Professional Documents

Culture Documents

Pro Tech 1 Covers

Pro Tech 1 Covers

Uploaded by

weldsvOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pro Tech 1 Covers

Pro Tech 1 Covers

Uploaded by

weldsvCopyright:

Available Formats

1

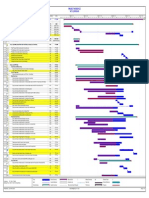

Abandonment

Exploration/

Delineation

Project Build

Phase and

Drilling

Initial Operating Phase

Plateau

Production

and Field Life

Extension

Completion

and Production

Optimisation

Intervention

Artificial Lift

Time

Cummulative Income stream /$

/$ Cummulative Investment/ Cost Profile

Introduction

Time

Ref. No. PT/2,

PT/1, Version 1.1 Date of issue

17 / 69 / 00

Reservoir Production Concepts

Reservoir

Pressure

Oil

G.O.R Prod

Oil

Prod

G.O.R

500

Pressure

G.O.R

Time-Year

Oil Prod (1000)

Reservoir

Pressure

5000

10

Gas Break

through

Pressure

Oil

Prod

Rate

250

2500

G.O.R

BSW %

20

10

0

0

Time-Year

Ref. No. PT/1, Version 1.1 Date of issue

7 / 9 / 00

Performance of Flowing Wells

y,,yyy

,y,y,y,y,yyyy

,y,y,y,y ,y,y

,,

,,,

,,,yyyy

yy

,,,

yy,

WELL

Pwf

Bottomhole Flowing Pressure

rw

Pe

Pe

re

2.875"

2.5"

4"

PWF

IPR

Oil Production Rate

Ref. No. PT/1, Version 1.1 Date of issue

7 / 9 / 00

Wellbore Completion Concepts

Upper Seal

Sealing Element

Bypass

Upper Cone

Slips

Lower Cone

Left - Hand

Screw Head

Inner Mandrel

Friction Blocks

Upper Split Nut

Lower Split Nut

Ref. No. PT/1, Version 1.1 Date of issue

7 / 9 / 00

Wireline Services

Locking Screw

Top Sub

Coller

Steel Shearpin

Key Retainer

Spring

Standard Key

Self-Releasing

Profile

Lower Key

Retainer

Sheave

Guard

Body

Sheave

Wheel

Oil Reservoir

Gland Nut

Top Gland

Packing

Swivel Bearings

Pressure Relief Valve

Bottom Gland

Internal B.O.P.

Quick Union

Internal B.O.P.

Retainer

Ref. No. PT/1, Version 1.1 Date of issue

7 / 9 / 00

Completion Equipment

Xmas tree

Tubing hanger

Adaptor spool

Spacer spool to compensate

for abence of 7" / 7 5/8"

tie break

Compact spool

9 5/8" casing hanger

13 3/8" casing hanger

20" casing head housing

36" conductor

20"

13 3/8

9 5/8

Production tubing

Ref. No. PT/1, Version 1.1 Date of issue

7 / 9 / 00

Multiple Zone Completions

Ref. No. PT/1, Version 1.1 Date of issue

7 / 9 / 00

Perforating

80

80 Gms.

11

100

80

10

150

13.8"

50

26

Grams of Explosive

18 - 21

35

54

1.1

36

7

9 - 15

1.0

19

0.9

16

6

0.8

37

0.7

0.6

0.5

3

Entrance Hole (tenths - inches)

Penetration (inches)

0.4

Berea sandstone

core

0.3

1.375

1

11

1 16

28

2

34 3238

3

Radial Distance, (Inches)

18

1

44

0.2

Radial extent of consolidation

0.1 permeability, this region and inward

Significantly5 reduced

5

8

5Significant

Gun Diameter (inches)

grain

fracturing: original grain-to-grain

6

contacts remain intact. Low permeability, diminishing radially

0.75

Significant grain fracturing: grain separation parallel to

perforation axis. Assumed low flow resistance

0.50

0.30

0.20

Open

Perforation

Intense fracturing, debris, quartz and carbonate

fines. Assumed low flow resistance

0

Ref. No. PT/1, Version 1.1 Date of issue

7 / 9 / 00

1

2

Linear Distance, (Inches)

