Professional Documents

Culture Documents

Article Tunnel Celing Collapsed

Article Tunnel Celing Collapsed

Uploaded by

gemotorresCopyright:

Available Formats

You might also like

- Boston 2024 Bid BookDocument284 pagesBoston 2024 Bid BookKyle Clauss100% (2)

- Stonecutters BridgeDocument20 pagesStonecutters BridgeMarcos MorrisonNo ratings yet

- Case Study Presentation - Bostons Big DIgDocument15 pagesCase Study Presentation - Bostons Big DIgAjay Gupta67% (3)

- 1 PDFDocument7 pages1 PDFJose Luis Martinez SaavedraNo ratings yet

- Boston Resin ProblemDocument11 pagesBoston Resin ProblemJulio LópezNo ratings yet

- Latex ModificatedDocument24 pagesLatex ModificatedjonathasiohanathanNo ratings yet

- MCL 9904Document11 pagesMCL 9904linamohdzhor4815No ratings yet

- Precast PrestressDocument60 pagesPrecast PrestressPantatNyanehBurikNo ratings yet

- 213 - CROSS Newsletter 11Document6 pages213 - CROSS Newsletter 11wnock49No ratings yet

- Highway Bridge CollapseDocument2 pagesHighway Bridge Collapserao_gsv7598100% (1)

- Nicoll Highway IncidentDocument8 pagesNicoll Highway IncidentAnonymous PeeXLtNsMpNo ratings yet

- Box Girder 2Document8 pagesBox Girder 2steelageNo ratings yet

- 028 - Pressley Destructive Testing 1049Document12 pages028 - Pressley Destructive Testing 1049tomNo ratings yet

- Big Ceiling CollapseDocument4 pagesBig Ceiling CollapseJianhua WuNo ratings yet

- 305 - 1987 Seminars - Some Current Developments Aust Pipe Industry+ PDFDocument64 pages305 - 1987 Seminars - Some Current Developments Aust Pipe Industry+ PDFChen YishengNo ratings yet

- Expert IzaDocument98 pagesExpert IzaflorinelvvNo ratings yet

- WTC 2013 - Design of SCL in Soft Ground A UK Perspective - J SuDocument9 pagesWTC 2013 - Design of SCL in Soft Ground A UK Perspective - J SuJorge Baños LloredoNo ratings yet

- Composite Materials For Bridge ConstructionDocument18 pagesComposite Materials For Bridge ConstructionPatrick MalelangNo ratings yet

- Inspection of Anchorages Supporting WatersideDocument11 pagesInspection of Anchorages Supporting WatersideLiliana RibeiroNo ratings yet

- Immersed Cross SectionsDocument17 pagesImmersed Cross SectionsAlexandra MoldovanNo ratings yet

- Structural Design of Immersed TunnelsDocument17 pagesStructural Design of Immersed TunnelsTrong TranNo ratings yet

- 0783f83a-a395-4d5f-a25d-6548c52ac9a0Document14 pages0783f83a-a395-4d5f-a25d-6548c52ac9a0Tiago SilvaNo ratings yet

- Inquiry Paper - Greg KellerDocument8 pagesInquiry Paper - Greg Kellerapi-263245803No ratings yet

- Bridges - All - Paper - Integral Abutments For Steel Bridges by E Wasserman - 10-1996Document44 pagesBridges - All - Paper - Integral Abutments For Steel Bridges by E Wasserman - 10-1996Xuejian LiuNo ratings yet

- Diaphragm DetailsDocument54 pagesDiaphragm DetailswalidNo ratings yet

- Life Extension of Bridges, 2010Document6 pagesLife Extension of Bridges, 2010LvisionNo ratings yet

- 2011 Bridge SarkadyDocument17 pages2011 Bridge SarkadyTan Duy LeNo ratings yet

- UnlversDocument55 pagesUnlversCan AcarNo ratings yet

- DOD - Handbook of Paints & CoatingsDocument20 pagesDOD - Handbook of Paints & Coatingsjohn_p47No ratings yet

- ICGE 15 KN 04 EndicottDocument11 pagesICGE 15 KN 04 EndicottJavine BongNo ratings yet

- Human Factors and Bridge FailureDocument3 pagesHuman Factors and Bridge FailureJameson J Mtanga0% (1)

- Literature ReviewDocument32 pagesLiterature ReviewMathew Sebastian100% (6)

- FRP Bridges 2012 Dawlish Footbridge Paper Kendall Smith GoughDocument14 pagesFRP Bridges 2012 Dawlish Footbridge Paper Kendall Smith GoughDavid Kendall100% (1)

