Professional Documents

Culture Documents

Highway Bridge Collapse

Highway Bridge Collapse

Uploaded by

rao_gsv7598Copyright:

Available Formats

You might also like

- Business PlanDocument15 pagesBusiness Planrao_gsv7598No ratings yet

- Light Rail Operations: Phoenix Regional Standard Operating ProceduresDocument5 pagesLight Rail Operations: Phoenix Regional Standard Operating Proceduresmkashkooli_scribdNo ratings yet

- A Half-Inch To Failure (Sept 2009) PDFDocument4 pagesA Half-Inch To Failure (Sept 2009) PDFUnknownNo ratings yet

- Article Tunnel Celing CollapsedDocument2 pagesArticle Tunnel Celing CollapsedgemotorresNo ratings yet

- 2019 HWY18MH009 BMG AbstractDocument7 pages2019 HWY18MH009 BMG AbstractBryan VillalobosNo ratings yet

- Precast PrestressDocument60 pagesPrecast PrestressPantatNyanehBurikNo ratings yet

- Latex ModificatedDocument24 pagesLatex ModificatedjonathasiohanathanNo ratings yet

- Turn It inDocument7 pagesTurn It inPhilip MandaliosNo ratings yet

- The Infamous Gusset PlatesDocument10 pagesThe Infamous Gusset PlatesDeen ZakariaNo ratings yet

- 1 PDFDocument7 pages1 PDFJose Luis Martinez SaavedraNo ratings yet

- HWY18MH009 Investigative UpdateDocument6 pagesHWY18MH009 Investigative UpdateepraetorianNo ratings yet

- FIU Bridge Collapse Investigative ReportDocument2 pagesFIU Bridge Collapse Investigative ReportGary DetmanNo ratings yet

- Replacement of Elastomeric Bearings & Installation of Monitoring Systems Thereafter at Keppel Viaduct in SingaporeDocument18 pagesReplacement of Elastomeric Bearings & Installation of Monitoring Systems Thereafter at Keppel Viaduct in SingaporeSanja RadovicNo ratings yet

- Human Factors and Bridge FailureDocument3 pagesHuman Factors and Bridge FailureJameson J Mtanga0% (1)

- UnlversDocument55 pagesUnlversCan AcarNo ratings yet

- 028 - Pressley Destructive Testing 1049Document12 pages028 - Pressley Destructive Testing 1049tomNo ratings yet

- Minnesota BridgeDocument20 pagesMinnesota BridgeKY PengNo ratings yet

- Looking To Load and Resistance Factor RatingDocument17 pagesLooking To Load and Resistance Factor Ratingsmartman35No ratings yet

- MDOT Research Report R1515 239284 7Document40 pagesMDOT Research Report R1515 239284 7Erik Wahyu PradanaNo ratings yet

- Hao - I35W - NoteDocument7 pagesHao - I35W - NoteJobs feelNo ratings yet

- Monismith LectureDocument77 pagesMonismith LectureAbdulhaq Hadi AlhaddadNo ratings yet

- LinkslabasceDocument15 pagesLinkslabascepravin awalkondeNo ratings yet

- Long Term Health Monitoring of Post-Tensioning Box Girder BridgesDocument14 pagesLong Term Health Monitoring of Post-Tensioning Box Girder BridgesSetyo Hardono100% (1)

- Incident Investigation and Reporting - TaroDocument9 pagesIncident Investigation and Reporting - TaroJosielyn TarsNo ratings yet

- 73-Article Text-329-1-10-20190904Document5 pages73-Article Text-329-1-10-20190904Ghiyas UddinNo ratings yet

- Load Testing of Bridges - Global State-Of-Practice - India's Top Construction, Infrastructure & Civil EngineerDocument11 pagesLoad Testing of Bridges - Global State-Of-Practice - India's Top Construction, Infrastructure & Civil Engineercristina_romanescuNo ratings yet

- How To Determine Internal Force at Gusset Plate InterfaceDocument20 pagesHow To Determine Internal Force at Gusset Plate Interfacehieu49xfNo ratings yet

- Accelerated Brideg Construction in Washington StateDocument16 pagesAccelerated Brideg Construction in Washington StatesyedabdulhannanNo ratings yet

- Iricen Journal Sept. 2008Document52 pagesIricen Journal Sept. 2008js kalyana ramaNo ratings yet

- Box Girder 2Document8 pagesBox Girder 2steelageNo ratings yet

- RepairsDocument8 pagesRepairsSunday Michael OshiokeNo ratings yet

- GRP 2Document6 pagesGRP 2Bethany BermoyNo ratings yet

- GT 1490the Observational Method Can Be Simple202Document4 pagesGT 1490the Observational Method Can Be Simple202h100% (1)

