Professional Documents

Culture Documents

05467625

05467625

Uploaded by

delviCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Tronic Universal Battery Charger - ManualDocument10 pagesTronic Universal Battery Charger - ManualrosstdevansNo ratings yet

- Ansi c12.19 2008Document580 pagesAnsi c12.19 2008adeleongiron100% (4)

- FPGA Based Real Time Sensor Data AcquisitionDocument26 pagesFPGA Based Real Time Sensor Data AcquisitiondelviNo ratings yet

- Implementation of UART With BIST Technique in Fpga: Bibin M C, Premananda B SDocument5 pagesImplementation of UART With BIST Technique in Fpga: Bibin M C, Premananda B SdelviNo ratings yet

- Nand FlashDocument7 pagesNand FlashdelviNo ratings yet

- Highly Scalable Horizontal Channel 3-D NAND Memory Excellent in Compatibility With Conventional Fabrication TechnologyDocument3 pagesHighly Scalable Horizontal Channel 3-D NAND Memory Excellent in Compatibility With Conventional Fabrication TechnologydelviNo ratings yet

- A Manufacturing Cost Model For 3-D Monolithic Memory Integrated CircuitsDocument8 pagesA Manufacturing Cost Model For 3-D Monolithic Memory Integrated CircuitsdelviNo ratings yet

- 2018 Mitsubishi Outlander Phev 111848Document28 pages2018 Mitsubishi Outlander Phev 111848Stefan MinculetNo ratings yet

- Specifications For Grid-Dependent Solar PV Systems - Division 48 14 - Solar PVDocument82 pagesSpecifications For Grid-Dependent Solar PV Systems - Division 48 14 - Solar PVntrkulja@hotmail.comNo ratings yet

- BEG Diesel Schulungen 2012 enDocument13 pagesBEG Diesel Schulungen 2012 enhelorcaNo ratings yet

- Minix NEO G4Document23 pagesMinix NEO G4xidraNo ratings yet

- Description Parametric Table: Low Power Low Offset Voltage Dual Comparators As393/393ADocument2 pagesDescription Parametric Table: Low Power Low Offset Voltage Dual Comparators As393/393AThiago Andrade RangelNo ratings yet

- U6 (Smart Card Chip) AT88SC DatasheetDocument17 pagesU6 (Smart Card Chip) AT88SC DatasheetilieNo ratings yet

- MELSERVO-JE Servo Amplifier: General-Purpose AC ServoDocument92 pagesMELSERVO-JE Servo Amplifier: General-Purpose AC ServoVN MÁY TỰ ĐỘNGNo ratings yet

- Echosmart DSB 771 791 UmDocument11 pagesEchosmart DSB 771 791 UmjuganaruNo ratings yet

- IC Compiler CommandsDocument8 pagesIC Compiler Commandsmaheshgowtham100% (2)

- MotoSimEG VRC EducationDocument2 pagesMotoSimEG VRC EducationAdán Rodriguez CuatlapantziNo ratings yet

- Ml493 Ttx54 Vtx54 Rev BDocument2 pagesMl493 Ttx54 Vtx54 Rev Bilter79No ratings yet

- GEK-86132G PowerVac ML18 BreakerDocument44 pagesGEK-86132G PowerVac ML18 Breakermikazuki augustNo ratings yet

- 1686 Alcatel Operacao PDFDocument43 pages1686 Alcatel Operacao PDFcomtekaccountsNo ratings yet

- Radar Safety Guidelines PDFDocument2 pagesRadar Safety Guidelines PDFMarijaŽaperNo ratings yet

- Mochad UsageDocument4 pagesMochad Usagejc.mt9335No ratings yet

- Chapter 1 ReviewQuestionsDocument2 pagesChapter 1 ReviewQuestionsJared AdesNo ratings yet

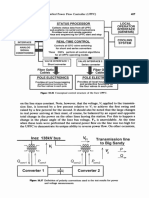

- Status Processor Local Operator Interface (Genesis) : Transmission Line Big Sandy Inez 138kV BusDocument4 pagesStatus Processor Local Operator Interface (Genesis) : Transmission Line Big Sandy Inez 138kV Busjack936No ratings yet

- NBN40 U1 UuDocument4 pagesNBN40 U1 UuKleberBuñayNo ratings yet

- History of AntennasDocument23 pagesHistory of AntennasNanda Kumar100% (1)

- Diamler EMC Test Compare of Diff OEMs (2012)Document4 pagesDiamler EMC Test Compare of Diff OEMs (2012)Martin BoianiNo ratings yet

- 9702 s09 Er PDFDocument23 pages9702 s09 Er PDFwaseem aminNo ratings yet

- Slow Light - Science and Applications (Optical Science and Engineering) 08-410Document410 pagesSlow Light - Science and Applications (Optical Science and Engineering) 08-410HamiltonNo ratings yet

- Corsair H105i v2 Liquid CPU Cooler Extreme PerformanceDocument12 pagesCorsair H105i v2 Liquid CPU Cooler Extreme PerformanceNguyenHoangNo ratings yet

