2 pagesICL8038 Linear Sweep Function Generator CCTian_new100% (1)

- The Copperbelt University School of Mathematics and Natural Sciences Department of Physics PH 110 Introductory PhysicsDocument3 pagesThe Copperbelt University School of Mathematics and Natural Sciences Department of Physics PH 110 Introductory PhysicsLazy BanditNo ratings yet

- Eee MPMCDocument2 pagesEee MPMCSekhar Reddy100% (1)

- Final Phase 1 PPT Major ProjectDocument21 pagesFinal Phase 1 PPT Major ProjectSpandana priyaNo ratings yet

- Luo ConverterDocument6 pagesLuo ConverterAndrei CocorNo ratings yet

- User Manual PEAK777VL2 100907Document61 pagesUser Manual PEAK777VL2 100907lightcomlc1No ratings yet

- Datasheet: SF-CPV-205 High Efficiency Concentrator PV PanelDocument2 pagesDatasheet: SF-CPV-205 High Efficiency Concentrator PV PanelsaaskinsNo ratings yet

- Mathematical Modelling of Buck ConverterDocument4 pagesMathematical Modelling of Buck ConverterEditor IJRITCCNo ratings yet

- Jntua B.tech 4-1 Eee r15 SyllabusDocument26 pagesJntua B.tech 4-1 Eee r15 Syllabusaravind0% (1)

- Technologies: Research and Application of A SCADA System For A MicrogridDocument11 pagesTechnologies: Research and Application of A SCADA System For A MicrogridDave KevinNo ratings yet

- DMA Controller - 8237Document9 pagesDMA Controller - 8237Umesh Harihara sudanNo ratings yet

- Introduction To Power Electronics (Benny Yeung)Document9 pagesIntroduction To Power Electronics (Benny Yeung)Souvik GanguliNo ratings yet

- Machines Lab ManualDocument124 pagesMachines Lab ManualpurushothNo ratings yet

- Electrical TechnologyDocument200 pagesElectrical Technologymjaji khulehNo ratings yet

- JNTUA JNTUH JNTUK - B Tech - 2019 - 3 2 - EEE - Power Electronic Controllers DrivesDocument9 pagesJNTUA JNTUH JNTUK - B Tech - 2019 - 3 2 - EEE - Power Electronic Controllers DrivesMayank SinghalNo ratings yet

- Power System Dynamics Imp QuestionsDocument2 pagesPower System Dynamics Imp QuestionsUpendra Roy100% (1)

- CBPSD-lab Manual PDFDocument40 pagesCBPSD-lab Manual PDFShiv Rajput80% (10)

- Fire Detection Using Embedded SystemsDocument2 pagesFire Detection Using Embedded Systemsnikhilvishwa100% (1)

- Pi Voltage Control Technique For 3 Phase Induuction Motor Using Simulink and ArduinoDocument37 pagesPi Voltage Control Technique For 3 Phase Induuction Motor Using Simulink and ArduinoPFANo ratings yet

- Load Flow Matrices IIT Roorkee Notes NPTELDocument88 pagesLoad Flow Matrices IIT Roorkee Notes NPTELconsultrail100% (1)

- Chapter 4 PDFDocument11 pagesChapter 4 PDF김채현No ratings yet

- SCR Firing CircuitsDocument4 pagesSCR Firing CircuitsShubham Bagal100% (1)

- TMS320F28335 DSP Programming Using MATLAB Simulink Embedded Coder: Techniques and AdvancementsDocument7 pagesTMS320F28335 DSP Programming Using MATLAB Simulink Embedded Coder: Techniques and AdvancementsSaid MerengueNo ratings yet

- EEE 2019 Lecture 4Document30 pagesEEE 2019 Lecture 4Emment ChromaNo ratings yet

- Implementation of A Microcontroller Based 5 KVA Automatic Voltage StabilizerDocument8 pagesImplementation of A Microcontroller Based 5 KVA Automatic Voltage StabilizerMawunyo100% (1)

- Generation of High Voltage DC Using Diodes & Capacitors in Ladder NetworkDocument6 pagesGeneration of High Voltage DC Using Diodes & Capacitors in Ladder NetworkEditor IJRITCCNo ratings yet

- EI8073 BMI QN BankDocument8 pagesEI8073 BMI QN BankKeerthana SahadevanNo ratings yet

- Microcontroller Systems (KON 309E) : Lecture Notes (WEEK 1)Document8 pagesMicrocontroller Systems (KON 309E) : Lecture Notes (WEEK 1)Dursun DurmasınNo ratings yet

- Solar-Powered Battery Charging With Highly Efficient Buck ConverterDocument20 pagesSolar-Powered Battery Charging With Highly Efficient Buck ConverterSusanNo ratings yet