- KSCE YounDocument15 pagesKSCE YounsdagnihotriNo ratings yet

- Replacement of Elastomeric Bearings & Installation of Monitoring Systems Thereafter at Keppel Viaduct in SingaporeDocument18 pagesReplacement of Elastomeric Bearings & Installation of Monitoring Systems Thereafter at Keppel Viaduct in SingaporeSanja RadovicNo ratings yet

- GT 1490the Observational Method Can Be Simple202Document4 pagesGT 1490the Observational Method Can Be Simple202h100% (1)

- FOUNDATION DESIGN & CONSTRUCTION IN HONG KONG - PRESENT & BEYOND, Daman Lee HK-Taiwan 2005Document28 pagesFOUNDATION DESIGN & CONSTRUCTION IN HONG KONG - PRESENT & BEYOND, Daman Lee HK-Taiwan 2005M Mushanif MuktiNo ratings yet

- Behavior of A Semiintegral Bridge Abutment Under Static and Temperature-Induced Cyclic LoadingDocument7 pagesBehavior of A Semiintegral Bridge Abutment Under Static and Temperature-Induced Cyclic LoadingIoannis BazosNo ratings yet

- Rehabilitation of Steel Bridge Decks.Document9 pagesRehabilitation of Steel Bridge Decks.Geert Henk WijnantsNo ratings yet

- 1201-Cheng Kim Hua Pipe Roof As Alternative in Building - UnderpassDocument11 pages1201-Cheng Kim Hua Pipe Roof As Alternative in Building - UnderpassCheng KimHuaNo ratings yet

- 期刊 - HIDDEN DEFECTS IN BRIDGE COMPONENTS - FORTHCOMING CIRIADocument13 pages期刊 - HIDDEN DEFECTS IN BRIDGE COMPONENTS - FORTHCOMING CIRIAfanfengliNo ratings yet

- 2001-04 BO-01-01 MTO Development of Flexible Link SlabDocument46 pages2001-04 BO-01-01 MTO Development of Flexible Link Slabcraig.mcleodNo ratings yet

- 2011 Bridge KlopperDocument13 pages2011 Bridge KlopperIndra MishraNo ratings yet

- The Asphalt Core Embankment Dam: A Very Competitive AlternativeDocument11 pagesThe Asphalt Core Embankment Dam: A Very Competitive AlternativeTrí Hồ Minh LêNo ratings yet

- The Design of Padma Multipurpose Bridge - Challenges and Solutions.Document10 pagesThe Design of Padma Multipurpose Bridge - Challenges and Solutions.Jahidul IslamNo ratings yet

- Tower FailuresDocument42 pagesTower FailuresTerrazas LitziNo ratings yet

- Concrete Capacity Design of Cazaly Hangers in Shallow MembersDocument26 pagesConcrete Capacity Design of Cazaly Hangers in Shallow MembersOliver LopezNo ratings yet

- Case Study Extending The Life of Austin Energy Holman Hillje 345kV Transmission Line (Paper)Document7 pagesCase Study Extending The Life of Austin Energy Holman Hillje 345kV Transmission Line (Paper)Scott WaltonNo ratings yet

- Epoxy Jointing of Concrete Bridge SegmentsDocument8 pagesEpoxy Jointing of Concrete Bridge SegmentscevivektNo ratings yet

- Booklet Sim 020205Document88 pagesBooklet Sim 020205anderson marcosNo ratings yet

- Sheet Pile Retaining Walls Design and Construction in A Brown Fields Environment Amir Holakoo KBRDocument6 pagesSheet Pile Retaining Walls Design and Construction in A Brown Fields Environment Amir Holakoo KBREng mohammadNo ratings yet

- 2013 Jiang Su Design of SCL Tunnel Using Sprayed WaterproofingDocument11 pages2013 Jiang Su Design of SCL Tunnel Using Sprayed WaterproofingParmeshwar KushwahaNo ratings yet

- A Cable-Stayed Bridge With Main Span of 1088 MetersDocument9 pagesA Cable-Stayed Bridge With Main Span of 1088 Metersmdkml2No ratings yet

- Failing Culverts Geo Technical PerspectiveDocument13 pagesFailing Culverts Geo Technical PerspectiveSammy DeeNo ratings yet

- Collisions of Heavy Goods Vehicles With BridgesDocument8 pagesCollisions of Heavy Goods Vehicles With BridgesPatrick DonelanNo ratings yet

- A Half-Inch To Failure (Sept 2009) PDFDocument4 pagesA Half-Inch To Failure (Sept 2009) PDFUnknownNo ratings yet

- Post-Damage Repair of Prestressed Concrete GirdersDocument10 pagesPost-Damage Repair of Prestressed Concrete GirdersNikhil JainNo ratings yet