- IR Remote Control BasicsDocument3 pagesIR Remote Control BasicsprettyaprilNo ratings yet

- ECI - Main ReportDocument47 pagesECI - Main ReportParthaSarathyNo ratings yet

- Smart Intelligent Aircraft StructuresDocument4 pagesSmart Intelligent Aircraft StructuresLoc Das NeyfusNo ratings yet

- NPCT6XX TPMDocument25 pagesNPCT6XX TPMC PNo ratings yet

- Deep Sea Electronics 7310Document2 pagesDeep Sea Electronics 7310ابراهيم حافظNo ratings yet

05467625

05467625

Uploaded by

delviCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

05467625

05467625

Uploaded by

delviCopyright:

Available Formats

2322

IEEE TRANSACTIONS ON MAGNETICS, VOL. 46, NO. 6, JUNE 2010

A Study of Write Margin of Spin Torque Transfer Magnetic Random

Access Memory Technology

Tai Min1 , Qiang Chen1 , Robert Beach1 , Guenole Jan1 , Cheng Horng1 , Witold Kula1 , Terry Torng1 , Ruth Tong1 ,

Tom Zhong1 , Denny Tang1 , Pokang Wang1 , Mao-min Chen1 , J. Z. Sun2 , J. K. Debrosse2 , D. C. Worledge2 ,

T. M. Maffitt2 , and W. J. Gallagher2

MagIC-IBM MRAM Alliance,MagIC Technologies, Inc., Milpitas, CA 95035 USA

IBM T. J. Watson Research Center, Yorktown Heights, NY 10598 USA

Key design parameters of 64 Mb STT-MRAM at 90-nm technology node are discussed. A design point was developed with adequate

TMR for fast read operation, enough energy barrier for data retention and against read disturbs, a write voltage satisfying the long term

reliability against dielectric breakdown and a write bit error rate below 1009 . A direct experimental method was developed to determine

the data retention lifetime that avoids the discrepancy in the energy barrier values obtained with spin current- and field-driven switching

measurements. Other parameters detrimental to write margins such as backhopping and the existence of a low breakdown population

are discussed. At low bit-error regime, new phenomenon emerges, suggestive of a bifurcation of switching modes. The dependence of the

bifurcated switching threshold on write pulse width, operating temperature, junction dimensions and external field were studied. These

show bifurcated switching to be strongly influenced by thermal fluctuation related to the spatially inhomogeneous free layer magnetization. An external field along easy axis direction assisting switching was shown to be effective for significantly reducing the percentage of

MTJs showing bifurcated switching.

Index TermsBifurcated switching, magnetic random access memory, magnetic tunneling junction, spin torque.

I. INTRODUCTION

PIN torque transfer (STT) MRAM has been intensively

studied as a candidate for future memory applications due

to its nonvolatility, fast write-time, and scalability with CMOS

technology [1], [2]. The critical element of the STT-MRAM

is the magnetic tunneling junction (MTJ) with an MgO barrier

which can provide high tunneling magnetoresistance

up to 1056% at room temperature [3]. Utilizing the STT induced switching as the writing mechanism also has a scaling

advantage: upon junction size reduction, the current needed to

switch the free layer orientation is decreased. However, magnetic thermal fluctuation can be significant for room temperature operation of magnetic memory cells below 100 nm, as it

affects STT switchings speed and threshold distribution. For

reliable write, the write current has to be high enough to ensure all devices are switched to desired states, while still remain low enough to avoid junction barrier breakdown. Currently, MTJs with a 1.2 nm or less Mg-oxide layer are necessary

due to the requirement of a low resistance-area product

for a reasonably low write voltage. The dielectric breakdown

of such thin MgO barriers under voltage/current stress therefore

becomes critical to the success of STT-MRAM technology. The

reliability of the thin oxide against breakdown determines the

upper limit of the programming voltage. To commercialize the

bit error rate has to

STT-MRAM with 64 Mb density, a

be achieved in both read and write operations. The key challenge in realizing this is the write margin between the minimum

programming voltage and the dielectric breakdown of MgO for

Manuscript received October 31, 2009; revised February 01, 2010; accepted

February 01, 2010. Current version published May 19, 2010. Corresponding

author: T. Min (e-mail: tai.min@headway.com).

Color versions of one or more of the figures in this paper are available online

at http://ieeexplore.ieee.org.

Digital Object Identifier 10.1109/TMAG.2010.2043069

a magnetic free layer with adequate thermal energy barrier for

reversal.

In this paper, we will discuss the key design parameters like

programming voltage, breakdown distribution, and thermal energy barrier with an emphasis on the experimental study of those

factors effects on the write error rate and the write margin. Particularly, we report new experimental discoveries of a low probability bifurcation of switching modes. Such bifurcated switch

increases programming voltage, and degrades the write margin

and thus should be understood and eliminated.

