Professional Documents

Culture Documents

Sizing Calculation PDF

Sizing Calculation PDF

Uploaded by

Dwi Cahyono SembadaCopyright:

Available Formats

You might also like

- GN 44 005 Acoustic Induced VibrationDocument33 pagesGN 44 005 Acoustic Induced VibrationMohamed Mostafa100% (1)

- Tube Rupture (Two Phase-Omega Method)Document1 pageTube Rupture (Two Phase-Omega Method)Saeid Rahimi MofradNo ratings yet

- Profile PT Inconis Nusa JayaDocument8 pagesProfile PT Inconis Nusa JayaDwi Cahyono SembadaNo ratings yet

- Worksheet On Thermal PhysicsDocument15 pagesWorksheet On Thermal Physicsilyasheee90180% (5)

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Document2 pagesMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqNo ratings yet

- AWS A5.12: Material Safety Data Sheet (MSDS)Document3 pagesAWS A5.12: Material Safety Data Sheet (MSDS)Mani VannanNo ratings yet

- A Demister Pad Is Similar To An Air Filter Except Instead of Removing Dust ParticlesDocument1 pageA Demister Pad Is Similar To An Air Filter Except Instead of Removing Dust ParticlesyogacruiseNo ratings yet

- Bundwall SampleDocument1 pageBundwall Samplewawen03No ratings yet

- Pressure - Vacuum Relief Valve - Part 1Document10 pagesPressure - Vacuum Relief Valve - Part 1winarnobNo ratings yet

- Pressure Vacuum Breather ValvesDocument4 pagesPressure Vacuum Breather ValvesAdhitya DarmadiNo ratings yet

- Fluid Handling Engineers: U S Agency - Taco DivDocument5 pagesFluid Handling Engineers: U S Agency - Taco DivsitehabNo ratings yet

- FlareTot - Total Flare AnalysisDocument8 pagesFlareTot - Total Flare AnalysisArjun KapoorNo ratings yet

- Fixed Water Spray Demand Calculations For Fire Protection of TanksDocument2 pagesFixed Water Spray Demand Calculations For Fire Protection of Tankssyamsoelbahri100% (1)

- Tank DesignDocument2 pagesTank DesignkamleshyadavmoneyNo ratings yet

- 25nb y StrainerDocument1 page25nb y StrainerKailas NimbalkarNo ratings yet

- Calculate Pressure Drop in Basket & Tee Strainers ReferenceDocument5 pagesCalculate Pressure Drop in Basket & Tee Strainers Referencebrock100% (1)

- Specification - Pipes FlangesDocument3 pagesSpecification - Pipes FlangesAco CvijeticNo ratings yet

- Emergency Vent Flam LiquidsDocument3 pagesEmergency Vent Flam LiquidsSharon LambertNo ratings yet

- Pipeline Hydraulics Modification ReqdDocument6 pagesPipeline Hydraulics Modification ReqdchemtahirNo ratings yet

- Condensate Tank - For 250Document3 pagesCondensate Tank - For 250Sakthi VelNo ratings yet

- Storage Tanks Calculation Template: Oil & Gas Production: Company Name: Site Name: RN: Fin: Epn: Cin: Data InputsDocument1 pageStorage Tanks Calculation Template: Oil & Gas Production: Company Name: Site Name: RN: Fin: Epn: Cin: Data InputsihllhmNo ratings yet

- Calculation Pressure DropDocument9 pagesCalculation Pressure Dropdasubhai0% (1)

- Chemical & Process Technology - Requirements of SDV Bypass Pressurization Line PDFDocument4 pagesChemical & Process Technology - Requirements of SDV Bypass Pressurization Line PDFvenkatrangan2003100% (1)

- Dps-3-1206-013-E1782-A4-2 (Final)Document449 pagesDps-3-1206-013-E1782-A4-2 (Final)Siva baalanNo ratings yet

- Specification Sheet: Case I Case Ii Operating ConditionsDocument1 pageSpecification Sheet: Case I Case Ii Operating ConditionsKailas NimbalkarNo ratings yet

- Line Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Document12 pagesLine Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Engr TheyjiNo ratings yet

- Line Sizing File (No Password)Document18 pagesLine Sizing File (No Password)Montian LuangsakultongNo ratings yet

- Data Sheet P-0560 - Hot Oil Drain Tank Sump PumpDocument2 pagesData Sheet P-0560 - Hot Oil Drain Tank Sump Pumpcygnus marine panamaNo ratings yet

- Sphere Design and Thickness Calculation (Div 2)Document6 pagesSphere Design and Thickness Calculation (Div 2)Asad KhanNo ratings yet

- PPGJ-PRO-CAL-183 Hot Oil Expansion Tank (D-1001)Document10 pagesPPGJ-PRO-CAL-183 Hot Oil Expansion Tank (D-1001)Tifano Khristiyanto100% (1)

- Tube Rupture (Two Phase-Omega Method) PDFDocument1 pageTube Rupture (Two Phase-Omega Method) PDFAmin RoisNo ratings yet

- Flare KO Drum Rev 2Document19 pagesFlare KO Drum Rev 2Rian Intan Saputra100% (1)

- Ows Piping Size2BLDocument3 pagesOws Piping Size2BLArindomNo ratings yet

- Ssags PSV SizingDocument5 pagesSsags PSV SizingEkundayo JohnNo ratings yet

- Surface Area Calculations Vessel TanksDocument5 pagesSurface Area Calculations Vessel Tanksdhavalesh1No ratings yet

- The Outside Diameter As Their Nominal DiameterDocument75 pagesThe Outside Diameter As Their Nominal Diameterngutor100% (2)

- Restrictive OrificeDocument11 pagesRestrictive Orificeligia hancu100% (1)

- Filter Separator Revised Feb 19 2004Document1 pageFilter Separator Revised Feb 19 2004motalebyNo ratings yet

- API STD 2000-2009, Calculation For Max. Flow Rates For Normal InbreathingDocument2 pagesAPI STD 2000-2009, Calculation For Max. Flow Rates For Normal InbreathingFendy ShirahNo ratings yet

- Vessel - Vertical Sizing - IPunitsDocument25 pagesVessel - Vertical Sizing - IPunitsAnders FTNo ratings yet

- Scribd DownloadDocument3 pagesScribd DownloadKemas Muhandis M.No ratings yet

- Tank Vent Sizing - Cheresources - Com CommunityDocument13 pagesTank Vent Sizing - Cheresources - Com CommunityharmlesdragonNo ratings yet

- R-216z-991 (Finger Type Slug Catcher)Document1 pageR-216z-991 (Finger Type Slug Catcher)Balaji Ganesan0% (1)

- Header DesignDocument12 pagesHeader DesignGun SmithNo ratings yet

- Valve CV Sizing Liquids GasesDocument24 pagesValve CV Sizing Liquids Gasesmath62210No ratings yet

- Pressure Relief Valve Sizing and Selection CheckDocument2 pagesPressure Relief Valve Sizing and Selection CheckGiftObionochieNo ratings yet

- Pressure Drop Equivalent Length of Pipes and Fittings - Engineers EdgeDocument2 pagesPressure Drop Equivalent Length of Pipes and Fittings - Engineers EdgeallovidNo ratings yet

- Control Valve Failure Relief Rate - Gas ServiceDocument3 pagesControl Valve Failure Relief Rate - Gas ServiceSaeid Rahimi Mofrad100% (2)

- Hydroulics Calculation and Gas PropertiesDocument3 pagesHydroulics Calculation and Gas PropertiesSteve WanNo ratings yet

- Desander Underground Type1Document8 pagesDesander Underground Type1Sambhav PoddarNo ratings yet

- Sample Sheet: Supply of PF Process Calculation Spreadsheet (Excel Forma)Document3 pagesSample Sheet: Supply of PF Process Calculation Spreadsheet (Excel Forma)mehfuzansari1No ratings yet

- PSV Sizing: The Relief Load Can Be Calculated Directly, in Pounds Per Hour, From The Following RelationshipDocument4 pagesPSV Sizing: The Relief Load Can Be Calculated Directly, in Pounds Per Hour, From The Following RelationshipAfees OlajideNo ratings yet

- API 650 Tank Design 1 1Document5 pagesAPI 650 Tank Design 1 1samy7354100% (1)

- Separator SizingDocument3 pagesSeparator SizingMaryJane Ayisha Sado-ObahNo ratings yet

- MP Condensate Flash VesselDocument4 pagesMP Condensate Flash VesselGanesh BhardwajNo ratings yet

- Tank Calculation Kasikan Gs Rev BDocument20 pagesTank Calculation Kasikan Gs Rev BTrian Desta Rizal80% (5)

- V1.1 Sizing Thermal Mass Flow Meter SizingDocument8 pagesV1.1 Sizing Thermal Mass Flow Meter SizingThori MFMNo ratings yet

- Retention TimeDocument13 pagesRetention TimejowarNo ratings yet

- Pressure Relief Valve Specification Sheet: General Job DataDocument2 pagesPressure Relief Valve Specification Sheet: General Job DataYücel KaosjunkieNo ratings yet

- API Tube Thickness Calculation1Document5 pagesAPI Tube Thickness Calculation1pandiangvNo ratings yet

- CN32083_HD (1)Document4 pagesCN32083_HD (1)fluence.ar.gbavaNo ratings yet

- Report Covid 2020 Hoshizora FoundationDocument36 pagesReport Covid 2020 Hoshizora FoundationDwi Cahyono SembadaNo ratings yet

- Company Profile PT Inconis 2015Document30 pagesCompany Profile PT Inconis 2015Dwi Cahyono SembadaNo ratings yet

- Company Profile Smartelco Smart SolutionDocument14 pagesCompany Profile Smartelco Smart SolutionDwi Cahyono SembadaNo ratings yet

