Professional Documents

Culture Documents

What Preparation Is Required Before A Magnetic Flux Leakage (MFL) Tank Inspection Takes Place

What Preparation Is Required Before A Magnetic Flux Leakage (MFL) Tank Inspection Takes Place

Uploaded by

cal2_uniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

What Preparation Is Required Before A Magnetic Flux Leakage (MFL) Tank Inspection Takes Place

What Preparation Is Required Before A Magnetic Flux Leakage (MFL) Tank Inspection Takes Place

Uploaded by

cal2_uniCopyright:

Available Formats

MFL Tank Inspection

Preparation

Q. What preparation is required before a magnetic

flux leakage (MFL) tank inspection takes place?

A. Cleaning requirements for Magnetic Flux Leakage (MFL) Inspection

Some preparation is required in order for a MFL inspection to take

place. Any product should be drained from the tank and the tank

should be cleaned.

Cleaning techniques will vary depending on the type of product stored

in the tank, the time since the tank was last cleaned and opinions

held by the engineer in charge of the cleaning operation. Acceptable

cleaning methods include shot blasting, grit blasting / sand blasting,

high pressure water jetting, ultra high pressure water jetting etc.

The media used in the blast cleaning process should be removed from

the floor before the inspection takes place. It is very difficult to

completely remove all of the shot from the surface of the floor. Two

problems can occur if the MFL scanner passes over any loose shot (or

any other loose ferrous material).

The shot will become embedded in the scanner rollers and cause

excessive vibration.

Spurious defect indications will be detected / recorded if any shot

passes underneath the sensor head. The aim of the cleaning process

is to remove any contaminants such as product residue, corrosion

build, scale and loose ferrous material from the surface of the tank

floor which can affect the quality of a MFL inspection.

Product residues can also give off toxic or flammable gasses. The floor

should be clean enough for a good visual inspection (you should be

looking at the surface of the steel, not a layer of product residue/scale

etc - see examples below).

Surface oxidisation / rust will not present a problem for MFL

inspections.

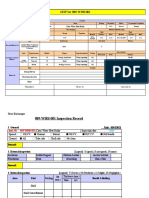

Tank floor conditions for MFL inspection - click on thumbnail for a

larger image

Acceptable conditions

Unacceptable conditions

Q Can I use Magnetic Flux Leakage (MFL) to inspect

the lap welds as well as the floor plates ?

No, Magnetic Flux Leakage is used to inspect the parent plate

material for corrosion defects and cannot be used for the lap welds.

The most common method of inspecting storage tank floor plate lap

welds is by use of a Vacuum Box.

Q Is MFL capable of detecting bottom side

corrosion as well as top side corrosion ?

Yes, the MFL flux leakage signal is a bi-polar signal which can be

detected at the top (near surface) of the tank floor even when the

corrosion originates on the bottom (far surface) of the tank floor.

Q Can MFL be used to size corrosion ?

Most MFL systems (like the MFL 2000) are simple detection devices

and require another inspection method , commonly ultrasonics, to

quantify the material loss. The FloormapVS2i system uses a

combination of MFL signal amplitude and defect width to quantify the

corrosion level and is currently achieving the same sizing accuracy as

manual UT.

Visit our MFL Equipment Page

Find more questions and answers for all other aspects of storage

tankage please click on the link below:

http://www.silverwingndt.com/ndt-knowledge/mfl-storage-tank-inspectionpreparation

You might also like

- E 570 - 97 Standard Practice For Flux Leakage Examination of Ferromagnetic Steel Tubular ProDocument6 pagesE 570 - 97 Standard Practice For Flux Leakage Examination of Ferromagnetic Steel Tubular ProJorge ToribioNo ratings yet

- IRIS Setup Guide - EN PDFDocument70 pagesIRIS Setup Guide - EN PDFpjhollowNo ratings yet

- Selection of NDT Techniques For Inspection of Heat Exchanger TubingDocument7 pagesSelection of NDT Techniques For Inspection of Heat Exchanger Tubingநந்த குமார் சம்பத் நாகராஜன்100% (1)

