Professional Documents

Culture Documents

June 23, 1925.: F . I: Zacher

June 23, 1925.: F . I: Zacher

Uploaded by

shamsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

June 23, 1925.: F . I: Zacher

June 23, 1925.: F . I: Zacher

Uploaded by

shamsCopyright:

Available Formats

June 23, 1925.

1,543,354

F. I: ZACHER

FOLDING MACHINE

Filed June 28, 1924

.1

' Patented June 23, 1925.

' 1,543,354

PATENT OFFICE.

FRED T. ZACHER, OF ST. LOUIS, MISSOURI.

FOLDING MACHINE.

Application ?led June 28, 1924. Serial No. 722,975.

To all whom it may concern:

advance and insure their individual feeding.

Be it known that I, FRED T. ZACHER. a Both of the rollers 72 and b are operated in '

citizen of the United States, residing at St.

a counterclockwise directlon as seen 1n Fm.

.

h

Louis. Missouri, have invented a new and 2. [The rolls a? are actuated by the belt (if

useful Folding Machine, of which the follow to move the sheets individually toward the

60

ing is a speci?cation.

10

folding mechanism. From the rolls d the

This invention relates to improvements in sheets pass between the buckling rolls 6 and

folding machines.

'

f and thence to the folding mechanism in

The invention comprises mechanism for cluding a roll 9 cooperating with the roll 7.

use in a sheet feeding and folding machine As is well known machines of the type illus

65

whereby, when a sheet ,is folded to form trated are operable to fold a sheet longitudi

page leaves. the leaves are secured together nally and transversely to provide a plurality

along the fold lines as an incident .to the of page leaves. Certain of the page leaves

are united at their folded ends which makes 7O

Another object of the invention is to pro it necessary to cut said'folded ends to per

operation of the folding mechanism. 1 15

vide mechanism of the characterand for the mit opening or separation of the leaves.

purpose stated in the preceding paragraph,

My invention comprises mechanism em

in combination with mechanism for cutting bodied in a folding machine for adhesively

the leaves at their end foldsto permit sepa-v uniting the page leaves of pamphlets along

ration of the leaves while said leaves remain their median fold lines and for cutting the

adhesively united along their median folded folded ends of the page leaves to'permit

75

separation thereof. As shown a shaft 1 is

Another object of the invention is' to pr0~ ., supported in advance of the folding mecha

line.

25

30

vide mechanism for discharging from the

machine the strips cut from the folded sheet

so that said. strips will not become mixed

.with the ?nished product.

Other objects will appear from the fol

nism in bearings 2 and is rotated by a belt

3 engaging a pulley 4 on the shaft 5 of the'

80

roller 6 and a pulley 6 on the shaft 1. _ A

disc 7 is attached to the shaft 1 and contacts

"with the sheets as they are fed to the folding

lowing description, reference being made to mechanism by the rolls 0?. The speed of ro

the drawing in whichtation of the disc 7 is the same as the speed

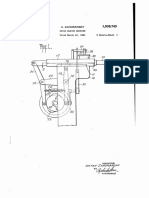

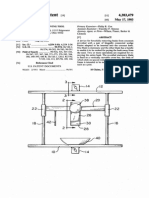

Fig. 1 is a plan view of a part of a well of movement of the sheets, so that the disc

85

known sheet feeding and folding machine 7 neither retards nor accelerates the move

35

which I have selected for the purpose of ment of the sheets passing to the folding

illustrating the embodiment of the present mechanism of the machine. Preferably a

invention.

