Professional Documents

Culture Documents

Assemblyman Bensen Head

Assemblyman Bensen Head

Uploaded by

Hrvoje ŠkaricaCopyright:

Available Formats

You might also like

- H145 Transition Pilot TrainingDocument6 pagesH145 Transition Pilot TrainingGourav DasNo ratings yet

- KR-1 Aircraft Rand Robinson Technical Manual + Plans Period Archive Material - EbayDocument1 pageKR-1 Aircraft Rand Robinson Technical Manual + Plans Period Archive Material - EbayConstantin VidraNo ratings yet

- Ultralight Aircraft of The U.S.ADocument106 pagesUltralight Aircraft of The U.S.Aendalkachew gudetaNo ratings yet

- Pilots Operating Handbook: FOR Zenith Stol CH 701Document27 pagesPilots Operating Handbook: FOR Zenith Stol CH 701seemple67% (3)

- 7-701 Construction Manual IntroDocument18 pages7-701 Construction Manual Intro69x4100% (3)

- Iso 21940-12-2016Document42 pagesIso 21940-12-2016Integrity Engineer33% (3)

- Evans VP-1 VolksplaneDocument3 pagesEvans VP-1 VolksplaneFernandoNo ratings yet

- Arnold-Inverse Pressure Gradient MatchingDocument7 pagesArnold-Inverse Pressure Gradient MatchingredxusNo ratings yet

- Emeraude ManualDocument23 pagesEmeraude ManuallarsandNo ratings yet

- Aerody Quizlet 489Document62 pagesAerody Quizlet 489Jecah Angelu S. SaquianNo ratings yet

- S18 TextDocument128 pagesS18 TextAndy SetiawanNo ratings yet

- 1961 08 10Document8 pages1961 08 10Uroš RoštanNo ratings yet

- 750 Flyer 2pageDocument2 pages750 Flyer 2pagemacshilNo ratings yet

- Mini Helicóptero 1Document130 pagesMini Helicóptero 1Abelardo Luna GarciaNo ratings yet

- SPinfo 1 PDFDocument127 pagesSPinfo 1 PDFSteven PollardNo ratings yet

- Export Sites Kitplanes 02 Data Media Pdfs Zenith STOL CH 750 0209 PDFDocument7 pagesExport Sites Kitplanes 02 Data Media Pdfs Zenith STOL CH 750 0209 PDFfintineanu_narcisNo ratings yet

- Chapter 01 IntroductionDocument46 pagesChapter 01 IntroductionMark Evan Salutin100% (1)

- Hornet Planos Ensamble FuselajeDocument24 pagesHornet Planos Ensamble FuselajeJorge Gonzalez100% (1)

- JT 59 PDFDocument2 pagesJT 59 PDFAndone AnutuNo ratings yet

- Brochure Cavalon ENG PDFDocument20 pagesBrochure Cavalon ENG PDFfjfluzNo ratings yet

- The STOL CH 701 - Packing ListDocument1 pageThe STOL CH 701 - Packing Listanon-54278275% (4)

- Spitfire Ultralight SpecificationsDocument3 pagesSpitfire Ultralight SpecificationsKamini DudetNo ratings yet

- Cozy Vs Long EZDocument4 pagesCozy Vs Long EZAbdul Adavuruku Okinobanyi100% (2)

- Sportster Bipe 40 ManualDocument32 pagesSportster Bipe 40 ManualMolocromNo ratings yet

- Midwest Production Plane Article 2013Document9 pagesMidwest Production Plane Article 2013api-220333293100% (1)

- Voievozi RomaniDocument81 pagesVoievozi RomaniRăzvan Curcă100% (1)

- 7 Wing Section1Document10 pages7 Wing Section1flyingfred100% (1)

- PEGA STOL - Static Longitudinal Stability Analysis ZENAIR CHDocument19 pagesPEGA STOL - Static Longitudinal Stability Analysis ZENAIR CHlaerciofilho100% (2)

- Aero Ebook - Choosing The Design of Your Aircraft - Chris Heintz PDFDocument6 pagesAero Ebook - Choosing The Design of Your Aircraft - Chris Heintz PDFGana tp100% (1)

- BHManual Wing1 28rev0Document28 pagesBHManual Wing1 28rev0viorelu99100% (1)

- Fuselage SectionsDocument1 pageFuselage SectionsFrancisco J. ArreolaNo ratings yet

- T-100D Mariah Q&ADocument8 pagesT-100D Mariah Q&AJorge BarnettNo ratings yet

- Gyroplane SafetyDocument13 pagesGyroplane Safetyrpr01No ratings yet

- Manual Magic Laser Operators ManualDocument16 pagesManual Magic Laser Operators ManualtrojanburroNo ratings yet

