Professional Documents

Culture Documents

Shackel PDF Crosby in MM

Shackel PDF Crosby in MM

Uploaded by

kanchanabalajiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shackel PDF Crosby in MM

Shackel PDF Crosby in MM

Uploaded by

kanchanabalajiCopyright:

Available Formats

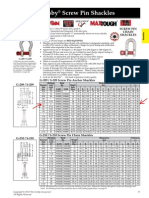

BOLT TYPE

ANCHOR

SHACKLES

G-2130 S-2130

Bolt Type Anchor shackles with thin

head bolt - nut with cotter pin. Meets the

performance requirements of Federal

Specification RR-C-271D Type IVA,

Grade A, Class 3, except for those provisions required of the contractor. For

additional information, see page 391.

s e l k c a h S

G-2130 S-2130

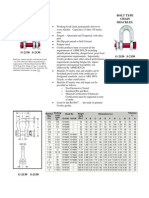

G-2150 S-2150

e p y T

t l o B

Capacities 1/3 thru 150 metric tons.

BOLT TYPE

Working Load Limit permanently shown on every shackle.

CHAIN

Forged Quenched and Tempered, with alloy pins.

SHACKLES

Hot Dip galvanized or Self Colored.

Fatigue rated (1/3t - 55t).

Shackles 25t and larger are RFID EQUIPPED.

Crosby products meet or exceed all requirements of

ASME B30.26 including identification, ductility, design factor, proof load

and temperature requirements. Importantly, Crosby products meet other

critical performance requirements including fatigue life, impact

properties and material traceability, not addressed by ASME B30.26.

Sizes 1/2t-25t meet the performance requirements of EN13889:2003.

Shackles 55 metric tons and smaller can be furnished proof tested with

certificates to designated standards, such as ABS, DNV, Lloyds, or other

G-2150 S-2150

certification when requested at time of order.

Bolt Type Chain shackles. Thin hex head

Shackles 85 metric tons and larger can be provided as follows.

bolt - nut with cotter pin. Meets the

Non Destructive Tested

performance requirements of Federal

Serialized Pin and Bow

Specification RR-C271D Type IVB, Grade

Material Certification (Chemical) Certification must be

A, Class 3, except for those provisions

requested at time of order.

required of the contractors. For

additional information, see page 391.

Look for the Red Pin . . . the mark of genuine Crosby quality.

Type Approval and certification in accordance with ABS 2006 Steel Vessel

Rules 1-1-17.7, and ABS Guide for Certification of Cranes.

y b s o r C

Nominal

Size

(in.)

3/16

1/4

5/16

3/8

7/16

1/2

5/8

3/4

7/8

1

1-1/8

1-1/4

1-3/8

1-1/2

1-3/4

2

2-1/2

3

3-1/2

4

Working

Load

Limit

(t) *

1/3

1/2

3/4

1

1-1/2

2

3-1/4

4-3/4

6-1/2

8-1/2

9-1/2

12

13-1/2

17

25

35

55

85

120

150

SN2130HeaderStock No.

G-2130

1019464

1019466

1019468

1019470

1019471

1019472

1019490

1019515

1019533

1019551

1019579

1019597

1019613

1019631

1019659

1019677

1019695

1019711

1019739

1019757

S-2130

1019481

1019506

1019524

1019542

1019560

1019588

1019604

1019622

1019640

1019668

1019686

1019702

-

Weight

Each

(kg)

.03

.05

.10

.15

.22

.36

.62

1.23

1.79

2.28

3.75

5.31

7.18

8.62

15.4

23.7

44.6

70

120

153

Dimensions

(mm)

