Professional Documents

Culture Documents

UCL - Biochemical and Microbial Engineering (LBIRC2108)

UCL - Biochemical and Microbial Engineering (LBIRC2108)

Uploaded by

Ruben MarquezCopyright:

Available Formats

You might also like

- Ethical Dimensions in The Health Professions PDFDocument2 pagesEthical Dimensions in The Health Professions PDFJames0% (7)

- 2010 CC 3.6 Engine Schematic R36Document19 pages2010 CC 3.6 Engine Schematic R36Dungani AllanNo ratings yet

- HollowWorld - HWA1 - NightwailDocument71 pagesHollowWorld - HWA1 - NightwailPascal LeroyNo ratings yet

- UCL Chemical Engineering Module DescriptionsDocument65 pagesUCL Chemical Engineering Module DescriptionsChughtai Ammar100% (1)

- Aut - CG4017 - Part ADocument78 pagesAut - CG4017 - Part AzuopengxiangNo ratings yet

- MSC Handbook BiochemDocument74 pagesMSC Handbook Biochem393852019100% (1)

- Kurse DTUDocument9 pagesKurse DTUdavid0205No ratings yet

- Ac 2009-1438: A Novel Open-Ended Liquid-Liquid Extraction Module For The Chemical Engineering LaboratoryDocument25 pagesAc 2009-1438: A Novel Open-Ended Liquid-Liquid Extraction Module For The Chemical Engineering LaboratoryAnara AlamNo ratings yet

- L4 - Life Cycle Assessment-Week 5Document67 pagesL4 - Life Cycle Assessment-Week 5Sulaksha WimalasenaNo ratings yet

- Processes: Conceptual Design of An Operator Training Simulator For A Bio-Ethanol PlantDocument20 pagesProcesses: Conceptual Design of An Operator Training Simulator For A Bio-Ethanol PlantchemNo ratings yet

- Biochemical EmgineeringDocument15 pagesBiochemical EmgineeringzaryabnadeemNo ratings yet

- Analysis and Synthesis of BiprocessesDocument4 pagesAnalysis and Synthesis of BiprocessesNeils ArenósNo ratings yet

- Advances and Practices of Bioprocess Scale-Up: Advances in Biochemical Engineering/Biotechnology January 2015Document16 pagesAdvances and Practices of Bioprocess Scale-Up: Advances in Biochemical Engineering/Biotechnology January 2015Andréia AnschauNo ratings yet

- Bit3012 Bioprocess-Engineering-And-bioreactor-Design Eth 1.1 40 Bit3012Document2 pagesBit3012 Bioprocess-Engineering-And-bioreactor-Design Eth 1.1 40 Bit3012Rohit GuptaNo ratings yet

- Diseño Procesos, Enseñanza ApropiadaDocument4 pagesDiseño Procesos, Enseñanza ApropiadaVictor Esteban CondorNo ratings yet

- Life Cycle ManagementDocument9 pagesLife Cycle ManagementBagus YudhaNo ratings yet

- Subject 1. Introduction OCWDocument37 pagesSubject 1. Introduction OCWfgfNo ratings yet

- Che461-Week1 - Fall 2017 (16 Slides)Document16 pagesChe461-Week1 - Fall 2017 (16 Slides)Nouman AliNo ratings yet

- JRC116599 - Deliverable - b37 - Public - Version (ID 7366919)Document36 pagesJRC116599 - Deliverable - b37 - Public - Version (ID 7366919)Gabriel DiazNo ratings yet

- Bioreactors: Catalan (Cat) Francesc - Godia@uab - Cat Francesc Gòdia CasablancasDocument4 pagesBioreactors: Catalan (Cat) Francesc - Godia@uab - Cat Francesc Gòdia CasablancasNeils ArenósNo ratings yet

- Microbiological Laboratory TechniquesDocument41 pagesMicrobiological Laboratory TechniquesSivarami VangaNo ratings yet

- Invited Paper Multi-Unit Integration in Microfluidic Processes: Current Status and Future HorizonsDocument8 pagesInvited Paper Multi-Unit Integration in Microfluidic Processes: Current Status and Future HorizonsMada Sanjaya WsNo ratings yet

- Certified Renewable Energy Project DeveloperDocument7 pagesCertified Renewable Energy Project DeveloperosvaldoNo ratings yet

- Application of Scilab-Xcos For Process Control Applied To Educational Process ProjectsDocument12 pagesApplication of Scilab-Xcos For Process Control Applied To Educational Process ProjectsNicolás Pérez BarrigaNo ratings yet

- Biochemical Engineering OverviewDocument3 pagesBiochemical Engineering OverviewAaush Bhardwaj SinghNo ratings yet

- BT 0306Document3 pagesBT 0306ashuna249396No ratings yet

- Process Mining Applied To The Change Control Board Process Discovering Real Processes in Software Development Process Masterthesis PDFDocument94 pagesProcess Mining Applied To The Change Control Board Process Discovering Real Processes in Software Development Process Masterthesis PDFkam_anwNo ratings yet