- DRY MOIST - Coal TM Reduction Dilution RateDocument1 pageDRY MOIST - Coal TM Reduction Dilution RateDwi Cahyono SembadaNo ratings yet

- Activity Coefficient: Encyclopædia Britannica SearchDocument5 pagesActivity Coefficient: Encyclopædia Britannica SearchAdeniran JoshuaNo ratings yet

- Chapter 4 - Interface Mass TransferDocument17 pagesChapter 4 - Interface Mass Transferngoc.nguyenlamNo ratings yet

- Sop 1Document2 pagesSop 1AnnuNo ratings yet

- MCQs Suface Tension & Interficial TensionDocument15 pagesMCQs Suface Tension & Interficial Tensionmukul sidhque100% (1)

- 1982 - Method of Encapsulating WasteDocument11 pages1982 - Method of Encapsulating WasteÉrica RodriguesNo ratings yet

- Vacuum Insulated CO2 and Cryogenic Storage TanksDocument13 pagesVacuum Insulated CO2 and Cryogenic Storage Tankssli223No ratings yet

- Module 1 - Chapter 1 Fluid MechanicsDocument24 pagesModule 1 - Chapter 1 Fluid MechanicsKlucifer Xin100% (4)

- States of Matter PoetryDocument20 pagesStates of Matter PoetrySaqib HussainNo ratings yet

- Phase 1 Test-2 Class IX WTDocument2 pagesPhase 1 Test-2 Class IX WTpankaj16xissNo ratings yet

- PhET - States of Matter in Html5Document3 pagesPhET - States of Matter in Html5Anonymous 52Z8ZFkvNo ratings yet

- Viscoelastic Solid-Repellent Coatings For Extreme Water Saving and Global SanitationDocument9 pagesViscoelastic Solid-Repellent Coatings For Extreme Water Saving and Global SanitationyiporNo ratings yet

- Physics PW Last 5 Years Pyq Complete Class 11Document316 pagesPhysics PW Last 5 Years Pyq Complete Class 11Neeru GuptaNo ratings yet

- Latest Copy of Class 8 Physics Question Bank 1Document101 pagesLatest Copy of Class 8 Physics Question Bank 1KAMLESH PATIDARNo ratings yet

- Behind JNTUK - MOPUDocument10 pagesBehind JNTUK - MOPUfrAnkEnstEin liveNo ratings yet

- E 28 - 14Document6 pagesE 28 - 14ruben carcamoNo ratings yet

- Is 335 1993 Transformer (Insulating Oil)Document19 pagesIs 335 1993 Transformer (Insulating Oil)Shailesh DaswantNo ratings yet

- Plant ExtractDocument18 pagesPlant ExtractParth PatelNo ratings yet

- Sp20 DescripcionDocument2 pagesSp20 DescripcionJuan Pablo Moreno Téllez Moreno TéllezNo ratings yet

- Rotary Vane Vs Liquid Ring CompessorsDocument2 pagesRotary Vane Vs Liquid Ring Compessorsmember1000No ratings yet

- 300-0063A AguaDocument8 pages300-0063A AguaneoegoNo ratings yet

- Flow Assurance Training Course-1 Underlined (IOGPT)Document108 pagesFlow Assurance Training Course-1 Underlined (IOGPT)Abid Hussain100% (5)

- Biocouture Grow Your Own Material Recipe Creative Common LicenseDocument2 pagesBiocouture Grow Your Own Material Recipe Creative Common LicenseGiada DaolioNo ratings yet

- Igcse 52 Solidsliquids&GasesDocument39 pagesIgcse 52 Solidsliquids&GasesHany ElGezawy100% (1)

- The Kinetic Molecular Theory of MatterDocument39 pagesThe Kinetic Molecular Theory of MatterSilhouette DreamNo ratings yet

- Advanced Series PLASTIC Pumps: Advance Your ProcessDocument35 pagesAdvanced Series PLASTIC Pumps: Advance Your ProcessJuan Mac LeanNo ratings yet

- Surface Tension and The Principle of Corresponding StatesDocument4 pagesSurface Tension and The Principle of Corresponding StatesJose Francisco Olivares QuevedoNo ratings yet

- Test Bank For Mosbys Respiratory Care Equipment 10th Edition J M CairoDocument36 pagesTest Bank For Mosbys Respiratory Care Equipment 10th Edition J M Cairotrigraphlaudably.3i52id100% (51)

- Unit Operations and Unit ProcessesDocument3 pagesUnit Operations and Unit ProcesseslaurenNo ratings yet

Sizing Calculation PDF

Sizing Calculation PDF

Uploaded by

Dwi Cahyono SembadaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sizing Calculation PDF

Sizing Calculation PDF

Uploaded by

Dwi Cahyono SembadaCopyright:

Available Formats

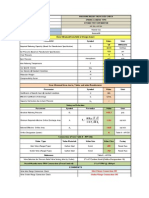

Pressure Relief Valve Reference Drawing

Date Prepared: 2014-07-21 14:49

PSV Identification

Customer

Requisition #

Job #

PT. PP (Persero)

Job Description

+12476

Tag #

Terminal LPG Banyuwangi

Tag Description

P / ID

NACE

PSV-2101/2102/2103

ASME Code

No

Fluid State

ASME Sec. VIII

Operating Pressure

16 Bar G

Resolved ASME Area

Gas (Volume)

Set Pressure

10.797 in

35 C

Cold Diff. Test P.

0 Bar G

Operating to Set %

35 C

No Rupture Disk, 1

Variable Back P.

0 Bar G

Relief Temp.

Rupture Disk Coeff.

9.7176 in

Constant Back P.

18 Bar G

Operating Temp.

Resolved API Area

18 Bar G

Over Pressure

88.889 %

Percent Over P.

1.8 Bar G

10 %

26QA12-120

API Letter

API Area

ASME Area

11.05 in

12.27 in

Size

Rating

Facing

Inlet:

6.0 in

300 #

RF

Outlet:

8.0 in

150 #

RF

Valve Design

Conventional

Cap Constrn

Test Gag

Screwed Cap

Max. Rel. Cap.

React. Force

139617 m/hr

4179 lbs

No

Noise

122.23 dBa

Materials

Body (1)

Carbon Steel (SA-216 Gr. WCB)

Bonnet (2)

Carbon Steel (SA-216 Gr. WCB)

Nozzle (5)

316 SS

Disc (4)

316 SS

Dimensions

Weight

Dim A

430 lb

Dim C

45 in

Dim E

9 7/16

in

Guide (8)

Dim B

Spring (18)

Dim F

13/

16

in

316 SS

9 1/2 in

2 1/4

Chrome Alloy

in

Bellows (15)

N/A

Name Plate Capacity

Air

Water

93612 Nm/hr

Steam

-

Tag Notes

1. We assume :

- Operating Pressure = 16 BarG, 10% lower than Setting Pressure (18 BarG)

Operating Pressure = 16 BarG, 10% lower than Setting Pressure (18 BarG)

Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

Constant Back Pressure = 0 BarG

Variable Back Pressure = 0 BarG

2. Based on data sheet, we can not offer size requested 6"-150#RF x 6"-150#RF, because

Set. Pressure 18 Barg is too high, maxsimum Set. Pressure for ANSI Class 150# is. 11.4

BarG, so we offer size 6"300#RF x 8"-150#RF.

Please customer to verify and confirm for data above.

SizeMaster 4.3.2.13, DB: D:\DATA SIZE MASTER\SM JAS 2013-lf

End of 26QA12-120 Valve Reference Drawing

Tag +12476: PSV-2101/2102/2103 - Data Sheet

Pressure Relief Valve Data Sheet

Date Prepared: 2014-07-21 14:50

General Job Data

Customer

Requisition #

Job #

PT. PP (Persero)

Job Description

+12476

Prepared By

Checked By

Terminal LPG Banyuwangi

Approved By

Job Status

System Admin

Revision #

Sizing/Selecting

PSV Identification

Tag #

Tag Description

Tag Status

PSV-2101/2102/2103

P / ID

Discharge To Revision #

Valve Selected

Plant #

Drawing # Index # Issue For

0

Service

Inlet Line # Outlet Line #

V-001-004

Revised By

System Admin

Sizing Basis

ASME Code

Cause of Over Pressure

ASME Sec. VIII

Fluid State

Blocked Discharge

Rupture Disk Coeff.

Gas (Volume)

NACE

No

No Rupture Disk, 1

Process Parameters

MAWP

Max. Design T.

- Bar G

- C

Min. Design T.

- C

Operating

Pressure

16 Bar G

Operating

Temp.

35 C

Constant Back

P.

0 Bar G

Set Pressure

18 Bar G

Relief Temp.

35 C

Variable Back P.

0 Bar G

Operating to Set %

88.889 %

Percent Over P.

10 %

Over Pressure

1.8 Bar G

1.0133 Bar Abs

Relief Pressure

20.813 Bar Abs

Cold Diff. Test P.

18 Bar G

1274.7 Mol Wt

Gas Flow Const.

363.5

44 sp gr

Compressibility

0.01

Atm Pressure

Compressible State

Fluid

LPG Vapor

Req. Flow Cap.

122860 Nm/hr

Calculated Area

10.797 in

Resolved ASME Area:

Molecular Weight

Specific Gravity

Specific Heat Ratio

10.797 in

1.49

(Resolved by Maximum)

Resolved API Area:

9.7176 in

Model Selection

Manufacturer

Farris

API Letter

Inlet Size

6.0 in

Outlet Size

8.0 in

Model Number

26QA12-120

API Area

11.05 in

In. Rating

300 #

Out. Rating

150 #

Valve Design

Conventional

ASME Area

12.27 in

In. Facing

RF

Out. Facing

RF

Cap Constrn

Screwed Cap

Test Gag

NACE

No

No

Quantity

Name Plate Capacity (Air): 93612 Nm3/hr

Model Materials

Body

Carbon Steel (SA-216 Gr. WCB)

Bonnet

Nozzle

316 SS

Disc

Guide

316 SS

Spring

Bellows

2014-07-21 14:50

Carbon Steel (SA-216 Gr. WCB)

316 SS

Chrome Alloy

N/A

Page 1

Tag +12476: PSV-2101/2102/2103 - Data Sheet

Sizing Scenarios

Scenario

Fluid

State

Cause of

Over P.

