Professional Documents

Culture Documents

Cqi 9 Errata AIAG

Cqi 9 Errata AIAG

Uploaded by

Rafael AlvesCopyright:

Available Formats

You might also like

- VW - 10131 - enDocument64 pagesVW - 10131 - enKinga EnNo ratings yet

- Manual KPM-QS Users Guide V2 2Document40 pagesManual KPM-QS Users Guide V2 2EnriqueNo ratings yet

- ABC Risk ClassificationDocument1 pageABC Risk ClassificationdocsenNo ratings yet

- Conducting Temperature Uniformity Surveys of Furnaces Used To Heat Treat Steel ProductsDocument4 pagesConducting Temperature Uniformity Surveys of Furnaces Used To Heat Treat Steel Productssaran saranNo ratings yet

- AIAG CQI-9 TUS RequirementsDocument10 pagesAIAG CQI-9 TUS RequirementsNethajiNo ratings yet

- CQI 9 3rd Edition Errata SheetDocument2 pagesCQI 9 3rd Edition Errata SheetANONIMONo ratings yet

- Dead Endclamp Failure AnalysisDocument26 pagesDead Endclamp Failure AnalysisRK KumarNo ratings yet

- Bonding In-Process Inspection ChecklistDocument1 pageBonding In-Process Inspection ChecklistRonnel LeanoNo ratings yet

- UntitledDocument19 pagesUntitledSuresh KumarNo ratings yet

- 2019 - KIA US Supplier Quality Manual KR GA PD SQD S 0001 - 02!19!2019Document32 pages2019 - KIA US Supplier Quality Manual KR GA PD SQD S 0001 - 02!19!2019rekik99266No ratings yet

- Paris IATF Stakeholder Event IATF Vision and Strategy PDFDocument22 pagesParis IATF Stakeholder Event IATF Vision and Strategy PDFHosam Elden Mostafa MasaranyNo ratings yet

- VDADocument20 pagesVDASting GonsalisNo ratings yet

- Statistical Methods For Quality ControlDocument2 pagesStatistical Methods For Quality ControlAntonio Lara0% (1)

- Agilent Calibration FrequencyDocument6 pagesAgilent Calibration Frequencyzilangamba_s4535No ratings yet

- QC 080000-2005 (2nd Ed) IECQ-HSPMDocument16 pagesQC 080000-2005 (2nd Ed) IECQ-HSPMISO Vintecom100% (1)

- System-Based, Customer-Centered Quality Plan For ManufacturersDocument9 pagesSystem-Based, Customer-Centered Quality Plan For ManufacturersmsbarretosNo ratings yet

- Gage R&R (Xbar/R) For ResponseDocument5 pagesGage R&R (Xbar/R) For ResponsebhaskarNo ratings yet

- Cal ChecklistDocument9 pagesCal ChecklistImad AghilaNo ratings yet

- Birla Institute of Technology & Science, Pilani Work Integrated Learning Programmes Division Manufacturing ExcellenceDocument7 pagesBirla Institute of Technology & Science, Pilani Work Integrated Learning Programmes Division Manufacturing Excellencebalaji817150No ratings yet

- Part Submission Warrant - PSWDocument2 pagesPart Submission Warrant - PSWPuneet Sharma100% (1)

- PPAP 4th Edition (Errata Added)Document79 pagesPPAP 4th Edition (Errata Added)CHITHIRANNo ratings yet

- Prosses Audit VDA6.3Document32 pagesProsses Audit VDA6.3pkj009No ratings yet

- GM Customer Specifics - Rev 05-07-15Document34 pagesGM Customer Specifics - Rev 05-07-15hugocronyNo ratings yet

- Quality Management Systems GuideDocument27 pagesQuality Management Systems Guidesunmeet singhNo ratings yet

- Lean ProductionDocument17 pagesLean ProductionTahir Naeem JattNo ratings yet

- MSA Dial Vernier Calipers ExampleDocument1 pageMSA Dial Vernier Calipers ExampleyendiNo ratings yet

- Technical Data Sheet - DST-DEGREEZ-6 - 2020 UKDocument1 pageTechnical Data Sheet - DST-DEGREEZ-6 - 2020 UKBala Sb0% (1)

- 5 S and Six SigmaDocument19 pages5 S and Six SigmaAnandraj004No ratings yet

- Supplier Controlled - Safe Launch PlanDocument6 pagesSupplier Controlled - Safe Launch PlanMario RojasNo ratings yet

- Benutzerhandbuch QTR Online Englische Version PDFDocument34 pagesBenutzerhandbuch QTR Online Englische Version PDFBrian BoruNo ratings yet

