Professional Documents

Culture Documents

Us 5237927

Us 5237927

Uploaded by

wewewewCopyright:

Available Formats

You might also like

- Instant Download Practice of Qualitative Research Engaging Students in The Research Process 3rd Edition Hesse Biber Test Bank PDF Full ChapterDocument32 pagesInstant Download Practice of Qualitative Research Engaging Students in The Research Process 3rd Edition Hesse Biber Test Bank PDF Full Chapterjanelevotraw1983100% (13)

- CCC-TRI-24 - Knight Errand (Part Three of The Storm Series)Document27 pagesCCC-TRI-24 - Knight Errand (Part Three of The Storm Series)grant walker100% (1)

- American Sign Language For Dummies (Sample) PDFDocument8 pagesAmerican Sign Language For Dummies (Sample) PDFLeo DaoNo ratings yet

- F1249 PDFDocument6 pagesF1249 PDFjai soni100% (1)

- J.C. Hutcheson - Judgment Intuitive - The Function of The Hunch in Judicial Decision (Cornell Law Review, 1929)Document16 pagesJ.C. Hutcheson - Judgment Intuitive - The Function of The Hunch in Judicial Decision (Cornell Law Review, 1929)ArnOmkarNo ratings yet

- Olin BWP Primer Patent - US3062146Document5 pagesOlin BWP Primer Patent - US3062146orpheus1972No ratings yet

- United States Patent (19) 11 4,226,186: Peck 45 (Oct. 7, 1980Document4 pagesUnited States Patent (19) 11 4,226,186: Peck 45 (Oct. 7, 1980KundanNo ratings yet

- Us 4715285Document2 pagesUs 4715285dgfsduuwioNo ratings yet

- Us 4058649Document6 pagesUs 4058649yigitilgazNo ratings yet

- Applying Label On Tubes Machine - US2007084556A1 - Description - 20240304 - 1240Document2 pagesApplying Label On Tubes Machine - US2007084556A1 - Description - 20240304 - 1240hana.hovorkovaNo ratings yet

- B32B 27/16 (2006.01) B65D 65/40 (2006.01) B32B 27/32 (2006.01)Document34 pagesB32B 27/16 (2006.01) B65D 65/40 (2006.01) B32B 27/32 (2006.01)Timi FadiranNo ratings yet

- Us5361479 PDFDocument5 pagesUs5361479 PDFmohammadreza91No ratings yet

- United States Patent (19) 11 Patent Number: 5,804,612Document4 pagesUnited States Patent (19) 11 Patent Number: 5,804,612Thuận LêNo ratings yet

- Unites States m1 3,791,297: Ate-T" 1191'Document4 pagesUnites States m1 3,791,297: Ate-T" 1191'rte678No ratings yet

- Us5080735 PDFDocument4 pagesUs5080735 PDFchecolonoskiNo ratings yet

- Us4014719 PDFDocument5 pagesUs4014719 PDFchecolonoskiNo ratings yet

- Patent 4Document4 pagesPatent 4PankajNo ratings yet

- Antifog 2Document19 pagesAntifog 2Javier BecerraNo ratings yet

- Gland Packings PumpDocument13 pagesGland Packings PumpJitu Jena100% (1)

- Us2932251 PDFDocument4 pagesUs2932251 PDFchecolonoskiNo ratings yet

- WM 100////// 44/1? .... .-A S 1: G. B. Young EtalDocument6 pagesWM 100////// 44/1? .... .-A S 1: G. B. Young EtalchecolonoskiNo ratings yet

- Us 5160773Document6 pagesUs 5160773Huan ZhangNo ratings yet

- U/ /////////I It //////////// ///.////: (12) United States Patent (10) Patent No.: US 6,607,011 B2Document4 pagesU/ /////////I It //////////// ///.////: (12) United States Patent (10) Patent No.: US 6,607,011 B2ererNo ratings yet

- Folding MachineDocument5 pagesFolding MachineShubhamNo ratings yet

- Us 3292539Document3 pagesUs 3292539dgfhjsdg hfsdhyjNo ratings yet

- United States Patent 1191: (54) Heat and Kinetic Absorption LiningDocument3 pagesUnited States Patent 1191: (54) Heat and Kinetic Absorption Liningdavid19775891No ratings yet

- United States Patent (10) Patent No.: US 8,251,371 B2Document4 pagesUnited States Patent (10) Patent No.: US 8,251,371 B2shamsNo ratings yet

- APV Evaporation HandbookDocument68 pagesAPV Evaporation HandbookМаксим ХилоNo ratings yet

- United States Patent Office: Patented Apr. 6, 1971Document3 pagesUnited States Patent Office: Patented Apr. 6, 1971Alexander Franco CastrillonNo ratings yet

- US20090266482A1Document7 pagesUS20090266482A1Alexander Franco CastrillonNo ratings yet

- LL L'L///"/"Z//: (12) United States PatentDocument4 pagesLL L'L///"/"Z//: (12) United States PatentwewewewNo ratings yet

- Us 3024303Document3 pagesUs 3024303Samar RashidNo ratings yet

- United States Patent (191 (111 4,379,197: Cipriani Et A1. (45) Apr. 5, 1983Document3 pagesUnited States Patent (191 (111 4,379,197: Cipriani Et A1. (45) Apr. 5, 1983Siswand BIn Mohd AliNo ratings yet

- Us7247372 PDFDocument12 pagesUs7247372 PDFrevider451No ratings yet

- United States Patent (19) : Keough (45) Date of Patent: Mar. 10, 1987Document11 pagesUnited States Patent (19) : Keough (45) Date of Patent: Mar. 10, 1987113314No ratings yet

