Professional Documents

Culture Documents

Main Functions of Production Facility

Main Functions of Production Facility

Uploaded by

dbircs1981Copyright:

Available Formats

You might also like

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- OEM Pall Prufier Brochure PDFDocument8 pagesOEM Pall Prufier Brochure PDFhaggNo ratings yet

- Bilge Water Instructions & Requirements - ENDocument5 pagesBilge Water Instructions & Requirements - ENclaudioNo ratings yet

- Surface Facilities 2 PDFDocument54 pagesSurface Facilities 2 PDFBadzlinaKhairunizzahraNo ratings yet

- Poulan 60cc ChainsawDocument4 pagesPoulan 60cc ChainsawTim Shawn HicksNo ratings yet

- CAT079 SwitchDocument232 pagesCAT079 SwitchDan688100% (1)

- Seb D 029103Document937 pagesSeb D 029103Ravinder Singh100% (6)

- Oilfield Processing Measurement and Control Oil and Gas SeparationDocument8 pagesOilfield Processing Measurement and Control Oil and Gas SeparationAnonymous 8te2h1No ratings yet

- Apv H35Document18 pagesApv H35petrakou aglaia100% (1)

- Instrument Air Compressor PDFDocument54 pagesInstrument Air Compressor PDFpradeep1987cool100% (1)

- Amine Basic Practices Guideline PDFDocument64 pagesAmine Basic Practices Guideline PDFrajeshpillai26787No ratings yet

- General Engineering Knowledge For Marine EngineersDocument31 pagesGeneral Engineering Knowledge For Marine EngineersSrini VasanNo ratings yet

- Compressor Water Wash SystemDocument10 pagesCompressor Water Wash SystemCarlos GonzálezNo ratings yet

- 43 (Lecture - Instrumentation For P&ID's - Cookbook)Document55 pages43 (Lecture - Instrumentation For P&ID's - Cookbook)Darkmatter DarkmatterrNo ratings yet

- Appendix G - All FTPDocument81 pagesAppendix G - All FTPRaja AntonyNo ratings yet

- Vaccum Dehydrator 1Document7 pagesVaccum Dehydrator 1Simbu ArasanNo ratings yet

- Chap 5 - Production Operations and FacilitiesDocument56 pagesChap 5 - Production Operations and FacilitiesOnniey 1201No ratings yet

- Clarke-Providing Adequate Raw Water Supply To The Heat Exchanger Cooled Fire Pump EnginesDocument4 pagesClarke-Providing Adequate Raw Water Supply To The Heat Exchanger Cooled Fire Pump EnginesAnonymous CMS3dL1TNo ratings yet

- Fresh Water GeneratorDocument13 pagesFresh Water GeneratorPrem Cesc NathNo ratings yet

- PurifierDocument4 pagesPurifierRizal Falevy100% (1)

- 8187-116 Mechanical System DescriptionDocument5 pages8187-116 Mechanical System DescriptionJoelle SalamounNo ratings yet

- System Description: Purebilge Bilgewater Cleaning SystemDocument18 pagesSystem Description: Purebilge Bilgewater Cleaning SystemМаксимNo ratings yet

- All About Marine Enginnering OralsDocument76 pagesAll About Marine Enginnering OralsUdana Hettiarachchi100% (3)

- Every Day Checks in Engine Room Rounds From Funnel To Tunnel On ShipDocument5 pagesEvery Day Checks in Engine Room Rounds From Funnel To Tunnel On ShipjoyceNo ratings yet

- Fuel Gas System - Candidate PDFDocument11 pagesFuel Gas System - Candidate PDFbelil206No ratings yet

- 11.17 Water and Waste (ATA 38) : System Lay-OutDocument22 pages11.17 Water and Waste (ATA 38) : System Lay-OutnajibNo ratings yet

- Vaccum DehydratorDocument4 pagesVaccum DehydratorSimbu ArasanNo ratings yet

- MutharasanDocument4 pagesMutharasanGodwin GodwinNo ratings yet

- 01 Hydraulic GroupDocument81 pages01 Hydraulic Groupgica100% (1)