- CP 8plainpluggage CalibrationproceduresDocument1 pageCP 8plainpluggage CalibrationproceduresSenthil_KNo ratings yet

- Testing Leather - Unit 1Document8 pagesTesting Leather - Unit 1Daniel MoralesNo ratings yet

- Stellantis Ex PSA Scorecard Quick Reference Guide July 2021Document3 pagesStellantis Ex PSA Scorecard Quick Reference Guide July 2021白子健No ratings yet

- Metravi GM-197 Gauss Meter User ManualDocument20 pagesMetravi GM-197 Gauss Meter User ManualRichaNo ratings yet

- Sae J121M-2013Document5 pagesSae J121M-2013phan hoai nam PhanNo ratings yet

- VDA Volume 6.3 2016 Chapter 9.1 Process Audit EvaluationDocument1 pageVDA Volume 6.3 2016 Chapter 9.1 Process Audit EvaluationYo GoldNo ratings yet

- How To Manage The Transition Successfully: Technical GuideDocument8 pagesHow To Manage The Transition Successfully: Technical GuideSudhagarNo ratings yet

- Group Exercise Covering Audit Situations From P5, P6, P7Document3 pagesGroup Exercise Covering Audit Situations From P5, P6, P7sankusi_rkflNo ratings yet

- Process Failure Mode and Effects Analysis: SEV OCC DETDocument15 pagesProcess Failure Mode and Effects Analysis: SEV OCC DETMomoZhNo ratings yet

- Single Minute Exchange of Dies - Ashita Nair - Kashmira KulkarniDocument13 pagesSingle Minute Exchange of Dies - Ashita Nair - Kashmira KulkarnirockinskullNo ratings yet

- Ashok LeylandDocument2 pagesAshok Leylandindu296No ratings yet

- VDA 6.3-Analysis Tool: User ManualDocument23 pagesVDA 6.3-Analysis Tool: User ManualIstvan KisNo ratings yet

- APQP Overview PDFDocument86 pagesAPQP Overview PDFnajibNo ratings yet

- Process Layout ImprovementDocument5 pagesProcess Layout ImprovementhappyrockzzNo ratings yet

- What Is Your Company's Cost of Poor Quality (CoPQ) - Tools For Calculating and Reducing ItDocument4 pagesWhat Is Your Company's Cost of Poor Quality (CoPQ) - Tools For Calculating and Reducing ItfaidbNo ratings yet

- PSWDocument2 pagesPSWLinda G. CordovaNo ratings yet

- Cqi 9Document55 pagesCqi 9Balram Ji0% (1)

- APQP - QuestionnaireDocument2 pagesAPQP - QuestionnaireLOGANATHAN V100% (1)

- JBM Group 12 Pillar Internal Auditor Exam 2022-23Document30 pagesJBM Group 12 Pillar Internal Auditor Exam 2022-23Ravi javaliNo ratings yet

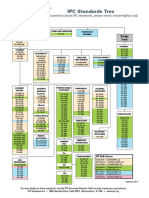

- IPC-SpecTree - IPC SpecTree 2014-09Document1 pageIPC-SpecTree - IPC SpecTree 2014-09edubrunno100% (1)

- PAPP Checklists and FormsDocument4 pagesPAPP Checklists and FormsA M100% (1)

- IATF 16949 QMS Upgrade SampleDocument3 pagesIATF 16949 QMS Upgrade Sampleusama_waly4166No ratings yet

- SAQP Elements OverviewDocument38 pagesSAQP Elements OverviewBoštjan Dokl MenihNo ratings yet

- A Process Capability Study On CNC Operation by The Application of Statistical Process Control ApproachDocument14 pagesA Process Capability Study On CNC Operation by The Application of Statistical Process Control ApproachvivgukgjujgNo ratings yet

- TOtal Quality ControlDocument54 pagesTOtal Quality ControlSAMGPRONo ratings yet

- Formel Q-Capability Version 6.0 Supplier Training - Product AuditDocument11 pagesFormel Q-Capability Version 6.0 Supplier Training - Product AuditVijay LadNo ratings yet

- Layered Process Audit ChecksheetDocument3 pagesLayered Process Audit ChecksheetKevin Poore100% (1)

- APQPStatus Reporting GuidelinesDocument19 pagesAPQPStatus Reporting GuidelinesskluxNo ratings yet

- Healthcare 09 00201 v2Document9 pagesHealthcare 09 00201 v2om vermaNo ratings yet

- Corrosion of Stainless Steels of Cryogenic Hydrocarbon Flare Tips BurnersDocument13 pagesCorrosion of Stainless Steels of Cryogenic Hydrocarbon Flare Tips Burnersravikanth_rNo ratings yet