- United States Patent (19) (11) Patent Number: 4,891,253: Mueller (45) Date of Patent: Jan. 2, 1990Document6 pagesUnited States Patent (19) (11) Patent Number: 4,891,253: Mueller (45) Date of Patent: Jan. 2, 1990Joe budarNo ratings yet

- EP1447347A1 - Lollipop Wrapper PatentDocument12 pagesEP1447347A1 - Lollipop Wrapper PatentIka WindaNo ratings yet

- Us 3823668Document4 pagesUs 3823668wewewewNo ratings yet

- Illlllllllllllillllllllllllllllllllllillllllllllllllllllll - L - L - L - L - LLDocument18 pagesIlllllllllllllillllllllllllllllllllllillllllllllllllllllll - L - L - L - L - LLSteric ZeytraNo ratings yet

- US4199486Document7 pagesUS4199486fadrolNo ratings yet

- United States Patent 119) ' (111 4,213,924: Shirley, Jr. (45) Jul. 22, 1980Document13 pagesUnited States Patent 119) ' (111 4,213,924: Shirley, Jr. (45) Jul. 22, 1980Javier Alejandro Rodriguez MelgozaNo ratings yet

- User'S Manual: Instructions For Using Petropoxy 154Document10 pagesUser'S Manual: Instructions For Using Petropoxy 154eddie_f22No ratings yet

- July 19, 1960: ObjectDocument3 pagesJuly 19, 1960: ObjectVansala GanesanNo ratings yet

- Us 5610365Document5 pagesUs 5610365dgfhjsdg hfsdhyjNo ratings yet

- United States Patent (19) : Symon Et Al. 45) Feb. 21, 1984Document5 pagesUnited States Patent (19) : Symon Et Al. 45) Feb. 21, 1984EceNo ratings yet

- Elastomer-Ptfe Compositions, Additives, and Manufacturing Methods - Us4962136Document16 pagesElastomer-Ptfe Compositions, Additives, and Manufacturing Methods - Us4962136Franco GentiliNo ratings yet

- Us6391935 PDFDocument10 pagesUs6391935 PDFBilen SeleshiNo ratings yet

- PatentDocument4 pagesPatentbcshendeNo ratings yet

- United States Patent (191 (11) Patent Number: 5 363 542: Sorem Et A1. (45) Date of Patent: Nov. 15, 1994Document6 pagesUnited States Patent (191 (11) Patent Number: 5 363 542: Sorem Et A1. (45) Date of Patent: Nov. 15, 1994mohammadreza91No ratings yet

- United States Patent (19) : (45) Date of Patent: " Apr. 4, 1989Document10 pagesUnited States Patent (19) : (45) Date of Patent: " Apr. 4, 1989Niki Wijaya SariNo ratings yet

- US3960807Document5 pagesUS3960807Sayyed Abdul QayyumNo ratings yet

- Us 4925562Document7 pagesUs 4925562César Fernando Melquiades BravoNo ratings yet

- US460Document5 pagesUS460bbNo ratings yet

- Aashto T 84Document10 pagesAashto T 84alicarlos1350% (2)

- United States Patent (19) : Tokiwa Et Al. (54) Starch-Containing BiodegradableDocument6 pagesUnited States Patent (19) : Tokiwa Et Al. (54) Starch-Containing BiodegradableGabii Van CauwenbergheNo ratings yet

- Patents: Device For Introducing A Seal Ring Into A Rotatable MountingDocument1 pagePatents: Device For Introducing A Seal Ring Into A Rotatable MountingAlejandro MorenoNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument4 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentAPEX SONNo ratings yet

- US4229241Document11 pagesUS4229241mohd iqbalNo ratings yet

- U.S. Patent 4,293,314: Gelled Fuel-Air Explosive October 6, 1981.From EverandU.S. Patent 4,293,314: Gelled Fuel-Air Explosive October 6, 1981.No ratings yet

- Atmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionFrom EverandAtmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionNo ratings yet

- Advances in Air Conditioning Technologies: Improving Energy EfficiencyFrom EverandAdvances in Air Conditioning Technologies: Improving Energy EfficiencyNo ratings yet

- Us 8809689Document7 pagesUs 8809689wewewewNo ratings yet

- Us 5149907Document7 pagesUs 5149907wewewewNo ratings yet

- United States Patent (191: WinerDocument5 pagesUnited States Patent (191: WinerwewewewNo ratings yet

- United States Patent (191: Ahlstriim Et A1. (11) Patent Number: (45) Date of PatentDocument5 pagesUnited States Patent (191: Ahlstriim Et A1. (11) Patent Number: (45) Date of PatentwewewewNo ratings yet

- Us 3690255Document5 pagesUs 3690255wewewewNo ratings yet

- Us 5775636Document6 pagesUs 5775636wewewewNo ratings yet

- United States Patent: Ronn Et Al. (10) Patent N0.: (45) Date of PatentDocument7 pagesUnited States Patent: Ronn Et Al. (10) Patent N0.: (45) Date of PatentwewewewNo ratings yet

- United States Patent (191: Hau (11) Patent Number: (45) Date of PatentDocument7 pagesUnited States Patent (191: Hau (11) Patent Number: (45) Date of PatentwewewewNo ratings yet

- United States Patent: Berej Noi Et AlDocument6 pagesUnited States Patent: Berej Noi Et AlwewewewNo ratings yet

- LL L'L///"/"Z//: (12) United States PatentDocument4 pagesLL L'L///"/"Z//: (12) United States PatentwewewewNo ratings yet

- (A Oe Émgoueogmo: +2 (ll/l4fl2Document6 pages(A Oe Émgoueogmo: +2 (ll/l4fl2wewewewNo ratings yet