A

9.65

11.9

13.5

16.8

19.1

20.6

26.9

31.8

36.6

42.9

46.0

51.5

57.0

60.5

73.0

82.5

105

127

133

140

B

6.35

7.85

9.65

11.2

12.7

16.0

19.1

22.4

25.4

28.7

31.8

35.1

38.1

41.4

51.0

57.0

70.0

82.5

95.5

108

C

22.4

28.7

31.0

36.6

42.9

47.8

60.5

71.5

84.0

95.5

108

119

133

146

178

197

267

330

372

368

D

4.85

6.35

7.85

9.65

11.2

12.7

16.0

19.1

22.4

25.4

28.7

31.8

35.1

38.1

44.5

51.0

66.5

76.0

92.0

104

E

15.2

19.8

21.3

26.2

29.5

33.3

42.9

51.0

58.0

68.5

74.0

82.5

92.0

98.5

127

146

184

200

229

254

F

14.2

15.5

19.1

23.1

26.9

30.2

38.1

46.0

53.0

60.5

68.5

76.0

84.0

92.0

106

122

145

165

203

229

Tolerance

+/H

37.3

46.7

53.0

63.0

74.0

83.5

106

126

148

167

190

210

233

254

313

348

453

546

626

653

L

24.9

32.5

37.3

45.2

51.5

58.5

74.5

89.0

102

119

131

146

162

175

225

253

327

365

419

468

N

4.85

6.35

7.85

9.65

11.2

12.7

17.5

20.6

24.6

26.9

31.8

35.1

38.1

41.1

57.0

61.0

79.5

92.0

105

116

C

1.50

1.50

3.30

3.30

3.30

3.30

6.35

6.35

6.35

6.35

6.35

6.35

6.35

6.35

6.35

6.35

6.35

6.35

6.35

6.35

A

1.50

1.50

1.50

1.50

1.50

1.50

1.50

1.50

1.50

1.50

1.50

1.50

3.30

3.30

3.30

3.30

6.35

6.35

6.35

6.35

Working

Dimensions

Tolerance

Nominal

SN2150HeaderStock No.

Weight

Load

(mm)

+/Size

Each

Limit

G-2150

S-2150

A

B

D

F

G

K

M

P

R

G

A

(in.)

(kg)

(t)*

1/4

1/2

1019768

.06

11.9 7.85 6.35 15.5 19.1 40.4 24.6 39.6 6.35 1.50 1.50

5/16

3/4

1019770

.10

13.5 9.65 7.85 19.1 25.4 48.5 29.5 46.2 7.85 1.50 1.50

3/8

1

1019772

.15

16.8 11.2 9.65 23.1 31.0 58.5 35.8 55.0 9.65 3.30 1.50

7/16

1-1/2

1019774

.22

19.1 12.7 11.2 26.9 36.1 67.5 41.1 63.5 11.2 3.30 1.50

1/2

2

1019775 1019784

.34

20.6 16.0 12.7 30.2 41.4 77.0 46.0 71.0 12.7 3.30 1.50

5/8

3-1/4

1019793 1019800

.67

26.9 19.1 16.0 38.1 51.0 95.5 58.5 89.5 16.0 3.30 1.50

3/4

4-3/4

1019819 1019828

1.14

31.8 22.4 19.1 46.0 60.5 115 70.0 103 20.6 6.35 1.50

7/8

6-1/2

1019837 1019846

1.74

36.6 25.4 22.4 53.0 71.5 135 81.0 120 24.6 6.35 1.50

1

8-1/2

1019855 1019864

2.52

42.9 28.7 25.4 60.5 81.0 151 93.5 135 25.4 6.35 1.50

1-1/8

9-1/2

1019873 1019882

3.45

46.0 31.8 28.7 68.5 91.0 172 103 150 31.8 6.35 1.50

1-1/4

12

1019891 1019908

4.90

51.5 35.1 31.8 76.0 100 191 115 165 35.1 6.35 1.50

1-3/8

13-1/2

1019917 1019926

6.24

57.0 38.1 35.1 84.0 111 210 127 183 38.1 6.35 3.30

1-1/2

17

1019935 1019944

8.39

60.5 41.4 38.1 92.0 122 230 137 196 41.1 6.35 3.30

1-3/4

25

1019953 1019962

14.2

73.0 51.0 44.5 106 146 279 162 230 54.0 6.35 3.30

2

35

1019971 1019980

21.2

82.5 57.0 51.0 122 172 312 184 264 60.0 6.35 3.30

2-1/2

55

1019999 1020004

38.6

105 70.0 66.5 145 203 377 238 344 66.5 6.35 6.35

3

85

1020013

56

127 82.5 76.0 165 216 429 279 419 89.0 6.35 6.35

* NOTE: Maximum Proof Load is 2.0 times the Working Load Limit. Minimum Ultimate Strength is 6 times the Working Load Limit.