- New Sheet - CorrectedDocument19 pagesNew Sheet - CorrectedklashincoviskyNo ratings yet

- SyserrDocument1,743 pagesSyserrBogdan Paul IvanNo ratings yet

- Introduction To Process Dynamics and ControlDocument44 pagesIntroduction To Process Dynamics and ControlEthio Dangote TubeNo ratings yet

- On A/C All: Wiring Diagram ManualDocument3 pagesOn A/C All: Wiring Diagram ManualatrflyerNo ratings yet

- Physics Form 4 Chapter 2Document13 pagesPhysics Form 4 Chapter 2niknadhiraNo ratings yet

- Description Dermatological StatusDocument6 pagesDescription Dermatological StatusNazmun LailahNo ratings yet

- Rolls-Royce Corporation CEBsDocument24 pagesRolls-Royce Corporation CEBsEstevamNo ratings yet

- MM103 Lab 4Document4 pagesMM103 Lab 4Shivneel SwamyNo ratings yet

- Computer Fundamentals: Pradeep K. Sinha & Priti SinhaDocument0 pagesComputer Fundamentals: Pradeep K. Sinha & Priti SinhaWamiq ReyazNo ratings yet

- PlantsDocument11 pagesPlantsSUHANA BERANo ratings yet

- Shah Darshika PDFDocument130 pagesShah Darshika PDFSachin PatelNo ratings yet

- Abonacci Trading: Credit: Bobi Abonacci ContactDocument4 pagesAbonacci Trading: Credit: Bobi Abonacci ContactUjangNo ratings yet

- Parallel Lines Cut by A TransversalDocument2 pagesParallel Lines Cut by A TransversalAnita MeghaniNo ratings yet

- En ENSOL - Installation Instruction Flat RoofDocument24 pagesEn ENSOL - Installation Instruction Flat Roofخالد بنسالمNo ratings yet

- LESSON EXEMPLAR in SCIENCE 11-General Chemistry 1Document5 pagesLESSON EXEMPLAR in SCIENCE 11-General Chemistry 1UdieokfchwNo ratings yet

- Extrusion D'une Barre D'aluminium: Mise en Œuvre Des MatériauxDocument4 pagesExtrusion D'une Barre D'aluminium: Mise en Œuvre Des Matériauxelouis2No ratings yet

- Tool WearDocument8 pagesTool WearSai KrishnaNo ratings yet

- KIFAYAT Tahsili Chemistry V1 (Free Disterbution)Document58 pagesKIFAYAT Tahsili Chemistry V1 (Free Disterbution)res weqrNo ratings yet

- Beam ExpanderDocument12 pagesBeam ExpanderRio Ananda PutraNo ratings yet

- Major Takeaways of SDET ProgramDocument3 pagesMajor Takeaways of SDET ProgramMalli PikkiliNo ratings yet

- Solution Manual For Geometry 1St Edition by Martin Gay Isbn 0134173651 9780134173658 Full Chapter PDFDocument27 pagesSolution Manual For Geometry 1St Edition by Martin Gay Isbn 0134173651 9780134173658 Full Chapter PDFsteven.davis655100% (10)

- Samia PDFDocument7 pagesSamia PDFMohamed Sayed AbdoNo ratings yet

- Peos Pos PsosDocument8 pagesPeos Pos Psossubhani cseNo ratings yet

- New Time Table 2081Document2 pagesNew Time Table 2081shankalprajkhanalNo ratings yet

- HKOH SNDL Int ReqDocument2 pagesHKOH SNDL Int ReqMuhammad AsfandyarNo ratings yet

- PIEAS Fellowship MS Mechanical Engineering Paper 2012Document16 pagesPIEAS Fellowship MS Mechanical Engineering Paper 2012Mazhar aliNo ratings yet

- The Fixed Dummy BlockDocument6 pagesThe Fixed Dummy Blockdjamila alfadis100% (1)

- TS00E v1.2 Student Noteset PDFDocument303 pagesTS00E v1.2 Student Noteset PDFpatrick morris100% (1)

Cqi 9 Errata AIAG

Cqi 9 Errata AIAG

Uploaded by

Rafael AlvesOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cqi 9 Errata AIAG

Cqi 9 Errata AIAG

Uploaded by

Rafael AlvesCopyright:

Available Formats

CQI-9 Special Process: Heat Treat System Assessment, 2nd Edition Errata Sheet

Page

Item #

Original Language (see BOLD)

Corrected Version Language (see highlight)