- PP - FP - 2004 - 008 - Eng - 02-EURO RESEARCH IMPROV FATIGA RESISTANCEDocument23 pagesPP - FP - 2004 - 008 - Eng - 02-EURO RESEARCH IMPROV FATIGA RESISTANCEJean PierreNo ratings yet

- A Guide to Some of the Equations used in Constructing a Suspension BridgeFrom EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeNo ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- ASTM C507 - Elliptical Pipe RINKER PDFDocument1 pageASTM C507 - Elliptical Pipe RINKER PDFgemotorresNo ratings yet

- FP McCann Precast Concrete Headwalls InstallationDocument4 pagesFP McCann Precast Concrete Headwalls InstallationgemotorresNo ratings yet

- ASTM C507 - Elliptical Pipe RINKER PDFDocument1 pageASTM C507 - Elliptical Pipe RINKER PDFgemotorresNo ratings yet

- AASHTO LRFD 7th Ed - Load Factors and CombinationsDocument10 pagesAASHTO LRFD 7th Ed - Load Factors and CombinationsgemotorresNo ratings yet

- Time MGMT Role GoalDocument29 pagesTime MGMT Role GoalgemotorresNo ratings yet

- 12x6x7aircraft Rated ManholeDocument1 page12x6x7aircraft Rated ManholegemotorresNo ratings yet

- Breaks Evaluation CIP09pDocument2 pagesBreaks Evaluation CIP09pgemotorresNo ratings yet

- Tire - Specifications BIASDocument7 pagesTire - Specifications BIASgemotorres0% (1)

- Boeing - Calculate Aircraft Tire Contact AreaDocument4 pagesBoeing - Calculate Aircraft Tire Contact Areagemotorres50% (2)

- Faa Strength Rating ConversionsDocument4 pagesFaa Strength Rating ConversionsgemotorresNo ratings yet

- Anchor Design in ConcreteDocument8 pagesAnchor Design in ConcretegemotorresNo ratings yet

- Weir Walls & Baffles in Pump Station Wet WellsDocument4 pagesWeir Walls & Baffles in Pump Station Wet WellsgemotorresNo ratings yet

- Manual For Stormwater Detention CalculatorDocument10 pagesManual For Stormwater Detention CalculatorgemotorresNo ratings yet

- Loading Static and DynamicDocument9 pagesLoading Static and DynamicgemotorresNo ratings yet

- Cip Wma 21 01 03Document34 pagesCip Wma 21 01 03britalbNo ratings yet

- Geotechnical Engineering: Networked Instrumentation For The Transbay Transit Center, San Francisco, CaliforniaDocument10 pagesGeotechnical Engineering: Networked Instrumentation For The Transbay Transit Center, San Francisco, Californiajeremy pontillasNo ratings yet

- Big DigDocument15 pagesBig DigPramodNo ratings yet

- How To Get Appointed Ocn370397207Document46 pagesHow To Get Appointed Ocn370397207api-241896162No ratings yet

- Bonded Anchors in Concrete Under Sustained LoadingDocument128 pagesBonded Anchors in Concrete Under Sustained LoadingUbaid Ahmed MughalNo ratings yet

- All Electronic Tolling Presentation Aug. 22 2016Document45 pagesAll Electronic Tolling Presentation Aug. 22 2016Gintautas DumciusNo ratings yet

- Boston Big Dig Key FactDocument8 pagesBoston Big Dig Key Factdianisme freelanceNo ratings yet

- Best Practices Roadway TunnelsDocument186 pagesBest Practices Roadway Tunnelsalwil144548100% (1)

- RTC-NE 2023 Recruit Information Guide v2.0 07FEB23Document14 pagesRTC-NE 2023 Recruit Information Guide v2.0 07FEB23Brittany DNo ratings yet

- The Unofficial Guide To Boston Updated 8.15.11Document71 pagesThe Unofficial Guide To Boston Updated 8.15.11megafieldNo ratings yet

- Dig 1049Document56 pagesDig 1049crunchyjewNo ratings yet

- 90 To Springfield MemoDocument7 pages90 To Springfield MemoJarred JohnsonNo ratings yet

- Usa Bigdig ProfileDocument71 pagesUsa Bigdig ProfileKatolik95No ratings yet

Article Tunnel Celing Collapsed

Article Tunnel Celing Collapsed

Uploaded by

gemotorresOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Article Tunnel Celing Collapsed

Article Tunnel Celing Collapsed

Uploaded by

gemotorresCopyright:

Available Formats

32

TheStructuralEngineer

April 2013

Professional guidance

Structural failure

Interstate 90 Connector

Tunnel ceiling collapse

On 2 December 2012, concrete ceiling

panels fell from the roof of a 4.7km-long road

tunnel west of Tokyo, Japan. The ceiling

panels were suspended above the tunnel

roadway and the falling panels crushed three

vehicles and resulted in nine fatalities. The

tunnel reopened in late December, and while

a number of publications speculate that the

cause of the failure may be associated with

a failed support bracket or concrete anchor,

the ndings of an official investigation are yet

to be released at the time of writing.

