Professional Documents

Culture Documents

3.-Recycle of Wastewater From Lead-Zinc Sulfide Ore

3.-Recycle of Wastewater From Lead-Zinc Sulfide Ore

Uploaded by

JorgeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3.-Recycle of Wastewater From Lead-Zinc Sulfide Ore

3.-Recycle of Wastewater From Lead-Zinc Sulfide Ore

Uploaded by

JorgeCopyright:

Available Formats

Journal of Environmental Protection, 2013, 4, 5-9

doi:10.4236/jep.2013.41b002 Published Online January 2013 (http://www.SciRP.org/journal/jep)

Recycle of Wastewater from Lead-Zinc Sulfide Ore

Flotation Process by Ozone/BAC Techonlogy

Liu Xingyu1, Chen Bowei1, Li Wenjuan1, Song Yongsheng1, Wen Jiankang1, Wang Dianzuo2

1

National Engineering Laboratory of Biohydrometallurgy, General Research Institute for Nonferrous Metals, Beijing, China;

General Research Institute for Nonferrous Metals, Beijing, China.

Email: wellwoodliu@gmail.com

2

Received 2013

ABSTRACT

Lead-zinc sulphide ore contains lead sulphide (galena), and zinc sulphide (sphalerite). In the first flotation stage, galena

is rendered hydrophobic with an organic collector such as xanthate, while sphalerite is kept from floating by depressants,

and in the second flotation stage, activator was used to activated zinc flotation. Since the organic regent used are different in the two flotation stage, wastewater from the second zinc flotation stage cant be directly recycled to the first lead

flotation stage. Wastewater from flotation process for concentrating lead-zinc sulphide ore often containing organic

compounds such as diethyldithiocarbamate(DDTC), xanthate, terpenic oil(2# oil) and thionocarbamate esters (Z-200),

are environmentally hazardous. Their removal from contaminated water and the reuse of the water is one of the main

challenges facing lead-zinc sulphide ore processing plants. In this study, synthetic wastewater containing DDTC, xanthate, 2# oil and Z-200 at concentrations ranging from 21 to 42 mg/L was fed into an Ozone/Biological activated carbon

(BAC) reactor. Analyses of the effluent indicated a chemical oxygen demand (COD) removal over 86.21% and Total

organic carbon (TOC) removal over 90.00% were achieved under Hydraulic retention time (HRT) of 4h and O3 feeding

concentration of 33.3 mg/L. The effluent was further recycled to the lab scale lead concentrating process and no significant difference was found in compare with fresh water. Furthermore, lead-zinc sulphide mineral concentrating process

was carried out at lab scale. The produced wastewater was treated by Ozone/BAC reactor at O3 feeding concentration of

16.7 mg/L and HRT of 4h. The effluent analysis showed that TOC removal was 74.58%. This effluent was recycled to

the lab scale lead-zinc sulphide mineral concentrating process and the recovery of lead was not affected. The results

showed that by using Ozone/BAC technology, the lead-zinc sulphide mineral processing wastewater could be recycled.

Keywords: Lead-Zinc Sulphide Ore; Ozone/BAC; Flotation Wastewater; Recycle

1. Introduction

Flotation is in fact the most common process in metallic

mineral separation and is the main way for recovering

valuable metals as lead (Pb) and zinc (Zn) (Barbaro,

2000). For Lead-zinc sulphide ore, the most widely used

method is that of two stage selective flotation, where the

zinc and iron minerals are depressed, allowing the galena

to float, followed by the activation of the zinc minerals in

the lead tailings to allow a zinc float (Wills and NapierMunn, 2005; Kinal et al., 2009). Wastewater from flotation

process for concentrating lead-zinc sulphide ore often

containing organic compounds such as DDTC, xanthate,

2# oil and Z-200, are environmentally hazardous. Since

the organic regent used are different in the two flotation

stage, wastewater from the second zinc flotation stage

cant be directly recycled to the first lead flotation stage.

Thus such organic regents removal from contaminated

water and the reuse of the water is one of the main

Copyright 2013 SciRes.

challenges facing lead-zinc sulphide ore processing plants.