Section 3.5.5 Initial TUS

17

3.5.5

17

3.5.6

Section 3.5.6 Periodic TUS (For CQI-9,

Section 3.5.6 Periodic TUS (For CQI-9, a

a minimum of once per year periodic TUS

minimum of once per year periodic TUS is

is required)

required)

- Minimum and maximum temperature

Minimum and maximum temperature ranges shall

ranges shall be tested per AMS 2750D.

be tested per AMS 2750D. Exception: If the

Exception: If the operating range of the

operating range of the Qualified Work Zone is equal

Qualified Work Zone is equal to or less than

to or less than 170oC (306oF) then only one

o

o

85 C (153 F) then only one temperature is

temperature is required to be tested. The

required to be tested. The temperature

temperature shall be within the operating range of

shall be within the operating range of the

the Qualified Work Zone.

Qualified Work Zone.

43

A1.9

All hardness test equipment (for each scale

All hardness test equipment (for each scale used)

used) shall be calibrated semi-annually

shall be calibrated annually minimum, and verified

minimum, and verified daily minimum per

daily minimum per the applicable ASTM standard.

the applicable ASTM standard.

48

B1.7

54

C1.3

58

D1.2

62

E1.8

All hardness test equipment (for each scale

All hardness test equipment (for each scale used)

used) shall be calibrated semi-annually

shall be calibrated annually minimum, and verified

minimum, and verified daily minimum per

daily minimum per the applicable ASTM standard.

the applicable ASTM standard.

65

E4.2

Every 2 hours minimum

Section 3.5.5 Initial TUS

Minimum and maximum temperature

Minimum and maximum temperature ranges

ranges shall be tested per AMS 2750D.

shall be tested per AMS 2750D. Exception: If the

Exception: If the operating range of the

operating range of the Qualified Work Zone is

Qualified Work Zone is equal to or less

equal to or less than 170oC (306oF) then only

o

o

than 85 C (153 F) then only one

one temperature is required to be tested. The

temperature is required to be tested. The

temperature shall be within the operating range

temperature shall be within the operating

of the Qualified Work Zone.

range of the Qualified Work Zone.

All hardness test equipment (for each scale

All hardness test equipment (for each scale used)

used) shall be calibrated semi-annually

shall be calibrated annually minimum, and verified

minimum, and verified daily minimum per

daily minimum per the applicable ASTM standard.

the applicable ASTM standard.

All hardness test equipment (for each scale

All hardness test equipment (for each scale used)

used) shall be calibrated semi-annually

shall be calibrated annually minimum, and verified

minimum, and verified daily minimum per

daily minimum per the applicable ASTM standard.

the applicable ASTM standard.

All hardness test equipment (for each scale

All hardness test equipment (for each scale used)

used) shall be calibrated semi-annually

shall be calibrated annually minimum, and verified

minimum, and verified daily minimum per

daily minimum per the applicable ASTM standard.

the applicable ASTM standard.

Every 4 hours minimum

CLARIFICATION TO "GENERAL NOTES FOR AMS 2750D"

PAGES 16 & 17, CQI-09 2nd Edition

General Notes for AMS 2750D

AMS 2750D is referenced in the Pyrometry Section (Section 2.0) of the Process Tables. Heat treat suppliers

are not required to comply to all sections of AMS 2750D. Heat treat suppliers shall comply to the sections

of AMS 2750D that are given below. These sections reference thermocouples, the calibration of

thermocouples and instrumentation, and the procedure for conducting furnace temperature uniformity

surveys (TUS).

Thermocouples and Instrumentation

- Section 3.1 Temperature Sensors (Thermocouples)

- Section 3.2 Instrumentation - Note: Frequency reductions per AMS 2750D are not

allowed by CQI-9

Compliance to the following sections in 3.2, are not required by CQI-9

Section Number

3.2.5.1 & 2

3.2.5.3.1

3.2.5.5

Explanation

Temperature controlling instruments purchased prior to 1 year after

the release of AMS 2750D are exempt of 3.2.5.1 and 3.2.5.2.

One point sensor input is acceptable.

Sensitivity checks during calibration are not required.

CLARIFICATION TO "GENERAL NOTES FOR AMS 2750D"

PAGES 16 & 17, CQI-09 2nd Edition

System Accuracy Test (SAT) Procedure (Section 3.4)

NOTE: Refer to AMS 2750D as directed

-

SAT shall be performed by one of the two methods listed below:

1) Probe Method: The temperature indication of the furnace control instrument connected to the

control sensor (CS) shall be within +/- 5C (or +/- 10F) of the corrected temperature

indication of the test sensor (TS) on a test instrument. This test shall be performed monthly

at a typical operating temperature utilizing the procedures detailed in AMS 2750D Section

3.4.4, System Accuracy Test Procedure.