Relief Load

Capacity

Max Rel Cap

Case A

Gas

Blocked

Discharge

122860 Nm/hr

139617 Nm/hr

Relief T. React. Force

35 C

Noise

Atm (dBa)

4179 lbs

122.23

Noise

Required

Flare (dBa)

Area

91.671

10.797 in

Scenario: Case A / Gas Volume -- Blocked Discharge

Required Flow Capacity

Vgas

122860 Nm/hr

Relief Temperature

Trelief

35 C

Compressibility

0.01

Gas Flow Constant

363.5

Discharge Coeff. (0.9 x Kd )

KGas

0.8577

Flow

Critical

Rupture Disk Coefficient

Flow

KCCF

Relief Pressure

Prelief

20.813 Bar Abs

Specific Gravity

Ggas

Molecular Weight

1274.7 Mol Wt

Ratio of Specific Heats

Vapor Flow Factor

M vapor

Kb

Discharge Coefficient

k

Kd

Vapor Flow Factor

Kv

ASME Area (Actual)

Fluid Type (User Defined)

LPG Vapor

44 sp gr

1.49

0.953

10.797 in

Tag Notes

1. We assume :

- Operating Pressure = 16 BarG, 10% lower than Setting Pressure (18 BarG)

- Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

- Constant Back Pressure = 0 BarG

- Variable Back Pressure = 0 BarG

2. Based on data sheet, we can not offer size requested 6"-150#RF x 6"-150#RF, because Set.

Pressure 18 Barg is too high, maxsimum Set. Pressure for ANSI Class 150# is. 11.4 BarG, so we

offer size 6"300#RF x 8"-150#RF.

Please customer to verify and confirm for data above.

SizeMaster 4.3.2.13, DB: D:\DATA SIZE MASTER\SM JAS 2013-lf

2014-07-21 14:50

End of PSV-2101/2102/2103 Data Sheet

Page 2

Pressure Relief Valve Reference Drawing

Date Prepared: 2014-07-21 14:50

PSV Identification

Customer

Requisition #

Job #

PT. PP (Persero)

Job Description

+12476

Tag #

Terminal LPG Banyuwangi

Tag Description

P / ID

NACE

PSV-2301/2302/2303

ASME Code

No

Fluid State

ASME Sec. VIII

Operating Pressure

16 Bar G

Resolved ASME Area

Gas (Volume)

Set Pressure

10.797 in

35 C

Cold Diff. Test P.

0 Bar G

Operating to Set %

35 C

No Rupture Disk, 1

Variable Back P.

0 Bar G

Relief Temp.

Rupture Disk Coeff.

9.7176 in

Constant Back P.

18 Bar G

Operating Temp.

Resolved API Area

18 Bar G

Over Pressure

88.889 %

Percent Over P.

1.8 Bar G

10 %

26QA12-120

API Letter

API Area

ASME Area

11.05 in

12.27 in

Size

Rating

Facing

Inlet:

6.0 in

300 #

RF

Outlet:

8.0 in

150 #

RF

Valve Design

Conventional

Cap Constrn

Test Gag

Screwed Cap

Max. Rel. Cap.

React. Force

139617 m/hr

4179 lbs

No

Noise

122.23 dBa

Materials

Body (1)

Carbon Steel (SA-216 Gr. WCB)

Bonnet (2)

Carbon Steel (SA-216 Gr. WCB)

Nozzle (5)

316 SS

Disc (4)

316 SS

Dimensions

Weight

Dim A

430 lb

Dim C

45 in

Dim E

9 7/16

in

Guide (8)

Dim B

Spring (18)

Dim F

13/

16

in

316 SS

9 1/2 in

2 1/4

Chrome Alloy

in

Bellows (15)

N/A

Name Plate Capacity

Air

Water

93612 Nm/hr

Steam

-

Tag Notes

1. We assume :

- Operating Pressure = 16 BarG, 10% lower than Setting Pressure (18 BarG)

Operating Pressure = 16 BarG, 10% lower than Setting Pressure (18 BarG)

Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

Constant Back Pressure = 0 BarG

Variable Back Pressure = 0 BarG

2. Based on data sheet, we can not offer size requested 6"-150#RF x 6"-150#RF, because

Set. Pressure 18 Barg is too high, maxsimum Set. Pressure for ANSI Class 150# is. 11.4

BarG, so we offer size 6"300#RF x 8"-150#RF.

Please customer to verify and confirm for data above.

SizeMaster 4.3.2.13, DB: D:\DATA SIZE MASTER\SM JAS 2013-lf

End of 26QA12-120 Valve Reference Drawing

Tag +12476: PSV-2301/2302/2303 - Data Sheet

Pressure Relief Valve Data Sheet

Date Prepared: 2014-07-21 14:50

General Job Data

Customer

Requisition #

Job #

PT. PP (Persero)

Job Description

+12476

Prepared By

Checked By

Terminal LPG Banyuwangi

Approved By

Job Status

System Admin

Revision #

Sizing/Selecting

PSV Identification

Tag #

Tag Description

Tag Status

PSV-2301/2302/2303

P / ID

Discharge To Revision #

Valve Selected

Plant #

Drawing # Index # Issue For

0

Service

Inlet Line # Outlet Line #

V-001-004

Revised By

System Admin

Sizing Basis

ASME Code

Cause of Over Pressure

ASME Sec. VIII

Fluid State

Blocked Discharge

Rupture Disk Coeff.

Gas (Volume)

NACE

No

No Rupture Disk, 1

Process Parameters

MAWP

Max. Design T.

- Bar G

- C

Min. Design T.

- C

Operating

Pressure

16 Bar G

Operating

Temp.

35 C

Constant Back

P.

0 Bar G

Set Pressure

18 Bar G

Relief Temp.

35 C

Variable Back P.

0 Bar G

Operating to Set %

88.889 %

Percent Over P.

10 %

Over Pressure

1.8 Bar G

1.0133 Bar Abs

Relief Pressure

20.813 Bar Abs

Cold Diff. Test P.

18 Bar G

1274.7 Mol Wt

Gas Flow Const.

363.5

44 sp gr

Compressibility

0.01

Atm Pressure

Compressible State

Fluid

LPG Vapor

Req. Flow Cap.

122860 Nm/hr

Calculated Area

10.797 in

Resolved ASME Area:

Molecular Weight

Specific Gravity

Specific Heat Ratio

10.797 in

1.49

(Resolved by Maximum)

Resolved API Area:

9.7176 in

Model Selection

Manufacturer

Farris

API Letter

Inlet Size

6.0 in

Outlet Size

8.0 in

Model Number

26QA12-120

API Area

11.05 in

In. Rating

300 #

Out. Rating

150 #

Valve Design

Conventional

ASME Area

12.27 in

In. Facing

RF

Out. Facing

RF

Cap Constrn

Screwed Cap

Test Gag

NACE

No

No

Quantity

Name Plate Capacity (Air): 93612 Nm3/hr

Model Materials

Body

Carbon Steel (SA-216 Gr. WCB)

Bonnet

Nozzle

316 SS

Disc

Guide

316 SS

Spring

Bellows

2014-07-21 14:50

Carbon Steel (SA-216 Gr. WCB)

316 SS

Chrome Alloy

N/A

Page 1

Tag +12476: PSV-2301/2302/2303 - Data Sheet

Sizing Scenarios

Scenario

Fluid

State

Cause of

Over P.

Relief Load

Capacity

Max Rel Cap

Case A

Gas

Blocked

Discharge

122860 Nm/hr

139617 Nm/hr

Relief T. React. Force

35 C

Noise

Atm (dBa)

4179 lbs

122.23

Noise

Required

Flare (dBa)

Area

91.671

10.797 in

Scenario: Case A / Gas Volume -- Blocked Discharge

Required Flow Capacity

Vgas

122860 Nm/hr

Relief Temperature

Trelief

35 C

Compressibility

0.01

Gas Flow Constant

363.5

Discharge Coeff. (0.9 x Kd )

KGas

0.8577

Flow

Critical

Rupture Disk Coefficient

Flow

KCCF

Relief Pressure

Prelief

20.813 Bar Abs

Specific Gravity

Ggas

Molecular Weight

1274.7 Mol Wt

Ratio of Specific Heats

Vapor Flow Factor

M vapor

Kb

Discharge Coefficient

k

Kd

Vapor Flow Factor

Kv

ASME Area (Actual)

Fluid Type (User Defined)

LPG Vapor

44 sp gr

1.49

0.953

10.797 in

Tag Notes

1. We assume :

- Operating Pressure = 16 BarG, 10% lower than Setting Pressure (18 BarG)

- Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

- Constant Back Pressure = 0 BarG

- Variable Back Pressure = 0 BarG

2. Based on data sheet, we can not offer size requested 6"-150#RF x 6"-150#RF, because Set.

Pressure 18 Barg is too high, maxsimum Set. Pressure for ANSI Class 150# is. 11.4 BarG, so we

offer size 6"300#RF x 8"-150#RF.

Please customer to verify and confirm for data above.

SizeMaster 4.3.2.13, DB: D:\DATA SIZE MASTER\SM JAS 2013-lf

2014-07-21 14:50

End of PSV-2301/2302/2303 Data Sheet

Page 2

Pressure Relief Valve Reference Drawing

Date Prepared: 2014-07-21 14:50

PSV Identification

Customer

Requisition #

Job #

PT. PP (Persero)

Job Description

+12476

Tag #

Terminal LPG Banyuwangi

Tag Description

P / ID

NACE

PSV-2101/2102/2103

ASME Code

No

Fluid State

ASME Sec. VIII

Operating Pressure

16 Bar G

Resolved ASME Area

Gas (Volume)

Set Pressure

10.797 in

35 C

Cold Diff. Test P.