- Us 3823668Document4 pagesUs 3823668wewewewNo ratings yet

- Sept. 13, 1966: J. Marsh EtalDocument4 pagesSept. 13, 1966: J. Marsh EtalwewewewNo ratings yet

- United States Patent (191Document7 pagesUnited States Patent (191wewewewNo ratings yet

- Ester: United States PatentDocument5 pagesEster: United States PatentwewewewNo ratings yet

- Us 20010047736Document6 pagesUs 20010047736wewewewNo ratings yet

- United States Patent (10) Patent N0.: US 7,540,240 B2Document4 pagesUnited States Patent (10) Patent N0.: US 7,540,240 B2wewewewNo ratings yet

- Us 5299499Document5 pagesUs 5299499wewewewNo ratings yet

- United States Patent: CarverDocument4 pagesUnited States Patent: CarverwewewewNo ratings yet

- Beginner's Guide To IOS 11 App Development Using Swift 4Document215 pagesBeginner's Guide To IOS 11 App Development Using Swift 4Franklin morelNo ratings yet

- Self-Laminating Labels For Laser Ink Jet Printers: Product BulletinDocument2 pagesSelf-Laminating Labels For Laser Ink Jet Printers: Product BulletinKATHERINENo ratings yet

- C 113Document3 pagesC 113Mahmoud Taha100% (1)

- Blacklidge Emulsions v. Russell StandardDocument9 pagesBlacklidge Emulsions v. Russell StandardPriorSmartNo ratings yet

- NEMA-WC27500 - Standard For Aerospace and Industrial Electrical CableDocument7 pagesNEMA-WC27500 - Standard For Aerospace and Industrial Electrical Cabledaymon100% (1)

- The Modern Asphalt Pavement 1904 PDFDocument617 pagesThe Modern Asphalt Pavement 1904 PDFV Venkata NarayanaNo ratings yet

- Rolling (Metalworking) : From Wikipedia, The Free EncyclopediaDocument12 pagesRolling (Metalworking) : From Wikipedia, The Free Encyclopediarhajtv100% (1)

- Exadata X10M OEDA DifferencesDocument10 pagesExadata X10M OEDA DifferencesjonseverloveNo ratings yet

- CM 3 WholesalingDocument11 pagesCM 3 WholesalingSubratKumarNo ratings yet

- Textbook Contract Law Uk Edition Emily Finch Ebook All Chapter PDFDocument53 pagesTextbook Contract Law Uk Edition Emily Finch Ebook All Chapter PDFjim.shepherd977100% (16)

- Test Bank For Principles of Behavior 7th Edition Richard W MalottDocument19 pagesTest Bank For Principles of Behavior 7th Edition Richard W Malottloudly.nereisnai6100% (42)

- 305855no Bake HADocument9 pages305855no Bake HAAshok KhannaNo ratings yet

- Markevitch, Dimitry - The Cello As An Accompanying Instrument in The 18th CenturyDocument4 pagesMarkevitch, Dimitry - The Cello As An Accompanying Instrument in The 18th CenturyMirko100% (1)

- Asme E213Document4 pagesAsme E213Bryan Jimenes DorantesNo ratings yet

- M 144-07 Calcium Chloride PDFDocument4 pagesM 144-07 Calcium Chloride PDFWalticoZegarraHerreraNo ratings yet

- Ms Bikanervala v. Ms Aggarwal BikanerwalaDocument2 pagesMs Bikanervala v. Ms Aggarwal BikanerwalaPrashant KumawatNo ratings yet

- KTI v. AppleDocument13 pagesKTI v. AppleMikey CampbellNo ratings yet

- Sites of KintallaDocument8 pagesSites of KintallaEpiphanyJoeNo ratings yet

- Prizeman - Ave Maria - Voz-PianoDocument4 pagesPrizeman - Ave Maria - Voz-PianoRoneque100% (2)

- ks2 Mathematics 2014 Mental Maths TranscriptDocument6 pagesks2 Mathematics 2014 Mental Maths TranscriptMona AlyNo ratings yet

- Sight Word Card Game Dobble Spot Ittypegame Set 1Document9 pagesSight Word Card Game Dobble Spot Ittypegame Set 1Cem OngderNo ratings yet

- E1710 11Document7 pagesE1710 11mithileshNo ratings yet

- Lecture 3 - Intelectual Property RightsDocument16 pagesLecture 3 - Intelectual Property RightsMarvin BucsitNo ratings yet

- WIPO Academy Advanced Distance Learning Course On Basics of Patent Drafting (DL320E15S1)Document7 pagesWIPO Academy Advanced Distance Learning Course On Basics of Patent Drafting (DL320E15S1)cresjohnNo ratings yet

- Financial Accounting Canadian Canadian 5th Edition Libby Solutions ManualDocument24 pagesFinancial Accounting Canadian Canadian 5th Edition Libby Solutions ManualDannyJohnsonobtk100% (65)

Us 5237927

Us 5237927

Uploaded by

wewewewCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us 5237927

Us 5237927

Uploaded by

wewewewCopyright:

Available Formats

- US005237927A

Umted States Patent [191

[11] Patent Number:

Gonzalez et al.

[45]

[54]

ENERGETIC CONSUMABLE CARTRIDGE

3,770,563 11/1973 0061115106111. . ................. .. 102/431

CASE

3,877,374

4/1975

3,927,616

12/1975

Axelrod et a1.

3,987,731

10/719746

Brzuskiewicz . . . . . . .

[75]

Inventors:

AlltOlliO F. Gonzalez; wllll?m L-

OMeara, 130th Of Tallahassee, F18.

.

[731

Ass18nee=

'

01" Cm'Wmm cheshlre 00m

Cook ......................... .. 102/431

. . . . ..