II. EXPERIMENTAL PROCEDURE

Test chips with 4-k to 1-M bit fully integrated with 90-nm

CMOS technology have been built to study various parameters

critical to the development of STT-MRAM product. These

tests quantify the breakdown distributions [4], back-hopping

[5][7] and programming voltages with bit error rate (BER)

[9]. The MTJ structure is seed

down to the level of

layer/PtMn/CoFeB/Ru/CoFeB/MgO/CoFeB/capping

layer

type and was patterned using 248-nm lithography and reactive

ion etching into elliptical pillars. The MTJ dimensions studied

160 to

nm . The MgO

are in the range of 55

thickness is under 1.2 nm and the

value ranges from

m . To obtain the breakdown distributions, 2 k

4 k MTJs were tested destructively via a sequence of square

voltage pulses with pulse widths and heights incremented until

device breakdown. The MTJ resistance was monitored by

measuring its current under 100 mV bias across the full circuit

including lead and FET resistances each time after the stress

voltage pulse. Both stress voltage and resistance measurements

were performed through the same pads, an equivalent 2-point

probe configuration that includes CMOS multiplexing circuits

for junction array addressing. The total parasitic resistance was

estimated around 170 . A positive bias corresponds to the

current flowing from the free layer to the reference layer.

0018-9464/$26.00 2010 IEEE

MIN et al.: STUDY OF WRITE MARGIN OF SPIN TORQUE TRANSFER MAGNETIC RANDOM ACCESS MEMORY TECHNOLOGY

2323

III. RESULTS AND DISCUSSIONS

For a 1 T-1 MTJ 64 Mb STT-MRAM product, there are several aspects that need to be considered concurrently: 1) high

and low resistance distribution for fast read; 2) enough

energy barrier against read and thermal disturbs; 3) low programming current/voltage for compact cell size 4) robust tunrange studied here, the

neling barrier for reliability. In the

value at 50 mV is around 120% with standard deviation

of

and parallel resistance

around 3.6% and 4.0% of

their means, respectively. The separation between the high and

, adequate for read. The

low resistance means is around

key challenge is to lower the write voltage/current. For this, a

macrospin model [6], [10] is often used to guide the direction

for lowering the write voltage/current

(1)

where

is the critical switching current density at 0 K;

and

are the magnetization and thickness of the free layer;

is effective anisotropic field including crystalline and shape

anisotropy;

is the external field; is the spin transfer efficiency; is the Gilbert damping constant; is the electron

charge, and is Plancks constant. At finite temperature, the

switching threshold is thermally distributed [11], [12], and the

critical switching current density becomes

(2)

where

is the energy barrier;

is the pulse width of

is the inswitching voltage/current; is the temperature;

verse of attempt frequency, and is Boltzmanns constant. The

via

.

switching voltage is related through

The values of

, ,

, ,

, and

have to be balanced

to have lowest switching voltage with enough thermal barrier

and resistance of MTJ

for data retention, adequate

, ,

, were kept as low as the

for read. The values of

minimum data retention requirement allowed; similarly the

value of MTJ was set as low as possible, limited by the

and

for read-out. The challenge is lowering

required

and

and their distributions so as to have the enough

the

write margin between the write voltage for

and the

tunnel junction breakdown voltage distribution.

A. Data Retention

The required energy barrier against thermal disturb has been

is in the

discussed extensively and a value of

range needed to be adequate for data retention. The value

is usually obtained by data fitting to (2). However the value

(and

) thus obtained can vary significantly depending on the

range of pulse widths used, as shown in Fig. 1. Here, the

values of 200 MTJs were measured with pulse widths in two

totally different ranges of time scales: 50 9500 ns and 9.5

9500 ms. The average value of

as a function of pulse width

was plotted in Fig. 1(a) and fitted to (2). The

value obtained

while

from

from the nanosecond range is only around

the pulse width in the second range can be up to a factor 1.83

for the same group of samples. The

value

higher to

can also be obtained by measuring the

at various measuring

Fig. 1. (a) Critical switching voltage as a function of pulse width and (b)

(in Oe) as a function of measurement dwell time (b).

dwell time then fitting this data to the following formula [14],

[15]:

(3)

obtained by this

As shown in the Fig. 1(b), the value of

method can be an additional factor of 2 higher, similar to the

results reported by [16]. This experiment indicates that it is not

by simply fitting to (2), especially when

accurate to obtain

the pulse width is on the nano-second scale. The discrepancy beobtained with and without spin current

tween the values of

could be due to the fact that the spin current injected into MTJ

can induce nonuniform magnetization distributions [17], [18]

which invalidate the macrospin assumption used to derive (2).

obtained without spin current is more

For data retention, the

relevant. To determine what value and distribution of

(and

hence ) is required for adequate data retention, we adopted a

direct approach of determining the thermally induced switching

probability (TISP) function for MTJs with various volumes,

s and baking times by measuring the switched devices after

being stored at elevated temperature for various time periods

without external magnetic fields. 4-k test chips were used in this

experiment. For a given MTJ design, the percentage of switched

devices depends on baking temperature, duration, and junction

. The percentage of switched device vs Hc gives TISP as

a function of Hc. These TISP data can be fitted very well by

the cumulative distribution function (CDF) of a Gaussian distribution with two independent parameters. Once the dependence

of these two parameters of CDF on MTJ volume, baking temperature and time were determined experimentally, the data retention can be estimated for any given MTJ design. For MTJs

nm , the minimum requirement of

with sizes of

2324

Fig. 2. Weibull plots for various stressing voltage of the MTJ population with

the high breakdown distribution.