Ozonation of water is a well-known technology and

the strong oxidative properties of ozone have been well

documented (Glaze et al., 1987). Ozone alone has the

ability to generate hydroxyl radicals (OH) when applied

to wastewater due to side reactions with electron-rich

moieties, such as amines, phenols, and alkoxylated

aromatics (Nothe et al., 2009; Pocostales et al. 2010). In

this way, the aromatic or hydrophobic organic compounds

can be converted to more hydrophilic, biodegradable

organic compounds, such as aldehydes, carboxylic acids,

ketones and other organic acids (Huang et al., 2005;

Hammes et al., 2006). With respect to oxidation byproducts,

recent studies suggest that post-ozone biological filtration (BAC) is sufficient to eliminate the toxicity that has

been attributed to ozonation of effluent organic matter

(EfOM) (Chiang et al., 2002; Xu et al., 2007; Stalter et al.,

2010). Since Oone/BAC technology has many advantages

such as low cost, high efficiency, short HRT, it might be

JEP

Recycle of Wastewater from Lead-Zinc Sulfide Ore Flotation Process by Ozone/BAC Techonlogy

a suitable treatment for wastewater effluent from leadzinc sulphide ore flotation.

The purpose of this study was to determine whether

ozone/BAC technology could be applied in lead-zinc

sulphide ore flotation wastewater treatment. That include

investigate the characteristics of degradation/conversion

of organic regents used in lead-zinc flotation process in

ozone/BAC process and whether the treated water could

be reused back to lead circuit. The following sections

summarize the methodology and results from synthetic

flotation wastewater and real lab produced flotation

wastewater treatment over the course of five months of

continuous operation and the evaluation of recycle of the

treated water.

2. Materials and Methods

2.1. Synthetic Wastewater and Real Lab

Produced Wastewater

Synthetic wastewater and real lab produced wastewater

were fed into ozonation and BAC treatment system, respectively. Synthetic wastewater composed of DDTC,

xanthate, 2# oil and Z-200, with concentration adjusted

to concentrations ranging from 21 to 42 mg/L. The above

regents were provided by Chehe lead-zinc mining Crop.

(Guanxi, China). The lead-zinc sulphide ore used in this

research were provided by Zhangbeizhuan lead-zinc mine

(Heibei, China). Table 1 were the chemical composition

of the two Zhangbeizhuan lead-zinc sulphide ore samples

used in this research. The lab produced wastewater was

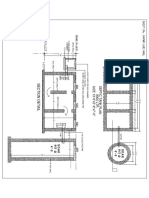

from lab scale Zhangbeizhuan lead-zinc sulphide ore flotation process via a flow sheet showed in Figure 1.

Table 1. Chemical composition of the two Zhanbeizhuan leadzinc sulphide ore samples used in this research.

Composition (%)

Elements

Sample A

Sample B

Cu

0.071

Pb

3.47

2.86

Zn

1.87

2.01

Fe

9.41

Cd

0.014

Ca

0.29

Mg

0.46

As

1.87

Al2O3

10.03

SiO2

57.88

Ag/g/t

93.5

Au/g/t

0.4

Mo

0.001

0.98

Figure 1. Flow sheet of the Zhangbeizhuan lead-zinc sulphide ore flotation process (time used were minute, concentration showed

were mg/l).

Copyright 2013 SciRes.

JEP

Recycle of Wastewater from Lead-Zinc Sulfide Ore Flotation Process by Ozone/BAC Techonlogy

2.2. Reactor Set-Up and Reuse of the Treated

Wastewater

Ozone was generated from oxygen by means of a PLASMA

ozone generator with maximum capacity of 20 mg/min.

The ozone reaction chamber is a 10 20 20 (cm) rectangular plexiglas tank and had working volume of 2 L.

There was a cover on the top of the tank that prevented the

volatilization of ozone. The tank was fitted at the bottom

with a stone diffuser connected to the ozone generator.

Because of this configuration, ozone concentration in the

gas phase could not be independently adjusted and the

dose of ozone was controlled by changing the gas flow

rate. Effluent was drawn from a port at 10 cm above the

base and entered another similar plexiglas tank filled with

activated carbon for BAC treatment. During the start-up

stage, activated sludge were inoculated in to the BAC

reactor which would allow the growth of bacteria on the

surface of the activated carbon.

During the whole experiments, the HRT of ozone reactor and BAC reactor were maintained at 2 h, 2 h respecttively. The reuse of the treated water to the lead flotation

circuit was conducted via a flow sheet showed in Figure

2.