This collapse was a stark reminder of

the failure of ceiling panels in the Interstate

90 (I-90) Connector Tunnel in Boston,

Massachusetts, in 2006, and a number

of the key ndings from this failure are

discussed here1.

The I-90 Connecter Tunnel was

constructed as part of the CA/T project in

Boston, also known as the Big Dig. The

project was regarded as one of the most

costly and complex public infrastructure

projects in the US, and it was completed

in 2006 at a nal project cost in excess of

US$14 billion. In essence, the project was

undertaken to improve traffic ow in Boston

by providing 259km of highway lanes,

including 8km of tunnel, six interchanges

and 200 bridges. It spanned a 20 year

period and was project managed by Bechtel/

Parsons Brinckerhoff (B/PB).

The incident site in the I-90 Connector

Tunnel, known as the D Street portal,

was opened to traffic in December 2000,

and consisted of approximately 800m of

cut-and-cover tunnel. The D Street portal

ceiling was installed by Modern Continental

Construction Company in 1999 and 2000,

TSE16_32-33.indd 32

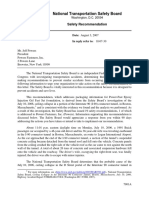

Figure 1

Typical adhesive anchor

and roof hanger plate assembly

3/4"

Epoxy

Concrete

roof

5"

0.55"

Seal plug

0.9"

3"

Roof

hanger plate

COURTESY: NATIONAL TRANSPORT SAFETY BOARD

Sean Brady highlights

potential similarities

between the recent Sasago

road tunnel collapse in Japan

and the catastrophic failure

of part of Bostons I-90

Connector Tunnel in 2006.

with the failed section being installed in

November 1999. The suspended ceiling

consisted of concrete ceiling panels and

associated steel support framework, and

it was suspended from the tunnel roof by

stainless steel anchors held in place with

epoxy adhesive. Notably, the specication

produced by the tunnel ceiling designer,

Gannett Fleming, did not contain criteria with

respect to the long term performance of the

anchoring system (Figure 1).

The incident occurred at approximately

23:00h on Monday the 10 July, 2006, more

than six years after the D Street portal

opened to traffic. A car travelling eastbound

in the tunnel was struck by about 24t of

falling ceiling panels and steel framework

that detached from the tunnel roof. The

right hand side of the car was crushed, with

the driver suffering minor injuries and the

passenger, the drivers wife, being fatally

injured (Figure 2).

An investigation into the collapse was

commenced by the National Transportation

Safety Board (NTSB), who established that

all 20 epoxied anchors that connected

the ceiling panels M1 support beam had

pulled free from the tunnel roof. Further, an

examination of the hardened epoxy, which

was still attached to the failed anchors,

suggested that a number of the anchors

had been pulled some distance out of the

tunnel roof (displaced) prior to the incident

occurring.

Following the collapse, an inspection of the

remaining 634 anchors in the D Street tunnel

found that 161 of them had measureable

displacement consistent with them being

gradually pulled out by the weight of the

concrete ceiling panels (Figure 3). Given this

evidence, the NTSB concluded by July 2006,

a signicant portion of the adhesive anchors

used to support the D Street portal ceilings

had displaced to the extent that, without

corrective action, several of the ceiling

modules in the three portal tunnels were at

imminent risk of failure and collapse1.

With respect to the installation of the

tunnel ceiling, the NTSB found that all of

these anchors had been subject to, and

passed, a short term proof load test prior to

being put into service. It was also ascertained

that the design loads on each anchor were

well below the expected average ultimate

Sealing washer

Lock washer

Nut

Anchor

Not to

scale

load capacity published by the anchor

supplier1. The NTSB also established that,

while all of the anchors may not have been

installed in a manner that would result

in maximum performance, improper or

decient anchor installation procedures or

practices alone would not account for all

of the anchor failures that were observed

before and after the accident1.

