Professional Documents

Culture Documents

450 Volt Emergency Generator Switchboard Control and Instrumentation Panel

450 Volt Emergency Generator Switchboard Control and Instrumentation Panel

Uploaded by

BharatiyulamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

450 Volt Emergency Generator Switchboard Control and Instrumentation Panel

450 Volt Emergency Generator Switchboard Control and Instrumentation Panel

Uploaded by

BharatiyulamCopyright:

Available Formats

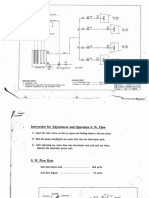

450 VOLT EMERGENCY GENERATOR SWITCHBOARD

CONTROL AND INSTRUMENTATION PANEL

GENERAL INFORMATION

The 450 volt emergency generator switchboard consists of a control panel and

instrumentation panel, emergency generator output breaker (52E), and a power

distribution sections. This chapter will discuss the control and instrumentation section.

DETAILED INFORMATION

Major Components of the Control and Instrumentation

Components mounted on panel door:

• Ammeter

• Kilowatt Meter

• Voltmeter

• 27 (under voltage relay normal)

• Frequency Meter

• 27E (under voltage relay emergency)

• Normal Power Available Lamp

• Emergency Power Available Lamp

• Auto-Off-Manual Switch (voltage regulator)

• Volt ADJ RHEO

• Mode Selector Switch 43 (Test Auto Off Man) with Amber Lamp

• 52 ECS Breaker Control (trip close) with Amber and Blue Lamps

• Emerg Gen Heater Switch with White Lamp

• Ammeter Switch

• Voltmeter Switch

• Ground Detector Lamp(s) and Test Pushbutton

• Governor Speed Adjustment Switch (Synchronizing Motor)

Components mounted inside switchboard enclosure:

• Basler Electronic Voltage Regulator

• KATO Volt-Per-Hertz Sensing Module

• KATO Auto-Manual Module (generator excitation control)

• KATO Pilot Exciter (permanent magnet generator)

• Simplex Automatic Engine Starting Control System

BASLER ELECTRONIC VOLTAGE REGULATOR

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 1

The Model No. SR-A voltage regulator consists of transformers, transistors, thyrtstors

(SCR's), silicon diodes, resistors and capacitors. The regulators contain no electrolytic

capacitors, are not subject to wear from moving parts and are relatively unaffected by

temperature, humidity, vibration or shock.

The voltage regulator senses the generator voltage, compares a rectified sample of that

voltage with a reference zener diode voltage and supplies the exciter field current

required to maintain he predetermined ratio between generator voltage and the

reference voltage. Voltage regulation is less than +/- 1/2% average voltage. Response

time is (16) milliseconds.

VOLTS PER HERTZ MODULE

A KATO Volts-per-Hertz module is utilized with the emergency generator. Where

satisfactory engine speed recovery, following large step changes in load, is dependent

upon a decrease in power demand upon the engine. The Volts-per-Hertz assembly

reduces demand on the engine under speed operation by reducing the generator

output.

The Volts-per-Hertz assembly also provides generator and voltage regulator under

frequency protection by keeping the voltage regulator output and generator field

excitation below the safe maximum level during under speed operation such as engine

idle.

AUTO MANUAL MODULE

The auto-manual module is a single-phase bridge rectifier and an autotransformer. It

receives ac power and delivers manually-controllable do power.

Via an AUTO-OFF-MANUAL switch the operator can connect the generator exciter field

to the automatic voltage regulator or the manual control circuitry or can remove all input

to the exciter field. In the OFF position the switch removes input power to the automatic

voltage regulator. The switch is mounted on the emergency switchboard control an

instrument panel.

• "AUTO" - Connects the generator exciter field and the 120 VAC PMG power to the

Basler Automatic Voltage Regulator.

• "OFF" - Removes input power to the voltage regulator and input power to the

generator, exciter.

• "MAN" - Removes input power to the auto voltage regulator and connects 120 VAC

power from PMG to a stationary bridge rectifier.

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 2

SIMPLEX AUTOMATIC ENGINE STARTING CONTROL SYSTEM

The Simplex Automatic Engine Control is used to automatically start and stop a diesel

engine upon closure and opening of control contacts. The automatic engine control also

provides automatic engine protection and visual annunciation upon failure of the engine

to function properly in the following areas: overcrank, low oil pressure, overspeed, high

water temperature. An additional shutdown circuit is provided for the Halon Fire Fighting

System.

The engine control switch (ACS) is used to determine auto start mode of operation.

"Off/Reset" position is used to deactivate or reset the auto-start unit. "Auto" position is

used for remote starting of the engine. "Run/Test" position is used for local operation to

start the engine or for test purposes.

Normal engine shutdown occurs by placing the engine control switch (ACS) in the

"Off/Reset" position. The engine will automatically shut down under any one or more of

the fault conditions as designated above, along with a light indication of which particular

fault occurred. After the fault is corrected, the engine control switch (ACS) must be

momentarily placed in the "Off/Reset" position.

OPERATION

AUTOMATIC TRANSFER SCHEME FOR EMERGENCY POWER

The operation of the automatic bus transfer equipment is designed to assure a

continuous source of power for all emergency power loads energized from the

emergency switchboard.

The "43" (bus transfer) switch located on the front of the emergency switchboard is

manually operated with the following positions: TEST, AUTO, OFF, MAN.

The switch can be locked and the key removed in the AUTO position only.

The TEST position is spring returned to the AUTO position. All other positions are

maintaining.

AUTO

With the VOLT REG switch and selector switch "43" in AUTO and under normal

conditions; the emergency generator circuit breaker 52E is OPEN and the normal

bus-tie circuit breaker 52N is CLOSED so that the emergency switchgear bus is

supplied from the ship's service main switchgear through the bus-tie circuit.

