Professional Documents

Culture Documents

Amercoat 37-B-1 / 37-G-1: Product Data/ Application Instructions

Amercoat 37-B-1 / 37-G-1: Product Data/ Application Instructions

Uploaded by

Tony KhouryOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Amercoat 37-B-1 / 37-G-1: Product Data/ Application Instructions

Amercoat 37-B-1 / 37-G-1: Product Data/ Application Instructions

Uploaded by

Tony KhouryCopyright:

Available Formats

Amercoat

Amercoat 37-B-1 / 37-G-1

Temperature Indicating Paint Blue/Green

Product Data/

Application Instructions

Indicates potential dangerous hot spots

Colour changes

37-B-1: above 200C/392F from blue to

white

37-G-1: above 260C/500F from green to

white

Good weathering resistance

Colour change is irreversible

Physical Data

Finish ..................................... flat

Colour .................................... 37-B-1: blue

37-G-1: green

Components .......................... 1

Curing mechanism ................ evaporation of solvents

Volume solids ........................ 44% (ASTM D2697; 7 day)

Typical Uses

Amercoat 37-B-1 and Amercoat 37-G-1 are designed to

indicate potentially dangerous "hot spots" on the exterior of

reactors and pressure vessels resulting from the breakdown

of internal insulation. A perceptible colour change marks the

area where overheating has occurred. Colour retention is

excellent to the threshold temperature. Above the threshold

temperature an irreversible progressive discoloration occurs

at a rate determined by time and temperature.

VOC* ..................................... 37-B-1

EC SED 1999/13/EC ........... 384 g/kg (449 g/l)

UK PG6/23(92) Appendix 3 . 458 g/l

VOC* ...................................... 37-G-1

EC SED 1999/13/EC ........... 398 g/kg (487 g/l)

UK PG6/23(92) Appendix 3 . 486 g/l

Dry film thickness .................. 25 - 40 m

Number of coats .................... 1

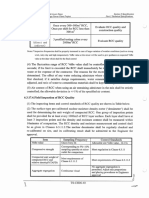

Amercoat 37-B-1

up to 175C/347F

maintains deep blue colour

at 200 - 230C (392 - 446F) perceptible change to light blue

green in 36 to 60 hours

at 260C/500F

changing to white in 24 hours

Amercoat 37-G-1

up to 260C/500F

at 280C/536F

at 315C/599F

at 400C/752F

maintains deep green colour

fading observed after three weeks

perceptible change after 18 hours

colour change to white after 3

hours

Recommended Systems

Amercoat 37-B-1 and Amercoat 37-G-1 are self-priming and

may be applied directly to bare steel. For best steel protection

priming with Dimetcote 11 is recommended.

Calculated coverage...............

(at 25 m)...............

37-B-1

2

18.8 m /l

37-G-1

2

17.6 m /l

Allow for application losses, surface irregularities, etc.

Temperature resistance ........ 37-B-1

37-G-1

175C

260C

347F

500F

(dry heat; maximum without

changing of colour)

Specific gravity ...................... 37-B-1

1.18 kg/l

Flash points

(Closed Cup)........................

37-B-1 .................................

37-G-1 .................................

Thinner/cleaner ...................

C

40

40

24

37-G-1

1.22 kg/l

F

104

104

75

* VOC figures are quoted according to both the EC directive

1999/13/EC which are theoretically calculated figures and the UK

PG6/23(92) Appendix 3 which are practically determined figures.

Page 1 of 4

Revision date: 08-11-2007

Amercoat 37-B-1 / 37-G-1

Repair

Application Data

Spot blast areas to Sa 2, feathering edges of intact

coating. Thoroughly remove dust or abrasive residue before

touch up.

Substrate ............................... suitably primed steel / abrasive

blasted steel

Application methods .............. conventional or airless spray, brush

or roller*

Surface Preparation

Coating performance is in general is proportional to the

degree of surface preparation. Abrasive blasting is usually

the most effective and economical method.

DIRECT APPLICATION ON STEEL - Blast steel surfaces to

a minimum of Sa 2 (ISO 8501-1) or Steel Structures

Painting Council SP-10. Note: blast to achieve a surface

profile not to exceed 75 m as determined with Testex Tape

or similar instrument. Remove abrasive residues and dust

from surface.

APPLICATION ON PRIMED STEEL - (primed with

Dimetcote 11) Refer to specifications of the specific primer

being used. Prior to coating, primed surface must be clean,

dry, undamaged and free of all contaminants including salt

deposits. Round of all rough welds and remove weld

spatter.