0 Bar G

Operating to Set %

35 C

No Rupture Disk, 1

Variable Back P.

0 Bar G

Relief Temp.

Rupture Disk Coeff.

9.7176 in

Constant Back P.

18 Bar G

Operating Temp.

Resolved API Area

18 Bar G

Over Pressure

88.889 %

Percent Over P.

1.8 Bar G

10 %

26QA12-120

API Letter

API Area

ASME Area

11.05 in

12.27 in

Size

Rating

Facing

Inlet:

6.0 in

300 #

RF

Outlet:

8.0 in

150 #

RF

Valve Design

Conventional

Cap Constrn

Test Gag

Screwed Cap

Max. Rel. Cap.

React. Force

139617 m/hr

4179 lbs

No

Noise

122.23 dBa

Materials

Body (1)

Carbon Steel (SA-216 Gr. WCB)

Bonnet (2)

Carbon Steel (SA-216 Gr. WCB)

Nozzle (5)

316 SS

Disc (4)

316 SS

Dimensions

Weight

Dim A

430 lb

Dim C

45 in

Dim E

9 7/16

in

Guide (8)

Dim B

Spring (18)

Dim F

13/

16

in

316 SS

9 1/2 in

2 1/4

Chrome Alloy

in

Bellows (15)

N/A

Name Plate Capacity

Air

Water

93612 Nm/hr

Steam

-

Tag Notes

1. We assume :

- Operating Pressure = 16 BarG, 10% lower than Setting Pressure (18 BarG)

Operating Pressure = 16 BarG, 10% lower than Setting Pressure (18 BarG)

Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

Constant Back Pressure = 0 BarG

Variable Back Pressure = 0 BarG

2. Based on data sheet, we can not offer size requested 6"-150#RF x 6"-150#RF, because

Set. Pressure 18 Barg is too high, maxsimum Set. Pressure for ANSI Class 150# is. 11.4

BarG, so we offer size 6"300#RF x 8"-150#RF.

Please customer to verify and confirm for data above.

SizeMaster 4.3.2.13, DB: D:\DATA SIZE MASTER\SM JAS 2013-lf

End of 26QA12-120 Valve Reference Drawing

Tag +12476: PSV-2101/2102/2103 - Data Sheet

Pressure Relief Valve Data Sheet

Date Prepared: 2014-07-21 14:50

General Job Data

Customer

Requisition #

Job #

PT. PP (Persero)

Job Description

+12476

Prepared By

Checked By

Terminal LPG Banyuwangi

Approved By

Job Status

System Admin

Revision #

Sizing/Selecting

PSV Identification

Tag #

Tag Description

Tag Status

PSV-2101/2102/2103

P / ID

Discharge To Revision #

Valve Selected

Plant #

Drawing # Index # Issue For

0

Service

Inlet Line # Outlet Line #

V-001-004

Revised By

System Admin

Sizing Basis

ASME Code

Cause of Over Pressure

ASME Sec. VIII

Fluid State

Blocked Discharge

Rupture Disk Coeff.

Gas (Volume)

NACE

No

No Rupture Disk, 1

Process Parameters

MAWP

Max. Design T.

- Bar G

- C

Min. Design T.

- C

Operating

Pressure

16 Bar G

Operating

Temp.

35 C

Constant Back

P.

0 Bar G

Set Pressure

18 Bar G

Relief Temp.

35 C

Variable Back P.

0 Bar G

Operating to Set %

88.889 %

Percent Over P.

10 %

Over Pressure

1.8 Bar G

1.0133 Bar Abs

Relief Pressure

20.813 Bar Abs

Cold Diff. Test P.

18 Bar G

1274.7 Mol Wt

Gas Flow Const.

363.5

44 sp gr

Compressibility

0.01

Atm Pressure

Compressible State

Fluid

LPG Vapor

Req. Flow Cap.

122860 Nm/hr

Calculated Area

10.797 in

Resolved ASME Area:

Molecular Weight

Specific Gravity

Specific Heat Ratio

10.797 in

1.49

(Resolved by Maximum)

Resolved API Area:

9.7176 in

Model Selection

Manufacturer

Farris

API Letter

Inlet Size

6.0 in

Outlet Size

8.0 in

Model Number

26QA12-120

API Area

11.05 in

In. Rating

300 #

Out. Rating

150 #

Valve Design

Conventional

ASME Area

12.27 in

In. Facing

RF

Out. Facing

RF

Cap Constrn

Screwed Cap

Test Gag

NACE

No

No

Quantity

Name Plate Capacity (Air): 93612 Nm3/hr

Model Materials

Body

Carbon Steel (SA-216 Gr. WCB)

Bonnet

Nozzle

316 SS

Disc

Guide

316 SS

Spring

Bellows

2014-07-21 14:50

Carbon Steel (SA-216 Gr. WCB)

316 SS

Chrome Alloy

N/A

Page 1

Tag +12476: PSV-2101/2102/2103 - Data Sheet

Sizing Scenarios

Scenario

Fluid

State

Cause of

Over P.

Relief Load

Capacity

Max Rel Cap

Case A

Gas

Blocked

Discharge

122860 Nm/hr

139617 Nm/hr

Relief T. React. Force

35 C

Noise

Atm (dBa)

4179 lbs

122.23

Noise

Required

Flare (dBa)

Area

91.671

10.797 in

Scenario: Case A / Gas Volume -- Blocked Discharge

Required Flow Capacity

Vgas

122860 Nm/hr

Relief Temperature

Trelief

35 C

Compressibility

0.01

Gas Flow Constant

363.5

Discharge Coeff. (0.9 x Kd )

KGas

0.8577

Flow

Critical

Rupture Disk Coefficient

Flow

KCCF

Relief Pressure

Prelief

20.813 Bar Abs

Specific Gravity

Ggas

Molecular Weight

1274.7 Mol Wt

Ratio of Specific Heats

Vapor Flow Factor

M vapor

Kb

Discharge Coefficient

k

Kd

Vapor Flow Factor

Kv

ASME Area (Actual)

Fluid Type (User Defined)

LPG Vapor

44 sp gr

1.49

0.953

10.797 in

Tag Notes

1. We assume :

- Operating Pressure = 16 BarG, 10% lower than Setting Pressure (18 BarG)

- Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

- Constant Back Pressure = 0 BarG

- Variable Back Pressure = 0 BarG

2. Based on data sheet, we can not offer size requested 6"-150#RF x 6"-150#RF, because Set.

Pressure 18 Barg is too high, maxsimum Set. Pressure for ANSI Class 150# is. 11.4 BarG, so we

offer size 6"300#RF x 8"-150#RF.

Please customer to verify and confirm for data above.

SizeMaster 4.3.2.13, DB: D:\DATA SIZE MASTER\SM JAS 2013-lf

2014-07-21 14:50

End of PSV-2101/2102/2103 Data Sheet

Page 2

Pressure Relief Valve Reference Drawing

Date Prepared: 2014-07-21 14:50

PSV Identification

Customer

Requisition #

Job #

PT. PP (Persero)

Job Description

+12476

Tag #

Terminal LPG Banyuwangi

Tag Description

P / ID

NACE

PSV-2401/2402/2403

ASME Code

No

Fluid State

ASME Sec. VIII

Operating Pressure

16 Bar G

Resolved ASME Area

Gas (Volume)

Set Pressure

10.797 in

35 C

Cold Diff. Test P.

0 Bar G

Operating to Set %

35 C

No Rupture Disk, 1

Variable Back P.

0 Bar G

Relief Temp.

Rupture Disk Coeff.

9.7176 in

Constant Back P.

18 Bar G

Operating Temp.

Resolved API Area

18 Bar G

Over Pressure

88.889 %

Percent Over P.

1.8 Bar G

10 %

26QA12-120

API Letter

API Area

ASME Area

11.05 in

12.27 in

Size

Rating

Facing

Inlet:

6.0 in

300 #

RF

Outlet:

8.0 in

150 #

RF

Valve Design

Conventional

Cap Constrn

Test Gag

Screwed Cap

Max. Rel. Cap.

React. Force

139617 m/hr

4179 lbs

No

Noise

122.23 dBa

Materials

Body (1)

Carbon Steel (SA-216 Gr. WCB)

Bonnet (2)

Carbon Steel (SA-216 Gr. WCB)

Nozzle (5)

316 SS

Disc (4)

316 SS

Dimensions

Weight

Dim A

430 lb

Dim C

45 in

Dim E

9 7/16

in

Guide (8)

Dim B

Spring (18)

Dim F

13/

16

in

316 SS

9 1/2 in

2 1/4

Chrome Alloy

in

Bellows (15)

N/A

Name Plate Capacity

Air

Water

93612 Nm/hr

Steam

-

Tag Notes

1. We assume :

- Operating Pressure = 16 BarG, 10% lower than Setting Pressure (18 BarG)

Operating Pressure = 16 BarG, 10% lower than Setting Pressure (18 BarG)

Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

Constant Back Pressure = 0 BarG

Variable Back Pressure = 0 BarG

2. Based on data sheet, we can not offer size requested 6"-150#RF x 6"-150#RF, because

Set. Pressure 18 Barg is too high, maxsimum Set. Pressure for ANSI Class 150# is. 11.4

BarG, so we offer size 6"300#RF x 8"-150#RF.

Please customer to verify and confirm for data above.

