Professional Documents

Culture Documents

248 T Bearing (Sliding) H

248 T Bearing (Sliding) H

Uploaded by

manoj_structureOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

248 T Bearing (Sliding) H

248 T Bearing (Sliding) H

Uploaded by

manoj_structureCopyright:

Available Formats

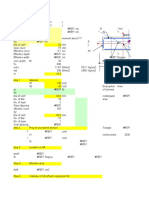

Design of Bearings for Gangnani Bridge

DESIGN CALCULATION FOR FIXED BEARING

Design Data

Span of bridge

Standard Temp.

Rotation ( Total)

Rotation(due to permanent action)

Rotation ( due to variable action)

Grade of concrete

Concrete stress ( Non seismic)

Concrete stress ( seismic)

Neoprene Pad stress

PTFE stress (working )

Steel stress(working ) for design use

65

+-25

0.01 x

0.0075 x

0.0025 x

M40

20

25

35

40

280

m

C

1.30 =

1.30 =

1.30 =

Mpa

Mpa

Mpa

Mpa

Mpa

DESIGN DIMENSION OF FIXED BEARING

Neoprene pad dia

Neoprene pad thickness

Pot base effective dia (actual)

Pot base thickness

Pot internal dia

Pot depth

Pot wall thickness

Piston effective contact dia

Piston thickness above spiggot

Spiggot projection

Bolt diameter

No. of bolt per component

Bolt flange thickness

No of sealing ring

Total thickness of rings

Dia of pedestal

Vertical face of Piston

Length of Lug

Thickness of distribution plate

Dia of distribution plate

Kailash Builders

372.0

26.0

480.00

28.00

372.00

47.00

44.00

480.00

30.00

36.00

20.00

12

16.00

2

4.00

960.00

9.00

20.00

25

620

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

nos

mm

nos

mm

mm

mm

mm

mm

mm

0.013 radian

0.00975 radian

0.00325 radian

Design of Bearings for Gangnani Bridge

Loading and Requirement

Non Seismic Case

Load

MT

Vertical Load

Dead Load + Live load

250.00

Total

250.00

Horizental Load

Total

Longitudinal

Transverse

Resultant

25.00

0.00

25

Seismic Case

Load

MT

Vertical Load

Dead Load + Live load

250.00

Total

250.00

Horizental Load

Total

Longitudinal

Transverse

Resultant

41.20

0.00

41.20

Movement of superstructure

0.00 +

0.00 +

0.00 =

Calculation for permissible stresses in Pedestal concrete

Loaded area ( A2 )

x 480.00

^ 2.00

/ 4 = 180955.7368 mm^2

Dispersed area( A1)

x 960.00

^ 2.00

/ 4 = 723822.9474 mm^2

Permissible concrete stress

A1

A2

x 0.25 fck

20 Mpa

Non Seismic Case

Design of Neoprene Pad (IRC-83 part (iii) clause 926.2.3)

Neoprene pad stress

Kailash Builders

250.00

0.785

x 10000

=

x 372 ^ 2

23 Mpa <

Hence OK

35 Mpa

Design of Bearings for Gangnani Bridge

Concrete stress at Pot Base (IRC-83 part (iii) clause 926.1.5)

I . Direct Bearing stress due to vertical load

=

250.00

0.785

14 Mpa <

x 10000

x 480 ^ 2

20 Mpa

Hence OK

II.Flexural stress due to active resulting from acting horizontal force

Eccentricity

Stress

28 +

26 +

4 =

25 x

10000 x

0.0982 x

480.0 ^ 3

1.336 Mpa

58

mm

58

III.Flexural stress due to induced resulting from resistance to Rotation

1) M. e.d. =

di^3 x ( k1 .p + k2. v)

di =

k1=

k2 =

p =

v =

M .ed =

=

=

2)

372.0 mm

2.09

89.314

0.00975 radian

0.00325 radian

372.0

51478848

15991389.3 N-mm

di / he =

^3 x(

x 0.311

M . R.d =

M . R.d =

Total induced moment =

=

=

15

2.2

k2

14.31

89.314

12.5

58.8

15

101

0.0098 +

89.3 x

186.00 x

9300000 N-mm

M .ed +

15991389 +

25291389

0.0982 x

Kailash Builders

12.5

1.8

372.0

186

186.00 mm

25.00 t

= 14.31

14.31

2.089

2.09 x

0.20 x

=

372.0

26.0

k1

0.2 x C x H

C=

H=

Stress

IRC- 83 Part (iii) clause 926.1.5.1

2.3

M . R.d

9300000

25291389

480.0 ^ 3

Mpa

25.00 x

10000

0.0033

Design of Bearings for Gangnani Bridge

Total flexual stress

1.336 +

2.33 =

3.665 Mpa

<

15.00 Mpa

Hence OK

( IRC-83-iii-clause 926.2.1.3)

IV.Coexisting direct and Flexural stress check (IRC-83-iii-clause 926.2.1.3)

Stress =

13.82

20

3.66 =

15.00

<

0.94

1.00

Hence OK

Concrete stress at Piston Base

I.Direct bearing stress due to Vertical load (IRC-83-iii-clause 926.1.5)

Stress =

250.00 x

0.785

10000

x 480 ^ 2

<

13.82 Mpa

172.5 Mpa

Hence OK

II.Flexual stress due to active moment resulting from acting horizental force

e =

Stress

30 +

=

=

36 -

4.00 =

62 mm

25 x

10000 x

0.0982 x

480.0 ^ 3

1.428 Mpa

62

III.Flexural stress due to induced moment resulting from resistance to Rotation

1) M. e.d. =

di =

k1=

k2 =

p =

v =

Kailash Builders

di^3 x ( k1 .p + k2. v)

372.0 mm

2.09

89.314

0.00975 radian

0.00325 radian

IRC- 83 Part (iii) clause 926.1.5.1

di / he =

372.0

26.0

= 14.31

k1

14.31

2.089

12.5

1.8

15

2.2

k2

14.31

89.314

12.5

58.8

15

101

Design of Bearings for Gangnani Bridge

M .ed =

=

=

2)

372.0

51478848

15991389.3 N-mm

^3 x(

x 0.311

M . R.d =

89.3 x

0.0033

372.0

186

186.00 mm

25.00 t

M . R.d =

0.20 x

=

186.00 x

25.00 x

10000

9300000 N-mm

Total induced moment =

M .ed +

15991389 +

25291389

=

=

=

0.0982 x

Total flexual stress

0.0098 +

0.2 x C x H

C=

H=

Stress

2.09 x

2.3

1.428 +

M . R.d

9300000

25291389

480.0 ^ 3

Mpa

2.33 =

3.757 Mpa

<

151.80 Mpa

Hence OK

( IRC-83-iii-clause 926.2.1.)

IV.Coexisting direct and Flexural stress check (IRC-83-iii-clause 926.2.1.3)

Stress =

13.82

172.5

Design of Pot Wall

Force from Pad

3.76 =

151.80

1.00

Hence OK

( IRC-83-iii-clause 926.3.1.1.7)

=

Pressure from Pad ( P1 ) =

=

Total horizental force on wall =

372.00 x

26.00 x

222474.651634

2 x

47.00 x 44.00

53.79 Mpa

25.00 t

Total Horizental stress into wall due to horizental force ( P2 )

Kailash Builders

<

0.10

23

= 222474.652 N ( per one section of ring)

Design of Bearings for Gangnani Bridge

Total P

=

=

=

25 x

10000

2 x

47.00 x 44.00

60.44 Mpa

P1 + P2

53.79 + 60.44

114.23

Mpa

<

168 Mpa

( IRC-83-iii-clause 926.2.2.)