- 111 CRDocument35 pages111 CRJames McguireNo ratings yet

- 0783f83a-a395-4d5f-a25d-6548c52ac9a0Document14 pages0783f83a-a395-4d5f-a25d-6548c52ac9a0Tiago SilvaNo ratings yet

- Bridges - All - Paper - Integral Abutments For Steel Bridges by E Wasserman - 10-1996Document44 pagesBridges - All - Paper - Integral Abutments For Steel Bridges by E Wasserman - 10-1996Xuejian LiuNo ratings yet

- Expert IzaDocument98 pagesExpert IzaflorinelvvNo ratings yet

- Weigh-in-Motion-Based Fatigue Damage AssessmentDocument10 pagesWeigh-in-Motion-Based Fatigue Damage Assessmentmomo3No ratings yet

- Analysis of Deck Slab and Tee Beam of A BridgeDocument59 pagesAnalysis of Deck Slab and Tee Beam of A Bridgenvnrev86% (66)

- Fundamental PrinciplesDocument22 pagesFundamental PrinciplesmehdiNo ratings yet

- Loading Tests of Existing Concrete StructuresDocument14 pagesLoading Tests of Existing Concrete StructuresAmir DhotharNo ratings yet

- Boston Resin ProblemDocument11 pagesBoston Resin ProblemJulio LópezNo ratings yet

- Northgate Ped BridgeDocument27 pagesNorthgate Ped BridgetfooqNo ratings yet

- Incremental Launch Method For Steel Truss Bridge ErectionDocument11 pagesIncremental Launch Method For Steel Truss Bridge ErectionaapennsylvaniaNo ratings yet

- Minimizing Construction Problems in Segmentally Precast Box Girder Bridges PDFDocument285 pagesMinimizing Construction Problems in Segmentally Precast Box Girder Bridges PDFAditya PratamaNo ratings yet

- Foundation WorksDocument27 pagesFoundation WorksDean SamuelNo ratings yet

- A Cable-Stayed Bridge With Main Span of 1088 MetersDocument9 pagesA Cable-Stayed Bridge With Main Span of 1088 Metersmdkml2No ratings yet

- MCL 9904Document11 pagesMCL 9904linamohdzhor4815No ratings yet

- FB&L Pontoon TransportationDocument109 pagesFB&L Pontoon TransportationHizbar ArsjadNo ratings yet

- Precast Prestressed Concrete Short Span BridgesDocument41 pagesPrecast Prestressed Concrete Short Span Bridgescdestudos100% (1)

- Structural Strength Rules Applied To Container Ships: Kinya Ishibashi, Kei Sugimoto, Tomohiro SUGIMOTODocument10 pagesStructural Strength Rules Applied To Container Ships: Kinya Ishibashi, Kei Sugimoto, Tomohiro SUGIMOTOKarim KarimNo ratings yet

- Wisconsin Dot: Development of A Bridge Construction Live Load Analysis GuideDocument171 pagesWisconsin Dot: Development of A Bridge Construction Live Load Analysis GuidedunglxNo ratings yet

- TRBRakoczyResidualCapacityofDamagedGirder RevisedDocument17 pagesTRBRakoczyResidualCapacityofDamagedGirder RevisedabdulNo ratings yet

- Construction and Long-Term Monitoring of A Concrete Box Culvert Bridge Reinforced With GFRP BarsDocument45 pagesConstruction and Long-Term Monitoring of A Concrete Box Culvert Bridge Reinforced With GFRP BarsAli M. MohammedNo ratings yet

- Assessment and Reconstruction of Bridges in Trinidad and TobagoDocument7 pagesAssessment and Reconstruction of Bridges in Trinidad and Tobagoikk_10No ratings yet

- Us 84 Mississippi River Bridge - Truss Pin and Link ReplacementDocument15 pagesUs 84 Mississippi River Bridge - Truss Pin and Link ReplacementAlejandro CalderonNo ratings yet

- Continuity Diaphragm For Skewed Continuous Span PrecastDocument2 pagesContinuity Diaphragm For Skewed Continuous Span PrecastDiego Estrada Paz100% (1)

- Collisions of Heavy Goods Vehicles With BridgesDocument8 pagesCollisions of Heavy Goods Vehicles With BridgesPatrick DonelanNo ratings yet

- Report Truss Bridge 160716155917 PDFDocument65 pagesReport Truss Bridge 160716155917 PDFStefanoNo ratings yet

- Motor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12From EverandMotor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12No ratings yet

- A Guide to Some of the Equations used in Constructing a Suspension BridgeFrom EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeNo ratings yet

- Amie SyllabusDocument10 pagesAmie SyllabuspvirgosharmaNo ratings yet

- Cooling TowerDocument2 pagesCooling Towerrao_gsv7598No ratings yet

- How Rocks and Lights ConnectedDocument34 pagesHow Rocks and Lights Connectedrao_gsv7598No ratings yet