IMPORTANT - Apply Amercoat 37-B-1 / 37-G-1 as soon as

possible after surface preparation to prevent any

contamination. Do not leave blasted steel uncoated

overnight. In case of contamination, remove contaminants.

Spot blast steel if needed.

Environmental Conditions

(during application)

Air temperature .................... 5 to 50C

Surface temperature ............ 5 to 60C

To prevent moisture condensation during application, surface

temperature must be at least 3C/5F above dew point. Never

apply coatings under reverse environmental conditions. Ensure

good ventilation when applied in confined areas to assist

evaporation and elimination of solvents.

Drying Times

(ASTM D1640; at 25 m)

Amercoat 37-B-1

C/F . 30/86

20/68

dry through........................... 20

30

dry to recoat or topcoat

(minimum)............................ 8

16

(maximum)........................... not restricted

10/50

60 (minutes)

48 (hours)

Amercoat 37-G-1

C/F . 30/86

20/68

dry through........................... 3

4

dry to recoat or topcoat

(minimum)............................ 16

24

(maximum)........................... not restricted

Application Equipment

The following equipment is listed as a guide and suitable

equipment from other manufacturers may be used.

Adjustments of pressure and change of tip size may be

needed to obtain the proper spray characteristics.

AIRLESS SPRAY - Standard airless spray equipment, such

as Graco, DeVilbiss, Nordson-Bede, Spee-Flo or others

having a 0.013 to 0.021 inch (0.33 mm) fluid tip or larger.

CONVENTIONAL SPRAY - Industrial equipment such as

DeVilbiss MBC or JGA gun with 78 or 765 air cap and "E"

fluid tip and heavy mastic spring or Binks No. 18 or 62 with

a 66 x 63 PB nozzle setup. Separate air and fluid pressure

regulators, mechanical pot agitator and a moisture and oil

trap in the main air supply line are recommended.

MIXER - Use power mixer powered by an air motor or an

explosion proof electric motor.

41 to 122F

41 to 140F

10/50

16 (hours)

48 (hours)

NOTE: drying times are dependent on air and steel temperature,

applied film thickness, ventilation and other environmental

conditions. Times are proportionally shorter at higher temperature

and longer at lower temperatures. Prior to recoating ensure surface

is clean. Maximum recoat time depends on coating system to be

used. Consult your PPG representative for specific

recommendations.

Thinner/cleaner ..................... Amercoat 65

Brush or roller application may require additional coats.

Application Data Summary

Like all high performance coatings, Amercoat 37-B-1 and

Amercoat 37-G-1 must be applied as recommended to

obtain the maximum protection for which these coatings are

formulated. To obtain the maximum performance for which

Amercoat 37-B-1 and Amercoat 37-G-1 are formulated,

strict adherence to all application instructions, precautions,

conditions and limitations is necessary. If conditions exist

that are not within the requirements or limitations described,

consult your PPG representative.

Page 2 of 4

Revision date: 08-11-2007

Amercoat 37-B-1 / 37-G-1

Application Procedure

Amercoat 37-B-1 and Amercoat 37-G-1 are packaged

as 5 l in a 5 l can; thinner/cleaner is Amercoat 65.

1. Flush equipment with Thinner before use.

2. Thin only if necessary for workability, add up to

10% by volume.

3. Apply a wet coat even, parallel passes. Overlap

each pass 50% to avoid bare areas, pinholes or

holidays. When applying directly over inorganic

zincs at full thickness, bubbling may occur. A test

patch is recommended and if bubbling occurs,

apply a "mist coat". Consult your PPG

representative for further information.

4. Double coat all welds, rough spots, sharp edges

and corners, rivets, bolts, etc.

5. Application at 70 to 100 m wet film thickness will

normally provide 25-40 m dry film.

6. Small damaged or bare areas and random

pinholes or holidays can be touched up by brush.

Repair larger areas by spray.

7. In confined areas ventilate with clean air during

application and drying until all solvents are

removed. Temperature and humidity of ventilating

air must be such that moisture condensation will

not form on surface.

# For conventional spray, use adequate air pressure

and volume to ensure proper atomization.

# Normal recommended dry film thickness is 25 to

40 m.

8. Clean all equipment with Thinner immediately after

use or at least after each working day or shift.