- Bede BD-5 - WikipediaDocument13 pagesBede BD-5 - WikipediaOzan Öztürk100% (1)

- R/C Soaring Digest - Jul 2004Document19 pagesR/C Soaring Digest - Jul 2004Aviation/Space History LibraryNo ratings yet

- Homebuilt Kit Aircraft Construction Details & Article LibraryDocument4 pagesHomebuilt Kit Aircraft Construction Details & Article LibraryChukkaNo ratings yet

- AK1-3 Helicopter Standard Specification PDFDocument49 pagesAK1-3 Helicopter Standard Specification PDFEstevam Gomes de AzevedoNo ratings yet

- Metal Smith MiniplaneDocument4 pagesMetal Smith Miniplanetdfsks50% (2)

- Kitfox Model 5 With ExtrasDocument20 pagesKitfox Model 5 With ExtrasrcbifNo ratings yet

- Colomban CriCri J Aircraft Flight ManualDocument33 pagesColomban CriCri J Aircraft Flight Manuallegoulu21100% (1)

- Colomban MC-30 Luciole G-CIBJ 11-19 InvestigationDocument4 pagesColomban MC-30 Luciole G-CIBJ 11-19 InvestigationHua Hidari YangNo ratings yet

- Mtosport Maintenance PDFDocument191 pagesMtosport Maintenance PDFBen FriskneyNo ratings yet

- PLANOS AutogiroDocument11 pagesPLANOS Autogirorobochoa100% (1)

- Piper J-3 CubDocument15 pagesPiper J-3 CubAviation/Space History Library100% (8)

- 19 Steps To Legal Eagle XL Frame Build 1Document14 pages19 Steps To Legal Eagle XL Frame Build 1Ennocent MugabeNo ratings yet

- Piper CubDocument84 pagesPiper CubDavid Scott100% (1)

- Plans Aircraft FleaDocument28 pagesPlans Aircraft FleaNofriagara Davit Harnawan100% (2)

- Clark Y Airfoil PDFDocument1 pageClark Y Airfoil PDFAziz Fahrur50% (2)

- Superior Uav - 2003Document6 pagesSuperior Uav - 2003SivaramanNo ratings yet

- 7 Horiz Tail 2Document10 pages7 Horiz Tail 2babumohallah100% (1)

- 701 Material ListDocument1 page701 Material ListIdris100% (1)

- MC15 Cri Cri Plans Binder PDFDocument44 pagesMC15 Cri Cri Plans Binder PDFrocketmench100% (1)

- EAA - EAA Experimenter - A Tool For Understanding Power, Drag, and Prop Design PDFDocument4 pagesEAA - EAA Experimenter - A Tool For Understanding Power, Drag, and Prop Design PDFdjaverNo ratings yet

- Basic Gyroplane Constructions Standards PDFDocument35 pagesBasic Gyroplane Constructions Standards PDFakar64No ratings yet

- Fabric CoveringDocument38 pagesFabric Coveringwordpower777100% (3)

- Lancair Legacy ChecklistDocument7 pagesLancair Legacy ChecklistSara JamesNo ratings yet

- Aerodynamics ProjectDocument45 pagesAerodynamics ProjectRj JagadeshNo ratings yet

- Design of UltralightDocument58 pagesDesign of UltralightZafran Nabil100% (1)

- How2 Make HovercraftDocument25 pagesHow2 Make Hovercraftnikkobasica100% (2)

- User Manual: Flymentor 3DDocument35 pagesUser Manual: Flymentor 3DHrvoje ŠkaricaNo ratings yet

- Rexeoth Control Panel BF-1Document4 pagesRexeoth Control Panel BF-1Hrvoje ŠkaricaNo ratings yet

- 3000 Series: Premium Hall Effect JoysticksDocument7 pages3000 Series: Premium Hall Effect JoysticksHrvoje ŠkaricaNo ratings yet

- RS232 Connections, and Wiring Up Serial DevicesDocument5 pagesRS232 Connections, and Wiring Up Serial DevicesHrvoje ŠkaricaNo ratings yet

- Engine Valve Lash - Inspect/AdjustDocument4 pagesEngine Valve Lash - Inspect/AdjustHrvoje ŠkaricaNo ratings yet

- Berco Product Line Brochure PDFDocument16 pagesBerco Product Line Brochure PDFHrvoje ŠkaricaNo ratings yet

