Professional Documents

Culture Documents

Simulation of A Circulating Fluidized Bed Combustor With Shrinking Core and Emission Models

Simulation of A Circulating Fluidized Bed Combustor With Shrinking Core and Emission Models

Uploaded by

Azharuddin_kfupmOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Simulation of A Circulating Fluidized Bed Combustor With Shrinking Core and Emission Models

Simulation of A Circulating Fluidized Bed Combustor With Shrinking Core and Emission Models

Uploaded by

Azharuddin_kfupmCopyright:

Available Formats

ScienceAsia 30 (2004): 365-374

Simulation of a Circulating Fluidized Bed Combustor

with Shrinking Core and Emission Models

Natthapong Ngampradit,a,* Pornpote Piumsomboon,a and Boonrod Sajjakulnukitb

a

Fuels Research Center, Department of Chemical Technology, Chulalongkorn University, Bangkok,

Thailand, 10330.

Department of Alternative Energy Development and Efficiency, Bangkok, Thailand, 10330.

Corresponding author: E-mail: Ng_natthapong@yahoo.com

Received 8 Apr 2004

Accepted 3 Sep 2004

ABSTRACT: A Circulating Fluidized Bed Combustor (CFBC) is a highly efficient combustor. It can handle

various types of solid fuels such as coal, biomass or agricultural wastes. Coal and biomass have been used as

fuel to generate heat for a boiler in many industries. To predict the proper amount of mixed fuel and to

reduce the emission from coal burning, a rigorous mathematical model for the CFBC is needed. This paper

describes the CFBC model developed as additional subroutines working with ASPEN PLUS version 11.1. The

model was divided into three parts: reaction, hydrodynamic, and gas emission. In the first part, the reactions

in the combustor were represented by a Continuous Stirred Tank Reactor (CSTR) module. The module was

modified by adding the shrinking core model for calculating the size and the weight fraction of particles in

each region. In the second part, the hydrodynamics in CFBC were divided into two regions: a lower region

with one interval, and an upper region with three intervals. In each region the characteristics, such as the

height of the bed, void, and volume, were calculated and sent to CSTR module for adjusting reaction rates

in the regions. In the third part, gas emission models were used to calculate the kinetic rates of NO, N2O and

the conversion of SO2 to predict the emission to the environment.

KEYWORDS: Circulating Fluidized Bed Combustor, Shrinking Core Model, CFBC simulation.

INTRODUCTION

Circulating Fluidized Bed Combustors (CFBCs) are

widely used in many industries for steam production

and power generation. The advantages of the CFBC are

high combustion efficiency, high heat transfer rate, and

fuel flexibility. Various kinds of fuel can be used such

as coals, biomass and agricultural wastes. The process

is also considered to be clean technology, since it has

potentials to reduce NOx and SO2 emissions. In Thailand,

the industries that use such technology are mainly the

pulp and paper industries since there are large amounts

of agricultural wastes, such as eucalyptus bark, bagasse

and pith, left from processes.

Sotudeh-Gharebeagh et al.1 simulated the CFBC for

coal combustion using ASPEN PLUS based on an

isothermal assumption. The kinetic and hydrodynamic

subroutines were used for calculating the rates of

reactions and predicting the mean axial voidage profile

in upper region. The results expressed in terms of

combustion efficiency and emission level. Huilin et al.2

computed a Circulating Fluidized Bed (CFB) boiler with

wide particle size distributions by considering the

hydrodynamics, heat transfer and combustion of coal.

The models predicted the flue gas temperature, the

chemical gas species, such as O2, CO and CO2, and the

char concentration distributions in both axial and radial

locations along the furnace. Mukadi et al.3 developed

a mathematical model of kinetic reactions to predict

gas emissions in an internally CFBC for treatment of

industrial solid wastes. Liu and Gibbs4 presented the

model applied to a 12 MWth CFB boiler using a typical

wood biomass-pinewood chips as a fuel to predict NO

and N2O emissions. Chen et al.5 developed the model

of fluidized bed combustion and studied the emissions

of NOx and N2O for char combustion, while Winter et

al.6 developed the mechanism of NO and N2O from the

single particle of petroleum coke and up to a pilot scale.

Natthapong et al.7 presented a model of CFBC with

shrinking core model of mixed fuel to predict the size

change along a riser.

While most of the previous work focused on either

coal or biomass as a fuel, the work in our group has

been focused on mixed fuel. In our earlier publication,

a CFBC model developed under ASPEN PLUS for

various types of fuel, for example, coal, bark, pith or

mixed fuel was presented. The model included the

shrinking core models for estimating the size change

of the solid fuel along the riser. In this paper, the models

were extended by including detail reactions of

emissions. The emission models, such as the rates of

N2O and NOx formation and the fractional conversion

366

ScienceAsia 30 (2004)

of limestone to absorb SO2, were added. Algorithms for

computing the rates and predicting the emissions to

the environment were developed.

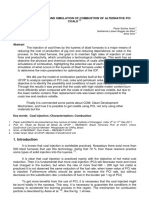

1. Modeling Approaches

1.1 Assumptions of the Reaction Model

1) The fuel, limestone, and primary air were fed at

the bottom of the CFBC with a uniform temperature.

2) The simulated combustor was a rectangular

column with the surface area of 36.31 m2 and the

height of 21.84 m (Fig. 1). In the proposed model, the

secondary and tertiary air was fed into the combustor

at the specified height.

3) The combustion of volatile matters occurred

instantaneously at the bottom of the combustor.

4) Char combustion occurred slowly after volatile

matters were combusted.

5) Fuel particles and gas temperatures were equal

to the bed temperatures varying with respect to the

height of the riser.

6) The attrition of the char particles was neglected.

7) All steps of the reactions were calculated with an

isothermal at 850 OC.

1.2 Dimension of CFBC

The model was developed for simulating one of the

combustors in a major pulp and paper company in

Thailand. The CFBC was divided into two regions: the

lower and upper regions. The lower region represented

the dense bed, and the upper region the dilute bed

fluidization. Each region was composed of kinetic

reactions, hydrodynamics and emission sections. In

the lower region or the dense bed, the primary air was

fed at the bottom of the combustor. The secondary and

the tertiary air was fed at the height of 1.703 m and

3.203 m, respectively.

1) Devolatilization and volatilite combustion.

2) Char combustion

3) NOx formation

4) SO2 absorption

The algorithms of simulations were divided in three

parts: reaction, hydrodynamic, and gas emission part.

The reaction and gas emission parts were used in the

char combustion step. The gas emission part was used

to calculate the NOx formation and SO2 absorption.

Each reaction will be simulated by using reaction

modules of ASPEN, depending on the type of the

reactions. All blocks were to be simulated as shown in

Fig. 2. The details of the simulations were described as

followed.

1.3.1 Devolatilization and V

Vo

olatilite

Combustion.

The yield reactor was used to simulate the

decomposition of char or biomass to the constituting

components such as carbon, oxygen, hydrogen,

nitrogen, sulfur and ash at the lower region.