, number of notches 8 are formed in the pe

Fig. 2 is a sectional view on the line 2-2 riphery. of the disc 7 to receive and apply to

of Fig. 1.

the sheet passing under the disc 9. su?icient

The sheet

feeding and folding machine in

90:

quantity of paste to secure the sheet together

' which the present invention is shown is along the fold line of the leaves forming the 96

40

known as the Cleveland folder, the sheet. pamphlet. A_ paste receptacle 9 has'arms 10

feeding mechanism of which is in substantial engaging the shaft 1 and is supported in

conformity with the disclosure of Trautman proper relationship to' the disc 7 by a con

Patent No. 1,413,245, dated April 18. 1922, nection 11 extending to- some stationary part

45

50

and the folding mechanism of which is sub

stantially disclosed in Olson Patent No.v

1,390,213, dated September 6, 1921. As dis

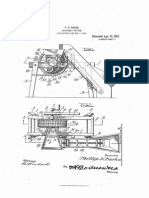

closed in said patents the feeding rollers b

of the machine. A slotted discharge chute

12 extends from the bottom of the receptacle

9 toward the disc 7 and receives the disc 7

in the slot in the end of said. chute. As the

and 7) move the sheets from the supporting disc 7 rotates a part of the paste in the re

table 0 to the delivery table comprising ceptacle 9 adheres to the periphery of said . 105

angularly positioned horizontal rolls 0?. The disc and enters the notches 8 and as the disc

feeding rollers b and I) operate upon the rotates the paste is deposited in a straight

sheets in the well known manner; the upper line upon the sheet passing to the folding

and larger roller 6 engaging and individu

mechanism.

35

100

ally advancing the topmost sheet to the rolls

' '

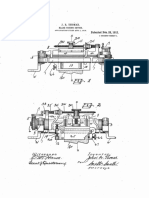

The roll 6 is formed with a number of

d. while the lower roller 6 acts upon the spaced circumferential grooves 13 which per

edges of the adjacent sheets to retard their mit the Sheets to pass said roll without the

110

1,543,354

line of paste making contact with the roll. a shaft, a disc adjustable on said shaft in

The disc 7 may be placed in any one of vari

line with any selected one of said grooves,

30

ous selected adjustments on the shaft 1 as means for applying adhesive material to the

required by the. width of the sheets being periphery of said disc, means for rotating

folded. In any of its adjusted positions the said shaft and said disc, and means for feed

disc 7 is in line with one of the grooves 13. ing sheets of paper toward said rolls and

I am aware that the invention may be into contact with said disc whereby a line of 85

varied and that it may be applied to dif

ferent types of folding machines.

'

adhesive material is applied to each sheet of

paper in line with the groove with which

>

I do not restrict myself unessentially in said disc alines.

3. In a machine of the character de

these or otherparticulars, but what I claim

and desire to secure by Letters Patent is t scribed, the combination of a lower and an

1. In a machine of the character de upper buckling roll. the latter of which has

15

20

26

40

scribed, the combination with a, lower and a number of circumferential grooves, a shaft

an upper buckling roll, the latter of which supported parallel with said rolls, a disc

has a circumferential groove, and devices adjustable on said shaft in line with any

for feeding sheets between said rolls, of a one of said grooves, a receptacle pivotally 45

disc supported above said devices in line supported by said shaft, means for conduct

with said groove, a receptacle, means for ing adhesive material from said shaft to the

conducting adhesive material from said periphery of said disc, devices for feeding

receptacle to the periphery of said disc, and sheets of paper between said rolls, and 50'

means for rotating said disc and thereby means for rotating said disc into contact

applying a line of said adhesive material to with the paper passing to said rolls and

thereby applying a line of adhesive material

the sheets in line with said groove.

2. In a machine of the character de to the paper in line with the groove with

scribed, the combination with a lower and which said disc alines.

an upper buckling roll, the latter of which

FRED T. ZAGHER.

has a number of circumferential grooves, of ~

You might also like

- RCC Design SheetsDocument40 pagesRCC Design Sheetsashuswara85% (26)

- CSSD Project-1Document45 pagesCSSD Project-1Pia20% (5)

- SK125SR SK135SR-2 Mic ASIA PDFDocument16 pagesSK125SR SK135SR-2 Mic ASIA PDFtom souza100% (3)

- Rang Dong Joint Stock Company's Strategy ManagementDocument53 pagesRang Dong Joint Stock Company's Strategy ManagementThanh Hoa Le100% (1)

- US2009857 FORMADOR SOBRES PotdevinDocument3 pagesUS2009857 FORMADOR SOBRES PotdevinJhonnatan E Avendaño FlorezNo ratings yet