- Ct02 Ect Extended AsmeDocument1 pageCt02 Ect Extended AsmeVasyaNo ratings yet

- Rubber Closures For Containers PDFDocument2 pagesRubber Closures For Containers PDFKarla RodríguezNo ratings yet

- ABSTRACT On HolographyDocument4 pagesABSTRACT On HolographyAftab Popatia80% (5)

- To Measure The Point Angle, Helix Angle and Depth of Flute of A Drill Bit With The Help of Coordinate Measuring Machine (CMM) .Document7 pagesTo Measure The Point Angle, Helix Angle and Depth of Flute of A Drill Bit With The Help of Coordinate Measuring Machine (CMM) .Umair AnwarNo ratings yet

- FAQ's - NDT - MFL Magnetic Flux Leakage Storage Tank Inspection PDFDocument2 pagesFAQ's - NDT - MFL Magnetic Flux Leakage Storage Tank Inspection PDFJai PatelNo ratings yet

- Tank Floor Inspection SolutionsDocument3 pagesTank Floor Inspection SolutionsNoble PrinceNo ratings yet

- 5085 in Service Inspection of Ammonia Storage TanksDocument8 pages5085 in Service Inspection of Ammonia Storage TanksLudiNo ratings yet

- Method of Corrosion MappingDocument14 pagesMethod of Corrosion MappingNur Abdillah SiddiqNo ratings yet

- Scorpion Tank Shell InspectionDocument4 pagesScorpion Tank Shell Inspectionநந்த குமார் சம்பத் நாகராஜன்100% (1)

- DLA Corrosion Probe en 201608 WebDocument2 pagesDLA Corrosion Probe en 201608 WebDennis ChaiNo ratings yet

- Study On Pitting Corrosion of Storage Tank Bottom Steel in Acidic Condition Using Acoustic EmissionDocument12 pagesStudy On Pitting Corrosion of Storage Tank Bottom Steel in Acidic Condition Using Acoustic EmissionAnonymous hBBam1nNo ratings yet

- Pipescan MFL Pipe InspectionDocument4 pagesPipescan MFL Pipe InspectionRICARDO3454No ratings yet

- As1710 VS En10160Document1 pageAs1710 VS En10160Biju_PottayilNo ratings yet

- Asme Sec V A-15-2006Document4 pagesAsme Sec V A-15-2006Muhammed Abo-FandoodNo ratings yet

- What'S in Your Coiled Tubing?: Roderic K. Stanley, PH D, I. EngDocument30 pagesWhat'S in Your Coiled Tubing?: Roderic K. Stanley, PH D, I. EngAriel TerrensNo ratings yet

- APIRP586 Sec 1 Heat Exch Tubing InspsecondballottrackDocument48 pagesAPIRP586 Sec 1 Heat Exch Tubing InspsecondballottrackUsman NaseemNo ratings yet

- SEIP For 089-WHB-001: Claus Waste Heat BoilerDocument6 pagesSEIP For 089-WHB-001: Claus Waste Heat BoilerThinh NguyenNo ratings yet

- Silverwing B Scan ReportDocument46 pagesSilverwing B Scan ReportpjhollowNo ratings yet

- UT Procedure PDFDocument14 pagesUT Procedure PDFAbhayNo ratings yet

- BPF-V-270 Test Separator-Cm-Pvir-Xxxxx-20Document32 pagesBPF-V-270 Test Separator-Cm-Pvir-Xxxxx-20Agung Prastyo WibowoNo ratings yet

- Procedure For UtDocument12 pagesProcedure For UtMohammad SyeduzzamanNo ratings yet

- Phasor XS Flange Face PaperDocument32 pagesPhasor XS Flange Face PapervrapciudorianNo ratings yet

- Sims ManualDocument76 pagesSims Manualjose ocanaNo ratings yet

- Inspection Storage Tank STD 129Document10 pagesInspection Storage Tank STD 129kanip_No ratings yet