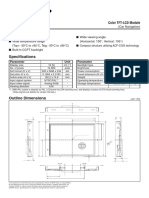

- LQ5AW126Document1 pageLQ5AW126Hrvoje ŠkaricaNo ratings yet

- Berco Product Line Brochure PDFDocument16 pagesBerco Product Line Brochure PDFHrvoje ŠkaricaNo ratings yet

- Sillybus LWTR AustraliaDocument221 pagesSillybus LWTR AustraliaJeremy KumarNo ratings yet

- Vilter VSG VSSG Compressor Unit Manual Units Built Before July 1 2013 en Us 1574674Document112 pagesVilter VSG VSSG Compressor Unit Manual Units Built Before July 1 2013 en Us 1574674Carlos Roberto TamarizNo ratings yet

- 2013 Aeronautical Accessories CatalogDocument313 pages2013 Aeronautical Accessories CatalogMario Lopes100% (2)

- BLR 212Document8 pagesBLR 212Karadias100% (1)

- Ship Helicopter TransfersDocument16 pagesShip Helicopter TransfersCapt M J Thavapunithan JohnNo ratings yet

- 8-Blade Element Theory in Forward FlightDocument22 pages8-Blade Element Theory in Forward Flightnikhil raoNo ratings yet

- CH2Document5 pagesCH2wawalandNo ratings yet

- YSR Helicopter-Crash ReportDocument139 pagesYSR Helicopter-Crash ReportHemskanna100% (1)

- On The Modeling of Hydraulic Components in Rotorcraft SystemsDocument10 pagesOn The Modeling of Hydraulic Components in Rotorcraft SystemsmecambNo ratings yet

- Mi-8 Ice Protection SystemDocument54 pagesMi-8 Ice Protection Systemdiako lopezNo ratings yet

- AeroCraft Systems GBDocument20 pagesAeroCraft Systems GBrospuraNo ratings yet

- UH-60A Blackhawk Eng. Simulation Program, Vol. 1, Math ModelDocument361 pagesUH-60A Blackhawk Eng. Simulation Program, Vol. 1, Math Modelmanitheaerialfighter100% (1)

- R50 Helicopter ManualDocument11 pagesR50 Helicopter ManualsanjuNo ratings yet

- Helicopter Transmission SystemsDocument113 pagesHelicopter Transmission SystemsAlaye AkpanaNo ratings yet

- 6 - Bell206b3-Fm-01-AxaDocument6 pages6 - Bell206b3-Fm-01-AxaAlberto MunozNo ratings yet

- (THESIS) Krishnan Morphing BladeDocument106 pages(THESIS) Krishnan Morphing BladeJamilaWeinPerilloQuintanaNo ratings yet

- Helicopters: Technical Data 2019Document4 pagesHelicopters: Technical Data 2019Huda Lestra100% (1)

- Design and Development of SwashplateDocument58 pagesDesign and Development of SwashplateNsv DineshNo ratings yet

- OVERSPEEDDocument17 pagesOVERSPEEDalsaidiamjad28No ratings yet

- What Is A RotorDocument16 pagesWhat Is A Rotorefekan35No ratings yet

- Gyro Plane PDFDocument10 pagesGyro Plane PDFHasanUSLUM100% (1)

- Raptor G4 Parts ListDocument3 pagesRaptor G4 Parts List000001146No ratings yet

- 07a82104 Helicopterengineering1hDocument7 pages07a82104 Helicopterengineering1hRaj SamuelNo ratings yet

- Caracteristicas RM300Document16 pagesCaracteristicas RM300Julio MezaNo ratings yet

- A Critical Analysis of Small But Heavy-Lift Multirotor and Their Flight ControllersDocument20 pagesA Critical Analysis of Small But Heavy-Lift Multirotor and Their Flight Controllers029Muhammad Robith Fikris SholihNo ratings yet

- Fm-Ec135p2 24193407Document155 pagesFm-Ec135p2 24193407superdby100% (3)

- HeliguideDocument166 pagesHeliguideapi-26338869100% (2)

Assemblyman Bensen Head

Assemblyman Bensen Head

Uploaded by

Hrvoje ŠkaricaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assemblyman Bensen Head

Assemblyman Bensen Head

Uploaded by

Hrvoje ŠkaricaCopyright:

Available Formats

Assemblyman

1 od 5

http://webspace.webring.com/people/al/lwb47/Assemblyman.html

THIS IS A PART COPY OF THE BENSEN HEAD

CONSTRUCTION MANUAL

THE ONLY PARTS MISSING FROM THIS DOCUMENT ARE REFERENCES TO

ITEMS AVAILABLE FROM THE BENSEN COMPANY AS THIS IS NO LONGER

POSSIBLE.