IEEE TRANSACTIONS ON MAGNETICS, VOL. 46, NO. 6, JUNE 2010

Fig. 3. Write voltage (V ) at 10 BER versus RA value of MgO for two

different MTJ designs. The V of Design-2 was lowered to be consistent with

the level of the maximum voltage allowed by the long term reliability breakdown

requirements.

and Ave is 190 Oe and 12% for adequate data retention idle

storage at 125 C for 1 year and 1-bit error correction. Details

of this method will be published elsewhere.

B. Junction Breakdown Distributions

For desired junction

, the MgO tunnel barrier is less

than 12 thick. A dielectric at such thin thickness poses new

challenges as the dielectric breakdown was known to have

two distinct distributions [4]. The majority MTJs have high

breakdown value (HBD) while a small percentage of MTJs

exhibit low values of breakdown (LBD). The peak-to-peak

to the HBD distributions can be

separation between the

but only

as high as

for LBD distribution. As described in [4], besides the low

breakdown induced defects, some MTJs with very different

LBD characteristics, behave identically otherwise to the HBD

,

and IV curves of this type

MTJs. The values of

of LBD MTJs were identical to those of MTJs with the HBD

distribution. It is suspected therefore that the LBD is caused

by a spatially nonuniform MgO barriereither in thicknesses,

stoichiometry or nonuniform Boron distribution at the MgO

interface. These result in spatial variation of the tunneling current which can concentrate on spots with low barrier heights,

developing into a breakdown spot. MTJ structure and process

play a dominate role in determining the percentage of MTJs in

the LBD population and have to be optimized to eliminate the

LBD distribution. At present the percentage of LBD MTJ can

be lowered to 0.1% but efforts are still needed to eliminate

LBD MTJs completely.

separation between

In order to determine whether

peak-to-peak value of HBD and

distribution is enough for

a reliable product, time dependent device breakdown (TDDB)

measurements were performed on the HBD MTJs under various stress conditions, as shown by Fig. 2. The measured

TDDB follows the standard Weibull distribution. Following

the approach of [19] and applying a relatively loose criteria

that allows 20% chip failure after ten years of random access

operation with a 30% duty cycle and 2 bit ECC, the maximum

is around 350

allowed voltage across the MTJ

400 mV at an

value

m for current MTJ structure

and processes, as shown in Fig. 3. Also included in Fig. 3 are

of two different

two curves of write voltage at

Fig. 4. BER curves versus applied voltage measured three times for a single

MTJ. An existence of abnormal bifurcated switching process at lower probability is demonstrated.

MTJ designs. The

of Design-2 can marginally meet the

requirement of maximum allowed voltage dictated by the long

term reliability of MgO breakdown. Clearly, continuing efforts

to improve the MTJ design and processes are still required to

and reduce their sigmas in

further lowering , raise

order to widen the write margin.

C. Write Margin: Back-Hopping and Bifurcated Switching

For write margin assessment, BER vs write voltage was rou. For 50

tinely collected on 128 MTJs down to a level of

100 ns pulse widths BER vs pulse height can be fitted very

and read

well by a Gaussian CDF, as shown in Fig. 4. The

values can be determined by extrapolating

disturb voltage

which corresponds

the average BER curve to the level of

to a

. For the Design-2 shown in Fig. 3, the

is around 370 mV and

is around 101 mV, higher than the

100-mv read bias voltage.

However, several new failure mechanisms were discovered

that can significantly erode the write margin. One of them is

the so-called backhopping phenomena [16][19], [27] in which

the magnetization of free layer can switch back to its original

state after a successful write operation. The root cause of the

backhopping is believed to be the abnormal reduction of energy

barrier at high bias, possibly due to the effect of Joule heating,

the impact of field-like term and/or the de-stabilizing of the reference layer interacting with free layer via polarized electrons

MIN et al.: STUDY OF WRITE MARGIN OF SPIN TORQUE TRANSFER MAGNETIC RANDOM ACCESS MEMORY TECHNOLOGY

Fig. 5. Increasing the pulse width of applied switching voltage can reduce the

low-probability-bifurcated-switching significantly.

2325

Fig. 7. Reducing the short axis of ellipse can reduce the percentage of MTJ

with low-probability-bifurcated-switching.

Fig. 8. FMR images of two MTJs with same aspect ratio but different short

axis of ellipse. More FMR peaks for MTJ with larger short axis.