- Us2018240 PDFDocument4 pagesUs2018240 PDFPolygrapack SA DE CVNo ratings yet

- US2126921Document5 pagesUS2126921Jhonnatan E Avendaño Florez100% (1)

- Us1955360 PDFDocument8 pagesUs1955360 PDFRodrigoPomaNo ratings yet

- US2099314Document3 pagesUS2099314Jhonnatan E Avendaño Florez100% (1)

- Us1434007 PDFDocument5 pagesUs1434007 PDFsebastian escobarNo ratings yet

- Web Separator US3463377Document5 pagesWeb Separator US3463377chupalaNo ratings yet

- Manual Paper CollatorDocument6 pagesManual Paper CollatorMuhidin HasyimNo ratings yet

- M © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815Document3 pagesM © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815James LindonNo ratings yet

- No. 687,172. Patlmtedl Nov. I9, I90I.: Variable Speed GearingDocument4 pagesNo. 687,172. Patlmtedl Nov. I9, I90I.: Variable Speed Gearingbelchior alvaroNo ratings yet

- June 16, 1964: C. R. Steele Disintegrator Having Downwardly Inclined Baffles Filed Nov. 17, 1960Document6 pagesJune 16, 1964: C. R. Steele Disintegrator Having Downwardly Inclined Baffles Filed Nov. 17, 1960RodrigoPomaNo ratings yet

- Dec. 10, 1940. E. N. Necke 2,224,606Document4 pagesDec. 10, 1940. E. N. Necke 2,224,606Mary HullNo ratings yet

- United States Patent (19) : Meyer 11 Patent Number: 45 Date of Patent: Foreign Patent DocumentsDocument8 pagesUnited States Patent (19) : Meyer 11 Patent Number: 45 Date of Patent: Foreign Patent DocumentsUvxtalNo ratings yet

- Filed Oct. 22, 1951: P. C. HuttonDocument5 pagesFiled Oct. 22, 1951: P. C. HuttonGalo YambayNo ratings yet

- 1895 - Us570025Document5 pages1895 - Us570025Enrico Bruce GioloNo ratings yet

- Title: Bedsheet TensionerDocument6 pagesTitle: Bedsheet TensionerRA Mikael Master MindNo ratings yet

- Braiding MachineDocument7 pagesBraiding Machinejojaberi100% (1)

- Patented May 27, 1919.: S. H. GarstDocument4 pagesPatented May 27, 1919.: S. H. GarstKrozeNo ratings yet

- Cloth Tow Target Low Drag Sleeve (1944)Document4 pagesCloth Tow Target Low Drag Sleeve (1944)CAP History LibraryNo ratings yet

- Us2935914 PDFDocument14 pagesUs2935914 PDFMichael LaneNo ratings yet

- A. Zahoransky 1,936,743: Filed March 2, 1931 2. Sheets-Sheet .Document4 pagesA. Zahoransky 1,936,743: Filed March 2, 1931 2. Sheets-Sheet .AGUAVIVANJNo ratings yet

- United States Patent - (191: Mayeux Et AlDocument4 pagesUnited States Patent - (191: Mayeux Et AlRodrigoPomaNo ratings yet

- Folding AparatusDocument4 pagesFolding AparatusUbunterNo ratings yet

- Coco Inven PDFDocument4 pagesCoco Inven PDFsushil-funNo ratings yet

- 19mg WK.: June 1, 1954 J. H. Breisch 2,579,786Document5 pages19mg WK.: June 1, 1954 J. H. Breisch 2,579,786Azri LunduNo ratings yet

- Us955823 PDFDocument3 pagesUs955823 PDFSashikant SharmaNo ratings yet

- Howe MacHine Co. v. National Needle Co., 134 U.S. 388 (1890)Document8 pagesHowe MacHine Co. v. National Needle Co., 134 U.S. 388 (1890)Scribd Government DocsNo ratings yet

- Broom Sewing MachineDocument8 pagesBroom Sewing MachineMarcio André KviatkovskiNo ratings yet