Shipping Data

Packaging .................... 5 l in 5 l can

Shipping weight ........... approx. 6 kg

Shelf life ....................... 1 year from shipment date

when stored indoors in

unopened, original

containers at 5 to 40C (41

to 104F).

Page 3 of 4

Revision date: 08-11-2007

Amercoat 37-B-1 / 37-G-1

Caution

This product is flammable. Keep away from heat and

open flame. Keep container closed. Use with

adequate ventilation. Avoid prolonged and repeated

contact with skin. If used in confined areas, observe

the following precautions to prevent hazards of fire or

explosion or damage to the health:

1. circulate adequate fresh air continuously during

application and drying;

2. use fresh air masks and explosion proof

equipment;

3. prohibit all flames, sparks, welding and smoking.

Do not empty into drains. Take precautionary

measures against static discharges. For specific

information on hazardous ingredients, required

ventilation, possible consequences of contact and

safety measures see Safety Data Sheet.

Safety

Since improper use and handling can be hazardous

to health and cause of fire or explosion, safety

precautions included with Product Data/Application

Instruction and Material Safety Data Sheet must be

observed during all storage, handling, use and drying

periods.

Warranty

PPG warrants its products to be free from defects in

material and workmanship. PPGs sole obligations

and Buyers exclusive remedy in connection with the

products shall be limited, at PPGs option, to either

replacement of products not conforming this warranty

or credit to Buyers account in the invoiced amount of

the non-conforming products. Any claim under this

warranty must be made by Buyer to PPG in writing

within five (5) days of Buyers discovery of the

claimed defect, but in no event later than the

expiration of the applicable shelf life, or one year from

the delivery date, whichever is earlier. Buyers failure

to notify PPG of such non-conformance as required

herein shall bar Buyer from recovery under this

warranty.

Any recommendations or suggestion relating to the

use of the products made by PPG, whether in its

technical literature, or response to specific enquiry, or

otherwise, is based on data believed to be reliable;

however, the products and information are intended

for use by Buyers having requisite skill and knowhow in the industry, and therefore it is Buyer to satisfy

itself of the suitability of the products for its own

particular use and it shall be deemed that Buyer has

done so, as its sole discretion and risk. Variation in

environment, changes in procedures of use, or

extrapolation of data may cause unsatisfactory

results.

Limitation of Liability

PPGs liability on any claim of any kind, including

claims based upon PPGs negligence or strict liability,

for any loss or damage arising out of, connected with,

or resulting from the use of the products, shall in no

case exceed the purchase price allocable to the

products or part thereof which give rise to the claim.

In no event shall PPG be liable for consequential or

incidental damages.

Due to PPGs policy of continuous product

improvement, the information contained in this

Product Data/Application Instructions sheet is subject

to change without notice. It is the Buyers

responsibility to check that this issue is current prior to

using the product. For the most up-to-date Product

Data/Application Instructions always refer to the

PPG Protective & Marine Coatings website at

www.ppgpmc.com

To avoid any confusion that may arise through

translation into other languages, the English version

of the Product Data/Application Instructions will be the

governing literature and must be referred to in case of

deviations with product literature in other languages.

Condition of Sale

All our transactions are subject to our Terms and

Conditions of Sale.

PPG makes no other warranties concerning the

product. No other warranties, whether express,

implied or statutory, such as warranties of

merchantability or fitness particular purpose,

shall apply. In no event shall PPG be liable for

consequential or incidental damages.

PPG Industries Netherlands BV

Tel +(31) 345 587 200

www.ppgpmc.com

Ameron Coatings has become part of PPG Industries

Page 4 of 4

Revision date:08-11-2007

You might also like

- Amercoat 56E Polyamide Epoxy High Solids Tank LiningDocument4 pagesAmercoat 56E Polyamide Epoxy High Solids Tank LiningMuhammad MustahsinNo ratings yet

- 67 31085 IM515E 2016 1 2 2 MaterialSelection 06Document21 pages67 31085 IM515E 2016 1 2 2 MaterialSelection 06GiovannaPachecoNo ratings yet

- Amercoat 68 BSDocument4 pagesAmercoat 68 BSStephen Francis BothelloNo ratings yet

- Dimecote 9 Inorganic Zinc Silicate CoatingDocument4 pagesDimecote 9 Inorganic Zinc Silicate Coatingabdulgafoor54No ratings yet

- SES Amercoat Dimetcote 9Document4 pagesSES Amercoat Dimetcote 9kamalkashNo ratings yet