- Ferrite Meter Manual OPMS FMP30Ferit 902-530 enDocument36 pagesFerrite Meter Manual OPMS FMP30Ferit 902-530 enFmc2100% (1)

- Standard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodDocument7 pagesStandard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodMauricio FernándezNo ratings yet

- Al-Iris E-25a-02-003 PDFDocument12 pagesAl-Iris E-25a-02-003 PDFHao TranNo ratings yet

- Vaccum Box Test ProcedureDocument3 pagesVaccum Box Test ProcedureAJOJOY009No ratings yet

- Sample NTD Inspection ReportDocument127 pagesSample NTD Inspection ReportGeorge NicolaidesNo ratings yet

- Positive Material Identification (PMI)Document1 pagePositive Material Identification (PMI)fehmohdNo ratings yet

- Standard Practice For Secondary Calibration of Acoustic Emission SensorsDocument8 pagesStandard Practice For Secondary Calibration of Acoustic Emission SensorsArpan NandyNo ratings yet

- Pipescan MFL Pipe Inspection PDFDocument4 pagesPipescan MFL Pipe Inspection PDFJoseph MidouNo ratings yet

- Brochure SLOFECDocument11 pagesBrochure SLOFECAnup NairNo ratings yet

- 034-Saferad ProcedureDocument34 pages034-Saferad ProcedureasikurNo ratings yet

- Eddy Current White PaperDocument25 pagesEddy Current White PapervrapciudorianNo ratings yet

- TankInspectionTechniques3Document136 pagesTankInspectionTechniques3Zenon Kociuba100% (1)

- Tubing TestDocument16 pagesTubing Testbenergy84100% (1)

- BHS-TEPC-SIEVERT-ACFM-2022-001-Rev.01 - ACFM Inspection (Hassyan Power Plant)Document11 pagesBHS-TEPC-SIEVERT-ACFM-2022-001-Rev.01 - ACFM Inspection (Hassyan Power Plant)Saddam HossainNo ratings yet

- FLOORMAP3Di R MFL Tank Bottom InspectionDocument6 pagesFLOORMAP3Di R MFL Tank Bottom Inspectionjose ocanaNo ratings yet

- MFL Storage Tank Inspection LimitationsDocument3 pagesMFL Storage Tank Inspection LimitationsSatya RaoNo ratings yet

- Iris Report For Heat Exchanger: Tables of ContentsDocument4 pagesIris Report For Heat Exchanger: Tables of Contentsprasad_kcpNo ratings yet

- Profile Radiography Article Estimationof CorrosionDocument10 pagesProfile Radiography Article Estimationof Corrosioncoolguy12345No ratings yet

- ACME Chemicals: High Pressure Steam (HS) PipingDocument40 pagesACME Chemicals: High Pressure Steam (HS) PipingRamu NallathambiNo ratings yet

- Tube Probe Selection OlympusDocument12 pagesTube Probe Selection OlympusTechnical A-Star Testing & Inspection MalaysiaNo ratings yet

- Aws Application of Phased Array UltrasonicDocument7 pagesAws Application of Phased Array UltrasonicDileep KumarNo ratings yet

- RT Film Classification - C1 To C6Document31 pagesRT Film Classification - C1 To C6Ravindira C Dev100% (1)

- 18 Inch 9 5 MM Combo (MFL+CLP+IMU) (Ver Data Sheet Pàg. 8) PDFDocument19 pages18 Inch 9 5 MM Combo (MFL+CLP+IMU) (Ver Data Sheet Pàg. 8) PDFOscar Miguel Fuquen SanabriaNo ratings yet

- CN-11-Section 11 Teletest Functional Tests and Troubleshooting Rev0.1Document18 pagesCN-11-Section 11 Teletest Functional Tests and Troubleshooting Rev0.1Tĩnh Hồ TrungNo ratings yet

- EPRI Automated Analysis of Bobbin CoilProbe Eddy Current DataDocument97 pagesEPRI Automated Analysis of Bobbin CoilProbe Eddy Current DataaldeanucuNo ratings yet