. . . . . ..

4,363,273 12/ 1982 -Luebben et al. .

..... .. 102/431

..... .. 102/431

12/1982

Lippler et a1.

..... .. 102/289

5/1987 Brasquies et a1.

102/431

4,709,636 12/1987 Mueller =1 a1. ......... ,.

[22]

1 d:

F e

[51]

1111.015 ............................................ ..

0 1. 21 1991

c

[52]

us. c1. .................................. .. 102/431; 102/465;

F423 5/192

102/700

~

References Cite

US PATENT DOCUMENTS

102/431

FOREIGN PATENT DOCUMENTS

of Search ............. ..102/331, 464; 149/97,700,

98

102/431

. . . . . .. 102/431

4,365,558

4,649,827

mm N 779661

[56]

Date of Patent: ' Aug. 24, 1993

4,581,998 4/1986 110m, Jr. e111.

[21]

5,237,927

27590013

5/1987 Fm ------------------------------ -- 102/43

Pn'mayy Examiner-Harold J. Tudor

Attorney, Agent, of

[57]

R.

_

ABSIRACI

An energetic combustible cartridge case comprises a

tubular body of a plastic nonfelted sheet propellant and

895,558

3,397,637

8/1901 Harris ................................ .. 102/431

8/ 1968 Bobinski et al. .

102/431

an outer coating portion of a thermoset polymeric resin

such as a polyurethane. The sheet propellant is a colloi

3,670,223

glartLein et al. ................... .. 102/431

da] nitrocellulosc composition which preferably com

3,703,

raa

3,706,280 12/1972 Bobinski et a1. .................. .. 102/431

timcsofgiagigtfafeomon of nmoglyceme and methylene

3,727,512

4/1973

g Y

3,730,094

5/1973 Quinian

Berger ........ ..

3,769,873 11/1973 Abel .......................... .. 102/431

4 Claims, 1 Dl?Wlllg Sheet

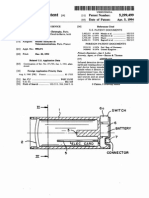

US. Patent

5,237,927

Aug. 24, 1993

B

._

_

...

1

.

\.

/_ H

:

_

_

_r

W

..

5,237,927

a resin binder is coated ?rst with polyvinyl alcohol resin

and then with a copolymer of vinylidine chloride and

ENERCETIC CONSUMABLE CARTRIDGE CASE

acrylonitrile. The resultant case is said to be resistant to

FIELD OF THE INVENTION

moisture and oil.

Another example of a protective coating for a case

This invention relates generally to cartridges and 5

less propelling charge or combustible casings is dis

more particularly to combustible cartridge cases

closed in U.S. Pat. No. 4,363,273 to Luebben et al. This

adapted to contain a propellant charge and support a

patent discloses a two step composite coating for a

projectile.

porous NC case permeated with a polyurethane which

BACKGROUND OF THE INVENTION

has a ?rst undercoating containing metal particles

Combustible containers for propellant compositions

bonded to the case and an outer coating of a polyure

thane resin. This composite coating allegedly makes the

cartridge resistant to ignition when exposed to contact

in commercial use at the present time typically are fabri

cated by a felting process utilizing paper or cardboard

materials. An illustrative container material is Kraft

paper employing 13.4 percent nitrogen containing nitro

15

cellulose, and the paper can be coated, impregnated or

dipped to incorporate various optional additives as de

sired.

with hot surfaces, a very desirable feature. The outer

coating provides the moisture seal.

Other patents describing coatings or moisture resis

tant combustible cases include U.S. Pat. Nos. 3,397,637;

3,670,649; 3,703,868; 3,706,280; 3,727,512; 3,769,873;

Among the disadvantages of the prior art combusti

3,770,563; 3,877,374; 4,649,827; and 4,709,636.

_

ble containers is the tendency to leave a burn residue in 20

A new casing for molding directly to a solid molded

the combustion chamber of the gun, and the tendency

or compacted propelling charge is disclosed in copend

to absorb moisture during long term storage. Accord

ing U.S. patent application Ser. No. 07/576,576, ?led

ingly, new containers which are clean burning during

Aug. 31, 1990, now U.S. Pat. No. 5,069,133, and as

use and are moisture resistant are highly desired by the

ammunition manufacturing community.

25

Conventional combustible cases are constructed by a

tirety by reference. This copending application dis

felting process or spiral wrapping nitrocellulose im

closes an encased propellant such as Ball Powder

pregnated Kraft paper on a mandrel and then soaking

the case so formed in a solution such as a polyurethane

and solvent. The polyurethane and solvent is distributed

through the tubular body of the case. This soak yields a

concentration gradient of polyurethane across the wall

thickness of the tubular case. Conversely, the polyure

thane resin may be premixed with the felting nitrocellu

lose and kraft ?bers, eliminating the polyurethane soak

signed to the Assignee of the present invention. This

copending application is incorporated herein in its en- -

30

propellant made by Olin Corporation. The solid self

supporting propellant charge is encased in an overwrap

ping of an elastomeric coating composition free of any

cellulosic compound, and preferably comprises a poly

urethane. As such, the coating is very thin and is thus

completely incinerated during the ballistic cycle. Thus

an energetic constituant in the coating is not needed.