For Working Load Limit reduction due to side loading applications, see page 74.

Individually Proof Tested with certification.

Furnished in Anchor style only and furnished with Round Head Bolts with welded handles.

Copyright 2008 The Crosby Group, Inc.

All Rights Reserved

67

Shackles

Crosby Bolt Type Shackles

You might also like

- Field Welding Procedures Manual - Contractor VersionDocument102 pagesField Welding Procedures Manual - Contractor Versionlaz_k100% (2)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Catalogue - Crosby G-2130 Bolt Type Shackle PDFDocument1 pageCatalogue - Crosby G-2130 Bolt Type Shackle PDFAnindya SaputraNo ratings yet

- Bolt Type Anchor Shackles Bolt Type Chain ShacklesDocument1 pageBolt Type Anchor Shackles Bolt Type Chain ShacklesMikiNo ratings yet

- Crosby Bolt-Type Shackles: Bolt Type Anchor Shackle G-2130 S-2130 Bolt Type Chain Shackle G-2150 S-2150Document2 pagesCrosby Bolt-Type Shackles: Bolt Type Anchor Shackle G-2130 S-2130 Bolt Type Chain Shackle G-2150 S-2150gdgfdNo ratings yet

- Screw Pin Anchor ShacklesDocument1 pageScrew Pin Anchor Shacklesnikka2012No ratings yet

- Screw Pin Anchor Shackles Screw Pin Chain ShacklesDocument1 pageScrew Pin Anchor Shackles Screw Pin Chain ShacklesJulius HendraNo ratings yet

- CrosbyDocument1 pageCrosbybdispoNo ratings yet

- Crosby G2140 ShackleDocument1 pageCrosby G2140 Shacklepgarrett775814233No ratings yet

- Crosby ShacklesDocument6 pagesCrosby Shacklessabah8800No ratings yet

- 82Document1 page82Drajat DarmawanNo ratings yet

- Screw Pin Anchor Shackles Screw Pin Chain ShacklesDocument1 pageScrew Pin Anchor Shackles Screw Pin Chain Shacklesfcesar1986No ratings yet

- Launchers & ReceiversDocument7 pagesLaunchers & Receiverssagar1503100% (1)

- Pernos Huck C50LDocument4 pagesPernos Huck C50LAngelina Santiago JimenezNo ratings yet

- Crosby 2130 2150Document1 pageCrosby 2130 2150Sumner TingNo ratings yet

- Gate Valve CataogueDocument4 pagesGate Valve CataogueAditya B. RyantoNo ratings yet

- Crosby Bolt Type Shackles: Testing The LimitsDocument1 pageCrosby Bolt Type Shackles: Testing The LimitsStephen KokoNo ratings yet

- ID Fan Dodge BRGDocument4 pagesID Fan Dodge BRGjhanduNo ratings yet

- Catálogo M-DA InglêsDocument20 pagesCatálogo M-DA Inglêsjf2003No ratings yet

- Crosby Alloy Screw Pin Shackles: All Rights Reserved 72Document1 pageCrosby Alloy Screw Pin Shackles: All Rights Reserved 72theCrosbyGroupNo ratings yet

- Spence StrainersDocument132 pagesSpence StrainersRahul LavandNo ratings yet

- Api Plan 11Document6 pagesApi Plan 11johnsaballaNo ratings yet

- Viking Extended Coverage Quick Respons SidewallDocument6 pagesViking Extended Coverage Quick Respons SidewallguspriyNo ratings yet

