Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

114 views52c Nail Loads

52c Nail Loads

Uploaded by

fabiothekingjamesnail

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- BS 3580 (Strength of Screw Threads)Document24 pagesBS 3580 (Strength of Screw Threads)Arun NagrathNo ratings yet

- Philips MX 550Document20 pagesPhilips MX 550aalNo ratings yet

- 201012182932953Document5 pages201012182932953Sanjay Singh100% (1)

- BS 4235-1-1972 Specification For Metric Keys and Keyways. Parallel and Taper KeysDocument26 pagesBS 4235-1-1972 Specification For Metric Keys and Keyways. Parallel and Taper Keysjaffliang100% (5)

- Design and Fabrication of Manually Operated 4-Row Mat Type Nursery Rice TransplanterDocument45 pagesDesign and Fabrication of Manually Operated 4-Row Mat Type Nursery Rice TransplanterJaja Gallardo BonafeNo ratings yet

- New Microsoft Word DocumentDocument21 pagesNew Microsoft Word Documentأحمد دعبسNo ratings yet

- Uniform Standardfor Wood Containers 2009Document44 pagesUniform Standardfor Wood Containers 2009McArthur2010No ratings yet

- White Paper Load Carrying Capacity PPT 2.2.18Document46 pagesWhite Paper Load Carrying Capacity PPT 2.2.18Dhiren DarjiNo ratings yet

- Pallet Specification 18kgDocument3 pagesPallet Specification 18kgjaderNo ratings yet

- BS Iso 8611Document24 pagesBS Iso 8611Eng MessiNo ratings yet

- As 3600-09 RC-SL-001Document4 pagesAs 3600-09 RC-SL-001Bunkun15No ratings yet

- Packaging and Shipping GuidelinesDocument58 pagesPackaging and Shipping GuidelinesPurnama Solusi IndoNo ratings yet

- 33KV GloveDocument1 page33KV GloveSrf SaharinNo ratings yet

- JDN Monocrane - Manufacturers of Overhead Lifting EquipmentDocument19 pagesJDN Monocrane - Manufacturers of Overhead Lifting EquipmentJDN MonocraneNo ratings yet

- 6th Edition: Product GuideDocument108 pages6th Edition: Product GuideMohd Asri TaipNo ratings yet

- 13 Safety Related International StandardsDocument17 pages13 Safety Related International StandardsNathan RodriguesNo ratings yet

- Tyre Degradation Mew PsDocument3 pagesTyre Degradation Mew PsTatak Bay AhmedNo ratings yet

- Zoll AED Plus Automated External Defribillator Administrators GuideDocument54 pagesZoll AED Plus Automated External Defribillator Administrators Guidemah_rizalNo ratings yet

- Tow Bar Installation RENAULT CLIO 2 98-05Document2 pagesTow Bar Installation RENAULT CLIO 2 98-05vomitNo ratings yet

- British Steel Sections Datasheets PDFDocument18 pagesBritish Steel Sections Datasheets PDFSteven KuaNo ratings yet

- FEM1.001 Engl Order 402762Document314 pagesFEM1.001 Engl Order 402762rikon rikonNo ratings yet

- 0005product CertificationDocument46 pages0005product CertificationMostafa AboaliNo ratings yet

- FirePro General Product Catalogue 2018 ULDocument74 pagesFirePro General Product Catalogue 2018 ULAngel MirandaNo ratings yet

- Shackles Carbines and Karabiners 2013Document7 pagesShackles Carbines and Karabiners 2013sealion72No ratings yet

- A Guide To Shackles For Lifting Purposes: BenefitsDocument14 pagesA Guide To Shackles For Lifting Purposes: BenefitsHelderNo ratings yet

- A Guide To Shackles For Lifting Purposes: BenefitsDocument14 pagesA Guide To Shackles For Lifting Purposes: BenefitsArsalan AhmadNo ratings yet

- 14 - HS Bolts - Practice Note - MAT1010 PDFDocument5 pages14 - HS Bolts - Practice Note - MAT1010 PDFvodugu123No ratings yet

- ABC2017 065 17 Jessey Lee Design Guidelines For Post Installed and Cast in Anchors in Australia For Safety Critical ApplicationsDocument11 pagesABC2017 065 17 Jessey Lee Design Guidelines For Post Installed and Cast in Anchors in Australia For Safety Critical ApplicationsDuncanNo ratings yet