- Rock Forming MineralsDocument2 pagesRock Forming Mineralsrao_gsv7598No ratings yet

- Stadium FailureDocument1 pageStadium Failurerao_gsv7598No ratings yet

- Results Q1FY11 12Document1 pageResults Q1FY11 12rao_gsv7598No ratings yet

- Plane Crashes Involving The ATR 42 and ATR 72Document4 pagesPlane Crashes Involving The ATR 42 and ATR 72HuaseongNo ratings yet

- FINALDocument24 pagesFINALJewel higuitNo ratings yet

- Capital Connector Briefing Sheet Post AwardDocument2 pagesCapital Connector Briefing Sheet Post AwardJeff MorrisNo ratings yet

- Tis 0012 Axle Loads and Weight Distribution Issue 1 PDFDocument4 pagesTis 0012 Axle Loads and Weight Distribution Issue 1 PDFDon Procopio II100% (1)

- Latihan Soal Peralatan KonstruksiDocument19 pagesLatihan Soal Peralatan KonstruksiGibral MaulanaNo ratings yet

- John D Rockefeller EssayDocument5 pagesJohn D Rockefeller Essayjvscmacaf100% (2)

- Social and Environmental Impacts of Driverless CarsDocument9 pagesSocial and Environmental Impacts of Driverless CarsAcademic JournalNo ratings yet

- Traffic Demand Management in DhakaDocument16 pagesTraffic Demand Management in DhakaSarwar_hossain24No ratings yet

- How Do You Teach Preschoolers About Road SafetyDocument2 pagesHow Do You Teach Preschoolers About Road SafetyArmilyn Jean CastonesNo ratings yet

- Airline Industry: Mayank RanjanDocument35 pagesAirline Industry: Mayank RanjanMayank RanjanNo ratings yet

- 2007 Owners LIT 11626 20 60 PDFDocument106 pages2007 Owners LIT 11626 20 60 PDFDan DiceaNo ratings yet

- Material HandlingDocument27 pagesMaterial HandlingAnand DubeyNo ratings yet

- Review Module 14 Basic Transportation Engineering Part 2Document1 pageReview Module 14 Basic Transportation Engineering Part 2RamonNo ratings yet

- Kochi StudyDocument244 pagesKochi StudyPriyanka BastinNo ratings yet

- Aptis SpeakingDocument4 pagesAptis SpeakingMageswari MarimuthoNo ratings yet

- IDS's Assignment111Document19 pagesIDS's Assignment111Rahul ShresthaNo ratings yet

- Car ParkingDocument478 pagesCar Parkingmohan890No ratings yet

- High Friction Surfacing: About Ennis-FlintDocument2 pagesHigh Friction Surfacing: About Ennis-FlintZaheer DoomahNo ratings yet

- Article 4Document9 pagesArticle 4peppamadrigal97No ratings yet

- Unbg 0115Document9 pagesUnbg 0115Georgiy DaneliaNo ratings yet

- JUSTIFICATIONDocument2 pagesJUSTIFICATIONyoshNo ratings yet

- Residential Design GuideDocument80 pagesResidential Design Guideoceanvast100% (3)

- DLIMS Habib UllahDocument1 pageDLIMS Habib Ullahabubakarsiddique7157296No ratings yet

- Case 5: Keretapi Tanah Melayu BHDDocument20 pagesCase 5: Keretapi Tanah Melayu BHDJaladi Muda100% (2)

- Bo de Thi Tieng Anh Vao 10 Cac Tinh 1Document22 pagesBo de Thi Tieng Anh Vao 10 Cac Tinh 1Huong Lan TangNo ratings yet

- Trip DistributionDocument26 pagesTrip Distributionthouseef06No ratings yet

- Baggage at Schiphol ENGDocument4 pagesBaggage at Schiphol ENGAsemMashrapovaNo ratings yet

- Traffic Study Manual SampleDocument12 pagesTraffic Study Manual SampleRaheel ADNANNo ratings yet

- Itinerary SingaporeDocument5 pagesItinerary Singapore411452123No ratings yet

Highway Bridge Collapse

Highway Bridge Collapse

Uploaded by

rao_gsv7598Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Highway Bridge Collapse

Highway Bridge Collapse

Uploaded by

rao_gsv7598Copyright:

Available Formats

36

TheStructuralEngineer

October 2013

Professional guidance

I-35W Bridge

The I-35W Highway Bridge collapse: les s

From its initial design to

the stockpiling of materials

during subsequent

renovation, Sean Brady

details a succession

of failures and missed

opportunities that resulted in

the catastrophic collapse of a

highway bridge in Minnesota.