Some sections of the drawing pack have omitted dimensions for hole locations, to assist

the builder who might not have a full machine shop; or precision inspection tools. The

construction steps are arranged in a manner of stacked parts; clamping and drill-through

holes which will allow for greater accuracy on the finished assembly. All holes should be

drilled 1/32-1/16 undersized and reamed to finished size.

Rectangular bar stock may not be flat ,square ,or may have some bow or twist, and may

not be the precise dimension described. The surfaces that join or bear on each other may

have to be filed or machined flat to match drawing dimensions

(comment )

variation from sizes stated is ok by a small amount but basic geometry must not be altered

,tolerances and press fit dimensions must be kept to)

CONSTRUCTION STEPS

Upper Fork Assembly

-5

Fork

Drill (2) holes in one piece only,

Drill and ream (1) hole in each piece to 0.875 + - 0.005

Press in a 12-DU-08 Bushing into each hole.

-8

Housing

Square and parallel the (2) 3.750 sides of the block.

Bore the 2.24404 + - 0.0003 hole ( make sure the hole is in the centre of the block .

Face both sides of the block square to the bore.

-6

Stop

Previous

Forum

Carefully centre and< drill

the 1

hole

Assn.

Like

Off

Easy Surf Improvised Aircraft Homebuilders

Suprise Me! Next >

7.3.2015. 18:51

Assemblyman

2 od 5

http://webspace.webring.com/people/al/lwb47/Assemblyman.html

Drill (4) holes as shown

Mill or file (2) 8.5 degree bevels parallel with the faces of the block.Make sure the 3

dimension is flush or slightly undersize with the sides of -8 Housing.

-9

Retainer

Centre and drill the 1 hole.

-4

-5

Top centre

Bottom centre

Machine to dimensions shown: O.D. 1.1812 +/-0.0002. Faces must be 90 degrees to

1.1812 Dia.and the 0.500 hole must be concentric with the diameter.

-22

Teeter Block

Square and parallel the 1 x 2 sides of the block.

Drill (4) holes and ream. ( make sure the 0.750 +/- 0.003 location of the 0.500 hole

and the 0.375 hole are located from the same side of the block . The placement of these

holes determines the centering of the rotor rotating axis with the bearing centre.

-3

Pivots

Carefully machine and maintain a GOOD SURFACE FINISH on the

0.7497 +/- 0.0002 Dia. Make sure base and flat on shoulder are 90 degrees to O.D. The

0.375 hole must be centered with the O.D. as otherwise this would cyclic the offset blade

pitch

Drill the 0.375 hole

Press 5206 Bearing into -8 Housing. Flush bearing race with face sides of block.

Insert -4 Top Centre into bearing I.D.

Install -3 pivot with washer into each 12-DU-08 Bushing on -5 Fork . Attach Forks to -22

Teeter block with 3/8 hardware. Tighten nut to 300 lbs.

Insert bolt through bearing and -4 Top Centre . Place -10 Bottom Centre

over bolt, and on top of -4 Top Centre. ( this is used temporarily as a spacer)

Locate Forks and -22 Teeter Block over bolt, and on top of -10 Bottom Centre (

Spacer ). This assembly method will assure the centering of the Teeter Bolt with the

Bearing Centre, and also determine the height of the Teeter Bolt from the Bearing face .

Align the -5 Forks with the -8 Housing and clamp. Pick up the (2) drilled holes in -5

< Previous

Forum

Assn.

Like

Off

Easy Surf Improvised Aircraft Homebuilders

Suprise Me! Next >

7.3.2015. 18:51

Assemblyman

3 od 5

http://webspace.webring.com/people/al/lwb47/Assemblyman.html

Fork and drill through the Fork and Housing assembly .

Attach assembly with AN hardware and torque to 50 to 70 inch/lbs.

Remove -22 Teeter Block from -5 Forks

Centre -6 Stop on top of -8 Housing. Make sure bevelled edges are up. Centre -9 Retainer

on bottom of -8 Housing and clamp assembly.

Pick up and drill through the assembly, the (4) holes in -6 Stop. Attach assembly with

AN hardware and torque.( Saw off bolt ends to leave two threads beyond lock nut.

Remove the Bolt and install -10 Bottom Centre used as spacer into 5206 Bearing I.D.

This completes the Upper Fork assembly

Lower Gimbal Pivot Construction

-12

Torque Tube

Machine as per drawing. If the overhead Azimuth Stick is to be used drill a 1 hole, 2

deep in end of Torque Tube, to accommodate the 1 tube of stick. The (2) drilled holes

are laid out and drilled for the -18 Slotted Angle. Use the locating dimension shown on

the -17 Crossarm (Note : If the joystick is to be used the front 3 of the torque tube can be

cut off. The (2) holes for the -17 Cross Arm attachment are transferred from holes

drilled in the Cross Arm.