Hence OK

Seismic Case

Design of Neoprene Pad (IRC-83 part (iii) clause 926.2.3)

Neoprene pad stress

250.00

0.785

x 10000

=

x 372 ^ 2

23 Mpa <

x 10000

x 480 ^ 2

14 Mpa <

35 Mpa

Hence OK

Concrete stress at Pot Base (IRC-83 part (iii) clause 926.1.5)

I . Direct Bearing stress due to vertical load

=

250.00

0.785

25 Mpa

Hence OK

II.Flexural stress due to active resulting from acting horizontal force

Eccentricity

Stress

=

=

28 +

26 +

4 =

41 x

10000 x

0.0982 x

480.0 ^ 3

2.201 Mpa

58

mm

58

III.Flexural stress due to induced resulting from resistance to Rotation

1) M. e.d. =

di =

k1=

k2 =

p =

v =

Kailash Builders

di^3 x ( k1 .p + k2. v)

372.0 mm

2.09

89.314

0.00975 radian

0.00325 radian

IRC- 83 Part (iii) clause 926.1.5.1

di / he =

372.0

26.0

= 14.31

k1

14.31

2.089

12.5

1.8

15

2.2

k2

14.31

89.314

12.5

58.8

15

101

Design of Bearings for Gangnani Bridge

M .ed =

=

=

2)

372.0

51478848

15991389.3 N-mm

^3 x(

x 0.311

M . R.d =

89.3 x

186.00 x

25.00 x

10000

0.20 x

=

9300000 N-mm

Total induced moment =

M .ed +

15991389 +

25291389

=

=

=

0.0982 x

=

2.3

2.201 +

M . R.d

9300000

25291389

480.0 ^ 3

Mpa

2.33 =

4.530 Mpa

<

15.00 Mpa

Hence OK

( IRC-83-iii-clause 926.2.1.3)

IV.Coexisting direct and Flexural stress check (IRC-83-iii-clause 926.2.1.3)

Stress =

13.82

25

4.53 =

19.50

<

0.78

Hence OK

Concrete stress at Piston Base

I.Direct bearing stress due to Vertical load (IRC-83-iii-clause 926.1.5)

Stress =

250.00 x

0.785

10000

x 480 ^ 2

<

13.82 Mpa

Hence OK

Kailash Builders

0.0033

186.00 mm

25.00 t

M . R.d =

Total flexual stress

0.0098 +

0.2 x C x H

C=

H=

Stress

2.09 x

172.5 Mpa

1.00

Design of Bearings for Gangnani Bridge

II.Flexual stress due to active moment resulting from acting horizontal force

e =

30 +

Stress

=

=

36 -

4.00 =

62 mm

41 x

10000 x

0.0982 x

480.0 ^ 3

2.353 Mpa

62

III.Flexural stress due to induced moment resulting from resistance to Rotation

1) M. e.d. =

di^3 x ( k1 .p + k2. v)

di =

k1=

k2 =

p =

v =

M .ed =

=

=

2)

372.0 mm

2.09

89.314

0.00975 radian

0.00325 radian

372.0

51478848

15991389.3 N-mm

di / he =

= 14.31

14.31

2.089

12.5

1.8

15

2.2

k2

14.31

89.314

12.5

58.8

15

101

2.09 x

0.0098 +

89.3 x

186.00 x

41.20 x

10000

0.2 x C x H

C=

H=

M . R.d =

186.00 mm

41.20 t

0.20 x

Total induced moment =

=

=

15326400 N-mm

M .ed +

15991389 +

31317789

=

0.0982 x

=

Kailash Builders

372.0

26.0

k1

^3 x(

x 0.311

M . R.d =

Stress

IRC- 83 Part (iii) clause 926.1.5.1

2.9

M . R.d

15326400

31317789

480.0 ^ 3

Mpa

0.0033

Design of Bearings for Gangnani Bridge

Total flexual stress

2.353 +

2.88 =

5.237 Mpa

<

151.80 Mpa

Hence OK

( IRC-83-iii-clause 926.2.1.)

IV.Coexisting direct and Flexural stress check (IRC-83-iii-clause 926.2.1.3)

Stress =

13.82

172.5

Design of Pot Wall

Force from Pad

5.24 =

151.80

<

0.11

1.00

Hence OK

( IRC-83-iii-clause 926.3.1.1.7)

=

372.00 x

Pressure from Pad ( P1 ) =

26.00 x

23

= 222474.652 N ( per one section of ring)

222474.651634

2 x

47.00 x 44.00

53.79 Mpa

Total horizental force on wall =

41.20 t

Total Horizental stress into wall due to horizental force ( P2 )

=

Total P

=

=

=

41 x

10000

2 x

47.00 x 44.00

99.61 Mpa

P1 + P2

53.79 + 99.61

153.40

Mpa

<

Hence OK

Kailash Builders

168 Mpa

( IRC-83-iii-clause 926.2.2.)

Design of Bearings for Gangnani Bridge

MISCELLANEOUS DESIGN CHECKS

Rotation capacity

( IRC-83 part III - clause 926.2.3)

Check compression at edge of Neoprene Pad

Max . Permitted =

=

=

0.15

Rotation ( Radius )

15 % of T

x 22.00

3.3 mm

( T is the thickness of neoprene pad less thick of ring)

( IRC-83 part -III - clause 926.2.3)

=

372

=

3.3

x 0.5

0.018 radian

>

0.01 radian

Hence OK

D/ T ratio of Neoprene Pad

( IRC-83 part -III - clause 926.2.3)

=

372.0

26.0

14.31

< 15

Hence OK

Vertical face of Piston required

Width =

( IRC-83 part -III - clause 926.3.1.3.1)

1.3 x Seismic H Load x

( Pot dia

- 1.50 )

1.30 x

370.50

41.20 x

x 0.75

6.884

<

10000

x 0.75 x 280

10000

x 280

9.00 mm

Hence OK

Bolt Design ( Non Seismic )

Total horizental force

Kailash Builders

( IRC-83 part -III - clause 926.3.6)

25 t

Design of Bearings for Gangnani Bridge

Contribution to resistance by Bolts ( F1 )

Nos of Bolts

Diameter of Bolt

Cross section area

Total cross section area

Shear strenght of bolt Gr 8.8

Shear strenght of bolt Gr 8.8

=

=

=

=

=

=

12

20.00

245.00

2940.0

190

190

Total shear force offer by the Bolts ( F1 ) =

nos

mm

mm

mm

Mpa

Mpa ( Seismic case )

2940.00

x 190

10000

55.9 t ( Non -Seismic Case)

2940.00

x 190

10000

55.9 t ( Seismic Case)

Total shear force offer by the Bolts ( F1 ) =

Contribution to resistance by Friction ( F2 )

Vertical load ( min)

0 t ( Non-seismic )

Vertical load ( min)

0 t ( Seismic )

Co-efficient of friction between concrete and steel

Friction Force ( F2 )