- Us 1893840Document6 pagesUs 1893840Robert BercovitzNo ratings yet

- April 2, 1963 R. I. Lund: Mixing Mill Accumulating Shelf Filed Feb. 8. 1962Document5 pagesApril 2, 1963 R. I. Lund: Mixing Mill Accumulating Shelf Filed Feb. 8. 1962Eduardo Fernandez DazaNo ratings yet

- Jurnal Bubut FixsafasfasfDocument6 pagesJurnal Bubut FixsafasfasfAdiBimaSanjaya100% (1)

- United States Patent (191 1111 Patent Number: 4,991,386: Dirksen (45) Date of Patent: Feb. 12, 1991Document6 pagesUnited States Patent (191 1111 Patent Number: 4,991,386: Dirksen (45) Date of Patent: Feb. 12, 1991James LindonNo ratings yet

- Sept. 16, 1969 J. Marcovc-3,466,911: Filed Day L, 1967 2 Sheets-SheetDocument4 pagesSept. 16, 1969 J. Marcovc-3,466,911: Filed Day L, 1967 2 Sheets-SheetLucas RaithsNo ratings yet

- Us1223254 PDFDocument7 pagesUs1223254 PDFRodrigoPomaNo ratings yet

- Us2996100 PDFDocument8 pagesUs2996100 PDFerzrzretgertfertgeNo ratings yet

- United States Patent (19) : Primary Examiner-Samuel ScottDocument7 pagesUnited States Patent (19) : Primary Examiner-Samuel ScottRockerss RockerssNo ratings yet

- 1,138,232. Patented May 4, 1915,: 0, J, McgannDocument3 pages1,138,232. Patented May 4, 1915,: 0, J, McgannVyacheslavNo ratings yet

- Patente TrituradoraDocument11 pagesPatente TrituradoraDany ChimborazoNo ratings yet

- Us 5546957Document7 pagesUs 5546957SurgaveryNo ratings yet

- B. M. W. Hanson,: AzzzzessesDocument6 pagesB. M. W. Hanson,: Azzzzessesfrank saruhanNo ratings yet

- I Set: II. F TaxaDocument6 pagesI Set: II. F Taxafrank saruhanNo ratings yet

- United States Patent (191: Andersen Et A1Document5 pagesUnited States Patent (191: Andersen Et A1khoagleNo ratings yet

- Coin Sorter MechanismDocument7 pagesCoin Sorter MechanismSepi Itu Indah100% (1)

- US1685447Document5 pagesUS1685447Redirecting DecoyNo ratings yet

- Milliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaDocument4 pagesMilliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaOscar Lora SiñaniNo ratings yet

- QZZZZZZZZZZZZ: PATENTED AUG, 21, 1906. No. 829,327Document3 pagesQZZZZZZZZZZZZ: PATENTED AUG, 21, 1906. No. 829,327Galo YambayNo ratings yet

- Exemplary Hot Kiln Alignment ReportDocument4 pagesExemplary Hot Kiln Alignment Reportzain140No ratings yet

- (Patente 1) US1489458Document3 pages(Patente 1) US1489458diegoNo ratings yet

- Ulllted States Patent (19) (11) Patent Number: 5,901,540: Vella (45) Date 0f Patent: May 11, 1999Document12 pagesUlllted States Patent (19) (11) Patent Number: 5,901,540: Vella (45) Date 0f Patent: May 11, 1999James LindonNo ratings yet

- "A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Document7 pages"A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Guillermo Avila RiveraNo ratings yet

- US2447117Document6 pagesUS2447117MahnooshNo ratings yet

- US2182002Document5 pagesUS2182002Jhonnatan E Avendaño FlorezNo ratings yet

- H. J. Smith: Potato Cutting Machine 28 Filed 00Document3 pagesH. J. Smith: Potato Cutting Machine 28 Filed 00RodrigoPomaNo ratings yet

- Unidad IV Intercambiadores de CalorDocument4 pagesUnidad IV Intercambiadores de CalorRafael CórdobaNo ratings yet