SizeMaster 4.3.2.13, DB: D:\DATA SIZE MASTER\SM JAS 2013-lf

End of 26QA12-120 Valve Reference Drawing

Tag +12476: PSV-2401/2402/2403 - Data Sheet

Pressure Relief Valve Data Sheet

Date Prepared: 2014-07-21 14:51

General Job Data

Customer

Requisition #

Job #

PT. PP (Persero)

Job Description

+12476

Prepared By

Checked By

Terminal LPG Banyuwangi

Approved By

Job Status

System Admin

Revision #

Sizing/Selecting

PSV Identification

Tag #

Tag Description

Tag Status

PSV-2401/2402/2403

P / ID

Discharge To Revision #

Valve Selected

Plant #

Drawing # Index # Issue For

0

Service

Inlet Line # Outlet Line #

V-001-004

Revised By

System Admin

Sizing Basis

ASME Code

Cause of Over Pressure

ASME Sec. VIII

Fluid State

Blocked Discharge

Rupture Disk Coeff.

Gas (Volume)

NACE

No

No Rupture Disk, 1

Process Parameters

MAWP

Max. Design T.

- Bar G

- C

Min. Design T.

- C

Operating

Pressure

16 Bar G

Operating

Temp.

35 C

Constant Back

P.

0 Bar G

Set Pressure

18 Bar G

Relief Temp.

35 C

Variable Back P.

0 Bar G

Operating to Set %

88.889 %

Percent Over P.

10 %

Over Pressure

1.8 Bar G

1.0133 Bar Abs

Relief Pressure

20.813 Bar Abs

Cold Diff. Test P.

18 Bar G

1274.7 Mol Wt

Gas Flow Const.

363.5

44 sp gr

Compressibility

0.01

Atm Pressure

Compressible State

Fluid

LPG Vapor

Req. Flow Cap.

122860 Nm/hr

Calculated Area

10.797 in

Resolved ASME Area:

Molecular Weight

Specific Gravity

Specific Heat Ratio

10.797 in

1.49

(Resolved by Maximum)

Resolved API Area:

9.7176 in

Model Selection

Manufacturer

Farris

API Letter

Inlet Size

6.0 in

Outlet Size

8.0 in

Model Number

26QA12-120

API Area

11.05 in

In. Rating

300 #

Out. Rating

150 #

Valve Design

Conventional

ASME Area

12.27 in

In. Facing

RF

Out. Facing

RF

Cap Constrn

Screwed Cap

Test Gag

NACE

No

No

Quantity

Name Plate Capacity (Air): 93612 Nm3/hr

Model Materials

Body

Carbon Steel (SA-216 Gr. WCB)

Bonnet

Nozzle

316 SS

Disc

Guide

316 SS

Spring

Bellows

2014-07-21 14:51

Carbon Steel (SA-216 Gr. WCB)

316 SS

Chrome Alloy

N/A

Page 1

Tag +12476: PSV-2401/2402/2403 - Data Sheet

Sizing Scenarios

Scenario

Fluid

State

Cause of

Over P.

Relief Load

Capacity

Max Rel Cap

Case A

Gas

Blocked

Discharge

122860 Nm/hr

139617 Nm/hr

Relief T. React. Force

35 C

Noise

Atm (dBa)

4179 lbs

122.23

Noise

Required

Flare (dBa)

Area

91.671

10.797 in

Scenario: Case A / Gas Volume -- Blocked Discharge

Required Flow Capacity

Vgas

122860 Nm/hr

Relief Temperature

Trelief

35 C

Compressibility

0.01

Gas Flow Constant

363.5

Discharge Coeff. (0.9 x Kd )

KGas

0.8577

Flow

Critical

Rupture Disk Coefficient

Flow

KCCF

Relief Pressure

Prelief

20.813 Bar Abs

Specific Gravity

Ggas

Molecular Weight

1274.7 Mol Wt

Ratio of Specific Heats

Vapor Flow Factor

M vapor

Kb

Discharge Coefficient

k

Kd

Vapor Flow Factor

Kv

ASME Area (Actual)

Fluid Type (User Defined)

LPG Vapor

44 sp gr

1.49

0.953

10.797 in

Tag Notes

1. We assume :

- Operating Pressure = 16 BarG, 10% lower than Setting Pressure (18 BarG)

- Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

- Constant Back Pressure = 0 BarG

- Variable Back Pressure = 0 BarG

2. Based on data sheet, we can not offer size requested 6"-150#RF x 6"-150#RF, because Set.

Pressure 18 Barg is too high, maxsimum Set. Pressure for ANSI Class 150# is. 11.4 BarG, so we

offer size 6"300#RF x 8"-150#RF.

Please customer to verify and confirm for data above.

SizeMaster 4.3.2.13, DB: D:\DATA SIZE MASTER\SM JAS 2013-lf

2014-07-21 14:51

End of PSV-2401/2402/2403 Data Sheet

Page 2

Pressure Relief Valve Reference Drawing

Date Prepared: 2014-07-21 14:51

PSV Identification

Customer

Requisition #

PT. PP (Persero)

Tag #

Job #

Job Description

+12476

Terminal LPG Banyuwangi

Tag Description

P / ID

NACE

PSV-2411

No

ASME Code

ASME Sec. VIII

Operating Pressure

10 Bar G

Fluid State

Set Pressure

18 Bar G

Operating Temp.

35 C

Resolved ASME Area

Gas (Volume)

Relief Temp.

35 C

Resolved API Area

0.41489 in

Rupture Disk Coeff.

0.3734 in

Constant Back P.

No Rupture Disk, 1

Variable Back P.

0 Bar G

Cold Diff. Test P.

0 Bar G

Operating to Set %

18 Bar G

Over Pressure

55.556 %

Percent Over P.

3.78 Bar G

21 %

26JA10-120

API Letter

API Area

ASME Area

1.287 in

1.430 in

Size

Rating

Facing

Inlet:

2.0 in

150 #

RF

Outlet:

3.0 in

150 #

RF

Valve Design

Conventional

Max. Rel. Cap.

17820 m/hr

Cap Constrn

Test Gag

Screwed Cap

React. Force

523.78 lbs

No

Noise

113.29 dBa

Materials

Body (1)

Carbon Steel (SA-216 Gr. WCB)

Bonnet (2)

Carbon Steel (SA-216 Gr. WCB)

Nozzle (5)

316 SS

Disc (4)

316 SS

Dimensions

Weight

Dim A

58 lb

Dim C

23 in

Dim E

5 3/8

in

Guide (8)

Dim B

Spring (18)

Dim F

11/

16

in

316 SS

4 7/8 in

1 5/16

Chrome Alloy

in

Bellows (15)

N/A

Name Plate Capacity

Air

Water

10910 Nm/hr

Steam

-

Tag Notes

1. We assume :

- Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

- Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

- Constant Back Pressure = 0 BarG

- Variable Back Pressure = 0 BarG

Please customer to verify and confirm for data above.

SizeMaster 4.3.2.13, DB: D:\DATA SIZE MASTER\SM JAS 2013-lf

End of 26JA10-120 Valve Reference Drawing

Tag +12476: PSV-2411 - Data Sheet

Pressure Relief Valve Data Sheet

Date Prepared: 2014-07-21 14:51

General Job Data

Customer

Requisition #

Job #

PT. PP (Persero)

Job Description

+12476

Prepared By

Checked By

Terminal LPG Banyuwangi

Approved By

Job Status

System Admin

Revision #

Sizing/Selecting

PSV Identification

Tag #

Tag Description

Tag Status

PSV-2411

Plant #

P / ID

Discharge To

Revision #

Outlet Line #

Revised By

Valve Selected

Drawing #

Index # Issue For

0

Service

Inlet Line #

LPG Tank 0.2T2

System Admin

Sizing Basis

ASME Code

Cause of Over Pressure

ASME Sec. VIII

Fluid State

Blocked Discharge

Rupture Disk Coeff.

Gas (Volume)

NACE

No

No Rupture Disk, 1

Process Parameters

MAWP

Max. Design T.

- Bar G

- C

Min. Design T.

- C

Operating

Pressure

10 Bar G

Operating

Temp.

35 C

Constant Back

P.

0 Bar G

Set Pressure

18 Bar G

Relief Temp.

35 C

Variable Back P.

0 Bar G

Operating to Set %

55.556 %

Percent Over P.

21 %

Over Pressure

1.0133 Bar Abs

Relief Pressure

22.793 Bar Abs

Cold Diff. Test P.

18 Bar G

1274.7 Mol Wt

Gas Flow Const.

363.5

44 sp gr

Compressibility

0.01

Atm Pressure

3.78 Bar G

Compressible State

Fluid

LPG Vapor

Req. Flow Cap.

5170 Nm/hr

Calculated Area

0.41489 in

Resolved ASME Area:

Molecular Weight

Specific Gravity

Specific Heat Ratio

0.41489 in

1.49

(Resolved by Maximum)

Resolved API Area:

0.3734 in

Model Selection

Manufacturer

Farris

API Letter

Inlet Size

2.0 in

Outlet Size

3.0 in

Model Number

26JA10-120

API Area

1.287 in

In. Rating

150 #

Out. Rating

150 #

Valve Design

Conventional

ASME Area

1.430 in

In. Facing

RF

Out. Facing

RF

Cap Constrn

Screwed Cap

Test Gag

NACE

No

No

Quantity

Name Plate Capacity (Air): 10910 Nm3/hr

Model Materials

Body

Carbon Steel (SA-216 Gr. WCB)

Bonnet

Nozzle

316 SS

Disc

Guide

316 SS

Spring

Bellows

2014-07-21 14:52

Carbon Steel (SA-216 Gr. WCB)

316 SS

Chrome Alloy

N/A

Page 1

Tag +12476: PSV-2411 - Data Sheet

Sizing Scenarios

Scenario

Fluid

State

Cause of

Over P.