- Aircraft Hydraulic SystemDocument3 pagesAircraft Hydraulic SystemDesiree Cena CapunoNo ratings yet

- Liquid Flow Meter Proving and LACT UnitsDocument4 pagesLiquid Flow Meter Proving and LACT UnitsDayo IdowuNo ratings yet

- Automatic Operation of BoilerDocument23 pagesAutomatic Operation of BoilerSuhas KassaNo ratings yet

- Automatic Boiler ControlDocument16 pagesAutomatic Boiler ControlbadpplNo ratings yet

- Hyd System Maintenance N PnematicsDocument22 pagesHyd System Maintenance N PnematicsMarcus ThianNo ratings yet

- Fresh Water Generator DesignDocument4 pagesFresh Water Generator DesignVikk Suriya100% (1)

- Power Industry ApplicationsDocument47 pagesPower Industry ApplicationsFarshid PourmoezabadiNo ratings yet

- 1.preparation For Commissioning For BoilerDocument36 pages1.preparation For Commissioning For BoilerPrudhvi Raj100% (1)

- Maintenance Manual ABBDocument9 pagesMaintenance Manual ABBKARAM ZAKARIANo ratings yet

- BSL Presentation On BasicsDocument41 pagesBSL Presentation On BasicsSathishNo ratings yet

- FMSP 2Document40 pagesFMSP 2مصطفى عمرNo ratings yet

- 02B HRSGDocument50 pages02B HRSGrseclen100% (4)

- 43 (Lecture - Instrumentation For P&ID's - Cookbook)Document55 pages43 (Lecture - Instrumentation For P&ID's - Cookbook)Trí NguyễnNo ratings yet

- Technical Specs For RotavapourDocument2 pagesTechnical Specs For RotavapourANKIT SHARMANo ratings yet

- 3E Sanko SummitDocument5 pages3E Sanko SummitHarshey Anne PagariganNo ratings yet

- 3-Phase Test Separators VVFDocument2 pages3-Phase Test Separators VVFPetroFisicNo ratings yet

- Ipc Cep-0038-EaDocument11 pagesIpc Cep-0038-EaCh FazalNo ratings yet

- Chapter 02Document58 pagesChapter 02MJ LagradaNo ratings yet

- Final Functional Checks Are Carried Out After The Flushing ProcedureDocument20 pagesFinal Functional Checks Are Carried Out After The Flushing ProcedurePrudhvi RajNo ratings yet

- Alfa Laval Orca SeriesDocument2 pagesAlfa Laval Orca SeriesdumpuuNo ratings yet

- Load Sensing Valve TheoryDocument12 pagesLoad Sensing Valve TheorySammy Ulita100% (2)

- Fundamentals of Gas Pipeline Metering Stations - Pipeline & Gas JournalDocument4 pagesFundamentals of Gas Pipeline Metering Stations - Pipeline & Gas JournalMehedi HasanNo ratings yet

- Aviation: A. Aircraft Landing Gear Sys-TemsDocument21 pagesAviation: A. Aircraft Landing Gear Sys-TemsHugo AlmeidaNo ratings yet

- Vapor-Flo Humidity Generator Operation and Maintenance: Thermal Product SolutionsDocument14 pagesVapor-Flo Humidity Generator Operation and Maintenance: Thermal Product SolutionsVirginia MartelliNo ratings yet

- Ppt:-Piping SystemDocument35 pagesPpt:-Piping Systemaimri_cochin67% (12)

- PETOIL BOSS Characteristics Rev - Jun09 - EnglishDocument8 pagesPETOIL BOSS Characteristics Rev - Jun09 - EnglishSelma SelminhaNo ratings yet

- Nadesh WRONGDocument5 pagesNadesh WRONGGodwin GodwinNo ratings yet

- O M Manual W818 PDFDocument71 pagesO M Manual W818 PDFmujeebmehar100% (1)

- Turbine Interlocks and ProtectionDocument31 pagesTurbine Interlocks and ProtectionShambhu Mehta100% (2)

- Turbine SopDocument8 pagesTurbine SopDominic Daniel100% (1)