SAT Frequency:

o

o

Equipment operating at or above 760C (1400F) shall be checked monthly.

Equipment operating below 760C (1400F) shall be checked quarterly.

Example of Probe Method

Control Sensor

Over-Temp Sensor

Control Instrument

Part or Raw

Material

1500

1501

Lead Wire

Chart Recorder

Over Temp Test Sensor

Furnace Wall

Protection

Test Instrument

Furnace

Work Zone

B

Note: The test sensor can be a

resident thermocouple, refer to

AMS 2750 D section 3.4.4.2.1

EXAMPLE OF SYSTEM ACCURACY TEST (SAT)

CONTROL

INSTRUMENT

TEMPERATURE

INDICATION

(A)

o

900 C

(1652oF)

TEST

INSTRUMENT

TEMPERATURE

INDICATION

(B)

o

901.5 C

(1655oF)

TEST SENSOR

CORRECTION

FACTOR

(C)

o

-0.5 C

(-1.0oF)

TEST

INSTRUMENT

CORRECTION

FACTOR

(D)

o

+0.1 C

(+0.2oF)

TRUE TEST

TEMPERATURE

SAT

DIFFERENCE

(E)=(B)+(C)+(D)

(A) (E)

-1.1oC

(-2.2oF)

901.1 C

(1654.2oF)

CLARIFICATION TO "GENERAL NOTES FOR AMS 2750D"

PAGES 16 & 17, CQI-09 2nd Edition

2) Comparative Method: The relationship between the control system (sensor, leadwire, control

instrument) and any other permanently installed monitoring system such as over temperature

control system (sensor, leadwire, over temp instrument) or a load monitoring system (sensor,

leadwire, recording instrument) etc. at the time of the most recent conforming instrument

calibration test shall be established. This established relationship shall not differ by more

than +/-1C (or +/-2F) when checked weekly at a typical operating temperature.

Example of Comparative

Method

Control Instrument

Control Sensor

Over-Temp Sensor

Part or Raw

Material

1500

1501

Chart Recorder

Furnace

Work Zone

Over Temp

Protection

Furnace Wall

Other permanently installed thermocouple

(If utilized)

Note: It is strongly recommended that

the comparative check be performed at or near the original temperature

temperature

Any actions to correct a failing reading or validate a test result shall be documented.

Control Sensors (CS) failing to meet the requirements of SAT method 1 shall be changed. A

new TUS is not required unless the position of the control sensor changes. If new

thermocouple(s) are required in Test method 2, a new relationship must be established.

Thermocouple Replacement Schedule:

o

o

o

o

Base metal sensors (e.g. Type K, N, J, E) thermocouples shall be changed when needed

or annually at a minimum for equipment operating at or above 760C (1400F).

Base metal sensors (e.g. Type K, N, J, E) thermocouples shall be changed when needed

or every two years at a minimum for equipment operating below 760C (1400F).

Noble metal sensors (e.g. Type R and S) thermocouples shall be changed when needed

or every two years at a minimum for equipment operating at or above 760C (1400F).

Note: A new TUS is not required for any thermocouple replacement unless the position

of the control sensor(CS) is changed (CS)

CLARIFICATION TO "GENERAL NOTES FOR AMS 2750D"

PAGES 16 & 17, CQI-09 2nd Edition

Furnace Temperature Uniformity Survey (TUS)

o Section 3.5.2

Multiple Qualified Operating Temperature Ranges

o Section 3.5.3

Furnace Modifications

o Section 3.5.4

Furnace Repairs

o Section 3.5.5

Initial TUS

Section 3.5.6

o

o

o

o

o

o

o

o

o

Periodic TUS (For CQI-9, a minimum of once per year periodic

TUS is required)

Minimum and maximum temperature ranges shall be tested per AMS 2750D.

Exception: If the operating range of the Qualified Work Zone is equal to or less

than 170oC (306oF) then only one temperature is required to be tested. The

temperature shall be within the operating range of the Qualified Work Zone.

Section 3.5.8

Furnace Parameters During TUS

Section 3.5.9

Furnace Temperature at Insertion of TUS Sensors (Thermocouples)

Section 3.5.10 Load Condition

Section 3.5.11 Furnace Atmosphere During TUS

Section 3.5.13 Batch Furnaces, Salt Baths, Controlled Temperature Liquid Baths, and

Fluidized Bed Furnaces EXCEPT:

o

o

Minimum and maximum temperature ranges shall be tested per AMS 2750D.