If the emergency diesel SIMPLEX automatic engine starting control system is energized

and in AUTO, the amber status above selector switch "43" will be illuminated.

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 3

If the voltage on the bus-tie drops below 85% of rated (382.5 volts), the normal source

undervoltage relay "27" will drop out which will de-energize diesel start time (2E).

After a preset time of 5.0 seconds "2E" contacts close completing the circuit to the

SIMPLEX automatic engine starting control system, starting the emergency generator

engine.

When the emergency generator voltage builds up to 85 to 95% of rated, the emergency

source undervoftage relay "27E" will pick up and contacts of this relay will trip circuit

breaker 52N, disconnecting the emergency bus from the ship's service bus-tie.

Another contact on "27E" energizes timing relay "2".

When timing relay "2" contact closes, after its preset elapsed time of 0.5 to 5.0 seconds,

the emergency generator circuit breaker 52E will close connecting the emergency bus

to the emergency generator.

When voltage from the main switchboard has been restored to normal, the emergency

loads may be manually transferred to the normal source by positioning 52ECS

BREAKER CONTROL to trip and positioning SHIP SERVICE SWBD BUS TIE breaker

(52N) to CLOSE.

The emergency diesel engine is then manually stopped by positioning the "SIMPLEX"

ENGINE CONTROL SWITCH (ACS) to OFF/RESET.

TEST

When selector switch "43" is held in TEST position, a contact will be opened which will

remove voltage from undervoltage relay coil "27", simulating a loss of bus voltage.

The SIMPLEX automatic starting system will start the emergency diesel and the

emergency bus will be transferred to the emergency generator as described above.

When selector switch "43" is allowed to return to the AUTO position, the emergency bus

must be manually retransferred to the normal source as described above.

MANUAL

When Mode Selector Switch "43" is positioned to MANUAL, it disables the automatic

bus transfer (ABT) and emergency diesel automatic starting functions.

The emergency diesel can be started at the "SIMPLEX" by positioning the ENGINE

CONTROL SWITCH (ECS) to RUN TEST or by placing the ECS switch to AUTO and

starting the EDG by using the local start switch located on the EDG. When the EDG is

started locally it is secured by positioning the ECS switch to OFF/RESET.

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 4

Emergency generator 52E may be closed by positioning BREAKER CONTROL 52ECS

to CLOSE after manually opening SHIP SERVICE SWBD BUS TIE 52N.

OFF

All automatic functions are disabled and the emergency generator circuit breaker. In this

mode the control power to the Ship's Service Switchboard Bus Tie breaker is

disconnected. Therefore in this mode it is possible to back feed the ship's service

switchboard from the emergency generator.

BACKFEEDING THE SHIP'S SERVICE SWITCHBOARD FROM THE EMERGENCY

GENERATOR

Backfeeding the 450v ship's service switchboard from the emergency diesel generator

can by very useful during an emergency or critical mission situation. This is not a normal

nor automatic procedure, and should be performed only after careful consideration. This

procedure has been successfully used to maintain hotel and galley services.

The EDG Mode Selector Switch 43 is normally left in AUTO and locked in this postion.

Upon loss of ship's service power, the EDG will come on-line and supply power to the

emergency loads. If the Cheif Engineer determines that additional ship's service loads

are to be powered from the EDG, the following procedure should be adhered to:

• Strip the Ship's Service Switchboard of any electrical load that is not required.

Note: upon loss of ship's service power, LVP (low voltage protect) controllers

automatically remove most of the electrical load from the switchboard, i.e., HVAC

systems, auxiliary saltwater circulation pumps, A/C units, etc.

• If the array winch is required for retrieval, backfeeding the Ship's Service

Switchboard is not recommended. The Emergency Diesel Generator is rated for 250

KW, 450V, 320 amps. DO NOT EXCEED 320 AMPS.

• At the Emergency Switchboard, position Mode Selector Switch 43 to OFF. The

diesel should remain on-line. Reset and close the Ship's Service Switchboard Bus Tie

breaker (52N). The EDG will now backfeed the Ship's Service Switchboard.

• Most equipment normally powered from the Ship's Service Switchboard may now

be operated, but care must be taken not to exceed the EDG rating of 250 KW 450V,

320 amps. The fuel oil purifier should be used to maintain the EDG service fuel tank.

NOTE

!f the emergency generator is used to backfeed the ship's service

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 5

switchboard, under no circumstances should an attempt be made to

parallel with either shore power or main diesel generator power.

MAINTENANCE

Instrument Transformers

Molded transformers may be cleaned by scrubbing the insulation with detergent and a

stiff brush to remove accumulated dirt or oil film. Remove the detergent by washing with

clean water. Apply a light grade of silicone oil to the surface if restoration of original

surface appearance is desired.

Voltmeters, Ammeters, Wattmeters, Frequency Meters and Power Factor Meters

To clean the various meter plastic windows, use soap and water. DO NOT USE

CHEMICAL CLEANERS.

Pushbuttons

CR2940 pushbuttons are used for various application, i.e., ground detector. Keep

reasonably clean inside and out. If contacts become roughened by heating or arching,

they should be smoothed with a fine file.

Type SB-1 Emergency Switchboard Control Device "43" Switch

At regular intervals switches should be inspected for burning of contacts, for broken

shunts on the moving contacts and for contact wear. If contacts are slightly pitted or

coated with sulfide, scrape them gently with a sharp knife or dress with a fine file, such

as a #00 dental file. If the shunts are broken or the contacts are badly pitted, they

should be replaced.

Type SBM Voltmeter, Ammeter, Generator Breaker Control, Generator Heater,

Synchronizing and Frequency Switches

At regular intervals the switch contacts should be inspected for wear and burning. An

opening at the bottom of the switch has been provided for this purpose. If contacts are

slightly pitted or coated with sulfide, they should be cleaned with a flexible burnishing

tool

WARNING

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 6

Since many of the parts of this switch are molded of a polycarbonate

material, DD NOT use any lubricants and/or cleaning agents in any form

(including aerosol sprays commonly available). Hydrocarbons (oils and

related products may chemically attack such parts resulting in possible

switch failure.