The stoichiometric reactor (RSTOIC) was used to

simulate the volatile combustion processes. Three

reactions were considered in this model:

CO

C + 0.5O2

S + O2

SO2

H2 + 0.5O2

H2O

WATER

PB11-20

HEXT

STEAM

PB11-19

RSTOIC

PB11-21

CYCLONE

FLUE GAS

PB11-18

RCSTR

PB11-22

SSPLIT

FLY ASH

PB11-17

RCSTR

BOTTOM

PB11-16

RSTOIC

PB11-15

RCSTR

1.3 Simulation Procedures

For the combustion in each region, the combustion

of coal particles can be modeled using the following

reactions1:

PB11-14

RCSTR

AIR3

PB11-13

RSTOIC

PB11-12

RCSTR

PB11-11

RCSTR

AIR2

21.84 m

PB11-10

RSTOIC

PB11-9

RSTOIC

PB11-8

RCSTR

Secondary air

PB11-7

RCSTR

3.203 m

Tertiary air

AIR1

1.5 m

6.026 m

1.703 m

6.026 m

Fig. 1. Dimension of the combustor

Primary air

PB11-6

RSTOIC

LIME

PB11-1

RYIELD

PB11-2

RYIELD

PB11-3

RYIELD

PB11-4

RYIELD

PB11-5

RYIELD

CHAR

PITH

SLUDGE

F4

F5

Fig. 2. Simulation diagram for the CFBC

367

ScienceAsia 30 (2004)

In the first reaction, the volatile carbon fraction

reacts with oxygen to form CO only during the volatile

combustion process because of the oxygen depletion

in the lower region of the riser. For second reaction, 80

percent of sulfur in coal was assumed to be converted

to SO2 during the volatile combustion process. In the

last reaction, hydrogen is consumed during the volatile

combustion process.

1.3.2 Char combustion.

The Continuous Stirred Tank Reactor (CSTR) was

used to model as a well-mixed reaction with known

reaction kinetics. Two reactions considered in this

reactor are:

C + 0.5O2

CO + 0.5O2

CO

CO2

The first reaction was a heterogeneous reaction.

Then the shrinking core model and the hydrodynamic

subroutines were used to calculate rates of reactions,

particle size distribution, void and volume of reactor.

The flow chart for the calculation was shown in Fig. 3.

The second reaction was the homogeneous reaction of

CO and O2.

The emission level of CO from CFBC was strongly

dependent on the temperature and reactive

concentration. The rate of reaction can be calculated

BEGIN

Input properties from Aspen Plus

and those from hydrodynamics

subroutine such density,

pressure, temperature, particle

size, volume

Calculate time for

complete conversion (5),

(6) and (8)

Calculate mean

residence time (9)

No

For the reaction

control

Yes

Rt CO = 1.18 1013 fCO fO0.25 fH0.25O

P

exp 25000 C

Rg T

R g1T

Calculate mean

residence time (9)

Use residual

radius

No

For

the unconverted

fraction

Yes

Keep initial

radius of

particles

Calculate mean radius

Send all

values to

Aspen Plus

2Rk Ag

DA

= 2 + 0.6

D A

13

12

2Ru

(3)

where DA is the diffusion coefficient of A (m2. s-1), kAg

is the mass transfer coefficient of A (m.s-1), R is the

radius of particle (m), u is the velocity (m.s-1), is the

gas viscosity (kg.m-1.s-1), and is the gas density

(kg.m-3).

This correlation may be used to estimate kAg given

sufficient information about the other quantities.

Rearrange equation (3)

END

Fig. 3. The basic flowchart for calculating reaction rates and

particle sizes for a solid fuel.

(2)

That is,

Calculate mean

conversion (12), (13)

Calculate rate of

reaction

(1)

where C is the combustion gas concentration

(kmol.m-3), f is the mole fraction of each component, P

is the bed pressure (atm), Rg is the universal gas constant

(kcal.kmol-1.K-1), R g1 is the universal gas constant

(atm.cm3.g mol-1.K-1), Rt is the rate of reaction (kmol.

m-3.s-1), T is the bed temperature (K), is the void

fraction.

1.3.2.1. Shrinking Core Model9

The shrinking core model for an isothermal

spherical particle is divided into three steps:

1). Diffusion of reactant A from the main body of

gas through the gas film to the surface of the solid.

2). Reaction on the surface between reactant A and

solid.

3). Diffusion of reaction products from the surface

of the solid through the gas film back into the main

body of the gas.

In this model the ash layer was absent and did not

contribute any resistance. Then the complete

conversion time was calculated from above step.

Consider the correlation for estimating the mass

transfer coefficient of A, kAg , for a free-falling spherical

particle relative to a fluid, the Ranz and Marshall

correlation (1952) relates the Sherwood number, Sh ,

which incorporates kAg, to the Schmidt number, Sc , and

the Reynolds number, Re,10:, according to the following

equation:

Sh = 2 + 0.6Sc1 3 Re1 2

Calculate residual radius

with reaction control

equation (8)

Calculate residual

radius with diffusion

control equation (5), (6)

using the following equation1:

k Ag

D

DA

=

+ 0.3D A A

R

13

12

2u

R1 2

(4)

368

ScienceAsia 30 (2004)

or

k Ag =

K1 K 2

+

R R1 2

(5)

With the gas-film mass transfer controls, the

complete conversion time can be calculated using the

following equations:

Small particles

BR 2 fB

3bc Ag K 1

(m3).

The unconverted fraction of the reactant was given

by the following equations9:

fraction

mean value

unconverted

=

for

fraction

of

B unconverted allsizes in particles

of size R

i

(6)

fraction of

exit or entering

stream consisting

of particles

of size R i

where b is the stoichiometric coefficient, cAg is the

concentration of A (kmol.m-3), fB is the size parameters,

and B is the solid molar density (kmol.m-3).

For large particles

or in symbols

R 3 2fB

= B

3bc Ag K 2

r

fB = 1 c

R

(8)

where rc is the residual radius (m).

With chemical reaction control, the time for

complete conversion is

BR

bk s c Ag

(10)

where k0 and Ea were specified by Table 1, Ea is the

activation energy (J .kmol-1), ks is the first order reaction

rate constant base on unit surface (m.s-1), k0 is the

frequency factor (m/s), and Rg2 is the universal gas

constant (J.kmol-1.K-1).

The mean conversion for mixed flow of a size

mixture of particles of unchanging size, and uniform

gas composition is:

V (1 )

Ft

(11)

where Ft is the volumetric flow rate of solid (m3.s-1),

t is the residence time (s), and V is the reactor volume

Table 1. Kinetic data for each type of fuels.12,13

Frequency factor

(m/s)

Lignite

Bagasse

Bark

Sludge

R =0

Fc (R i )

Fc

(12)

(13)

for gas-film mass transfer control,

R

1 (R i ) 1 (R i ) 2

F (R )

1 XB =

+ ... c i (14)

t

3! t

Fc

R = 0 2!

where Fc is the mass flow rate of coal (kg .s-1).