Fig. 6. Increasing the substrate temperature from room temperature to 120 C

can significantly reduce the low-probability-bifurcated-switching.

[17][19], [27]. Increasing the value of

can reduce or eliminate the impact of back-hopping on write margin.

Another new phenomenon that erodes the write margin

reported first time here is that for a certain percentage of MTJs,

there exists another switching branch of the BER curve at a

lower BER level, as shown by Fig. 4. This switching branch

also follows a Gaussian CDF distribution, similar to that of

the main BER curve, suggesting that it might be caused by the

bifurcation of switching path but the probability for it to appear

is lower than that for main switching trajectory. We refer to

this type of switching branch as low probability bifurcated

switching (LPBS, type-C). The percentage of MTJs showing

.

LPBS increases as the BER is tested to levels lower than

The LPBS curve is not an occasional abnormality but is highly

repeatable. This is demonstrated in Fig. 4 in which repeating

the BER measurements three times produced identical main

BER and LPBS curves. Fig. 5 shows that the LPBS is strongly

affected by the thermal fluctuationsincreasing the pulse

width of applied voltage from 50 to 200 ns caused the LPBS

to decrease monotonically. This monotonic dependence of

LPBS on the pulse width was found all the way down to 10 ns,

i.e., approaching the precessional switching region. Similarly,

increasing the substrate temperature can also diminish the

LPBS, as shown in Fig. 6 in which the LPBS was reduced to a

as the substrate temperature is modestly

level lower than

increased from room temperature to 120 C. The percentage of

MTJs showing LPBS is also strongly affected by the dimensions of MTJ elliptical junction. Fig. 7 shows that when the

short axis of the MTJ increases from 55 nm to 90 100 nm,

the percentage of LPBS MTJs increases rapidly, independent

of the MTJ patterning process. Process A and B are two totally

different MTJ patterning process, indicating that the MTJ shape

irregularity caused by MTJ patterning process is not a dominant

nm, the aspect ratio of the

factor here. For short axis

ellipse was in the range from 2.0 to 4.0. Interestingly, the percentage of LPBS MTJs does not change much over this range.

To explore the MTJ dimension effect further, FMR spectra as

a function of applied hard axis field were collected for two

devices with same MTJ structure, process and aspect ratio

but different short axes, shown by Fig. 8. The device with the

nm clearly exhibits much more

longer short axis

high order excitation peaks than the device with the shorter axis

nm , indicating that more spin wave modes were

available for device with longer short axis. It is also observed

that for the MTJ design with more spatially nonuniform free

layer magnetization, the percentage of LPBS is higher and

greater number of high order FMR peaks are present. These

two results suggest that the appearance of LPBS is strongly

related to the spatial uniformity of free layer magnetization.

In the previous work [20] on the switching trajectories in the

precessional mode region, the initial magnetization direction is

critical for determining the switching trajectory, the time scale

for observed changes is in the ns or sub-ns region. Experiments

that attempted to change the initial magnetization direction were

performed by applying constant external field and tilting the

2326

IEEE TRANSACTIONS ON MAGNETICS, VOL. 46, NO. 6, JUNE 2010

Fig. 9. Percentage of LPBS MTJs normalized to the percentage of LPBS at

normalized to

and MTJ

is reduced exponentially against the

area for MTJ with dimensions varying from

nm to

nm .

H =0

H

84 2 178

H

1042 345

long axis of ellipse with respect to the reference layer magnetization direction. For the magnetic field applied along the hard

axis of ellipse, 20 40 Oe field along either hard axis direction

can reduce, enhance, create or have no effect on the LPBS. No

visible change of the percentage of LPBS MTJs was observed

for the wafers with tilted long axis MTJs. These results indicate

that changing the initial magnetization direction in our case has

no effect on LPBS and the time scale for LPBS ranges from 10

1000 ns range, suggesting the underlying mechanism of LPBS

is different from the bifurcation switching studied in the precessional region which is usually based on the macrospin model

which assumes homogenous magnetization [21][24].

The LPBS observed here is more of a thermal fluctuation

dominated process with a spatially nonuniform free layer magnetization. Since the LPBS is a thermal activation dominated

process, lowering the thermal barrier may help reduce the

appearance of LPBS MTJs. As shown by Fig. 9, applying an

easy axis field that assists switching can reduce the percentage

of LPBS MTJs significantly for various MTJ dimensions.

Increasing the easy axis field strength, the percentage of LPBS

MTJs can be reduced further. It is interesting to note that

the ratio of the percentage of LPBS MTJs normalized to the

decreases exponentially versus

percentage at

normalized to the product of

and MTJ area. The reason for

this relationship is not known at the present time.