In the early afternoon of 1 August 2007,

Progressive Contractors Inc. (PCI) were

preparing for a 160m long concrete

pavement pour on the southbound lanes of

the I-35W Highway Bridge in Minneapolis,

Minnesota. Seven previous pours had

been completed since the projects

commencement in June, and for this, the

eighth, 50mm of existing concrete wearing

course had been removed in preparation for

the pour planned for 7pm that evening.

PCIs preparations included stockpiling

gravel and sand on two of the bridges

southbound lanes, which was not an unusual

procedure, as the Minneapolis Department

of Transports (Mn/DOT) specication

provided only a one hour window between

initial concrete mixing and nal screeding

thus necessitating that concrete be mixed

as close to the placement site as possible.

By 2:30pm that afternoon, 84t of gravel, 90t

of sand, and 90t of construction vehicles,

equipment and personnel - totalling 264t

spread over an area of approx. 300m2 - was

in place for the pour.

As we now know, this pour never took

place. At 6:05pm a 300m section of the

main truss span collapsed, with a 140m

section falling 33m into the river below

(Figure 1). A total of 111 vehicles were on

the collapsed section, and only 17 were

recovered. Tragically, 13 people lost their

lives and 145 were injured.

The subsequent National Transportation

Safety Boards (NTSB) investigation would

identify undersized gusset plates, due to

a design error, in combination with recent

increases in dead load and live load as

the cause of the failure1. This article

explores how the load increases

TSE22_36-37.indd 36

occurred and the role they played in the

collapse, as well as exploring the design

error and, just as importantly, how it went

unnoticed throughout the bridges 40 year

service life.

The Bridge

The I-35W bridge was designed by

engineering consulting rm Sverdrup &

Parcel and Associates, and was opened

to traffic in 1967. It was 580m long, carried

eight lanes of traffic (four northbound

and four southbound), and comprised 11

approach spans and three truss spans.

By 2004 it carried an average of 141,000

vehicles daily.

Three major renovation/modication

projects were undertaken on the structure

during its lifetime, two of which increased

its dead load. In 1977 a wearing course

was applied to the bridge by milling 6mm

of concrete from the deck and replacing

it with 50mm of low slump concrete.

In 1998, renovations/modications

continued, primarily with the replacement

of the medium barrier, an upgrade of the

outside concrete traffic railings, and the

installation of an anti-icing system. At

the time of the collapse, the third set of

works was underway, which consisted of

the replacement of the concrete wearing

course, and the stockpiling of materials

occurred during these works.

Stockpiling

This was not the rst time such stockpiling

took place. Of the seven overlays completed,

stockpiling occurred on ve of them, with the

rst occasion being on an approach span

on the night of 6 July 2007. The rst staging

on the main truss span occurred on the

night of 23 July 2007. On the afternoon of 1

August, the staging for the eighth pour was

complete, with the NTSB estimating that the

loading, from the stockpiled materials alone,

was equivalent to four times the design live

load of the bridge. (The NTSBs estimate

was based on eyewitness accounts, postincident vehicle positions and, interestingly,

from a photograph taken by a passenger

travelling on a commercial airliner as it ew

over the bridge approximately 2 hours and 15

minutes before the collapse). How were PCI

permitted to stockpile such a signicant load

of sand and gravel on the structure?

On site, the Mn/DOT provides construction

inspectors. These inspectors were not trained

engineers and, as a result, the Mn/DOT

informed the NTSB that questions regarding

stockpiling should have been directed, in

writing, to the bridges project engineer.

However, the Mn/DOT had no policy that

specically required contractors to obtain

such permission. Thus, when preparing for

the pour on 23 July, the PCI foreman asked

the Mn/DOT inspector if material could be

staged on the span, and when the inspector

evidenced no concern about the staging

the PCI job foreman interpreted this as

permission1. So during the preparations on

1 August, PCI again commenced stockpiling

and permission was not obtained from an

Mn/DOT engineer.

Subsequent to the failure, the NTSB

investigated if Mn/DOT would have granted

approval for the stockpiling, if such a

request had been received. The Mn/DOT

stated that, due to the loading being four

times higher than the design live load, they

would likely not have granted approval

without rst undertaking analysis. The NTSB

requested that the Mn/DOT undertake such

analysis, and this load rating indicated that

the stockpiling was satisfactory. The NTSB

therefore, concluded that had Mn/DOT

made a decision based solely on such an

analysis, it likely would have approved the

stockpiling1.

