Professional Documents

Culture Documents

Acceptance PE2044

Acceptance PE2044

Uploaded by

hello17Copyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Harmonized "Cluster" Document: Service Fasteners Property Classes of SpecialDocument7 pagesHarmonized "Cluster" Document: Service Fasteners Property Classes of SpecialCeliaNo ratings yet

- Plowing-Induced Nanoexfoliation of Mono - and Multilayer MoS2 SurfacesDocument6 pagesPlowing-Induced Nanoexfoliation of Mono - and Multilayer MoS2 Surfaceshello17No ratings yet

- Nanoscale: 10.1039/D3NR01261ADocument19 pagesNanoscale: 10.1039/D3NR01261Ahello17No ratings yet

- Submit Lead FormDocument1 pageSubmit Lead Formhello17No ratings yet

- Fluid Mechanics Objective Type QuestionsDocument223 pagesFluid Mechanics Objective Type Questionshello17No ratings yet

- Broadband Combo PlanDocument1 pageBroadband Combo Planhello17No ratings yet

- University College of Engineering Time: 30 Minutes Sessional Quiz Max Marks: 40Document4 pagesUniversity College of Engineering Time: 30 Minutes Sessional Quiz Max Marks: 40hello17No ratings yet

- University College of Engineering Max Marks:30 1 Mid Term Test Time: 1 Hour Note: Use of Mobile Is Restricted All Ques Carry Equal MarksDocument2 pagesUniversity College of Engineering Max Marks:30 1 Mid Term Test Time: 1 Hour Note: Use of Mobile Is Restricted All Ques Carry Equal Markshello17No ratings yet

- Award Sheet Rtu Dat 2104 Me IeDocument1 pageAward Sheet Rtu Dat 2104 Me Iehello17No ratings yet

- "Carbon Nanotubes": Masters of TechnologyDocument2 pages"Carbon Nanotubes": Masters of Technologyhello17No ratings yet

- Certificate: This Is To Certify That The Pre-Thesis Seminar Entitled "Influence of Tic Reinforcement On TheDocument2 pagesCertificate: This Is To Certify That The Pre-Thesis Seminar Entitled "Influence of Tic Reinforcement On Thehello17No ratings yet

- Update Your Oil Mist Lubrication KnowledgeDocument2 pagesUpdate Your Oil Mist Lubrication Knowledgehello17No ratings yet

- General Engineering Knowledge For Marine EngineersDocument272 pagesGeneral Engineering Knowledge For Marine EngineersMANDEEP SINGHNo ratings yet

- Manual Pinch Valves BrochureDocument9 pagesManual Pinch Valves BrochureVenkatesh GangadharNo ratings yet

- c117 f16 PDFDocument1 pagec117 f16 PDFpradeepNo ratings yet

- Synthesis of Zinc Chloride Lab Revised Fall 2007Document4 pagesSynthesis of Zinc Chloride Lab Revised Fall 2007farid1484No ratings yet

- E l21s0 HPDocument2 pagesE l21s0 HPrinthusNo ratings yet

- Broggi 1818: Catalogue 2014 Cutlery Stainless Steel and Electro-Plated Stainless SteelDocument63 pagesBroggi 1818: Catalogue 2014 Cutlery Stainless Steel and Electro-Plated Stainless SteelBroggi 1818No ratings yet

- Asme Sec Viii Div 1 2017 Ucs 56Document1 pageAsme Sec Viii Div 1 2017 Ucs 56Anonymous hBBam1nNo ratings yet

- Normal Grating Manual 531-09Document36 pagesNormal Grating Manual 531-09esaraviaNo ratings yet

- FCS/BCS Series - Centrifugal Fans: Description DataDocument7 pagesFCS/BCS Series - Centrifugal Fans: Description DataHuyNo ratings yet

- HDADocument13 pagesHDAnetozxNo ratings yet

- Stainless Steel 316l (SA240)Document2 pagesStainless Steel 316l (SA240)Sugiarto SaptomoNo ratings yet

- 4541 KIM - Skema Kertas 1 & 2Document13 pages4541 KIM - Skema Kertas 1 & 2Yeow Pow Choo100% (1)

- Boiler Tube LeakagesDocument33 pagesBoiler Tube LeakagesVIBHAV0% (1)

- ASTM MNL 2 Manual On Vapor Degreasing 3rd EditionDocument50 pagesASTM MNL 2 Manual On Vapor Degreasing 3rd Edition320338100% (2)

- Cast Iron Gate Valves: OS& Y, Bolted Bonnet, JIS 10KDocument9 pagesCast Iron Gate Valves: OS& Y, Bolted Bonnet, JIS 10KSamuel GermatusNo ratings yet