- Life Cycle Assessment of Jute ProductsDocument47 pagesLife Cycle Assessment of Jute ProductsAnastasiya Disyak QuailNo ratings yet

- Man Chester Tics BrochureDocument6 pagesMan Chester Tics BrochurecondormuresNo ratings yet

- Bioreactor DesignDocument4 pagesBioreactor DesignMahendra Varma BoopathyNo ratings yet

- MEAE 235 - Fluid Mechanics & Hydraulic Machinery LabDocument63 pagesMEAE 235 - Fluid Mechanics & Hydraulic Machinery LabAnshikha NautiyalNo ratings yet

- Objectives and Results of The ProjectDocument1 pageObjectives and Results of The ProjectAndreeaNo ratings yet

- M TechDocument70 pagesM TechAjayMugundan ChandranNo ratings yet

- Bioreactor System With ArduinoDocument59 pagesBioreactor System With ArduinoingnavasNo ratings yet

- Anbumathi Capstone 2 - PROTOTYPEDocument34 pagesAnbumathi Capstone 2 - PROTOTYPESmall Stone Big MangoNo ratings yet

- 6103-Article Text-25925-1-10-20200119Document13 pages6103-Article Text-25925-1-10-20200119Dinarherlina 235No ratings yet

- TIP - 300 - Report - Final (1) (Automatisk Gjenopprettet)Document68 pagesTIP - 300 - Report - Final (1) (Automatisk Gjenopprettet)ravn.rydtun.winsvoldNo ratings yet

- ChE 210 Lecture 1 Introduction To Chemical Engineering CalculationsDocument18 pagesChE 210 Lecture 1 Introduction To Chemical Engineering CalculationsMay May MagluyanNo ratings yet

- New Survey Practice Lab ManualDocument72 pagesNew Survey Practice Lab ManualdheggekoppaNo ratings yet

- CoursedairyVII SemDocument81 pagesCoursedairyVII SemManu ChakkingalNo ratings yet

- Presentazione Corso ExamDocument6 pagesPresentazione Corso Examismail zanatyNo ratings yet

- 02whole - PDF Iternship ReportDocument60 pages02whole - PDF Iternship ReportWasyehun Tamrat100% (1)

- HDL Lab Manual 2022-23Document63 pagesHDL Lab Manual 2022-23meghana.ece.mittNo ratings yet

- Bioreactor Design and AnalysisDocument2 pagesBioreactor Design and AnalysisMarilyn GomesNo ratings yet

- Basic Bioprocesses EngineeringDocument4 pagesBasic Bioprocesses EngineeringNeils ArenósNo ratings yet

- Final Year Syllabus CopeDocument61 pagesFinal Year Syllabus CopeSachin ANo ratings yet

- Course DetailsDocument11 pagesCourse DetailsDasun NirmalaNo ratings yet

- opearating system manualDocument37 pagesopearating system manualGuruprasad PujariNo ratings yet

- Intelligent Energy Europe - Environmental Design in University Curricula and Architectural Training in EuropeDocument7 pagesIntelligent Energy Europe - Environmental Design in University Curricula and Architectural Training in EuropeElena EfodiNo ratings yet

- Course Title: Bioprocess Engineering: L T S SW/ FW P Total Credit UnitsDocument3 pagesCourse Title: Bioprocess Engineering: L T S SW/ FW P Total Credit UnitsDrishti MalhotraNo ratings yet

- CAM lAB MANUAL 2021 2022Document80 pagesCAM lAB MANUAL 2021 2022Bharath kumarNo ratings yet

- 21 Be 45Document3 pages21 Be 45Shaikh Mohd Arqam AltafNo ratings yet

- Sustainable Manufacturing: BITS PilaniDocument67 pagesSustainable Manufacturing: BITS PilaniPromodNo ratings yet

- TocDocument13 pagesTocSaurabh Vij100% (1)

- 1 ChemPlantDesign-Intro To Plant Design EconomicsDocument33 pages1 ChemPlantDesign-Intro To Plant Design Economicsfatiehah93No ratings yet

- Department of Chemical Engineering UTP Researcher Profile Name (Including Title) Contact InfoDocument3 pagesDepartment of Chemical Engineering UTP Researcher Profile Name (Including Title) Contact InfoEvan ChinNo ratings yet

- Final Design ReportDocument158 pagesFinal Design ReportahmedNo ratings yet

- Sólidos Tarea 1Document2 pagesSólidos Tarea 1Natalia RomeroNo ratings yet

- DC Final Report Local Energy GeneratorDocument88 pagesDC Final Report Local Energy Generatoramit25041699No ratings yet

- Dyeep: Tema: TemaDocument26 pagesDyeep: Tema: TemaAlevj DbNo ratings yet

- BE Biomedical Engg SEM 8Document21 pagesBE Biomedical Engg SEM 8Safwan Shaikh0% (2)