However, there was an issue with

the analysis. It only rated the bridges

main members and did not consider the

performance of gusset plates. The NTSB

investigation would identify a number of

gusset plates as being the weak link, due

to a design error in the structure. Once

their actual capacity was determined,

the increases to the bridges dead load,

as a result of the renovation works, in

combination with the stockpiled materials on

the 1 August, were sufficient to overstress

the structure. Conversely, the investigation

also concluded that if the gusset plates

been designed correctly, the loading would

not have been sufficient to cause the

collapse. Indeed, it is a testament to the

conservatism that is built into designs, that

the bridge survived for forty years despite

the presence of the design error the

loading on 1 August was simply the enabling

conditions necessary for the latent error to

culminate in catastrophic failure.

So how did this design error occur and how

did it go unnoticed for forty years despite the

design being subject to:

26/09/2013 10:53

37

s sons learned

An internal design review

Design reviews by both the Mn/DOT and

the Federal Highway Administration (FHWA)

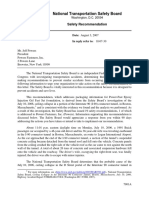

Figure 1

Collapsed

section of I-35W

Highway Bridge

The bridge being subjected to two load

ratings, and

the bridge being inspected more regularly

than required by best practice?

The investigation would uncover a

systematic breakdown in the very layers of

protection the engineering profession erects

to prevent such failures occurring.

Design

The NTSB was unable to track down the

original design calculations for the critical

gusset plates. However, documents from the

preliminary design stage were uncovered,

which provided some insight into the

gusset plate design. These (unchecked)

calculation sheets indicated that gusset

plate thickness was determined based only

on the forces that were expected to pass

across the splices between chord members.

Considering these forces alone, the gusset

plates were sized appropriately. However,

their correct design also required the

consideration of shearing forces introduced

into the gusset plates by the trusses

diagonal and vertical members which

would have resulted in thicker plates. The

NTSB found that while other gusset plates

were thickened between the preliminary

and nal design stages, the nal design

thickness for the critical gusset plates were

not increased, remaining the same as that

shown in the preliminary calculations. The

NTSB would conclude that even though the

bridge design rm knew how to correctly

calculate the effects of stress in gusset

plates, as evidenced by its correct design

of other gusset plates in this, and other,

structures, it failed to perform all necessary

calculations for the main truss gusset plates

of the I-35W bridge, resulting in some of the

gusset plates having inadequate capacity1.

Review

Moving to the review phase, the NTSB

began by examining the designers review

procedures, and identied that these

procedures, provided for an appropriate

level of review, including for the review of

gusset plate calculations. However, the

TSE22_36-37.indd 37

GETTY

And despite:

review did not have an explicit procedure for

ensuring all such calculations were actually

performed. Ultimately, the NTSB would

conclude that such a review process was

inadequate.

A failure to check that gusset calculations

were actually undertaken was also evident

in the Mn/DOT and FHWA reviews. While

the NTSB found that these authorities had

provision for checking calculations, these

provisions did not extend to checking

gusset plate calculations. Not only did

the authorities fail to identify the design

error, but their review processes were not

equipped to do so.

Load ratings

The same trend continued with the load

ratings undertaken in 1979 and 1998, neither

of which considered the gusset plates.

The NTSB concluded that had AASHTO

guidance included gusset plates in load

ratings, there would have been multiple

opportunities to detect the inadequate

capacity of the U10 gusset plates of the

I-35W bridge deck truss1. Interestingly,

the NTSB found that the reason for this

neglect was the apparent belief among

bridge owners that gusset plates were more

conservatively designed than the members

they connected. In other words, once the

capacity of the members was deemed to be

sufficient, it appears to have been assumed

that the gusset plates also had sufficient

capacity.

Inspections

Finally, opportunities to detect the error

through inspections were also missed.

The NTSB concluded that the bridge

was inspected in accordance with the

National Bridge Inspection Standards.

Indeed, it was inspected more frequently

than these standards required. However,

the inspections would not have been

expected to detect design errors because

they focused on quantifying condition.

Nevertheless, there was visual evidence in

seven of the eight critical gusset plates that

the NTSB described as symptomatic of the

inadequate capacity: photographs taken by

URS and the University of Minnesota in 1999

and 2003, both of whom were engaged

to undertake strain gauging on the bridge,

clearly show bowing in some of the critical

gusset plates. Based on these photographs,

the NTSB estimated this bowing to have

been in the order of 11mm to 25mm. Indeed,

one Mn/DOT Metro District bridge safety

inspection engineer was aware of the

bowing, but informed the NTSB investigators

that he believed it to have occurred during

construction of the bridge. Consequently,

the bowing was not noted in any inspection

report, and the NTSB found no evidence of

any analysis to determine why the distortion

had occurred or to what extent it had

affected the load-carrying capacity of the

gusset plates1.

The I-35W bridge is a reminder of the role

that human factors play in catastrophic

failures. From a technical perspective alone,

the failure could have been avoided. The

design of gusset plates was well understood,

but was not implemented correctly, while

the risks involved in stockpiling, obvious in

hindsight, went unexamined.