- Amercoat 253Document4 pagesAmercoat 253Sherif AbdelhameedNo ratings yet

- Dimetcote 6: Inorganic Zinc Silicate Coating Product Data/ Application InstructionsDocument4 pagesDimetcote 6: Inorganic Zinc Silicate Coating Product Data/ Application InstructionsYokesh Anand RNo ratings yet

- Amercoat 878 HSDocument4 pagesAmercoat 878 HSMario KoričanNo ratings yet

- Amercoat 4801 Glass Flake Vinyl EsterDocument4 pagesAmercoat 4801 Glass Flake Vinyl Esterilyasmd7No ratings yet

- Amerlock 400GFA High Solids Glassflake Epoxy CoatingDocument4 pagesAmerlock 400GFA High Solids Glassflake Epoxy CoatingSherif AbdelhameedNo ratings yet

- Amercoat 391PC: Solvent Free Epoxy Product Data/ Application InstructionsDocument4 pagesAmercoat 391PC: Solvent Free Epoxy Product Data/ Application InstructionsAchraf BoudayaNo ratings yet

- Amercoat 450E: Product Data/ Application InstructionsDocument4 pagesAmercoat 450E: Product Data/ Application Instructions전상문No ratings yet

- Amerlock 400 GFADocument4 pagesAmerlock 400 GFASherif AbdelhameedNo ratings yet

- PN78HBCDocument4 pagesPN78HBCLassadNo ratings yet

- Dimetcote 15 SlurryDocument4 pagesDimetcote 15 SlurryBiju_PottayilNo ratings yet

- Amerlock 400CDocument4 pagesAmerlock 400CLalit Bom MallaNo ratings yet

- Ameron PN220GDocument4 pagesAmeron PN220GLalit Bom MallaNo ratings yet

- 0400GF Amerlock 400 GF PDS PDFDocument4 pages0400GF Amerlock 400 GF PDS PDFRenny DevassyNo ratings yet

- 0400GF Amerlock 400 GF PDSDocument4 pages0400GF Amerlock 400 GF PDSRenny DevassyNo ratings yet

- PN450XDocument4 pagesPN450XOmer ChaudhryNo ratings yet

- Amercoat 878: Physical DataDocument2 pagesAmercoat 878: Physical Dataabdulgafoor54No ratings yet

- Amercoat 56E: Polyamide Epoxy Product Data/ Application InstructionsDocument4 pagesAmercoat 56E: Polyamide Epoxy Product Data/ Application InstructionsTony KhouryNo ratings yet

- Intergard 251 Tech Data SheetDocument0 pagesIntergard 251 Tech Data SheetL Mahender ReddyNo ratings yet

- PN450X PDSDocument4 pagesPN450X PDSPeshteenNo ratings yet

- Xylar Data SheetDocument3 pagesXylar Data Sheetsarath6725No ratings yet

- Carbothane+134+HG+PDS+3 11Document2 pagesCarbothane+134+HG+PDS+3 11James Everett AbdulNo ratings yet

- Penguard Tiecoat 100Document5 pagesPenguard Tiecoat 100Raja SNo ratings yet

- Carboguard 888 PDSDocument3 pagesCarboguard 888 PDSsalamrefighNo ratings yet

- TDS - Jotamastic 80 - English (Uk) - Issued.26.03.2009Document4 pagesTDS - Jotamastic 80 - English (Uk) - Issued.26.03.2009Joni EfwanNo ratings yet

- Intergard 276: Epoxy Undercoat/ Tie-CoatDocument4 pagesIntergard 276: Epoxy Undercoat/ Tie-CoatAhmed IbrahimNo ratings yet

- GARLOCK Gasket SheetsDocument59 pagesGARLOCK Gasket SheetsdanianishNo ratings yet

- 112.025 - SUMAZINC S-659 PRIMER RICO EM ZINCO - Inglês PDFDocument2 pages112.025 - SUMAZINC S-659 PRIMER RICO EM ZINCO - Inglês PDFFernando VittoNo ratings yet

- TDS 25740 Jotafloor EP SL Euk GBDocument5 pagesTDS 25740 Jotafloor EP SL Euk GBDavid TumboimbelaNo ratings yet

- Interbond 600 PDFDocument4 pagesInterbond 600 PDFTrịnh Minh KhoaNo ratings yet

- Jotafloor Screed PDFDocument5 pagesJotafloor Screed PDFJay Ram DhakalNo ratings yet