- SLOFEC PipeScanner DatasheetDocument6 pagesSLOFEC PipeScanner Datasheetkoib789No ratings yet

- HTHA Module Rev 7Document14 pagesHTHA Module Rev 7judicejrNo ratings yet

- MTDocument65 pagesMTIkram SyedNo ratings yet

- Asset Integrity Management A Complete Guide - 2020 EditionFrom EverandAsset Integrity Management A Complete Guide - 2020 EditionNo ratings yet

- SLOFEC TankScanningDocument7 pagesSLOFEC TankScanningツ ツNo ratings yet

- Sgs Ind MFL A4 en 10Document2 pagesSgs Ind MFL A4 en 10Shanmuga NavaneethanNo ratings yet

- Lecture 11 - Defects in Casting and Inspection of CastingsDocument8 pagesLecture 11 - Defects in Casting and Inspection of CastingsManan GuptaNo ratings yet

- Experimental Results in Ultrasound Reflection Tomography For Nondestructive TestingDocument5 pagesExperimental Results in Ultrasound Reflection Tomography For Nondestructive Testingcal2_uniNo ratings yet

- Shallow Cracks Help!: Case StudyDocument1 pageShallow Cracks Help!: Case Studycal2_uniNo ratings yet

- Metallurgy of MaterialsDocument15 pagesMetallurgy of Materialscal2_uniNo ratings yet

- On-Going Work Helps Verify Reliability of RadiographyDocument1 pageOn-Going Work Helps Verify Reliability of Radiographycal2_uniNo ratings yet

- Phased Array Ultrasonic Technique Speeds Up Examination of Aluminothermic Rail WeldsDocument1 pagePhased Array Ultrasonic Technique Speeds Up Examination of Aluminothermic Rail Weldscal2_uniNo ratings yet

- Virtual Ultrasonic Testing To The ForeDocument1 pageVirtual Ultrasonic Testing To The Forecal2_uniNo ratings yet

- Inducing Flaws Intentionally: Case StudyDocument1 pageInducing Flaws Intentionally: Case Studycal2_uniNo ratings yet

- Recent Developments in Ultrasonic NDT Modelling in CIVADocument7 pagesRecent Developments in Ultrasonic NDT Modelling in CIVAcal2_uniNo ratings yet

- Iron Carbon Equillibrium Diagram GandhidhamDocument22 pagesIron Carbon Equillibrium Diagram Gandhidhamcal2_uniNo ratings yet

- Api 5ue: Ultrasonic Flaw Detection TutorialDocument1 pageApi 5ue: Ultrasonic Flaw Detection Tutorialcal2_uniNo ratings yet

- Tone Burst Generators in Research Ultrasonic InstrumentationDocument1 pageTone Burst Generators in Research Ultrasonic Instrumentationcal2_uniNo ratings yet

- Arbitrary Function Generators in WavesDocument1 pageArbitrary Function Generators in Wavescal2_uniNo ratings yet

- Electromagnetic Acoustic Transducers (EMATs) UtDocument3 pagesElectromagnetic Acoustic Transducers (EMATs) Utcal2_uniNo ratings yet

- Refraction and Snell's LawDocument3 pagesRefraction and Snell's Lawcal2_uniNo ratings yet

- Mode ConversionDocument15 pagesMode Conversioncal2_uniNo ratings yet

- Wave Propagation: Vibrational MotionDocument2 pagesWave Propagation: Vibrational Motioncal2_uniNo ratings yet

- Reflection and Transmission Coefficients (Pressure)Document1 pageReflection and Transmission Coefficients (Pressure)cal2_uniNo ratings yet

- Attenuation of Sound WavesDocument2 pagesAttenuation of Sound Wavescal2_uniNo ratings yet

- Wavelength and Defect DetectionDocument1 pageWavelength and Defect Detectioncal2_uniNo ratings yet