0 x

0 =

0 t( Non-seismic case )

Friction Force ( F2 )

0 x

0 =

0 t ( Seismic case )

Total resistance offered =

( Non seismic case )

55.9 +

0 =

Total resistance offered =

( Seismic case )

55.9 +

DEWEL DESIGN

0.2

55.9 t

> 25.00 t

Hence OK

0 =

55.9 t

> 41.20 t

Hence OK

( IRC-83 part -III - clause 926.3.6.5)

Dia =

50 mm

Length

190 mm

Non-seismic case and Seismic case

Horizental force over Dowel by Bolt

=

3 x

245 x

Stress =

50 x

139650

190

190 =

=

139650 N

14.70 Mpa

< 15.00 Mpa

Hence OK

Kailash Builders

Design of Bearings for Gangnani Bridge

POT INTERFACE

( IRC-83 part -III - clause 926.3.1.1.7)

Non - Seismic

Shear stress at cylinder and base interface considering 1mm slice

Fluid Pressure ( P1 )

=

=

=

Horizental force ( P2) =

=

=

Total stress

he x cc

bp

26.0 x 23.00

44.00

13.59

Mpa

1.5

di

1.5 x

372.0 x

22.911

13.59 +

x H

x bp

250000

44.00

Mpa

22.91 =

36.5 Mpa

< 126.0 Mpa

Hence OK

51.3 Mpa

< 126.0 Mpa

Hence OK

Seismic

Shear stress at cylinder and base interface considering 1mm slice

Fluid Pressure ( P1 )

=

=

=

Horizental force ( P2) =

=

=

Total stress

Kailash Builders

he x cc

bp

26.0 x 23.00

44.00

13.59

Mpa

1.5

di

1.5 x

372.0 x

37.757

13.59 +

x H

x bp

412000

44.00

Mpa

37.76 =

Design of Bearings for Gangnani Bridge

Bearing stress at cylinder and base interface 1mm slice

Non-seismic case

Fluid pressuse( P1 )

Horizental force (P2)

6 x cc x he^

2 x

bp ^

6.0 x

2.0 x

Total stress

23.0 x 676.0

1936.00

24.1 Mpa

1.5 x

2

2

6.0 x H x ha

di x bp ^

2

1.5 x

6.0 x

372.0 x

250000 x 30.00

1936.00

93.7 Mpa

24.1 +

93.7 =

117.8 Mpa

< 184.8 Mpa

Hence OK

combine stressat cylindrical base interface considering 1mm slice

=

13881.55285396

133.7119050167 <

3997.32068922

252

Hence OK

Seismic case

Fluid pressuse( P1 )

Horizental force (P2)

6.0 x

2.0 x

2

2

23.0 x 676.0

1936.00

24.1 Mpa

1.5 x

Kailash Builders

6 x cc x he^

2 x

bp ^

1.5 x

154.5 Mpa

6.0 x H x ha

di x bp ^

2

6.0 x

372.0 x

412000 x 30.00

1936.00

Design of Bearings for Gangnani Bridge

Total stress

24.1 +

154.5 =

178.6 Mpa

< 184.8 Mpa

Hence OK

combine stressat cylindrical base interface considering 1mm slice

=

31881.5

7910.05059985

199.48 <

252

Hence OK

Stress into Lugs because of Horizontal force

Non-Seismic case

Total horizental force on bearing

Effective length of Lug taking shear

=

=

3.0 x

Thickness of Lug

Total cross sectional area of Lug

(Each Lug)

Total nos of Lug in each bearin

Horizental force on each Lug

Stress on Lug due to Horizental force

25 t

20.0 =

60.0 mm

16.00 mm

60.0 x

16.0 =

960 mm^2

12 nos

25

12

2t

20833.3333333

960

= 22 Mpa

<

126.0 Mpa

Hence OK

Seismic case

Total horizental force on bearing

Effective length of Lug taking shear

=

=

3.0 x

Thickness of Lug

Total cross sectional area of Lug

(Each Lug)

Total nos of Lug in each bearin

Horizental force on each Lug

Kailash Builders

25 t

20.0 =

60.0 mm

16.00 mm

60.0 x

16.0 =

12 nos

41.20

12

3t

960 mm^2

Design of Bearings for Gangnani Bridge

Stress on Lug due to Horizental force

34333.3333333

960

<

= 36 Mpa

Check for thickness of Piston in bending : Top

Maximum Vertical load

Effective dia of Piston

=

=

250.00 t

480.00 mm

Effective area of the Top plate which contact with concrete

=

3.142 x

480.000 ^ 2

4

=

180955.7 mm^2

Stress on Top Plate

250.000 x 10000

180955.7

13.8 Mpa

Diameter of loaded area (Pad) =

Projection of piston

372.0 mm

480.00

372.0

Bending moment on the Top Plate =

54.0 mm

13.8 x

54.0^ 2

2

20143.05 N-mm

Thickness of Top Plate reqd to cater the B.M. =

20143.05

1 x

=

25.6 mm

6

184.8

<

30.0 mm

Hence OK

Check for thickness of pot in bending : Bottom

Maximum Vertical load

Effective dia of Piston

=

=

250.00 t

480.00 mm

Effective area of the Bottom plate which contact with concrete

=

3.142 x

480.000 ^ 2

4

=

180955.7 mm^2

Stress on Bot Plate

=

Diameter of loaded area (Pad) =

Projection of piston

Kailash Builders

250.000 x 10000

180955.7

13.8 Mpa

372.0 mm

480.00

372.0

126.0 Mpa

Hence OK

54.0 mm

Design of Bearings for Gangnani Bridge

Bending moment on the Bot Plate =

13.8 x

54.0^ 2

2

20143.05 N-mm

Thickness of bottom Plate reqd to cater the B.M. =

20143.05

1 x

=

25.6 mm

6

184.8

<

28.0 mm

Hence OK

Kailash Builders

Design of Bearings for Gangnani Bridge

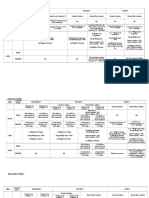

DESIGN CALCULATION FOR SLIDING BEARING

Design Data

Span of bridge

Standard Temp.

Rotation ( Total)

Rotation(due to permanent action)

Rotation ( due to variable action)

Grade of concrete

Concrete stress ( Non seismic)

Concrete stress ( seismic)

Neoprene Pad stress

PTFE stress (working )

Steel stress(working ) for design use

65

+-25

0.01 x

0.0075 x

0.0025 x

M40

20

25

35

40

280

m

C

1.30 =

1.30 =

1.30 =

Mpa

Mpa

Mpa

Mpa

Mpa

DESIGN DIMENSION OF SLIDING BEARING

Neoprene pad dia

Neoprene pad thickness

PTFE size

Pot base effective dia (actual)

Pot base thickness

Pot internal dia

Pot depth

Pot wall thickness

Slide plate contact area dia

Slide plate thickness

Stainless steel thick( Gr 304 )

Effective thickness of slide plate

Piston outer diameter

Piston thickness above spiggot

Spiggot projection

Slide plate dimension (Rect )