- FulltextThesis 2Document209 pagesFulltextThesis 2Kean PagnaNo ratings yet

- 1 Introduction To State EstimationDocument96 pages1 Introduction To State EstimationHarish BabuNo ratings yet

- Q MeterDocument14 pagesQ MeterShivam Kumar YadavNo ratings yet

- GATE Electrical by Kanodia PDF 1 200Document200 pagesGATE Electrical by Kanodia PDF 1 200Ankita Sogani Kothari100% (1)

- Electrical Drives Ans ControlsDocument40 pagesElectrical Drives Ans Controlsjeyasaravanan77No ratings yet

- Economic Dispatch Using Dynamic ProgrammingDocument22 pagesEconomic Dispatch Using Dynamic ProgrammingSyed Ali RazaNo ratings yet

- Lab # 01 To Study The Transient Response of RL Series Circuit MaterialsDocument4 pagesLab # 01 To Study The Transient Response of RL Series Circuit MaterialsYasir100% (1)

- Lecture 3-Photovoltaic MaterialDocument57 pagesLecture 3-Photovoltaic MaterialButchNo ratings yet

- 13A02601 Power Semiconductor Drives PDFDocument1 page13A02601 Power Semiconductor Drives PDFVelappagari Sekhar50% (2)

- Unit - 4 - Power Electronics and Energy Storage in Smart GridDocument50 pagesUnit - 4 - Power Electronics and Energy Storage in Smart GridsujithNo ratings yet

- Prof DR Johann W Kolar PDFDocument82 pagesProf DR Johann W Kolar PDFaswardiNo ratings yet

- Electrical MeasurementsDocument3 pagesElectrical MeasurementsSiva Prasad Padilam0% (1)

- A Tri-Band Wilkinson Power Divider Using Step-Impedance ResonatorDocument4 pagesA Tri-Band Wilkinson Power Divider Using Step-Impedance ResonatorDiya NoorNo ratings yet

- EEE F427 - Lecture 6Document29 pagesEEE F427 - Lecture 6james40440No ratings yet

- Pe SS Final Ex 2010Document4 pagesPe SS Final Ex 2010Saif UddinNo ratings yet

- Automatic Battery ChargerDocument2 pagesAutomatic Battery ChargervipincktyNo ratings yet

- Ee6503 - Power Electronics: 2 Marks and 16 Marks-Question Bank Unit 1 - Introduction Two MarksDocument30 pagesEe6503 - Power Electronics: 2 Marks and 16 Marks-Question Bank Unit 1 - Introduction Two Marksdishore312No ratings yet

- MINOR REPORT ON Energy Meter Using ADE7757Document55 pagesMINOR REPORT ON Energy Meter Using ADE7757Himanshu Patidar100% (5)

- Exp 1 DI Y-BusDocument6 pagesExp 1 DI Y-BusSriram Narayan100% (2)

- Chapter-1: 1.1.1 The Principle of WindmillDocument22 pagesChapter-1: 1.1.1 The Principle of WindmillVijay BavikattiNo ratings yet

- Electrical and Electronics Lab Manual For Mechanical EngineeringDocument21 pagesElectrical and Electronics Lab Manual For Mechanical EngineeringSreerag Kunnathu SugathanNo ratings yet

- EeeDocument268 pagesEeeNajiruddin ShaikNo ratings yet

- Why Is Secret Love So Important in Gita GovindaDocument7 pagesWhy Is Secret Love So Important in Gita GovindaReeta DuttaNo ratings yet

- Advanced Control SystemsDocument1 pageAdvanced Control SystemsReeta DuttaNo ratings yet

- EwsplotsDocument12 pagesEwsplotsReeta DuttaNo ratings yet

- Notice For E-Auction of 2 (Two) Residential Plots: Info@wbhidco - inDocument12 pagesNotice For E-Auction of 2 (Two) Residential Plots: Info@wbhidco - inReeta DuttaNo ratings yet

- Sr. No. Name / Address of Unit Nodal Officer Contact Details: View /download List of ItemsDocument2 pagesSr. No. Name / Address of Unit Nodal Officer Contact Details: View /download List of ItemsReeta DuttaNo ratings yet

- Advertising DesignDocument12 pagesAdvertising DesignReeta DuttaNo ratings yet

- Contact Details English For 22 02 21Document4 pagesContact Details English For 22 02 21Reeta DuttaNo ratings yet

- Jadavpur University: KOLKATA-700032Document25 pagesJadavpur University: KOLKATA-700032Reeta DuttaNo ratings yet

- All Complaints Forwarded Through Email Should Contain Contact Number & Complete Postal Address of The ComplainantDocument3 pagesAll Complaints Forwarded Through Email Should Contain Contact Number & Complete Postal Address of The ComplainantReeta DuttaNo ratings yet