- RJ Design-Guide 09Document15 pagesRJ Design-Guide 09CTN2010No ratings yet

- Wrekin Ductile Iron Products BrochureDocument20 pagesWrekin Ductile Iron Products BrochureggrapsasNo ratings yet

- 3600-2009 (A1)Document11 pages3600-2009 (A1)RekhaRaju0% (1)

- MFMA 2004 StandardsDocument38 pagesMFMA 2004 StandardsJuan Carlos MendezNo ratings yet

- Ancon Tapered Thread Couplers International VersionDocument16 pagesAncon Tapered Thread Couplers International VersionRanjan SinghNo ratings yet

- Datasheet Dramix RC 6535 BNDocument1 pageDatasheet Dramix RC 6535 BNSahil GandhiNo ratings yet

- Hangers Truss Boots July 2010 PDFDocument28 pagesHangers Truss Boots July 2010 PDFSachinNo ratings yet

- Concrete Structures AS3600-2009)Document11 pagesConcrete Structures AS3600-2009)TongYueHernNo ratings yet

- Tendon Grouting - VSLDocument46 pagesTendon Grouting - VSLIrshadYasinNo ratings yet

- James Walker O RingsDocument30 pagesJames Walker O RingsBu Lang NiNo ratings yet

- Lenton TerminatorDocument8 pagesLenton Terminatordanker1988No ratings yet

- Concrete LintelsDocument24 pagesConcrete LintelsAmber ChristensenNo ratings yet

- 1 Foundation Bolts MAT1011Document6 pages1 Foundation Bolts MAT1011vodugu123No ratings yet

- TN001 - High Strength Structural Bolt Assemblies To AS - NZS 1252Document6 pagesTN001 - High Strength Structural Bolt Assemblies To AS - NZS 1252Andy AcousticNo ratings yet

- Astm E92-23Document13 pagesAstm E92-23Saravana VelNo ratings yet

- Paper 118 Guidelines For Prequalification and Design of Post-Installed and Cast-In Anchors in Australia - 2Document11 pagesPaper 118 Guidelines For Prequalification and Design of Post-Installed and Cast-In Anchors in Australia - 2Tarek AbulailNo ratings yet

- Practice-Advisory-11 - Grade 500E Reo Good PracticeDocument8 pagesPractice-Advisory-11 - Grade 500E Reo Good PracticephiloconnorNo ratings yet

- Ellis Patents Cable Cleats Complete CatalogueDocument28 pagesEllis Patents Cable Cleats Complete CataloguefndprojectNo ratings yet

- (Backup) (Backup) LEEA ACADEMY STEP NOTES Foundation Aug2017 v1.7 Digital 114 119Document6 pages(Backup) (Backup) LEEA ACADEMY STEP NOTES Foundation Aug2017 v1.7 Digital 114 119Khaled RaafatNo ratings yet

- Rotabolt Tension Control James WalkerDocument12 pagesRotabolt Tension Control James Walkercvishwas1159No ratings yet

- Bollhoff Armstrong HeliCoilDocument28 pagesBollhoff Armstrong HeliCoilAce Industrial Supplies100% (1)

- CMP Products Technical Article On New IEC 62444 Cable Gland Standards 6.11.11 PDFDocument3 pagesCMP Products Technical Article On New IEC 62444 Cable Gland Standards 6.11.11 PDFparesh joshiNo ratings yet

- Cu Ni CatalogDocument48 pagesCu Ni CatalogbureqqNo ratings yet

- The New Joint Australian and New Zealand Bridge Design Standard AS/NZS 5100 - Part 6: Steel and Composite ConstructionDocument12 pagesThe New Joint Australian and New Zealand Bridge Design Standard AS/NZS 5100 - Part 6: Steel and Composite ConstructionStephen HicksNo ratings yet

- Steel Stud - TrackDocument16 pagesSteel Stud - TrackAmjad PervazNo ratings yet

- I-Sys Ss Csi Section 05 15 00 SpecDocument8 pagesI-Sys Ss Csi Section 05 15 00 SpecEmil John BaticulaNo ratings yet

- Wind Turbine Anchor Solutions - Sep 12 PDFDocument8 pagesWind Turbine Anchor Solutions - Sep 12 PDFAnonymous RKkPpe4No ratings yet

- Braided Cable SpecificationDocument32 pagesBraided Cable SpecificationmansurscribdNo ratings yet