In situations where a loose propellant charge, such as

Ball Powder @ propellant or stick propellant is used, a

ing step. In addition, the voids left during the drying

process prevents a perfect moisture seal. Thus the con

ventional case so constructed is not completely mois

separate container made of nitrocellulose impregnated

Kraft paper is generally used. These containers may be

In addition, the conventional case contributes mini 40 advantageously overwrapped as described in the above

patentsor as in the above mentioned copending applica

mal energy into the propulsion system. The propellant

tion to provide a moisture proof casing. However, use

charge carried within the case in conventional combus

of such a casing does not signi?cantly contribute to the

tible cartridge cases must have sufficient energy to gen

combustion process within the gun chamber. These

erate the bulk of the propelling gases as well as inciner

ate the casing in order to leave no residue within the 45 cases typically produce about 5% of the total propellant

tureproof.

gun chamber.

systemenergy.

Separately applied coatings help to provide a mois

ture seal. However, to provide this seal, the coating

provides adequate protection from the environment, is

must be nonporous, which tends to inhibit complete

combustion of the case. Accordingly, an energetic ma

the same time contributes substantial energy to the com

Therefore there is still a need for a casing which

totally consumed during the combustion process and at

bustion process.

terial can be incorporated into this coating.

One energetic protective coating for a caseless pro

pellant charge is disclosed in U.S. Pat. No. 3,730,094. In

SUMMARY OF THE INVENTION

The present invention solves the needs mentioned

this case a liquid mixture is applied to the exterior of the

caseless molded charge. The liquid mixture is an explo 55 above by providing a structurally self supportive casing

sive such as HMX or RDX and cellulose acetate in

made entirely of a plastic, nonfelted sheet propellant

acetone. The mixture is applied to the exterior of the

molded propelling charge and then the acetone evapo

rated. Cellulose acetate is added to improve the high

temperature characteristics of the mixture.

Another example of a combustible case coating is

found in U.S. Pat. No. 3,927,616. This patent discloses

an oil and water resistant coating of RDX dispersed in

a polymeric resin such as an alkyl methacrylate poly

mer.

Another protective coating for a combustible case is

disclosed in U.S. Pat. No. 3,987,731. In this patent, the

case, made of nitrocellulose (NC), reinforcing ?bers and

providing about twice the energy as conventional com

bustible cases.

This propellant material is a colloidal nitrocellulose

composition containing no cellulosic ?bers. It may con

tain a large portion of energetic material such as nitro

glycerine (NG) and diethylene glycol dinitrate

(DEGDN). This propellant material is formed as a

sheet and then rolled into a tube to form the casing. This

65

casing is then overwrapped with an elastomeric coating

composition as described in the copending application

mentioned above. The resultant casing for a propellant

charge is energetic, i.e. it provides at least 10% of the

5,237,927

total energy in the propellant system and is totally con

sumed during propellant burn and is totally impervious

For a 120 mm gun, the total thickness of the completed

case is preferably about 0.125 inches.

to moisture. In addition, the casing in accordance with

the invention is abrasion resistant and reduces the total

an oxygen balanced polyurethane resin to a thickness of

propellant charge required for a given ballistic result

5 preferably between about 0.01-0.06 inches to form the

because the casing itself is constructed of a propellant

material.

These and other aspects of the invention will become

outer coating portion 14. This outer portion provides a

homogeneous layer that is impervious to moisture and

The inner portion 12 is then preferably coated with

forms an abrasion resistant shell which protects the

apparent upon reading the following detailed descrip

inner propellant portion during storage and handling

tion when taken in conjunction with the accompanying

without having a deleterious effect on the combustion

drawing.

of the propellant of the inner portion. This coating

portion 14 can be applied as a spray or may be injection

BRIEF DESCRIPTION OF THE DRAWING

molded onto the inner portion 12.

It is to be understood that the above described em

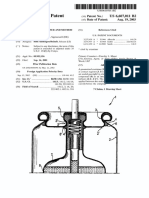

FIG. 1 as a longitudinal partial sectional view of a

combustible casing in accordance with the invention. 15 bodiments of the invention are illustrative only. Modi?

cations throughout may occur to those skilled in the art.

FIG. 2 is a longitudinal sectional view of an altema

Accordingly, it is intended that the invention is not to

tive embodiment of the combustible case in accordance

be limited to the embodiments disclosed herein but is

with the invention.

DETAILED DESCRIPTION OF THE

20

INVENTION

The combustible case in accordance with the present

invention comprises a tubular body 10 having an inner

de?ned by the scope and fair meaning of the appended

claims. All patents, patent applications and other docu

ments speci?cally referred to above are incorporated

herein by reference in their entirety.

What is claimed is:

1. An energetic combustible cartridge case compris

propellant portion 12 and an outer coating portion 14.

25 mg:

The inner propellant portion 12 is formed of a strip of

a hollow body for containing a propellant charge

sheet propellant such as JA2 which is wrapped in a

therein, said body having an inner portion of a

spiral or helical fashion about a forming mandrel. The

plastic, energetic, cellulosic ?ber free, colloidal

outer coating portion 14 is preferably a polyurethane

nitrocellulose

composition sheet propellant mate

coating made and applied as described in copending 30

rial containing nitroglycerine and diethylene gly

US. patent application Ser. No. 07/576,576.

col dinitrate and an outer coating portion adhered

The sheet propellant may be any propellant which

to the exterior of said inner portion, said coating

can be formed into a sheet material. Preferably, JA2 is

portion comprising thermoset resin material.

used. JA2 is about 60-65% nitrocellulose, l520% ni

2. The case according to claim 1 wherein said coating

troglycerine, and 15-20% diethylene glycol dinitrate 35 portion is free of any cellulosic compound.

(DEGDN). The JA2 sheet is preheated to between

about 4050 C. and then spiral wound around a cylin

3. The case according to claim 2 wherein said coating

comprises a polyurethane resin.