- Training Engineers for InnovationFrom EverandTraining Engineers for InnovationDenis LemaîtreNo ratings yet

- Management and Technologies of Water, Wastewater, Waste and Cir-cular Economy: WWW&CEFrom EverandManagement and Technologies of Water, Wastewater, Waste and Cir-cular Economy: WWW&CENo ratings yet

- Industrial & Environmental Biotechnology Course # KIBGE-707: Afsheen Aman, PH.DDocument18 pagesIndustrial & Environmental Biotechnology Course # KIBGE-707: Afsheen Aman, PH.DZiwaqarNo ratings yet

- Articulo MoleculasaDocument1 pageArticulo MoleculasaRuben MarquezNo ratings yet

- Art 4 1Document1 pageArt 4 1Ruben MarquezNo ratings yet

- Lecture 6 Amino Acid ProductionDocument19 pagesLecture 6 Amino Acid ProductionRuben MarquezNo ratings yet

- Art 4 3Document1 pageArt 4 3Ruben MarquezNo ratings yet

- Beer PresentationDocument27 pagesBeer PresentationRuben Marquez100% (1)

- Enzymatic Browning in Fruit2Document68 pagesEnzymatic Browning in Fruit2Ruben MarquezNo ratings yet

- Articulo Probioticos 1Document13 pagesArticulo Probioticos 1Ruben MarquezNo ratings yet

- Animal Cells BioreactorsDocument13 pagesAnimal Cells BioreactorsRuben MarquezNo ratings yet

- Problemas A Resolver TareaDocument8 pagesProblemas A Resolver TareaRuben Marquez0% (1)

- 160 PresentationDocument46 pages160 PresentationRuben MarquezNo ratings yet

- Bioprocesos Exámenes Actualizado Abril 2018 TareaDocument26 pagesBioprocesos Exámenes Actualizado Abril 2018 TareaRuben MarquezNo ratings yet

- EscritoHighlights REV AQRDocument1 pageEscritoHighlights REV AQRRuben MarquezNo ratings yet

- Contamination Free Air SupplyDocument14 pagesContamination Free Air SupplyRuben MarquezNo ratings yet

- Escrito Articulo Tablas y Figuras Articulo LISTO RUBENDocument10 pagesEscrito Articulo Tablas y Figuras Articulo LISTO RUBENRuben MarquezNo ratings yet

- Environmental Microbiology and BiotechnologyDocument20 pagesEnvironmental Microbiology and BiotechnologyRuben MarquezNo ratings yet

- Quizz de Cultivos ContinuosDocument12 pagesQuizz de Cultivos ContinuosRuben MarquezNo ratings yet

- Williams Bioreactors PDFDocument8 pagesWilliams Bioreactors PDFRuben MarquezNo ratings yet

- 2007 (De Villiers) Tom & LanguageDocument21 pages2007 (De Villiers) Tom & LanguageElizabeth MendozaNo ratings yet

- AV UWorld EOs (Rough Draft) - Data - Repeat LandscapeDocument139 pagesAV UWorld EOs (Rough Draft) - Data - Repeat LandscapeJonathan AiresNo ratings yet

- Investigating The Effect of Some Fabric Parameters On The Thermal Comfort Properties of Flat Knitted Acrylic Fabrics For Winter WearDocument11 pagesInvestigating The Effect of Some Fabric Parameters On The Thermal Comfort Properties of Flat Knitted Acrylic Fabrics For Winter WearSudipto BeheraNo ratings yet

- 2595 0118 BRJP 02 03 0255Document5 pages2595 0118 BRJP 02 03 0255tariNo ratings yet

- Poet, Lover, BirdwatcherDocument13 pagesPoet, Lover, BirdwatcherFhjjhhvNo ratings yet

- AIT Unit1 InternetDocument44 pagesAIT Unit1 InternetNaina_Dwivedi_6514No ratings yet

- Math BingoDocument6 pagesMath BingoKelly CollovaNo ratings yet

- Mycoplasma ContaminationDocument4 pagesMycoplasma ContaminationashueinNo ratings yet

- 1602lcd PDFDocument25 pages1602lcd PDFGHOST 22035No ratings yet

- Annual General Report On The Audit of Information Systems FY 2021-22Document69 pagesAnnual General Report On The Audit of Information Systems FY 2021-22ABINo ratings yet

- Guru 1 - 5 Whats NewDocument19 pagesGuru 1 - 5 Whats NewLuca RosacutaNo ratings yet

- 04-MiCOM C264 HMI - Rev GDocument34 pages04-MiCOM C264 HMI - Rev GSaddam Hossen BiplobNo ratings yet

- Data Analysis ProjectDocument18 pagesData Analysis ProjectDaylyn MosherNo ratings yet