- EvaporatingDocument5 pagesEvaporatingFadhil KhalidNo ratings yet

- In-Situ Fermentors CatalogueDocument4 pagesIn-Situ Fermentors CatalogueVineet GuptaNo ratings yet

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- PID Typical Arrangement For 3 Phase Separator VesselsDocument1 pagePID Typical Arrangement For 3 Phase Separator Vesselsdbircs1981No ratings yet

- PID Typical For Centrifugal Compressor System11Document1 pagePID Typical For Centrifugal Compressor System11dbircs1981No ratings yet

- Offshore P&ID SymbolsDocument1 pageOffshore P&ID Symbolsdbircs1981No ratings yet

- EP India 2013-14Document191 pagesEP India 2013-14dbircs1981No ratings yet

- 1 - S K VermaDocument31 pages1 - S K Vermadbircs1981No ratings yet

- Statistical Recovery Factor Calculation: Gas ReservoirsDocument1 pageStatistical Recovery Factor Calculation: Gas Reservoirsdbircs1981No ratings yet

- EP India 09-10 PDFDocument132 pagesEP India 09-10 PDFdbircs1981No ratings yet

- EP India 08-09Document136 pagesEP India 08-09dbircs1981No ratings yet

- How To Read Oil Analysis ReportDocument7 pagesHow To Read Oil Analysis Reportgshdavid100% (1)

- B&J Fuel InjectionDocument24 pagesB&J Fuel InjectionZeeshan Ahmad100% (1)

- Industrial Internship PresentationDocument39 pagesIndustrial Internship PresentationshuvrabanikNo ratings yet

- 17OILGASMINE Ketsela Tadesse S2 PDFDocument37 pages17OILGASMINE Ketsela Tadesse S2 PDFgetasewNo ratings yet

- ABSA 4th Class B HelpDocument53 pagesABSA 4th Class B HelpAnonymous eMaZdX9100% (1)

- Presentation On State of Power Crisis in BangladeshDocument10 pagesPresentation On State of Power Crisis in BangladeshrifatNo ratings yet

- BatuDocument22 pagesBatuUmran SaidNo ratings yet

- The Edmeston Heat Recovery System: Carbon Black - Glass - SteelDocument8 pagesThe Edmeston Heat Recovery System: Carbon Black - Glass - SteelffownNo ratings yet

- Tools Caterpillar PDFDocument158 pagesTools Caterpillar PDFJoao Silva100% (1)

- Wartsila TB 2stroke Troubleshooting & Maintenance On Injection Control UnitDocument21 pagesWartsila TB 2stroke Troubleshooting & Maintenance On Injection Control UnitVito Digeo100% (2)

- Nuevo Documento de Microsoft WordDocument3 pagesNuevo Documento de Microsoft WordRuben C. CanaviriNo ratings yet

- Advantages of 4 Stroke Engine:-: DifferencesDocument3 pagesAdvantages of 4 Stroke Engine:-: DifferencescidracNo ratings yet

- How PSA WorksDocument1 pageHow PSA WorksCallidus101No ratings yet

- Inspectorate Malaysia SDN BHD, JohorDocument3 pagesInspectorate Malaysia SDN BHD, JohorIan RidzuanNo ratings yet

- PV 544 Road Test November 1963Document4 pagesPV 544 Road Test November 1963aakk75No ratings yet

- Keenecatalog 2013Document44 pagesKeenecatalog 2013daks4uNo ratings yet

- Future LearningDocument14 pagesFuture LearninggoodNo ratings yet

- 325 B InjecteurDocument1 page325 B InjecteurSoufiane KadarNo ratings yet

- Naoc - Supply of Ago AdvertDocument1 pageNaoc - Supply of Ago Advertben.ekiyor3872No ratings yet

- Ethanol Distillation Process PDFDocument2 pagesEthanol Distillation Process PDFKurtNo ratings yet

- Initial SurveyDraft SURVEYDocument121 pagesInitial SurveyDraft SURVEYvnmcminhquang100% (1)

- CL 604-Power Plant PDFDocument38 pagesCL 604-Power Plant PDFBhaskerNegiNo ratings yet