The NTSB investigation focused on why

the epoxy failure occurred and discovered

ambiguities associated with the type and

specication of epoxy supplied. The epoxy

used in the construction was NRC-1000

Gold epoxy. This was available in Standard

Set or Fast Set versions. Based on tests on

epoxy samples, the NSTB concluded that

only Fast Set epoxy had been used in the D

Street portal. Further tests conrmed that

while the Standard Set and Fast Set epoxies

22/03/2013 13:38

www.thestructuralengineer.org

33

had similar performance under short term

loading, they were dramatically different

under long term loading situations, with Fast

Set epoxy exhibiting signicant displacement

when subject to constant loading. Based on

these ndings, the NTSB concluded that the

source of the anchor displacement that was

found in the D Street portal tunnels and that

precipitated the ceiling collapse was the poor

creep resistance of the Power-Fast Fast Set

epoxy used to install the anchors1.

The NTSB then set out to identify why

the ceiling installer, Modern Continental,

utilised an inappropriate formulation for

its application. Fundamentally, they found

no evidence that Modern Continental

was offered a choice or made a conscious

decision to use one epoxy formulation over

another1 and concluded that Modern

Continental was not aware, when its

employees installed the adhesive anchors

in the D Street portal, that the epoxy being

used was susceptible to creep and was

therefore unsuitable for this application1.

A review of the suppliers records

indicated signicant ambiguity associated

with the epoxy supplied. The NTSB found

that in 1997, prior to the D Street tunnel

installation, Powers, the epoxy supplier,

undertook creep testing on the Standard

Set epoxy and found that it met the required

standards. Then in February 2000, following

installation of the D Street tunnel ceiling, an

evaluation report issued by Powers noted

that the Fast Set epoxy was only permitted

for short-term loading scenarios a situation

that was quite different to what it would

experience in the tunnel. In a detailed

review of Powers documentation, the NTSB

learned that the Power-Fast Fast Set epoxy

had been tested for creep performance in

1995 and 1996 and had failed to meet the

standard1, thus potentially explaining the

recommendation for short term applications

only. Ultimately, the NTSB found that the

information that was provided by Powers

TSE16_32-33.indd 33

PRESS ASSOCIATION

PRESS ASSOCIATION

Figure 2

Approximately

24t of concrete

ceiling panels crush

a vehicle resulting in

a fatality

Figure 3

Displaced

hanger plates

regarding its Power-Fast epoxy was

inadequate and misleading, with the result

that Modern Continental used the Fast Set

formulation of the epoxy for the adhesive

anchors in the D Street portal even though

that formulation had been shown through

testing to be susceptible to creep under

sustained tension loading1. However, it also

concluded that Gannett Fleming approved

the D Street portal anchors without

identifying which epoxy formulation was

being used, even though the company was

provided with information indicating that one

version of the Power-Fast epoxy should be

used for short-term loading only1.

So once the Fast Set epoxy had been put

into service, was there an opportunity to

detect the potential for a catastrophic failure

prior to July 2006? The NTSB found two

such opportunities.

In September 1999, seven years before the

failure, and approximately two months after

installation, a Modern Continental employee

working in an adjacent tunnel on the Big Dig,

the HOV tunnel, noticed that a number of

anchors had started to pull out of the roof.

Further inspections over the next two weeks

showed this displacement was increasing. B/

PB initially suspected these displacements

were a result of improper installation by

Modern Continental, and it was agreed

between B/PB and Modern Continental to

replace the displaced anchors and subject

them to further short term load testing.

Crucially, despite concerns being voiced

by various individuals involved, the reason

for the displacement was not identied.

Two years later, in another portion of the

I-90 Connector Tunnel, it was found that

additional anchors had begun to pull out after

having been proof tested just two months

previously. As before, these anchors were

replaced and the cause of displacement

remained unknown. The NTSB concluded

that B/PB and Modern Continental should

have instituted a program to monitor anchor

performance to ensure that the actions

taken in response to the displacement were

effective. Had these organisations taken

such action, they likely would have found

that anchor creep was occurring and they

might have taken measures that would have

prevented this accident1.

A further issue cited by the NTSB as a

missed opportunity, was that of inspections.

Although an inspection manual had been

published by B/PB in 2003, no ceiling

inspections were undertaken between 2003

and the collapse. The NTSB concluded that

had the Massachusetts Turnpike Authority

inspected the area above the suspended

ceilings in the D Street portal tunnels, the

anchor creep that led to this accident would

likely have been detected, and action could

have been taken that would have prevented

this accident1.

Like many catastrophic structural

collapses in the past decade, a series of

errors, oversights, omissions and poor

communication (combined with missed

opportunities to identify the potential for

failure) culminated in loss of life, loss of

functionality, and undermined the integrity of

a key piece of transport infrastructure.

Sean Brady is the managing director of

Brady Heywood (www.bradyheywood.co.uk

& www.bradyheywood.com.au). The rm

provides forensic and investigative structural

engineering services and specialises in

determining the cause of engineering failure

and non-performance.