- Properties of Acoustic Plane WaveDocument1 pageProperties of Acoustic Plane Wavecal2_uniNo ratings yet

- Metal FoamDocument2 pagesMetal FoamSamiran MukherjeeNo ratings yet

- High-Accuracy Surface Scanning MethodDocument10 pagesHigh-Accuracy Surface Scanning Methodbertan dağıstanlıNo ratings yet

- Saint Gobain SGG DIAMANT®Document2 pagesSaint Gobain SGG DIAMANT®Mike LovisNo ratings yet

- As and A Level Physics Core Practical 8 Wavelength of Light (Student TeaDocument5 pagesAs and A Level Physics Core Practical 8 Wavelength of Light (Student TeaAmeerHamzaaNo ratings yet

- Magneto ResistanceDocument33 pagesMagneto ResistanceAkshdeep kaurNo ratings yet

- Captura 2023-06-26 A Las 6.28.46Document24 pagesCaptura 2023-06-26 A Las 6.28.46nazaret cervantes salasNo ratings yet

- Numerical Demonstration of The Soliton Self-FrequeDocument12 pagesNumerical Demonstration of The Soliton Self-Frequefaysal.nayan faysal.nayanNo ratings yet

- SVC Manual CLX-6260 Series Eng PDFDocument159 pagesSVC Manual CLX-6260 Series Eng PDFoclausellNo ratings yet

- GB - T 8163-2018Document8 pagesGB - T 8163-2018Dung HDNo ratings yet

- Facile and Economic Synthesis of Silica NanoparticlesDocument5 pagesFacile and Economic Synthesis of Silica Nanoparticlesireadall11No ratings yet

- FH0000EN03 Hardness Tester USDocument24 pagesFH0000EN03 Hardness Tester USMarcelo SánchezNo ratings yet

- CBSE Class 12 Physics Important Questions-Semiconductor DevicesDocument7 pagesCBSE Class 12 Physics Important Questions-Semiconductor DevicesGanesh Dhyani0% (1)

- Takex GS-5SN Data SheetDocument6 pagesTakex GS-5SN Data SheetJMAC SupplyNo ratings yet

- Assigenment QuestionsDocument4 pagesAssigenment Questionsphase_shekhar21No ratings yet

- ANTENNADocument53 pagesANTENNADarvis Peña AlmonteNo ratings yet

- Boeing FA-18 2010.teal - Group.december.2010Document18 pagesBoeing FA-18 2010.teal - Group.december.2010Jose Luis Magaña PizarroNo ratings yet

- Pajares, Gonzalo - Overview and Current Status of Remote Sensing Applications Based On Unmanned Aerial VehiclesDocument50 pagesPajares, Gonzalo - Overview and Current Status of Remote Sensing Applications Based On Unmanned Aerial VehiclesjuanjoNo ratings yet

- Instrumentation Physics CurriculumDocument1 pageInstrumentation Physics CurriculumKen RubioNo ratings yet

- Aoc E943fwsk Service ManualDocument51 pagesAoc E943fwsk Service ManualClaudio Robson Tobias50% (2)

- 5054 w10 QP 12Document16 pages5054 w10 QP 12mstudy123456No ratings yet

- Fiber Coupling PDFDocument54 pagesFiber Coupling PDFSurya TripathiNo ratings yet

- SHR-HTIR185 Long Range Thermal Imaging CameraDocument4 pagesSHR-HTIR185 Long Range Thermal Imaging CameraMary TianNo ratings yet

- Module 5 - PHOTONICSDocument35 pagesModule 5 - PHOTONICSHarith PES 2020No ratings yet

- Electromagnetic SpectrumDocument74 pagesElectromagnetic SpectrumGuiller Lanuza100% (1)

- Opt 428 DDocument156 pagesOpt 428 DNikita ToropovNo ratings yet

- 3D Bioprinting of SkinDocument32 pages3D Bioprinting of Skindaniel leon marinNo ratings yet

- PWR Bal CalDocument36 pagesPWR Bal Calarijeetdguy3051No ratings yet