Exception: If the operating range of the Qualified Work Zone is equal to or less

than 170oC (306oF) then only one temperature is required to be tested. The

temperature shall be within the operating range of the Qualified Work Zone.

3.5.13.3.2: CQI-9 requires that data from the TUS sensors is automatically

recorded.

Section 3.5.14 Continuous and Semi-Continuous Furnaces

Section 3.5.15 Alternative Testing Methods for Continuous and Semi-Continuous

Furnaces or Furnaces with Retorts or Muffles

Section 3.5.16 Temperature Uniformity Survey Sensor Failures

Section 3.5.18 Relocation of Hot or Cold Recording Sensors for Class A or C

Instrumentation

Section 3.5.20 Temperature Uniformity Survey Instrumentation

Section 3.5.21 Temperature Uniformity Survey Report

You might also like

- VW - 10131 - enDocument64 pagesVW - 10131 - enKinga EnNo ratings yet

- Manual KPM-QS Users Guide V2 2Document40 pagesManual KPM-QS Users Guide V2 2EnriqueNo ratings yet

- ABC Risk ClassificationDocument1 pageABC Risk ClassificationdocsenNo ratings yet

- Conducting Temperature Uniformity Surveys of Furnaces Used To Heat Treat Steel ProductsDocument4 pagesConducting Temperature Uniformity Surveys of Furnaces Used To Heat Treat Steel Productssaran saranNo ratings yet

- AIAG CQI-9 TUS RequirementsDocument10 pagesAIAG CQI-9 TUS RequirementsNethajiNo ratings yet

- CQI 9 3rd Edition Errata SheetDocument2 pagesCQI 9 3rd Edition Errata SheetANONIMONo ratings yet

- Dead Endclamp Failure AnalysisDocument26 pagesDead Endclamp Failure AnalysisRK KumarNo ratings yet

- Bonding In-Process Inspection ChecklistDocument1 pageBonding In-Process Inspection ChecklistRonnel LeanoNo ratings yet

- UntitledDocument19 pagesUntitledSuresh KumarNo ratings yet

- 2019 - KIA US Supplier Quality Manual KR GA PD SQD S 0001 - 02!19!2019Document32 pages2019 - KIA US Supplier Quality Manual KR GA PD SQD S 0001 - 02!19!2019rekik99266No ratings yet

- Paris IATF Stakeholder Event IATF Vision and Strategy PDFDocument22 pagesParis IATF Stakeholder Event IATF Vision and Strategy PDFHosam Elden Mostafa MasaranyNo ratings yet

- VDADocument20 pagesVDASting GonsalisNo ratings yet

- Statistical Methods For Quality ControlDocument2 pagesStatistical Methods For Quality ControlAntonio Lara0% (1)

- Agilent Calibration FrequencyDocument6 pagesAgilent Calibration Frequencyzilangamba_s4535No ratings yet

- QC 080000-2005 (2nd Ed) IECQ-HSPMDocument16 pagesQC 080000-2005 (2nd Ed) IECQ-HSPMISO Vintecom100% (1)

- System-Based, Customer-Centered Quality Plan For ManufacturersDocument9 pagesSystem-Based, Customer-Centered Quality Plan For ManufacturersmsbarretosNo ratings yet

- Gage R&R (Xbar/R) For ResponseDocument5 pagesGage R&R (Xbar/R) For ResponsebhaskarNo ratings yet

- Cal ChecklistDocument9 pagesCal ChecklistImad AghilaNo ratings yet

- Birla Institute of Technology & Science, Pilani Work Integrated Learning Programmes Division Manufacturing ExcellenceDocument7 pagesBirla Institute of Technology & Science, Pilani Work Integrated Learning Programmes Division Manufacturing Excellencebalaji817150No ratings yet

- Part Submission Warrant - PSWDocument2 pagesPart Submission Warrant - PSWPuneet Sharma100% (1)

- PPAP 4th Edition (Errata Added)Document79 pagesPPAP 4th Edition (Errata Added)CHITHIRANNo ratings yet

- Prosses Audit VDA6.3Document32 pagesProsses Audit VDA6.3pkj009No ratings yet

- GM Customer Specifics - Rev 05-07-15Document34 pagesGM Customer Specifics - Rev 05-07-15hugocronyNo ratings yet

- Quality Management Systems GuideDocument27 pagesQuality Management Systems Guidesunmeet singhNo ratings yet

- Lean ProductionDocument17 pagesLean ProductionTahir Naeem JattNo ratings yet

- MSA Dial Vernier Calipers ExampleDocument1 pageMSA Dial Vernier Calipers ExampleyendiNo ratings yet