- Amity: UniversityDocument10 pagesAmity: UniversityVinayak MangotraNo ratings yet

- ATO SubstitutionDocument1 pageATO SubstitutionMaggie VillacortaNo ratings yet

- Difficult Airway? Difficult Mask Ventilation?Document10 pagesDifficult Airway? Difficult Mask Ventilation?Parvathy R NairNo ratings yet

- Business Studies 2021 HSC Exam Pack NSW Education StandardsDocument3 pagesBusiness Studies 2021 HSC Exam Pack NSW Education Standardsmxstiia10No ratings yet

- CyclamenDocument9 pagesCyclamenLAUM1No ratings yet

- Workbook Lesson 1Document13 pagesWorkbook Lesson 1Giulia MennuniNo ratings yet

- Analysis of DrugsDocument53 pagesAnalysis of DrugsAnaliza Kitongan LantayanNo ratings yet

- 9Document4 pages9maithaNo ratings yet

- Femto SONDocument19 pagesFemto SONIlya KryuchkovNo ratings yet

- Mxs52 80bvmb SMDocument298 pagesMxs52 80bvmb SMJustoNo ratings yet

- O-Ring Material Offering Guide: ORD 5712 Effective September 2004Document84 pagesO-Ring Material Offering Guide: ORD 5712 Effective September 2004Samir FerreiraNo ratings yet

- EDA VHDL SimulationDocument19 pagesEDA VHDL SimulationYQ WNo ratings yet

- Eco-Friendly PlanDocument2 pagesEco-Friendly PlanPaulisky PicazosNo ratings yet

- Inclusive Education Program (IEP)Document2 pagesInclusive Education Program (IEP)floradawatNo ratings yet

UCL - Biochemical and Microbial Engineering (LBIRC2108)

UCL - Biochemical and Microbial Engineering (LBIRC2108)

Uploaded by

Ruben MarquezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UCL - Biochemical and Microbial Engineering (LBIRC2108)

UCL - Biochemical and Microbial Engineering (LBIRC2108)

Uploaded by

Ruben MarquezCopyright:

Available Formats

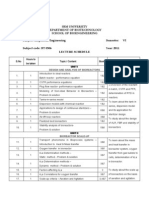

18/2/2015

UCLBiochemicalandMicrobialEngineering[LBIRC2108]

|agenda|directories|librairies|jobopportunities|campusmaps|

search...

|IntranetUCL|

COURSESDESCRIPTIONFOR20142015

>UCL>TEACHINGANDTRAINING >Studyprogramme>Fiched'activit

LBIRC2108

COURSEDESCRIPTION

> Studyprogramme

> Searchincourses

description

> Printablewebversion

> Document

[Versionfranaise]

BiochemicalandMicrobialEngineering[LBIRC2108]

5.0crditsECTS 30.0h+22.5h 2q >Schedule

Teacher(s)

AgathosSpyridon

Language

French

Place

ofthecourse

LouvainlaNeuve

Online

resources

Icampus

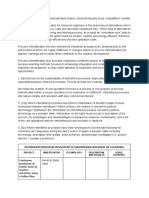

From design to scaleup on a pilot scale of microbial and enzymatic processes. Theoretical and

methodological foundations of applied chemical kinetics and design of chemical reactors with the

characteristics(kineticsandtransportphenomena)ofbiochemicalandmicrobiologicalprocessesinorderto

systematizetheprinciplesunderlyingtheanalysisanddesign/sizingofbioreactors.Specifics:

Mainthemes

(Micro)biologicalprocessescharacterizedkineticallyandthermodynamically:cellgrowth,itsmeasurement

orestimation,useofsubstrate(s),formationofproduct(s).Yields.Productivities.Kineticmodels.Parameter

estimation.Themethodologyofmaterialandenergybalancesfortheanalysisofbiotechnologicalsystems

and of their performance. Batch, continuous, semi continuous reactors. Transport phenomena applied to

theanalysisofaeration,agitation,rheology,scaleupandsterilizationofbioreactors.

a.Contributiondel'activitaurfrentielAA(AAduprogramme)

1.22.12.22.44.14.24.58.5

b.FormulationspcifiquepourcetteactivitdesAAduprogramme

Attheendofthisactivity,thestudentisableto:

Aims

1.Applythemethodologyofmaterialbalancestotheanalysisofbiotechnologicalsystems

2.Applythemethodologyofenergybalancetotheanalysisofbiotechnologicalsystems

3.Applythemethodologyofreactordesigntotheanalysisanddesign/sizingofbioreactors(area

ofbiochemicalandmicrobiologicalprocesses)inthespecificcaseofbatchreactors

4.Applythemethodologyofreactordesigntotheanalysisanddesign/sizingofbioreactorsinthe

specificcaseofCSTR(continuousstirredtankreactor).

5.Applythemethodologyofreactordesigntotheanalysisanddesign/sizingofbioreactorsinthe

specificcaseofsemicontinuousreactors(fedbatch).

