Professional Documents

Culture Documents

Valve Actuators Information On GlobalSpec

Valve Actuators Information On GlobalSpec

Uploaded by

arkan1976Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Valve Actuators Information On GlobalSpec

Valve Actuators Information On GlobalSpec

Uploaded by

arkan1976Copyright:

Available Formats

9/4/2014

Valve Actuators Information on GlobalSpec

Valve Actuators Information

Valve Actuators

Image Credit: Clark Solutions | Assured Automation | Hayward Flow Control

Valve actuators mount on valves and, in response to a signal, move a valve to a desired position using an outside power source. Selecting the correct valve actuator will

increase uptime, reduce maintenance costs, and increase plant safety. Most valve actuators come permanently lubricated and will operate best with instrument-quality

air. They can also be packaged with position sensing equipment, digital communication capacity, and motor protection.

Valve Method of Control and Function

Valve motion and operation style are important specifications to consider when selecting valve actuators.

Valve Function

There are two basic operating styles for valve actuators.

Start/stop valves, also known as on/off or isolating devices, limit actuator motion to preset open and closed positions.

Throttling or control devices provide controllable motion so that valves can be throttled as necessary. This type of actuator is paired with a positioner so the

actuator can move to the required position accurately.

Valve Method of Control

Rotary motion valves (rotary valves) such as ball, plug, and butterfly valves rotate a quarter-turn or more from open to close.

Linear motion valves (linear valves) such as gate, globe, diaphragm, pinch and angle-style valves have a sliding stem design that pushes the closure element

open or closed. The valve stem may rise during rotation, or may rise without rotation.

Actuation Method

There are several basic types of valve actuators: manual, electric, pneumatic, and hydraulic.

Manual valve actuators do not require an outside power source. They use a handwheel or lever to drive a series of gears whose ratio results in a higher output

torque compared to the input (manual) torque.

Image Credit: Samson

Electric valve actuators use a single-phase or three-phase alternating current (AC) or direct current (DC) motor to drive a combination of gears to generate the

desired torque level.

http://www.globalspec.com/learnmore/flow_transfer_control/valve_actuators_positioners/valve_actuators_general

1/5

9/4/2014

Valve Actuators Information on GlobalSpec

Image Credit: Valve World

Pneumatic valve actuators adjust valve position by converting air pressure into linear or rotary motion.

Image Credit: Nuclear Power Training

Similarly, electrohydraulic valve actuators and hydraulic valve actuators convert fluid pressure supply into linear or rotary motion.

Actuator Specifications

Below are specifications for rotary and linear valve actuators.

Rotary Actuator Specifications

Rotary actuators produce rotary motion or torque. The mechanical device produces motion in one direction to cause rotation. Electric versions of the rotary actuator have

continuous rotation, while servo or step motors are used to move the actuator to a fixed angular position.

Image Credit: Zakgear

Rack and pinion actuators consist of a housing to support a pinion, which is driven by a rack with cylinder pistons on the ends. Racks are available in single,

double, or multiple designs. The overall efficiency of rack and pinion actuators averages 85-90%. They are able to cover a wide range of torque outputs and

rotations range from a few degrees to five revolutions or more. The equation for calculating torque is:

M = Aprp

Where,

M - output torque,

A - cylinder piston area

p - operating pressure

rp - pitch radius of the pinion

Rotary actuators can be used in working pressures of up to 18 bar for pneumatic and 210 for hydraulic actuators with rotations of 90, 180, or 360.

As the media moves it creates dynamic torque, which results from non-uniform static pressure distribution on the closure (rotating) member of a quarter-turn

valve. Since the pressure is unevenly distributed, it is equal to the resultant force acting at the same distance from the stem axis. Dynamic torque acts on the

valve stem; it is the sum of the product of each resultant force and its offset distance. It can either aid or hinder the valve actuator. If the friction torque is less than

the dynamic torque, it will cause rotary motion if unchecked by the actuator.