2.3. Analytical Methods

TOC was measured with a TOC analyzer (SHIMADZU,

TOC-5000). COD were determined by the standard photo-

metric method (DWAF, 1992) using the Spectroquant

Nova 60 Photometer supplied by Merck NT PTY Ltd.

Samples for COD analyses were digested with Merck

Thermo reactor Model TR 300 and then analysed by the

Merck Nova 60 photometer.

3. Results and Discussion

3.1. Ozone/BAC Reactor Performance Treating

Synthetic Wastewater

Synthetic wastewater composed of DDTC, xanthate, 2# oil

and Z-200, with concentration adjusted to 42 mg/l, 28

mg/l, 21 mg/l and 21 mg/l respectively was feeding into the

ozone/BAC reactor. As mentioned before, the HRT was

maintained at 4 h. Different ozone feeding concentration

was applied to the ozone reactor. Under each feeding concentration, the reactor was operated for one week, and

then the influent and effluent were sampled for TOC and

COD analysis. Table 2 showed TOC and COD removal of

the Ozone/BAC reactor treating synthetic wastewater

under different feeding ozone concentration. Ozone feeding

concentration could significantly affect the TOC and COD

removal, at relative low feeding concentration of 13.2 mg/L,

the TOC removal were only 58.33% while at ozone feeding concentration of 33.3 mg/L, the TOC removal exceeded 90%. There is very strong correlation of TOC and

COD concentration according to the four organic regents

which added into the synthetic wastewater (Table 2).

Figure 2. Flow sheet of the lead flotation circuit which use the treated wastewater, untreated wastewater and fresh water.

Table 2. TOC and COD removal of the Ozone/BAC reactor treating synthetic wastewater.

Ozone concentration

(mg/L)

Influent TOC

(mg/L)

Effluent TOC

(mg/L)

TOC removal

(%)

Influent COD

(mg/L)

Effluent COD

(mg/L)

COD removal

(%)

13.3

18

7.5

58.33

85

42

50.59

16.7

18

5.4

70

87

50

42.53

22.2

18

1.8

90

116

16

86.21

33.3

18

1.8

90

98

12

87.76

66.6

18

82

22

73.17

Copyright 2013 SciRes.

JEP

Recycle of Wastewater from Lead-Zinc Sulfide Ore Flotation Process by Ozone/BAC Techonlogy

3.2. Reuse of the Treated Synthetic Wastewater

to the Lead Circuit

3.4. Reuse of the Treated Real Flotation

Wastewater to the Lead Circuit

Under the ozone feeding concentration of 33.3 mg/L, 10 L

effluent was collected and recycled to the lead circuit.

Zhangbeizhuang ore sample A was used for this part of

work. Table 3 showed the comparison of lead recovery

in the lead circuit using treated synthetic wastewater and

fresh water. Compared with fresh water, by using the treated

synthetic wastewater, the production rate was increased

from 10.31% to 11.81% while the lead grade in the lead

concentrate was decreased from 29.92% to 26.30%, thus

the lead recovery has no significant change(treated synthetic wastewater: 88.95%, fresh water: 88.89%). By

using the treated synthetic wastewater, zinc grade have

no significant change but the zinc recovery increased

from 15.5 to 18.61%, which indicate that using treated

synthetic wastewater, small amount of zinc may entering

lead circuit. This effect is now under further investigation.

Under the ozone feeding concentration of 16.7 mg/L, 10

L treated lab produced wastewater effluent was collected.

Together with another 10 L untreated lab produced wastewater and fresh water were applied to the lead flotation

process respectively. Zhangbeizhuang ore sample B was

used for this part of work. Table 5 showed the compareson of lead recovery in the lead circuit using treated real

lab produced wastewater, untreated real lab produced

wastewater and fresh water. Compared with fresh water,

by using the untreated lab produced wastewater, the

production rate was increased from 10.10% to 15.35%,

the lead recovery increased from 83.40% to 87.83%, and

the lead grade in the lead concentrate was significantly

decreased from 23.57% to 16.71%. Meanwhile, the zinc

grade in the lead concentrate increased from 2.62% to

8.84% and the zinc recovery in the lead concentrate increased from 12.05% to 65.34%. The above results indicated that directly recycle of zinc flotation wastewater to

the lead circuit may have negative effect on lead flotation,

large amount of zinc will entering lead circuit. When the

treated lab produced wastewater was used, all the indices

were nearly similar if compared with fresh water (Table

5). This indicated that by using ozone/BAC technology,

the treated flotation wastewater could recycle to lead

circuit, and the lead flotation was not affected.