As with most failures, there were numerous

occasions when the potential for failure could

have been identied, but such opportunities

were missed or the warning signs were

misinterpreted.

Sean Brady is the managing director of

Brady Heywood (www.bradyheywood.com.

au), based in Brisbane, Australia. The rm

provides forensic and investigative structural

engineering services and specialises in

determining the cause of engineering failure

and non-performance.

REFERENCES:

1) National Transport Safety Board

(2008) Highway Accident Report,

Collapse of I-35W Highway Bridge, Minneapolis,

Minnesota, August 1, 2007 [Online] Available

at: www.dot.state.mn.us/i35wbridge/ntsb/

nalreport.pdf (Accessed: October 2012)

26/09/2013 10:53

You might also like

- Business PlanDocument15 pagesBusiness Planrao_gsv7598No ratings yet

- Light Rail Operations: Phoenix Regional Standard Operating ProceduresDocument5 pagesLight Rail Operations: Phoenix Regional Standard Operating Proceduresmkashkooli_scribdNo ratings yet

- A Half-Inch To Failure (Sept 2009) PDFDocument4 pagesA Half-Inch To Failure (Sept 2009) PDFUnknownNo ratings yet

- Article Tunnel Celing CollapsedDocument2 pagesArticle Tunnel Celing CollapsedgemotorresNo ratings yet

- 2019 HWY18MH009 BMG AbstractDocument7 pages2019 HWY18MH009 BMG AbstractBryan VillalobosNo ratings yet

- Precast PrestressDocument60 pagesPrecast PrestressPantatNyanehBurikNo ratings yet

- Latex ModificatedDocument24 pagesLatex ModificatedjonathasiohanathanNo ratings yet

- Turn It inDocument7 pagesTurn It inPhilip MandaliosNo ratings yet

- The Infamous Gusset PlatesDocument10 pagesThe Infamous Gusset PlatesDeen ZakariaNo ratings yet

- 1 PDFDocument7 pages1 PDFJose Luis Martinez SaavedraNo ratings yet

- HWY18MH009 Investigative UpdateDocument6 pagesHWY18MH009 Investigative UpdateepraetorianNo ratings yet

- FIU Bridge Collapse Investigative ReportDocument2 pagesFIU Bridge Collapse Investigative ReportGary DetmanNo ratings yet

- Replacement of Elastomeric Bearings & Installation of Monitoring Systems Thereafter at Keppel Viaduct in SingaporeDocument18 pagesReplacement of Elastomeric Bearings & Installation of Monitoring Systems Thereafter at Keppel Viaduct in SingaporeSanja RadovicNo ratings yet

- Human Factors and Bridge FailureDocument3 pagesHuman Factors and Bridge FailureJameson J Mtanga0% (1)

- UnlversDocument55 pagesUnlversCan AcarNo ratings yet

- 028 - Pressley Destructive Testing 1049Document12 pages028 - Pressley Destructive Testing 1049tomNo ratings yet

- Minnesota BridgeDocument20 pagesMinnesota BridgeKY PengNo ratings yet

- Looking To Load and Resistance Factor RatingDocument17 pagesLooking To Load and Resistance Factor Ratingsmartman35No ratings yet

- MDOT Research Report R1515 239284 7Document40 pagesMDOT Research Report R1515 239284 7Erik Wahyu PradanaNo ratings yet

- Hao - I35W - NoteDocument7 pagesHao - I35W - NoteJobs feelNo ratings yet

- Monismith LectureDocument77 pagesMonismith LectureAbdulhaq Hadi AlhaddadNo ratings yet

- LinkslabasceDocument15 pagesLinkslabascepravin awalkondeNo ratings yet

- Long Term Health Monitoring of Post-Tensioning Box Girder BridgesDocument14 pagesLong Term Health Monitoring of Post-Tensioning Box Girder BridgesSetyo Hardono100% (1)

- Incident Investigation and Reporting - TaroDocument9 pagesIncident Investigation and Reporting - TaroJosielyn TarsNo ratings yet

- 73-Article Text-329-1-10-20190904Document5 pages73-Article Text-329-1-10-20190904Ghiyas UddinNo ratings yet

- Load Testing of Bridges - Global State-Of-Practice - India's Top Construction, Infrastructure & Civil EngineerDocument11 pagesLoad Testing of Bridges - Global State-Of-Practice - India's Top Construction, Infrastructure & Civil Engineercristina_romanescuNo ratings yet

- How To Determine Internal Force at Gusset Plate InterfaceDocument20 pagesHow To Determine Internal Force at Gusset Plate Interfacehieu49xfNo ratings yet

- Accelerated Brideg Construction in Washington StateDocument16 pagesAccelerated Brideg Construction in Washington StatesyedabdulhannanNo ratings yet