Height of Guide Bar

Width of Guide Bar

Length of piston flat

Bolt diameter

No. of bolt per component

Bolt flange thickness

No of sealing ring

Total thickness of rings

Dia of pedestal

Vertical face of Piston

Width of Lug

Thickness of distribution plate

Size of Distribution plate

Kailash Builders

480.0

480.0

380.0

26.0

380.0

480.00

28.00

380.00

47.00

40.00

430.00

22.00

3.00

24.00

420.00

15.00

36.00

490.00

20.00

27.50

360.00

20.00

10

16.00

2

4.00

960.00

10.00

20.00

25

630

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

nos

mm

nos

mm

mm

mm

mm

mm

mm

0.013 radian

0.00975 radian

0.00325 radian

Design of Bearings for Gangnani Bridge

Loading and Requirement

Non Seismic Case

Load

MT

Vertical Load

Dead Load + Live load

Total

250.00

250.00

Horizontal Load

Total

Longitudinal

Transverse

Resultant

25.00

0.00

25

Seismic Case

Load

MT

Vertical Load

Dead Load + Live load

Total

250.00

250.00

Horizontal Load

Total

Longitudinal

Transverse

Resultant

25.00

0.00

25.00

Movement of superstructure

13 mm

Calculation for permissible stresses in Pedestal concrete

Loaded area ( A2 )

x 480.0

^ 2.00

/ 4 =

180955.737 mm^2

Dispersed area( A1)

x 960.0

^ 2.00

/ 4 =

723822.947 mm^2

Permissible concrete stress

A1

A2

x 0.25 fck

20 Mpa

Non Seismic Case

Design of Neoprene Pad (IRC-83 part (iii) clause 926.2.3)

Neoprene pad stress

PTFE stress

Kailash Builders

250.00

0.785

x 10000

=

x 380 ^ 2

22 Mpa <

250.00

0.785

x 10000

=

x 380 ^ 2

22 Mpa <

35 Mpa

Hence OK

Hence OK

40 Mpa

Design of Bearings for Gangnani Bridge

Concrete stress at Pot Base (IRC-83 part (iii) clause 926.1.5)

I . Direct Bearing stress due to vertical load

=

250.00

0.785

14 Mpa <

x 10000

x 480 ^ 2

20 Mpa

Hence OK

II.Flexural stress due to active resulting from acting horizontal force

Eccentricity

Stress

28 +

26 +

4 =

25 x

10000 x

0.0982 x

480.0 ^ 3

1.336 Mpa

58

mm

58

III.Flexural stress due to induced resulting from resistance to Rotation

1) M. e.d. =

di^3 x ( k1 .p + k2. v)

di =

k1=

k2 =

p =

v =

M .ed =

=

=

2)

380.0 mm

2.14

94.508

0.00975 radian

0.00325 radian

di / he =

380.0

^3 x(

54872000

x 0.328

17998016 N-mm

M . R.d =

M . R.d =

Total induced moment =

=

=

15

2.2

k2

14.62

94.508

12.5

58.8

15

101

0.0098 +

94.5 x

190.0 x

9500000 N-mm

M .ed +

17998016 +

27498016

0.0982 x

Kailash Builders

12.5

1.8

380.0

190

190.00 mm

25.00 t

= 14.62

14.62

2.138

2.14 x

0.20 x

=

380.0

26.0

k1

0.2 x C x H

C=

H=

Stress

IRC- 83 Part (iii) clause 926.1.5.1

2.5

M . R.d

9500000

27498016

480.0 ^ 3

Mpa

25.00 x

10000

0.0033

Design of Bearings for Gangnani Bridge

Total flexual stress

1.336 +

2.53 =

3.868 Mpa

<

15.00 Mpa

Hence OK

( IRC-83-iii-clause 926.2.1.3)

IV.Coexisting direct and Flexural stress check (IRC-83-iii-clause 926.2.1.3)

Stress =

13.82

20

3.87 =

15.00

0.95

<

Hence OK

1.00

Concrete stress at Top Plate

I.Direct bearing stress due to Vertical load (IRC-83-iii-clause 926.1.5)

Stress =

250.00 x

0.785

10000

x 430 ^ 2

<

17.22 Mpa

172.5 Mpa

Hence OK

II.Flexual stress due to active moment resulting from acting horizental force

e =

Stress

22 +

=

=

3 =

25 mm

25 x

10000 x

0.0982 x

430.0 ^ 3

0.801 Mpa

25

III.Flexural stress due to induced moment resulting from resistance to Rotation

1) M. e.d. =

di =

k1=

k2 =

p =

v =

M .ed =

=

=

2)

di^3 x ( k1 .p + k2. v)

380.0 mm

2.14

94.508

0.00975 radian

0.00325 radian

di / he =

380.0

^3 x(

54872000

x 0.328

17998016 N-mm

M . R.d =

190.00 mm

380.0

26.0

= 14.62

k1

14.62

2.138

12.5

1.8

15

2.2

k2

14.62

94.508

12.5

58.8

15

101

0.0098 +

94.5 x

2.14 x

0.2 x C x H

C=

Kailash Builders

IRC- 83 Part (iii) clause 926.1.5.1

380.0

190

0.0033

Design of Bearings for Gangnani Bridge

H=

25.00 t

M . R.d =

0.20 x

=

M .ed +

17998016 +

27498016

=

=

=

0.0982 x

Total flexual stress

25.00 x

10000

9500000 N-mm

Total induced moment =

Stress

190.00 x

3.5

0.801 +

M . R.d

9500000

27498016

430.0 ^ 3

Mpa

3.52 =

4.324 Mpa

<

151.80 Mpa

Hence OK

( IRC-83-iii-clause 926.2.1.)

IV.Coexisting direct and Flexural stress check (IRC-83-iii-clause 926.2.1.3)

Stress =

13.82

172.5

Design of Pot Wall

4.32 =

151.80

0.11

<

Hence OK

1.00

( IRC-83-iii-clause 926.3.1.1.7)

Force from Pad

380.00 x

Pressure from Pad ( P1 ) =

26.00 x

22

217791 N ( per one section of ring)

217790.97476

2 x

47.00 x 40.00

57.92 Mpa

Total horizental force on wall =

25.00 t

Total Horizental stress into wall due to horizontal force ( P2 )

=

Total P

=

=

=

25 x

10000

2 x

47.00 x 40.00

66.49 Mpa

P1 + P2

57.92 + 66.49

124.41

Mpa

<

Hence OK

Kailash Builders

168 Mpa

( IRC-83-iii-clause 926.2.2.)