- LPO 1318 C LHD Latest - PDF - HTM - 2Document338 pagesLPO 1318 C LHD Latest - PDF - HTM - 2Gen Abimbolar OdukaleNo ratings yet

- Dec-2019 P TDocument60 pagesDec-2019 P TmaheshgupteNo ratings yet

- Automobile Chassis and Body EngDocument3 pagesAutomobile Chassis and Body EngAlenFluxNo ratings yet

- PP k24 Electronic Turbine FlowmeterDocument2 pagesPP k24 Electronic Turbine FlowmeterAriksonNo ratings yet

- Chapter 2 MHIDocument40 pagesChapter 2 MHIaunngageNo ratings yet

Main Functions of Production Facility

Main Functions of Production Facility

Uploaded by

dbircs1981Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Main Functions of Production Facility

Main Functions of Production Facility

Uploaded by

dbircs1981Copyright:

Available Formats

MAIN FUNCTIONS OF PRODUCTION FACILITY

Hori/Vert

Separators

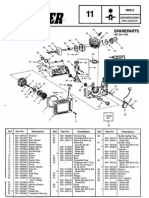

Enginer driven reciprocating compressor

Turbine driven centrifugal compressor

Hori/Vert

Glycol Dehydrator

Hori/Vert

Direct fired heater treaters

Gunbarrel tanks - where oil settles and gets treated

Lease Automatic Custody Transfer (LACT)

Hori/Vert

Skimmer Vessels

Upflow/Downflow CPIs

Floatation units

Cross-flow coalescers/separators

Hydrocyclones

Sedimentation tanks

Hydrocyclones

Filters

AUXILIARY SYSTEMS THAT SUPPORT THE PRODUCTION STATED ABOVE

1 Developing infrastructure to locate the items

Providing utlities to enable the process to work

Generating and distributing electricity

Providing and treating fuel gas or diesel

Providing instrument and power air

Treating water for desalting or boiler feed

Providing facilities

Living quarters

Switchgear and control rooms

Workshops

Cranes

Sewage treatment units

Safety Systems for detecting Hazards

MAKING THE EQUIPMENT WORK

Main items of process equipment have automatic instrumentation

that control the pressure and liquid level and sometimes temp

within the equipment

Pressure Controllers

Pressure Control Valve with pnematic actuator

Pressure Controller

Level controller

On/Off switch

Ever increasing/decreasing signal

Capacitance and inductance probes

Pressure differential measuring devices

CONTROLLING THE PROCESS

Operation of a Control Valve

Control Valves are used throughout the process to control pressure, level, temperature and

Basic System Configuration

Wellhead and manifold

The production system begins at the wellhead, which should include at least one choke, un

Pressure drop between well flowing tubing pressure (FTP) and initial separator operating pr

On offshore facilities, an auto shutdown valve should be installed on the wellhead

Gas is separated from liquids and water is separated from oil

For gas compression

Removing watervapor from gas

Removing water from oil and emulsion being treated

For accurate measuring and sampling of crude oil

For treating water - to be free from oil so that they can

be reinjected into the reservoir

For treating water - to be free from solid particles so that they can

be reinjected into the reservoir

To perform well testing and measurement so that gas, oil and water

production can be properly allocated to each well which is helpful

for accounting and reservoir depletion purposes

To power pnematic instruments and control valves to operate

atic actuator

, level, temperature and flow

de at least one choke, unless the well is on artificial lift

al separator operating pressure occurs across this choke

on the wellhead

Basin sediment and water to be 0.5% to 3% of crude

Salt limits are 10 to 25 pounds per 1000 bbl crude

You might also like

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- OEM Pall Prufier Brochure PDFDocument8 pagesOEM Pall Prufier Brochure PDFhaggNo ratings yet

- Bilge Water Instructions & Requirements - ENDocument5 pagesBilge Water Instructions & Requirements - ENclaudioNo ratings yet

- Surface Facilities 2 PDFDocument54 pagesSurface Facilities 2 PDFBadzlinaKhairunizzahraNo ratings yet

- Poulan 60cc ChainsawDocument4 pagesPoulan 60cc ChainsawTim Shawn HicksNo ratings yet