- Crosby® TurnbucklesDocument11 pagesCrosby® TurnbucklesMidfiild CosminNo ratings yet

- Liquidtight Strain Relief Cord and Cable Connectors: StraightDocument3 pagesLiquidtight Strain Relief Cord and Cable Connectors: Straighttajamul husainNo ratings yet

- Tee Type StrainersDocument3 pagesTee Type StrainersSrinu AmulojuNo ratings yet

- Mason Industries, Inc.: TYPE "C" Spring Mountings Provide A Packaged Solution ToDocument2 pagesMason Industries, Inc.: TYPE "C" Spring Mountings Provide A Packaged Solution ToAnunay BhatiaNo ratings yet

- HDP-Victaulic Estilo 995Document4 pagesHDP-Victaulic Estilo 995hugorubenzNo ratings yet

- Es LFB6080G2Document2 pagesEs LFB6080G2WattsNo ratings yet

- NSK CAT E1102k B182-205Document12 pagesNSK CAT E1102k B182-205Mohan RajNo ratings yet

- Idlers Cema DDocument12 pagesIdlers Cema Dcar97No ratings yet

- Min1244a12 - Tag 130-Pu-029Document7 pagesMin1244a12 - Tag 130-Pu-029Monty MathewsNo ratings yet

- Gemu Saunders ValvecataloqueDocument8 pagesGemu Saunders ValvecataloqueRavi ChaurasiaNo ratings yet

- ButterflyDocument6 pagesButterflysachin2010No ratings yet

- Crouse Hinds Exd JBDocument8 pagesCrouse Hinds Exd JBomh129No ratings yet

- Condensadora Westinghouse 5TR Mod DS3BA - DS5BADocument4 pagesCondensadora Westinghouse 5TR Mod DS3BA - DS5BAOscar Sanchez Velasquez0% (1)

- Area Drain For Outdoor Eye WashDocument4 pagesArea Drain For Outdoor Eye WashswapnilupgadeNo ratings yet

- ACUMULADORESDocument18 pagesACUMULADORESJuan GuillermoNo ratings yet

- Pulleys TechDocument8 pagesPulleys TechashkansoheylNo ratings yet

- Automatic Valve Gemue DB - 512 - GBDocument6 pagesAutomatic Valve Gemue DB - 512 - GBTaher Yusuf100% (1)

- Tas00002f8 1Document4 pagesTas00002f8 1Johnson Chng Hou KiatNo ratings yet

- SOPORTERIADocument28 pagesSOPORTERIAWilliamsh1aNo ratings yet

- G2DT-21 2HP-230V-60HZ-1FDocument8 pagesG2DT-21 2HP-230V-60HZ-1FDaniel AbantoNo ratings yet

- T101 Drilling MachineDocument4 pagesT101 Drilling MachineRemmy Torres VegaNo ratings yet

- Raccordi A Inserto Forgiato PDFDocument3 pagesRaccordi A Inserto Forgiato PDFpeppino di capriNo ratings yet

- Steel Supply Sub-Grades To EC3Document22 pagesSteel Supply Sub-Grades To EC3Anonymous iS33V5No ratings yet

- Turnbuckle Hook To EyeDocument1 pageTurnbuckle Hook To EyeeraswastaNo ratings yet

- 05.1 Crouse - Hinds. Caja de Derivacion GUADocument2 pages05.1 Crouse - Hinds. Caja de Derivacion GUAXinoko MosqueiraNo ratings yet

- Crosby Is Pleased To Announce That Selected Sizes of The "Original" Wide Body Shackles Are Now Available in A Screw Pin DesignDocument1 pageCrosby Is Pleased To Announce That Selected Sizes of The "Original" Wide Body Shackles Are Now Available in A Screw Pin Designpandavision76No ratings yet

- G-2130 / S-2130 Bolt Type Anchor ShacklesDocument1 pageG-2130 / S-2130 Bolt Type Anchor Shacklesramy abazaNo ratings yet