This article rst appeared in the March

2013 edition of Engineers Australia magazine.

REFERENCES:

1) National Transport Safety Board

(2007) Highway Accident Report, Ceiling

Collapse in the Interstate 90 Connector Tunnel,

Boston, Massachusetts, July 10, 2006 [Online]

Available at: www.ntsb.gov/doclib/reports/2007/

HAR0702.pdf (Accessed: March 2013)

22/03/2013 13:39

You might also like

- Boston 2024 Bid BookDocument284 pagesBoston 2024 Bid BookKyle Clauss100% (2)

- Stonecutters BridgeDocument20 pagesStonecutters BridgeMarcos MorrisonNo ratings yet

- Case Study Presentation - Bostons Big DIgDocument15 pagesCase Study Presentation - Bostons Big DIgAjay Gupta67% (3)

- 1 PDFDocument7 pages1 PDFJose Luis Martinez SaavedraNo ratings yet

- Boston Resin ProblemDocument11 pagesBoston Resin ProblemJulio LópezNo ratings yet

- Latex ModificatedDocument24 pagesLatex ModificatedjonathasiohanathanNo ratings yet

- MCL 9904Document11 pagesMCL 9904linamohdzhor4815No ratings yet

- Precast PrestressDocument60 pagesPrecast PrestressPantatNyanehBurikNo ratings yet

- 213 - CROSS Newsletter 11Document6 pages213 - CROSS Newsletter 11wnock49No ratings yet

- Highway Bridge CollapseDocument2 pagesHighway Bridge Collapserao_gsv7598100% (1)

- Nicoll Highway IncidentDocument8 pagesNicoll Highway IncidentAnonymous PeeXLtNsMpNo ratings yet

- Box Girder 2Document8 pagesBox Girder 2steelageNo ratings yet

- 028 - Pressley Destructive Testing 1049Document12 pages028 - Pressley Destructive Testing 1049tomNo ratings yet

- Big Ceiling CollapseDocument4 pagesBig Ceiling CollapseJianhua WuNo ratings yet

- 305 - 1987 Seminars - Some Current Developments Aust Pipe Industry+ PDFDocument64 pages305 - 1987 Seminars - Some Current Developments Aust Pipe Industry+ PDFChen YishengNo ratings yet

- Expert IzaDocument98 pagesExpert IzaflorinelvvNo ratings yet

- WTC 2013 - Design of SCL in Soft Ground A UK Perspective - J SuDocument9 pagesWTC 2013 - Design of SCL in Soft Ground A UK Perspective - J SuJorge Baños LloredoNo ratings yet

- Composite Materials For Bridge ConstructionDocument18 pagesComposite Materials For Bridge ConstructionPatrick MalelangNo ratings yet

- Inspection of Anchorages Supporting WatersideDocument11 pagesInspection of Anchorages Supporting WatersideLiliana RibeiroNo ratings yet

- Immersed Cross SectionsDocument17 pagesImmersed Cross SectionsAlexandra MoldovanNo ratings yet

- Structural Design of Immersed TunnelsDocument17 pagesStructural Design of Immersed TunnelsTrong TranNo ratings yet

- 0783f83a-a395-4d5f-a25d-6548c52ac9a0Document14 pages0783f83a-a395-4d5f-a25d-6548c52ac9a0Tiago SilvaNo ratings yet

- Inquiry Paper - Greg KellerDocument8 pagesInquiry Paper - Greg Kellerapi-263245803No ratings yet

- Bridges - All - Paper - Integral Abutments For Steel Bridges by E Wasserman - 10-1996Document44 pagesBridges - All - Paper - Integral Abutments For Steel Bridges by E Wasserman - 10-1996Xuejian LiuNo ratings yet

- Diaphragm DetailsDocument54 pagesDiaphragm DetailswalidNo ratings yet

- Life Extension of Bridges, 2010Document6 pagesLife Extension of Bridges, 2010LvisionNo ratings yet

- 2011 Bridge SarkadyDocument17 pages2011 Bridge SarkadyTan Duy LeNo ratings yet

- UnlversDocument55 pagesUnlversCan AcarNo ratings yet

- DOD - Handbook of Paints & CoatingsDocument20 pagesDOD - Handbook of Paints & Coatingsjohn_p47No ratings yet

- ICGE 15 KN 04 EndicottDocument11 pagesICGE 15 KN 04 EndicottJavine BongNo ratings yet

- Human Factors and Bridge FailureDocument3 pagesHuman Factors and Bridge FailureJameson J Mtanga0% (1)