The most common cause of rotary actuator failure is the introduction of shock and surge pressures beyond the maximum rated working pressure of the unit. Failure often

occurs in actuators that have rotational speeds in excess of 10 RPM, control of a large mass in the horizontal plane or moving over the center, or operation of a long lever

arm.

Linear Actuator Specifications

A linear actuator is an assembly that creates motion and force along a straight line. Linear actuators use an external energy source and various methods to achieve this

motion. Mechanical, hydraulic, pneumatic, and electric actuators can be designed as linear actuators. Hydraulic and pneumatic actuators inherently produce linear

motion, while other types provide linear motion from rotating motors.

http://www.globalspec.com/learnmore/flow_transfer_control/valve_actuators_positioners/valve_actuators_general

2/5

9/4/2014

Valve Actuators Information on GlobalSpec

Image Credit: Wikipedia

Performance specifications for linear actuators include valve stem stroke length, actuation time, number of turns, and actuator force or seating thrust.

Valve stem stroke length- Stroke is a term used to define the travel required by the valve from fully open to fully closed. The stroke of an actuated valve is

determined by the actuator if the actuator selected has a stroke that is less than the stroke of the valve. Using an actuator with fewer strokes than the valve will

"short stroke" the valve and the full CV rating of the valve will not be realized.

Actuation time- The time it takes to fully close the linear motion valve

Actuator force or seating thrust- The actuator must supply enough force to overcome the pressure in the system to close the closing element and keep it

closed.

Load capacity- Actuators handle static and dynamic loads. Static load capacity is how much load the actuator can support when the device is not moving.

Dynamic load capacity is the load the actuator can support while it is in use.

Actuator

Type

Advantages

Disadvantages

Mechanical

Cheap. Repeatable. No power source required. Self-contained. Identical

behavior extending or retracting.

Manual operation only. No automation.

Electromechanical

Cheap. Repeatable. Operation can be automated. Self-contained.

Identical behavior extending or retracting. DC or stepping motors.

Position feedback possible. Can be remotely controlled.

Many moving parts prone to wear.

Linear motor

Simple design. Minimum of moving parts. High speeds possible. Selfcontained. Identical behavior extending or retracting.

Low force.

Piezoelectric

Very small motions possible.

Requires position feedback to be repeatable. Short

travel. Low speed. High voltages required. Expensive.

Good in compression only, not in tension.

Hydraulic

Very high forces possible.

Can leak. Requires position feedback for repeatability.

External hydraulic pump required. Some designs perform

well in compression only.

Pneumatic

Strong, light, simple, fast.

Precise position control impossible except at full stops

Chart Credit: Wikipedia.

General Specifications

General specifications for all types of valve actuators include:

Power source- In general, actuators are powered with either electricity or fluid (air-pneumatic, liquid- hydraulic). The electricity required for actuators depends on

their size; large actuators require three-phase supply and small valves can be operated on a single-phase. Occasionally a DC supply is available as an emergency

backup. Fluid powered actuators have more variations; the type of media, available pressure of media, and cylinder size must all be considered when selecting an

actuator powered by fluid.

The type of valve is also an important consideration. Proper actuator sizing can only be done when the user knows the type of valve it will be fitted to, if the valve

is multi-turn or quarter turn, whether it has a rising or non-rising stem, and the power requirements of the valve. Knowing the type of valve is also important in order

to calculate the torque requirement of the valve. This data can generally be requested from the valve manufacturer.

Control signal input type- There are three basic types of control signal inputs: milliampere, voltage, and pressure.

Voltage - Devices that use AC voltage or DC voltage are commonly available. The signal is typically a discrete voltage supply of 120/240 VAC or 12/24 VAC.

Supply pressure- Supply pressure is the input pressure needed to achieve a desired torque or thrust output. Companies specify air supply pressure for

pneumatic actuators and fluid supply pressure for hydraulic actuators. Compressed air in pneumatic actuators normally ranges from 60 to 100 psig.

Valve stem diameter- The valve stem diameter can be combined with the lead and pitch of the valve stem thread in order to size the automation required for the

valve. It can also be used with the valve size and the pressure drop across the valve to calculate torque demand.