4. An energetic combustible cartridge case compris

drical mandrel. The inner propellant portion 12 is then

cooled to room temperature and removed from the

mandrel.

mg:

a tubular body for containing a propellant charge

A single wrap, as shown in FIG. 1, of preferably

is shown in FIG. 2, wound in opposite directions. In the

therein, said body having an inner portion having

at least two overlapping spiral wrapped layers of

an energetic plastic cellulosic ?ber free, colloidal

nitrocellulose composition sheet propellant con

latter case, each wrap 12:: and 1212 will be about 0.05

taining nitroglycerine and diethylene glycol dini

about 0.10 inch thickness can be used for a 120 mm case.

Alternatively, double wraps 12a and 12b can be used, as

inch thick. Winding the wraps in opposite directions

trate and an outer coating portion adhered to the

ensures that any gaps in the butt joined sides of the wrap

are covered. The total thickness of inner portion 12 can

range from 0.01 to 0.1 of the bore diameter of the gun.

exterior of said inner portion comprising an elasto

meric thermoset resin material.

#

50

55

65

You might also like

- Instant Download Practice of Qualitative Research Engaging Students in The Research Process 3rd Edition Hesse Biber Test Bank PDF Full ChapterDocument32 pagesInstant Download Practice of Qualitative Research Engaging Students in The Research Process 3rd Edition Hesse Biber Test Bank PDF Full Chapterjanelevotraw1983100% (13)

- CCC-TRI-24 - Knight Errand (Part Three of The Storm Series)Document27 pagesCCC-TRI-24 - Knight Errand (Part Three of The Storm Series)grant walker100% (1)

- American Sign Language For Dummies (Sample) PDFDocument8 pagesAmerican Sign Language For Dummies (Sample) PDFLeo DaoNo ratings yet

- F1249 PDFDocument6 pagesF1249 PDFjai soni100% (1)

- J.C. Hutcheson - Judgment Intuitive - The Function of The Hunch in Judicial Decision (Cornell Law Review, 1929)Document16 pagesJ.C. Hutcheson - Judgment Intuitive - The Function of The Hunch in Judicial Decision (Cornell Law Review, 1929)ArnOmkarNo ratings yet

- Olin BWP Primer Patent - US3062146Document5 pagesOlin BWP Primer Patent - US3062146orpheus1972No ratings yet

- United States Patent (19) 11 4,226,186: Peck 45 (Oct. 7, 1980Document4 pagesUnited States Patent (19) 11 4,226,186: Peck 45 (Oct. 7, 1980KundanNo ratings yet

- Us 4715285Document2 pagesUs 4715285dgfsduuwioNo ratings yet

- Us 4058649Document6 pagesUs 4058649yigitilgazNo ratings yet

- Applying Label On Tubes Machine - US2007084556A1 - Description - 20240304 - 1240Document2 pagesApplying Label On Tubes Machine - US2007084556A1 - Description - 20240304 - 1240hana.hovorkovaNo ratings yet

- B32B 27/16 (2006.01) B65D 65/40 (2006.01) B32B 27/32 (2006.01)Document34 pagesB32B 27/16 (2006.01) B65D 65/40 (2006.01) B32B 27/32 (2006.01)Timi FadiranNo ratings yet

- Us5361479 PDFDocument5 pagesUs5361479 PDFmohammadreza91No ratings yet

- United States Patent (19) 11 Patent Number: 5,804,612Document4 pagesUnited States Patent (19) 11 Patent Number: 5,804,612Thuận LêNo ratings yet

- Unites States m1 3,791,297: Ate-T" 1191'Document4 pagesUnites States m1 3,791,297: Ate-T" 1191'rte678No ratings yet

- Us5080735 PDFDocument4 pagesUs5080735 PDFchecolonoskiNo ratings yet

- Us4014719 PDFDocument5 pagesUs4014719 PDFchecolonoskiNo ratings yet

- Patent 4Document4 pagesPatent 4PankajNo ratings yet

- Antifog 2Document19 pagesAntifog 2Javier BecerraNo ratings yet

- Gland Packings PumpDocument13 pagesGland Packings PumpJitu Jena100% (1)

- Us2932251 PDFDocument4 pagesUs2932251 PDFchecolonoskiNo ratings yet

- WM 100////// 44/1? .... .-A S 1: G. B. Young EtalDocument6 pagesWM 100////// 44/1? .... .-A S 1: G. B. Young EtalchecolonoskiNo ratings yet

- Us 5160773Document6 pagesUs 5160773Huan ZhangNo ratings yet

- U/ /////////I It //////////// ///.////: (12) United States Patent (10) Patent No.: US 6,607,011 B2Document4 pagesU/ /////////I It //////////// ///.////: (12) United States Patent (10) Patent No.: US 6,607,011 B2ererNo ratings yet

- Folding MachineDocument5 pagesFolding MachineShubhamNo ratings yet

- Us 3292539Document3 pagesUs 3292539dgfhjsdg hfsdhyjNo ratings yet

- United States Patent 1191: (54) Heat and Kinetic Absorption LiningDocument3 pagesUnited States Patent 1191: (54) Heat and Kinetic Absorption Liningdavid19775891No ratings yet

- United States Patent (10) Patent No.: US 8,251,371 B2Document4 pagesUnited States Patent (10) Patent No.: US 8,251,371 B2shamsNo ratings yet

- APV Evaporation HandbookDocument68 pagesAPV Evaporation HandbookМаксим ХилоNo ratings yet

- United States Patent Office: Patented Apr. 6, 1971Document3 pagesUnited States Patent Office: Patented Apr. 6, 1971Alexander Franco CastrillonNo ratings yet

- US20090266482A1Document7 pagesUS20090266482A1Alexander Franco CastrillonNo ratings yet