Emergency Switchboard Instantaneous Auxiliary Relay and Undervoltage Relay

Due to the vital role of relays in the operation of a power system, it is important that a

periodic test program be followed. It is recommended that the points listed under

ACCEPTANCE TEST in G.E. INSTRUCTIONS GEH-1739E and GEI-90806, which is

included in Volume 2 of G.E. Technical Manual for Ocean Surveillance Ship T-AGOS

GEK-83187, be performed at an interval of from one to two years.

For cleaning relay contacts a flexible burnishing tool should be used. This consists of a

flexible strip of metal with an etched-roughened surface resembling in effect a superfine

file. The polishing action is so delicate that no scratches are left, yet it will clean off any

corrosion thoroughly and rapidly. Its flexibility ensures cleaning the actual points on

contact.

Do not use knives, files, abrasive paper or cloth of any kind to clean contact relays.

EMERGENCY GENERATOR AND SWITCHBOARD

2 Generator Breaker Close Timer

2E. Diesel Start Timer

27 Normal Source Undervoltage Relay

27E Emergency Source Undervoltage Relay

43 Mode Selector Switch

52E Emergency Generator Output Breaker

52N Normal Source Circuit Breaker

52ECS Generator Circuit Breaker Control Switch

PB Generator Breaker Close Pushbutton

83E Control Power Transfer Relay

AM Ammeter

VM Voltmeter

AS Ammeter Switch

VS Voltmeter Switch

WM Wattmeter

FM Frequency Meter

CT Current Transformer

PT Potential Transformer

TC Trip Coil

TDC Time Delay Close

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 7

TDE Time Delay On Energization

TDDE Time Delay De-energization

UVD Undervoltage Coil for Generator Breaker

TDUV Time Delay Auxiliary Box

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 8

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 9

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 10

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 11

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 12

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 13

450 VOLT EMERGENCY SWITCHBOARD

GENERAL INFORMATION

The switchboard provides control, protection, and distribution of power at 450 VAC, 120

VAC to emergency loads within the vessel. The emergency switchboard also has a 24

VDC section used to supply Main Generator Diesel control voltage, Generator Engine

Module "Cold Start" voltage, and Engine Order Telegraph "Current Failure Alarm"

power.

NOTE:

When the cold start pushbutton is depressed a ground fault will appear

on the ground detector lights at the 24 VDC section of the EDG

switchboard and on the Main Diesel Control battery charger. This Is

because this circuit uses hull ground as a return path. Therefore the Cold

Start pushbutton should not be depressed except for testing and when In

actual use.

The emergency switchboard is connected to the 450 volt ship's service switchboard

through either of two bus tie breakers, I.e., either Port 1 X or Starboard 3Y.

DETAILED INFORMATION

Switchboard Distribution

450 Volt AC Section

• 52N & 52E Status Indicators

• OPEN (amber) and CLOSE (blue) lamps

• Main breaker 52E (1 ESG-4P).

• S.S. Swbd. bus-tie 52N (P437).

• Miscellaneous molded case feeder breakers:

• EP401 - Bilge Pump #2

• EP402 - Submersible Pump Outlets

• EP403 - Bow Thruster Seawater Cooling Pump

• EP404 - Fire and Ballast Pump #2

• EP405 - SURTASS Array Emer. Winch

• EP406 - Starting Air Compressor #1

• EP407 - Elextronic Power Panel Tranformer

• EP408 - Steering Gear Pump #2

• EP409 - Emergency Lighting Panel, 120 Volt Transformer

• EP41 0 - Emergency Switchboard Transformer 120V

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 14

• EP411 - SURTASS Array Winch

• EP412 - Spare

• P437 - Ship's Service SWBD Bus Tie (52N)

• Spare

• Spare

• Spare

The generator output breaker 52E (1 ESG-4P) receives power from the emergency

generator when it is in operation.

Power to the emergency switchboard is normally available through the SHIP SERVICE

SWBD BUS-TIE 1T (52N, P437).

NOTE

Only one source of power at a time may be applied to the emergency

switchboard.

120 Volt AC Section

• EP110-1 - EDG Jacket Water Heaters

• EP110-2 - Spare

• EP110-3 - Array Power Panel

• EP110-4 - EDG Battery Charger

• EP110-5 - Emergency Lighting Panel

• EP110-6 - Spare

• EP110-7 - Emergency Lighting Panel

• EP110-8A - Emergency Lighting Panel

• EP110-9 - Emergency Lighting Panel

• EP110-10 -MCSC (Emergency Power source)

• EP110-11 - WSC-6 Unit #5

• EP110-12 -DC Switchboard Battery Charger (24 VDC Section)

24 Volt DC Section

• P024-1 - Main Generator #1 Control 24 VDC (including Cold Start)

• P024-2 - Main Generator #2 Control 24 VDC (including Cold Start)

• P024-3 - Main Generator #3 Control 24 VDC (including Cold Start)

• P024-4 - Main Generator #4 Control 24 VDC (including Cold Start)

• P024-5 - Spare

• P024-6 -'Current Failure Alarm (' Engine Order Telegraph)

The 24 VDC emergency switchboard is served by the 120 VAC emergency switchboard

via circuit breaker 3U (DC SWBD BATTERY CHARGER)

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 15

The molded case feeder breakers are manually operated though most are normally left

in the CLOSED position.

The ship service switchboard bus-tie breaker 52N is interlocked with the emergency

switchboard ABT.

The emergency switchboard ABT consists of the Mode Selector Switch (device 43),

52E, and various relays located in and beneath the switchboard instrumentation and

control panel.