Design of Bearings for Gangnani Bridge

Seismic Case

Design of Neoprene Pad (IRC-83 part (iii) clause 926.2.3)

Neoprene pad stress

PTFE stress

250.00

0.785

x 10000

=

x 380 ^ 2

22 Mpa <

250.00

0.785

x 10000

=

x 380 ^ 2

22 Mpa <

35 Mpa

Hence OK

40 Mpa

Hence OK

Concrete stress at Pot Base (IRC-83 part (iii) clause 926.1.5)

I . Direct Bearing stress due to vertical load

=

250.00

0.785

14 Mpa <

x 10000

x 480 ^ 2

25 Mpa

Hence OK

II.Flexural stress due to active resulting from acting horizontal force

Eccentricity

Stress

28 +

26 +

4 =

25 x

10000 x

0.0982 x

480.0 ^ 3

1.336 Mpa

58

mm

58

III.Flexural stress due to induced resulting from resistance to Rotation

1) M. e.d. =

di^3 x ( k1 .p + k2. v)

di =

k1=

k2 =

p =

v =

M .ed =

=

=

2)

380.0 mm

2.14

94.508

0.00975 radian

0.00325 radian

di / he =

380.0

^3 x(

54872000

x 0.328

17998016 N-mm

M . R.d =

380.0

26.0

= 14.62

k1

14.62

2.138

12.5

1.8

15

2.2

k2

14.62

94.508

12.5

58.8

15

101

0.0098 +

94.5 x

25.00 x

10000

2.14 x

0.2 x C x H

C=

H=

M . R.d =

190.00 mm

25.00 t

0.20 x

Kailash Builders

IRC- 83 Part (iii) clause 926.1.5.1

190.00 x

9500000 N-mm

0.0033

Design of Bearings for Gangnani Bridge

Total induced moment =

M .ed +

17998016 +

27498016

=

=

Stress

=

0.0982 x

Total flexual stress

2.5

1.336 +

M . R.d

9500000

27498016

480.0 ^ 3

Mpa

2.53 =

3.868 Mpa

<

18.75 Mpa

Hence OK

( IRC-83-iii-clause 926.2.1.3)

IV.Coexisting direct and Flexural stress check (IRC-83-iii-clause 926.2.1.3)

Stress =

13.82

25

3.87 =

19.50

0.75

<

Hence OK

1.00

stress at Top Plate

I.Direct bearing stress due to Vertical load (IRC-83-iii-clause 926.1.5)

Stress =

250.00 x

0.785

10000

x 430 ^ 2

<

17.22 Mpa

172.5 Mpa

Hence OK

II.Flexual stress due to active moment resulting from acting horizontal force

e =

Stress

22 +

=

=

3 =

25 mm

25 x

10000 x

0.0982 x

430.0 ^ 3

0.801 Mpa

25

III.Flexural stress due to induced moment resulting from resistance to Rotation

1) M. e.d. =

di =

k1=

k2 =

p =

v =

Kailash Builders

di^3 x ( k1 .p + k2. v)

380.0 mm

2.14

94.508

0.00975 radian

0.00325 radian

IRC- 83 Part (iii) clause 926.1.5.1

di / he =

380.0

26.0

= 14.62

k1

14.62

2.138

12.5

1.8

15

2.2

k2

14.62

94.508

12.5

58.8

15

101

Design of Bearings for Gangnani Bridge

M .ed =

=

=

2)

380.0

^3 x(

54872000

x 0.328

17998016 N-mm

M . R.d =

2.14 x

0.0098 +

94.5 x

25.00 x

10000

0.0033

0.2 x C x H

C=

H=

190.00 mm

25.00 t

M . R.d =

0.20 x

=

9500000 N-mm

Total induced moment =

M .ed +

17998016 +

27498016

=

=

Stress

=

0.0982 x

Total flexual stress

190.00 x

3.5

0.801 +

M . R.d

9500000

27498016

430.0 ^ 3

Mpa

3.52 =

4.324 Mpa

<

151.80 Mpa

Hence OK

( IRC-83-iii-clause 926.2.1.)

IV.Coexisting direct and Flexural stress check (IRC-83-iii-clause 926.2.1.3)

Stress =

13.82

172.5

Design of Pot Wall

4.32 =

151.80

0.11

<

Hence OK

1.00

( IRC-83-iii-clause 926.3.1.1.7)

Force from Pad

380.00 x

Pressure from Pad ( P1 ) =

26.00 x

22

217791 N ( per one section of ring)

217790.97476

2 x

47.00 x 40.00

57.92 Mpa

Total horizental force on wall =

25.00 t

Total Horizental stress into wall due to horizental force ( P2 )

=

Total P

=

=

=

Kailash Builders

25 x

10000

2 x

47.00 x 40.00

66.49 Mpa

P1 + P2

57.92 + 66.49

124.41

Mpa

<

168 Mpa

( IRC-83-iii-clause 926.2.2.)

Design of Bearings for Gangnani Bridge

Hence OK

MISCELLANEOUS DESIGN CHECKS

Rotation capacity

( IRC-83 part III - clause 926.2.3)

Check compression at edge of Neoprene Pad

Max . Permitted =

=

=

15 % of T

x 22.00

3.3 mm

0.15

Rotation ( Radius )

( T is the thickness of neoprene pad less thick of ring)

( IRC-83 part -III - clause 926.2.3)

3.3

x 0.5

380

=

0.017 radian

>

0.01 radian

Hence OK

D/ T ratio of Neoprene Pad

( IRC-83 part -III - clause 926.2.3)

=

380.0

26.0

14.6 Mpa

< 15 Mpa

Hence OK

Vertical face of Piston required

Width =

( Pot dia

( IRC-83 part -III - clause 926.3.1.3.1)

1.3 x Seismic H Load x

- 1.50 )

1.30 x

378.50

25.00 x

x 0.75

4.1

<

10000

x 0.75 x 280

10000

x 280

10.00 mm

Hence OK

Kailash Builders

Design of Bearings for Gangnani Bridge

Slidling Capacity

( IRC-83 part -III - clause 926.3.1.1.6.1)

Slide plate dimension (Rect )

480.00

Effective dia of concrete at top

Preset in Long. Direction

Longitudinal movement

Movement possible in one direction

490.00 mm

430.00 mm

0 mm

480.00 430.00

50.00 0.00

2

50.00 0.00

2

Movement possible in other direction

=

=

50.00 mm

25.0 mm

>

25.0 mm

>

13.0 mm

13.0 mm

Hence OK

Guides

Inside Dimension of slide plate

Length of Piston

490.00 435.00 -

Bolt Design ( Non Seismic )

Total horizontal force

27.50 10.00 -

27.50

5.00

435.00 mm

420.00 mm

=

=

( IRC-83 part -III - clause 926.3.6)

25 t

Contribution to resistance by Bolts ( F1 )

Nos of Bolts

Biameter of Bolt

Cross section area

Total cross section area

Shear strenght of bolt Gr 8.8

Shear strenght of bolt Gr 8.8

=

=

=

=

=

=

10

20.00

245.00

2450.0

190

190

Total shear force offer by the Bolts ( F1 ) =

nos

mm

mm

mm

Mpa

Mpa ( Seismic case )

2450.00

x 190

10000

46.6 t ( Non -Seismic Case)

2450.00

x 190

10000

46.6 t ( Seismic Case)

Total shear force offer by the Bolts ( F1 ) =

Contribution to resistance by Friction ( F2 )

Vertical load ( min)

0 t ( Non-seismic )

Vertical load ( min)

0 t ( Seismic )

Co-efficient of friction between concrete and steel

0.2

Friction Force ( F2 )

0 x

0 =

0 t( Non-seismic case )

Friction Force ( F2 )

0 x

0 =

0 t ( Seismic case )

Total resistance offered =

46.6 +

0 =

Kailash Builders

46.6 t

Design of Bearings for Gangnani Bridge

> 25.00 t

Hence OK

( Non seismic case )

Total resistance offered =

( Seismic case )

46.6 +

46.6 t

> 25.00 t

Hence OK

DOWEL DESIGN

Dia =

Length =

0 =

( IRC-83 part -III - clause 926.3.6.5)