Another interesting new phenomena that was observed when

is present is the appearance of a new

the assisting easy axis

type of LPBS (type-G) which can be fit by the probability distribution function (PDF) of a Gaussian distribution instead of CDF,

Oe. As the pulse width

as shown by Fig. 10 in which

increases from 10 to 200 ns, the peak value of type-G LPBS remains unchanged at 450 mV while its amplitude and sigma is

reduced monotonically, similar to the pulse width dependence

of the amplitude and sigma of type-C LPBS. The type-G LPBS

can be completely isolated from the main BER curve when the

pulse width is greater than 50 ns. Fig. 11 shows the effect of

strength on the type-G LPBS at fixed pulse width, 50 ns in this

case. By increasing the

from 10 Oe to 60 Oe, the peak position of type-G LPBS moves towards lower voltage and the peak

value increases rapidly.

The exact mechanism for the appearance of the two types

of LPBS is not known at this point. The speculation that it

H = 60

Fig. 10. BER curves under assisting easy axis field

Oe showing

a new type of bifurcated switching which follows a Gaussian distribution. Increasing pulse width reduces the peak value and sigma of this type LPBS but

does not change the peak position.

Fig. 11. At 50-ns pulse width, increasing the assisting easy axis field will lower

the peak position and raising the amplitude of type-G low-probability-bifurcated-switching.

is caused by the bifurcation of multiple trajectories of spin

torque transfer induced switching with different energy barrier

and probability needs more concrete evidence. Bifurcation of

switching trajectories of nano-magnet system described by

LandauLifshitzGilbert equation has been studied theoretically [21][24] with findings of the existence of stable limit

cycles (self-oscillation). Experimentally, bifurcated switching

between static state and the self-oscillation, between to two

self-oscillation states [25] and between two C-states [26] were

reported. The MTJ system driven by spin polarized current is

intrinsically a nonlinear open system far from equilibrium [22]

and bifurcation theory is applicable to describing the dynamic

process of this system. However, the fact that for the MTJ

with more inhomogeneous free layers, larger sizes, and thus

more available spin wave modes, more devices exhibit LPBS

suggests that the switching process in our MTJ spin system

is highly noncoherent and complex. It is possible that in this

highly spatial nonuniform magnetization system, local stable

nodes and limit cycles can exist and under the right conditions,

portions of free layer magnetization can be locked into these

local stable nodes or stable limit cycles which will result in the

whole magnetization system failing to switch. The probability

of falling into those nodes/limit cycles should be lower than

MIN et al.: STUDY OF WRITE MARGIN OF SPIN TORQUE TRANSFER MAGNETIC RANDOM ACCESS MEMORY TECHNOLOGY

that for the main switching trajectory which should be the path

with the lowest energy barrier. Thermal agitation via either

longer pulses or higher substrate temperatures will allow the

spin system of MTJ to find the path with lowest energy barrier

and will also enhance the chance of escaping the local stable

node or stable limit cycle. Clearly, rigorous work on studying

the nonlinear dynamics of LLG equation of highly spatial

nonuniform magnetization system is needed to understand the

underlying physics of the LPBS so that solutions can be found

to eliminate it. The existence of LPBS increases the value of

and could raise the error floor to an unacceptable level for a

STT-MRAM product.

In summary, we have demonstrated that it is feasible to develop an MTJ design and fabrication process to meet the requirements of data retention, long term dielectric reliability with

write and read disturb error rate for a 64 Mb STT-MRAM

product. Nevertheless, continuing effort to reduce the critical

switching voltage/current is still needed and understanding and

eliminating both LPBS and LBD distribution are essential for

the STT-MRAM to be a successful product.

IV. CONCLUSION

Key design parameters of a 64-Mb STT-MRAM product

development were discussed. In the effort to reducing the

switching voltage/current, the values of free layer magnetization, thickness, anisotropic field and resistance-area product

have to be considered concurrently. It was found that there is

big discrepancy between the thermal barrier values obtained

with and without the spin polarized current. An experimental

method was developed to determine the required coercivity and

sigma for a given MTJ dimensions to have thermal barriers adequate for data retention and avoiding read disturbs. Two distinct

breakdown distributions with high and low breakdown value

were found in todays MTJ structure with less than 12-A thick

MgO spacer. For the MTJ population with high breakdown

value, time-dependent-device-breakdown study was performed

which resulted in a maximum write voltage in the range of 350

400 mV. Bit error rates were routinely collected to study

the write voltage and write margin of various MTJ designs.

Backhopping during the write operation was discussed and

eliminating its impact on write errors was shown to require

higher energy barriers. The existence of two types of bifurcated

switching modes was discovered, which are detrimental to the

write margin. These types of bifurcated switching have lower

probability than the main switching path and exist in the both

near-precessional and thermal regions. Their dependence on

pulse width of applied voltage, substrate temperature, MTJ

dimensions and constant external field were investigated. It

was found that an external field along the easy axis to assist

switching can significantly reduce the percentage of MTJ

showing multiple switching modes. Much work is needed to

understand and eliminate the bifurcated switching modes and

the low value breakdown distribution for STT-MRAM to be a

successful commercial product.

2327

REFERENCES

[1] M. Hosomi et al., in Proc. IEDM Tech. Dig., 2005, pp. 459462.