- Literature ReviewDocument32 pagesLiterature ReviewMathew Sebastian100% (6)

- FRP Bridges 2012 Dawlish Footbridge Paper Kendall Smith GoughDocument14 pagesFRP Bridges 2012 Dawlish Footbridge Paper Kendall Smith GoughDavid Kendall100% (1)

- KSCE YounDocument15 pagesKSCE YounsdagnihotriNo ratings yet

- Replacement of Elastomeric Bearings & Installation of Monitoring Systems Thereafter at Keppel Viaduct in SingaporeDocument18 pagesReplacement of Elastomeric Bearings & Installation of Monitoring Systems Thereafter at Keppel Viaduct in SingaporeSanja RadovicNo ratings yet

- GT 1490the Observational Method Can Be Simple202Document4 pagesGT 1490the Observational Method Can Be Simple202h100% (1)

- FOUNDATION DESIGN & CONSTRUCTION IN HONG KONG - PRESENT & BEYOND, Daman Lee HK-Taiwan 2005Document28 pagesFOUNDATION DESIGN & CONSTRUCTION IN HONG KONG - PRESENT & BEYOND, Daman Lee HK-Taiwan 2005M Mushanif MuktiNo ratings yet

- Behavior of A Semiintegral Bridge Abutment Under Static and Temperature-Induced Cyclic LoadingDocument7 pagesBehavior of A Semiintegral Bridge Abutment Under Static and Temperature-Induced Cyclic LoadingIoannis BazosNo ratings yet

- Rehabilitation of Steel Bridge Decks.Document9 pagesRehabilitation of Steel Bridge Decks.Geert Henk WijnantsNo ratings yet

- 1201-Cheng Kim Hua Pipe Roof As Alternative in Building - UnderpassDocument11 pages1201-Cheng Kim Hua Pipe Roof As Alternative in Building - UnderpassCheng KimHuaNo ratings yet

- 期刊 - HIDDEN DEFECTS IN BRIDGE COMPONENTS - FORTHCOMING CIRIADocument13 pages期刊 - HIDDEN DEFECTS IN BRIDGE COMPONENTS - FORTHCOMING CIRIAfanfengliNo ratings yet

- 2001-04 BO-01-01 MTO Development of Flexible Link SlabDocument46 pages2001-04 BO-01-01 MTO Development of Flexible Link Slabcraig.mcleodNo ratings yet

- 2011 Bridge KlopperDocument13 pages2011 Bridge KlopperIndra MishraNo ratings yet

- The Asphalt Core Embankment Dam: A Very Competitive AlternativeDocument11 pagesThe Asphalt Core Embankment Dam: A Very Competitive AlternativeTrí Hồ Minh LêNo ratings yet

- The Design of Padma Multipurpose Bridge - Challenges and Solutions.Document10 pagesThe Design of Padma Multipurpose Bridge - Challenges and Solutions.Jahidul IslamNo ratings yet

- Tower FailuresDocument42 pagesTower FailuresTerrazas LitziNo ratings yet

- Concrete Capacity Design of Cazaly Hangers in Shallow MembersDocument26 pagesConcrete Capacity Design of Cazaly Hangers in Shallow MembersOliver LopezNo ratings yet

- Case Study Extending The Life of Austin Energy Holman Hillje 345kV Transmission Line (Paper)Document7 pagesCase Study Extending The Life of Austin Energy Holman Hillje 345kV Transmission Line (Paper)Scott WaltonNo ratings yet

- Epoxy Jointing of Concrete Bridge SegmentsDocument8 pagesEpoxy Jointing of Concrete Bridge SegmentscevivektNo ratings yet

- Booklet Sim 020205Document88 pagesBooklet Sim 020205anderson marcosNo ratings yet

- Sheet Pile Retaining Walls Design and Construction in A Brown Fields Environment Amir Holakoo KBRDocument6 pagesSheet Pile Retaining Walls Design and Construction in A Brown Fields Environment Amir Holakoo KBREng mohammadNo ratings yet

- 2013 Jiang Su Design of SCL Tunnel Using Sprayed WaterproofingDocument11 pages2013 Jiang Su Design of SCL Tunnel Using Sprayed WaterproofingParmeshwar KushwahaNo ratings yet

- A Cable-Stayed Bridge With Main Span of 1088 MetersDocument9 pagesA Cable-Stayed Bridge With Main Span of 1088 Metersmdkml2No ratings yet

- Failing Culverts Geo Technical PerspectiveDocument13 pagesFailing Culverts Geo Technical PerspectiveSammy DeeNo ratings yet

- Collisions of Heavy Goods Vehicles With BridgesDocument8 pagesCollisions of Heavy Goods Vehicles With BridgesPatrick DonelanNo ratings yet