6.Applymasstransferphenomenaintheanalysisofdifferentoperations(aeration,agitation,etc.)

thatcantakeplaceinbioreactors.

7. Apply the phenomena of energy transfer to the analysis of different operations (aeration,

agitation,etc.)thatcantakeplaceinbioreactors.

8. Apply the phenomena of transfer of momentum to the analysis of different operations (aeration,

agitation,etc.)cantakeplaceinbioreactors.

9.Applythemethodologyofchemicalkineticsappliedtotheanalysisanddesign/sizingofbioreactors(area

ofbiochemicalandmicrobiologicalprocesses).

10. Search for real values of constants ''or of other parameters in correlations that are essential to the

design/sizingofbiologicalreactors.

11. As part of the design of a new biological reactor propose in a reasoned manner (with its advantages

and limitations) the design of the most appropriate reactor with respect to the industrial context under

consideration.

Evaluation

methods

Teaching

methods

http://www.uclouvain.be/encours2014LBIRC2108.html

Writtenexaminationin2parts

1.Examinationrequiringshortanswersbutbasedonatheoreticaldevelopment

2.Examinationfocusedonproblemsolving

1. Lectures, lectures with guided questions, including presentations of concrete examples from industry

with case analysis by the instructor [conventional lectures, interactive presentations using audiovisual

equipment(videoprojections,powerpoint)]

2. Exercise sessions in teams, guided. These exercises are designed to familiarize the student with the

methodology of solving quantitative problems in the design and analysis of bioprocesses: makes use of

calculationsforsizingorperformance,constructionofflowsheetscombiningunitoperations,searchofreal

values of constants or other parameters of correlations useful in design or modeling / optimization of

1/2

18/2/2015

UCLBiochemicalandMicrobialEngineering[LBIRC2108]

bioprocesses.

Theactivitybeginswithafacetofacepresenceonly

Content

Definitions:Definitionsinbioengineeringquantitiesandreactorsmicrobialprocesses'yieldsofbiological

processes in a reactor. Kinetic models of microbial growth. Modeling of a batch reactor modeling of a

continuous stirred biological system with and without recycling ' twostage continuous stirred systems.

Enzymatic process reactors design and performance. Sterilization processes. Scaleup from laboratory

scale through pilot scale to industrial scale. Bioseparations engineering. Ideal recovery process: primary

separation, isolation, purification and polishing. Separation devices in industrial cell culture: continuous

perfusionreactorwithcellretention.Advantagesandlimitationsofeachdesigninanindustrialcontext.

Bibliography

Mandatory supports(available on icampus): Notes, slides, chapters and sections specified from the

textbooks "Bioprocess Engineering Principles" by Pauline M. Doran 2nd edition (2013) and "Bioprocess

Engineering"byMichaelL.Shuler&FikretKargi2ndedition(2002)

Other supports: video projections, recommended reading: chapters and sections from the above

textbooks

Cycleandyear

ofstudy

>Premireannedemaster[120]bioingnieur:chimieetbioindustries,finalitspcialise

Facultyorentity

incharge

>AGRO

<<<Pageprcdente

|Webmaster:UniversitcatholiquedeLouvain|information:infocontact|privacy|rules|

|adress:1,Placedel'UniversitB1348LouvainlaNeuve(Belgique)Tel:+32(0)10/47.21.11Fax:+32(0)10/47.29.99|

http://www.uclouvain.be/encours2014LBIRC2108.html

2/2

You might also like

- Ethical Dimensions in The Health Professions PDFDocument2 pagesEthical Dimensions in The Health Professions PDFJames0% (7)

- 2010 CC 3.6 Engine Schematic R36Document19 pages2010 CC 3.6 Engine Schematic R36Dungani AllanNo ratings yet

- HollowWorld - HWA1 - NightwailDocument71 pagesHollowWorld - HWA1 - NightwailPascal LeroyNo ratings yet

- UCL Chemical Engineering Module DescriptionsDocument65 pagesUCL Chemical Engineering Module DescriptionsChughtai Ammar100% (1)

- Aut - CG4017 - Part ADocument78 pagesAut - CG4017 - Part AzuopengxiangNo ratings yet

- MSC Handbook BiochemDocument74 pagesMSC Handbook Biochem393852019100% (1)

- Kurse DTUDocument9 pagesKurse DTUdavid0205No ratings yet

- Ac 2009-1438: A Novel Open-Ended Liquid-Liquid Extraction Module For The Chemical Engineering LaboratoryDocument25 pagesAc 2009-1438: A Novel Open-Ended Liquid-Liquid Extraction Module For The Chemical Engineering LaboratoryAnara AlamNo ratings yet

- L4 - Life Cycle Assessment-Week 5Document67 pagesL4 - Life Cycle Assessment-Week 5Sulaksha WimalasenaNo ratings yet

