Professional Documents

Culture Documents

By-Pass: (Machine Code: A899)

By-Pass: (Machine Code: A899)

Uploaded by

Cristian BobaruOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

By-Pass: (Machine Code: A899)

By-Pass: (Machine Code: A899)

Uploaded by

Cristian BobaruCopyright:

Available Formats

BY-PASS

(Machine Code: A899/B415)

10 August, 2001

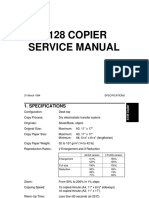

SPECIFICATIONS

1 OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Paper Size:

Standard sizes

A6 lengthwise to A3

HLT lengthwise to DLT

Non-standard sizes

Width: 90 to 305 mm

Length: 148 to 432 mm

Paper Weight:

52 g/m2 ~ 157 g/m2, 16 lb ~ 42 lb

Tray Capacity:

50 sheets (80 g/m2, 20 lb)

Paper Feed System:

Friction Pad Paper Feed

1.2 MECHANICAL COMPONENT LAYOUT

1

Options

B415V500.WMF

1. Paper Feed Roller

2. Paper End Sensor

3. Paper Size Sensor Board

B415-1

ELECTRICAL COMPONENT LAYOUT

10 August, 2001

1.3 ELECTRICAL COMPONENT LAYOUT

2

B415V501.WMF

1. Paper End Sensor

2. Paper Feed Clutch

3. Paper Size Sensor Board

1.4 ELECTRICAL COMPONENT DESCRIPTION

Symbol

Sensors

S1

S2

Name

Paper End

Paper Size

Sensor Board

Magnetic Clutches

MC1

Paper Feed

Function

Informs the copier/printer when the by-pass

tray runs out of paper.

Detects the paper width.

Starts paper feed from the by-pass tray.

B415-2

Index No.

1

3

10 August, 2001

BASIC OPERATION

2 DETAILED DESCRIPTIONS

2.1 BASIC OPERATION

[A]

[B]

[C]

B415D503.WMF

The by-pass unit uses a friction pad paper feed mechanism. The transport roller

gear in the main copier/printer drives the gear on the paper feed clutch [B] through

a series of gears.

Options

When paper is placed in the tray, the paper end sensor [C] switches off. When the

Start button is pressed, the paper feed clutch [B] is activated and the paper feed

roller [A] feeds the paper one sheet at a time.

B415-3

PAPER SIZE DETECTION

10 August, 2001

2.2 PAPER SIZE DETECTION

[A]

[B]

B415D504.WMF

The paper size sensor board [B] monitors the paper width. The rear side fence [A]

is connected to the terminal plate. The pattern for each paper width is unique.

Therefore, the copier/printer determines which paper has been placed in the bypass tray by the signal output from the board. However, the copier will not

determine the paper length from the by-pass tray hardware (refer to Original Size

Detection in the manual for the base copier for details on how paper length is

determined).

B415-4

10 August, 2001

PAPER FEED ROLLER/FRICTION PAD/PAPER END SENSOR

3 REPLACEMENT AND ADJUSTMENT

3.1 PAPER FEED ROLLER/FRICTION PAD/PAPER END

SENSOR

[A]

B415R501.WMF

[C]

[D]

B415R505.WMF

1. Remove the upper cover [A] (2 screws).

2. Remove the paper end sensor bracket [B] (1 screw).

3. Remove the paper feed roller [C] (snap-fit).

4. If removing the friction pad [D], do so at this time.

B415-5

Options

[B]

PAPER SIZE SENSOR BOARD

10 August, 2001

3.2 PAPER SIZE SENSOR BOARD

[B]

[A]

[C]

B415R502.WMF

[H]

[F]

[G]

[D]

[E]

B415R503.WMF

1. Remove the rear cover [A] (2 screws).

2. Remove the by-pass tray [B] (1 connector, 2 release levers [C]).

3. Remove the lever [D] (1 snap ring, 1 pin).

4. While pushing the release lever [E], remove the paper tray [F].

5. Remove the by-pass width sensor [G].

NOTE: When installing the by-pass width sensor [G], move the side fence inward

all the way so that the seal on the side face gear faces the surface with the

seal [H] on the by-pass width sensor.