In the event of power failure (85% of normal voltage) on the 450 Volt Ship's Service

Bus, the emergency generator automatically starts, bus-tie breaker 52N automatically

opens (disconnecting the Ship's Service bus and emergency bus) and breaker 52E

closes to connect the emergency generator output to the emergency bus and it's loss.

Once the ship's service power has been restored to the ship's service switchboard

normal operation can be restored by manually reconnecting the emergency loads to the

ship's service bus via 52N and manually shutting down the emergency diesel.

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 16

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 17

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 18

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 19

Generator Output Broker - 52E

General Electric type AKR - 4A - 30 - 400 amp frame marine drawout with door closed

-Solid State overcurrent trip device.

This circuit breaker is of the drawout type with the switchboard compartment closed. As

the compartment door is mounted on the switchboard frame, the breaker has a deep

telescoping escutcheon, which allows the breaker to be disconnected. There are four

breaker positions.

CONNECTED

Breaker is fully inserted in the compartment with the power and control disconnects fully

engaged. The breaker must be tripped to rack into or out of this position.

TEST

Power and control disconnects are disengaged, but the secondary control disconnects

are engaged to permit breaker operation without energizing the power circuit.

DISCONNECTED

All disconnects are disengaged.

WITHDRAWN

With the compartment door open and the breaker fully extended out on the side track

extension, the breaker can be lifted off the tracks. Two protruding pins on each side of

the breaker can drop into slots on the slide rails to properly position the breaker for

racking in or out. Breaker position in connected - test - disconnected is indicated by

markings on the left and right sides of the escutcheon.

BREAKER REMOVAL

1. Trip the breaker and open the door.

2. Insert the racking handle into the racking screw opening and rotate counterclockwise

to move the breaker from CONNECTED through TEST to the DISCONNECTED

position, where the jack screw mechanically stops. The breaker closing spring will be

discharged automatically a few turns before the end of the racking action.

3. Pull the breaker out on the track as far as it will go.

4. Release the track locks and then pull the breaker out on the slide rail extension until

it is fully extended.

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 20

5. Before lifting the breaker off the track, verify the breaker is open and the spring is

discharged.

6. Due to the weight of the breaker a suitable lifting rig with spreader bar should be

used. Hoist the breaker until the side pins dear the track slots, swing the breaker

forward until the primary disconnects clear the compartment. Lower the breaker onto a

flat surface with no objects that could damage the internal mechanism.

INSERTING THE BREAKER

1. Before lifting the breaker, insure that the racking cams on the breaker are properly

positioned for engaging the pins in the compartment. To do this, ascertain the racking

screw is fully counterclockwise. Also, insure that the breaker is open.

2. With the lifting rig and spreader bar, raise the breaker above the elevation of the

tracks and extend the tracks fully.

3. Slowly lower and guide the breaker so that the mounting pins drop into the racks.

Remove the lifting assembly.

4. Push the breaker into the compartment until it reaches the track stops. This is the

DISCONNECT position where the breaker racking arms are positioned to engage the

compartment racking pins.

5. Insert the racking handle into the racking screw opening in the escutcheon and

rotate clockwise. The breaker will travel through the TEST position to the CONNECTED

position where the jackscrew mechanically stops.

NOTE

If control power Is available, the charging motor will charge the closing

spring when the breaker reaches the TEST position.

MAINTENANCE

Generator Output Breaker Clean Lubricate and Inspect

Periodic inspection, lubrication and operation of the breaker is recommended to assure

reliable performance. Under normal conditions an annual inspection is suggested,

though more frequent operation is recommended to maintain the mechanism free and

lubricated.

After the breaker has been de-energized manually and electrically operate the breaker

several times, checking for obstructions or excessive friction and insure the electrical

attachments function properly.

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 21

With the breaker removed from the compartment, or in fully withdrawn position on the

racks, visually inspect the breaker for loose hardware. Also, check the bottom of the

compartment for hardware that has fallen from the breaker.

Remove the arc quenchers from the breaker to inspect the arc quencher barriers and

contacts for breaking or excessive burning. Should are quencher barriers or contacts be

eroded to half their original thickness they should be replaced. Inspect the breaker

arcing tips and main contacts for burning or damage. A thin film of contact lubricant

should be applied to the main contacts only, before remounting the arc quenchers.

Inspect insulating parts for any evidence of overheating, damage or thermal aging.

Bearing points and sliding surfaces should be lightly lubricated with a thin film of Mobil

GE Lubricant D50H15. The disconnect studs should be cleaned and greased with GE

D50H47. Use kerosene to remove hardened grease and dirt from latch and bearing

surfaces.

Performance of the solid state trip device (Micro VersaTrip) can be checked with the

test unit specifically designed for this purpose. (GE Test Set TVTS-1).

With the breaker racked in to the TEST position and control power available with the

generator running, the spring charging motor will charge the closing spring. The breaker

may now be closed and tripped electrically to check operation of the mechanism and

auxiliary circuits.

CLEAN AND INSPECT EMERGENCY SWITCHBOARD

OBJECTIVE: Establish procedure for cleaning and inspecting switchboards.

TOOLS AND EQUIPMENT:

Standard mechanics tools, AC/DC volt/ohmmeter, clean dry rags, vacuum cleaner.

GENERAL INFORMATION AND INSTRUCTIONS:

This procedure should be used in conjunction with switchboard insulation resistance

measurement operation sheets.

REFERENCES:

G.E. Manual GEK-83187 Volume 1 & 2

TBC Drawing No. 320-0000301

READ THIS BEFORE PROCEEDING

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 22

PRECAUTIONS:

Observe all standard safety precautions associated with electrical and mechanical

equipment.

WARNING

De-energize equipment completely before attempting any work on

connections, buses, cables or wires. This Includes de-energizing any

connections to outside primary or secondary sources, such as

transformers, tie lines, space heaters, alarm circuits, etc.