- Anodes For Cu-EWDocument28 pagesAnodes For Cu-EWvictor perez villegasNo ratings yet

- Cathodic Protection Guidelines - 8Document27 pagesCathodic Protection Guidelines - 8Noli OtebaNo ratings yet

- Operational Information The Two Stroke Crosshead Engine The CrankshaftDocument9 pagesOperational Information The Two Stroke Crosshead Engine The CrankshaftAbhishek Singh ChauhanNo ratings yet

- Types of StairsDocument32 pagesTypes of StairsArnav Dasaur100% (1)

- Legal-Guidelines Technical Specifications For The Installation of Telecommunications Masts and Towers ApendixDocument70 pagesLegal-Guidelines Technical Specifications For The Installation of Telecommunications Masts and Towers Apendixmoji678No ratings yet

- Segregation and Banding in Carbon and Alloy Steel - 2013-10-07 - Industrial HeatingDocument3 pagesSegregation and Banding in Carbon and Alloy Steel - 2013-10-07 - Industrial HeatingharieduidNo ratings yet

- Arc Reinforcement Handbook 6ed 2010Document78 pagesArc Reinforcement Handbook 6ed 2010Anthony L. FelderNo ratings yet

- Pfi Es-41 2003Document2 pagesPfi Es-41 2003bayu212100% (1)

- Specification of Civil WorksDocument208 pagesSpecification of Civil WorksPrantik Adhar SamantaNo ratings yet

- Otds BrochureDocument27 pagesOtds Brochurewei6cnNo ratings yet

- Providing High-Quality Zinc Coatings (Hot-Dip) : Standard Practice ForDocument8 pagesProviding High-Quality Zinc Coatings (Hot-Dip) : Standard Practice Forkyeong cheol leeNo ratings yet

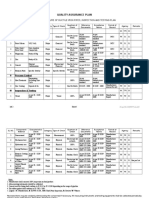

- Quality Assurance Plan: For Manufacture of Ductile Iron Pipes, Inspection and Testing PlanDocument2 pagesQuality Assurance Plan: For Manufacture of Ductile Iron Pipes, Inspection and Testing PlanNaveen NagisettiNo ratings yet

- Mineral ResourcesDocument7 pagesMineral ResourcesTudor PipirigNo ratings yet

- 03 Doetsch PDFDocument10 pages03 Doetsch PDFNeelima MishraNo ratings yet

Acceptance PE2044

Acceptance PE2044

Uploaded by

hello17Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acceptance PE2044

Acceptance PE2044

Uploaded by

hello17Copyright:

Available Formats

InternationalConferenceon

Industrial,Mechanical and Production

Engineering:

Advancements and Current Trends

November 27- 29, 2014

Organized by Department of Mechanical Engineering

Maulana Azad National Institute of Technology, Bhopal 462051,India

(An Institute of National Importance )

Chairman

Dr. Siraj Ahmed

HOD, Mech.

Coordinators

Dr. Ajay Verma

Dr. Arvind Kumar

Dr. M.K. Pradhan

Organising Committee

Dr. Geeta Agnihotri

Dr. N. D. Mittal

Dr. Gajendra Dixit

Dr. R. M. Sarviya

Dr. A. R. Siddiqui

Dr. J. L. Bhagoria

Dr. S. P. S. Rajput

Dr. Rajesh Gupta

Dr. Sanjay Soni

Dr. R.K Mandaloi

Dr. R. K Dwivedi

Dr. K.R. Aharwal

Dr. Rajesh Purohit

Dr. C. M. Krishna

Dr. V.K Soni

Dr. AM Lanjewar

Dr. Vilas Warudkar

Prof. Ajay Pandey

Dr. P. K. Soni

Dr. Amit Telang

Dr. Alok Singh

Dr. P Mishra

Dr. Manoj Arya

Dr. Vishal Parashar

Dr. R. S Rana

Prof. Amit Suhane

Prof. Akhilesh Soni

Dr. M.Vishwakarma

Patron

Chief Patron

Honourable Director

Honourable Chairman

Dr.Appukuttan K.K

Dr.G.K.Mehta

Date: 29-09-2014

To

Prashant Mittal,Dr.G.Dixit

Sub: Acceptance of the research paper for oral presentation in ICIMPACT 2014.

Dear Sir/Madam,

We are pleased to inform you that your research paper titled DRY SLIDING BEHAVIOUR OF 2014

ALUMINUM ALLOY REINFORCED WITH SIC COMPOSITE , with Paper codePE2044 has been

accepted by the panel of reviewers for oral presentation in the conference with following comments.

The overall format of the paper should be as specified in web site. http://icimpact.weebly.com/fullpaper.html.

Please make necessary changes in the manuscript and submit camera ready paper by 10th October, 2014

and the

registration fee alognwith duly signed copyright form and registration form (Forms available on the

website).