- ERIKS20 20Oring20Technical20ManualDocument219 pagesERIKS20 20Oring20Technical20ManualEfrain SaldañaNo ratings yet

- Development of Elevator Ropes: Tech Tip 15Document2 pagesDevelopment of Elevator Ropes: Tech Tip 15أحمد دعبسNo ratings yet

- Din 00976-1 2002 (En)Document7 pagesDin 00976-1 2002 (En)angelbeatNo ratings yet

- Elevator-Ropes Usha MartinDocument24 pagesElevator-Ropes Usha MartinAlberto Tavares100% (2)

- Radtech Man (Fibre Rebar)Document48 pagesRadtech Man (Fibre Rebar)pete0980No ratings yet

- Review of Standard IS 2750:1964 and Present Trends in Scaffolding To Cater To Demand of Construction Industries - AR/0066Document23 pagesReview of Standard IS 2750:1964 and Present Trends in Scaffolding To Cater To Demand of Construction Industries - AR/0066VinodNo ratings yet

- Mikalor: Hose ClampsDocument20 pagesMikalor: Hose Clamps김상철No ratings yet

- Autoinvoice Import Program 010413Document8 pagesAutoinvoice Import Program 010413ganeshch17No ratings yet

- 300715J Rock Digitizer User ManualDocument367 pages300715J Rock Digitizer User ManualCarlos SanchezNo ratings yet

- Ethical Hacking: EnumerationDocument37 pagesEthical Hacking: Enumerationjaya prasannaNo ratings yet

- Unit 1: The Information AGE: Prepared By: Ms. Alona Baja InstructorDocument26 pagesUnit 1: The Information AGE: Prepared By: Ms. Alona Baja InstructorDana Marie LopezNo ratings yet

- Module 3 Mid Mod Assessment Study GuideDocument1 pageModule 3 Mid Mod Assessment Study Guideapi-293336914No ratings yet

- Three Squirrels and A Pile of NutsDocument6 pagesThree Squirrels and A Pile of NutsAnurag GoelNo ratings yet

- Chapter 9-Querying A DatabaseDocument35 pagesChapter 9-Querying A Databaseaustinfru7No ratings yet

- Mobile Print App BrochureDocument2 pagesMobile Print App Brochuredev DayalNo ratings yet

- Oracle - PLSQLDocument32 pagesOracle - PLSQLLeo MallickNo ratings yet

- Thesis in Latex TemplateDocument4 pagesThesis in Latex Templatexkwkizzgf100% (2)

- CCNA 1 (v5.1 + v6.0) Chapter 11 Exam Answers 2018 - 100% FullDocument1 pageCCNA 1 (v5.1 + v6.0) Chapter 11 Exam Answers 2018 - 100% FullsssNo ratings yet

- DAA Marking SchemeDocument4 pagesDAA Marking SchemeEvan RobertsonNo ratings yet

- Sonar (SRF08)Document8 pagesSonar (SRF08)Ruben MagalhãesNo ratings yet

- FMEA GN E-Mar18 PDFDocument137 pagesFMEA GN E-Mar18 PDFJanakirama SaiNo ratings yet

- BRIDGE HEALTH MONITORING SYSTEM USING IOT Synopsis Final PrinciiDocument5 pagesBRIDGE HEALTH MONITORING SYSTEM USING IOT Synopsis Final Princiisunil lumar h uNo ratings yet

- Podcast Rubric Y7Document1 pagePodcast Rubric Y7owenmccNo ratings yet

- Com 134 Syllabus Fall 2012Document8 pagesCom 134 Syllabus Fall 2012KarlyWayNo ratings yet

- Deploy The Extrahop Discover Appliance With Vmware: Virtual Machine RequirementsDocument19 pagesDeploy The Extrahop Discover Appliance With Vmware: Virtual Machine RequirementsGame GMNo ratings yet

- Programming Guideline DOCU v14 en PDFDocument109 pagesProgramming Guideline DOCU v14 en PDFcontroljotaNo ratings yet

- PH 1.5-Modbus InstructionDocument20 pagesPH 1.5-Modbus InstructionkepyarNo ratings yet

- MFT Platform Server in A Clustered Windows EnvironmentDocument6 pagesMFT Platform Server in A Clustered Windows EnvironmentiverajNo ratings yet

- System III Console Instruction ManualDocument64 pagesSystem III Console Instruction ManualEddy RoaNo ratings yet