-13

Lateral Pivot

Square and parallel the (2) 1 x 2 sides of block . Lay out, drill and ream the 0.375

hole .

-11

Long. Fork

Locate, Drill and ream the 0.375 hole in both -11 blocks. Drill (2) holes in (1) piece

only.

Attach -11 Forks to -12 Torque Tube with AN hardware. Insert -13 Lateral Pivot block in

position , flush with base and sides of -11 Forks and clamp. Pick up (2) pre-drilled

holes in -11 Fork and drill through.

Bolt assembly together with AN hardware and torque

Loosen 3/8 Pivot Bolt ,and check for free pivot action ( 0.003 to 0.005 clearance ) if

assembly is too tight, file or mill sides of -12 Torque Tube. If assembly is too loose file or

mill sides of -13 Lateral

Pivot Block.

< Previous

Forum

Like

Easy Surf Improvised Aircraft Homebuilders

Assn.

Off

Suprise Me!

Next >

7.3.2015. 18:51

Assemblyman

4 od 5

http://webspace.webring.com/people/al/lwb47/Assemblyman.html

-14 and -15

Lateral Forks

Machine complete as per drawing

Attach to -13 Lateral Pivot with AN hardware. Clamp torque Tube assembly in vice ,and

level with a bubble protractor. Pivot Gimbal assembly fully forward, stopping on -14

Front Fork. Check angle of tilt with bubble protractor, placed on -13 Lateral Pivot Block.

Correct tilt angle: 9 to 10 degrees. File if necessary the 10 degree bevel of front fork to

obtain the correct reading.

Now pivot the Gimbal assembly fully rearward, stopping on the-15 Rear Lateral Fork.

Check the angle of tilt with bubble protractor, The correct angle is 7 to 8 degrees . File

if necessary the 8 degree bevel on the -15 Rear Lateral Fork to obtain the correct reading.

Gimbal Head Assembly

Mount the Upper Fork Assembly onto the Torque Tube with bolt . Torque up the

castellated nut to 360 in-lbs. Dont forget to COTTERPIN THE NUT ! Without the

cotter-pin there is a danger the nut may unscrew in flight.

Lubricate the Gimbal Pivot bolts and the mating faces with a light film of grease.

Tighten castellated nuts as you would a wheel bearing. ( snug up the nut to expel excess

grease, and then back off (1) castellation at a time until a free pivot is obtained.)

COTTER-PIN BOTH PIVOT CASTELLATED NUTS.

For Joystick use ,attach Cross-Arm and -18 Slotted bracket.

For Overhead Azimuth Stick attach -18 bracket

TO INSTALL OVERHEAD STICK : Clamp entire head assembly in a vice. Level Torque

Tube both londitudally and laterally. Insert overhead stick in drilled 1 hole and align

stick to be vertical to cross arm

(this I think is a typing error but is includes as it is the original text )

and through drill Th (2) 3/16 attaching holes. Secure with 3/16 bolts and torque.

Rotor Hub Assembly

Centre the -22 Teeter Block on the Hub Bar, both span-wise and cross-wise, and clamp.

Drill (2) 5/16 through holes. Secure with AN hardware. Torque 5/16 nuts to 140 in/lbs.

Clamp head assembly in vice and level Torque Tube and -6 Stop plate. Attach Hub

assembly with AN hardware . check flapping angle clearance of Hub. Tilt Hub fully

rearwards in contact with bevel on -6 Stop Plate .Check angle of tilt. Correct angle is

8-1/2 TO 9 DEGREES. File bevel on -6 Stop Plate if necessary to correct tilt angle.

Repeat procedure by tilting Hub fully forward, contacting bevel on -6 Stop Plate. Tilt

angle should be the same.

The Hub MUST pivot FREELY in the DU Bushing when the Teeter bolt nut is torqued

to 300 in/lbs. Lateral clearance of -3 Pivots should be 0.003 to 0.010. If excessive

< Previous

Like clearance

Easy Surf Improvised

Aircraft

Homebuilders

machine the seat end

of -3 PivotsForum

to correct lateral

.If clearance

is to tight

Assn.

Off

Suprise Me!

Next >

7.3.2015. 18:51

Assemblyman

5 od 5

http://webspace.webring.com/people/al/lwb47/Assemblyman.html

,machine the shoulder faces of -3 Pivots.

The DU Bushings are self-lubricating dry bushings, requiring no lubrication. They are

made of globular bronze and teflon-lead coat material. Do not grease them to avoid the

accumulation of grit.