50 mm

190 mm

Non-seismic case and Seismic case

Horizental force over Dowel by Bolt

=

3 x

245 x

Stress =

190 =

139650.00

50 x

190

139650 N

14.70 Mpa

< 15.00 Mpa

Hence OK

Stress in Guide Bar

(Non Seismic )

Shear stress

25.00 x 10000

27.50 x 360.00

Eccentricity

Moment

5 +

25.00 x

Flexual stress

0.5 x

10000 x

25 Mpa

15 =

12.5 =

<

126 Mpa

Hence OK

12.5 mm

3125000 N-mm

M

x

6

L x H^ 2

=

=

360.00 x

69 Mpa

3125000 x 6

27.50 ^ 2

<

168 Mpa

Hence OK

Combine stress at the Top Plate Guide Bar inter face

4743.1

82 Mpa

1913.07

<

252 Mpa

Hence OK

Stress in Guide Bar

( Seismic )

Shear stress

25.00 x 10000

27.50 x 360.00

Eccentricity

Moment

5 +

25.00 x

Kailash Builders

0.5 x

10000 x

25 Mpa

15 =

12.5 =

<

126 Mpa

Hence OK

12.5 mm

3125000 N-mm

Design of Bearings for Gangnani Bridge

Flexual stress

M

x

6

L x H^ 2

=

=

360.00 x

69 Mpa

3125000 x 6

27.50 ^ 2

<

168 Mpa

Hence OK

Combine stress at the Top Plate Guide Bar inter face

4743.1

82 Mpa

1913.07

<

252 Mpa

Hence OK

POT INTERFACE

( IRC-83 part -III - clause 926.3.1.1.7)

Non - Seismic

Shear stress at cylinder and base interface considering 1mm slice

Fluid Pressure ( P1 )

=

=

=

Horizental force ( P2) =

=

=

Total stress

Kailash Builders

he x cc

bp

26.0 x 22.04

40.00

14.33

Mpa

1.5

di

1.5 x

380.0 x

24.671

14.33 +

x H

x bp

250000

40.00

Mpa

24.67 =

39.0 Mpa

< 126 Mpa

Hence OK

Design of Bearings for Gangnani Bridge

Seismic

Shear stress at cylinder and base interface considering 1mm slice

Fluid Pressure ( P1 )

he x cc

bp

26.0 x 22.04

40.00

14.33

Mpa

=

=

=

Horizental force ( P2) =

1.5

di

1.5 x

380.0 x

24.671

=

=

Total stress

14.33 +

x H

x bp

250000

40.00

Mpa

24.67 =

39.0 Mpa

< 126 Mpa

Hence OK

Bearing stress at cylinder and base interface 1mm slice

Non-seismic case

Fluid pressuse( P1 )

Horizental force (P2)

6 x cc x he^

2 x

bp ^

6.0 x

2.0 x

Total stress

22.0 x 676.0

1600.00

27.9 Mpa

1.5 x

1.5 x

6.0 x H x ha

di x bp ^ 2

6.0 x

380.0 x

19309.888928

154.50809036 <

27.9 +

4562.86105982

252

Hence OK

Kailash Builders

250000 x 30.00

1600.00

111.0 Mpa

111.0 =

combine stressat cylindrical base interface considering 1mm slice

=

2

2

139.0 Mpa

<

185 Mpa

Hence OK

Design of Bearings for Gangnani Bridge

Seismic case

Fluid pressuse( P1 )

6 x cc x he^

2 x

bp ^

6.0 x

2.0 x

Horizental force (P2)

22.0 x 676.0

1600.00

27.9 Mpa

1.5 x

1.5 x

Total stress

2

2

6.0 x H x ha

di x bp ^ 2

6.0 x

380.0 x

250000 x 30.00

1600.00

111.0 Mpa

27.9 +

111.0 =

139.0 Mpa

<

185 Mpa

Hence OK

combine stressat cylindrical base interface considering 1mm slice

=

19309.9

4562.86105982

154.51 <

252

Hence OK

Stress into Lugs because of Horizontal force

Non-Seismic case

Total horizontal force on bearing

Effective length of Lug taking shear

=

=

3.0 x

Thickness of Lug

Total cross sectional area of Lug

(Each Lug)

Total nos of Lug in each bearin

Horizental force on each Lug

Stress on Lug due to Horizental force

Kailash Builders

25 t

20.0 =

60 mm

16.00 mm

60.0 x

16.0 =

960 mm^2

12 nos

25

12

2t

20833.333333

960

= 22 Mpa

<

126 Mpa

Hence OK

Design of Bearings for Gangnani Bridge

Seismic case

Total horizental force on bearing

Effective length of Lug taking shear

3.0 x

Thickness of Lug

Total cross sectional area of Lug

(Each Lug)

Total nos of Lug in each bearin

Horizental force on each Lug

Stress on Lug due to Horizental force

25 t

20.0 =

60 mm

16.00 mm

60.0 x

16.0 =

960 mm^2

10 nos

25.00

10

3t

25000

960

= 26 Mpa

<

126 Mpa

Hence OK

Check for thickness of Piston in bending : Top

Maximum Vertical load

Effective dia of Piston

=

=

250.00 t

430.00 mm

Effective area of the Top plate which contact with concrete

=

3.142 x

430.000 ^ 2

4

=

145220.1 mm^2

Stress on Top Plate

250.000 x 10000

145220.1

17.2 Mpa

Diameter of loaded area (Pad) =

Projection of piston

380.0 mm

430.00

Bending moment on the Top Plate =

380.0

25.0 mm

17.2 x

25.0^ 2

2

5379.76 N-mm

Thickness of Top Plate reqd to cater the B.M. =

5379.76

1 x

=

13.2 mm

6

184.8

<

24 mm

Hence OK

Kailash Builders

Design of Bearings for Gangnani Bridge

Check for thickness of pot in bending : Bottom

Maximum Vertical load

Effective dia of Piston

=

=

250.00 t

480.00 mm

Effective area of the Bottom plate which contact with concrete

=

3.142 x

480.000 ^ 2

4

=

180955.7 mm^2

Stress on Bot Plate

250.000 x 10000

180955.7

13.8 Mpa

Diameter of loaded area (Pad) =

Projection of piston

380.0 mm

480.00

Bending moment on the Bot Plate =

380.0

50.0 mm

13.8 x

50.0^ 2

2

17269.42 N-mm

Thickness of bottom Plate reqd to cater the B.M. =

17269.42

1 x

=

23.7 mm

6

184.8

<

28 mm

Hence OK

Kailash Builders

You might also like

- Final Pot Ptfe Design Sheet - 02.01.13Document47 pagesFinal Pot Ptfe Design Sheet - 02.01.13Sandeep Kumar75% (4)

- CribDocument1 pageCribskumarsrNo ratings yet

- Underground Winding SystemsDocument58 pagesUnderground Winding SystemsRuben Castro Quispe100% (1)

- ELASTOMERIC and POT PTFEDocument10 pagesELASTOMERIC and POT PTFESwapnil KNo ratings yet

- 2850-1992 KN S (Type - A1) Span P 51 Anti Uplift ArrangementDocument9 pages2850-1992 KN S (Type - A1) Span P 51 Anti Uplift ArrangementGaurav PatilNo ratings yet

- Design of Elastomeric BearingsDocument6 pagesDesign of Elastomeric BearingsHarshitha GaneshNo ratings yet