- ASPEN TutorialDocument33 pagesASPEN TutorialAnoy Das MahapatraNo ratings yet

- JBoss Enterprise Application Platform 6.3 Development Guide en USDocument468 pagesJBoss Enterprise Application Platform 6.3 Development Guide en USwar_ningNo ratings yet

- Mtcloud ComputingDocument18 pagesMtcloud ComputingMohammed SajjadNo ratings yet

- Using Encompass Docs SolutionDocument90 pagesUsing Encompass Docs SolutionLiang WangNo ratings yet

- Manual DiffMergeDocument71 pagesManual DiffMergeavioluguberNo ratings yet

52c Nail Loads

52c Nail Loads

Uploaded by

fabiothekingjames0 ratings0% found this document useful (0 votes)

114 views1 pagenail

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentnail

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

114 views1 page52c Nail Loads

52c Nail Loads

Uploaded by

fabiothekingjamesnail

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

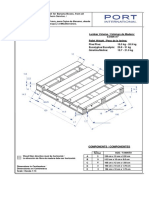

PalletLink Datasheet

Ref: 52c

www.palletlink.co.uk

BS 1202 Part 1 Nails - Steel nails

The first British Standard change in 26 years for the construction, pallet and case nail

supplier finally took place in January 2000. The well established BS 1202 : 1974 was

withdrawn and replaced by a European version which deletes a number of old favourite

sizes. BS EN 10230-1 : 2000: Steel wire nails - Part 1 - Loose nails for general

applications is the new standard to work to now, it contains terminology, permissible

lengths, diameters, etc. PalletLink has monitored and commented on drafts over the

several year preparation period and was instrumental in annular ring nail shank

diameters being measured over the plain shank portion, not over the rings, as in earlier

drafts of 10230.

Apart from the above standard for nail sizes, there are two other standards for pallet nails, one testing for bend

strength and one for nail performance quality levels.

1. Test methods for loose and collated nails were published in BS EN 409: 1993 (building) and BS EN ISO 12777-1:

1997 (pallets).

2. Minimum nail performance quality levels were worked on by BSI, CEN and ISO through new pallet and pallet

repair committees. The result was ISO 15629: 2002: "Pallets for materials handling - Quality of fasteners for assembly

of new and repair of used wooden flat pallets" was led by a USA Convenor. It is now adopted by CEN and is a

National Standard in many countries. It contains specific requirements for nail bending strength classed as high,

medium and low quality of respectively 6.0Nm, 5.4Nm and 4.5Nm. For clinched pallet deck-mat nails 2.5Nm, 2.2Nm,

1.9 Nm. These are useful levels for pallet designers though the nail making industry has been slow to react to the

presence of the standard.

In general the USA use stronger nails than Europe called "stiff stock". PalletLink have the test equipment for this test,

but beware, the favourite in the USA the MIBANT nail test machine was designed in 1960, it was assessed by

ISO/TC51 in 1992 and is not accurate. The Rockhi Robiment (Germany) designed in the 1980's or the Verus 127

(UK) designed in 2000 are accurate devices. PalletLink have worked with all three machines extensively.

The MIBANT measures a nail bend strength as an angle of bend after the elastic limit is passed and therefore mixes

plastic modulus with elastic modulus. It also tests nails close to the head where rings are absent and since failure of

pallet joints in the field does not normally happen at that point it gives a misleadingly high result.

The Verus 127 improves on previous nail testers and is nearest to the EN ISO 12777-1 recommended fulcrum bending

position principles and it tests at the weakest point of a nail, amongst the rings.

Copyright PalletLink while every effort is made to ensure accuracy of the data given, PalletLink cannot accept liability for loss or damage

arising out of the use of the information. The details supplied are relevant as at the date of this publication which is one example in an extensive

series of PalletLink Datasheets. Members are advised to contact PalletLink if in doubt over any aspect of pallet or case manufacture or usage.