[2] H. Yoda et al., Spin torque transfer switching of perpendicular magnetoresistive elements for high density MRAMs, presented at the Dig.

Intermag, 2008, FA-04.

[3] L. Jiang et al., Large tunnel magnetoresistance of 1056% at room temperature in MgO based double barrier magnetic tunnel junction, Appl.

Phys. Exp., vol. 2, p. 083002, 2009.

[4] Q. Chen et al., Study of dielectric breakdown distributions in magnetic tunneling junction with MgO barrie, J. Appl. Phys., vol. 105, p.

07C931, 2009.

[5] R. Beach et al., A statistical study of magnetic tunnel junctions for

high-density Spin Torque Transfer-MRAM (STT-MRAM), presented

at the IEDM Tech. Dig., 2008.

[6] J. Z. Sun, Spin current interaction with a monodomain magnetic body:

A model study, Phys. Rev. B, vol. 62, p. 570, 2000.

[7] Z. Li et al., Thermally assisted magnetization reversal in the presence

of a spin-transfer torque, Phys. Rev. B, vol. 69, p. 134416, 2004.

[8] R. H. Koch et al., Time resolved reversal of spin transfer switching in

a nanomagnet, Phys. Rev. Lett., vol. 92, p. 088302, 2004.

[9] Y. Huai et al., Spin-transfer switching current distribution and reduction in magnetic tunneling junction-based structures, IEEE Trans.

Magn., vol. 41, no. 10, p. 2621, Oct. 2005.

[10] Z. Li et al., Perpendicular spin torques in magnetic tunnel junctions,

Phys. Rev. Lett., vol. 100, p. 246602, 2008.

[11] M. P. Sharrock, IEEE Trans. Magn., vol. 26, p. 193, 1990.

[12] S. Oh et al., Switching characteristics and bias voltage dependence

of spin torque switching in MgO based magnetic tunnel junctions.,

presented at the Intermag, 2008, GD-01.

[13] X. Zhu et al., Spin transfer excited regular and chaotic spin waves in

current perpendicular to plane spin valves, J. Appl. Phys., vol. 95, p.

6630, 2004.

[14] K. Lee et al., Micromagnetic investigation of dynamics of magnetization switching induced by a spin polarized current, Appl. Phys. Lett.,

vol. 88, p. 132506, 2006.

[15] J. Das et al., Area scaling and voltage dependence of time-to-breakdown in magnetic tunnel junctions, J. Appl. Phys., vol. 91, p. 7712,

2002.

[16] T. Min et al., Back-hopping after spin torque transfer induced magnetization switching in magnetic tunneling junction cells, J. Appl. Phys.,

vol. 105, p. 07D126, 2009.

[17] J. Sun et al., High-bias backhopping in nanosecond time-domain spintorque switches of MgO-based magnetic tunnel junctions, J. Appl.

Phys., vol. 105, p. 07D109, 2009.

[18] J. Sun et al., Spin-transfer-driven reversal in magnetic tunnel junctions: Torques, dynamics, and thermal activation effects, presented at

the Dig. Intermag, 2009, ED-02.

[19] H. Ohmori et al., Back hopped switching error in spin transfer torque

MRAM, presented at the Intermag, 2009, CT-05.

[20] T. Devolder et al., Electric time-domain observation of magnetization switching induced by spin transfer in magnetic nanostructures, J.

Appl. Phys., vol. 103, p. 07A723, 2008.

[21] Y. Acremann et al., Bifurcation in precessional switching, Appl.

Phys. Lett., vol. 79, p. 2228, 2001.

[22] G. Bertotti et al., Magnetization switching and microwave oscillations

in nanomagnets driven by spin-polaried currents, Phys. Rev. Lett., vol.

94, p. 127206, 2005.

[23] C. Serpico et al., Thermal stability in spin-torque-driven magnetization dynamics, J. Appl. Phys., vol. 99, p. 08G505, 2006.

[24] P. Gorley et al., Application of self-organization methods to currentinduced magnetization dynamics of a single-domain ferromagnet, J.

Appl. Phys., vol. 101, p. 034504, 2007.

[25] I. N. Krivorotov et al., Time-domain studies of very-large-angle magnetization dynamics exicted by spin transfer torques, Phys. Rev. B, vol.

77, p. 054440, 2008.

[26] J. P. Strachan et al., Direct observation of spin-torque driven magnetization reversal through nonuniform modes, Phys. Rev. Lett., vol. 100,

p. 247201, 2008.