Power Sources to the Emergency Switchboards

• Auto start panel - set too off/reset.

• Port emergency bus tie breaker - open.

• Starboard emergency bus tie breaker - open.

• Emergency generator space heater breaker - open L128-1 P.

• Emergency diesel start batteries - disconnected.

• Emergency 24 volt switchboard supply battery breaker-open P024-7.

• MCSC 105 volt power supply breaker- open MCSC power panel CB 5.

OPERATION STEPS KEY POINTS

1. Using the power sources to Verify power is off with an

switchboards above, AC/DC volt meter.

de-energize all sources of

power'to the switchboard to

be cleaned.

2. On the EDG switchboard, See AKR breaker

rack generator breaker out to information sheet for

clean the breaker and breaker. racking instructions

compartment Section III pg. 23-7

3. Thoroughly clean components Do not use compressed

located within switchboard air or cleaning solvents.

compartments. Use a vacuum

cleaner and clean dry rags only.

4. Inspect buses and connections

for signs of overheating, due to

poor connections.

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 23

5. Check all bus connection, bus

mounting, and bus bracing bolts

for tightness.

6. Check all control wiring connections

for tightness.

7. Inspect compartment floors for

loose hardware.

8. Proceed with insulation resistance

measurement operations.

9. Replace all protective covers

450 VOLT EMERGENCY SWITCHBOARD INSULATION RESISTANCE MEASUREMENT

OBJECTIVE: Establish a procedures for taking insulation resistance measurements

of the 450 volt emergency switchboard.

TOOLS AND EQUIPMENT:

500 volt megger, AC/DC Volt Ohmmeter, 40°C insulation resistance correction factor

chart.

GENERAL INFORMATION AND INSTRUCTIONS:

Duration of application of an insulation resistance test potential should be one minute

with readings taken at the end of the one minute test. A correction factor must be used

to bring readings to a 40°C value (see Section III Appendix A). Insulation resistance

readings should be permanently recorded for future trend analysis.

REFERENCES:

G.E. Manual GEK 83187, Volume 2

TBC Drawing 320-0000301, Sheet 2

READ THIS BEFORE PROCEEDING

PRECAUTIONS:

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 24

Observe all normal safety precautions associated with electrical and mechanical

equipment.

WARNING

De-energize equipment completely before attempting any work on

connections, buses, cables or wires. This includes de-energizing any

connections to outside primary or secondary sources, such as

transformers, tie lines, space heaters, alarm circuits, etc.

Power Sources to the Emergency Switchboards

• Auto start panel - set too off/reset.

• Part emergency bus tie breaker- open.

• Starboard emergency bus tie breaker - open.

• Emergency generator space heater breaker - open Li 28-1 P.

• Emergency diesel start batteries - disconnected.

• Emergency 24 volt switchboard supply battery breaker - open P024-7.

• MCSC 105 volt power supply breaker - open MCSC. power panel CB 5.

OPERATION STEPS KEY POINTS

1. Using the power sources to Verify power is off

switchboards information with an AC/DC volt meter.

above, de-energize all sources

of power to the 450 volt emergency

switchboard.

2. Open all feeder circuit breakers Isolate buses from feeder

on the 450 volt emergency cables and loads.

switchboard.

3. At the emergency generator Disconnects

control section,remove fuses instrumentation

FP and PN. tranformer and ground

detection lamp.

4. Connect megger leads to test

the 450 volt emergency switchboard

to hull ground at 500 volts.

5. Record readings after one minute Megger readings will

of megger potential application. usually start low and

then increase during the

one minute period.

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 25

6. Record bus compartment This information is used

temperature at the time insulation in converting the megger

resistance test is performed. readings to 40°C.

7. Utilizing megger readings and temperatures originally obtained and the 40°C

insulation resistance correction factor chart, calculate and record readings for future

trend analysis (see Section III Appendix Ay.

8. Replace fuses FP and FN.

9. Replace all covers before

re-energizing switchboard.

120 VAC AND 24VDC EMERGENCY SWITCHBOARD INSULATION RESISTANCE

MEASUREMENT

OBJECTIVE: Establish a procedures for taking insulation resistance measurements

of the 120 VAC 24VDC emergency switchboards.

TOOLS AND EQUIPMENT:

500 volt megger, AC/DC Volt Ohmeter, 40°C insulation resistance correction factor

chart.

GENERAL INFORMATION AND INSTRUCTIONS:

Duration of application of an insulation resistance test potential should be one minute

with readings taken at the end of the one minute test. A correction factor must be used

to bring readings to a 40°C value (see Section III Appendix Aj. Insulation resistance

readings should be permanently recorded for future trend analysis.

REFERENCES:

G.E. Manual GEK 83187, Volume 2

TBC Drawing 320-0000301, Sheet 2

READ THIS BEFORE PROCEEDING

PRECAUTIONS:

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 26

Observe all normal safety precautions associated with electrical and mechanical

equipment.

WARNING

De-energize equipment completely before attempting any work on

connections, buses, cables or wires. This includes de-energizing any

connections to outside primary or secondary sources, such as

transformers, tie lines, space heaters, alarm circuits, eta

Power Sources to the Emergency Switchboards

• Auto start panel - set too off/reset.

• Port emergency bus tie breaker - open.

• Starboard emergency bus tie breaker- open.

• Emergency generator space heater breaker- open L128-1 P.

• Emergency diesel start batteries - disconnected.

• Emergency 24 volt switchboard supply battery breaker- open P024-7.

• MCSC 105 volt power supply breaker - open MCSC power panel CB 5.

OPERATION STEPS KEY POINTS

1. At the 450 volt emergency switchboard, De-energizes 450/120

volt open EP 410. transformer supplying

120 volt A.C. emergency

switchboard.

