Professional Documents

Culture Documents

Q

Q

Uploaded by

Gaurav AroraCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- N2006 PidDocument8 pagesN2006 PidSarah KempNo ratings yet

- Din 7984Document12 pagesDin 7984Nikola MilovanovićNo ratings yet

- Final PPT 123Document26 pagesFinal PPT 123Narender KumarNo ratings yet

- 13 Moon Pocket - Calendar PDFDocument16 pages13 Moon Pocket - Calendar PDFAfua OshunNo ratings yet

- Anchor Presentation Hilti 2011 PDFDocument8 pagesAnchor Presentation Hilti 2011 PDFNelsonDay100% (1)

- The New Empirical Formula Based On Dynamic Probing Test Results in Fine Cohesive SoilsDocument10 pagesThe New Empirical Formula Based On Dynamic Probing Test Results in Fine Cohesive SoilsabualamalNo ratings yet

- ElectricalEngineerigLabManual IIECE PDFDocument75 pagesElectricalEngineerigLabManual IIECE PDFUpender Rao SunkishalaNo ratings yet

- June 2015 QP - Unit 4 Edexcel Physics A-LevelDocument24 pagesJune 2015 QP - Unit 4 Edexcel Physics A-LeveltyNo ratings yet

- MCA4020-Model Question PaperDocument18 pagesMCA4020-Model Question PaperAppTest PINo ratings yet

- Linear Regression Analysis: Gaurav Garg (IIM Lucknow)Document96 pagesLinear Regression Analysis: Gaurav Garg (IIM Lucknow)Sakshi JainNo ratings yet

- S9 Q4 Week 2Document10 pagesS9 Q4 Week 2Mary Grace CatubiganNo ratings yet

- IETE-Journal of Research Template PDFDocument7 pagesIETE-Journal of Research Template PDFMadan R HonnalagereNo ratings yet

- AB1202 Week 5Document4 pagesAB1202 Week 5amos liewNo ratings yet

- Korean Volume BMS 1002Document9 pagesKorean Volume BMS 1002killeremailNo ratings yet

- Piezoelectric Shoe GeneratorDocument8 pagesPiezoelectric Shoe GeneratorJalla PavanNo ratings yet

- ACI 562 16 The ACI Concrete Repair CodeDocument7 pagesACI 562 16 The ACI Concrete Repair CodeDonny. B TampubolonNo ratings yet

- 9A04603 Digital Signal Processing16Document4 pages9A04603 Digital Signal Processing16Mahaboob SubahanNo ratings yet

- Expt 4-Ionic EquilibriaDocument42 pagesExpt 4-Ionic EquilibriatwinkledreampoppiesNo ratings yet

- Field Work No. 2 Differential Leveling With and Without Turning PointsDocument23 pagesField Work No. 2 Differential Leveling With and Without Turning PointsJohn Andrae MangloNo ratings yet

- Unisteri SL enDocument8 pagesUnisteri SL enJimmyNo ratings yet

- Sieve Analysis2 PDFDocument4 pagesSieve Analysis2 PDFAnonymous 8BXDrNxZP6No ratings yet

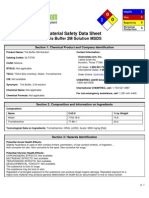

- MSDS Tris BufferDocument6 pagesMSDS Tris BuffervombyNo ratings yet

- Lecture 2 (CE-860)Document29 pagesLecture 2 (CE-860)MUHAMMAD AHMAD JAMILNo ratings yet

- Strength Lab 2 FullDocument11 pagesStrength Lab 2 FullWajisa JomworawongNo ratings yet

- JTCC PsDocument57 pagesJTCC PsTatjana MicevskaNo ratings yet

- Inpipe Products: Foam Pig Specification TableDocument1 pageInpipe Products: Foam Pig Specification TableMohamedNo ratings yet

- Paulino, Paul Tyrone R. Assignment 3Document14 pagesPaulino, Paul Tyrone R. Assignment 3Tyrone PaulinoNo ratings yet

- Proact™ Digital Speed Control System For Models I and Ii: Installation and Operation ManualDocument68 pagesProact™ Digital Speed Control System For Models I and Ii: Installation and Operation ManualKawarauNo ratings yet

- Gambica Bs en 61439 Guide Ed2 2013Document47 pagesGambica Bs en 61439 Guide Ed2 2013Osama_Othman0150% (2)

Q

Q

Uploaded by

Gaurav AroraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Q

Q

Uploaded by

Gaurav AroraCopyright:

Available Formats

Q.C.Q.