- Iricen Journal Sept. 2008Document52 pagesIricen Journal Sept. 2008js kalyana ramaNo ratings yet

- Box Girder 2Document8 pagesBox Girder 2steelageNo ratings yet

- RepairsDocument8 pagesRepairsSunday Michael OshiokeNo ratings yet

- GRP 2Document6 pagesGRP 2Bethany BermoyNo ratings yet

- GT 1490the Observational Method Can Be Simple202Document4 pagesGT 1490the Observational Method Can Be Simple202h100% (1)

- 111 CRDocument35 pages111 CRJames McguireNo ratings yet

- 0783f83a-a395-4d5f-a25d-6548c52ac9a0Document14 pages0783f83a-a395-4d5f-a25d-6548c52ac9a0Tiago SilvaNo ratings yet

- Bridges - All - Paper - Integral Abutments For Steel Bridges by E Wasserman - 10-1996Document44 pagesBridges - All - Paper - Integral Abutments For Steel Bridges by E Wasserman - 10-1996Xuejian LiuNo ratings yet

- Expert IzaDocument98 pagesExpert IzaflorinelvvNo ratings yet

- Weigh-in-Motion-Based Fatigue Damage AssessmentDocument10 pagesWeigh-in-Motion-Based Fatigue Damage Assessmentmomo3No ratings yet

- Analysis of Deck Slab and Tee Beam of A BridgeDocument59 pagesAnalysis of Deck Slab and Tee Beam of A Bridgenvnrev86% (66)

- Fundamental PrinciplesDocument22 pagesFundamental PrinciplesmehdiNo ratings yet

- Loading Tests of Existing Concrete StructuresDocument14 pagesLoading Tests of Existing Concrete StructuresAmir DhotharNo ratings yet

- Boston Resin ProblemDocument11 pagesBoston Resin ProblemJulio LópezNo ratings yet

- Northgate Ped BridgeDocument27 pagesNorthgate Ped BridgetfooqNo ratings yet

- Incremental Launch Method For Steel Truss Bridge ErectionDocument11 pagesIncremental Launch Method For Steel Truss Bridge ErectionaapennsylvaniaNo ratings yet

- Minimizing Construction Problems in Segmentally Precast Box Girder Bridges PDFDocument285 pagesMinimizing Construction Problems in Segmentally Precast Box Girder Bridges PDFAditya PratamaNo ratings yet

- Foundation WorksDocument27 pagesFoundation WorksDean SamuelNo ratings yet

- A Cable-Stayed Bridge With Main Span of 1088 MetersDocument9 pagesA Cable-Stayed Bridge With Main Span of 1088 Metersmdkml2No ratings yet

- MCL 9904Document11 pagesMCL 9904linamohdzhor4815No ratings yet

- FB&L Pontoon TransportationDocument109 pagesFB&L Pontoon TransportationHizbar ArsjadNo ratings yet

- Precast Prestressed Concrete Short Span BridgesDocument41 pagesPrecast Prestressed Concrete Short Span Bridgescdestudos100% (1)

- Structural Strength Rules Applied To Container Ships: Kinya Ishibashi, Kei Sugimoto, Tomohiro SUGIMOTODocument10 pagesStructural Strength Rules Applied To Container Ships: Kinya Ishibashi, Kei Sugimoto, Tomohiro SUGIMOTOKarim KarimNo ratings yet

- Wisconsin Dot: Development of A Bridge Construction Live Load Analysis GuideDocument171 pagesWisconsin Dot: Development of A Bridge Construction Live Load Analysis GuidedunglxNo ratings yet

- TRBRakoczyResidualCapacityofDamagedGirder RevisedDocument17 pagesTRBRakoczyResidualCapacityofDamagedGirder RevisedabdulNo ratings yet

- Construction and Long-Term Monitoring of A Concrete Box Culvert Bridge Reinforced With GFRP BarsDocument45 pagesConstruction and Long-Term Monitoring of A Concrete Box Culvert Bridge Reinforced With GFRP BarsAli M. MohammedNo ratings yet

- Assessment and Reconstruction of Bridges in Trinidad and TobagoDocument7 pagesAssessment and Reconstruction of Bridges in Trinidad and Tobagoikk_10No ratings yet

- Us 84 Mississippi River Bridge - Truss Pin and Link ReplacementDocument15 pagesUs 84 Mississippi River Bridge - Truss Pin and Link ReplacementAlejandro CalderonNo ratings yet

- Continuity Diaphragm For Skewed Continuous Span PrecastDocument2 pagesContinuity Diaphragm For Skewed Continuous Span PrecastDiego Estrada Paz100% (1)

- Collisions of Heavy Goods Vehicles With BridgesDocument8 pagesCollisions of Heavy Goods Vehicles With BridgesPatrick DonelanNo ratings yet