- Crosby ShackleDocument1 pageCrosby ShacklevrandyNo ratings yet

- Guide To Structural Steel Selection - G-SpecificationsDocument56 pagesGuide To Structural Steel Selection - G-SpecificationsFelix RanillaNo ratings yet

- T101 Drilling MachineDocument4 pagesT101 Drilling MachineFranklin Avendaño ArapaNo ratings yet

- T101 Drilling Machine BrochureDocument4 pagesT101 Drilling Machine BrochureRicardo OrtegaNo ratings yet

- API 6A FlangesDocument2 pagesAPI 6A Flangesjayakumar04985No ratings yet

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Metal Tanks (Heavy Gauge) World Summary: Market Values & Financials by CountryFrom EverandMetal Tanks (Heavy Gauge) World Summary: Market Values & Financials by CountryNo ratings yet

- The Institution of Engineers (India) : IntpeDocument8 pagesThe Institution of Engineers (India) : IntpekanchanabalajiNo ratings yet

- Reference Data - : Metric Conversion ChartDocument29 pagesReference Data - : Metric Conversion ChartkanchanabalajiNo ratings yet

- Wireless Broadband Contract SME Izwi ConnectixDocument6 pagesWireless Broadband Contract SME Izwi ConnectixkanchanabalajiNo ratings yet

- FS2 Learning Journey: Expressive Art & DesignDocument2 pagesFS2 Learning Journey: Expressive Art & DesignkanchanabalajiNo ratings yet

- DB 200 SLDocument2 pagesDB 200 SLkanchanabalajiNo ratings yet

- Gems Winchester - Karama Boys PDFDocument1 pageGems Winchester - Karama Boys PDFkanchanabalajiNo ratings yet

- (13630) Literacy - Writing Captions 04052016Document1 page(13630) Literacy - Writing Captions 04052016kanchanabalajiNo ratings yet

- Structures WorksheetDocument6 pagesStructures WorksheetkanchanabalajiNo ratings yet

- Write The Questions For The Pictures Using Is' or Can' and Answers Using Yes' or No'Document1 pageWrite The Questions For The Pictures Using Is' or Can' and Answers Using Yes' or No'kanchanabalajiNo ratings yet

- Vssc-P-Advt-127-2014 - 19.08.2014Document88 pagesVssc-P-Advt-127-2014 - 19.08.2014kanchanabalajiNo ratings yet

- Agency Fees: Bedrooms: Bathrooms: Size:: Rahul 0554455686-043868800Document1 pageAgency Fees: Bedrooms: Bathrooms: Size:: Rahul 0554455686-043868800kanchanabalajiNo ratings yet

- (13342) Literacy - Captions 28042016Document1 page(13342) Literacy - Captions 28042016kanchanabalajiNo ratings yet

- (13342) Literacy - Captions 28042016Document1 page(13342) Literacy - Captions 28042016kanchanabalajiNo ratings yet

- Wavy Lines: NameDocument10 pagesWavy Lines: NamekanchanabalajiNo ratings yet

- Wopq Asme Section IxDocument2 pagesWopq Asme Section IxkanchanabalajiNo ratings yet

- Fccla Info SheetDocument1 pageFccla Info Sheetapi-245161396No ratings yet

- Tizon, R. - Patient History, Gordon's, Lab Results, Drug StudyDocument10 pagesTizon, R. - Patient History, Gordon's, Lab Results, Drug StudyRoyce Vincent TizonNo ratings yet

- The Abcs of Technical WritingDocument30 pagesThe Abcs of Technical WritingMayeng's VlogNo ratings yet

- Advanced Data Research PaperDocument6 pagesAdvanced Data Research Papersaurabh20apr100% (1)

- The Setting SunDocument11 pagesThe Setting Sunrahafalasaker22No ratings yet

- Understanding Supply Chain ManagementDocument58 pagesUnderstanding Supply Chain Managementrl magsinoNo ratings yet