- Processes: Conceptual Design of An Operator Training Simulator For A Bio-Ethanol PlantDocument20 pagesProcesses: Conceptual Design of An Operator Training Simulator For A Bio-Ethanol PlantchemNo ratings yet

- Biochemical EmgineeringDocument15 pagesBiochemical EmgineeringzaryabnadeemNo ratings yet

- Analysis and Synthesis of BiprocessesDocument4 pagesAnalysis and Synthesis of BiprocessesNeils ArenósNo ratings yet

- Advances and Practices of Bioprocess Scale-Up: Advances in Biochemical Engineering/Biotechnology January 2015Document16 pagesAdvances and Practices of Bioprocess Scale-Up: Advances in Biochemical Engineering/Biotechnology January 2015Andréia AnschauNo ratings yet

- Bit3012 Bioprocess-Engineering-And-bioreactor-Design Eth 1.1 40 Bit3012Document2 pagesBit3012 Bioprocess-Engineering-And-bioreactor-Design Eth 1.1 40 Bit3012Rohit GuptaNo ratings yet

- Diseño Procesos, Enseñanza ApropiadaDocument4 pagesDiseño Procesos, Enseñanza ApropiadaVictor Esteban CondorNo ratings yet

- Life Cycle ManagementDocument9 pagesLife Cycle ManagementBagus YudhaNo ratings yet

- Subject 1. Introduction OCWDocument37 pagesSubject 1. Introduction OCWfgfNo ratings yet

- Che461-Week1 - Fall 2017 (16 Slides)Document16 pagesChe461-Week1 - Fall 2017 (16 Slides)Nouman AliNo ratings yet

- JRC116599 - Deliverable - b37 - Public - Version (ID 7366919)Document36 pagesJRC116599 - Deliverable - b37 - Public - Version (ID 7366919)Gabriel DiazNo ratings yet

- Bioreactors: Catalan (Cat) Francesc - Godia@uab - Cat Francesc Gòdia CasablancasDocument4 pagesBioreactors: Catalan (Cat) Francesc - Godia@uab - Cat Francesc Gòdia CasablancasNeils ArenósNo ratings yet

- Microbiological Laboratory TechniquesDocument41 pagesMicrobiological Laboratory TechniquesSivarami VangaNo ratings yet

- Invited Paper Multi-Unit Integration in Microfluidic Processes: Current Status and Future HorizonsDocument8 pagesInvited Paper Multi-Unit Integration in Microfluidic Processes: Current Status and Future HorizonsMada Sanjaya WsNo ratings yet

- Certified Renewable Energy Project DeveloperDocument7 pagesCertified Renewable Energy Project DeveloperosvaldoNo ratings yet

- Application of Scilab-Xcos For Process Control Applied To Educational Process ProjectsDocument12 pagesApplication of Scilab-Xcos For Process Control Applied To Educational Process ProjectsNicolás Pérez BarrigaNo ratings yet

- Biochemical Engineering OverviewDocument3 pagesBiochemical Engineering OverviewAaush Bhardwaj SinghNo ratings yet

- BT 0306Document3 pagesBT 0306ashuna249396No ratings yet

- Process Mining Applied To The Change Control Board Process Discovering Real Processes in Software Development Process Masterthesis PDFDocument94 pagesProcess Mining Applied To The Change Control Board Process Discovering Real Processes in Software Development Process Masterthesis PDFkam_anwNo ratings yet

- Life Cycle Assessment of Jute ProductsDocument47 pagesLife Cycle Assessment of Jute ProductsAnastasiya Disyak QuailNo ratings yet

- Man Chester Tics BrochureDocument6 pagesMan Chester Tics BrochurecondormuresNo ratings yet

- Bioreactor DesignDocument4 pagesBioreactor DesignMahendra Varma BoopathyNo ratings yet

- MEAE 235 - Fluid Mechanics & Hydraulic Machinery LabDocument63 pagesMEAE 235 - Fluid Mechanics & Hydraulic Machinery LabAnshikha NautiyalNo ratings yet

- Objectives and Results of The ProjectDocument1 pageObjectives and Results of The ProjectAndreeaNo ratings yet

- M TechDocument70 pagesM TechAjayMugundan ChandranNo ratings yet

- Bioreactor System With ArduinoDocument59 pagesBioreactor System With ArduinoingnavasNo ratings yet

- Anbumathi Capstone 2 - PROTOTYPEDocument34 pagesAnbumathi Capstone 2 - PROTOTYPESmall Stone Big MangoNo ratings yet

- 6103-Article Text-25925-1-10-20200119Document13 pages6103-Article Text-25925-1-10-20200119Dinarherlina 235No ratings yet

- TIP - 300 - Report - Final (1) (Automatisk Gjenopprettet)Document68 pagesTIP - 300 - Report - Final (1) (Automatisk Gjenopprettet)ravn.rydtun.winsvoldNo ratings yet