3.3. Ozone/BAC Reactor Performance Treating

Real Lab Produced Wastewater

Lab scale Zhangbeizhuang ore sample B flotation was

carried out for the production of real lab flotation wastewater. Table 4 showed TOC removal of the Ozone/BAC

reactor treating real lab produced flotation wastewater

under different ozone feeding concentration. Unlike synthetic wastewater, there is no strong correlation between

ozone feeding concentration and the TOC removal. Under feeding ozone concentration of 16.7 mg/l, the highest

TOC removal of 74.58% was achieved. It is worth to

note that TOC of the lab produced wastewater is lower

than the synthetic wastewater. The removal rate for the

produced wastewater is lower than synthetic wastewater,

this may due to more complex organic within the produced wastewater.

4. Conclusions

This study investigates the performance of ozone/BAC

treatment processes for synthetic lead-zinc flotation wastewater and real lab produced lead-zinc flotation wastewater, and evaluates the reuse of treated water back to lead

circuit. The conclusions obtained from this study are as

follows:

Table 3. Comparison of lead recovery in the lead circuit using treated synthetic wastewater and fresh water.

Production rate (%)

Lead grade(%)

Zinc grade (%)

Lead recovery(%)

Zinc recovery(%)

A*

B*

A*

B*

A*

B*

A*

B*

A*

B*

Lead concentrate

11.87

10.31

26.3

29.92

2.87

2.84

89

88.89

18.6

15.5

Tailing

88.13

89.69

0.44

0.43

1.69

1.78

11.1

11.11

81.4

84.5

Raw ore

100

100

3.51

3.47

1.83

1.9

100

100

100

100

A: treated synthetic wastewater; B: fresh water.

Table 4. TOC removal of the Ozone/BAC reactor treating real lab produced flotation wastewater.

Ozone concentration (mg/l)

Influent TOC (mg/l)

Effluent TOC (mg/l)

TOC removal (%)

13.3

14.4

5.06

64.86

16.7

14.4

3.66

74.58

22.2

14.4

4.04

71.94

33.3

14.4

5.31

63.13

66.6

14.4

6.49

54.93

Copyright 2013 SciRes.

JEP

Recycle of Wastewater from Lead-Zinc Sulfide Ore Flotation Process by Ozone/BAC Techonlogy

Table 5. Comparison of lead recovery in the lead circuit using treated lab produced wastewater, untreated lab produced

wastewater and fresh water.

Raw ore

Lead concentrate

Tailing

A*

B*

C*

A*

B*

C*

A*

B*

C*

Production rate (%)

100

100

100

9.66

15.35

10.1

90.34

84.65

89.9

Lead grade (%)

2.75

2.92

2.85

23.69

16.71

23.57

0.51

0.42

0.53

Zinc grade (%)

1.98

2.08

1.99

2.73

8.84

2.62

1.9

0.85

1.92

Lead recovery (%)

100

100

100

82.4

87.83

83.4

17.6

12.17

16.6

100

100

100

12.9

65.34

12.05

87.09

34.66

87.95

Zinc recovery (%)

*

A: treated lab produced wastewater; B: untreated lab produced wastewater; *C: fresh water.

a) By using ozone/BAC reactor, under HRT of 4h and

O3 feeding concentration of 33.3 mg/L, synthetic wastewater composed of DDTC, xanthate, 2# oil and Z-200

could be effectively treated, the COD removal over 86.21%

and TOC removal over 90.00%. The reuse of synthetic

wastewater to lead circuit has no significant difference in

compare with fresh water.

b) Directly reuse of lab produced flotation wastewater

to the lead circuit has negative effect on lead flotation. By

using ozone/BAC reactor, under HRT of 4h and feeding

ozone concentration of 16.7 mg/l, the highest TOC removal of 74.58% was achieved when treating lab produced flotation wastewater. The treated wastewater could

recycle to lead circuit, and the lead flotation was not affected.

c) The above results showed that by using Ozone/BAC

technology, the lead-zinc sulphide mineral processing

wastewater could be recycled.