For reaction control,

R

1 (R i ) 1 (R i ) 2

F (R )

+ ... c i (15)

1 XB =

t

20 t

R =0 4

Fc

m

(9)

Ea

k s = k 0 exp

R g2T

t=

1 X B = [1 X B (R i )]

Rm

(7)

59600 *

210870 *

86560 *

22140 *

*unit of frequency factor is m/(Ks)

Activated energy

(J/kmol)

1.492

1.246

4.207

4.476

10 8

10 7

10 7

10 7

1.3.2.2. Algorithm of Shrinking-core model

Fig. 3 describes the procedure to calculate the

reaction rate, size distribution, and weight fractions of

particles for solid fuel of a certain size by using the

equations described in the previous section. The first

step started with acquiring the physical properties and

hydrodynamic data from ASPEN and hydrodynamic

subroutine, respectively. The data were used to calculate

the rate of the reactions, the time required for complete

combustion of the particles in each region of the riser,

and the determination of mass transfer or reaction

controlled. Then, the mean residence time would be

calculated. The time would be used to determine the

reaction conversion and the remaining size of the

particles after the reaction. Since all of the particles

would not be burnt completely, the size of the particles

to be passed on the next region would be calculated by

averaging the sizes of the unburnt and the burnt

fractions. The size of the unburnt fraction would be

assumed to be the same as the initial size when the

particles moved into the specified region.

1.3.2.3. Hydrodynamic Model

In this paper, the hydrodynamics model described

in Sotudeh-Gharebaagh1 was adopted.

(1) The lower region

In this region, the perfect mixing between the solid

369

ScienceAsia 30 (2004)

1 * u

Z ac = ln *

a d,avg

(16)

where a is the decay ratio, u is the axial voidage in

the acceleration zone, d,avg is the mean voidage of the

lower region, and * is the axial voidage at saturated

conditions.

The mean axial voidage in the fully developed zone

is defined as,

u,3,avg =

=1+

1

G s

1+

U 2s

(17)

5.6

+ 0.47Frt0.41

Fr

(18)

where Fr is the Froude number, Frt is the particle

Froude number, Gs is the net solid circulation flux (kg

m-2.s-1), U2 is the superficial gas velocity in dilute bed

(m.s-1), is the slip factor, and s is the solid density

(kg.m-3).

In this work, the upper region was divided into

three sections for various void fractions as illustrated

in Fig. 4.

The mean void fraction in each section of the upper

region was calculated from the following equation:

1

d , avg *

a L

(e a Z ni e a Z ni 1 )

u , ni , avg = *

Formation of N2O

N2 + 2NO

RtB = KBCNO

(22)

KB = 3FP exp( 9000 / T)

(23)

Reduction of NO by char

2NO + 2C

(24)

KC = 555.6FP exp(-14193/T)

(25)

2NO + 2CO

N2 + O 2

RtA = KACO

KA =

1000

FP T exp( 19000 / T )

3

N2 + 2CO2

RtD = KDCNO

(26)

KD = 5.67x103 exp(-13952/T)

(27)

Reduction of N2O by char

N2O + C

RtE = KECN

N2 + CO

(28)

2O

KE = 13.36FP exp(-16677/T)

(29)

Destruction of N2O

N2O + CO

N2 + CO2

(30)

2O

KF = 2.51 x 1011 exp(-23180/T)CCO

1.3.3 NOx Formation.

CSTR was used to simulate the emission of NOx and

N 2O with respect to the reaction rates following

reactions rates5:

(31)

Solid fraction profile

Mean solid fraction used in simulation

(1-4)

Riser height Z

Formation of NO

N2 + 2CO

RtC = KCCNO

RtF = KFCN

(19)

2N2O

U3

(1-3)

Upper region

and the gas phase was assumed. The mean void can be

considered constant and may be obtained using the

correlation of Kunni and Levenspiel(1991)11.

(2) The upper region

The upper region consists of two zones: an

acceleration zone, and a fully developed zone.

The height of the acceleration zone1 can be find

from:

U2

2NO

(1-2)

(20)

U1

Z=0

Lower region

(21)

where FP is the specific surface area (m-1).

(1-1)

Solid fraction 1-

Fig. 4. Variation of void fraction with height in the riser1

370

ScienceAsia 30 (2004)

external mass transfer coefficient cm. s-1), and i is the

porosity of particle after calcinations.

Using equation (34), the moles of SO2 removed per

unit volume become

Thermal decomposition of N2O

2N2O

RtG = KGCN

2N2 + O2

(32)

2O

KG = 1.75x108 exp(-23800/T)

rSO 2, i =

(33)

The algorithms of NO and N2O emissions.

Normally, the reactions of NO and N2O emissions

are presented in the network reactions. Most of reaction

rates occurred both in series and parallel reactions,

while the computer simulations calculated in the

sequential reaction. This simulation arranges the rates

of reactions in two parts. In the first part, the formation

reactions of NO and N2O were calculated. In the second

part, the reduction reactions of NO and N2O were

calculated by considering the rate of reaction, by which

the faster reaction was calculated before the slower

one.

1.3.4 SO 2 Absorption.

RSTOIC is used to model the capture of sulfur in the

CFBC. The SO 2 captured by limestone can be

represented by the following reactions:

CaCO3

CaO + CO2

CaO + SO2 + 0.5O2

CaSO4

The fractional conversion of CaO to CaSO4 is

strongly affected by the physical and chemical properties

of limestone, hydrodynamics parameters, mass transfer

resistance, temperature, reactive concentration,

particle size distribution and operating condition. The

fractional conversion can be calculated from the

following expression1

(35)

= 35D0P.3

(36)

3CYSO 2, i a t

1

(e 1 i 1)

t i ln1 +

a1

R sK V

Rs

1

3CYSO 2, i K V

t i = l sp

and

AL

F1 (i 1)

(39)

where A is the cross section area of combustor (m2),

Fl is the mass flow rate of limestone in the feed (kg s-1),

ti is the mean residence time of sorbent particles in ith

interval of the bed (s), and l is the density of limestone

particles (kg.m-3), sp is the volume fraction occupied

by sorbent particles, L1 is the height of dense bed (m),

and

4

= 1 X CaO, i 1

2

(40)

Since SO2 is well mixed in each interval of the bed,

an overall SO2 balance gives

YSO 2 , i =

L1 R SO 2 ,1 rSO 2 ,1

(41)

CU1

L R SO 2 , i rSO 2 , i

)

(42)

CU 2

FW

c

s

where R SO ,1 = 32AL

1

(43)

and R SO ,1 =

2

where DP is the average sorbent surface particle

diameter (cm), KV is the volumetric rate constant (kmol

m-3.s-1), Rs is the mean sorbent particle radius (cm),

VCaO is the molar volume of CaO (m3.kmol-1), XCaO,i is the

fractional conversion of CaO in the ith interval, YSO ,i is

the mole fraction of SO2 in the ith interval, is the

2

(37)

The mean residence time of sorbent particles can

be calculated by the following equation.

AL 1

t 1 = l sp

(38)

F1

YSO 2 ,1 =

1 3CYSO 2, i a1t i

(e 1)

t i ln1 +

a1

R sK V

VCaO

(34)

Rs

1

1 I

3

CY

K

SO 2 , i

V

where a 1 = 3.33 10 4 exp (R s )

VCaOFl

1 I AL 100

(1 X

SO 2 , i 1

)F W

32 AL

(i 1)

(44)

where R SO ,1 is the rate SO2 generation per unit

volume of dense bed (kmol.m-3.s-1), and Ws is the sulfur

weight fraction in dry-based coal.