10

Well Intervention

B

Payback

Period

A

-ve

Net Present Value

Cumulative Cash Flow

+ve

Time

Project 1

Return on Investement = B/A

Project 2

IRR 1

IRR 2

Discount Rate

NPV Profile for Comparing Projects

Ref. No. PT/1, Version 1.1 Date of issue

7 / 9 / 00

Completion Installation Practices,

Procedures and Programming

Option

2

Circulate Whilst Lowering

Final Tubing Joints

- Observe Pressure Increase

LocatePolished

Bore Receptacle

Mark Tubing On Drill Floor

To SSSV if Control Line

Not Attached

PHASE 3

Pull Back Tubing

To Allow Space Out

Tubing

Landoff/Space Out

To Adequate Depth to

Adjust Tubing Length

Run Back With SSSV

Without Control Line

and Tubing Hanger

Locate Seals Within

Polished Bore

Land Off Tubing Hanger

in THS to Achieve the

Required Seal Length

Movement Capacity

Go To Completion

Final Testing

Ref. No. PT/1, Version 1.1 Date of issue

7 / 9 / 00

Examination and Model Solutions

RE

SI

TU

E

RS

R:

EA

CO

.:

:

RE

8 Pages

O

TI

E: RA

M

T

:

IS

yyyy

,,,,

yyyy

,,,,

yyyy

,,,,

yyyy

,,,,

t

no

o

td n

bu

o

on inati

cti

se xam

is

th

e e hed

te

l th inis

ple unti

f

m

is

l

Co sea

Date:

Solution

Part I

(1) Based on a PI of 6 STB/d/psi and a static reservoir pressure of

Subject:

3700psi, draw the IPR as a straight line through the points.

INSTRUCTIONS TO CANDIDATES

(a)

q=0

1. Complete the sections above but do not seal until the examination is finished.

2. Insert in box on right the numbers of the questions attempted.

(b)

No.

Mk.

Pwf = Pi = 3700

q = 6000 STB/d at Pwf = 2700psi

3. Start each question on a new page.

4. Rough working should be confined to left hand pages.

(2) Based upon a THP of 200 psi, calculate the bottomhole flowing

5. This book must be handed in entire with the top corner sealed.

pressures from the gradient curves supplied.

6. Additional books must bear the name of the candidate, be sealed and be affixed to

the first book by means of a tag provided

qo

STB/d

Pth

psi

PLEASE READ EXAMINATION REGULATIONS ON BACK

COVER

1000

200

2000

3000

4000

6000

8000

200

200

200

200

200

Depth

Equiv

Ft

Actual

Depth

Ft

2000

1850

1750

1600

1350

1200

7000

7000

7000

7000

7000

7000

Total

Equiv

Depth

Ft

9000

8850

8750

8600

8350

8200

Pwf

psi

2650

2650

2650

2680

2700

2780

Plot pwf versus qo to obtain the tubing performance curve

4000

Pwf

psi

3100

3000

TPR

TPR

IPR s = 0

S=+5

2000

IPR s = 0

S = + 10

1000

1000

2000

3000

4000

Qo

Ref. No. PT/1, Version 1.1 Date of issue

7 / 9 / 00

5000

6000

7000

8000

9000

You might also like

- Well Intervention Zone ChangeDocument6 pagesWell Intervention Zone ChangeLawNo ratings yet

- Nodal Systems Analysis of Oil and Gas WellsDocument13 pagesNodal Systems Analysis of Oil and Gas Wellsrafael0j0moreno0r100% (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- ResEngCh10 PDFDocument131 pagesResEngCh10 PDFweldsv50% (2)

- Re Seng ExamDocument7 pagesRe Seng Examweldsv100% (2)

- HSBC in ChinaDocument3 pagesHSBC in ChinaSandra Lee50% (2)

- Eva Value Based Management PDFDocument2 pagesEva Value Based Management PDFPamelaNo ratings yet

- Project On Prudent Cas Ltd.Document48 pagesProject On Prudent Cas Ltd.vaibhav_sharma_650% (4)

- Work Instruction On Tube ExpansionDocument40 pagesWork Instruction On Tube Expansionjayaarnav100% (1)

- P9127 - Piping Pressure Testing - Rev 0 - GENERICDocument20 pagesP9127 - Piping Pressure Testing - Rev 0 - GENERICmengelito almonte100% (1)

- Drilling Application: Name of Company: Well Name & Number: Date: July 12, 2013Document1 pageDrilling Application: Name of Company: Well Name & Number: Date: July 12, 2013scrbdgharaviNo ratings yet