A

Q.1.

a)

Discuss the theory underlying the control charts for fraction defectives.

b)

State and explain the conditions favourable for economic use of control charts

for defects per unit.

c)

An item is made in lots of 100 each. The lots are subjected to 100%

inspection. The record sheet for the first 20 lots inspected showed that a total of 80

items were defective.

(a)

Determine the trial control limits for np chart.

(b)

Assuming all points fall within the control limits. What is your estimate

of the process average faction defective p?

(c)

If this p remains unchanged, what is the probability that the 21 st lot will

contain exactly 2 defectives? That it will contain 2 or more defectives?

Q.2.

a)

b)

Distinguish between:

(i)

defect and defective

(ii)

p chart and np chart

(iii)

c-chart and u chart

(iv)

class A and class B defects

The number of defectives in lots for a particular item is shown below.

consists of 400 items.

Lot No.

1

2

3

No. of defects 24

38

52

per lot np

Q.3.

4

26

5

36

6

30

7

42

8

52

9

20

10

16

(i)

compute centre line on np chart

(ii)

plot np chart

(iii)

draw conclusions

(iv)

calculate revised control limits, if you feel necessary.

11

20

Each lot

12

24

a) What is acceptance sampling? State the advantages of acceptance sampling over

100% inspection.

b) Draw a neat sketch of an OC curve. Show and explain its different zones and salient

points. Also, state the characteristics of an OC curve.

c) A double sampling plan: n1 = 150, c1 = 2, n2 = 300, c2 = 4 is used for inspection of a 1.5%

defective lot. What is the probability of acceptance and average total inspection?

d) Draft a single sampling by attribute plan which will meet the following requirements:

0. 05

b = 0.10

Q.4.

p1 = 0.02

a =

p2 = 0.05

a) Differentiate between:

i) Random Sample and Systematic Sample

ii) AOQL and AQL

iii) ATI and ASN

iv) Producers Risk and Consumers Risk

b) Discuss the method of determination of AOQL in the laboratory.

c) Determine the equations of the rejection and acceptance lines for an item-by-

item sequential plan in which

p0-.50 = 0.05

and

p0-.10 = 0.15

Compute the respective acceptance and rejection numbers where n is 20,40,60,80 and 100. In

this calculation make the rejection number the next whole number above d 2and the acceptance

number the next whole number below d1.

d) In a double sampling plan,

N = 5,000, n1 = 100, c1 = 0, n1 + n2 = 200, c2 = 2

(i)

(ii)

Compute the probability of acceptance of 1% defective lot.

Assume that a lot rejected by the proposed sampling plan will be 100% inspected. What

will be the AOQ if submitted lots are 1% defective?

(iii)

Considering both the inspection of samples and inspection of rejected lots, what will be

the average number of articles inspected per lot if the submitted product is 1% defective?

Q.5. (a) What is TQM? Describe the following in connection with TQM:

(i)

Zero Defect Concept

(iii) JIT Manufacturing

(ii) Workers attitude

(iv) People Involvement

(b) What are Quality Circles? Name and briefly discuss the various problem solving

techniques.

Q.6. (a) Define TQM. Explain how TQM can be ensured. Discuss the need of training for

Quality Management.

(b) State the characteristics advantages and limitations of Quality Circles.

Q.7. (a) Briefly discuss the ISO-9000 series standards.

(b) State the outstanding features of ISO: 9000 series standards.

(c) Write a short note on Six Sigma Concept.

Q.8. (a) Describe the benefits of ISO :9000 series standards.

(b) Describe the various steps necessary for obtaining ISO: 9000 standards registration.