[4]

Glaze, W.H., Kang, J.-W. and Chapin, D.H., 1987. The

Chemistry of Water Treatment Processes Involving

Ozone, Hydrogen Peroxide and Ultraviolet Radiation.

Ozone: Science & Engineering 9(4), 335-352.

[5]

Nothe, T., Fahlenkamp, H. and Sonntag, C.v., 2009.

Ozonation of Wastewater: Rate of Ozone Consumption

and Hydroxyl Radical Yield. Environmental Science &

Technology 43(15), 5990-5995.

[6]

Pocostales, J.P., Sein, M.M., Knolle, W., von Sonntag, C.

and

Schmidt,

T.C.,

2010.

Degradation

of

Ozone-Refractory Organic Phosphates in Wastewater by

Ozone and Ozone/Hydrogen Peroxide (Peroxone): The

Role of Ozone Consumption by Dissolved Organic Matter. Environmental Science & Technology 44(21),

8248-8253.

[7]

Huang, W.-J., Fang, G.-C. and Wang, C.-C., 2005. The

determination and fate of disinfection by-products from

ozonation of polluted raw water. Science of The Total

Environment 345(13), 261-272.

[8]

Hammes, F., Salhi, E., Kster, O., Kaiser, H.-P., Egli, T.

and von Gunten, U., 2006. Mechanistic and kinetic evaluation of organic disinfection by-product and assimilable

organic carbon (AOC) formation during the ozonation of

drinking water. Water Research 40(12), 2275-2286.

[9]

Chiang, P.C., Chang, E.E. and Liang, C.H., 2002. NOM

characteristics and treatabilities of ozonation processes.

Chemosphere 46(6), 929-936.

5. Acknowledgements

This work was financially supported by National Science

and technology support program of China (2009BAB45B01).

REFERENCES

[1]

Barbaro, M., 2000. Encyclopedia of Separation Science.

Editor-in-Chief: Ian, D.W. (ed), pp. 3215-3218, Academic Press, Oxford.

[2]

Wills, B.A. and Napier-Munn, T., 2005. Wills' Mineral

Processing Technology (Seventh Edition), pp. 267-352,

Butterworth-Heinemann, Oxford.

[3]

Kinal, J., Greet, C. and Goode, I., 2009. Effect of grinding media on zinc depression in a lead cleaner circuit.

Minerals Engineering 22(910), 759-765.

Copyright 2013 SciRes.

[10] Xu, B., Gao, N.-Y., Sun, X.-F., Xia, S.-J., Simonnot,

M.-O., Causserand, C., Rui, M. and Wu, H.-H., 2007.

Characteristics of organic material in Huangpu River and

treatability with the O3-BAC process. Separation and Purification Technology 57(2), 348-355.

[11] Stalter, D., Magdeburg, A. and Oehlmann, J., 2010.

Comparative toxicity assessment of ozone and activated

carbon treated sewage effluents using an in vivo test battery. Water Research 44(8), 2610-2620.

[12] DWAF, 1992. Analytical Methods Manual,, Department

of Water Affairs & Forestry, Pretoria

JEP

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Sanitation Code - Chapter 17 Revised IRRDocument32 pagesSanitation Code - Chapter 17 Revised IRRBoni MagtibayNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Abu Dhabi Storm Water Design CriteriaDocument19 pagesAbu Dhabi Storm Water Design CriteriaonspsnonsNo ratings yet

- Liu 2009Document6 pagesLiu 2009JorgeNo ratings yet

- Manual Dow PDFDocument181 pagesManual Dow PDFJorgeNo ratings yet

- Carbon Activado HAC Equivale Calgon F-200Document2 pagesCarbon Activado HAC Equivale Calgon F-200JorgeNo ratings yet

- Concentrador de OxigenoDocument2 pagesConcentrador de OxigenoJorge50% (2)

- Grundfos CR1 Pump User ManualDocument84 pagesGrundfos CR1 Pump User ManualSmital50% (2)

- County of Monterey and Mcwra Reply Brief A.12!04!019Document6 pagesCounty of Monterey and Mcwra Reply Brief A.12!04!019L. A. PatersonNo ratings yet

- Class 10 Water Resources Question BankDocument11 pagesClass 10 Water Resources Question BankHarean RakkshadNo ratings yet