Relief Load

Capacity

Max Rel Cap

Case A

Gas

Blocked

Discharge

5170 Nm/hr

17820 Nm/hr

Relief T. React. Force

35 C

Noise

Atm (dBa)

Noise

Flare (dBa)

113.29

84.966

523.78 lbs

Required

Area

0.41489 in

Scenario: Case A / Gas Volume -- Blocked Discharge

Required Flow Capacity

Vgas

5170 Nm/hr

Relief Temperature

Trelief

35 C

Compressibility

0.01

Gas Flow Constant

363.5

Discharge Coeff. (0.9 x Kd )

KGas

0.8577

Flow

Critical

Rupture Disk Coefficient

Flow

KCCF

Relief Pressure

Prelief

22.793 Bar Abs

Specific Gravity

Ggas

Molecular Weight

1274.7 Mol Wt

Ratio of Specific Heats

Vapor Flow Factor

M vapor

Kb

Discharge Coefficient

k

Kd

Vapor Flow Factor

Kv

ASME Area (Actual)

Fluid Type (User Defined)

LPG Vapor

44 sp gr

1.49

0.953

0.41489 in

Tag Notes

1. We assume :

- Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

- Constant Back Pressure = 0 BarG

- Variable Back Pressure = 0 BarG

Please customer to verify and confirm for data above.

SizeMaster 4.3.2.13, DB: D:\DATA SIZE MASTER\SM JAS 2013-lf

2014-07-21 14:52

End of PSV-2411 Data Sheet

Page 2

Pressure Relief Valve Reference Drawing

Date Prepared: 2014-07-21 14:52

PSV Identification

Customer

Requisition #

PT. PP (Persero)

Tag #

Job #

Job Description

+12476

Terminal LPG Banyuwangi

Tag Description

P / ID

NACE

PSV-2411

No

ASME Code

ASME Sec. VIII

Operating Pressure

10 Bar G

Fluid State

Set Pressure

18 Bar G

Operating Temp.

35 C

Resolved ASME Area

Gas (Volume)

Relief Temp.

35 C

Resolved API Area

0.41489 in

Rupture Disk Coeff.

0.3734 in

Constant Back P.

No Rupture Disk, 1

Variable Back P.

0 Bar G

Cold Diff. Test P.

0 Bar G

Operating to Set %

18 Bar G

Over Pressure

55.556 %

Percent Over P.

3.78 Bar G

21 %

26JA10-120

API Letter

API Area

ASME Area

1.287 in

1.430 in

Size

Rating

Facing

Inlet:

2.0 in

150 #

RF

Outlet:

3.0 in

150 #

RF

Valve Design

Conventional

Max. Rel. Cap.

17820 m/hr

Cap Constrn

Test Gag

Screwed Cap

React. Force

523.78 lbs

No

Noise

113.29 dBa

Materials

Body (1)

Carbon Steel (SA-216 Gr. WCB)

Bonnet (2)

Carbon Steel (SA-216 Gr. WCB)

Nozzle (5)

316 SS

Disc (4)

316 SS

Dimensions

Weight

Dim A

58 lb

Dim C

23 in

Dim E

5 3/8

in

Guide (8)

Dim B

Spring (18)

Dim F

11/

16

in

316 SS

4 7/8 in

1 5/16

Chrome Alloy

in

Bellows (15)

N/A

Name Plate Capacity

Air

Water

10910 Nm/hr

Steam

-

Tag Notes

1. We assume :

- Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

- Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

- Constant Back Pressure = 0 BarG

- Variable Back Pressure = 0 BarG

Please customer to verify and confirm for data above.

SizeMaster 4.3.2.13, DB: D:\DATA SIZE MASTER\SM JAS 2013-lf

End of 26JA10-120 Valve Reference Drawing

Tag +12476: PSV-2411 - Data Sheet

Pressure Relief Valve Data Sheet

Date Prepared: 2014-07-21 14:52

General Job Data

Customer

Requisition #

Job #

PT. PP (Persero)

Job Description

+12476

Prepared By

Checked By

Terminal LPG Banyuwangi

Approved By

Job Status

System Admin

Revision #

Sizing/Selecting

PSV Identification

Tag #

Tag Description

Tag Status

PSV-2411

Plant #

P / ID

Discharge To

Revision #

Outlet Line #

Revised By

Valve Selected

Drawing # Index # Issue For

0

Service

Inlet Line #

LPG Pump Suction

System Admin

Sizing Basis

ASME Code

Cause of Over Pressure

ASME Sec. VIII

Fluid State

Blocked Discharge

Rupture Disk Coeff.

Gas (Volume)

NACE

No

No Rupture Disk, 1

Process Parameters

MAWP

Max. Design T.

- Bar G

- C

Min. Design T.

- C

Operating

Pressure

10 Bar G

Operating

Temp.

35 C

Constant Back

P.

0 Bar G

Set Pressure

18 Bar G

Relief Temp.

35 C

Variable Back P.

0 Bar G

Operating to Set %

55.556 %

Percent Over P.

21 %

Over Pressure

1.0133 Bar Abs

Relief Pressure

22.793 Bar Abs

Cold Diff. Test P.

18 Bar G

1274.7 Mol Wt

Gas Flow Const.

363.5

44 sp gr

Compressibility

0.01

Atm Pressure

3.78 Bar G

Compressible State

Fluid

LPG Vapor

Req. Flow Cap.

5170 Nm/hr

Calculated Area

0.41489 in

Resolved ASME Area:

Molecular Weight

Specific Gravity

Specific Heat Ratio

0.41489 in

1.49

(Resolved by Maximum)

Resolved API Area:

0.3734 in

Model Selection

Manufacturer

Farris

API Letter

Inlet Size

2.0 in

Outlet Size

3.0 in

Model Number

26JA10-120

API Area

1.287 in

In. Rating

150 #

Out. Rating

150 #

Valve Design

Conventional

ASME Area

1.430 in

In. Facing

RF

Out. Facing

RF

Cap Constrn

Screwed Cap

Test Gag

NACE

No

No

Quantity

Name Plate Capacity (Air): 10910 Nm3/hr

Model Materials

Body

Carbon Steel (SA-216 Gr. WCB)

Bonnet

Nozzle

316 SS

Disc

Guide

316 SS

Spring

Bellows

2014-07-21 14:52

Carbon Steel (SA-216 Gr. WCB)

316 SS

Chrome Alloy

N/A

Page 1

Tag +12476: PSV-2411 - Data Sheet

Sizing Scenarios

Scenario

Fluid

State

Cause of

Over P.

Relief Load

Capacity

Max Rel Cap

Case A

Gas

Blocked

Discharge

5170 Nm/hr

17820 Nm/hr

Relief T. React. Force

35 C

Noise

Atm (dBa)

Noise

Flare (dBa)

113.29

84.966

523.78 lbs

Required

Area

0.41489 in

Scenario: Case A / Gas Volume -- Blocked Discharge

Required Flow Capacity

Vgas

5170 Nm/hr

Relief Temperature

Trelief

35 C

Compressibility

0.01

Gas Flow Constant

363.5

Discharge Coeff. (0.9 x Kd )

KGas

0.8577

Flow

Critical

Rupture Disk Coefficient

Flow

KCCF

Relief Pressure

Prelief

22.793 Bar Abs

Specific Gravity

Ggas

Molecular Weight

1274.7 Mol Wt

Ratio of Specific Heats

Vapor Flow Factor

M vapor

Kb

Discharge Coefficient

k

Kd

Vapor Flow Factor

Kv

ASME Area (Actual)

Fluid Type (User Defined)

LPG Vapor

44 sp gr

1.49

0.953

0.41489 in

Tag Notes

1. We assume :

- Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

- Constant Back Pressure = 0 BarG

- Variable Back Pressure = 0 BarG

Please customer to verify and confirm for data above.

SizeMaster 4.3.2.13, DB: D:\DATA SIZE MASTER\SM JAS 2013-lf

2014-07-21 14:52

End of PSV-2411 Data Sheet

Page 2

Pressure Relief Valve Reference Drawing

Date Prepared: 2014-07-21 14:52

PSV Identification

Customer

Requisition #

PT. PP (Persero)

Tag #

Job #

Job Description

+12476

Terminal LPG Banyuwangi

Tag Description

P / ID

NACE

PSV-6101

No

ASME Code

Fluid State

ASME Sec. VIII

Operating Pressure

10 Bar G

Set Pressure

18 Bar G

Operating Temp.

35 C

Resolved ASME Area

Gas (Volume)

Relief Temp.

35 C

Resolved API Area

12.047 in

Rupture Disk Coeff.

10.843 in

Constant Back P.

No Rupture Disk, 1

Variable Back P.

0 Bar G

Cold Diff. Test P.

0 Bar G

Operating to Set %

18 Bar G

Over Pressure

55.556 %

Percent Over P.

1.8 Bar G

10 %

26QA12-120

API Letter

API Area

ASME Area

11.05 in

12.27 in

Size

Rating

Facing

Inlet:

6.0 in

300 #

RF

Outlet:

8.0 in

150 #

RF

Valve Design

Conventional

Max. Rel. Cap.

12222 m/hr

Cap Constrn

Test Gag

Screwed Cap

React. Force

4029.8 lbs

No

Noise

109.92 dBa

Materials

Body (1)

Carbon Steel (SA-216 Gr. WCB)

Bonnet (2)

Carbon Steel (SA-216 Gr. WCB)

Nozzle (5)

316 SS

Disc (4)

316 SS

Dimensions

Weight

Dim A

430 lb

Dim C

45 in

Dim E

9 7/16

in

Guide (8)

Dim B

Spring (18)

Dim F

13/

16

in

316 SS

9 1/2 in

2 1/4

Chrome Alloy

in

Bellows (15)

N/A

Name Plate Capacity

Air

Water

93612 Nm/hr

Steam

-

Tag Notes

1. We assume :

- Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

- Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

- Constant Back Pressure = 0 BarG

- Variable Back Pressure = 0 BarG

2. We can not input Ratio of Specific Heat 0.975, because value of Ratio of Specific Heat

must be 1 or 2.5.