2. Open all feeder circuit breakers Isolates buses from

on the 120 volt A.C. and 24 volt D.C. feeder cables and loads.

switchboards.

3. At the rear of the 120 VAC/24 VDC

switchboard, remove fuses for

ground detection lamps on both buses.

4. Connect megger leads to test the

buses to hull ground at 500 volts.

5. Record readings after one minute Megger readings will

of megger potential application. usually start low and then

increase during the one

minute period.

6. Record bus compartment This information is used

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 27

temperature at the time the in converting the megger

insulation resistance test is readings to 40°C.

performed.

7. Utilizing megger readings and temperature originally obtained and the 40°C

insulation resistance correction factor chart, calculate and record readings for future

trend analysis (see Section III Appendix A).

8. Replace fuses for ground detection lamps.

9. Replace all covers before re-energizing switchboard.

Daniel Robson T/V KINGS POINTER Revised: 3/21/02

Chief Engineer Emergency Switchboard Page: 28

You might also like

- Ship Automation for Marine Engineers and ETOs A. Yakimchuk-страницы-4,13,50,62,101,108-109,130,132-136,139-156,160,199-201,207,216-217Document38 pagesShip Automation for Marine Engineers and ETOs A. Yakimchuk-страницы-4,13,50,62,101,108-109,130,132-136,139-156,160,199-201,207,216-217Roma RoMa100% (1)

- Quarter 3 - Module 1-W1&W2: Computer Systems Servicing (CSS)Document18 pagesQuarter 3 - Module 1-W1&W2: Computer Systems Servicing (CSS)AC Balio100% (5)

- SINGLE LINE DIAGRAM (H-8001) Rev 2Document13 pagesSINGLE LINE DIAGRAM (H-8001) Rev 2wahyuNo ratings yet

- GloEn-Patrol Troubleshooting (BWMS)Document114 pagesGloEn-Patrol Troubleshooting (BWMS)NikulNo ratings yet

- OMM807100043 - 3 (PID Controller Manual)Document98 pagesOMM807100043 - 3 (PID Controller Manual)cengiz kutukcu100% (3)

- Daiichi Nekken C-28C Manual v2.0Document23 pagesDaiichi Nekken C-28C Manual v2.0giro roskyNo ratings yet

- Power Management SystemDocument51 pagesPower Management Systemsj_hecklers75% (4)

- Remo ConDocument351 pagesRemo ContosveNo ratings yet

- M-31-3 Main Engine (3-3) PDFDocument554 pagesM-31-3 Main Engine (3-3) PDFRaja SegarNo ratings yet

- Yantai BKJ2 Marine Master-Slave ClockDocument7 pagesYantai BKJ2 Marine Master-Slave ClockFront Crown100% (1)

- Marine Panels Training ManualDocument36 pagesMarine Panels Training Manual290602100% (5)

- Measuring Team ProductivityDocument27 pagesMeasuring Team ProductivityAdhitya Setyo Pamungkas100% (1)

- Comptia Security Sy0 601 Exam Objectives (2 0)Document24 pagesComptia Security Sy0 601 Exam Objectives (2 0)tha_flameNo ratings yet

- Marine Electro-Technology Test Part1Document6 pagesMarine Electro-Technology Test Part1Grid Lock100% (1)

- 1.H2219-20 MSBD (Rev.e - 11.04.11)Document138 pages1.H2219-20 MSBD (Rev.e - 11.04.11)Aleksandr AndreevNo ratings yet

- All Electric Ship Integrated Power Systems PDFDocument6 pagesAll Electric Ship Integrated Power Systems PDFMario BogdanovicNo ratings yet

- Air Circuit Breaker-ChintDocument66 pagesAir Circuit Breaker-Chintdmugalloy100% (1)

- Synchronizing and Synchronizing EquipmentDocument10 pagesSynchronizing and Synchronizing EquipmentLog in 2007No ratings yet

- Main Switchboard Maintenance PDFDocument17 pagesMain Switchboard Maintenance PDFAzman HanafiahNo ratings yet

- ICAF Comissioning Check List - MPE Catodic ASDocument4 pagesICAF Comissioning Check List - MPE Catodic ASBùi Công Lộc100% (1)

- DG Maintenance Manual PDFDocument39 pagesDG Maintenance Manual PDFvij200950% (2)

- Parallel Operation of Three-Phase AlternatorsDocument12 pagesParallel Operation of Three-Phase AlternatorsNayan Manna100% (2)

- AvK Voltage RegulatorsDocument9 pagesAvK Voltage RegulatorsABDUL GHAFOORNo ratings yet

- Nakakita Seisakusho ValveDocument2 pagesNakakita Seisakusho ValveMohd Faris Amzar Mat ZamNo ratings yet

- Generator TheoryDocument4 pagesGenerator TheoryRachit KhannaNo ratings yet

- #Marine Electricity GenerationDocument29 pages#Marine Electricity GenerationThe Linden Tree StoreNo ratings yet

- Mgps ManualDocument9 pagesMgps ManualMandeep Singh Kahlon100% (2)

- Preferential TripsDocument1 pagePreferential TripsKr ManuNo ratings yet

- Synchronous Generator J.Majumder MIE Senior FacultyDocument18 pagesSynchronous Generator J.Majumder MIE Senior FacultyQuang Tiên100% (1)

- Drawing PDFDocument18 pagesDrawing PDFJeremiah LangoeyNo ratings yet

- AD-0377-C C20 - Alarm Monitoring Control and Power ManagementDocument317 pagesAD-0377-C C20 - Alarm Monitoring Control and Power ManagementMic Utu67% (3)

- VDR HyundaiDocument28 pagesVDR HyundaiDIPIN PNo ratings yet

- Radar TankDocument48 pagesRadar TankMuhammad NuhNo ratings yet

- (Manual) Whistle SystemDocument13 pages(Manual) Whistle SystemSergei KurpishNo ratings yet