The details of the Bank Account is provided here for Early Bird Registration.

Bank Name

State Bank of India

Branch

MANIT, Bhopal

Account Name

ICIMPACT

IFSC Code

SBIN0001608

Account No.

33702570480

Please feel free to contact in case of any clarification about registration and any other matter at the

contact details given below.

Regards

Dr. M.K. Pradhan

Coordinator, ICIMPACT2014

Reviewers comment

1.

2.

3.

4.

5.

In the introduction section citations are numbers it should be changed to authors name with year like (Pradhan 2014)

References should be in APA format arranged alphabetically; they must be cited inside the article as (Pradhan 2014) not as

a number.

Figures/ Graphs should be of good quality so that it is visible properly on printing

How this work is novel from other work? Include this as part of discussion.

Some portion of the following para is matching with the published artcle, this should be modified and rewritten by own words to avoid

plagiarism issue.

Muffle Furnace and a stirrer assembly, was used to yield the composite. The stirrer assembly comprised of a graphite stirrer, which was coupled to a

variable speed vertical drilling machine with range of 80 to 890 rpm through a steel shaft. The stirrer was manufactured by cutting and shaping a

graphite block to preferred shape and size manually. The stirrer comprised of three blades at an angle of 120 apart. Crucible made of Clay graphite

of 1.5 Kg capacity was placed inside the furnace. About 1Kg of alloy in solid form (hexagonal rod) was melted at 820C in the resistance furnace.

Preheating of reinforcement (Silicon carbide) was done for one hour to eliminate moisture and gases from the sur face of the particulates. The

reinforcement particles were separated by sieve shaker. The stirrer was then dropped vertically up to 3 cm from the bottom end of the crucible (the

total height of the melt was 9 cm). The speed of the stirrer was progressively elevated to 800 rpm and the preheated reinforced (SiC) particles were

progressively added with a spoon at the rate of 1 0 - 20g/min into the melt The speed controller kept a constant speed of the stirrer, since the stirrer

speed decreases by 50 - 60 rpm due to the increase in viscosity of the melt when particulates were added in the melt. After reinforcement addition,

stirring was sustained for 8 to 12 minutes for proper mixing of prepared particles in the matrix. The melt was kept in the crucible nearly for half minute

in static condition and then it wa http://www.ijera.com/papers/Vol2_issue6/DF26727731.pdf

Phone: (0755)4051631, 32, 33, +919406623070 + 919826674815, +918889152316

Fax: (0755)2670562,

E-mail: icimpact14@gmail.com, icimpactmanit@gmail.com Home Page: http://icimpact.weebly.com/, http://www.manit.ac.in

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Harmonized "Cluster" Document: Service Fasteners Property Classes of SpecialDocument7 pagesHarmonized "Cluster" Document: Service Fasteners Property Classes of SpecialCeliaNo ratings yet

- Plowing-Induced Nanoexfoliation of Mono - and Multilayer MoS2 SurfacesDocument6 pagesPlowing-Induced Nanoexfoliation of Mono - and Multilayer MoS2 Surfaceshello17No ratings yet

- Nanoscale: 10.1039/D3NR01261ADocument19 pagesNanoscale: 10.1039/D3NR01261Ahello17No ratings yet

- Submit Lead FormDocument1 pageSubmit Lead Formhello17No ratings yet

- Fluid Mechanics Objective Type QuestionsDocument223 pagesFluid Mechanics Objective Type Questionshello17No ratings yet

- Broadband Combo PlanDocument1 pageBroadband Combo Planhello17No ratings yet

- University College of Engineering Time: 30 Minutes Sessional Quiz Max Marks: 40Document4 pagesUniversity College of Engineering Time: 30 Minutes Sessional Quiz Max Marks: 40hello17No ratings yet

- University College of Engineering Max Marks:30 1 Mid Term Test Time: 1 Hour Note: Use of Mobile Is Restricted All Ques Carry Equal MarksDocument2 pagesUniversity College of Engineering Max Marks:30 1 Mid Term Test Time: 1 Hour Note: Use of Mobile Is Restricted All Ques Carry Equal Markshello17No ratings yet

- Award Sheet Rtu Dat 2104 Me IeDocument1 pageAward Sheet Rtu Dat 2104 Me Iehello17No ratings yet

- "Carbon Nanotubes": Masters of TechnologyDocument2 pages"Carbon Nanotubes": Masters of Technologyhello17No ratings yet

- Certificate: This Is To Certify That The Pre-Thesis Seminar Entitled "Influence of Tic Reinforcement On TheDocument2 pagesCertificate: This Is To Certify That The Pre-Thesis Seminar Entitled "Influence of Tic Reinforcement On Thehello17No ratings yet