- Plugback For Sidetrack Procedure Proposed PDFDocument4 pagesPlugback For Sidetrack Procedure Proposed PDFPatrícia MouraNo ratings yet

- FYP QuestionsDocument8 pagesFYP QuestionsSafa HinaiNo ratings yet

- Schedule - MT. Elpindo IIDocument2 pagesSchedule - MT. Elpindo IIjoyan1426No ratings yet

- Leak-Off Test ProceduresDocument15 pagesLeak-Off Test ProceduresS MariusNo ratings yet

- Sample IPCDocument10 pagesSample IPCArshad MahmoodNo ratings yet

- 23 - Well Control Worksheet-Surface BOPDocument2 pages23 - Well Control Worksheet-Surface BOPAseem PandeyNo ratings yet

- Well Control Worksheet For A Surface Bop Stack: CANNON 1-21Document2 pagesWell Control Worksheet For A Surface Bop Stack: CANNON 1-21scrbdgharaviNo ratings yet

- Well Control Worksheet For A Surface Bop Stack: CANNON 1-21Document2 pagesWell Control Worksheet For A Surface Bop Stack: CANNON 1-21scrbdgharaviNo ratings yet

- Lecture12b - Basic Gaslift Sec 5 - Mandrel Spacing DesignDocument14 pagesLecture12b - Basic Gaslift Sec 5 - Mandrel Spacing Designreborn2100% (1)

- Identification of Well Problems Using Well TestingDocument42 pagesIdentification of Well Problems Using Well TestingIseghohi GodswillNo ratings yet

- 01-Revitalizing Production LoggingDocument17 pages01-Revitalizing Production LoggingCarlos Valdivieso100% (1)

- IBP013 04 Horizontal Single-Trip Gravel Pack and Selective Stimulation System For Deep Water Extended Reach WellsDocument8 pagesIBP013 04 Horizontal Single-Trip Gravel Pack and Selective Stimulation System For Deep Water Extended Reach WellsUlrich MandakNo ratings yet

- Gas Pipeline and Gas Metering and Regulating Station ProjectDocument18 pagesGas Pipeline and Gas Metering and Regulating Station ProjectAnonymous 7vljJzH100% (1)

- G08 00 PEN CJP 001 - Rev0Document7 pagesG08 00 PEN CJP 001 - Rev0mengelito almonteNo ratings yet

- Nodal System Analysis of Oil and Gas WellsDocument27 pagesNodal System Analysis of Oil and Gas Wellsdaniel_figo17No ratings yet

- 10 Nodal System Analysis of Oil and Gas WellsDocument13 pages10 Nodal System Analysis of Oil and Gas WellsSultan_Mehmood_7287100% (5)

- IPM-RP-WCI-001 Backreaming and Reaming Recommended PracticesDocument7 pagesIPM-RP-WCI-001 Backreaming and Reaming Recommended PracticesGhinet Teodor-ioanNo ratings yet

- OTC-28103-MS Intelligent Completions Used During Extended Well Test of Exploratory Wells in BrazilDocument5 pagesOTC-28103-MS Intelligent Completions Used During Extended Well Test of Exploratory Wells in BrazilFernando SteimetzNo ratings yet

- Lex Sheers Multi Phase Meters Day 1Document81 pagesLex Sheers Multi Phase Meters Day 1candra100% (5)

- Valve Gate Open Lag Time in Conventional Hot Runner System: March 2018Document6 pagesValve Gate Open Lag Time in Conventional Hot Runner System: March 2018Vineela ChNo ratings yet

- Steam Blowing ProcedureDocument37 pagesSteam Blowing ProcedureIslam Fawzy100% (2)

- JAS-EPC-SP-DYN-20-R1-PR-004 FAT Procedure - RevbDocument13 pagesJAS-EPC-SP-DYN-20-R1-PR-004 FAT Procedure - RevbAgus SuriptoNo ratings yet

- Drilling Application: Name of Company: Well Name & Number: DateDocument1 pageDrilling Application: Name of Company: Well Name & Number: DatescrbdgharaviNo ratings yet

- Project Outputs-1Document17 pagesProject Outputs-1P Timilsina PrakashNo ratings yet

- Artificial LiftDocument94 pagesArtificial LiftAndres100% (2)

- Section10 - POST-DRILLING ACTIVITIESDocument16 pagesSection10 - POST-DRILLING ACTIVITIESMohamed ElshoraNo ratings yet