- Data Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateDocument3 pagesData Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateJaymar ManualNo ratings yet

- Us2218783 PDFDocument4 pagesUs2218783 PDFlandagoNo ratings yet

- No. 679,020. Patented July 23, 1901.: (G) '... H."G SG 70Document3 pagesNo. 679,020. Patented July 23, 1901.: (G) '... H."G SG 70AlecsandrNo ratings yet

- BYY "So: June 7, 1966 M, A Brown 3,254,776Document7 pagesBYY "So: June 7, 1966 M, A Brown 3,254,776Yu YangNo ratings yet

- US2259748Document3 pagesUS2259748Christian MavarezNo ratings yet

- TEPZZ - 6 48B - T: European Patent SpecificationDocument13 pagesTEPZZ - 6 48B - T: European Patent SpecificationshamsNo ratings yet

- Nickel and Cobalt MaterialsDocument2 pagesNickel and Cobalt MaterialsshamsNo ratings yet

- Advanced NDTEquipmentsDocument4 pagesAdvanced NDTEquipmentsshamsNo ratings yet

- Microturbine Energy SystemsDocument16 pagesMicroturbine Energy SystemsshamsNo ratings yet

- TEPZZ - 4 885B - T: European Patent SpecificationDocument10 pagesTEPZZ - 4 885B - T: European Patent SpecificationshamsNo ratings yet

- European Patent Application: A Seal in A Gas Turbine and A Method of Manufacturing A SealDocument3 pagesEuropean Patent Application: A Seal in A Gas Turbine and A Method of Manufacturing A SealshamsNo ratings yet

- European Patent Specification F01D 11/00, F16J 15/34,: Printed by Jouve, 75001 PARIS (FR)Document16 pagesEuropean Patent Specification F01D 11/00, F16J 15/34,: Printed by Jouve, 75001 PARIS (FR)shamsNo ratings yet

- European Patent Specification: Turbine Engine With An Abradable SealDocument10 pagesEuropean Patent Specification: Turbine Engine With An Abradable SealshamsNo ratings yet

- Gas Turbine Blade CoatingsDocument1 pageGas Turbine Blade Coatingsshams100% (1)

- European Patent Specification F01D 11/00: Printed by Jouve, 75001 PARIS (FR)Document10 pagesEuropean Patent Specification F01D 11/00: Printed by Jouve, 75001 PARIS (FR)shamsNo ratings yet

- United States Patent: Arness Et A) - (10) Patent N0.: (45) Date of PatentDocument12 pagesUnited States Patent: Arness Et A) - (10) Patent N0.: (45) Date of PatentshamsNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0108418 A1Document5 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0108418 A1shamsNo ratings yet

- European Patent Specification F01D 11/00, F01D 5/26: Printed by Jouve, 75001 PARIS (FR)Document13 pagesEuropean Patent Specification F01D 11/00, F01D 5/26: Printed by Jouve, 75001 PARIS (FR)shamsNo ratings yet

- United States Patent (10) Patent No.: US 8,251,371 B2Document4 pagesUnited States Patent (10) Patent No.: US 8,251,371 B2shamsNo ratings yet

- Tepzz 7Z 58B - T: European Patent SpecificationDocument17 pagesTepzz 7Z 58B - T: European Patent SpecificationshamsNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,430,626 B1Document9 pagesUlllted States Patent (10) Patent N0.: US 8,430,626 B1shamsNo ratings yet

- Gas Turbine Compressor Washing State of The Art - Field ExperiencesDocument8 pagesGas Turbine Compressor Washing State of The Art - Field Experiencesshams100% (1)

- Improved Power Plant PerformanceDocument3 pagesImproved Power Plant Performanceshams100% (2)

- Welding and Weld Repair of Single Crystal Gas Turbine Alloys PDFDocument8 pagesWelding and Weld Repair of Single Crystal Gas Turbine Alloys PDFshamsNo ratings yet

- Braze Weld TechnicalDocument7 pagesBraze Weld TechnicalimupathanNo ratings yet

- Standard Operating ProcedureDocument8 pagesStandard Operating ProcedureYayan SupyanNo ratings yet