- LL L'L///"/"Z//: (12) United States PatentDocument4 pagesLL L'L///"/"Z//: (12) United States PatentwewewewNo ratings yet

- Us 3024303Document3 pagesUs 3024303Samar RashidNo ratings yet

- United States Patent (191 (111 4,379,197: Cipriani Et A1. (45) Apr. 5, 1983Document3 pagesUnited States Patent (191 (111 4,379,197: Cipriani Et A1. (45) Apr. 5, 1983Siswand BIn Mohd AliNo ratings yet

- Us7247372 PDFDocument12 pagesUs7247372 PDFrevider451No ratings yet

- United States Patent (19) : Keough (45) Date of Patent: Mar. 10, 1987Document11 pagesUnited States Patent (19) : Keough (45) Date of Patent: Mar. 10, 1987113314No ratings yet

- United States Patent (19) (11) Patent Number: 4,891,253: Mueller (45) Date of Patent: Jan. 2, 1990Document6 pagesUnited States Patent (19) (11) Patent Number: 4,891,253: Mueller (45) Date of Patent: Jan. 2, 1990Joe budarNo ratings yet

- EP1447347A1 - Lollipop Wrapper PatentDocument12 pagesEP1447347A1 - Lollipop Wrapper PatentIka WindaNo ratings yet

- Us 3823668Document4 pagesUs 3823668wewewewNo ratings yet

- Illlllllllllllillllllllllllllllllllllillllllllllllllllllll - L - L - L - L - LLDocument18 pagesIlllllllllllllillllllllllllllllllllllillllllllllllllllllll - L - L - L - L - LLSteric ZeytraNo ratings yet

- US4199486Document7 pagesUS4199486fadrolNo ratings yet

- United States Patent 119) ' (111 4,213,924: Shirley, Jr. (45) Jul. 22, 1980Document13 pagesUnited States Patent 119) ' (111 4,213,924: Shirley, Jr. (45) Jul. 22, 1980Javier Alejandro Rodriguez MelgozaNo ratings yet

- User'S Manual: Instructions For Using Petropoxy 154Document10 pagesUser'S Manual: Instructions For Using Petropoxy 154eddie_f22No ratings yet

- July 19, 1960: ObjectDocument3 pagesJuly 19, 1960: ObjectVansala GanesanNo ratings yet

- Us 5610365Document5 pagesUs 5610365dgfhjsdg hfsdhyjNo ratings yet

- United States Patent (19) : Symon Et Al. 45) Feb. 21, 1984Document5 pagesUnited States Patent (19) : Symon Et Al. 45) Feb. 21, 1984EceNo ratings yet

- Elastomer-Ptfe Compositions, Additives, and Manufacturing Methods - Us4962136Document16 pagesElastomer-Ptfe Compositions, Additives, and Manufacturing Methods - Us4962136Franco GentiliNo ratings yet

- Us6391935 PDFDocument10 pagesUs6391935 PDFBilen SeleshiNo ratings yet

- PatentDocument4 pagesPatentbcshendeNo ratings yet

- United States Patent (191 (11) Patent Number: 5 363 542: Sorem Et A1. (45) Date of Patent: Nov. 15, 1994Document6 pagesUnited States Patent (191 (11) Patent Number: 5 363 542: Sorem Et A1. (45) Date of Patent: Nov. 15, 1994mohammadreza91No ratings yet

- United States Patent (19) : (45) Date of Patent: " Apr. 4, 1989Document10 pagesUnited States Patent (19) : (45) Date of Patent: " Apr. 4, 1989Niki Wijaya SariNo ratings yet

- US3960807Document5 pagesUS3960807Sayyed Abdul QayyumNo ratings yet

- Us 4925562Document7 pagesUs 4925562César Fernando Melquiades BravoNo ratings yet

- US460Document5 pagesUS460bbNo ratings yet

- Aashto T 84Document10 pagesAashto T 84alicarlos1350% (2)

- United States Patent (19) : Tokiwa Et Al. (54) Starch-Containing BiodegradableDocument6 pagesUnited States Patent (19) : Tokiwa Et Al. (54) Starch-Containing BiodegradableGabii Van CauwenbergheNo ratings yet

- Patents: Device For Introducing A Seal Ring Into A Rotatable MountingDocument1 pagePatents: Device For Introducing A Seal Ring Into A Rotatable MountingAlejandro MorenoNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument4 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentAPEX SONNo ratings yet

- US4229241Document11 pagesUS4229241mohd iqbalNo ratings yet

- U.S. Patent 4,293,314: Gelled Fuel-Air Explosive October 6, 1981.From EverandU.S. Patent 4,293,314: Gelled Fuel-Air Explosive October 6, 1981.No ratings yet

- Atmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionFrom EverandAtmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionNo ratings yet

- Advances in Air Conditioning Technologies: Improving Energy EfficiencyFrom EverandAdvances in Air Conditioning Technologies: Improving Energy EfficiencyNo ratings yet

- Us 8809689Document7 pagesUs 8809689wewewewNo ratings yet

- Us 5149907Document7 pagesUs 5149907wewewewNo ratings yet

- United States Patent (191: WinerDocument5 pagesUnited States Patent (191: WinerwewewewNo ratings yet

- United States Patent (191: Ahlstriim Et A1. (11) Patent Number: (45) Date of PatentDocument5 pagesUnited States Patent (191: Ahlstriim Et A1. (11) Patent Number: (45) Date of PatentwewewewNo ratings yet

- Us 3690255Document5 pagesUs 3690255wewewewNo ratings yet

- Us 5775636Document6 pagesUs 5775636wewewewNo ratings yet

- United States Patent: Ronn Et Al. (10) Patent N0.: (45) Date of PatentDocument7 pagesUnited States Patent: Ronn Et Al. (10) Patent N0.: (45) Date of PatentwewewewNo ratings yet