52c/JH/SJ/10 40 2015

You might also like

- BS 3580 (Strength of Screw Threads)Document24 pagesBS 3580 (Strength of Screw Threads)Arun NagrathNo ratings yet

- Philips MX 550Document20 pagesPhilips MX 550aalNo ratings yet

- 201012182932953Document5 pages201012182932953Sanjay Singh100% (1)

- BS 4235-1-1972 Specification For Metric Keys and Keyways. Parallel and Taper KeysDocument26 pagesBS 4235-1-1972 Specification For Metric Keys and Keyways. Parallel and Taper Keysjaffliang100% (5)

- Design and Fabrication of Manually Operated 4-Row Mat Type Nursery Rice TransplanterDocument45 pagesDesign and Fabrication of Manually Operated 4-Row Mat Type Nursery Rice TransplanterJaja Gallardo BonafeNo ratings yet

- New Microsoft Word DocumentDocument21 pagesNew Microsoft Word Documentأحمد دعبسNo ratings yet

- Uniform Standardfor Wood Containers 2009Document44 pagesUniform Standardfor Wood Containers 2009McArthur2010No ratings yet

- White Paper Load Carrying Capacity PPT 2.2.18Document46 pagesWhite Paper Load Carrying Capacity PPT 2.2.18Dhiren DarjiNo ratings yet

- Pallet Specification 18kgDocument3 pagesPallet Specification 18kgjaderNo ratings yet

- BS Iso 8611Document24 pagesBS Iso 8611Eng MessiNo ratings yet

- As 3600-09 RC-SL-001Document4 pagesAs 3600-09 RC-SL-001Bunkun15No ratings yet

- Packaging and Shipping GuidelinesDocument58 pagesPackaging and Shipping GuidelinesPurnama Solusi IndoNo ratings yet

- 33KV GloveDocument1 page33KV GloveSrf SaharinNo ratings yet

- JDN Monocrane - Manufacturers of Overhead Lifting EquipmentDocument19 pagesJDN Monocrane - Manufacturers of Overhead Lifting EquipmentJDN MonocraneNo ratings yet

- 6th Edition: Product GuideDocument108 pages6th Edition: Product GuideMohd Asri TaipNo ratings yet

- 13 Safety Related International StandardsDocument17 pages13 Safety Related International StandardsNathan RodriguesNo ratings yet

- Tyre Degradation Mew PsDocument3 pagesTyre Degradation Mew PsTatak Bay AhmedNo ratings yet

- Zoll AED Plus Automated External Defribillator Administrators GuideDocument54 pagesZoll AED Plus Automated External Defribillator Administrators Guidemah_rizalNo ratings yet

- Tow Bar Installation RENAULT CLIO 2 98-05Document2 pagesTow Bar Installation RENAULT CLIO 2 98-05vomitNo ratings yet

- British Steel Sections Datasheets PDFDocument18 pagesBritish Steel Sections Datasheets PDFSteven KuaNo ratings yet

- FEM1.001 Engl Order 402762Document314 pagesFEM1.001 Engl Order 402762rikon rikonNo ratings yet

- 0005product CertificationDocument46 pages0005product CertificationMostafa AboaliNo ratings yet

- FirePro General Product Catalogue 2018 ULDocument74 pagesFirePro General Product Catalogue 2018 ULAngel MirandaNo ratings yet

- Shackles Carbines and Karabiners 2013Document7 pagesShackles Carbines and Karabiners 2013sealion72No ratings yet

- A Guide To Shackles For Lifting Purposes: BenefitsDocument14 pagesA Guide To Shackles For Lifting Purposes: BenefitsHelderNo ratings yet

- A Guide To Shackles For Lifting Purposes: BenefitsDocument14 pagesA Guide To Shackles For Lifting Purposes: BenefitsArsalan AhmadNo ratings yet

- 14 - HS Bolts - Practice Note - MAT1010 PDFDocument5 pages14 - HS Bolts - Practice Note - MAT1010 PDFvodugu123No ratings yet

- ABC2017 065 17 Jessey Lee Design Guidelines For Post Installed and Cast in Anchors in Australia For Safety Critical ApplicationsDocument11 pagesABC2017 065 17 Jessey Lee Design Guidelines For Post Installed and Cast in Anchors in Australia For Safety Critical ApplicationsDuncanNo ratings yet

- RJ Design-Guide 09Document15 pagesRJ Design-Guide 09CTN2010No ratings yet

- Wrekin Ductile Iron Products BrochureDocument20 pagesWrekin Ductile Iron Products BrochureggrapsasNo ratings yet

- 3600-2009 (A1)Document11 pages3600-2009 (A1)RekhaRaju0% (1)

- MFMA 2004 StandardsDocument38 pagesMFMA 2004 StandardsJuan Carlos MendezNo ratings yet

- Ancon Tapered Thread Couplers International VersionDocument16 pagesAncon Tapered Thread Couplers International VersionRanjan SinghNo ratings yet