Every time the Hub is installed, the Teeter Bolt nut MUST be torqued to 300 in/lbs. and

COTTER-PINNED ! This then assures that the -3 Pivot bushing becomes an integral

structure with the Teeter Block.

This completes the rotor head ,the remainder has been abridged to cover mounting the

assembly between the cheek plates and setting the spring pressure

Mount head between cheek plates with a gap of about 0.170 between top of plates and

bottom of -13 Lateral Pivot Block, adjust to give 51/2 to 6 degrees of travel either side.

Tilt Torque Bar fully back and pre-load the trim spring to 30lbs tension using a spring

balance.

Return to home page

Hosting by WebRing.

Improvised Aircraft Homebuilders Assn.

< Prev / Talk / Like / Sites / Join / Surprise / Next >

< Previous

Forum

Assn.

Like

Off

Easy Surf Improvised Aircraft Homebuilders

Suprise Me! Next >

7.3.2015. 18:51

You might also like

- H145 Transition Pilot TrainingDocument6 pagesH145 Transition Pilot TrainingGourav DasNo ratings yet

- KR-1 Aircraft Rand Robinson Technical Manual + Plans Period Archive Material - EbayDocument1 pageKR-1 Aircraft Rand Robinson Technical Manual + Plans Period Archive Material - EbayConstantin VidraNo ratings yet

- Ultralight Aircraft of The U.S.ADocument106 pagesUltralight Aircraft of The U.S.Aendalkachew gudetaNo ratings yet

- Pilots Operating Handbook: FOR Zenith Stol CH 701Document27 pagesPilots Operating Handbook: FOR Zenith Stol CH 701seemple67% (3)

- 7-701 Construction Manual IntroDocument18 pages7-701 Construction Manual Intro69x4100% (3)

- Iso 21940-12-2016Document42 pagesIso 21940-12-2016Integrity Engineer33% (3)

- Evans VP-1 VolksplaneDocument3 pagesEvans VP-1 VolksplaneFernandoNo ratings yet

- Arnold-Inverse Pressure Gradient MatchingDocument7 pagesArnold-Inverse Pressure Gradient MatchingredxusNo ratings yet

- Emeraude ManualDocument23 pagesEmeraude ManuallarsandNo ratings yet

- Aerody Quizlet 489Document62 pagesAerody Quizlet 489Jecah Angelu S. SaquianNo ratings yet

- S18 TextDocument128 pagesS18 TextAndy SetiawanNo ratings yet

- 1961 08 10Document8 pages1961 08 10Uroš RoštanNo ratings yet

- 750 Flyer 2pageDocument2 pages750 Flyer 2pagemacshilNo ratings yet

- Mini Helicóptero 1Document130 pagesMini Helicóptero 1Abelardo Luna GarciaNo ratings yet

- SPinfo 1 PDFDocument127 pagesSPinfo 1 PDFSteven PollardNo ratings yet

- Export Sites Kitplanes 02 Data Media Pdfs Zenith STOL CH 750 0209 PDFDocument7 pagesExport Sites Kitplanes 02 Data Media Pdfs Zenith STOL CH 750 0209 PDFfintineanu_narcisNo ratings yet

- Chapter 01 IntroductionDocument46 pagesChapter 01 IntroductionMark Evan Salutin100% (1)

- Hornet Planos Ensamble FuselajeDocument24 pagesHornet Planos Ensamble FuselajeJorge Gonzalez100% (1)

- JT 59 PDFDocument2 pagesJT 59 PDFAndone AnutuNo ratings yet

- Brochure Cavalon ENG PDFDocument20 pagesBrochure Cavalon ENG PDFfjfluzNo ratings yet

- The STOL CH 701 - Packing ListDocument1 pageThe STOL CH 701 - Packing Listanon-54278275% (4)

- Spitfire Ultralight SpecificationsDocument3 pagesSpitfire Ultralight SpecificationsKamini DudetNo ratings yet

- Cozy Vs Long EZDocument4 pagesCozy Vs Long EZAbdul Adavuruku Okinobanyi100% (2)

- Sportster Bipe 40 ManualDocument32 pagesSportster Bipe 40 ManualMolocromNo ratings yet

- Midwest Production Plane Article 2013Document9 pagesMidwest Production Plane Article 2013api-220333293100% (1)

- Voievozi RomaniDocument81 pagesVoievozi RomaniRăzvan Curcă100% (1)

- 7 Wing Section1Document10 pages7 Wing Section1flyingfred100% (1)