- United States Patent (191: Hau (11) Patent Number: (45) Date of PatentDocument7 pagesUnited States Patent (191: Hau (11) Patent Number: (45) Date of PatentwewewewNo ratings yet

- United States Patent: Berej Noi Et AlDocument6 pagesUnited States Patent: Berej Noi Et AlwewewewNo ratings yet

- LL L'L///"/"Z//: (12) United States PatentDocument4 pagesLL L'L///"/"Z//: (12) United States PatentwewewewNo ratings yet

- (A Oe Émgoueogmo: +2 (ll/l4fl2Document6 pages(A Oe Émgoueogmo: +2 (ll/l4fl2wewewewNo ratings yet

- Us 3823668Document4 pagesUs 3823668wewewewNo ratings yet

- Sept. 13, 1966: J. Marsh EtalDocument4 pagesSept. 13, 1966: J. Marsh EtalwewewewNo ratings yet

- United States Patent (191Document7 pagesUnited States Patent (191wewewewNo ratings yet

- Ester: United States PatentDocument5 pagesEster: United States PatentwewewewNo ratings yet

- Us 20010047736Document6 pagesUs 20010047736wewewewNo ratings yet

- United States Patent (10) Patent N0.: US 7,540,240 B2Document4 pagesUnited States Patent (10) Patent N0.: US 7,540,240 B2wewewewNo ratings yet

- Us 5299499Document5 pagesUs 5299499wewewewNo ratings yet

- United States Patent: CarverDocument4 pagesUnited States Patent: CarverwewewewNo ratings yet

- Beginner's Guide To IOS 11 App Development Using Swift 4Document215 pagesBeginner's Guide To IOS 11 App Development Using Swift 4Franklin morelNo ratings yet

- Self-Laminating Labels For Laser Ink Jet Printers: Product BulletinDocument2 pagesSelf-Laminating Labels For Laser Ink Jet Printers: Product BulletinKATHERINENo ratings yet

- C 113Document3 pagesC 113Mahmoud Taha100% (1)

- Blacklidge Emulsions v. Russell StandardDocument9 pagesBlacklidge Emulsions v. Russell StandardPriorSmartNo ratings yet

- NEMA-WC27500 - Standard For Aerospace and Industrial Electrical CableDocument7 pagesNEMA-WC27500 - Standard For Aerospace and Industrial Electrical Cabledaymon100% (1)

- The Modern Asphalt Pavement 1904 PDFDocument617 pagesThe Modern Asphalt Pavement 1904 PDFV Venkata NarayanaNo ratings yet

- Rolling (Metalworking) : From Wikipedia, The Free EncyclopediaDocument12 pagesRolling (Metalworking) : From Wikipedia, The Free Encyclopediarhajtv100% (1)

- Exadata X10M OEDA DifferencesDocument10 pagesExadata X10M OEDA DifferencesjonseverloveNo ratings yet

- CM 3 WholesalingDocument11 pagesCM 3 WholesalingSubratKumarNo ratings yet

- Textbook Contract Law Uk Edition Emily Finch Ebook All Chapter PDFDocument53 pagesTextbook Contract Law Uk Edition Emily Finch Ebook All Chapter PDFjim.shepherd977100% (16)

- Test Bank For Principles of Behavior 7th Edition Richard W MalottDocument19 pagesTest Bank For Principles of Behavior 7th Edition Richard W Malottloudly.nereisnai6100% (42)

- 305855no Bake HADocument9 pages305855no Bake HAAshok KhannaNo ratings yet

- Markevitch, Dimitry - The Cello As An Accompanying Instrument in The 18th CenturyDocument4 pagesMarkevitch, Dimitry - The Cello As An Accompanying Instrument in The 18th CenturyMirko100% (1)

- Asme E213Document4 pagesAsme E213Bryan Jimenes DorantesNo ratings yet

- M 144-07 Calcium Chloride PDFDocument4 pagesM 144-07 Calcium Chloride PDFWalticoZegarraHerreraNo ratings yet

- Ms Bikanervala v. Ms Aggarwal BikanerwalaDocument2 pagesMs Bikanervala v. Ms Aggarwal BikanerwalaPrashant KumawatNo ratings yet

- KTI v. AppleDocument13 pagesKTI v. AppleMikey CampbellNo ratings yet

- Sites of KintallaDocument8 pagesSites of KintallaEpiphanyJoeNo ratings yet

- Prizeman - Ave Maria - Voz-PianoDocument4 pagesPrizeman - Ave Maria - Voz-PianoRoneque100% (2)

- ks2 Mathematics 2014 Mental Maths TranscriptDocument6 pagesks2 Mathematics 2014 Mental Maths TranscriptMona AlyNo ratings yet

- Sight Word Card Game Dobble Spot Ittypegame Set 1Document9 pagesSight Word Card Game Dobble Spot Ittypegame Set 1Cem OngderNo ratings yet

- E1710 11Document7 pagesE1710 11mithileshNo ratings yet

- Lecture 3 - Intelectual Property RightsDocument16 pagesLecture 3 - Intelectual Property RightsMarvin BucsitNo ratings yet

- WIPO Academy Advanced Distance Learning Course On Basics of Patent Drafting (DL320E15S1)Document7 pagesWIPO Academy Advanced Distance Learning Course On Basics of Patent Drafting (DL320E15S1)cresjohnNo ratings yet

- Financial Accounting Canadian Canadian 5th Edition Libby Solutions ManualDocument24 pagesFinancial Accounting Canadian Canadian 5th Edition Libby Solutions ManualDannyJohnsonobtk100% (65)