- Design Calculation of Spherical MSM Slide Guide (T) Bearing - 1800 KN (GB7) PDFDocument6 pagesDesign Calculation of Spherical MSM Slide Guide (T) Bearing - 1800 KN (GB7) PDFDusmantaKumarSahooNo ratings yet

- Elastomeric Bearing 21.6mDocument8 pagesElastomeric Bearing 21.6mnaresh KUMARNo ratings yet

- 1.0 Bearing-38.973 (Skew)Document37 pages1.0 Bearing-38.973 (Skew)vinoraamNo ratings yet

- Longitudinal BearingDocument6 pagesLongitudinal BearingDPJAIN INFRASTRUCTURENo ratings yet

- FB. 60M - Free Bearing DesignDocument10 pagesFB. 60M - Free Bearing DesignBasava SowmyaNo ratings yet

- Section Modulus CalculatorDocument14 pagesSection Modulus CalculatorSuyenthan SathishNo ratings yet

- Shear Conection Design - IS 800-2007Document4 pagesShear Conection Design - IS 800-2007Swapnil ToraskarNo ratings yet

- Bearing Design-30.0m - PSCDocument5 pagesBearing Design-30.0m - PSCSHARATH VASUPRADA100% (1)

- Elastromatric Bearing PadDocument7 pagesElastromatric Bearing PadIlancheral NedumaranNo ratings yet

- Loads On Pot - Ptfe Bearing - 3x17m SpanDocument12 pagesLoads On Pot - Ptfe Bearing - 3x17m SpanMalayKumarDebNo ratings yet

- Idn - 4Document5 pagesIdn - 4Anh KyNo ratings yet

- Bearing Design Method ADocument6 pagesBearing Design Method ALartit LIANTHAVYVANHNo ratings yet

- Bolted Connections: DR S R Satish Kumar, IIT MadrasDocument30 pagesBolted Connections: DR S R Satish Kumar, IIT MadraspjuvvadiNo ratings yet

- Fatigue Check in Prestressed GirderDocument3 pagesFatigue Check in Prestressed GirderViplawNo ratings yet

- Plate GirderDocument74 pagesPlate Girderarif_rubin100% (1)

- Cost Comparison PCC Vs RCC ReturnDocument3 pagesCost Comparison PCC Vs RCC Returndesign MridcNo ratings yet

- Elastomeric Bearings: 6 (1) Design Load On BearingsDocument8 pagesElastomeric Bearings: 6 (1) Design Load On BearingsCivil MexNo ratings yet

- 70R Loading, Live LoadDocument12 pages70R Loading, Live LoadTashi TamangNo ratings yet

- SDPL CH 148-160 Shuttering Design For Girder-Layout-23Document1 pageSDPL CH 148-160 Shuttering Design For Girder-Layout-23Sudeep JoshiNo ratings yet

- Bolted Splice DesignDocument8 pagesBolted Splice DesignAnonymous sfkedkymNo ratings yet

- TSR NIRMAN Bow String Girder Launching Design Note-06.05.2022Document1 pageTSR NIRMAN Bow String Girder Launching Design Note-06.05.2022sups madiNo ratings yet

- Bearing Pot Cum 27-08-2020Document48 pagesBearing Pot Cum 27-08-2020Hymavathi MNo ratings yet

- Design of Pot Ptfe Bearing (Free Bearing) As Per Irc 83:2002 (Part 3)Document7 pagesDesign of Pot Ptfe Bearing (Free Bearing) As Per Irc 83:2002 (Part 3)DPJAIN INFRASTRUCTURENo ratings yet

- 4.3 Design Values of Bending Moments and Shear ForcesDocument7 pages4.3 Design Values of Bending Moments and Shear Forcesmn4webNo ratings yet

- Design of Welded Plate GirderDocument25 pagesDesign of Welded Plate GirderJinshad UppukodenNo ratings yet

- Spliced ColumnsDocument10 pagesSpliced ColumnsgvlanushaNo ratings yet

- HMM Infra LTD, Anbala: Design of Trestle (Cribs)Document10 pagesHMM Infra LTD, Anbala: Design of Trestle (Cribs)Anonymous sfkedkymNo ratings yet

- Bridge PortionDocument16 pagesBridge PortionNagara SelvarajNo ratings yet

- Thulo Neti Khola Bridge - Abutment Design: Fig: Abutment (All Dimensions in Metres)Document4 pagesThulo Neti Khola Bridge - Abutment Design: Fig: Abutment (All Dimensions in Metres)Himal KafleNo ratings yet

- Design of POT-PTFE (Fixed)Document8 pagesDesign of POT-PTFE (Fixed)NONGTHONNo ratings yet

- Design of Cantilever Slab As Per Is 456 2000Document2 pagesDesign of Cantilever Slab As Per Is 456 2000airtelNo ratings yet

- Spread Sheet of Plate Girder-Is800-2007Document3 pagesSpread Sheet of Plate Girder-Is800-2007yedida v r aviswanadh100% (1)

- JSPL SectionsDocument7 pagesJSPL SectionsDebasish MondalNo ratings yet

- 2000 MM 1900 MM: Check For Crack Width As Per Is 456-2000Document1 page2000 MM 1900 MM: Check For Crack Width As Per Is 456-2000karthikmr85No ratings yet

- Elastomeric Bearing 13-09-13Document27 pagesElastomeric Bearing 13-09-13bulganinganguliNo ratings yet

- Calculation of Bearing ForcesDocument15 pagesCalculation of Bearing ForcesSajib DasNo ratings yet

- 2 - Axle Load PDFDocument17 pages2 - Axle Load PDFDebanjan MukherjeeNo ratings yet

- IRC Rigid Pavement DesignDocument15 pagesIRC Rigid Pavement DesignAjay SastryNo ratings yet

- Beam Bending Strenght Aisc 9th EditionDocument17 pagesBeam Bending Strenght Aisc 9th EditionKory Estes100% (1)

- DistributionTheory RevBDocument102 pagesDistributionTheory RevBNasser AmmariNo ratings yet

- Base Plate Design - Concrete Beam TheoryDocument3 pagesBase Plate Design - Concrete Beam TheoryDarsHan MoHanNo ratings yet

- Column Splice End Plate DesignDocument3 pagesColumn Splice End Plate DesigninnovativekarthiNo ratings yet

- Seismic ArrestorDocument8 pagesSeismic ArrestorankitNo ratings yet

- Pipe CulvertDocument14 pagesPipe CulvertPraveen M balaramNo ratings yet

- Design of Elastomeric Bearing Based On IRC 083-2-1987Document4 pagesDesign of Elastomeric Bearing Based On IRC 083-2-1987Babita SharmaNo ratings yet

- Unit 5 Plate Girder&GantryGirder NotesDocument18 pagesUnit 5 Plate Girder&GantryGirder NotesGautham SgNo ratings yet

- Precast Rib Beam DesignDocument1 pagePrecast Rib Beam Designanshutomar7915100% (1)

- SteelDocument80 pagesSteelAnonymous HJ7hmihhNo ratings yet

- Aci BeamDocument6 pagesAci BeamkumsbamaNo ratings yet

- Step by Step Design of PSC Girder by Working Stress MethodDocument50 pagesStep by Step Design of PSC Girder by Working Stress Methodpravin100% (3)