B415-6

10 August, 2001

PAPER FEED CLUTCH

3.3 PAPER FEED CLUTCH

[D]

[B]

[A]

B415R504.WMF

[C]

1. Remove the rear cover [A] (2 screws).

2. Remove the spring.

3. Remove the drive gear and drive gear bracket [B] (1 E-ring, 1 spring).

4. Remove the paper feed clutch bracket [C] (2 screws).

Options

5. Remove the paper feed clutch [D] (1 connector).

B415-7

You might also like

- Reach and ICAS Sample Questions Writing Persuasive Paper IDocument6 pagesReach and ICAS Sample Questions Writing Persuasive Paper IGreta Lo100% (1)

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0From EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Rating: 5 out of 5 stars5/5 (1)

- 13 - Copes-Vulcan ValvesDocument7 pages13 - Copes-Vulcan ValvesshalegpNo ratings yet

- Code of Safe Working Practices for Merchant Seafarers: Consolidated edition (incorporating amendments 1-6)From EverandCode of Safe Working Practices for Merchant Seafarers: Consolidated edition (incorporating amendments 1-6)No ratings yet

- Ricoh Mp2500 - PartsDocument105 pagesRicoh Mp2500 - PartsEdon SurfistNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Parts Catalog: Allison TransmissionDocument24 pagesParts Catalog: Allison TransmissionZafiro Feliz GalanNo ratings yet

- Guidelines For The Development and Validation of Spreadsheets PDFDocument21 pagesGuidelines For The Development and Validation of Spreadsheets PDFraj kumar chaudharyNo ratings yet

- Truck ABSDocument1 pageTruck ABSRowan Cornelius0% (3)

- 1-Bin Tray Unit: (Machine Code: A898)Document6 pages1-Bin Tray Unit: (Machine Code: A898)Cristian BobaruNo ratings yet

- Duplex: (Machine Code: A896)Document12 pagesDuplex: (Machine Code: A896)Cristian BobaruNo ratings yet

- Bridge Unit: (Machine Code: A897)Document9 pagesBridge Unit: (Machine Code: A897)Cristian BobaruNo ratings yet

- Interchange Unit: (Machine Code: B300)Document6 pagesInterchange Unit: (Machine Code: B300)Cristian BobaruNo ratings yet

- Paper Tray Unit: (Machine Code: A860)Document22 pagesPaper Tray Unit: (Machine Code: A860)Cristian BobaruNo ratings yet

- 4560SMDocument369 pages4560SMCristian BobaruNo ratings yet

- Manual Servicio Ricoh Fenix 4527-4127-4027-5035-5135-5535 PDFDocument368 pagesManual Servicio Ricoh Fenix 4527-4127-4027-5035-5135-5535 PDFDockmax CopierNo ratings yet

- En Handout FS6030 1.0 PDFDocument76 pagesEn Handout FS6030 1.0 PDFDanis WaraNo ratings yet

- Toshiba 2060 2860 2870 Manual de ReparacionDocument280 pagesToshiba 2060 2860 2870 Manual de Reparacion1cisco1No ratings yet

- Toshiba 2060 Service ManualDocument280 pagesToshiba 2060 Service ManualAnonymous egTruyVdxvNo ratings yet

- Auto Reverse Document Feeder (B386) : Machine CodeDocument26 pagesAuto Reverse Document Feeder (B386) : Machine CodeCristian BobaruNo ratings yet

- A3/11"x17" Tray Unit Type 850/2105 (B331)Document10 pagesA3/11"x17" Tray Unit Type 850/2105 (B331)Amer RafiqueNo ratings yet