- Part 1 Rocks and MineralsDocument9 pagesPart 1 Rocks and MineralsSimon DruryNo ratings yet

- Anti AIDS HerbsDocument6 pagesAnti AIDS Herbskhansa maryamNo ratings yet

- ALH - Video Hub - Level3 - Worksheets - AnswerkeyDocument3 pagesALH - Video Hub - Level3 - Worksheets - AnswerkeyJulliana SantosNo ratings yet

- BSH Home Appliances: By: Finn O'Toole Luke Wilson Mohammad Saghir Hannah Morrison Nicole SaundersDocument12 pagesBSH Home Appliances: By: Finn O'Toole Luke Wilson Mohammad Saghir Hannah Morrison Nicole SaundersByan SaghirNo ratings yet

- Ranisch Sorgner Posthumanism IntroductionDocument316 pagesRanisch Sorgner Posthumanism IntroductionЕсения КалининаNo ratings yet

- Learning EvidenceDocument5 pagesLearning EvidenceArtperture Fotografía100% (3)

- Metrology in Health A Pilot StudyDocument11 pagesMetrology in Health A Pilot StudyMarcos AguiarNo ratings yet

- The CockroachDocument4 pagesThe Cockroachnatalie100% (1)

- Management Information Systems 7th Edition Sousa Solutions Manual DownloadDocument15 pagesManagement Information Systems 7th Edition Sousa Solutions Manual DownloadLouis Held100% (27)

- Describe Your Best Teacher Colleague in Terms of His/her Physical and Mental AppearancesDocument4 pagesDescribe Your Best Teacher Colleague in Terms of His/her Physical and Mental AppearanceserditaNo ratings yet

- Inspiring Thoughts of Swami Vivekananda On Education and Society - Part 1Document12 pagesInspiring Thoughts of Swami Vivekananda On Education and Society - Part 1Viswanadham Vangapally100% (1)

- Narrative Report in ResearchDocument2 pagesNarrative Report in ResearchSarah Jane EnriquezNo ratings yet

- Source: Family Background:: Flight Mechanic World War II Oklahoma Dust BowlDocument4 pagesSource: Family Background:: Flight Mechanic World War II Oklahoma Dust BowlClay Cyril Jastiva LambitNo ratings yet

- The Blue Lotus 11Document180 pagesThe Blue Lotus 11Yusuf MartinNo ratings yet

- The Carrefour AssignmentDocument16 pagesThe Carrefour AssignmentMohit MalviyaNo ratings yet

- Math 308 Solutions To Conceptual Problems - Chapter 1Document3 pagesMath 308 Solutions To Conceptual Problems - Chapter 1Mehul JoshiNo ratings yet

- Control Units System - Ul Product Iq 4100esDocument13 pagesControl Units System - Ul Product Iq 4100escnreyes3No ratings yet

- (2010) Rediscovering Performance Management - Systems, Learning and Integration - Brudan PDFDocument17 pages(2010) Rediscovering Performance Management - Systems, Learning and Integration - Brudan PDFsartika dewiNo ratings yet

- Core Drilling Guidelines at Toronto PearsonDocument9 pagesCore Drilling Guidelines at Toronto PearsonWinda BanyuradjaNo ratings yet

- SAP Cloud For Sales Solution Brief - Sap LayoutDocument9 pagesSAP Cloud For Sales Solution Brief - Sap Layoutphogat projectNo ratings yet

- Blood RelationsDocument5 pagesBlood RelationsRamNagalNo ratings yet

- Online Home Test For Mensa NZDocument4 pagesOnline Home Test For Mensa NZRekaNo ratings yet

- 2 Ethico-legal-POWERPOINT-BASIC As of January 12, 2009 (1) .Document81 pages2 Ethico-legal-POWERPOINT-BASIC As of January 12, 2009 (1) .Crystal Mae Castrodes Daquipil100% (1)

- Lab Report 2 Sku 3043Document7 pagesLab Report 2 Sku 3043Nelviana NahNo ratings yet