- Report Truss Bridge 160716155917 PDFDocument65 pagesReport Truss Bridge 160716155917 PDFStefanoNo ratings yet

- Motor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12From EverandMotor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12No ratings yet

- A Guide to Some of the Equations used in Constructing a Suspension BridgeFrom EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeNo ratings yet

- Amie SyllabusDocument10 pagesAmie SyllabuspvirgosharmaNo ratings yet

- Cooling TowerDocument2 pagesCooling Towerrao_gsv7598No ratings yet

- How Rocks and Lights ConnectedDocument34 pagesHow Rocks and Lights Connectedrao_gsv7598No ratings yet

- Rock Forming MineralsDocument2 pagesRock Forming Mineralsrao_gsv7598No ratings yet

- Stadium FailureDocument1 pageStadium Failurerao_gsv7598No ratings yet

- Results Q1FY11 12Document1 pageResults Q1FY11 12rao_gsv7598No ratings yet

- Plane Crashes Involving The ATR 42 and ATR 72Document4 pagesPlane Crashes Involving The ATR 42 and ATR 72HuaseongNo ratings yet

- FINALDocument24 pagesFINALJewel higuitNo ratings yet

- Capital Connector Briefing Sheet Post AwardDocument2 pagesCapital Connector Briefing Sheet Post AwardJeff MorrisNo ratings yet

- Tis 0012 Axle Loads and Weight Distribution Issue 1 PDFDocument4 pagesTis 0012 Axle Loads and Weight Distribution Issue 1 PDFDon Procopio II100% (1)

- Latihan Soal Peralatan KonstruksiDocument19 pagesLatihan Soal Peralatan KonstruksiGibral MaulanaNo ratings yet

- John D Rockefeller EssayDocument5 pagesJohn D Rockefeller Essayjvscmacaf100% (2)

- Social and Environmental Impacts of Driverless CarsDocument9 pagesSocial and Environmental Impacts of Driverless CarsAcademic JournalNo ratings yet

- Traffic Demand Management in DhakaDocument16 pagesTraffic Demand Management in DhakaSarwar_hossain24No ratings yet

- How Do You Teach Preschoolers About Road SafetyDocument2 pagesHow Do You Teach Preschoolers About Road SafetyArmilyn Jean CastonesNo ratings yet

- Airline Industry: Mayank RanjanDocument35 pagesAirline Industry: Mayank RanjanMayank RanjanNo ratings yet

- 2007 Owners LIT 11626 20 60 PDFDocument106 pages2007 Owners LIT 11626 20 60 PDFDan DiceaNo ratings yet

- Material HandlingDocument27 pagesMaterial HandlingAnand DubeyNo ratings yet

- Review Module 14 Basic Transportation Engineering Part 2Document1 pageReview Module 14 Basic Transportation Engineering Part 2RamonNo ratings yet

- Kochi StudyDocument244 pagesKochi StudyPriyanka BastinNo ratings yet

- Aptis SpeakingDocument4 pagesAptis SpeakingMageswari MarimuthoNo ratings yet

- IDS's Assignment111Document19 pagesIDS's Assignment111Rahul ShresthaNo ratings yet

- Car ParkingDocument478 pagesCar Parkingmohan890No ratings yet

- High Friction Surfacing: About Ennis-FlintDocument2 pagesHigh Friction Surfacing: About Ennis-FlintZaheer DoomahNo ratings yet

- Article 4Document9 pagesArticle 4peppamadrigal97No ratings yet

- Unbg 0115Document9 pagesUnbg 0115Georgiy DaneliaNo ratings yet

- JUSTIFICATIONDocument2 pagesJUSTIFICATIONyoshNo ratings yet

- Residential Design GuideDocument80 pagesResidential Design Guideoceanvast100% (3)

- DLIMS Habib UllahDocument1 pageDLIMS Habib Ullahabubakarsiddique7157296No ratings yet

- Case 5: Keretapi Tanah Melayu BHDDocument20 pagesCase 5: Keretapi Tanah Melayu BHDJaladi Muda100% (2)

- Bo de Thi Tieng Anh Vao 10 Cac Tinh 1Document22 pagesBo de Thi Tieng Anh Vao 10 Cac Tinh 1Huong Lan TangNo ratings yet

- Trip DistributionDocument26 pagesTrip Distributionthouseef06No ratings yet

- Baggage at Schiphol ENGDocument4 pagesBaggage at Schiphol ENGAsemMashrapovaNo ratings yet

- Traffic Study Manual SampleDocument12 pagesTraffic Study Manual SampleRaheel ADNANNo ratings yet

- Itinerary SingaporeDocument5 pagesItinerary Singapore411452123No ratings yet