- Ricoh FT 4215 A128 Service ManualDocument45 pagesRicoh FT 4215 A128 Service ManualJaime Rios100% (1)

- Paper Tray Unit: (Machine Code: B385)Document17 pagesPaper Tray Unit: (Machine Code: B385)Cristian BobaruNo ratings yet

- FT4015 (A219) Service ManualDocument262 pagesFT4015 (A219) Service ManualRaúl Lerma VallesNo ratings yet

- SM Sharp AR-M 280Document40 pagesSM Sharp AR-M 280RostocanieNo ratings yet

- Service Manual - Brother - DCP 7030 - Parts GuideDocument37 pagesService Manual - Brother - DCP 7030 - Parts Guidexpglobal100% (1)

- Toshiba Copier 3560-3570 Parts & ServiceDocument122 pagesToshiba Copier 3560-3570 Parts & ServiceRamón Colón100% (1)

- A161/A162 COPIER Service ManualDocument9 pagesA161/A162 COPIER Service Manualصابر الصابرNo ratings yet

- Ftp-628 Mcl101/103, Easy Loading Method: Battery Drive, Ftp-608 Series 2" HDocument6 pagesFtp-628 Mcl101/103, Easy Loading Method: Battery Drive, Ftp-608 Series 2" HanilmentNo ratings yet

- Auto Reverse Document Feeder: (Machine Code: B379)Document30 pagesAuto Reverse Document Feeder: (Machine Code: B379)Cristian BobaruNo ratings yet

- Spring Push Pneumatic Push: Standard Series Standard Series DP/S DP/P Dimensions (MM)Document2 pagesSpring Push Pneumatic Push: Standard Series Standard Series DP/S DP/P Dimensions (MM)Arturo Garza SantosNo ratings yet

- MX-LC13 Service ManualDocument43 pagesMX-LC13 Service ManualDoicho AndonovNo ratings yet

- CHM-18XX Service Manual RevA 2Document30 pagesCHM-18XX Service Manual RevA 2stereojos86No ratings yet

- Pioneer Deh 3100r Deh 3130rDocument69 pagesPioneer Deh 3100r Deh 3130revagualdaNo ratings yet

- Cassete AcDocument28 pagesCassete Acmohan238No ratings yet

- Parts Reference List MODEL: FAX4750 / FAX5750 MFC8300 / MFC8600 /MFC8700Document27 pagesParts Reference List MODEL: FAX4750 / FAX5750 MFC8300 / MFC8600 /MFC8700yankeeguy2No ratings yet

- Machine Code: A862Document20 pagesMachine Code: A862Cristian BobaruNo ratings yet

- SHARP-AR-5316 Service ManualDocument19 pagesSHARP-AR-5316 Service Manualchrisban35100% (4)

- CTS-30C Operation ManualDocument62 pagesCTS-30C Operation ManualOussama KhelilNo ratings yet

- Service Manual: Digital Copier Option Staple SorterDocument5 pagesService Manual: Digital Copier Option Staple SorterromanggNo ratings yet

- Venus C1a/C1b (B132/B181/B200) : Parts CatalogDocument280 pagesVenus C1a/C1b (B132/B181/B200) : Parts Catalogadryan90000No ratings yet

- Shift Tray Unit: (Machine Code: B313)Document8 pagesShift Tray Unit: (Machine Code: B313)Cristian BobaruNo ratings yet

- ProductSupportGuide A2238CDocument20 pagesProductSupportGuide A2238CRicoh Company LtdNo ratings yet

- Parts Reference List: MODEL: MFC-P2500 / HL-P2500Document27 pagesParts Reference List: MODEL: MFC-P2500 / HL-P2500zdjulicgmailcomNo ratings yet