- Wastewater Treatment Notes PDFDocument45 pagesWastewater Treatment Notes PDFmykaren1No ratings yet

- Iowa DNR May 22nd, 2024 Litigation ReportDocument5 pagesIowa DNR May 22nd, 2024 Litigation ReportA.W. CarrosNo ratings yet

- Septic Tank DetailDocument1 pageSeptic Tank DetailVishnu PrajapatiNo ratings yet

- SLS 745 2004 Part 2Document46 pagesSLS 745 2004 Part 2Nidas SameeraNo ratings yet

- Water Efficiency Technology Fact Sheet: Incinerating ToiletsDocument5 pagesWater Efficiency Technology Fact Sheet: Incinerating ToiletsMark Johnson San JuanNo ratings yet

- 18CIV59 Syllabus CoverageDocument2 pages18CIV59 Syllabus CoveragePrajwal SuaresNo ratings yet

- Field Performance Analysis and Optimization of Gas Condensate Systems Using Zero-Dimensional Reservoir ModelsDocument2 pagesField Performance Analysis and Optimization of Gas Condensate Systems Using Zero-Dimensional Reservoir ModelsAruna JayamanjulaNo ratings yet

- Assessment of Groundwater Quality in Gorakhpur City For Drinking PurposeDocument8 pagesAssessment of Groundwater Quality in Gorakhpur City For Drinking PurposeIJRASETPublicationsNo ratings yet

- Environmental Eng Assignment CA2 SIT ShreyosiDocument16 pagesEnvironmental Eng Assignment CA2 SIT ShreyosiDebjyoti MitraNo ratings yet

- GG Organics Company ProfileDocument7 pagesGG Organics Company ProfileSeenivasan Kannan MbaNo ratings yet

- Green Ships - Keeping Oceans BlueDocument6 pagesGreen Ships - Keeping Oceans BlueslemaNo ratings yet

- Dimension StoneDocument12 pagesDimension Stoneyrdgcgf5664100% (1)

- Insect Nuisance Associated With Sewage Treatment WorksDocument85 pagesInsect Nuisance Associated With Sewage Treatment WorksAnonymous 0K5XdaNo ratings yet

- Guide To The Preparation of A Working Plan Scrapyard / Elv FacilityDocument6 pagesGuide To The Preparation of A Working Plan Scrapyard / Elv FacilityNebojsa RedzicNo ratings yet

- Biosand Filter Manual: Design, Construction, Installation, Operation and MaintenanceDocument10 pagesBiosand Filter Manual: Design, Construction, Installation, Operation and Maintenancealang_businessNo ratings yet

- Product Safety Information Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument9 pagesProduct Safety Information Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingmicNo ratings yet

- Benthic Macroinvertebrates in Freshwaters - Taxa Tolerance Values, Metrics, and ProtocolsDocument128 pagesBenthic Macroinvertebrates in Freshwaters - Taxa Tolerance Values, Metrics, and Protocolstiago_henrique_3100% (1)

- Module 7 Irrigation StructureDocument20 pagesModule 7 Irrigation StructureSrivvass ReddyNo ratings yet

- Coliforms-Fecal: Usepa A-1 Medium Method 8368 Most Probable Number (MPN) MethodDocument6 pagesColiforms-Fecal: Usepa A-1 Medium Method 8368 Most Probable Number (MPN) MethodSitiKurniaFatimahNo ratings yet

- CH 3 - Environmental Protection ActDocument49 pagesCH 3 - Environmental Protection ActShivani ShahNo ratings yet

- Section17 Road DrainageDocument17 pagesSection17 Road DrainageSyamil Dzulfida0% (1)

- 20.1.4 Other Pollution CIE IGCSE Biology RevisiDocument1 page20.1.4 Other Pollution CIE IGCSE Biology Revisilama tarigNo ratings yet

- Evs ProjectDocument9 pagesEvs ProjectAmit Hadawale80% (45)

- Municipal Waste Management ReportDocument52 pagesMunicipal Waste Management Reportxrisstina100% (3)

- Sewage Treatment Plant, HYSTPN-016Document28 pagesSewage Treatment Plant, HYSTPN-016Avinash NathNo ratings yet

- Purity FG2: Safety Data SheetDocument9 pagesPurity FG2: Safety Data SheetyomarNo ratings yet