- Interzinc 75V: Zinc-Rich EpoxyDocument4 pagesInterzinc 75V: Zinc-Rich EpoxyTrịnh Minh KhoaNo ratings yet

- (Painting) Jotamastic 87Document5 pages(Painting) Jotamastic 87Mohd FadliNo ratings yet

- Jotatherm TB550 Data SheetDocument7 pagesJotatherm TB550 Data Sheet이선엽No ratings yet

- Resist GTI - English (Uk) - Issued.06.12.2007Document4 pagesResist GTI - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- TDS Jotafloor EPC 300 Plus Euk GBDocument6 pagesTDS Jotafloor EPC 300 Plus Euk GBAhmed IbrahimNo ratings yet

- Jotamastic 87 Aluminium - English (Uk) - Issued.04.01.Document4 pagesJotamastic 87 Aluminium - English (Uk) - Issued.04.01.Mohamed FaragNo ratings yet

- MTM44 1 Datasheet Issue6Document6 pagesMTM44 1 Datasheet Issue6Leolix PavlixNo ratings yet

- TDS 48342 Jotatemp 1000 Euk GBDocument5 pagesTDS 48342 Jotatemp 1000 Euk GBhenryNo ratings yet

- Stonclad GR Product DataDocument2 pagesStonclad GR Product DataAnonymous aii1ilNo ratings yet

- Marathon 1000GF Technical Data SheetDocument5 pagesMarathon 1000GF Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Jotatemp 1000 Ceramic: Technical Data SheetDocument5 pagesJotatemp 1000 Ceramic: Technical Data Sheetebastien2No ratings yet

- International Interswift 6800HS Antifouling Product Data SheetDocument4 pagesInternational Interswift 6800HS Antifouling Product Data Sheetadul sungkatinNo ratings yet

- Amerlock 400gfaDocument4 pagesAmerlock 400gfaKhaled bouhlelNo ratings yet

- Instruction Manual: Heto Gel Dryer GD-2Document16 pagesInstruction Manual: Heto Gel Dryer GD-2Eclecticindia EclecticindiaNo ratings yet

- Penguard Express ZPDocument5 pagesPenguard Express ZPMustafa Al-YasseriNo ratings yet

- Carbothane 134 Series PDS Sept 2012Document2 pagesCarbothane 134 Series PDS Sept 2012salamrefighNo ratings yet

- Jotatemp 1000Document5 pagesJotatemp 1000Mangesh MohiteNo ratings yet

- Protective Coating-3Document0 pagesProtective Coating-3Sivaratnam NavatharanNo ratings yet

- TDS - Barrier 90 - English (Uk) - Issued.05.10.2011Document4 pagesTDS - Barrier 90 - English (Uk) - Issued.05.10.2011ansarALLAAHNo ratings yet

- Soft Natural Rubber Lining: Technical Data SheetDocument2 pagesSoft Natural Rubber Lining: Technical Data SheetSantosh JayasavalNo ratings yet

- Masterprotect 1813 MsDocument5 pagesMasterprotect 1813 MsMeera BaiNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (7)

- GRP and Buildings: A Design Guide for Architects and EngineersFrom EverandGRP and Buildings: A Design Guide for Architects and EngineersNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- method statement-olaya towers- F15Document4 pagesmethod statement-olaya towers- F15Tony KhouryNo ratings yet

- Method Statement IPS 3 Concrete Nesma IWTTP Jubail RC 2015Document4 pagesMethod Statement IPS 3 Concrete Nesma IWTTP Jubail RC 2015Tony KhouryNo ratings yet

- method statement-olaya towers- C12Document3 pagesmethod statement-olaya towers- C12Tony KhouryNo ratings yet

- Acrymastic 100 Product Data: Elastomeric Roofing/ Water Proofing CompoundDocument1 pageAcrymastic 100 Product Data: Elastomeric Roofing/ Water Proofing CompoundTony KhouryNo ratings yet

- Amerlock 2C: Fast Drying High Solids Epoxy Product Data/ Application InstructionsDocument4 pagesAmerlock 2C: Fast Drying High Solids Epoxy Product Data/ Application InstructionsTony KhouryNo ratings yet

- Amercoat 56E: Polyamide Epoxy Product Data/ Application InstructionsDocument4 pagesAmercoat 56E: Polyamide Epoxy Product Data/ Application InstructionsTony KhouryNo ratings yet