- DCP 8080dn, DCP 8085dn, MFC 8480dn, MFC 8680dn, MFC 8880dn, MFC 8890dw PL H 1Document39 pagesDCP 8080dn, DCP 8085dn, MFC 8480dn, MFC 8680dn, MFC 8880dn, MFC 8890dw PL H 1DuplessisNo ratings yet

- Despiece MP2000 PDFDocument83 pagesDespiece MP2000 PDFAnonymous UHcbrUNo ratings yet

- Thermal Printer Head ftp-642mcl001Document7 pagesThermal Printer Head ftp-642mcl001Sveto SlNo ratings yet

- IBM Infoprint 6700 - PartsDocument14 pagesIBM Infoprint 6700 - PartsJonathan LongNo ratings yet

- BRT - DCP7045 DCP7030 DCP7032 DCP7040 DCP7045N MFC7320 MFC7340 MFC7345N MFC7440N MFC7450 MFC7840N MFC7840WDocument37 pagesBRT - DCP7045 DCP7030 DCP7032 DCP7040 DCP7045N MFC7320 MFC7340 MFC7345N MFC7440N MFC7450 MFC7840N MFC7840WOFBA srlNo ratings yet

- Products Electronic IndustryDocument19 pagesProducts Electronic IndustrygiorgiokNo ratings yet

- 11-0207 - Metering Application Guide Rev 6Document10 pages11-0207 - Metering Application Guide Rev 6perijoyNo ratings yet

- Sharp AR-5316 - 5320 - SMDocument19 pagesSharp AR-5316 - 5320 - SMNegru MihaiNo ratings yet

- PL DCP7030 DCP7040 MFC7440N MFC7840W Eng PDFDocument37 pagesPL DCP7030 DCP7040 MFC7440N MFC7840W Eng PDFRolando Alvarez UtrillaNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7From EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7No ratings yet

- Programmable Logic Controllers: A Practical Approach to IEC 61131-3 using CoDeSysFrom EverandProgrammable Logic Controllers: A Practical Approach to IEC 61131-3 using CoDeSysNo ratings yet

- Duplicator JP730 JP735Document174 pagesDuplicator JP730 JP735Cristian BobaruNo ratings yet

- 4045 PDFDocument195 pages4045 PDFCristian BobaruNo ratings yet

- L - AcuLaser C4100-C4000 - SM - 1003 PDFDocument650 pagesL - AcuLaser C4100-C4000 - SM - 1003 PDFCristian BobaruNo ratings yet

- Toshiba E-Studio 160 200 250 Dp-1600 2000 2500 PCDocument194 pagesToshiba E-Studio 160 200 250 Dp-1600 2000 2500 PCmboroncoiNo ratings yet

- Parts Guide Sharp MX-M 202-232D PDFDocument86 pagesParts Guide Sharp MX-M 202-232D PDFCristian Bobaru100% (2)

- 7013-XXX SM PDFDocument250 pages7013-XXX SM PDFCristian BobaruNo ratings yet

- WCP 123 - 128Document713 pagesWCP 123 - 128Razvan StroieNo ratings yet

- Quick Scan Features Setup Guide: Xerox Workcentre 5222/5225/5230Document14 pagesQuick Scan Features Setup Guide: Xerox Workcentre 5222/5225/5230Cristian BobaruNo ratings yet

- IG DrafStation RJ90x Rev. 1.1 PDFDocument29 pagesIG DrafStation RJ90x Rev. 1.1 PDFCristian BobaruNo ratings yet

- Xerox7142 Profiles OverviewDocument1 pageXerox7142 Profiles OverviewCristian BobaruNo ratings yet

- Exploded Views DrafStation PDFDocument12 pagesExploded Views DrafStation PDFCristian BobaruNo ratings yet

- 06/13/2007 5-1 Xerox 7142 Wide Format Printer Parts ListDocument33 pages06/13/2007 5-1 Xerox 7142 Wide Format Printer Parts ListCristian BobaruNo ratings yet