- A Half-Inch To Failure (Sept 2009) PDFDocument4 pagesA Half-Inch To Failure (Sept 2009) PDFUnknownNo ratings yet

- Post-Damage Repair of Prestressed Concrete GirdersDocument10 pagesPost-Damage Repair of Prestressed Concrete GirdersNikhil JainNo ratings yet

- PP - FP - 2004 - 008 - Eng - 02-EURO RESEARCH IMPROV FATIGA RESISTANCEDocument23 pagesPP - FP - 2004 - 008 - Eng - 02-EURO RESEARCH IMPROV FATIGA RESISTANCEJean PierreNo ratings yet

- A Guide to Some of the Equations used in Constructing a Suspension BridgeFrom EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeNo ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- ASTM C507 - Elliptical Pipe RINKER PDFDocument1 pageASTM C507 - Elliptical Pipe RINKER PDFgemotorresNo ratings yet

- FP McCann Precast Concrete Headwalls InstallationDocument4 pagesFP McCann Precast Concrete Headwalls InstallationgemotorresNo ratings yet

- ASTM C507 - Elliptical Pipe RINKER PDFDocument1 pageASTM C507 - Elliptical Pipe RINKER PDFgemotorresNo ratings yet

- AASHTO LRFD 7th Ed - Load Factors and CombinationsDocument10 pagesAASHTO LRFD 7th Ed - Load Factors and CombinationsgemotorresNo ratings yet

- Time MGMT Role GoalDocument29 pagesTime MGMT Role GoalgemotorresNo ratings yet

- 12x6x7aircraft Rated ManholeDocument1 page12x6x7aircraft Rated ManholegemotorresNo ratings yet

- Breaks Evaluation CIP09pDocument2 pagesBreaks Evaluation CIP09pgemotorresNo ratings yet

- Tire - Specifications BIASDocument7 pagesTire - Specifications BIASgemotorres0% (1)

- Boeing - Calculate Aircraft Tire Contact AreaDocument4 pagesBoeing - Calculate Aircraft Tire Contact Areagemotorres50% (2)

- Faa Strength Rating ConversionsDocument4 pagesFaa Strength Rating ConversionsgemotorresNo ratings yet

- Anchor Design in ConcreteDocument8 pagesAnchor Design in ConcretegemotorresNo ratings yet

- Weir Walls & Baffles in Pump Station Wet WellsDocument4 pagesWeir Walls & Baffles in Pump Station Wet WellsgemotorresNo ratings yet

- Manual For Stormwater Detention CalculatorDocument10 pagesManual For Stormwater Detention CalculatorgemotorresNo ratings yet

- Loading Static and DynamicDocument9 pagesLoading Static and DynamicgemotorresNo ratings yet

- Cip Wma 21 01 03Document34 pagesCip Wma 21 01 03britalbNo ratings yet

- Geotechnical Engineering: Networked Instrumentation For The Transbay Transit Center, San Francisco, CaliforniaDocument10 pagesGeotechnical Engineering: Networked Instrumentation For The Transbay Transit Center, San Francisco, Californiajeremy pontillasNo ratings yet

- Big DigDocument15 pagesBig DigPramodNo ratings yet

- How To Get Appointed Ocn370397207Document46 pagesHow To Get Appointed Ocn370397207api-241896162No ratings yet

- Bonded Anchors in Concrete Under Sustained LoadingDocument128 pagesBonded Anchors in Concrete Under Sustained LoadingUbaid Ahmed MughalNo ratings yet

- All Electronic Tolling Presentation Aug. 22 2016Document45 pagesAll Electronic Tolling Presentation Aug. 22 2016Gintautas DumciusNo ratings yet

- Boston Big Dig Key FactDocument8 pagesBoston Big Dig Key Factdianisme freelanceNo ratings yet

- Best Practices Roadway TunnelsDocument186 pagesBest Practices Roadway Tunnelsalwil144548100% (1)

- RTC-NE 2023 Recruit Information Guide v2.0 07FEB23Document14 pagesRTC-NE 2023 Recruit Information Guide v2.0 07FEB23Brittany DNo ratings yet

- The Unofficial Guide To Boston Updated 8.15.11Document71 pagesThe Unofficial Guide To Boston Updated 8.15.11megafieldNo ratings yet

- Dig 1049Document56 pagesDig 1049crunchyjewNo ratings yet

- 90 To Springfield MemoDocument7 pages90 To Springfield MemoJarred JohnsonNo ratings yet

- Usa Bigdig ProfileDocument71 pagesUsa Bigdig ProfileKatolik95No ratings yet