- ChE 210 Lecture 1 Introduction To Chemical Engineering CalculationsDocument18 pagesChE 210 Lecture 1 Introduction To Chemical Engineering CalculationsMay May MagluyanNo ratings yet

- New Survey Practice Lab ManualDocument72 pagesNew Survey Practice Lab ManualdheggekoppaNo ratings yet

- CoursedairyVII SemDocument81 pagesCoursedairyVII SemManu ChakkingalNo ratings yet

- Presentazione Corso ExamDocument6 pagesPresentazione Corso Examismail zanatyNo ratings yet

- 02whole - PDF Iternship ReportDocument60 pages02whole - PDF Iternship ReportWasyehun Tamrat100% (1)

- HDL Lab Manual 2022-23Document63 pagesHDL Lab Manual 2022-23meghana.ece.mittNo ratings yet

- Bioreactor Design and AnalysisDocument2 pagesBioreactor Design and AnalysisMarilyn GomesNo ratings yet

- Basic Bioprocesses EngineeringDocument4 pagesBasic Bioprocesses EngineeringNeils ArenósNo ratings yet

- Final Year Syllabus CopeDocument61 pagesFinal Year Syllabus CopeSachin ANo ratings yet

- Course DetailsDocument11 pagesCourse DetailsDasun NirmalaNo ratings yet

- opearating system manualDocument37 pagesopearating system manualGuruprasad PujariNo ratings yet

- Intelligent Energy Europe - Environmental Design in University Curricula and Architectural Training in EuropeDocument7 pagesIntelligent Energy Europe - Environmental Design in University Curricula and Architectural Training in EuropeElena EfodiNo ratings yet

- Course Title: Bioprocess Engineering: L T S SW/ FW P Total Credit UnitsDocument3 pagesCourse Title: Bioprocess Engineering: L T S SW/ FW P Total Credit UnitsDrishti MalhotraNo ratings yet

- CAM lAB MANUAL 2021 2022Document80 pagesCAM lAB MANUAL 2021 2022Bharath kumarNo ratings yet

- 21 Be 45Document3 pages21 Be 45Shaikh Mohd Arqam AltafNo ratings yet

- Sustainable Manufacturing: BITS PilaniDocument67 pagesSustainable Manufacturing: BITS PilaniPromodNo ratings yet

- TocDocument13 pagesTocSaurabh Vij100% (1)

- 1 ChemPlantDesign-Intro To Plant Design EconomicsDocument33 pages1 ChemPlantDesign-Intro To Plant Design Economicsfatiehah93No ratings yet

- Department of Chemical Engineering UTP Researcher Profile Name (Including Title) Contact InfoDocument3 pagesDepartment of Chemical Engineering UTP Researcher Profile Name (Including Title) Contact InfoEvan ChinNo ratings yet

- Final Design ReportDocument158 pagesFinal Design ReportahmedNo ratings yet

- Sólidos Tarea 1Document2 pagesSólidos Tarea 1Natalia RomeroNo ratings yet

- DC Final Report Local Energy GeneratorDocument88 pagesDC Final Report Local Energy Generatoramit25041699No ratings yet

- Dyeep: Tema: TemaDocument26 pagesDyeep: Tema: TemaAlevj DbNo ratings yet

- BE Biomedical Engg SEM 8Document21 pagesBE Biomedical Engg SEM 8Safwan Shaikh0% (2)

- Training Engineers for InnovationFrom EverandTraining Engineers for InnovationDenis LemaîtreNo ratings yet

- Management and Technologies of Water, Wastewater, Waste and Cir-cular Economy: WWW&CEFrom EverandManagement and Technologies of Water, Wastewater, Waste and Cir-cular Economy: WWW&CENo ratings yet

- Industrial & Environmental Biotechnology Course # KIBGE-707: Afsheen Aman, PH.DDocument18 pagesIndustrial & Environmental Biotechnology Course # KIBGE-707: Afsheen Aman, PH.DZiwaqarNo ratings yet

- Articulo MoleculasaDocument1 pageArticulo MoleculasaRuben MarquezNo ratings yet

- Art 4 1Document1 pageArt 4 1Ruben MarquezNo ratings yet

- Lecture 6 Amino Acid ProductionDocument19 pagesLecture 6 Amino Acid ProductionRuben MarquezNo ratings yet

- Art 4 3Document1 pageArt 4 3Ruben MarquezNo ratings yet

- Beer PresentationDocument27 pagesBeer PresentationRuben Marquez100% (1)

- Enzymatic Browning in Fruit2Document68 pagesEnzymatic Browning in Fruit2Ruben MarquezNo ratings yet

- Articulo Probioticos 1Document13 pagesArticulo Probioticos 1Ruben MarquezNo ratings yet

- Animal Cells BioreactorsDocument13 pagesAnimal Cells BioreactorsRuben MarquezNo ratings yet