- ElectricalDocument44 pagesElectricalRachitNo ratings yet

- High Voltage On ShipsDocument10 pagesHigh Voltage On ShipsBogdan Ancuta100% (2)

- MITSUBISHI - FX3U Users Manual - Hardware Edition PDFDocument520 pagesMITSUBISHI - FX3U Users Manual - Hardware Edition PDFindra putraNo ratings yet

- MGPSDocument9 pagesMGPSMikhail BagliukNo ratings yet

- Ship's Emergency PowerDocument3 pagesShip's Emergency Powerrajjsmit1989No ratings yet

- HIMAP A1 Communication EDocument51 pagesHIMAP A1 Communication Emaronnam100% (1)

- Sp01954 Egc Alarm List Rev5Document11 pagesSp01954 Egc Alarm List Rev5Tomislav BanićNo ratings yet

- Standard Safety High Voltage 12Document4 pagesStandard Safety High Voltage 12clinthenNo ratings yet

- HYUNDAI (HGN HGS) - Manual - EN - 2018.07Document52 pagesHYUNDAI (HGN HGS) - Manual - EN - 2018.07alberto100% (2)

- LEOCH DJ Series VRLA Battery ManualDocument23 pagesLEOCH DJ Series VRLA Battery ManualMoiz MehmoodNo ratings yet

- Cargo Water Ingress Alarm Device User Manual: Jiangsu Yuanwang Instrument Co., LTDDocument24 pagesCargo Water Ingress Alarm Device User Manual: Jiangsu Yuanwang Instrument Co., LTDrp100% (1)

- Instruction Manual For Loading MonitorDocument114 pagesInstruction Manual For Loading MonitorRM HaroonNo ratings yet

- Navtex Manual - FurunoDocument84 pagesNavtex Manual - FurunoBob TigerNo ratings yet

- EC-9A Main SwitchboardDocument130 pagesEC-9A Main SwitchboardABDUL GHAFOORNo ratings yet

- Shipboard Electrical EquipmentDocument16 pagesShipboard Electrical EquipmentastefanovichNo ratings yet

- AUTRONICADocument102 pagesAUTRONICApedrodany9098No ratings yet

- Ship RadarDocument123 pagesShip RadarGucci King WrightNo ratings yet

- Crompton Reverse Power RelayDocument2 pagesCrompton Reverse Power RelayMohamed100% (1)

- 6.2. F-MPC60B - Manual - English PDFDocument68 pages6.2. F-MPC60B - Manual - English PDFThủy Tiên100% (1)

- Installation and Operation Manual: Proact™ Ii Electric Powered Actuator and DriverDocument32 pagesInstallation and Operation Manual: Proact™ Ii Electric Powered Actuator and DriverDjebali MouradNo ratings yet

- Marine DistributionSystem PDFDocument17 pagesMarine DistributionSystem PDFGreg Rivas100% (1)

- IotaITS 75C SwitchDocument4 pagesIotaITS 75C SwitchJohn Melanathy IINo ratings yet

- Sion HG11 - 02 - en - 2006-12-21 - 3AE1Document64 pagesSion HG11 - 02 - en - 2006-12-21 - 3AE1Mahmoud_EldeekNo ratings yet

- Calibration ChokeDocument11 pagesCalibration ChokeAmar BadradineNo ratings yet

- Electric Power Supply & Distribution On BoardDocument35 pagesElectric Power Supply & Distribution On BoardMarjan Brčić100% (1)

- Emergency SwitchboardDocument7 pagesEmergency SwitchboardHUYNH NHAT VUNo ratings yet

- Sb60 08 ElectricalDocument39 pagesSb60 08 ElectricalMgc Elektronik100% (1)

- KGW Double Deck Crane Eh 2x25t - 22m - Lo-Ro CarrierDocument167 pagesKGW Double Deck Crane Eh 2x25t - 22m - Lo-Ro CarrierArun Tiwari100% (1)

- Horticultural Society, Hyderabad - Diary 2022Document476 pagesHorticultural Society, Hyderabad - Diary 2022BharatiyulamNo ratings yet

- Welcome: SEVA Org. & BharatiyulamDocument20 pagesWelcome: SEVA Org. & BharatiyulamBharatiyulamNo ratings yet

- Sila Silpam NuvveDocument204 pagesSila Silpam NuvveBharatiyulamNo ratings yet

- Nature Book PDFDocument2 pagesNature Book PDFBharatiyulam100% (1)

- NATUECO Book PDFDocument112 pagesNATUECO Book PDFpuvichandranNo ratings yet

- Vaaradhi With SEVA OrgDocument10 pagesVaaradhi With SEVA OrgBharatiyulamNo ratings yet

- EPU of Bio-Pesticides PDFDocument170 pagesEPU of Bio-Pesticides PDFBharatiyulamNo ratings yet

- Kabeer Suktimuktavali Sankara Sreeramarao 1960Document76 pagesKabeer Suktimuktavali Sankara Sreeramarao 1960BharatiyulamNo ratings yet

- Antioxidant SSR PDFDocument81 pagesAntioxidant SSR PDFBharatiyulamNo ratings yet

- Online Seat Booking For ExaminationDocument6 pagesOnline Seat Booking For ExaminationBharatiyulam100% (1)

- Bharatiyulam Invitation For You On Facebook Forward ItDocument1 pageBharatiyulam Invitation For You On Facebook Forward ItBharatiyulamNo ratings yet

- Prevention of Static ElectricityDocument1 pagePrevention of Static ElectricityBharatiyulamNo ratings yet

- Okka Rupayee Chaalu BharatiyulamDocument2 pagesOkka Rupayee Chaalu BharatiyulamManindar KumarNo ratings yet