- Update Your Oil Mist Lubrication KnowledgeDocument2 pagesUpdate Your Oil Mist Lubrication Knowledgehello17No ratings yet

- General Engineering Knowledge For Marine EngineersDocument272 pagesGeneral Engineering Knowledge For Marine EngineersMANDEEP SINGHNo ratings yet

- Manual Pinch Valves BrochureDocument9 pagesManual Pinch Valves BrochureVenkatesh GangadharNo ratings yet

- c117 f16 PDFDocument1 pagec117 f16 PDFpradeepNo ratings yet

- Synthesis of Zinc Chloride Lab Revised Fall 2007Document4 pagesSynthesis of Zinc Chloride Lab Revised Fall 2007farid1484No ratings yet

- E l21s0 HPDocument2 pagesE l21s0 HPrinthusNo ratings yet

- Broggi 1818: Catalogue 2014 Cutlery Stainless Steel and Electro-Plated Stainless SteelDocument63 pagesBroggi 1818: Catalogue 2014 Cutlery Stainless Steel and Electro-Plated Stainless SteelBroggi 1818No ratings yet

- Asme Sec Viii Div 1 2017 Ucs 56Document1 pageAsme Sec Viii Div 1 2017 Ucs 56Anonymous hBBam1nNo ratings yet

- Normal Grating Manual 531-09Document36 pagesNormal Grating Manual 531-09esaraviaNo ratings yet

- FCS/BCS Series - Centrifugal Fans: Description DataDocument7 pagesFCS/BCS Series - Centrifugal Fans: Description DataHuyNo ratings yet

- HDADocument13 pagesHDAnetozxNo ratings yet

- Stainless Steel 316l (SA240)Document2 pagesStainless Steel 316l (SA240)Sugiarto SaptomoNo ratings yet

- 4541 KIM - Skema Kertas 1 & 2Document13 pages4541 KIM - Skema Kertas 1 & 2Yeow Pow Choo100% (1)

- Boiler Tube LeakagesDocument33 pagesBoiler Tube LeakagesVIBHAV0% (1)

- ASTM MNL 2 Manual On Vapor Degreasing 3rd EditionDocument50 pagesASTM MNL 2 Manual On Vapor Degreasing 3rd Edition320338100% (2)

- Cast Iron Gate Valves: OS& Y, Bolted Bonnet, JIS 10KDocument9 pagesCast Iron Gate Valves: OS& Y, Bolted Bonnet, JIS 10KSamuel GermatusNo ratings yet

- Anodes For Cu-EWDocument28 pagesAnodes For Cu-EWvictor perez villegasNo ratings yet

- Cathodic Protection Guidelines - 8Document27 pagesCathodic Protection Guidelines - 8Noli OtebaNo ratings yet

- Operational Information The Two Stroke Crosshead Engine The CrankshaftDocument9 pagesOperational Information The Two Stroke Crosshead Engine The CrankshaftAbhishek Singh ChauhanNo ratings yet

- Types of StairsDocument32 pagesTypes of StairsArnav Dasaur100% (1)

- Legal-Guidelines Technical Specifications For The Installation of Telecommunications Masts and Towers ApendixDocument70 pagesLegal-Guidelines Technical Specifications For The Installation of Telecommunications Masts and Towers Apendixmoji678No ratings yet

- Segregation and Banding in Carbon and Alloy Steel - 2013-10-07 - Industrial HeatingDocument3 pagesSegregation and Banding in Carbon and Alloy Steel - 2013-10-07 - Industrial HeatingharieduidNo ratings yet

- Arc Reinforcement Handbook 6ed 2010Document78 pagesArc Reinforcement Handbook 6ed 2010Anthony L. FelderNo ratings yet

- Pfi Es-41 2003Document2 pagesPfi Es-41 2003bayu212100% (1)

- Specification of Civil WorksDocument208 pagesSpecification of Civil WorksPrantik Adhar SamantaNo ratings yet

- Otds BrochureDocument27 pagesOtds Brochurewei6cnNo ratings yet

- Providing High-Quality Zinc Coatings (Hot-Dip) : Standard Practice ForDocument8 pagesProviding High-Quality Zinc Coatings (Hot-Dip) : Standard Practice Forkyeong cheol leeNo ratings yet

- Quality Assurance Plan: For Manufacture of Ductile Iron Pipes, Inspection and Testing PlanDocument2 pagesQuality Assurance Plan: For Manufacture of Ductile Iron Pipes, Inspection and Testing PlanNaveen NagisettiNo ratings yet

- Mineral ResourcesDocument7 pagesMineral ResourcesTudor PipirigNo ratings yet

- 03 Doetsch PDFDocument10 pages03 Doetsch PDFNeelima MishraNo ratings yet