3. Based on data sheet, we can not offer size requested 3"-150#RF x 4"-150#RF, due to

Required Capacity 12000 Nm3/hr is too large. So we offer size 6"-300#RF x 8"-150#RF.

Please customer to verify and confirm for data above.

SizeMaster 4.3.2.13, DB: D:\DATA SIZE MASTER\SM JAS 2013-lf

End of 26QA12-120 Valve Reference Drawing

Tag +12476: PSV-6101 - Data Sheet

Pressure Relief Valve Data Sheet

Date Prepared: 2014-07-21 14:52

General Job Data

Customer

Requisition #

Job #

PT. PP (Persero)

Job Description

+12476

Prepared By

Checked By

Terminal LPG Banyuwangi

Approved By

Job Status

System Admin

Revision #

Sizing/Selecting

PSV Identification

Tag #

Tag Description

Tag Status

PSV-6101

Plant #

P / ID

Discharge To

Revision #

Outlet Line #

Revised By

Valve Selected

Drawing #

Index # Issue For

0

Service

Inlet Line #

C-01 Discharge

System Admin

Sizing Basis

ASME Code

Cause of Over Pressure

ASME Sec. VIII

Fluid State

Blocked Discharge

Rupture Disk Coeff.

Gas (Volume)

NACE

No

No Rupture Disk, 1

Process Parameters

MAWP

Max. Design T.

- Bar G

- C

Min. Design T.

- C

Operating

Pressure

10 Bar G

Operating

Temp.

35 C

Constant Back

P.

0 Bar G

Set Pressure

18 Bar G

Relief Temp.

35 C

Variable Back P.

0 Bar G

Operating to Set %

55.556 %

Percent Over P.

10 %

Over Pressure

1.8 Bar G

1.0133 Bar Abs

Relief Pressure

20.813 Bar Abs

Cold Diff. Test P.

18 Bar G

1274.7 Mol Wt

Gas Flow Const.

315

44 sp gr

Compressibility

0.98

Atm Pressure

Compressible State

Fluid

LPG Vapor

Req. Flow Cap.

12000 Nm/hr

Calculated Area

12.047 in

Resolved ASME Area:

Molecular Weight

Specific Gravity

Specific Heat Ratio

12.047 in

(Resolved by Maximum)

Resolved API Area:

10.843 in

Model Selection

Manufacturer

Farris

API Letter

Inlet Size

6.0 in

Outlet Size

8.0 in

Model Number

26QA12-120

API Area

11.05 in

In. Rating

300 #

Out. Rating

150 #

Valve Design

Conventional

ASME Area

12.27 in

In. Facing

RF

Out. Facing

RF

Cap Constrn

Screwed Cap

Test Gag

NACE

No

No

Quantity

Name Plate Capacity (Air): 93612 Nm3/hr

Model Materials

Body

Carbon Steel (SA-216 Gr. WCB)

Bonnet

Nozzle

316 SS

Disc

Guide

316 SS

Spring

Bellows

2014-07-21 14:52

Carbon Steel (SA-216 Gr. WCB)

316 SS

Chrome Alloy

N/A

Page 1

Tag +12476: PSV-6101 - Data Sheet

Sizing Scenarios

Scenario

Fluid

State

Cause of

Over P.

Relief Load

Capacity

Max Rel Cap

Case A

Gas

Blocked

Discharge

12000 Nm/hr

12222 Nm/hr

Relief T. React. Force

35 C

4029.8 lbs

Noise

Atm (dBa)

Noise

Required

Flare (dBa)

Area

109.92

82.438

12.047 in

Scenario: Case A / Gas Volume -- Blocked Discharge

Required Flow Capacity

Vgas

12000 Nm/hr

Relief Temperature

Trelief

35 C

Compressibility

0.98

Gas Flow Constant

315

Discharge Coeff. (0.9 x Kd )

KGas

0.8577

Flow

Critical

Rupture Disk Coefficient

Flow

KCCF

Relief Pressure

Prelief

20.813 Bar Abs

Specific Gravity

Ggas

Molecular Weight

1274.7 Mol Wt

Ratio of Specific Heats

Vapor Flow Factor

M vapor

Kb

Discharge Coefficient

k

Kd

Vapor Flow Factor

Kv

ASME Area (Actual)

Fluid Type (User Defined)

LPG Vapor

44 sp gr

1

0.953

12.047 in

Tag Notes

1. We assume :

- Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

- Constant Back Pressure = 0 BarG

- Variable Back Pressure = 0 BarG

2. We can not input Ratio of Specific Heat 0.975, because value of Ratio of Specific Heat

must be 1 or 2.5.

3. Based on data sheet, we can not offer size requested 3"-150#RF x 4"-150#RF, due to

Required Capacity 12000 Nm3/hr is too large. So we offer size 6"-300#RF x 8"-150#RF.

Please customer to verify and confirm for data above.

SizeMaster 4.3.2.13, DB: D:\DATA SIZE MASTER\SM JAS 2013-lf

2014-07-21 14:52

End of PSV-6101 Data Sheet

Page 2

Pressure Relief Valve Reference Drawing

Date Prepared: 2014-07-21 14:53

PSV Identification

Customer

Requisition #

Job #

PT. PP (Persero)

Tag #

Job Description

+12476

Terminal LPG Banyuwangi

Tag Description

P / ID

NACE

PSV-3001A/B/C

ASME Code

ASME Sec. VIII

Operating Pressure

13 Bar G

No

Fluid State

Resolved ASME Area

Liquid (Volume)

2.5392 in

Set Pressure

35 C

Cold Diff. Test P.

0 Bar G

Operating to Set %

35 C

No Rupture Disk, 1

Variable Back P.

7 Bar G

Relief Temp.

Rupture Disk Coeff.

2.2853 in

Constant Back P.

18 Bar G

Operating Temp.

Resolved API Area

11 Bar G

Over Pressure

72.222 %

Percent Over P.

1.8 Bar G

10 %

26LA10L-120

API Letter

API Area

ASME Area

2.853 in

3.170 in

Size

Rating

Facing

Inlet:

3.0 in

150 #

RF

Outlet:

4.0 in

150 #

RF

Valve Design

Conventional

Max. Rel. Cap.

324.59 m/hr

Cap Constrn

Test Gag

Screwed Cap

React. Force

No

Noise

80.883 lbs

Materials

Body (1)

Carbon Steel (SA-216 Gr. WCB)

Bonnet (2)

Carbon Steel (SA-216 Gr. WCB)

Nozzle (5)

316 SS

Disc (4)

316 SS

Dimensions

Weight

Dim A

145 lb

Dim C

28 1/2 in

Dim E

6 1/8

in

11/

16

Guide (8)

Dim B

Spring (18)

Dim F

in

316 SS

6 1/2 in

1 1/2

Chrome Alloy

in

Bellows (15)

N/A

Name Plate Capacity

Air

Water

-

242.8 m/hr

Steam

-

Tag Notes

1. We assume :

- Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

- Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

- Constant Back Pressure = 7 BarG

- Variable Back Pressure = 0 BarG

Please customer to verify and confirm for data above.

SizeMaster 4.3.2.13, DB: D:\DATA SIZE MASTER\SM JAS 2013-lf

End of 26LA10L-120 Valve Reference Drawing

Tag +12476: PSV-3001A/B/C - Data Sheet

Pressure Relief Valve Data Sheet

Date Prepared: 2014-07-21 14:53

General Job Data

Customer

Requisition #

Job #

PT. PP (Persero)

Job Description

+12476

Prepared By

Checked By

Terminal LPG Banyuwangi

Approved By

Job Status

System Admin

Revision #

Sizing/Selecting

PSV Identification

Tag #

Tag Description

Tag Status

PSV-3001A/B/C

Plant #

P / ID

Discharge To Revision #

Valve Selected

Drawing # Index # Issue For

0

Service

Inlet Line # Outlet Line #

Pump Discharge

Revised By

System Admin

Sizing Basis

ASME Code

Cause of Over Pressure

ASME Sec. VIII

Fluid State

Blocked Discharge

Rupture Disk Coeff.

Liquid (Volume)

NACE

No

No Rupture Disk, 1

Process Parameters

MAWP

Max. Design T.

- Bar G

- C

Min. Design T.

- C

Operating

Pressure

13 Bar G

Operating

Temp.

35 C

Constant Back

P.

7 Bar G

Set Pressure

18 Bar G

Relief Temp.

35 C

Variable Back P.

0 Bar G

Operating to Set %

72.222 %

Percent Over P.

10 %

Over Pressure

1.8 Bar G

1.0133 Bar Abs

Relief Pressure

20.813 Bar Abs

Cold Diff. Test P.

11 Bar G

Atm Pressure

Non-Compressible State

Fluid Type

LPG Liquid

Specific Gravity

0.56 sp gr

Viscosity Type

Req. Flow Cap.

260 m/hr

Viscosity

Calculated Area

2.5392 in

Reynolds #

Resolved ASME Area:

2.5392 in

(Resolved by Maximum)

Resolved API Area:

Absolute

0.667 Centipoise

1511470

2.2853 in

Model Selection

Manufacturer

Farris

API Letter

Inlet Size

3.0 in

Outlet Size

4.0 in

Model Number

26LA10L-120

API Area

2.853 in

In. Rating

150 #

Out. Rating

150 #

Valve Design

Conventional

ASME Area

3.170 in

In. Facing

RF

Out. Facing

RF

Cap Constrn

Screwed Cap

Test Gag

NACE

No

No

Quantity

Name Plate Capacity (Water): 242.8 m3/hr

Model Materials

Body

Carbon Steel (SA-216 Gr. WCB)

Bonnet

Nozzle

316 SS

Disc

Guide

316 SS

Spring

Bellows

2014-07-21 14:53

Carbon Steel (SA-216 Gr. WCB)

316 SS

Chrome Alloy

N/A

Page 1

Tag +12476: PSV-3001A/B/C - Data Sheet

Sizing Scenarios

Scenario

Fluid

State

Cause of

Over P.