The fractional sulfur capture for each reactor ( X )

can be calculated from

2

SO 2 , i

371

ScienceAsia 30 (2004)

(i 1)

(46)

RESULTS AND DISCUSSION

The fuel included in the simulator were lignite,

bagasse, bark and sludge. The proximate and ultimate

analyses for each type of fuel are shown in Tables 2 and

3. The simulation results for both single fuel and mixed

fuel between lignite and biomass were investigated. In

case of mixed fuel, since there are a number of

combinations among fuel, the mixtures of bagasse,

bark and sludge were selected to demonstrate the model

prediction. The kinetic data for calculating the rates of

reactions in the RCSTR block are tabulated in Table 1.

The model was used to simulate the operation of a

CFBC that produced 110 tons per hour of steam at

510 oC and 110 barg. The fuel to be considered were

both single and mixed fuel. In case of single fuel,

4 kg s-1of lignite was fed into the combustor. In the

Table 2. Proximate analysis for each type of fuel.8

Proximate

Lignite

analysis (Wt.%)

Moisture

Fixed carbon

Volatile matter

Ash

19.86

34.85

34.84

10.45

Bagasse

35.49

7.71

55.23

1.57

Bark

Sludge

39.66

9.09

48.85

2.4

65.42

2.9

13.18

18.5

Table 3. Ultimate analysis for each type of fuel.8

Ultimate

analysis (Wt.%)

Ash

Carbon

Hydrogen

Nitrogen

Sulfur

Oxygen

Lignite

Bagasse

Bark

Sludge

Lower

Upper1

Upper2

Upper3

Lower

Upper 2

Upper 1

Upper 3

2

1

0

4.0:0.0 3.6:0.6 3.2:1.1 2.8:1.7 2.4:2.2 2.0:2.8

Ratio of lignite :bagasse

4

3

Lower

Upper 2

Upper 1

Upper 3

2

1

0

4.0:0.0 3.6:0.6 3.2:1.1 2.8:1.7 2.4:2.3 2.0:2.8

Ratio of lignite:bark

13.04

68.15

5.09

1.24

0.59

11.89

2.44

48.64

5.87

0.16

0.07

42.82

2.82

48.40

6.72

0.19

0.00

41.87

18.50

41.19

5.40

1.70

0.72

32.49

Table 4. The results of reactor data for 4.0 kg/s of lignite

Region

-2

Rate of reaction * 10 (kmol /s)

YSO 2 , iCU 2 A

X SO 2 , i = 1

W

FC s 1 X SO i 1

2,

32

Rate of reaction * 10-2 (kmol/s)

(45)

other case, the mixed fuel between lignite and biomass

were considered. Each simulation of the mixtures

decreased the lignite flow rate by 10 %. The flow rate

of biomass was increased for keeping the constant of

amount of carbon. The results of the simulation are

shown in Fig. 5 to 8.

Fig. 5 shows the combustion rates of lignite in mixed

fuel for each region in the CFBC, where there were

three kinds of mixed fuel and three compositions. All

simulation cases showed the same trend. The rates of

reactions decreased along the riser height. The reason

is that, in the lower region, the carbon concentration

was high due to the feed, while in the upper region there

was only residual carbon left from the lower region.

However in the upper region zone 1, the conversion

was closed to zero because of the shortest residence

time as shown in Table 4. The conversion in the upper

region zone 3 was higher than that in the upper region

zone 2, because the residence time in zone 3 was longer

than zone 2. Compared with the various ratios of lignite

and biomass, the reaction rates of lignite decreased

slightly when increased the flow rate of biomass. This

is due to the decrease in the concentration of lignite in

V

olume

Volume

(m3)

61.84

16.70

33.34

681.14

Height

(m)

1.70

0.46

0.92

18.76

Residence time

(s)

19009

1601

11000

85544

-2

Rate of reaction * 10 (kmol /s)

X SO 2 ,1

YSO 2 , iCU1A

=1

W

FC s

32

4

3

Lower

Upper 2

Upper 1

Upper 3

2

1

0

4.0:0.0 3.6:0.7 3.2:1.3 2.8:2.1 2.4:2.7 2.0:3.3

Ratio of lignite:sludge

Fig. 5. Rates of the combustion of lignite in mixed fuel for

each region in the CFBC: (a) lignite&bagasse, (b)

lignite&bark, and (c) lignite&sludge.

372

ScienceAsia 30 (2004)

3

2

1

O2 (%)

CO (%)

H2O(%)

NO (ppm)

80

60

6000

40

4000

20

2000

Lower

Upper 2

2.0:2.8

Upper 1

Upper 3

4.0:0.0 3.6:0.6 3.2:1.1 2.8:1.7 2.4:2.2 2.0:2.8

Ratio of lignite:bagasse

100

3

2

1

0

80

O2 (%)

CO (%)

H2O(%)

No (ppm)

N2 (%)

CO2 (%)

SO2 (ppm)

N2O (ppm)

8000

60

6000

40

4000

20

2000

3.6:0.6

3.2:1.1

2.8:1.7

2.4:2.3

2.0:2.8

Upper 1

Upper 3

3

2

1

0

3.6:0.7

3.2:1.3 2.8:2.0 2.4:2.7

Ratio of lignite:sludge

100

Amount of flue gas (%)

Lower

Upper 2

0

4.0:0.0 3.6:0.6 3.2:1.1 2.8:1.7 2.4:2.3 2.0:2.8

Ratio of lignite:bark

Ratio of lignite :bark

10000

Amount of flue gas (ppm)

3.2:1.1 2.8:1.7 2.4:2.2

Ratio of lignite :bagasse

10000

8000

Rate of reaction * 10-2(kmol /s)

N2 (%)

CO2 (%)

SO2 (ppm)

N2O (ppm)

Amount of flue gas (ppm)

Upper 1

Upper 3

Amount of flue gas (%)

3.6:0.6

Rate of reaction * 10-2(kmol/s)

100

a

Lower

Upper 2

2.0:3.3

Fig. 6. Rates of the combustion of biomass in mixed fuel for

each region in the CFBC: (a) lignite&bagasse, (b)

lignite&bark, and (c) lignite&sludge.

80

O2 (%)

CO (%)

H2O(%)

No (ppm)

N2 (%)

CO2 (%)

SO2 (ppm)

N2O (ppm)

10000

8000

60

6000

40

4000

20

2000

Amount of flue gas (ppm)

Fig. 7 shows the compositions of gas emission when

different types of mixed fuel were used. All the

simulation cases show the same patterns of responses.

For example, Table 6 shows the emissions gas from the

lignite and bagasse combustion. The results show that

the amount of N2O was small, which is in agreement

with literatures4,5, while the amount of NO was high

when the amount of biomass was increased. This result

does not agree with that of Liu et al.14. This is due to the

fact that rate of NO formation in this simulation, equation

(20), depended the oxygen concentration only. Then

the amount of nitrogen does not affect the NO

conversion. However, the amount of CO decreased

because of the complete combustion with higher oxygen

concentration when the biomass was increased. Finally,

Amount of flue gas (%)

-2

Rate of reaction * 10 (kmol /s)

the mixed fuel.

Fig. 6 shows the combustion rates of biomass for

different types of materials in the mixed fuel. The

reaction rates increased with the increase in the fraction

in the fuel. For example, at the 2.0:2.8 of lignite and

bagasse ratio, the reaction rate increased to 3.87

10-2 kmol s-1 or about 5 times when compared with the

reaction rate at the lignite and bagasse ratio at 3.6:0.6.