- Technical Data Sheet - DST-DEGREEZ-6 - 2020 UKDocument1 pageTechnical Data Sheet - DST-DEGREEZ-6 - 2020 UKBala Sb0% (1)

- 5 S and Six SigmaDocument19 pages5 S and Six SigmaAnandraj004No ratings yet

- Supplier Controlled - Safe Launch PlanDocument6 pagesSupplier Controlled - Safe Launch PlanMario RojasNo ratings yet

- Benutzerhandbuch QTR Online Englische Version PDFDocument34 pagesBenutzerhandbuch QTR Online Englische Version PDFBrian BoruNo ratings yet

- CP 8plainpluggage CalibrationproceduresDocument1 pageCP 8plainpluggage CalibrationproceduresSenthil_KNo ratings yet

- Testing Leather - Unit 1Document8 pagesTesting Leather - Unit 1Daniel MoralesNo ratings yet

- Stellantis Ex PSA Scorecard Quick Reference Guide July 2021Document3 pagesStellantis Ex PSA Scorecard Quick Reference Guide July 2021白子健No ratings yet

- Metravi GM-197 Gauss Meter User ManualDocument20 pagesMetravi GM-197 Gauss Meter User ManualRichaNo ratings yet

- Sae J121M-2013Document5 pagesSae J121M-2013phan hoai nam PhanNo ratings yet

- VDA Volume 6.3 2016 Chapter 9.1 Process Audit EvaluationDocument1 pageVDA Volume 6.3 2016 Chapter 9.1 Process Audit EvaluationYo GoldNo ratings yet

- How To Manage The Transition Successfully: Technical GuideDocument8 pagesHow To Manage The Transition Successfully: Technical GuideSudhagarNo ratings yet

- Group Exercise Covering Audit Situations From P5, P6, P7Document3 pagesGroup Exercise Covering Audit Situations From P5, P6, P7sankusi_rkflNo ratings yet

- Process Failure Mode and Effects Analysis: SEV OCC DETDocument15 pagesProcess Failure Mode and Effects Analysis: SEV OCC DETMomoZhNo ratings yet

- Single Minute Exchange of Dies - Ashita Nair - Kashmira KulkarniDocument13 pagesSingle Minute Exchange of Dies - Ashita Nair - Kashmira KulkarnirockinskullNo ratings yet

- Ashok LeylandDocument2 pagesAshok Leylandindu296No ratings yet

- VDA 6.3-Analysis Tool: User ManualDocument23 pagesVDA 6.3-Analysis Tool: User ManualIstvan KisNo ratings yet

- APQP Overview PDFDocument86 pagesAPQP Overview PDFnajibNo ratings yet

- Process Layout ImprovementDocument5 pagesProcess Layout ImprovementhappyrockzzNo ratings yet

- What Is Your Company's Cost of Poor Quality (CoPQ) - Tools For Calculating and Reducing ItDocument4 pagesWhat Is Your Company's Cost of Poor Quality (CoPQ) - Tools For Calculating and Reducing ItfaidbNo ratings yet

- PSWDocument2 pagesPSWLinda G. CordovaNo ratings yet

- Cqi 9Document55 pagesCqi 9Balram Ji0% (1)

- APQP - QuestionnaireDocument2 pagesAPQP - QuestionnaireLOGANATHAN V100% (1)

- JBM Group 12 Pillar Internal Auditor Exam 2022-23Document30 pagesJBM Group 12 Pillar Internal Auditor Exam 2022-23Ravi javaliNo ratings yet

- IPC-SpecTree - IPC SpecTree 2014-09Document1 pageIPC-SpecTree - IPC SpecTree 2014-09edubrunno100% (1)

- PAPP Checklists and FormsDocument4 pagesPAPP Checklists and FormsA M100% (1)

- IATF 16949 QMS Upgrade SampleDocument3 pagesIATF 16949 QMS Upgrade Sampleusama_waly4166No ratings yet

- SAQP Elements OverviewDocument38 pagesSAQP Elements OverviewBoštjan Dokl MenihNo ratings yet

- A Process Capability Study On CNC Operation by The Application of Statistical Process Control ApproachDocument14 pagesA Process Capability Study On CNC Operation by The Application of Statistical Process Control ApproachvivgukgjujgNo ratings yet

- TOtal Quality ControlDocument54 pagesTOtal Quality ControlSAMGPRONo ratings yet

- Formel Q-Capability Version 6.0 Supplier Training - Product AuditDocument11 pagesFormel Q-Capability Version 6.0 Supplier Training - Product AuditVijay LadNo ratings yet