- EnOcean Occupancy Sensor Operational Description v1.2 04Document11 pagesEnOcean Occupancy Sensor Operational Description v1.2 04Reeta DuttaNo ratings yet

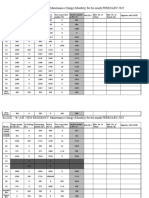

- Maintenance Charge SheetDocument14 pagesMaintenance Charge SheetReeta DuttaNo ratings yet

- 4 Pro EC44 Full Manual ENDocument274 pages4 Pro EC44 Full Manual ENrogermantilla08No ratings yet

- AED InstructionDocument23 pagesAED InstructionVivek JhaNo ratings yet

- Analysing Electric Field Distribution of HV Standard Capacitor Using Finite Element MethodDocument7 pagesAnalysing Electric Field Distribution of HV Standard Capacitor Using Finite Element MethodsreekanthaNo ratings yet

- 5G's Impact On RF Front-End IndustryDocument40 pages5G's Impact On RF Front-End IndustryAngel TrianoNo ratings yet

- Multiplexing and DemultiplexingDocument10 pagesMultiplexing and DemultiplexingCharming buddyNo ratings yet

- Optimal Design and Control of Axial-Flux Brushless DC Wheel Motor For Electrical VehiclesDocument10 pagesOptimal Design and Control of Axial-Flux Brushless DC Wheel Motor For Electrical Vehiclesfre12345No ratings yet

- Service Manual: ChassisDocument66 pagesService Manual: ChassisAsnake TegenawNo ratings yet

- WL005 - WL10: Silicon Bridge Rectifiers WOBDocument3 pagesWL005 - WL10: Silicon Bridge Rectifiers WOBtarpinoNo ratings yet

- Four-Pole Squirrel-Cage Induction Motor 579493 (8221-05) : Labvolt Series DatasheetDocument3 pagesFour-Pole Squirrel-Cage Induction Motor 579493 (8221-05) : Labvolt Series DatasheetAntonioVelizNo ratings yet

- Tstatccpq 501Document2 pagesTstatccpq 501Street StockNo ratings yet

- Physics Trilogy ElectricityDocument9 pagesPhysics Trilogy ElectricityProject InfoNo ratings yet

- Current ElectricityDocument9 pagesCurrent ElectricityShadab HanafiNo ratings yet

- Last Update CVDocument3 pagesLast Update CVNouhAhmedNo ratings yet

- Brochure Uniflair Chiller TRA - 60HzDocument7 pagesBrochure Uniflair Chiller TRA - 60HzMasab AnisNo ratings yet

- TR-6-C Sonixs 1650x600 Manual 2016 Rev ADocument300 pagesTR-6-C Sonixs 1650x600 Manual 2016 Rev Agoretty cantonNo ratings yet

- Signals & Systems Unit IIDocument16 pagesSignals & Systems Unit IIvsalaiselvamNo ratings yet

- Gps 4Document17 pagesGps 4admidNo ratings yet

- Siemens Power Engineering Guide 7E 56Document1 pageSiemens Power Engineering Guide 7E 56mydearteacherNo ratings yet

- Radio Navigation Question RN MCQDocument85 pagesRadio Navigation Question RN MCQpontoo56% (9)

- Shivani Senior Firmwareengineer Mobile: +91-9837923883 E-MailDocument5 pagesShivani Senior Firmwareengineer Mobile: +91-9837923883 E-MailAbhishek MishraNo ratings yet

- 4090-9101 Modulo Zona ZAMDocument2 pages4090-9101 Modulo Zona ZAMJ Luis CallasNo ratings yet

- Force On Jumping RingDocument4 pagesForce On Jumping Ringvotasugs756No ratings yet

- MC34063 STmicroDocument23 pagesMC34063 STmicroFady HachemNo ratings yet

- Automatic Generation ControlDocument5 pagesAutomatic Generation ControlMuhammad Nizamuddin100% (1)

- Cybenetics - Evaluation - Report - Galax - OMEGA GL650SDocument11 pagesCybenetics - Evaluation - Report - Galax - OMEGA GL650Sintel boyNo ratings yet

- Introduction To Noise in Adc Systems: Ti Precision Labs - AdcsDocument15 pagesIntroduction To Noise in Adc Systems: Ti Precision Labs - AdcsSouptik PaulNo ratings yet

- Introduction To Computer ProcessorsDocument14 pagesIntroduction To Computer ProcessorsNEET ncert readingNo ratings yet

- A Study of Backing Layer Structure ForDocument3 pagesA Study of Backing Layer Structure ForaliNo ratings yet

- Integrated Access Backhauled Networks: NtroductionDocument5 pagesIntegrated Access Backhauled Networks: NtroductionRoshan RajuNo ratings yet