- High-Pressure Gas Lift For Deep, Sour Production - OnePetroDocument3 pagesHigh-Pressure Gas Lift For Deep, Sour Production - OnePetrovissusamuraiNo ratings yet

- Test Specification Nyt-1664-CDocument18 pagesTest Specification Nyt-1664-CMauro Antonio BergantiniNo ratings yet

- Efficient Completions: R AdjetDocument18 pagesEfficient Completions: R AdjetSalman QamarNo ratings yet

- 08pp2 PLBGDocument31 pages08pp2 PLBGabc3579No ratings yet

- Spe 181400 MSDocument18 pagesSpe 181400 MSlishushijieyouyituiNo ratings yet

- Increasing The Profits & Production of Mature Fields Through Optimized Jet Pump Design & Operational ConsiderationsDocument9 pagesIncreasing The Profits & Production of Mature Fields Through Optimized Jet Pump Design & Operational ConsiderationsIndra BayuNo ratings yet

- AG-101 Frac Design Proposal V2Document30 pagesAG-101 Frac Design Proposal V2ayman morsyNo ratings yet

- Deck JobsDocument6 pagesDeck Jobsthaw koNo ratings yet

- Sop of Octangonal BlenderDocument3 pagesSop of Octangonal BlenderHamidNo ratings yet

- Procedure For Mainline Hydrotest by NitrogenDocument10 pagesProcedure For Mainline Hydrotest by Nitrogenmauls291No ratings yet

- IB-14 - SCON - TBG Punch - Scope of Work Rev 00Document11 pagesIB-14 - SCON - TBG Punch - Scope of Work Rev 00Samson ObinnaNo ratings yet

- Duct & Vent EngineeringDocument70 pagesDuct & Vent Engineeringtop20202080% (5)

- Nodal Systems Analysis of Oil and Gas Wells - 00014714Document13 pagesNodal Systems Analysis of Oil and Gas Wells - 00014714Jorge LuisNo ratings yet

- Sample QAPDocument3 pagesSample QAPsniperiNo ratings yet

- Project Facilities BDocument6 pagesProject Facilities Bijhbfa0% (1)

- Kent Introl Multi Phase SizingDocument18 pagesKent Introl Multi Phase SizingBuzurjmeherNo ratings yet

- Sondex PLT User GuideDocument24 pagesSondex PLT User GuideJean Carlo0% (1)

- Section 2-Type of Flow TestingDocument15 pagesSection 2-Type of Flow TestingAhmed ManieaNo ratings yet

- Evaluation of Differential Pressure Sticking and Stuck Pipe in Oil and Gas Drilling Technology and Its Production OperationsDocument17 pagesEvaluation of Differential Pressure Sticking and Stuck Pipe in Oil and Gas Drilling Technology and Its Production OperationsMahaveer Singh RathoreNo ratings yet

- SOC Alerada H13-6 MSI+MTI Logging Procedure TGT 03.11.2022 Rev2Document11 pagesSOC Alerada H13-6 MSI+MTI Logging Procedure TGT 03.11.2022 Rev2mohanedNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Course:-28117 Class: - 289033a: Section I Well Performance Evaluation Section II Completion DesignDocument13 pagesCourse:-28117 Class: - 289033a: Section I Well Performance Evaluation Section II Completion Designweldsv100% (2)

- Res Eng CH 15Document29 pagesRes Eng CH 15weldsvNo ratings yet

- ResEngModSol PDFDocument29 pagesResEngModSol PDFweldsvNo ratings yet

- ResEngCh14 PDFDocument73 pagesResEngCh14 PDFweldsvNo ratings yet

- Equilibrium Ratio Prediction and CalculationDocument28 pagesEquilibrium Ratio Prediction and CalculationweldsvNo ratings yet

- Questions 1Document1 pageQuestions 1weldsvNo ratings yet

- Res Eng CH 3Document16 pagesRes Eng CH 3weldsvNo ratings yet

- Producing The ReservoirDocument13 pagesProducing The ReservoirweldsvNo ratings yet

- Re Seng CoversDocument19 pagesRe Seng CoversweldsvNo ratings yet

- Basic Geologic Concepts 1Document2 pagesBasic Geologic Concepts 1weldsvNo ratings yet

- Petroleum Geology and Reservoirs: Lesson 2Document2 pagesPetroleum Geology and Reservoirs: Lesson 2weldsvNo ratings yet