- Wing Wall DesignDocument19 pagesWing Wall DesignMAGED MOHMMED AHMED QASEMNo ratings yet

- Retaining WallDocument41 pagesRetaining Wallp_ignatiusNo ratings yet

- Trafo Found DesignDocument6 pagesTrafo Found DesignIrshad Khan100% (1)

- Workbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsDocument26 pagesWorkbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsShubham mishraNo ratings yet

- Combined Gusset Plate DesignDocument3 pagesCombined Gusset Plate Designkalpanaadhi100% (3)

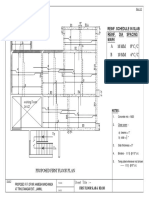

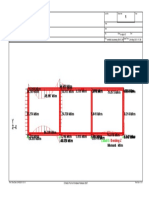

- Front ElevationDocument1 pageFront Elevationmanoj_structureNo ratings yet

- DeflectionDocument22 pagesDeflectionrobertantoreniNo ratings yet

- Presentation On Analysis and Design of TDocument49 pagesPresentation On Analysis and Design of Tmanoj_structureNo ratings yet

- B 10 MM 8" C/C 10 MM 6" C/C A: Reinf. Schedule in Slab Reinf. Dia Spacing MarkDocument1 pageB 10 MM 8" C/C 10 MM 6" C/C A: Reinf. Schedule in Slab Reinf. Dia Spacing Markmanoj_structureNo ratings yet

- Hamesh Manchanda GF Slab 1Document1 pageHamesh Manchanda GF Slab 1manoj_structureNo ratings yet

- Asi 810 05 R1Document1 pageAsi 810 05 R1manoj_structureNo ratings yet

- Concrete Design Excel SheetDocument16 pagesConcrete Design Excel SheetCleth Hiren Santos25% (4)

- 14-Apr-07 24-May-2013 11:38 Vented Causeway 3M X 3M Analysis For Class A Double Lane Loading - STDDocument1 page14-Apr-07 24-May-2013 11:38 Vented Causeway 3M X 3M Analysis For Class A Double Lane Loading - STDmanoj_structureNo ratings yet

- Is 802 - Load CombinationDocument3 pagesIs 802 - Load Combinationmanoj_structureNo ratings yet

- Stringers ISMC MM Th. CHQ Plate Decking X Girder ISMCDocument1 pageStringers ISMC MM Th. CHQ Plate Decking X Girder ISMCmanoj_structureNo ratings yet

- PLAN1a PDFDocument1 pagePLAN1a PDFmanoj_structureNo ratings yet

- First Floor Layout PlanDocument1 pageFirst Floor Layout Planmanoj_structureNo ratings yet

- Structural MechanicsDocument649 pagesStructural MechanicsNanda Moreira100% (1)

- Rpt. 195 Load Rating Bridges W o Plans 1j0rx7yDocument66 pagesRpt. 195 Load Rating Bridges W o Plans 1j0rx7yMahmoud BayatNo ratings yet

- Design and Fabrication of Automatic Shoe Polishing Machine: Technical ReportDocument5 pagesDesign and Fabrication of Automatic Shoe Polishing Machine: Technical Reportesubalew tadesseNo ratings yet

- M.tech ME Machine Design R17Document51 pagesM.tech ME Machine Design R17Lakshmi Narayana SNo ratings yet

- IRC 112-2011 Concrete Road Bridges PDFDocument289 pagesIRC 112-2011 Concrete Road Bridges PDFBiswa Balla89% (18)

- Ahammed & Melchers 1996Document6 pagesAhammed & Melchers 1996Michael McconnellNo ratings yet

- Life Assessment Ship Unloader CraneDocument5 pagesLife Assessment Ship Unloader CraneArif SugihartoNo ratings yet

- Plate Theory Slides From WEB PDFDocument20 pagesPlate Theory Slides From WEB PDFHarish ShridharamurthyNo ratings yet

- Collings, David - Steel Concrete Composite Bridges (2005, Thomas Telford Publishing) PDFDocument195 pagesCollings, David - Steel Concrete Composite Bridges (2005, Thomas Telford Publishing) PDFjasmina100% (2)

- At 14 2Document7 pagesAt 14 2Icz Fuentes100% (1)

- Static Analysis of Tractor Trolley AxleDocument5 pagesStatic Analysis of Tractor Trolley AxleseventhsensegroupNo ratings yet

- Material Properties: (ESE - 1992) (ESE - 1992)Document121 pagesMaterial Properties: (ESE - 1992) (ESE - 1992)Sanket ManeNo ratings yet

- Análisis e Investigación de Fallas de Fractura en El Eje de Transmisión de PositivoDocument18 pagesAnálisis e Investigación de Fallas de Fractura en El Eje de Transmisión de Positivojohnny oreNo ratings yet

- Ship Collision Finite Element AnalysisDocument29 pagesShip Collision Finite Element AnalysisGobinda SinhaNo ratings yet

- Thesis FulltextDocument472 pagesThesis FulltextBhaskar ReddyNo ratings yet

- Tool LifeDocument22 pagesTool LifeDhruv Bhalala100% (1)

- AISC Design Guide 29 - Vertical Bracing Connections - Analysis and Design 2 de 2 PDFDocument196 pagesAISC Design Guide 29 - Vertical Bracing Connections - Analysis and Design 2 de 2 PDFMartin Cristobal CupitayNo ratings yet

- Study On The Residual Stress of Bar With Straightening by Two RollsDocument6 pagesStudy On The Residual Stress of Bar With Straightening by Two RollsArmando FaríasNo ratings yet

- Mahalakshmi: Engineering CollegeDocument16 pagesMahalakshmi: Engineering CollegeVijeesh VijayalayamNo ratings yet

- UNIT-5 SpringsDocument6 pagesUNIT-5 SpringsUday Narasimha100% (2)

- Eng TipsDocument5 pagesEng TipsBenedictus MurdonoNo ratings yet

- 59-Numerical Analysis of Masonry Arch Bridges Benefits and Limits of Damage MechanicsDocument8 pages59-Numerical Analysis of Masonry Arch Bridges Benefits and Limits of Damage MechanicsvttrlcNo ratings yet

- ICMPT 2019 Proceedindgs PDFDocument762 pagesICMPT 2019 Proceedindgs PDFBiswajitRoyNo ratings yet

- Design Provisions For Shear WallsDocument13 pagesDesign Provisions For Shear WallsRm1262No ratings yet

- Filling and Emptying State of Silos Above DischargDocument6 pagesFilling and Emptying State of Silos Above DischargBartłomiej MinorNo ratings yet

- AP-T188-11 - Review of Structural Design Procedures For Foamed Bitumen PavementsDocument82 pagesAP-T188-11 - Review of Structural Design Procedures For Foamed Bitumen Pavementsaskarah100% (1)

- Mechanics:-: AS Level Physics: Terms & DefinitionsDocument7 pagesMechanics:-: AS Level Physics: Terms & DefinitionsJenniferNo ratings yet

- Eaton Metal SealsDocument60 pagesEaton Metal SealsmyegnrNo ratings yet

- Design For Punching Shear Strength With ACI 318-95: Aci Structural Journal Technical PaperDocument11 pagesDesign For Punching Shear Strength With ACI 318-95: Aci Structural Journal Technical PaperJoseph AsfourNo ratings yet