- CAT079 SwitchDocument232 pagesCAT079 SwitchDan688100% (1)

- Seb D 029103Document937 pagesSeb D 029103Ravinder Singh100% (6)

- Oilfield Processing Measurement and Control Oil and Gas SeparationDocument8 pagesOilfield Processing Measurement and Control Oil and Gas SeparationAnonymous 8te2h1No ratings yet

- Apv H35Document18 pagesApv H35petrakou aglaia100% (1)

- Instrument Air Compressor PDFDocument54 pagesInstrument Air Compressor PDFpradeep1987cool100% (1)

- Amine Basic Practices Guideline PDFDocument64 pagesAmine Basic Practices Guideline PDFrajeshpillai26787No ratings yet

- General Engineering Knowledge For Marine EngineersDocument31 pagesGeneral Engineering Knowledge For Marine EngineersSrini VasanNo ratings yet

- Compressor Water Wash SystemDocument10 pagesCompressor Water Wash SystemCarlos GonzálezNo ratings yet

- 43 (Lecture - Instrumentation For P&ID's - Cookbook)Document55 pages43 (Lecture - Instrumentation For P&ID's - Cookbook)Darkmatter DarkmatterrNo ratings yet

- Appendix G - All FTPDocument81 pagesAppendix G - All FTPRaja AntonyNo ratings yet

- Vaccum Dehydrator 1Document7 pagesVaccum Dehydrator 1Simbu ArasanNo ratings yet

- Chap 5 - Production Operations and FacilitiesDocument56 pagesChap 5 - Production Operations and FacilitiesOnniey 1201No ratings yet

- Clarke-Providing Adequate Raw Water Supply To The Heat Exchanger Cooled Fire Pump EnginesDocument4 pagesClarke-Providing Adequate Raw Water Supply To The Heat Exchanger Cooled Fire Pump EnginesAnonymous CMS3dL1TNo ratings yet

- Fresh Water GeneratorDocument13 pagesFresh Water GeneratorPrem Cesc NathNo ratings yet

- PurifierDocument4 pagesPurifierRizal Falevy100% (1)

- 8187-116 Mechanical System DescriptionDocument5 pages8187-116 Mechanical System DescriptionJoelle SalamounNo ratings yet

- System Description: Purebilge Bilgewater Cleaning SystemDocument18 pagesSystem Description: Purebilge Bilgewater Cleaning SystemМаксимNo ratings yet

- All About Marine Enginnering OralsDocument76 pagesAll About Marine Enginnering OralsUdana Hettiarachchi100% (3)

- Every Day Checks in Engine Room Rounds From Funnel To Tunnel On ShipDocument5 pagesEvery Day Checks in Engine Room Rounds From Funnel To Tunnel On ShipjoyceNo ratings yet

- Fuel Gas System - Candidate PDFDocument11 pagesFuel Gas System - Candidate PDFbelil206No ratings yet

- 11.17 Water and Waste (ATA 38) : System Lay-OutDocument22 pages11.17 Water and Waste (ATA 38) : System Lay-OutnajibNo ratings yet

- Vaccum DehydratorDocument4 pagesVaccum DehydratorSimbu ArasanNo ratings yet

- MutharasanDocument4 pagesMutharasanGodwin GodwinNo ratings yet

- 01 Hydraulic GroupDocument81 pages01 Hydraulic Groupgica100% (1)

- Aircraft Hydraulic SystemDocument3 pagesAircraft Hydraulic SystemDesiree Cena CapunoNo ratings yet

- Liquid Flow Meter Proving and LACT UnitsDocument4 pagesLiquid Flow Meter Proving and LACT UnitsDayo IdowuNo ratings yet

- Automatic Operation of BoilerDocument23 pagesAutomatic Operation of BoilerSuhas KassaNo ratings yet

- Automatic Boiler ControlDocument16 pagesAutomatic Boiler ControlbadpplNo ratings yet

- Hyd System Maintenance N PnematicsDocument22 pagesHyd System Maintenance N PnematicsMarcus ThianNo ratings yet