- Datasheet Dramix RC 6535 BNDocument1 pageDatasheet Dramix RC 6535 BNSahil GandhiNo ratings yet

- Hangers Truss Boots July 2010 PDFDocument28 pagesHangers Truss Boots July 2010 PDFSachinNo ratings yet

- Concrete Structures AS3600-2009)Document11 pagesConcrete Structures AS3600-2009)TongYueHernNo ratings yet

- Tendon Grouting - VSLDocument46 pagesTendon Grouting - VSLIrshadYasinNo ratings yet

- James Walker O RingsDocument30 pagesJames Walker O RingsBu Lang NiNo ratings yet

- Lenton TerminatorDocument8 pagesLenton Terminatordanker1988No ratings yet

- Concrete LintelsDocument24 pagesConcrete LintelsAmber ChristensenNo ratings yet

- 1 Foundation Bolts MAT1011Document6 pages1 Foundation Bolts MAT1011vodugu123No ratings yet

- TN001 - High Strength Structural Bolt Assemblies To AS - NZS 1252Document6 pagesTN001 - High Strength Structural Bolt Assemblies To AS - NZS 1252Andy AcousticNo ratings yet

- Astm E92-23Document13 pagesAstm E92-23Saravana VelNo ratings yet

- Paper 118 Guidelines For Prequalification and Design of Post-Installed and Cast-In Anchors in Australia - 2Document11 pagesPaper 118 Guidelines For Prequalification and Design of Post-Installed and Cast-In Anchors in Australia - 2Tarek AbulailNo ratings yet

- Practice-Advisory-11 - Grade 500E Reo Good PracticeDocument8 pagesPractice-Advisory-11 - Grade 500E Reo Good PracticephiloconnorNo ratings yet

- Ellis Patents Cable Cleats Complete CatalogueDocument28 pagesEllis Patents Cable Cleats Complete CataloguefndprojectNo ratings yet

- (Backup) (Backup) LEEA ACADEMY STEP NOTES Foundation Aug2017 v1.7 Digital 114 119Document6 pages(Backup) (Backup) LEEA ACADEMY STEP NOTES Foundation Aug2017 v1.7 Digital 114 119Khaled RaafatNo ratings yet

- Rotabolt Tension Control James WalkerDocument12 pagesRotabolt Tension Control James Walkercvishwas1159No ratings yet

- Bollhoff Armstrong HeliCoilDocument28 pagesBollhoff Armstrong HeliCoilAce Industrial Supplies100% (1)

- CMP Products Technical Article On New IEC 62444 Cable Gland Standards 6.11.11 PDFDocument3 pagesCMP Products Technical Article On New IEC 62444 Cable Gland Standards 6.11.11 PDFparesh joshiNo ratings yet

- Cu Ni CatalogDocument48 pagesCu Ni CatalogbureqqNo ratings yet

- The New Joint Australian and New Zealand Bridge Design Standard AS/NZS 5100 - Part 6: Steel and Composite ConstructionDocument12 pagesThe New Joint Australian and New Zealand Bridge Design Standard AS/NZS 5100 - Part 6: Steel and Composite ConstructionStephen HicksNo ratings yet

- Steel Stud - TrackDocument16 pagesSteel Stud - TrackAmjad PervazNo ratings yet

- I-Sys Ss Csi Section 05 15 00 SpecDocument8 pagesI-Sys Ss Csi Section 05 15 00 SpecEmil John BaticulaNo ratings yet

- Wind Turbine Anchor Solutions - Sep 12 PDFDocument8 pagesWind Turbine Anchor Solutions - Sep 12 PDFAnonymous RKkPpe4No ratings yet

- Braided Cable SpecificationDocument32 pagesBraided Cable SpecificationmansurscribdNo ratings yet

- ERIKS20 20Oring20Technical20ManualDocument219 pagesERIKS20 20Oring20Technical20ManualEfrain SaldañaNo ratings yet

- Development of Elevator Ropes: Tech Tip 15Document2 pagesDevelopment of Elevator Ropes: Tech Tip 15أحمد دعبسNo ratings yet

- Din 00976-1 2002 (En)Document7 pagesDin 00976-1 2002 (En)angelbeatNo ratings yet

- Elevator-Ropes Usha MartinDocument24 pagesElevator-Ropes Usha MartinAlberto Tavares100% (2)