This is due to the higher concentration of carbon from

the biomass. The rates decreased rapidly at high

position in the riser since most of the biomass was

burnt in the lower region. The reaction rates in the

upper region were close to zero. The example for

reaction rate of bagasse at 0.6 kmol s-1 was shown in

Table 5.

0

4.0:0.0 3.6:0.7 3.2:1.3 2.8:2.1 2.4:2.7 2.0:3.3

Ratio of lignite:sludge

Fig. 7. The composition of flue gas for different kinds of mixed

fuel: (a) lignite&bagasse, (b) lignite&bark, and (c)

lignite&sludge.

373

ScienceAsia 30 (2004)

the results also showed that the amount of SO2 was

small

The Prediction of Size Distribution

The example was to demonstrate the size

distribution predictions in each region of the riser. The

particle sizes of biomass and lignite were divided into

2 and 3 subintervals, respectively. The case shown here

was the combustion of single fuel, lignite. The initial

radius and weight fraction of lignite are shown in

Table 7. The predictions of the size distribution and the

weight fraction in each region are shown in Table 8.

In the lower region, where the combustion occurred,

most of the smallest particles were burnt. Therefore, its

weight fraction almost disappeared. However, the radii

of particles did not decrease because the mean

residence time was higher than the time to complete

conversion. Thus, the algorithm program kept the initial

radius for the unconverted particles. For the second

interval, weight fraction reduced from 0.52 to 0.16,

Table 5. Rate of combustion of bagasse at ratio 3.6:0.6

Region

Rate of combustion (kmol/s)

Lower

Upper 1

Upper 2

Upper 3

7.71

2.65

1.66

2.61

x

x

x

x

CONCLUSIONS

10-3

10-5

10-8

10-11

Table 6. The emissions of lignite and bagasse combustion.

Ratio of lignite and

bagasse

Amount of gas emission

O2

4.0:0.0

3.6:0.6

3.2:1.1

2.8:1.7

2.4:2.2

2.0:2.8

2.42

2.51

2.59

2.69

2.78

2.85

(%)

CO CO2

0.81

0.59

0.34

0.12

0.01

0.01

SO2

(ppm)

NO N2O

13.97 120

1

14.10 101 22

14.26 83 33

14.38 65 41

14.41

51 915

14.31

87 3197

16

18

18

17

17

17

Table 7.. Initial radius and weight fraction of lignite.

No.

Inter

val size

Interval

(m)

1

2

3

0-0.001

0.001-0.04

0.04-0.075

Mean initial radius W

eight fraction

Weight

(m)

0.0005

0.0205

0.0575

0.08

0.52

0.40

while that for the third interval increased. This was due

to the lower region having small volume, which implied

the short residence time. Thus, only the small particles

would be burnt completely. The mass of the larger

particles reduced more slowly, causing high weight

fraction in this interval. Nevertheless, the combustion

in this region caused the mean particle size in the thirdinterval to reduce to 0.0552 m.

The upper region was divided into three regions.

The weight fraction of the second-interval particles

increased in the first upper regions. The reason is that

the large particles had time to reduce their sizes into

the second-interval particles.

Since the second and third upper regions had large

volume, their residence times would be long. Therefore,

most of the small and medium particles were burnt in

the regions. Thus, the particles left in these regions

were the particles falling in the third-interval size. This

observation was noticed with high weight fraction in

this interval and the mean particle size was reduced to

0.0524 m as shown in Table 8.

This paper proposed a model for simulating the

CFBC using single or mixed fuel. The major improvement

from the previous model was the consideration of solid

fuel-size change during the combustion. The shrinking

core model was included in the simulation to calculate

the size distribution and weight fractions in each region

of the riser. The modification reflected the phenomena

in the riser better than the previous model did.

Moreover, the details of emission models were added

in the simulation to predict the formation of NO, N2O,

and SO2. For different biomass fractions in the fuel, the

simulation output demonstrated the trend of gas

emission, which can be used for environment

protection consideration. Although the results from

the simulation were not yet validated with the

experimental data, the trends of the solution seemed

to be reasonable.

ACKNOWLEDGEMENTS

This research study was supported by the Petroleum

Table 8. The predictions of size distribution and weight fraction in each region.

Region

V

olume (m3)

Volume

Mean radius (m)

W

eight fraction

Weight

Interval 1 Interval 2 Interval 3

Lower

Upper 1

Upper 2

Upper 3

61.84

16.70

33.34

681.14

0.0005

0.0005

0.0005

0.0005

0.0205

0.0201

0.0201

0.0201

0.0552

0.0551

0.0524

0.0524

Interval 1

Interval 2

Interval 3

0.0007

0.0116

0.0018

0.0022

0.16

0.61

0.15

0.22

0.84

0.38

0.85

0.78

374

and Petrochemical Technology Consortium, the

Ratchadaphisek Somphot Endowment, and the

Graduate School of Chulalongkorn University.

REFERENCES

1. Sotudeh-Gharebaagh R, Legros R, Chaouki J, and Paris J

(1998) Simulation of Circulating Fluidized Bed Reactors

using ASPEN PLUS. Fuel 77

77, 327-37.

2. Huilin L, Rushan B, Wenti L, Binxi L and Lidan Y (2000)

Computations of a circulating fluidized-bed boiler with wide

particle size distributions. Ind. Eng. Chem. Res 39

39, 3212-20.

3. Mukadi L, Guy C, and Legros R (2000) Prediction of Gas

Emissions in an Internally Circulating Fluidized Bed

Combustor for Treatment of Industrial Solid Wastes. Fuel 79

79,

1125-36.

4. Liu H. and Gibbs BM (2002) Modeling of NO and N2O

emissions from biomass-fired circulating fluidized bed

combustors. Fuel 81

81, 271-80.

5. Chen Z, Lin M, Ignowski J, Kelly B, Linjewile TM, and

Agarwal PK (2001) Mathematical Modeling of Fluidized

Bed Combustion.4: N 2 O and NO x Emission from the

Combustion of Char. Fuel 80

80, 1259-72.

6. Winter F, Loffler G, Wartha C, Hofbauer H, Preto F, and

Anthony EJ (1999) The NO and N2O Formation Mechanism

Under Circulating Fluidized Bed Combustor Conditions:from

the Single Particle to the Pilot-Scale. The Canadian Journal of

Chemical Engineering 77, 275-83.

7. Ngampradit N, Piumsomboon P, and Sajjakulnukit B (2002)

Simulation of a Circulating Fluidized Bed Combustor with

the Shrinking Core Model Using the Aspen Plus. 9th APCChE

Congress and CHEMECA

8. Boiler Plant Design Basis (accessed June 1992) Siam Kraft

Industry Co., Ltd., Thailand

9. Levenspiel O (1972) Fluid-particle reactions. In: Chemical

Reaction Engineering, 2nd ed. pp 357-400 John Wiley & Sons,

Singapore.

10. Missen RW, Mims CA, and Saville BA (1999) Multiphase

reacting systems. In: Introduction to Chemical Reaction Engineering

and Kinetics, pp 224-39 John Wiley & Sons, New York, USA.