- Problemas A Resolver TareaDocument8 pagesProblemas A Resolver TareaRuben Marquez0% (1)

- 160 PresentationDocument46 pages160 PresentationRuben MarquezNo ratings yet

- Bioprocesos Exámenes Actualizado Abril 2018 TareaDocument26 pagesBioprocesos Exámenes Actualizado Abril 2018 TareaRuben MarquezNo ratings yet

- EscritoHighlights REV AQRDocument1 pageEscritoHighlights REV AQRRuben MarquezNo ratings yet

- Contamination Free Air SupplyDocument14 pagesContamination Free Air SupplyRuben MarquezNo ratings yet

- Escrito Articulo Tablas y Figuras Articulo LISTO RUBENDocument10 pagesEscrito Articulo Tablas y Figuras Articulo LISTO RUBENRuben MarquezNo ratings yet

- Environmental Microbiology and BiotechnologyDocument20 pagesEnvironmental Microbiology and BiotechnologyRuben MarquezNo ratings yet

- Quizz de Cultivos ContinuosDocument12 pagesQuizz de Cultivos ContinuosRuben MarquezNo ratings yet

- Williams Bioreactors PDFDocument8 pagesWilliams Bioreactors PDFRuben MarquezNo ratings yet

- 2007 (De Villiers) Tom & LanguageDocument21 pages2007 (De Villiers) Tom & LanguageElizabeth MendozaNo ratings yet

- AV UWorld EOs (Rough Draft) - Data - Repeat LandscapeDocument139 pagesAV UWorld EOs (Rough Draft) - Data - Repeat LandscapeJonathan AiresNo ratings yet

- Investigating The Effect of Some Fabric Parameters On The Thermal Comfort Properties of Flat Knitted Acrylic Fabrics For Winter WearDocument11 pagesInvestigating The Effect of Some Fabric Parameters On The Thermal Comfort Properties of Flat Knitted Acrylic Fabrics For Winter WearSudipto BeheraNo ratings yet

- 2595 0118 BRJP 02 03 0255Document5 pages2595 0118 BRJP 02 03 0255tariNo ratings yet

- Poet, Lover, BirdwatcherDocument13 pagesPoet, Lover, BirdwatcherFhjjhhvNo ratings yet

- AIT Unit1 InternetDocument44 pagesAIT Unit1 InternetNaina_Dwivedi_6514No ratings yet

- Math BingoDocument6 pagesMath BingoKelly CollovaNo ratings yet

- Mycoplasma ContaminationDocument4 pagesMycoplasma ContaminationashueinNo ratings yet

- 1602lcd PDFDocument25 pages1602lcd PDFGHOST 22035No ratings yet

- Annual General Report On The Audit of Information Systems FY 2021-22Document69 pagesAnnual General Report On The Audit of Information Systems FY 2021-22ABINo ratings yet

- Guru 1 - 5 Whats NewDocument19 pagesGuru 1 - 5 Whats NewLuca RosacutaNo ratings yet

- 04-MiCOM C264 HMI - Rev GDocument34 pages04-MiCOM C264 HMI - Rev GSaddam Hossen BiplobNo ratings yet

- Data Analysis ProjectDocument18 pagesData Analysis ProjectDaylyn MosherNo ratings yet

- Amity: UniversityDocument10 pagesAmity: UniversityVinayak MangotraNo ratings yet

- ATO SubstitutionDocument1 pageATO SubstitutionMaggie VillacortaNo ratings yet

- Difficult Airway? Difficult Mask Ventilation?Document10 pagesDifficult Airway? Difficult Mask Ventilation?Parvathy R NairNo ratings yet

- Business Studies 2021 HSC Exam Pack NSW Education StandardsDocument3 pagesBusiness Studies 2021 HSC Exam Pack NSW Education Standardsmxstiia10No ratings yet

- CyclamenDocument9 pagesCyclamenLAUM1No ratings yet

- Workbook Lesson 1Document13 pagesWorkbook Lesson 1Giulia MennuniNo ratings yet

- Analysis of DrugsDocument53 pagesAnalysis of DrugsAnaliza Kitongan LantayanNo ratings yet

- 9Document4 pages9maithaNo ratings yet

- Femto SONDocument19 pagesFemto SONIlya KryuchkovNo ratings yet

- Mxs52 80bvmb SMDocument298 pagesMxs52 80bvmb SMJustoNo ratings yet

- O-Ring Material Offering Guide: ORD 5712 Effective September 2004Document84 pagesO-Ring Material Offering Guide: ORD 5712 Effective September 2004Samir FerreiraNo ratings yet

- EDA VHDL SimulationDocument19 pagesEDA VHDL SimulationYQ WNo ratings yet

- Eco-Friendly PlanDocument2 pagesEco-Friendly PlanPaulisky PicazosNo ratings yet

- Inclusive Education Program (IEP)Document2 pagesInclusive Education Program (IEP)floradawatNo ratings yet