- Fresh Water Generator DesignDocument4 pagesFresh Water Generator DesignVikk Suriya100% (1)

- Power Industry ApplicationsDocument47 pagesPower Industry ApplicationsFarshid PourmoezabadiNo ratings yet

- 1.preparation For Commissioning For BoilerDocument36 pages1.preparation For Commissioning For BoilerPrudhvi Raj100% (1)

- Maintenance Manual ABBDocument9 pagesMaintenance Manual ABBKARAM ZAKARIANo ratings yet

- BSL Presentation On BasicsDocument41 pagesBSL Presentation On BasicsSathishNo ratings yet

- FMSP 2Document40 pagesFMSP 2مصطفى عمرNo ratings yet

- 02B HRSGDocument50 pages02B HRSGrseclen100% (4)

- 43 (Lecture - Instrumentation For P&ID's - Cookbook)Document55 pages43 (Lecture - Instrumentation For P&ID's - Cookbook)Trí NguyễnNo ratings yet

- Technical Specs For RotavapourDocument2 pagesTechnical Specs For RotavapourANKIT SHARMANo ratings yet

- 3E Sanko SummitDocument5 pages3E Sanko SummitHarshey Anne PagariganNo ratings yet

- 3-Phase Test Separators VVFDocument2 pages3-Phase Test Separators VVFPetroFisicNo ratings yet

- Ipc Cep-0038-EaDocument11 pagesIpc Cep-0038-EaCh FazalNo ratings yet

- Chapter 02Document58 pagesChapter 02MJ LagradaNo ratings yet

- Final Functional Checks Are Carried Out After The Flushing ProcedureDocument20 pagesFinal Functional Checks Are Carried Out After The Flushing ProcedurePrudhvi RajNo ratings yet

- Alfa Laval Orca SeriesDocument2 pagesAlfa Laval Orca SeriesdumpuuNo ratings yet

- Load Sensing Valve TheoryDocument12 pagesLoad Sensing Valve TheorySammy Ulita100% (2)

- Fundamentals of Gas Pipeline Metering Stations - Pipeline & Gas JournalDocument4 pagesFundamentals of Gas Pipeline Metering Stations - Pipeline & Gas JournalMehedi HasanNo ratings yet

- Aviation: A. Aircraft Landing Gear Sys-TemsDocument21 pagesAviation: A. Aircraft Landing Gear Sys-TemsHugo AlmeidaNo ratings yet

- Vapor-Flo Humidity Generator Operation and Maintenance: Thermal Product SolutionsDocument14 pagesVapor-Flo Humidity Generator Operation and Maintenance: Thermal Product SolutionsVirginia MartelliNo ratings yet

- Ppt:-Piping SystemDocument35 pagesPpt:-Piping Systemaimri_cochin67% (12)

- PETOIL BOSS Characteristics Rev - Jun09 - EnglishDocument8 pagesPETOIL BOSS Characteristics Rev - Jun09 - EnglishSelma SelminhaNo ratings yet

- Nadesh WRONGDocument5 pagesNadesh WRONGGodwin GodwinNo ratings yet

- O M Manual W818 PDFDocument71 pagesO M Manual W818 PDFmujeebmehar100% (1)

- Turbine Interlocks and ProtectionDocument31 pagesTurbine Interlocks and ProtectionShambhu Mehta100% (2)

- Turbine SopDocument8 pagesTurbine SopDominic Daniel100% (1)

- EvaporatingDocument5 pagesEvaporatingFadhil KhalidNo ratings yet

- In-Situ Fermentors CatalogueDocument4 pagesIn-Situ Fermentors CatalogueVineet GuptaNo ratings yet

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- PID Typical Arrangement For 3 Phase Separator VesselsDocument1 pagePID Typical Arrangement For 3 Phase Separator Vesselsdbircs1981No ratings yet

- PID Typical For Centrifugal Compressor System11Document1 pagePID Typical For Centrifugal Compressor System11dbircs1981No ratings yet

- Offshore P&ID SymbolsDocument1 pageOffshore P&ID Symbolsdbircs1981No ratings yet