11. Kunii D and Levenspiel O (1991) High velocity fluidization.

In: Fluidization Engineering, 2nd ed. pp193-210 ButterworthHeinemann, Boston, England.

12. Gaur S and Reed TB (1998) Natural biomass. In. Thermal

Data for Natural and Synthetic Fules pp102-50 Marcel Dekker

Inc, New York, USA.

13. Yamskulna S (2000) Energy Management System Design

for Steam Power Plant, M.Sc. Thesis, Chulalongkorn

University, Thailand.

14. Liu DC, Mi T, Shen BX, and Feng B (2002) Reducing N2O

Emission by Co-Combustion of Coal and Biomass (Comm.).

Energy & Fuels 16, 525-6.

ScienceAsia 30 (2004)

You might also like

- Fault Code 5655: Aftertreatment 1 SCR Conversion Efficiency - Condition ExistsDocument3 pagesFault Code 5655: Aftertreatment 1 SCR Conversion Efficiency - Condition Existspanchoreyes1100% (3)

- NORSOK S-003 - Rev.3 - Environmental Care PDFDocument36 pagesNORSOK S-003 - Rev.3 - Environmental Care PDFAtreider100% (4)

- Renewable Energy and Sustainable Development: A Crucial ReviewDocument19 pagesRenewable Energy and Sustainable Development: A Crucial ReviewAlso FísicaNo ratings yet

- Ultra Low Nox BurnersDocument6 pagesUltra Low Nox BurnersRujisak MuangsongNo ratings yet

- Biomass Gasifier CalculationDocument10 pagesBiomass Gasifier CalculationH.J.Prabhu100% (5)

- Controlling LOI From Coal Reburning in A Coal-Fired Boiler: Hou-Peng Wan, Chyh-Sen Yang, B.R. Adams, S.L. ChenDocument7 pagesControlling LOI From Coal Reburning in A Coal-Fired Boiler: Hou-Peng Wan, Chyh-Sen Yang, B.R. Adams, S.L. ChenJayanath Nuwan SameeraNo ratings yet

- 517 141Document11 pages517 141sorincarmen88No ratings yet

- SCR NOx Sensor and Monitor CM2150 2220english VersionDocument20 pagesSCR NOx Sensor and Monitor CM2150 2220english VersionEdevaldo Santana100% (9)

- Best Available Techniques For Hydrogen Production by Steam Methane ReformingDocument18 pagesBest Available Techniques For Hydrogen Production by Steam Methane ReformingDuy NguyễnNo ratings yet

- v30 365 374 PDFDocument10 pagesv30 365 374 PDFMárcia CardosoNo ratings yet

- 49 1 Anaheim 03-04 0837Document2 pages49 1 Anaheim 03-04 0837castelo_grandeNo ratings yet

- Ref11 - SP10 - Danloy1 - Essen - New PDFDocument3 pagesRef11 - SP10 - Danloy1 - Essen - New PDFCofe MilkNo ratings yet

- A Computational Model of Catalyzed Carbon Sequestration: Back To Exploration - 2008 CSPG CSEG CWLS ConventionDocument4 pagesA Computational Model of Catalyzed Carbon Sequestration: Back To Exploration - 2008 CSPG CSEG CWLS ConventionsahanchemNo ratings yet

- Assignment 04,204107027Document14 pagesAssignment 04,204107027Shanku Pratim BorahNo ratings yet

- Heat and Mass Balances in The ULCOS Blast FurnaceDocument3 pagesHeat and Mass Balances in The ULCOS Blast FurnaceakshukNo ratings yet

- Powder Technology: James M. ParkerDocument7 pagesPowder Technology: James M. ParkerAzharuddin Ehtesham FarooquiNo ratings yet

- Activation of Waste Tire Char Upon Cyclic Oxygen Chemisorption#DesorptionDocument8 pagesActivation of Waste Tire Char Upon Cyclic Oxygen Chemisorption#DesorptionFrancisco HerasNo ratings yet

- Computational Evaluation of Emissions For Non-Premixed Natural Gas CombustionDocument3 pagesComputational Evaluation of Emissions For Non-Premixed Natural Gas CombustionijsretNo ratings yet

- Coal To Methanol p2Document8 pagesCoal To Methanol p2moeeezNo ratings yet

- Temperature ControlsDocument10 pagesTemperature Controlsmashaikh898470No ratings yet

- CFD Analysis of Circulating Fluidized Bed Combustion: Ravindra Kumar and K.M.PandeyDocument12 pagesCFD Analysis of Circulating Fluidized Bed Combustion: Ravindra Kumar and K.M.PandeyZakir HusainNo ratings yet

- Simulation of Processes For Efficient Methanol Production Using Co and Solar EnergyDocument6 pagesSimulation of Processes For Efficient Methanol Production Using Co and Solar EnergyaitormrNo ratings yet

- Development of The "Micro Combustor"Document6 pagesDevelopment of The "Micro Combustor"Haris AbdullaNo ratings yet

- E3sconf Icbt2018 01009Document10 pagesE3sconf Icbt2018 01009Belay AyalewNo ratings yet

- Hong AnalysisDocument38 pagesHong AnalysisleovenuNo ratings yet

- Cfd-Modelling For The Combustion of Solid Baled BiomassDocument6 pagesCfd-Modelling For The Combustion of Solid Baled BiomassMir Mustafa AliNo ratings yet

- Autothermal Reforming of Methane Design and PerforDocument7 pagesAutothermal Reforming of Methane Design and Perforromi moriNo ratings yet

- Combustion and Emission Characteristics of Rice Husk in A Rectangular Fluidized Bed CombustorDocument4 pagesCombustion and Emission Characteristics of Rice Husk in A Rectangular Fluidized Bed CombustorfelramNo ratings yet

- 09 Combustion (Burners, Combustion Systems)Document1 page09 Combustion (Burners, Combustion Systems)ahmed1581973No ratings yet

- Yeo Il Yoon, Il Hyun Baek, and Sang Do Park: To Whom All Correspondence Should Be Addressed. (E-Mail: Ihbaek@kier - Re.kr)Document8 pagesYeo Il Yoon, Il Hyun Baek, and Sang Do Park: To Whom All Correspondence Should Be Addressed. (E-Mail: Ihbaek@kier - Re.kr)Mohammed AsherNo ratings yet

- CFD Analisys CoalDocument6 pagesCFD Analisys CoalOscar DorantesNo ratings yet

- Homogeneous vs. Catalytic Combustion of Lean Methane-Air Mixtures in Reverse - Ow ReactorsDocument10 pagesHomogeneous vs. Catalytic Combustion of Lean Methane-Air Mixtures in Reverse - Ow ReactorsRohitKumarDiwakarNo ratings yet

- CFD Simulation of Pollutant Emission in Power Plant BoilersDocument8 pagesCFD Simulation of Pollutant Emission in Power Plant BoilersRajneesh VachaspatiNo ratings yet

- Evaluation of The Co2 Re Activity of Chars Obtained Under Conventional and Oxyfuel AtmospheresDocument5 pagesEvaluation of The Co2 Re Activity of Chars Obtained Under Conventional and Oxyfuel AtmospheresjulianapohlmannufrgsNo ratings yet