[27] S.-C. Oh et al., Nature Phys., vol. 5, p. 898, 2009.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Tronic Universal Battery Charger - ManualDocument10 pagesTronic Universal Battery Charger - ManualrosstdevansNo ratings yet

- Ansi c12.19 2008Document580 pagesAnsi c12.19 2008adeleongiron100% (4)

- FPGA Based Real Time Sensor Data AcquisitionDocument26 pagesFPGA Based Real Time Sensor Data AcquisitiondelviNo ratings yet

- Implementation of UART With BIST Technique in Fpga: Bibin M C, Premananda B SDocument5 pagesImplementation of UART With BIST Technique in Fpga: Bibin M C, Premananda B SdelviNo ratings yet

- Nand FlashDocument7 pagesNand FlashdelviNo ratings yet

- Highly Scalable Horizontal Channel 3-D NAND Memory Excellent in Compatibility With Conventional Fabrication TechnologyDocument3 pagesHighly Scalable Horizontal Channel 3-D NAND Memory Excellent in Compatibility With Conventional Fabrication TechnologydelviNo ratings yet

- A Manufacturing Cost Model For 3-D Monolithic Memory Integrated CircuitsDocument8 pagesA Manufacturing Cost Model For 3-D Monolithic Memory Integrated CircuitsdelviNo ratings yet

- 2018 Mitsubishi Outlander Phev 111848Document28 pages2018 Mitsubishi Outlander Phev 111848Stefan MinculetNo ratings yet

- Specifications For Grid-Dependent Solar PV Systems - Division 48 14 - Solar PVDocument82 pagesSpecifications For Grid-Dependent Solar PV Systems - Division 48 14 - Solar PVntrkulja@hotmail.comNo ratings yet

- BEG Diesel Schulungen 2012 enDocument13 pagesBEG Diesel Schulungen 2012 enhelorcaNo ratings yet

- Minix NEO G4Document23 pagesMinix NEO G4xidraNo ratings yet

- Description Parametric Table: Low Power Low Offset Voltage Dual Comparators As393/393ADocument2 pagesDescription Parametric Table: Low Power Low Offset Voltage Dual Comparators As393/393AThiago Andrade RangelNo ratings yet

- U6 (Smart Card Chip) AT88SC DatasheetDocument17 pagesU6 (Smart Card Chip) AT88SC DatasheetilieNo ratings yet

- MELSERVO-JE Servo Amplifier: General-Purpose AC ServoDocument92 pagesMELSERVO-JE Servo Amplifier: General-Purpose AC ServoVN MÁY TỰ ĐỘNGNo ratings yet

- Echosmart DSB 771 791 UmDocument11 pagesEchosmart DSB 771 791 UmjuganaruNo ratings yet

- IC Compiler CommandsDocument8 pagesIC Compiler Commandsmaheshgowtham100% (2)

- MotoSimEG VRC EducationDocument2 pagesMotoSimEG VRC EducationAdán Rodriguez CuatlapantziNo ratings yet

- Ml493 Ttx54 Vtx54 Rev BDocument2 pagesMl493 Ttx54 Vtx54 Rev Bilter79No ratings yet

- GEK-86132G PowerVac ML18 BreakerDocument44 pagesGEK-86132G PowerVac ML18 Breakermikazuki augustNo ratings yet

- 1686 Alcatel Operacao PDFDocument43 pages1686 Alcatel Operacao PDFcomtekaccountsNo ratings yet

- Radar Safety Guidelines PDFDocument2 pagesRadar Safety Guidelines PDFMarijaŽaperNo ratings yet

- Mochad UsageDocument4 pagesMochad Usagejc.mt9335No ratings yet

- Chapter 1 ReviewQuestionsDocument2 pagesChapter 1 ReviewQuestionsJared AdesNo ratings yet

- Status Processor Local Operator Interface (Genesis) : Transmission Line Big Sandy Inez 138kV BusDocument4 pagesStatus Processor Local Operator Interface (Genesis) : Transmission Line Big Sandy Inez 138kV Busjack936No ratings yet

- NBN40 U1 UuDocument4 pagesNBN40 U1 UuKleberBuñayNo ratings yet

- History of AntennasDocument23 pagesHistory of AntennasNanda Kumar100% (1)

- Diamler EMC Test Compare of Diff OEMs (2012)Document4 pagesDiamler EMC Test Compare of Diff OEMs (2012)Martin BoianiNo ratings yet

- 9702 s09 Er PDFDocument23 pages9702 s09 Er PDFwaseem aminNo ratings yet

- Slow Light - Science and Applications (Optical Science and Engineering) 08-410Document410 pagesSlow Light - Science and Applications (Optical Science and Engineering) 08-410HamiltonNo ratings yet

- Corsair H105i v2 Liquid CPU Cooler Extreme PerformanceDocument12 pagesCorsair H105i v2 Liquid CPU Cooler Extreme PerformanceNguyenHoangNo ratings yet

- IR Remote Control BasicsDocument3 pagesIR Remote Control BasicsprettyaprilNo ratings yet

- ECI - Main ReportDocument47 pagesECI - Main ReportParthaSarathyNo ratings yet

- Smart Intelligent Aircraft StructuresDocument4 pagesSmart Intelligent Aircraft StructuresLoc Das NeyfusNo ratings yet

- NPCT6XX TPMDocument25 pagesNPCT6XX TPMC PNo ratings yet

- Deep Sea Electronics 7310Document2 pagesDeep Sea Electronics 7310ابراهيم حافظNo ratings yet