- PRESTIGEDocument3 pagesPRESTIGEBharatiyulamNo ratings yet

- Meo Examination Part-Check ListDocument2 pagesMeo Examination Part-Check ListArun PrasadNo ratings yet

- PollutionDocument12 pagesPollutionBharatiyulamNo ratings yet

- Power Train Components MJHDocument17 pagesPower Train Components MJHBharatiyulamNo ratings yet

- Overseas Cadet ProgrammesDocument3 pagesOverseas Cadet ProgrammesBharatiyulamNo ratings yet

- Petroleum OilDocument5 pagesPetroleum OilgunapalshettyNo ratings yet

- Oil SpillsDocument5 pagesOil SpillsBharatiyulamNo ratings yet

- Navigation FormulaeDocument1 pageNavigation FormulaeBharatiyulam100% (1)

- MCA Stability BookletDocument19 pagesMCA Stability BookletBharatiyulam0% (1)

- The M. S. (Load Line) Regulations 1998 (Amended 2000)Document4 pagesThe M. S. (Load Line) Regulations 1998 (Amended 2000)BharatiyulamNo ratings yet

- MAM - I, Question BankDocument8 pagesMAM - I, Question BankBharatiyulamNo ratings yet

- Load Line DiagramDocument1 pageLoad Line DiagramBharatiyulamNo ratings yet

- Mca Formula SheetDocument4 pagesMca Formula SheetBharatiyulamNo ratings yet

- The Magnetic Compass CardDocument148 pagesThe Magnetic Compass CardBharatiyulamNo ratings yet

- Support/downloads or Scan Above QR Code For Detailed Policy WordingDocument10 pagesSupport/downloads or Scan Above QR Code For Detailed Policy Wordingraj VenkateshNo ratings yet

- Unit Iv Secondary and Auxilary Motions 12Document3 pagesUnit Iv Secondary and Auxilary Motions 129043785763No ratings yet

- Hot Cool 3 2012Document32 pagesHot Cool 3 2012thermosol5416No ratings yet

- BRR Course 5Document19 pagesBRR Course 5Wade SperryNo ratings yet

- 04-46 Analysis of Gold-Copper Braze Joint in Glidcop For UHV Components at The APS W.Toter S.SharmaDocument10 pages04-46 Analysis of Gold-Copper Braze Joint in Glidcop For UHV Components at The APS W.Toter S.SharmaKai XuNo ratings yet

- MT2OL-Ia6 2 1Document136 pagesMT2OL-Ia6 2 1QUILIOPE, JUSTINE JAY S.No ratings yet

- 9A03501 Thermal Engineering IIDocument4 pages9A03501 Thermal Engineering IIsivabharathamurthyNo ratings yet

- D5F-F5 (Draft Aug2021)Document6 pagesD5F-F5 (Draft Aug2021)Lame GamerNo ratings yet

- SkillsDocument7 pagesSkillsRufus RajNo ratings yet

- OptiMix - Manual - EN - Rev.03.05 (Mixer)Document89 pagesOptiMix - Manual - EN - Rev.03.05 (Mixer)Đức Nguyễn100% (2)

- Testbank: Applying Ifrs Standards 4eDocument11 pagesTestbank: Applying Ifrs Standards 4eSyed Bilal AliNo ratings yet

- Kalsi® Building Board Cladding: Kalsi® Clad Standard DimensionsDocument1 pageKalsi® Building Board Cladding: Kalsi® Clad Standard DimensionsDenis AkingbasoNo ratings yet

- BdwtvdytwDocument11 pagesBdwtvdytwharshit kuchhalNo ratings yet

- Using Value Stream Mapping To Eliminate Waste A CaDocument19 pagesUsing Value Stream Mapping To Eliminate Waste A CaRoger SalamancaNo ratings yet

- General Revision For Treasury Management (Please See That You Can Answer The Following 32 Questions and The MCQS)Document14 pagesGeneral Revision For Treasury Management (Please See That You Can Answer The Following 32 Questions and The MCQS)RoelienNo ratings yet

- Parasnis - 1951 - Study Rock MidlandsDocument20 pagesParasnis - 1951 - Study Rock MidlandsIsaac KandaNo ratings yet

- Bcsbi Pictorial BookDocument24 pagesBcsbi Pictorial BookMALAYADRI DUARINo ratings yet

- Maximo Training Material Day 2Document41 pagesMaximo Training Material Day 2ckombo9912100% (2)

- Form Service A40gDocument1 pageForm Service A40gBrando ImanuelNo ratings yet

- PTS MATH GRADE 3 ICP (2022-2023) - Abidah FixDocument4 pagesPTS MATH GRADE 3 ICP (2022-2023) - Abidah FixAnita Noor Maidah S.Pd.i. SD Lab UMNo ratings yet

- Jamboree GRE StudyPlan PDFDocument3 pagesJamboree GRE StudyPlan PDFMd Minhaj Ahmed AhmedNo ratings yet

- Gcrouch@wsu - Edu Rmancini@wsu - Edu Andreakl@wsu - Edu: Groups/chem.345Document5 pagesGcrouch@wsu - Edu Rmancini@wsu - Edu Andreakl@wsu - Edu: Groups/chem.345Daniel McDermottNo ratings yet

- FijiTimes - Feb 17 2012 Web PDFDocument48 pagesFijiTimes - Feb 17 2012 Web PDFfijitimescanadaNo ratings yet

- GraphsDocument18 pagesGraphssaloniNo ratings yet

- Thrift Banks ActDocument25 pagesThrift Banks ActMadelle Pineda100% (1)

- CentrifugationDocument10 pagesCentrifugationBk FNo ratings yet

- HITACHI 850, 850LC, 870H, 870LCH Components Parts Catalog (151-419) Page RecognitionDocument138 pagesHITACHI 850, 850LC, 870H, 870LCH Components Parts Catalog (151-419) Page RecognitionGeorge Zormpas100% (1)