Relief Load

Capacity

Max Rel Cap

Case A

Liquid

Blocked

Discharge

260 m/hr

324.59 m/hr

Relief T. React. Force

35 C

Noise

Atm (dBa)

80.883 lbs

Noise

Required

Flare (dBa)

Area

-

2.5392 in

Scenario: Case A / Liquid Volume -- Blocked Discharge

Required Flow Capacity

Vliquid

260 m/hr

Specific Gravity

Gliquid

0.56 sp gr

Discharge Coeff. (0.9 x Kd )

Kliquid

0.6516

Rupture Disk Coefficient

KCCF

Pset + Pover - P back

12.8 Bar G

Liquid Viscosity Factor

Ku

Liquid Flow Factor

Kw

Fluid Type

Viscosity Type

Discharge Coefficient

Qliquid

Kd

0.724

Trelief

35 C

User Defined

Req'd Flow Capacity

Absolute

Viscosity

0.667 Centipoise

Relief Temperature

Reynolds #

1511470

ASME Area (Actual)

2.5392 in

Tag Notes

1. We assume :

- Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

- Constant Back Pressure = 7 BarG

- Variable Back Pressure = 0 BarG

Please customer to verify and confirm for data above.

SizeMaster 4.3.2.13, DB: D:\DATA SIZE MASTER\SM JAS 2013-lf

2014-07-21 14:53

End of PSV-3001A/B/C Data Sheet

Page 2

Pressure Relief Valve Reference Drawing

Date Prepared: 2014-07-21 14:53

PSV Identification

Customer

Requisition #

Job #

PT. PP (Persero)

Tag #

Job Description

+12476

Terminal LPG Banyuwangi

Tag Description

P / ID

NACE

PSV-001

No

ASME Code

Fluid State

ASME Sec. VIII

Operating Pressure

7 Bar G

Gas (Volume)

Set Pressure

15 Bar G

Operating Temp.

35 C

Resolved ASME Area

Resolved API Area

0.19036 in

0.17132 in

Constant Back P.

35 C

No Rupture Disk, 1

Variable Back P.

0 Bar G

Relief Temp.

Rupture Disk Coeff.

Cold Diff. Test P.

0 Bar G

Operating to Set %

15 Bar G

Over Pressure

46.667 %

Percent Over P.

1.5 Bar G

10 %

26EA10-140

API Letter

API Area

ASME Area

0.196 in

0.225 in

Size

Rating

Facing

Inlet:

1.0 in

150 #

RF

Outlet:

2.0 in

150 #

RF

Valve Design

Conventional

Max. Rel. Cap.

236.4 m/hr

Cap Constrn

Test Gag

Packed Lever

React. Force

32.818 lbs

No

Noise

92.783 dBa

Materials

Body (1)

Carbon Steel (SA-216 Gr. WCB)

Bonnet (2)

Carbon Steel (SA-216 Gr. WCB)

Nozzle (5)

316 SS

Disc (4)

316 SS

Dimensions

Weight

Dim A

42 lb

Dim C

19 in

Dim E

4 1/8

in

1/

2

Guide (8)

Dim B

Spring (18)

Dim F

in

316 SS

4 1/2 in

1 3/16

Chrome Alloy

in

Bellows (15)

N/A

Name Plate Capacity

Air

Water

1445.1 Nm/hr

Steam

-

Tag Notes

1. We assume :

- Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

Constant Back Pressure = 0 BarG

Variable Back Pressure = 0 BarG

Ratio of Specific Heat = 1

Compressibility Factor = 0.9

2. We can not input Setting Pressure 1.5 BarG, lower than Operating Pressure 7 BarG. So

we input Setting Pressure 15 BarG.

Please customer to verify and confirm for data above.

SizeMaster 4.3.2.13, DB: D:\DATA SIZE MASTER\SM JAS 2013-lf

End of 26EA10-140 Valve Reference Drawing

Tag +12476: PSV-001 - Data Sheet

Pressure Relief Valve Data Sheet

Date Prepared: 2014-07-21 14:53

General Job Data

Customer

Requisition #

Job #

PT. PP (Persero)

Job Description

+12476

Prepared By

Checked By

Terminal LPG Banyuwangi

Approved By

Job Status

System Admin

Revision #

Sizing/Selecting

PSV Identification

Tag #

Tag Description

Tag Status

Drawing #

Issue For

PSV-001

Plant #

P / ID

Discharge To

Revision #

Outlet Line #

Revised By

Valve Selected

Index #

0

Service

Inlet Line #

IA Drum

System Admin

Sizing Basis

ASME Code

Cause of Over Pressure

ASME Sec. VIII

Fluid State

Blocked Discharge

Rupture Disk Coeff.

Gas (Volume)

NACE

No

No Rupture Disk, 1

Process Parameters

MAWP

- Bar G

Max. Design T.

Operating

Pressure

7 Bar G

Set Pressure

Operating to Set %

Atm Pressure

- C

Min. Design T.

- C

Operating

Temp.

35 C

Constant Back

P.

0 Bar G

15 Bar G

Relief Temp.

35 C

Variable Back P.

0 Bar G

46.667 %

Percent Over P.

10 %

Over Pressure

1.5 Bar G

1.0133 Bar Abs

Relief Pressure

17.513 Bar Abs

Cold Diff. Test P.

15 Bar G

811.16 Mol Wt

Gas Flow Const.

315

28 sp gr

Compressibility

0.98

Compressible State

Fluid

Air

Molecular Weight

Req. Flow Cap.

200 Nm/hr

Specific Gravity

Calculated Area

0.19036 in

Specific Heat Ratio

Resolved ASME Area:

0.19036 in

(Resolved by Maximum)

Resolved API Area:

0.17132 in

Model Selection

Manufacturer

Farris

API Letter

Inlet Size

1.0 in

Outlet Size

2.0 in

Model Number

26EA10-140

API Area

0.196 in

In. Rating

150 #

Out. Rating

150 #

Valve Design

Conventional

ASME Area

0.225 in

In. Facing

RF

Out. Facing

RF

Cap Constrn

Packed Lever

Test Gag

NACE

No

No

Quantity

Name Plate Capacity (Air): 1445.1 Nm3/hr

Model Materials

Body

Carbon Steel (SA-216 Gr. WCB)

Bonnet

Nozzle

316 SS

Disc

Guide

316 SS

Spring

Bellows

2014-07-21 14:53

Carbon Steel (SA-216 Gr. WCB)

316 SS

Chrome Alloy

N/A

Page 1

Tag +12476: PSV-001 - Data Sheet

Sizing Scenarios

Scenario

Fluid

State

Cause of

Over P.

Relief Load

Capacity

Max Rel Cap

Case A

Gas

Blocked

Discharge

200 Nm/hr

236.4 Nm/hr

Relief T. React. Force

35 C

Noise

Atm (dBa)

Noise

Flare (dBa)

92.783

69.587

32.818 lbs

Required

Area

0.19036 in

Scenario: Case A / Gas Volume -- Blocked Discharge

Required Flow Capacity

Vgas

200 Nm/hr

Relief Temperature

Trelief

35 C

Compressibility

0.98

Gas Flow Constant

315

Discharge Coeff. (0.9 x Kd )

KGas

0.8577

Flow

Critical

Rupture Disk Coefficient

Flow

KCCF

Relief Pressure

Prelief

17.513 Bar Abs

Specific Gravity

Ggas

Molecular Weight

811.16 Mol Wt

Ratio of Specific Heats

Vapor Flow Factor

M vapor

Kb

Discharge Coefficient

k

Kd

Vapor Flow Factor

Kv

ASME Area (Actual)

Fluid Type (User Defined)

Air

28 sp gr

1

0.953

0.19036 in

Tag Notes

1. We assume :

- Operating Temp. = 35 degC, equal with Relieving Temp. (35 degC)

- Constant Back Pressure = 0 BarG

- Variable Back Pressure = 0 BarG

- Ratio of Specific Heat = 1

- Compressibility Factor = 0.9

2. We can not input Setting Pressure 1.5 BarG, lower than Operating Pressure 7 BarG. So we

input Setting Pressure 15 BarG.

Please customer to verify and confirm for data above.

SizeMaster 4.3.2.13, DB: D:\DATA SIZE MASTER\SM JAS 2013-lf

2014-07-21 14:53

End of PSV-001 Data Sheet

Page 2

Pressure Relief Valve Reference Drawing

Date Prepared: 2014-07-21 14:53

PSV Identification

Customer

Requisition #

PT. PP (Persero)

Tag #

Job #

Job Description

+12476

Terminal LPG Banyuwangi

Tag Description

P / ID

NACE

PSV-5001

No

ASME Code

Fluid State

ASME Sec. VIII

Operating Pressure

10 Bar G

Liquid (Volume)

Set Pressure

13.5 Bar G

Operating Temp.

35 C

Relief Temp.

35 C

Resolved ASME Area

Resolved API Area

0.24232 in

Rupture Disk Coeff.

0.21809 in

Constant Back P.

No Rupture Disk, 1

Variable Back P.

0 Bar G

Cold Diff. Test P.

0 Bar G

Operating to Set %

13.5 Bar G

Over Pressure

74.074 %

Percent Over P.

1.35 Bar G

10 %

26FA10L-120

API Letter

API Area

ASME Area

0.307 in

0.371 in

Size

Rating

Facing

Inlet:

1.5 in

150 #

RF

Outlet:

2.0 in

150 #

RF

Valve Design

Conventional

Max. Rel. Cap.

30.62 m/hr

Cap Constrn

Test Gag

Screwed Cap