- PEGA STOL - Static Longitudinal Stability Analysis ZENAIR CHDocument19 pagesPEGA STOL - Static Longitudinal Stability Analysis ZENAIR CHlaerciofilho100% (2)

- Aero Ebook - Choosing The Design of Your Aircraft - Chris Heintz PDFDocument6 pagesAero Ebook - Choosing The Design of Your Aircraft - Chris Heintz PDFGana tp100% (1)

- BHManual Wing1 28rev0Document28 pagesBHManual Wing1 28rev0viorelu99100% (1)

- Fuselage SectionsDocument1 pageFuselage SectionsFrancisco J. ArreolaNo ratings yet

- T-100D Mariah Q&ADocument8 pagesT-100D Mariah Q&AJorge BarnettNo ratings yet

- Gyroplane SafetyDocument13 pagesGyroplane Safetyrpr01No ratings yet

- Manual Magic Laser Operators ManualDocument16 pagesManual Magic Laser Operators ManualtrojanburroNo ratings yet

- Bede BD-5 - WikipediaDocument13 pagesBede BD-5 - WikipediaOzan Öztürk100% (1)

- R/C Soaring Digest - Jul 2004Document19 pagesR/C Soaring Digest - Jul 2004Aviation/Space History LibraryNo ratings yet

- Homebuilt Kit Aircraft Construction Details & Article LibraryDocument4 pagesHomebuilt Kit Aircraft Construction Details & Article LibraryChukkaNo ratings yet

- AK1-3 Helicopter Standard Specification PDFDocument49 pagesAK1-3 Helicopter Standard Specification PDFEstevam Gomes de AzevedoNo ratings yet

- Metal Smith MiniplaneDocument4 pagesMetal Smith Miniplanetdfsks50% (2)

- Kitfox Model 5 With ExtrasDocument20 pagesKitfox Model 5 With ExtrasrcbifNo ratings yet

- Colomban CriCri J Aircraft Flight ManualDocument33 pagesColomban CriCri J Aircraft Flight Manuallegoulu21100% (1)

- Colomban MC-30 Luciole G-CIBJ 11-19 InvestigationDocument4 pagesColomban MC-30 Luciole G-CIBJ 11-19 InvestigationHua Hidari YangNo ratings yet

- Mtosport Maintenance PDFDocument191 pagesMtosport Maintenance PDFBen FriskneyNo ratings yet

- PLANOS AutogiroDocument11 pagesPLANOS Autogirorobochoa100% (1)

- Piper J-3 CubDocument15 pagesPiper J-3 CubAviation/Space History Library100% (8)

- 19 Steps To Legal Eagle XL Frame Build 1Document14 pages19 Steps To Legal Eagle XL Frame Build 1Ennocent MugabeNo ratings yet

- Piper CubDocument84 pagesPiper CubDavid Scott100% (1)

- Plans Aircraft FleaDocument28 pagesPlans Aircraft FleaNofriagara Davit Harnawan100% (2)

- Clark Y Airfoil PDFDocument1 pageClark Y Airfoil PDFAziz Fahrur50% (2)

- Superior Uav - 2003Document6 pagesSuperior Uav - 2003SivaramanNo ratings yet

- 7 Horiz Tail 2Document10 pages7 Horiz Tail 2babumohallah100% (1)

- 701 Material ListDocument1 page701 Material ListIdris100% (1)

- MC15 Cri Cri Plans Binder PDFDocument44 pagesMC15 Cri Cri Plans Binder PDFrocketmench100% (1)

- EAA - EAA Experimenter - A Tool For Understanding Power, Drag, and Prop Design PDFDocument4 pagesEAA - EAA Experimenter - A Tool For Understanding Power, Drag, and Prop Design PDFdjaverNo ratings yet

- Basic Gyroplane Constructions Standards PDFDocument35 pagesBasic Gyroplane Constructions Standards PDFakar64No ratings yet

- Fabric CoveringDocument38 pagesFabric Coveringwordpower777100% (3)

- Lancair Legacy ChecklistDocument7 pagesLancair Legacy ChecklistSara JamesNo ratings yet

- Aerodynamics ProjectDocument45 pagesAerodynamics ProjectRj JagadeshNo ratings yet

- Design of UltralightDocument58 pagesDesign of UltralightZafran Nabil100% (1)

- How2 Make HovercraftDocument25 pagesHow2 Make Hovercraftnikkobasica100% (2)

- User Manual: Flymentor 3DDocument35 pagesUser Manual: Flymentor 3DHrvoje ŠkaricaNo ratings yet

- Rexeoth Control Panel BF-1Document4 pagesRexeoth Control Panel BF-1Hrvoje ŠkaricaNo ratings yet