- Layered Process Audit ChecksheetDocument3 pagesLayered Process Audit ChecksheetKevin Poore100% (1)

- APQPStatus Reporting GuidelinesDocument19 pagesAPQPStatus Reporting GuidelinesskluxNo ratings yet

- Healthcare 09 00201 v2Document9 pagesHealthcare 09 00201 v2om vermaNo ratings yet

- Corrosion of Stainless Steels of Cryogenic Hydrocarbon Flare Tips BurnersDocument13 pagesCorrosion of Stainless Steels of Cryogenic Hydrocarbon Flare Tips Burnersravikanth_rNo ratings yet

- New Sheet - CorrectedDocument19 pagesNew Sheet - CorrectedklashincoviskyNo ratings yet

- SyserrDocument1,743 pagesSyserrBogdan Paul IvanNo ratings yet

- Introduction To Process Dynamics and ControlDocument44 pagesIntroduction To Process Dynamics and ControlEthio Dangote TubeNo ratings yet

- On A/C All: Wiring Diagram ManualDocument3 pagesOn A/C All: Wiring Diagram ManualatrflyerNo ratings yet

- Physics Form 4 Chapter 2Document13 pagesPhysics Form 4 Chapter 2niknadhiraNo ratings yet

- Description Dermatological StatusDocument6 pagesDescription Dermatological StatusNazmun LailahNo ratings yet

- Rolls-Royce Corporation CEBsDocument24 pagesRolls-Royce Corporation CEBsEstevamNo ratings yet

- MM103 Lab 4Document4 pagesMM103 Lab 4Shivneel SwamyNo ratings yet

- Computer Fundamentals: Pradeep K. Sinha & Priti SinhaDocument0 pagesComputer Fundamentals: Pradeep K. Sinha & Priti SinhaWamiq ReyazNo ratings yet

- PlantsDocument11 pagesPlantsSUHANA BERANo ratings yet

- Shah Darshika PDFDocument130 pagesShah Darshika PDFSachin PatelNo ratings yet

- Abonacci Trading: Credit: Bobi Abonacci ContactDocument4 pagesAbonacci Trading: Credit: Bobi Abonacci ContactUjangNo ratings yet

- Parallel Lines Cut by A TransversalDocument2 pagesParallel Lines Cut by A TransversalAnita MeghaniNo ratings yet

- En ENSOL - Installation Instruction Flat RoofDocument24 pagesEn ENSOL - Installation Instruction Flat Roofخالد بنسالمNo ratings yet

- LESSON EXEMPLAR in SCIENCE 11-General Chemistry 1Document5 pagesLESSON EXEMPLAR in SCIENCE 11-General Chemistry 1UdieokfchwNo ratings yet

- Extrusion D'une Barre D'aluminium: Mise en Œuvre Des MatériauxDocument4 pagesExtrusion D'une Barre D'aluminium: Mise en Œuvre Des Matériauxelouis2No ratings yet

- Tool WearDocument8 pagesTool WearSai KrishnaNo ratings yet

- KIFAYAT Tahsili Chemistry V1 (Free Disterbution)Document58 pagesKIFAYAT Tahsili Chemistry V1 (Free Disterbution)res weqrNo ratings yet

- Beam ExpanderDocument12 pagesBeam ExpanderRio Ananda PutraNo ratings yet

- Major Takeaways of SDET ProgramDocument3 pagesMajor Takeaways of SDET ProgramMalli PikkiliNo ratings yet

- Solution Manual For Geometry 1St Edition by Martin Gay Isbn 0134173651 9780134173658 Full Chapter PDFDocument27 pagesSolution Manual For Geometry 1St Edition by Martin Gay Isbn 0134173651 9780134173658 Full Chapter PDFsteven.davis655100% (10)

- Samia PDFDocument7 pagesSamia PDFMohamed Sayed AbdoNo ratings yet

- Peos Pos PsosDocument8 pagesPeos Pos Psossubhani cseNo ratings yet

- New Time Table 2081Document2 pagesNew Time Table 2081shankalprajkhanalNo ratings yet

- HKOH SNDL Int ReqDocument2 pagesHKOH SNDL Int ReqMuhammad AsfandyarNo ratings yet

- PIEAS Fellowship MS Mechanical Engineering Paper 2012Document16 pagesPIEAS Fellowship MS Mechanical Engineering Paper 2012Mazhar aliNo ratings yet

- The Fixed Dummy BlockDocument6 pagesThe Fixed Dummy Blockdjamila alfadis100% (1)

- TS00E v1.2 Student Noteset PDFDocument303 pagesTS00E v1.2 Student Noteset PDFpatrick morris100% (1)