Number of turns- The number of turns applies to multi-turn actuators. It defines the number of turns preformed as the rotating valve stem moves from the fully

closed to fully open position.

Location type- Valve actuators for hazardous locations are designed for environments with atmospheres that contain combustible or potentially explosive

http://www.globalspec.com/learnmore/flow_transfer_control/valve_actuators_positioners/valve_actuators_general

3/5

9/4/2014

Valve Actuators Information on GlobalSpec

mixtures. Devices for non-hazardous locations are designed for environments without the risk of combustion or explosion. Electric actuators are not recommended

in outdoor applications or hazardous locations since condensation can form inside the actuator, instead compressed air should be used if possible.

Operating temperature- The full range of ambient operating temperature. Pneumatic and electric actuators can be used in a wide temperature range.

Speed of Power Actuators

Actuators can vary in operating speed. The speed should be selected based on the speed and power requirements of the system and availability of energy to the

actuator.

Fast-acting actuators are best used when a system must be quickly isolated or opened. Fast action is provided by hydraulic, pneumatic, and solenoid actuators.

The speed of actuation is set by installing the correct orifice in the lines and the valve is closed by spring pressure, which is opposed by hydraulic or pneumatic

pressure to keep the valve open. Electrical motors can also provide fast actuation when the speed is set through the motor speed and gear ratio.

Slow-acting actuators are best used when cold water is injected into a hot system or slower opening is needed.

There is a direct relationship between the speed of the actuator and the power needed. An increase in valve/actuator speed requires an increase in horsepower. Threephase electric motor operators have a fixed speed, while smaller DC motors may have adjustable speeds. The speed of fluid powered actuators can be controlled using

a fluid control valve.

Failsafe Method

There are several fail-safe methods for valve actuators.

Devices can open or close valves in case of power failure, or in case of loss of control signal.

Close at no power

Close at no control

Open at no power

Open at no control

Double-acting actuators, those that need an actuation method to move (i.e. air to open, air to close), will fail in their last position if there is a loss of power, while a spring

return design will return to its initial position when there is a loss of power.

Spring return actuators are often chosen for fail-safe critical requirements since operators can select whether the valve would be left open or closed in the case of a power

failure. Spring return is common in pneumatic actuators and not widely available for electric actuators.

If the actuator is going to be spring-return, the failure mode (i.e., fail closed or fail open) must also be determined, using the following guidelines:

Double-acting operation- The torque output at the minimum air supply pressure should exceed the calculated torque requirements of the valve.

Spring-return operation, fail closed- The torque output at the minimum air supply pressure at the end of the spring stroke should exceed the torque required to

close the valve.

Spring-return operation, fail open- The torque output at the minimum air supply pressure at the end of the air stroke should exceed the torque required to open

the valve.

The leading cause of actuator failure is poor air quality as defined by ANSI/ISA - 7.0.01.

Actuator Size

Due to the wide variety of and variations in valves, the actuator must be sized to the specific valve in the system. Actuator sizing is best done after gathering information

on the type of actuator desired, and the torque requirements calculated. Actuator sizing is usually done using a manufacturer's sizing chart. Additional specifications to

consider are the required speed of operation since speed has a direct relationship to the power requirement.

If the actuator is undersized, it will be unable to overcome the forces against it. This will cause slow and erratic stroking. If the actuator is not stiff enough to hold the

close position, the closure element will slam into the seat, causing a pressure surge. If the actuator is oversized, it will cost more, weigh more, and be more sluggish in

terms of speed and response. Larger actuators may also provide a higher thrust that will damage internal valve parts. Actuators tend to be oversized because of safety

factors but smaller sizes function just as well when the built-in safety factors are considered.

Resources

Proper Actuator Sizing and Selection Reduces Downtime

How to Select Valve Actuators for Rotary Valves

Rotary Actuator Applications Guide

A DESCRIPTIVE DEFINITION OF VALVE ACTUATORS

Read user Insights about Valve Actuators

Related Products & Services

Electric Valve Actuators

Electric valve actuators mount on valves which, in response to a signal, automatically move to a desired position using an outside power source. Single-phase or

three-phase AC or DC motors drive a combination of gears to generate the desired torque level.