- Catalysts: Kinetic Monte-Carlo Simulation of Methane Steam Reforming Over A Nickel SurfaceDocument12 pagesCatalysts: Kinetic Monte-Carlo Simulation of Methane Steam Reforming Over A Nickel SurfacegiraulNo ratings yet

- ATR Compared To Other Shit PDFDocument7 pagesATR Compared To Other Shit PDFĐỗ Vũ ThưNo ratings yet

- Tn287-TN287 Modeling Coal Gasification With CFD and The Discrete Phase MethodDocument9 pagesTn287-TN287 Modeling Coal Gasification With CFD and The Discrete Phase MethodNenuko CrossNo ratings yet

- Art. 2 AdelantoDocument14 pagesArt. 2 AdelantoYuliiana HernandezNo ratings yet

- Oxy-Combustion Simulation of EthyleneDocument7 pagesOxy-Combustion Simulation of EthyleneStefan GrigoreanNo ratings yet

- Carbon Footprint Assessment of Low-Rank Coal-Based Acetylene SystemDocument6 pagesCarbon Footprint Assessment of Low-Rank Coal-Based Acetylene SystemS.P.No ratings yet

- Artigo Do TrabalhoDocument8 pagesArtigo Do TrabalhoRafaelTeixeiraNo ratings yet

- Methane Combustion With No CO Production: Daniel B UchiDocument26 pagesMethane Combustion With No CO Production: Daniel B UchiKhai HuynhNo ratings yet

- Peksen2009 (Conservation)Document12 pagesPeksen2009 (Conservation)Faris HamidiNo ratings yet

- SNG From Pet CokeDocument6 pagesSNG From Pet CokeSarath Jose KNo ratings yet

- Simulation and Optimization of Steam Generation in A Pulp and Paper MillDocument8 pagesSimulation and Optimization of Steam Generation in A Pulp and Paper MillDuilio Dante Hernandez AlegriaNo ratings yet

- Sequential Simulation of Dense Oxygen Permeation Membrane Reactor For Hydrogen Production From Oxidative Steam Reforming of Ethanol With ASPEN PLUS 20Document8 pagesSequential Simulation of Dense Oxygen Permeation Membrane Reactor For Hydrogen Production From Oxidative Steam Reforming of Ethanol With ASPEN PLUS 20serchNo ratings yet

- Coal To Methanol Conversion GasificationDocument10 pagesCoal To Methanol Conversion GasificationUmesh Kumar Sharma RamamoorthiNo ratings yet

- CFD NOx SCR With KineticsDocument10 pagesCFD NOx SCR With Kineticschaitu49No ratings yet

- CFD Analysis of Biomass Downdraft GasifierDocument4 pagesCFD Analysis of Biomass Downdraft GasifierArup DasNo ratings yet

- Cellulose PyrolysisDocument5 pagesCellulose PyrolysisVIxi OkNo ratings yet

- Experiences From Oxy Fuel Combustion of Bituminous Coal in A 150 KWTH Circulating Fluidized Bed Pilot FacilityDocument7 pagesExperiences From Oxy Fuel Combustion of Bituminous Coal in A 150 KWTH Circulating Fluidized Bed Pilot FacilityjdfhakfdNo ratings yet

- Simulation of Non-Premixed Natural Gas FlameDocument4 pagesSimulation of Non-Premixed Natural Gas FlameArul RizkiNo ratings yet

- A Comparative Analysis of Methanol Production Routes: Synthesis Gas Versus CO2 HydrogenationDocument10 pagesA Comparative Analysis of Methanol Production Routes: Synthesis Gas Versus CO2 HydrogenationMohanad El-HarbawiNo ratings yet

- India Kharagpur PCI - 2011Document12 pagesIndia Kharagpur PCI - 2011Carlos Frederico Campos de AssisNo ratings yet

- Novel Sorption-Enhanced Methanation With Simultaneous CO Removal For The Production of Synthetic Natural GasDocument12 pagesNovel Sorption-Enhanced Methanation With Simultaneous CO Removal For The Production of Synthetic Natural GasAmar GargNo ratings yet

- Modeling and Analysis A MethanolDocument10 pagesModeling and Analysis A MethanolVidal TxusNo ratings yet

- Kinetic Modeling of Biomass Steam Gasification System For Hydrogen Production With CO AdsorptionDocument7 pagesKinetic Modeling of Biomass Steam Gasification System For Hydrogen Production With CO Adsorptionprash_13No ratings yet

- Sadooghi PaperDocument5 pagesSadooghi PaperKarlaqd CaramónNo ratings yet

- System Use: Methanol Carbon andDocument8 pagesSystem Use: Methanol Carbon andakshukNo ratings yet

- CFD Analysis of A 210 MW Tangential Fired BoilerDocument6 pagesCFD Analysis of A 210 MW Tangential Fired BoilerInnovative Research PublicationsNo ratings yet

- Kurose Et Al NumrSimofPCC KONA ReviewDocument33 pagesKurose Et Al NumrSimofPCC KONA ReviewkarolNo ratings yet

- Methanol Synthesis (Safety)Document16 pagesMethanol Synthesis (Safety)furqankausarhaiderNo ratings yet

- Computational Analysis of Combustion of Separated Coal-Gas in O /CODocument9 pagesComputational Analysis of Combustion of Separated Coal-Gas in O /COilyaskureshiNo ratings yet

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsFrom EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerNo ratings yet

- Co-Production of Upgraded Bio-Oils and H - Rich Gas From Microalgae Via Chemical Looping PyrolysisDocument14 pagesCo-Production of Upgraded Bio-Oils and H - Rich Gas From Microalgae Via Chemical Looping PyrolysisAzharuddin_kfupmNo ratings yet

- Energies 16 02102Document20 pagesEnergies 16 02102Azharuddin_kfupmNo ratings yet

- Ceia Tin TopingDocument13 pagesCeia Tin TopingAzharuddin_kfupmNo ratings yet

- Thermodynamic Assessment of Membrane-Assisted Premixed and Non-Premixed Oxy-Fuel Combustion Power CyclesDocument8 pagesThermodynamic Assessment of Membrane-Assisted Premixed and Non-Premixed Oxy-Fuel Combustion Power CyclesAzharuddin_kfupmNo ratings yet

- Economic Analysis of Improved Alkaline Water Electrolysis: Wilhelm Kuckshinrichs, Thomas Ketelaer and Jan Christian KojDocument13 pagesEconomic Analysis of Improved Alkaline Water Electrolysis: Wilhelm Kuckshinrichs, Thomas Ketelaer and Jan Christian KojAzharuddin_kfupmNo ratings yet

- Ente201600095 Sup 0001 Misc - InformationDocument9 pagesEnte201600095 Sup 0001 Misc - InformationAzharuddin_kfupmNo ratings yet

- Concept Analysis of An Indirect Particle-Based Redox Process For Solar-Driven H O/Co SplittingDocument13 pagesConcept Analysis of An Indirect Particle-Based Redox Process For Solar-Driven H O/Co SplittingAzharuddin_kfupmNo ratings yet

- MMC 1Document2 pagesMMC 1Azharuddin_kfupmNo ratings yet

- Thermal Performance Analysis of Porous Medium Solar Receiver With Quartz Window To Minimize Heat Ux GradientDocument12 pagesThermal Performance Analysis of Porous Medium Solar Receiver With Quartz Window To Minimize Heat Ux GradientAzharuddin_kfupmNo ratings yet