- Radtech Man (Fibre Rebar)Document48 pagesRadtech Man (Fibre Rebar)pete0980No ratings yet

- Review of Standard IS 2750:1964 and Present Trends in Scaffolding To Cater To Demand of Construction Industries - AR/0066Document23 pagesReview of Standard IS 2750:1964 and Present Trends in Scaffolding To Cater To Demand of Construction Industries - AR/0066VinodNo ratings yet

- Mikalor: Hose ClampsDocument20 pagesMikalor: Hose Clamps김상철No ratings yet

- Autoinvoice Import Program 010413Document8 pagesAutoinvoice Import Program 010413ganeshch17No ratings yet

- 300715J Rock Digitizer User ManualDocument367 pages300715J Rock Digitizer User ManualCarlos SanchezNo ratings yet

- Ethical Hacking: EnumerationDocument37 pagesEthical Hacking: Enumerationjaya prasannaNo ratings yet

- Unit 1: The Information AGE: Prepared By: Ms. Alona Baja InstructorDocument26 pagesUnit 1: The Information AGE: Prepared By: Ms. Alona Baja InstructorDana Marie LopezNo ratings yet

- Module 3 Mid Mod Assessment Study GuideDocument1 pageModule 3 Mid Mod Assessment Study Guideapi-293336914No ratings yet

- Three Squirrels and A Pile of NutsDocument6 pagesThree Squirrels and A Pile of NutsAnurag GoelNo ratings yet

- Chapter 9-Querying A DatabaseDocument35 pagesChapter 9-Querying A Databaseaustinfru7No ratings yet

- Mobile Print App BrochureDocument2 pagesMobile Print App Brochuredev DayalNo ratings yet

- Oracle - PLSQLDocument32 pagesOracle - PLSQLLeo MallickNo ratings yet

- Thesis in Latex TemplateDocument4 pagesThesis in Latex Templatexkwkizzgf100% (2)

- CCNA 1 (v5.1 + v6.0) Chapter 11 Exam Answers 2018 - 100% FullDocument1 pageCCNA 1 (v5.1 + v6.0) Chapter 11 Exam Answers 2018 - 100% FullsssNo ratings yet

- DAA Marking SchemeDocument4 pagesDAA Marking SchemeEvan RobertsonNo ratings yet

- Sonar (SRF08)Document8 pagesSonar (SRF08)Ruben MagalhãesNo ratings yet

- FMEA GN E-Mar18 PDFDocument137 pagesFMEA GN E-Mar18 PDFJanakirama SaiNo ratings yet

- BRIDGE HEALTH MONITORING SYSTEM USING IOT Synopsis Final PrinciiDocument5 pagesBRIDGE HEALTH MONITORING SYSTEM USING IOT Synopsis Final Princiisunil lumar h uNo ratings yet

- Podcast Rubric Y7Document1 pagePodcast Rubric Y7owenmccNo ratings yet

- Com 134 Syllabus Fall 2012Document8 pagesCom 134 Syllabus Fall 2012KarlyWayNo ratings yet

- Deploy The Extrahop Discover Appliance With Vmware: Virtual Machine RequirementsDocument19 pagesDeploy The Extrahop Discover Appliance With Vmware: Virtual Machine RequirementsGame GMNo ratings yet

- Programming Guideline DOCU v14 en PDFDocument109 pagesProgramming Guideline DOCU v14 en PDFcontroljotaNo ratings yet

- PH 1.5-Modbus InstructionDocument20 pagesPH 1.5-Modbus InstructionkepyarNo ratings yet

- MFT Platform Server in A Clustered Windows EnvironmentDocument6 pagesMFT Platform Server in A Clustered Windows EnvironmentiverajNo ratings yet

- System III Console Instruction ManualDocument64 pagesSystem III Console Instruction ManualEddy RoaNo ratings yet

- ASPEN TutorialDocument33 pagesASPEN TutorialAnoy Das MahapatraNo ratings yet

- JBoss Enterprise Application Platform 6.3 Development Guide en USDocument468 pagesJBoss Enterprise Application Platform 6.3 Development Guide en USwar_ningNo ratings yet

- Mtcloud ComputingDocument18 pagesMtcloud ComputingMohammed SajjadNo ratings yet

- Using Encompass Docs SolutionDocument90 pagesUsing Encompass Docs SolutionLiang WangNo ratings yet

- Manual DiffMergeDocument71 pagesManual DiffMergeavioluguberNo ratings yet