- Design of Machine Elements ME1302 2 Marks QuestionDocument16 pagesDesign of Machine Elements ME1302 2 Marks QuestionPushparaj MariaNo ratings yet

- C 1361 Fatigue Ceramics PDFDocument8 pagesC 1361 Fatigue Ceramics PDFEmily OchoaNo ratings yet

- Practical Guide Edexcel2Document42 pagesPractical Guide Edexcel2Hady JawadNo ratings yet

- D93-15 Standard Test Methods For Flash Point by Pensky-Martens Closed Cup Tester - IP 34-99Document18 pagesD93-15 Standard Test Methods For Flash Point by Pensky-Martens Closed Cup Tester - IP 34-99Rony YudaNo ratings yet

- Carpentry Works (Ceiling and Partition Walls)Document26 pagesCarpentry Works (Ceiling and Partition Walls)Chris Ohlliver CuizonNo ratings yet

- XFEM Analysis of A Plate With An Edge Crack PDFDocument14 pagesXFEM Analysis of A Plate With An Edge Crack PDFNagaraj RamachandrappaNo ratings yet

- Review If Transparent Solar Photovoltaic TechnologiesDocument13 pagesReview If Transparent Solar Photovoltaic TechnologiesSharonNo ratings yet

- Driscal D Polymer PDFDocument1 pageDriscal D Polymer PDFMiguel DuranNo ratings yet

- 434 SMD FuseDocument3 pages434 SMD Fusekhuseyin13186No ratings yet

- American Fastener - ASTM, SAE, and ISO Grade MarkingsDocument4 pagesAmerican Fastener - ASTM, SAE, and ISO Grade MarkingsRay CoelloNo ratings yet

- Schedule No. 1. Plant and Mandatory Spare Parts Supplied From Abroad For 10MVA 66/33kV Substation at Kalimorok Trading CentreDocument9 pagesSchedule No. 1. Plant and Mandatory Spare Parts Supplied From Abroad For 10MVA 66/33kV Substation at Kalimorok Trading CentreSen Ben MirangaNo ratings yet

- PFD - Nitrogen Plant UTL Plaju (Cold Box)Document1 pagePFD - Nitrogen Plant UTL Plaju (Cold Box)Julia Dwi LestariNo ratings yet

- ME 6019 Non Destrictive Testing and Materials SyllabusDocument2 pagesME 6019 Non Destrictive Testing and Materials Syllabusbalaguru780% (2)

- 005-MDF Finsa - Fibrapan DOPDocument3 pages005-MDF Finsa - Fibrapan DOPAlan HakounNo ratings yet

- ResumeDocument17 pagesResumeJawad MunirNo ratings yet

- Air Conditioning System Using Vehicle SuspensionDocument14 pagesAir Conditioning System Using Vehicle Suspensiontushu patilNo ratings yet

- 1 s2.0 S0167663614001665 MainDocument18 pages1 s2.0 S0167663614001665 MainyasminaNo ratings yet

- Welding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVANDDocument2 pagesWelding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVANDvahid mobini100% (1)

- Vents: $9.99 $7.99 $7.99 $12.99 $18.99 TempressDocument1 pageVents: $9.99 $7.99 $7.99 $12.99 $18.99 TempressRoddy GonzalezNo ratings yet

- Chemcrete Profile 18072022Document25 pagesChemcrete Profile 18072022muhammad naumanNo ratings yet

- Inspect Upper and Lower Control Arms BushingsDocument5 pagesInspect Upper and Lower Control Arms BushingsERIKWTPNo ratings yet

- Transmission Connector Pinout PDFDocument2 pagesTransmission Connector Pinout PDFJuan parraNo ratings yet

- FUNDAMENTALS OF Reservoir Fluids3 - Updated-1Document28 pagesFUNDAMENTALS OF Reservoir Fluids3 - Updated-1adewaleNo ratings yet

- Chapter01 PDFDocument12 pagesChapter01 PDFRanjanNo ratings yet