Electrohydraulic Valve Actuators and Hydraulic Valve Actuators

Electrohydraulic valve actuators and hydraulic valve actuators convert fluid pressure supply pressure into motion.

Manual Valve Actuators

Manual valve actuators do not require an outside power source. They use a handwheel or lever to drive a series of gears whose ratio results in a higher output

torque compared to the input (manual) torque.

Pneumatic Valve Actuators

Pneumatic valve actuators adjust valve position by converting air pressure into linear or rotary motion.

Supplier Datasheets

View Suppliers by State

View Datasheets by Spec

http://www.globalspec.com/learnmore/flow_transfer_control/valve_actuators_positioners/valve_actuators_general

4/5

9/4/2014

Valve Actuators Information on GlobalSpec

Related Products

http://www.globalspec.com/learnmore/flow_transfer_control/valve_actuators_positioners/valve_actuators_general

5/5

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Carburizing, Nitriding, and Boronizing in Vacuum Furnaces - IpsenDocument9 pagesCarburizing, Nitriding, and Boronizing in Vacuum Furnaces - Ipsenarkan1976No ratings yet

- 8 Things You May Not Know About Hammurabi's Code - History ListsDocument10 pages8 Things You May Not Know About Hammurabi's Code - History Listsarkan1976No ratings yet

- Model 818/918 Liter Gauges: Select GaugeDocument2 pagesModel 818/918 Liter Gauges: Select Gaugearkan1976No ratings yet

- The Toolco GH1600 Range of Lathes: FeaturesDocument1 pageThe Toolco GH1600 Range of Lathes: Featuresarkan1976No ratings yet

- Generator Set Pre-Start-Up Checklist: Open & Enclosed Generator Sets Cooling SystemDocument2 pagesGenerator Set Pre-Start-Up Checklist: Open & Enclosed Generator Sets Cooling Systemarkan1976No ratings yet

- Working Pressure Ratings 081114Document1 pageWorking Pressure Ratings 081114arkan1976No ratings yet

- Hydro Electric Power Plant: V P H H Y HDocument10 pagesHydro Electric Power Plant: V P H H Y Harkan1976No ratings yet

- HeliusMCT UsersGuide AbaqusDocument113 pagesHeliusMCT UsersGuide Abaqusarkan1976No ratings yet

- Valve Leakage: Home Glossary ResourcesDocument3 pagesValve Leakage: Home Glossary Resourcesarkan1976No ratings yet

- The Effect of Cohesive-Law Parameters On Mixed-Mode FractureDocument38 pagesThe Effect of Cohesive-Law Parameters On Mixed-Mode Fracturearkan1976No ratings yet

- Tokyo Sokki 2013 Strain Gages Catalogue PDFDocument80 pagesTokyo Sokki 2013 Strain Gages Catalogue PDFRalf LeisNo ratings yet

- Guidelines For Coheseive Parameters Ebook 3Document11 pagesGuidelines For Coheseive Parameters Ebook 3arkan1976100% (1)

- Turbine Speed MeasurementDocument26 pagesTurbine Speed MeasurementAyyar Kandasamy100% (4)

- Energy Engineering - NU MIDEXAMDocument2 pagesEnergy Engineering - NU MIDEXAMLester Alfred M. OlasimanNo ratings yet

- Eapp Written OutputsDocument4 pagesEapp Written OutputsAbraham Philip ParenaNo ratings yet

- Distribution Study Material PDFDocument297 pagesDistribution Study Material PDFಶ್ರೀಕಾಂತ್ ತಿಪ್ಪೇರುದ್ರಪ್ಪ50% (2)