(c) Write a short note on Taguchis Quality Concept.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- N2006 PidDocument8 pagesN2006 PidSarah KempNo ratings yet

- Din 7984Document12 pagesDin 7984Nikola MilovanovićNo ratings yet

- Final PPT 123Document26 pagesFinal PPT 123Narender KumarNo ratings yet

- 13 Moon Pocket - Calendar PDFDocument16 pages13 Moon Pocket - Calendar PDFAfua OshunNo ratings yet

- Anchor Presentation Hilti 2011 PDFDocument8 pagesAnchor Presentation Hilti 2011 PDFNelsonDay100% (1)

- The New Empirical Formula Based On Dynamic Probing Test Results in Fine Cohesive SoilsDocument10 pagesThe New Empirical Formula Based On Dynamic Probing Test Results in Fine Cohesive SoilsabualamalNo ratings yet

- ElectricalEngineerigLabManual IIECE PDFDocument75 pagesElectricalEngineerigLabManual IIECE PDFUpender Rao SunkishalaNo ratings yet

- June 2015 QP - Unit 4 Edexcel Physics A-LevelDocument24 pagesJune 2015 QP - Unit 4 Edexcel Physics A-LeveltyNo ratings yet

- MCA4020-Model Question PaperDocument18 pagesMCA4020-Model Question PaperAppTest PINo ratings yet

- Linear Regression Analysis: Gaurav Garg (IIM Lucknow)Document96 pagesLinear Regression Analysis: Gaurav Garg (IIM Lucknow)Sakshi JainNo ratings yet

- S9 Q4 Week 2Document10 pagesS9 Q4 Week 2Mary Grace CatubiganNo ratings yet

- IETE-Journal of Research Template PDFDocument7 pagesIETE-Journal of Research Template PDFMadan R HonnalagereNo ratings yet

- AB1202 Week 5Document4 pagesAB1202 Week 5amos liewNo ratings yet

- Korean Volume BMS 1002Document9 pagesKorean Volume BMS 1002killeremailNo ratings yet

- Piezoelectric Shoe GeneratorDocument8 pagesPiezoelectric Shoe GeneratorJalla PavanNo ratings yet

- ACI 562 16 The ACI Concrete Repair CodeDocument7 pagesACI 562 16 The ACI Concrete Repair CodeDonny. B TampubolonNo ratings yet

- 9A04603 Digital Signal Processing16Document4 pages9A04603 Digital Signal Processing16Mahaboob SubahanNo ratings yet

- Expt 4-Ionic EquilibriaDocument42 pagesExpt 4-Ionic EquilibriatwinkledreampoppiesNo ratings yet

- Field Work No. 2 Differential Leveling With and Without Turning PointsDocument23 pagesField Work No. 2 Differential Leveling With and Without Turning PointsJohn Andrae MangloNo ratings yet

- Unisteri SL enDocument8 pagesUnisteri SL enJimmyNo ratings yet

- Sieve Analysis2 PDFDocument4 pagesSieve Analysis2 PDFAnonymous 8BXDrNxZP6No ratings yet

- MSDS Tris BufferDocument6 pagesMSDS Tris BuffervombyNo ratings yet

- Lecture 2 (CE-860)Document29 pagesLecture 2 (CE-860)MUHAMMAD AHMAD JAMILNo ratings yet

- Strength Lab 2 FullDocument11 pagesStrength Lab 2 FullWajisa JomworawongNo ratings yet

- JTCC PsDocument57 pagesJTCC PsTatjana MicevskaNo ratings yet

- Inpipe Products: Foam Pig Specification TableDocument1 pageInpipe Products: Foam Pig Specification TableMohamedNo ratings yet

- Paulino, Paul Tyrone R. Assignment 3Document14 pagesPaulino, Paul Tyrone R. Assignment 3Tyrone PaulinoNo ratings yet

- Proact™ Digital Speed Control System For Models I and Ii: Installation and Operation ManualDocument68 pagesProact™ Digital Speed Control System For Models I and Ii: Installation and Operation ManualKawarauNo ratings yet

- Gambica Bs en 61439 Guide Ed2 2013Document47 pagesGambica Bs en 61439 Guide Ed2 2013Osama_Othman0150% (2)