- Glossary: Ability, Effective Permeability, Relative PermeabilityDocument26 pagesGlossary: Ability, Effective Permeability, Relative PermeabilityweldsvNo ratings yet

- Drilling The Well: Figure 77. Variations in Hole Diameter Caused by Differences in Sedimentary Rock LayersDocument7 pagesDrilling The Well: Figure 77. Variations in Hole Diameter Caused by Differences in Sedimentary Rock LayersweldsvNo ratings yet

- Answers To Review Questions: Petroleum Geology and ReservoirsDocument1 pageAnswers To Review Questions: Petroleum Geology and ReservoirsweldsvNo ratings yet

- Mema FabmDocument29 pagesMema FabmJohuana Lhesty Sabordo Jabas100% (1)

- Statistics - Landmark Summaries Interpreting Typical Values and PercentilesDocument31 pagesStatistics - Landmark Summaries Interpreting Typical Values and PercentilesDr Rushen SinghNo ratings yet

- Yes Bank Failure Exposes India To Wider Credit Risk - Nomura - The Economic TimesDocument2 pagesYes Bank Failure Exposes India To Wider Credit Risk - Nomura - The Economic TimesTushar SharmaNo ratings yet

- TB 1Document16 pagesTB 1Zuhaib SultanNo ratings yet

- Fin Acc Part 2Document6 pagesFin Acc Part 2Jolina cunananNo ratings yet

- Interview QuestionsDocument20 pagesInterview QuestionsJatin PathakNo ratings yet

- Offshore Financial Freedom 3Document339 pagesOffshore Financial Freedom 3FhélixAbel LoyaNo ratings yet

- Mutual Fund 1Document3 pagesMutual Fund 1Lyra Joy CalayanNo ratings yet

- Dear Shareholders of Biglari Holdings Inc.Document9 pagesDear Shareholders of Biglari Holdings Inc.AAOI2No ratings yet

- Bacolod, Adinrane P. Bsba Finman IiiDocument25 pagesBacolod, Adinrane P. Bsba Finman IiichenlyNo ratings yet

- 1907 EMarketer GEN XDocument16 pages1907 EMarketer GEN XRodolfo CampaNo ratings yet

- Credit Swisse 21-03-2014Document31 pagesCredit Swisse 21-03-2014Alex NikovskiNo ratings yet

- MIB NotesDocument47 pagesMIB NotesAjay SinghNo ratings yet

- Barrick 2012 Q4Document13 pagesBarrick 2012 Q4Jesus SalamancaNo ratings yet

- Financial AnalysesDocument23 pagesFinancial AnalysesKunal KaduNo ratings yet

- Arshia Verma - Manasvi TewariDocument2 pagesArshia Verma - Manasvi Tewarikazan kazanNo ratings yet

- Extension and ContractionDocument5 pagesExtension and ContractionMonika Shekhawat100% (1)

- Securization and The Global EconomyDocument262 pagesSecurization and The Global EconomyHeeveerson Fonseca100% (1)

- You Need To Be A Little Crazy - The Truth About Starting and Growing - 2Document208 pagesYou Need To Be A Little Crazy - The Truth About Starting and Growing - 2musero100% (2)

- 2017 Foundations of Financial Risk Study GuideDocument8 pages2017 Foundations of Financial Risk Study Guidesujaysarkar85100% (1)

- Financial Statement Analysis Template: Ratio Formula RatioDocument1 pageFinancial Statement Analysis Template: Ratio Formula RatioMetilda MorasNo ratings yet

- In The Matter of Purshottam Budhwani - Appeal No.91 of 2013Document15 pagesIn The Matter of Purshottam Budhwani - Appeal No.91 of 2013Shyam SunderNo ratings yet

- PMS Guide August 2019Document88 pagesPMS Guide August 2019HetanshNo ratings yet

- Difference Between Expense and AllowanceDocument3 pagesDifference Between Expense and AllowancenishavinodNo ratings yet

- Dawood Islamic BankDocument57 pagesDawood Islamic BankMimi ZamanNo ratings yet

- Online or Offline? The Rise of Peer To Peer Lending in MicrofinanceDocument11 pagesOnline or Offline? The Rise of Peer To Peer Lending in MicrofinanceNgọc Minh Đỗ NguyễnNo ratings yet

- Vitae Resume TemplateDocument1 pageVitae Resume Templateapi-284033427No ratings yet