- EP India 2013-14Document191 pagesEP India 2013-14dbircs1981No ratings yet

- 1 - S K VermaDocument31 pages1 - S K Vermadbircs1981No ratings yet

- Statistical Recovery Factor Calculation: Gas ReservoirsDocument1 pageStatistical Recovery Factor Calculation: Gas Reservoirsdbircs1981No ratings yet

- EP India 09-10 PDFDocument132 pagesEP India 09-10 PDFdbircs1981No ratings yet

- EP India 08-09Document136 pagesEP India 08-09dbircs1981No ratings yet

- How To Read Oil Analysis ReportDocument7 pagesHow To Read Oil Analysis Reportgshdavid100% (1)

- B&J Fuel InjectionDocument24 pagesB&J Fuel InjectionZeeshan Ahmad100% (1)

- Industrial Internship PresentationDocument39 pagesIndustrial Internship PresentationshuvrabanikNo ratings yet

- 17OILGASMINE Ketsela Tadesse S2 PDFDocument37 pages17OILGASMINE Ketsela Tadesse S2 PDFgetasewNo ratings yet

- ABSA 4th Class B HelpDocument53 pagesABSA 4th Class B HelpAnonymous eMaZdX9100% (1)

- Presentation On State of Power Crisis in BangladeshDocument10 pagesPresentation On State of Power Crisis in BangladeshrifatNo ratings yet

- BatuDocument22 pagesBatuUmran SaidNo ratings yet

- The Edmeston Heat Recovery System: Carbon Black - Glass - SteelDocument8 pagesThe Edmeston Heat Recovery System: Carbon Black - Glass - SteelffownNo ratings yet

- Tools Caterpillar PDFDocument158 pagesTools Caterpillar PDFJoao Silva100% (1)

- Wartsila TB 2stroke Troubleshooting & Maintenance On Injection Control UnitDocument21 pagesWartsila TB 2stroke Troubleshooting & Maintenance On Injection Control UnitVito Digeo100% (2)

- Nuevo Documento de Microsoft WordDocument3 pagesNuevo Documento de Microsoft WordRuben C. CanaviriNo ratings yet

- Advantages of 4 Stroke Engine:-: DifferencesDocument3 pagesAdvantages of 4 Stroke Engine:-: DifferencescidracNo ratings yet

- How PSA WorksDocument1 pageHow PSA WorksCallidus101No ratings yet

- Inspectorate Malaysia SDN BHD, JohorDocument3 pagesInspectorate Malaysia SDN BHD, JohorIan RidzuanNo ratings yet

- PV 544 Road Test November 1963Document4 pagesPV 544 Road Test November 1963aakk75No ratings yet

- Keenecatalog 2013Document44 pagesKeenecatalog 2013daks4uNo ratings yet

- Future LearningDocument14 pagesFuture LearninggoodNo ratings yet

- 325 B InjecteurDocument1 page325 B InjecteurSoufiane KadarNo ratings yet

- Naoc - Supply of Ago AdvertDocument1 pageNaoc - Supply of Ago Advertben.ekiyor3872No ratings yet

- Ethanol Distillation Process PDFDocument2 pagesEthanol Distillation Process PDFKurtNo ratings yet

- Initial SurveyDraft SURVEYDocument121 pagesInitial SurveyDraft SURVEYvnmcminhquang100% (1)

- CL 604-Power Plant PDFDocument38 pagesCL 604-Power Plant PDFBhaskerNegiNo ratings yet

- LPO 1318 C LHD Latest - PDF - HTM - 2Document338 pagesLPO 1318 C LHD Latest - PDF - HTM - 2Gen Abimbolar OdukaleNo ratings yet

- Dec-2019 P TDocument60 pagesDec-2019 P TmaheshgupteNo ratings yet

- Automobile Chassis and Body EngDocument3 pagesAutomobile Chassis and Body EngAlenFluxNo ratings yet

- PP k24 Electronic Turbine FlowmeterDocument2 pagesPP k24 Electronic Turbine FlowmeterAriksonNo ratings yet

- Chapter 2 MHIDocument40 pagesChapter 2 MHIaunngageNo ratings yet