- www714 PDFDocument32 pageswww714 PDFmario_corrales1059No ratings yet

- @@@ Geothermal-WellsDocument44 pages@@@ Geothermal-WellsstarykltNo ratings yet

- Geology of Nigeria - Update 2010Document13 pagesGeology of Nigeria - Update 2010Sani SaboNo ratings yet

- Session 3 Power System Operation Corporation Limited POSOCO Experience PDFDocument70 pagesSession 3 Power System Operation Corporation Limited POSOCO Experience PDFpratap tantyNo ratings yet

- Analysis of Non-Isolated Bidirectional DC-DC Converter With ZVSDocument7 pagesAnalysis of Non-Isolated Bidirectional DC-DC Converter With ZVSAnuja VargheseNo ratings yet

- Electric Cables For Photovoltaic Systems: Irish Standard I.S. EN 50618:2014Document9 pagesElectric Cables For Photovoltaic Systems: Irish Standard I.S. EN 50618:2014Raj shah0% (1)

- Five Key Factors You Must Consider While Selecting Your PV Module SupplierDocument5 pagesFive Key Factors You Must Consider While Selecting Your PV Module SupplierNani JagadishNo ratings yet

- CS MultiskillDocument3 pagesCS MultiskillKrishNo ratings yet

- Nizam Solar PresentationDocument29 pagesNizam Solar PresentationShahrooz Leo QureshiNo ratings yet

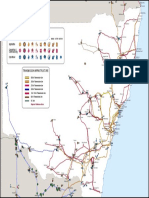

- NSW Generation MapDocument1 pageNSW Generation MapdsfsNo ratings yet

- Hitachi RAC Wiring and Pipe Guide 0516Document1 pageHitachi RAC Wiring and Pipe Guide 0516AhmedovoNo ratings yet

- Hydroelectric Energy Advantages and Disadvantages: American Journal of Energy ScienceDocument4 pagesHydroelectric Energy Advantages and Disadvantages: American Journal of Energy ScienceKalyana TarraNo ratings yet

- 2.what Are The Ecological PyramidsDocument3 pages2.what Are The Ecological PyramidsJanani VelmuruganNo ratings yet

- Environment Reporting: 1st Place - Conan Businge, Gerald Tenywa and Saudha Nakandha, New VisionDocument2 pagesEnvironment Reporting: 1st Place - Conan Businge, Gerald Tenywa and Saudha Nakandha, New VisionAfrican Centre for Media ExcellenceNo ratings yet

- Dunhm-Bush PRODUCT GUIDEDB Global Product GuideDocument19 pagesDunhm-Bush PRODUCT GUIDEDB Global Product GuideFalak KhanNo ratings yet

- Spalven Consulting-Reflectivity Solar ReportDocument13 pagesSpalven Consulting-Reflectivity Solar ReportDimas Manuel Botello AlbaNo ratings yet

- Waukesha VHPDocument2 pagesWaukesha VHPMadhana GopalNo ratings yet

- Customers AuditDocument17 pagesCustomers AuditBijuNo ratings yet

- Friedland Apes CorrelationDocument1 pageFriedland Apes Correlationapi-240829482No ratings yet

- Draft Guidebook On Net Metering 2021Document58 pagesDraft Guidebook On Net Metering 2021Javlin BaduaNo ratings yet

- Biorefineries PDFDocument16 pagesBiorefineries PDFNhận BưaNo ratings yet

- Presentation An Introduction To Wind and Solar Power ForecastingDocument44 pagesPresentation An Introduction To Wind and Solar Power ForecastingTito KurniawanNo ratings yet

- DCE 2009 SolutionsDocument48 pagesDCE 2009 Solutionspks_nikunjNo ratings yet

- Riyadh International Convention & Exhibition Center: Organized byDocument6 pagesRiyadh International Convention & Exhibition Center: Organized byWafa MersniNo ratings yet

- EP India 09-10 PDFDocument132 pagesEP India 09-10 PDFdbircs1981No ratings yet

- Innovative Design - BATSIO & Night Sky CoolingDocument6 pagesInnovative Design - BATSIO & Night Sky CoolingpeterhwilliamsNo ratings yet