- Apcs 2aDocument3 pagesApcs 2aTony KhouryNo ratings yet

- Msds Am 2cDocument5 pagesMsds Am 2cTony KhouryNo ratings yet

- S9 Unit 6 WorksheetsDocument10 pagesS9 Unit 6 WorksheetsyrkavinNo ratings yet

- Rohini 21698942227Document6 pagesRohini 21698942227MUSKAN PRNNo ratings yet

- Unit FDocument24 pagesUnit Fsoundu ranganathNo ratings yet

- Statistics ReviewDocument5 pagesStatistics Reviewsakuraikaze0% (1)

- OD - New Method For Reduce Polymerization ShrinkageDocument52 pagesOD - New Method For Reduce Polymerization ShrinkageLn ShenNo ratings yet

- Anatomy and Structure of Human Sense OrgansDocument3 pagesAnatomy and Structure of Human Sense OrgansMelanie GialogoNo ratings yet

- The Shadowgraph Imaging Technique and Its Modern Application To Fluid Jets and DropsDocument10 pagesThe Shadowgraph Imaging Technique and Its Modern Application To Fluid Jets and Dropsnsa10124No ratings yet

- Radiograph Interpretation - WeldsDocument7 pagesRadiograph Interpretation - WeldsDanut RusNo ratings yet

- Sedimentary Basin 1Document2 pagesSedimentary Basin 1Adedokun AbayomiNo ratings yet

- Stellite-6 Surface Layers Reinforced With Hard andDocument7 pagesStellite-6 Surface Layers Reinforced With Hard andlazaroccsNo ratings yet

- Test Equipments SummaryDocument164 pagesTest Equipments SummaryjacksonNo ratings yet

- Sizing The Protection Devices To Control Water Hammer DamageDocument7 pagesSizing The Protection Devices To Control Water Hammer DamageAs VilankNo ratings yet

- Geomembrane Technical DataDocument1 pageGeomembrane Technical DataYusufAliMuktiNo ratings yet

- Part 2 - Guided Wave Theory and Concepts RevdDocument192 pagesPart 2 - Guided Wave Theory and Concepts RevdHebert100% (1)

- 4.4 HW: Writing Exponential FunctionsDocument2 pages4.4 HW: Writing Exponential FunctionsYuchen FanNo ratings yet

- eveηr 300~500m3Document1 pageeveηr 300~500m3dana setiawanNo ratings yet

- Vibrations of Beams PDFDocument10 pagesVibrations of Beams PDFSathish UppuNo ratings yet

- GI Scintigraphy 1382731852503 4 PDFDocument10 pagesGI Scintigraphy 1382731852503 4 PDFMark M. AlipioNo ratings yet

- 2d TransformationsDocument38 pages2d TransformationsPoonam GholapNo ratings yet

- Stability of Retaining WallsDocument12 pagesStability of Retaining WallsDavid KegayaNo ratings yet

- DEVICE Reference GuideDocument302 pagesDEVICE Reference GuidesreevatsakurudiNo ratings yet

- Ultra-Wideband RCS Reduction and Gain Enhancement of Patterned-Surface-Based Aperture Coupling Patch Antenna With Optimized Arrangement MethodDocument7 pagesUltra-Wideband RCS Reduction and Gain Enhancement of Patterned-Surface-Based Aperture Coupling Patch Antenna With Optimized Arrangement MethodSubhanjali MyneniNo ratings yet

- Annexure-I: Ord. Bos - Ces: 21-9-2020Document92 pagesAnnexure-I: Ord. Bos - Ces: 21-9-2020faiz19aaNo ratings yet

- LSI Dakota Series Spec Sheet 10-90Document2 pagesLSI Dakota Series Spec Sheet 10-90Alan MastersNo ratings yet

- Mechanical Properties of SolidDocument22 pagesMechanical Properties of SolidTrillionare HackNo ratings yet

- Lesson Plan in TrapezoidDocument6 pagesLesson Plan in TrapezoidJohn Michael Jr., B. MercadoNo ratings yet

- Chemical Engineering Separations A Handbook For Students 1629902287Document93 pagesChemical Engineering Separations A Handbook For Students 1629902287Diya SofeaNo ratings yet

- Bernoulli ExperimentDocument10 pagesBernoulli ExperimentFatih YILMAZNo ratings yet

- Protech BrochureDocument28 pagesProtech BrochureLuis ReyesNo ratings yet