- International Journal of Heat and Mass TransferDocument8 pagesInternational Journal of Heat and Mass TransferAzharuddin_kfupmNo ratings yet

- CO Production From CO2 Via Reverse Water-Gas Shift Reaction Performed in A Chemical Looping Mode: Kinetics On Modified Iron..Document10 pagesCO Production From CO2 Via Reverse Water-Gas Shift Reaction Performed in A Chemical Looping Mode: Kinetics On Modified Iron..Azharuddin_kfupmNo ratings yet

- Gao 2016Document33 pagesGao 2016Azharuddin_kfupmNo ratings yet

- Aspen Plus Model For Moving Bed Coal GasifierDocument30 pagesAspen Plus Model For Moving Bed Coal GasifierAzharuddin_kfupm100% (3)

- Thermodynamic Analysis of Beam Down Solar Gas Turbine Power Plant Equipped With Concentrating Receiver..Document10 pagesThermodynamic Analysis of Beam Down Solar Gas Turbine Power Plant Equipped With Concentrating Receiver..Azharuddin_kfupmNo ratings yet

- Computational Fluid Dynamics For Microreactors Used in Catalytic Oxidation of PropaneDocument8 pagesComputational Fluid Dynamics For Microreactors Used in Catalytic Oxidation of PropaneAzharuddin_kfupmNo ratings yet

- Jiang2014 PDFDocument13 pagesJiang2014 PDFAzharuddin_kfupmNo ratings yet

- Experimental Modeling of Vertical Dynamics of Vehicles With Controlled SuspensionsDocument23 pagesExperimental Modeling of Vertical Dynamics of Vehicles With Controlled SuspensionsAzharuddin_kfupmNo ratings yet

- Characterization and Evaluation of Prepared Fe O /al O Oxygen Carriers For Chemical Looping ProcessDocument10 pagesCharacterization and Evaluation of Prepared Fe O /al O Oxygen Carriers For Chemical Looping ProcessAzharuddin_kfupmNo ratings yet

- (NATO ASI Series 110) Alirio Rodrigues, Carlos Costa, Rosa Ferreira (Auth.), Hugo I. de Lasa (Eds.)-Chemical Reactor Design and Technology_ Overview of the New Developments of Energy and PetrochemicalDocument838 pages(NATO ASI Series 110) Alirio Rodrigues, Carlos Costa, Rosa Ferreira (Auth.), Hugo I. de Lasa (Eds.)-Chemical Reactor Design and Technology_ Overview of the New Developments of Energy and PetrochemicalAzharuddin_kfupmNo ratings yet

- (Nanostructure Science and Technology 174) Balasubramanian Viswanathan, Vaidyanathan (Ravi) Subramanian, Jae Sung Lee (Eds.)-Materials and Processes for Solar Fuel Production-Springer-Verlag New YorkDocument246 pages(Nanostructure Science and Technology 174) Balasubramanian Viswanathan, Vaidyanathan (Ravi) Subramanian, Jae Sung Lee (Eds.)-Materials and Processes for Solar Fuel Production-Springer-Verlag New YorkAzharuddin_kfupmNo ratings yet

- UntitledDocument157 pagesUntitledPooja UdupaNo ratings yet

- Nitrogen. Too Much of A Vital ResourceDocument27 pagesNitrogen. Too Much of A Vital ResourceAlexandre FunciaNo ratings yet

- BioRes 08 2 1520 C Dion LOC Biomass Gas Syngas Greenhouse CO2 3168 PDFDocument19 pagesBioRes 08 2 1520 C Dion LOC Biomass Gas Syngas Greenhouse CO2 3168 PDFSecret SecretNo ratings yet

- 11 Combustion EquipmentDocument17 pages11 Combustion Equipmentabcde fghiNo ratings yet

- Lecture # 9 Smog BBA F2.Document15 pagesLecture # 9 Smog BBA F2.nimrashahidcommerceicomNo ratings yet

- Handbbok EDocument355 pagesHandbbok ENaing Tint LayNo ratings yet

- Ricardo Large Engines BrochureDocument28 pagesRicardo Large Engines BrochureMartin KratkyNo ratings yet

- Lcia Methods v.1.5.5Document23 pagesLcia Methods v.1.5.5Maulana BirrwildanNo ratings yet

- Ecological Concerns and Public Interests MessagesDocument18 pagesEcological Concerns and Public Interests MessagespriyaNo ratings yet

- Technical Spec GE Frame 9E'S - Rev1Document144 pagesTechnical Spec GE Frame 9E'S - Rev1Alaa Zora - OnlineNo ratings yet

- HEV Multiple Chioice, Mid-1Document14 pagesHEV Multiple Chioice, Mid-1KURAKULA VIMAL KUMARNo ratings yet

- Wartsila O E RT Flex96C B MIM Part CDocument385 pagesWartsila O E RT Flex96C B MIM Part CUhrin Imre100% (2)

- 9591-102-102-PVM-U-009-02A Nox CalculationsDocument16 pages9591-102-102-PVM-U-009-02A Nox CalculationsVijay PalNo ratings yet

- Gas Engines Emissions & Exhaust After-Treatment A&i GuideDocument36 pagesGas Engines Emissions & Exhaust After-Treatment A&i GuidelamNo ratings yet

- C02 Activity Worksheet: Year Might Affect These.)Document6 pagesC02 Activity Worksheet: Year Might Affect These.)chn pastranaNo ratings yet

- Otto Cycle: Internal Combustion EnginesDocument18 pagesOtto Cycle: Internal Combustion EnginesNajrul IslamNo ratings yet

- Energies: Optimized Design of A Swirler For A Combustion Chamber of Non-Premixed Flame Using Genetic AlgorithmsDocument25 pagesEnergies: Optimized Design of A Swirler For A Combustion Chamber of Non-Premixed Flame Using Genetic AlgorithmsDaniel AlejandroNo ratings yet

- International R&D Conclave: Emerging Opportunities & Challenges of R&D in Indian Power SectorDocument618 pagesInternational R&D Conclave: Emerging Opportunities & Challenges of R&D in Indian Power SectorParesh TadasNo ratings yet

- Exercise-U2-Topic 6 - EnergeticsDocument109 pagesExercise-U2-Topic 6 - EnergeticsLiang LuNo ratings yet

- BoilerOpt Presentation - PJBDocument21 pagesBoilerOpt Presentation - PJBenjineringNo ratings yet

- Emission Control SystemsDocument44 pagesEmission Control SystemsNilesh MeghwalNo ratings yet

- Pollutant Formation in Si EnginesDocument9 pagesPollutant Formation in Si EnginesChirudeep Reddy100% (1)

- CB-8391 CBND Technical Data - SpecificationsDocument43 pagesCB-8391 CBND Technical Data - SpecificationsRodrigo Lagos EscobarNo ratings yet

- 6FA DLN 2.6 Extended Interval Combustion System - GEA17898Document1 page6FA DLN 2.6 Extended Interval Combustion System - GEA17898atfrost4638No ratings yet

- Industrial Reporting Facilities Relevant ContributionDocument545 pagesIndustrial Reporting Facilities Relevant ContributionDinu VladNo ratings yet