- 3000 Series: Premium Hall Effect JoysticksDocument7 pages3000 Series: Premium Hall Effect JoysticksHrvoje ŠkaricaNo ratings yet

- RS232 Connections, and Wiring Up Serial DevicesDocument5 pagesRS232 Connections, and Wiring Up Serial DevicesHrvoje ŠkaricaNo ratings yet

- Engine Valve Lash - Inspect/AdjustDocument4 pagesEngine Valve Lash - Inspect/AdjustHrvoje ŠkaricaNo ratings yet

- Berco Product Line Brochure PDFDocument16 pagesBerco Product Line Brochure PDFHrvoje ŠkaricaNo ratings yet

- LQ5AW126Document1 pageLQ5AW126Hrvoje ŠkaricaNo ratings yet

- Berco Product Line Brochure PDFDocument16 pagesBerco Product Line Brochure PDFHrvoje ŠkaricaNo ratings yet

- Sillybus LWTR AustraliaDocument221 pagesSillybus LWTR AustraliaJeremy KumarNo ratings yet

- Vilter VSG VSSG Compressor Unit Manual Units Built Before July 1 2013 en Us 1574674Document112 pagesVilter VSG VSSG Compressor Unit Manual Units Built Before July 1 2013 en Us 1574674Carlos Roberto TamarizNo ratings yet

- 2013 Aeronautical Accessories CatalogDocument313 pages2013 Aeronautical Accessories CatalogMario Lopes100% (2)

- BLR 212Document8 pagesBLR 212Karadias100% (1)

- Ship Helicopter TransfersDocument16 pagesShip Helicopter TransfersCapt M J Thavapunithan JohnNo ratings yet

- 8-Blade Element Theory in Forward FlightDocument22 pages8-Blade Element Theory in Forward Flightnikhil raoNo ratings yet

- CH2Document5 pagesCH2wawalandNo ratings yet

- YSR Helicopter-Crash ReportDocument139 pagesYSR Helicopter-Crash ReportHemskanna100% (1)

- On The Modeling of Hydraulic Components in Rotorcraft SystemsDocument10 pagesOn The Modeling of Hydraulic Components in Rotorcraft SystemsmecambNo ratings yet

- Mi-8 Ice Protection SystemDocument54 pagesMi-8 Ice Protection Systemdiako lopezNo ratings yet

- AeroCraft Systems GBDocument20 pagesAeroCraft Systems GBrospuraNo ratings yet

- UH-60A Blackhawk Eng. Simulation Program, Vol. 1, Math ModelDocument361 pagesUH-60A Blackhawk Eng. Simulation Program, Vol. 1, Math Modelmanitheaerialfighter100% (1)

- R50 Helicopter ManualDocument11 pagesR50 Helicopter ManualsanjuNo ratings yet

- Helicopter Transmission SystemsDocument113 pagesHelicopter Transmission SystemsAlaye AkpanaNo ratings yet

- 6 - Bell206b3-Fm-01-AxaDocument6 pages6 - Bell206b3-Fm-01-AxaAlberto MunozNo ratings yet

- (THESIS) Krishnan Morphing BladeDocument106 pages(THESIS) Krishnan Morphing BladeJamilaWeinPerilloQuintanaNo ratings yet

- Helicopters: Technical Data 2019Document4 pagesHelicopters: Technical Data 2019Huda Lestra100% (1)

- Design and Development of SwashplateDocument58 pagesDesign and Development of SwashplateNsv DineshNo ratings yet

- OVERSPEEDDocument17 pagesOVERSPEEDalsaidiamjad28No ratings yet

- What Is A RotorDocument16 pagesWhat Is A Rotorefekan35No ratings yet

- Gyro Plane PDFDocument10 pagesGyro Plane PDFHasanUSLUM100% (1)

- Raptor G4 Parts ListDocument3 pagesRaptor G4 Parts List000001146No ratings yet

- 07a82104 Helicopterengineering1hDocument7 pages07a82104 Helicopterengineering1hRaj SamuelNo ratings yet

- Caracteristicas RM300Document16 pagesCaracteristicas RM300Julio MezaNo ratings yet

- A Critical Analysis of Small But Heavy-Lift Multirotor and Their Flight ControllersDocument20 pagesA Critical Analysis of Small But Heavy-Lift Multirotor and Their Flight Controllers029Muhammad Robith Fikris SholihNo ratings yet

- Fm-Ec135p2 24193407Document155 pagesFm-Ec135p2 24193407superdby100% (3)

- HeliguideDocument166 pagesHeliguideapi-26338869100% (2)