- wc7835 Sistem Administation PDFDocument258 pageswc7835 Sistem Administation PDFCristian BobaruNo ratings yet

- 701P46713 7142 Service Manual PDFDocument343 pages701P46713 7142 Service Manual PDFCristian BobaruNo ratings yet

- Burners For Pyrolysis FurnacesDocument7 pagesBurners For Pyrolysis FurnacesAleem QureshiNo ratings yet

- SyllabusDocument20 pagesSyllabusDewa SumartaNo ratings yet

- Daihatsu Sirion Model m300 Series Service Manual No9890 Door Lock Theft DeterrentDocument42 pagesDaihatsu Sirion Model m300 Series Service Manual No9890 Door Lock Theft DeterrentMarx RedzNo ratings yet

- Coatron M1 08-0544Document2 pagesCoatron M1 08-0544Moataz AlhammadiNo ratings yet

- CRM 7.0 Campaign AutomationDocument13 pagesCRM 7.0 Campaign AutomationImran AhmadNo ratings yet

- Tme 601Document14 pagesTme 601dearsaswatNo ratings yet

- Economic Dispatch - OPFDocument1 pageEconomic Dispatch - OPFAlok AgrawalNo ratings yet

- NSA Measurement MethodDocument7 pagesNSA Measurement MethodkshemantNo ratings yet

- Innomed Medical Inc. CA360-B ECG Board Replacement: Cardio-Aid 360-B DefibrillatorDocument5 pagesInnomed Medical Inc. CA360-B ECG Board Replacement: Cardio-Aid 360-B DefibrillatorEngy RamadanNo ratings yet

- RCDC Getting StartedDocument13 pagesRCDC Getting StartedEr Suresh Kumar100% (2)

- Novavox x100p Se Installation GuideDocument51 pagesNovavox x100p Se Installation GuidegregoryalussierNo ratings yet

- ASME A17.1 Elevator RecallDocument6 pagesASME A17.1 Elevator Recalltushar1128No ratings yet

- Finals - Bravo (BSMT 31-b1) Nav 5 313l3Document23 pagesFinals - Bravo (BSMT 31-b1) Nav 5 313l3Christian Felix Guevarra100% (1)

- Informe Inspc JLG MastilDocument1 pageInforme Inspc JLG Mastilanmec20No ratings yet

- Man-0520 R01Document134 pagesMan-0520 R01pelao1974No ratings yet

- IP Address Lab AnswersDocument3 pagesIP Address Lab Answersabdel2121No ratings yet

- An Analitical Approach To Demand-Capacity Method: M B Sonawane, S K Dubey, DR S V DeodharDocument7 pagesAn Analitical Approach To Demand-Capacity Method: M B Sonawane, S K Dubey, DR S V DeodharALINo ratings yet

- The Motherboard Reference TermsDocument6 pagesThe Motherboard Reference TermsMax PowerNo ratings yet

- Underhung Chlst-Sa 9616Document2 pagesUnderhung Chlst-Sa 9616Kiran Reddy100% (2)

- 14 References PDFDocument23 pages14 References PDFAgim KarajNo ratings yet

- Operation Manual: Metal-Clad SwitchgearDocument36 pagesOperation Manual: Metal-Clad Switchgearceti7No ratings yet

- Reference Calculation Output Design of Staircases:: Figure 9-1Document26 pagesReference Calculation Output Design of Staircases:: Figure 9-1kanishkaNo ratings yet

- Remote Control of ESPDocument7 pagesRemote Control of ESPM.IBRAHEEMNo ratings yet

- NDT Test Report NTP PDFDocument6 pagesNDT Test Report NTP PDFwawan kusnandar100% (1)

- Cognitive Frameworks: Learning GoalsDocument8 pagesCognitive Frameworks: Learning GoalshhumasNo ratings yet

- Ten3 PDFDocument3 pagesTen3 PDFDan TranNo ratings yet