Professional Documents

Culture Documents

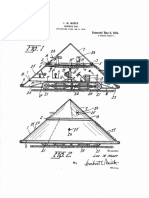

United States Patent

United States Patent

Uploaded by

PhanHathamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

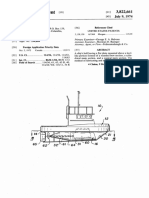

United States Patent

United States Patent

Uploaded by

PhanHathamCopyright:

Available Formats

United States Patent [19]

[11]

Patent Number:

4,657,112

Ream et al.

[45]

Date of Patent:

Apr. 14, 1987

[54]

MAST CONSTRUCTION FOR PEDESTAL

4,185,426

1/1980 Prescott .............................. .. 52/118

SCAFFOLD

4,258,825

3/1981

Collins .... ..

4,337,601 7/1982 Vaerk

175] Inventors= Michael D- Ream, Lafayette; Gerald

L. Cl?XtOll, Fresno, both Of Calif.

1731 Assignw Upright, Inc Berkeley, calif-

182/14

52/118

4,397,373 8/1983 Ream

182/63

4,459,786 7/1984 Pitman .... ..

52/ 118

31233133? 251322 1221111: ............ ................:'.'."1123133

[21] Appl' No: 856050

[22] Filed:

Apr. 25, 1986

Primary Examiner--Reinaldo P. Machado

Attorney, Agent, or Firm-Phillips, Moore, Lempio &

[51]

Int. cu .............................................. .. 1304c 1/22

Fmley

[52]

US. Cl. .................................... .. 182/63; 182/141;

[57]

[58] Field of Search .............. .. 182/631,82/.15%71,451%/1l418

182/127; 52/118 121 111

ABSTRACT

A Pedestal Scam! type having a base member a 116'

8601310 mast mounted vertically on the base member and

a work cage mounted in cantilever manner from the

[56]

References Cited

upper end of the mast. The majority of the nested tubu

U_$, PATENT DOCUMENTS

2948 363 8/1960 Hopfeld ............................ .. 182/141

lar mast sections are of rectangular cross-section and are

mm of thin'l'vaned sheet aluminum with mmded

2:966:956

corners and vert1ca1 stiffening ribs on each side thereof

V1961 Campbell .

____ " 182/63

3,509,955 5/1970 Mitchel}

3,931,698

4,003,163

132/615

extending the height thereof. Plastic slide blocks at the

52/118

inner corners of the upper end and at the outer corners

52/118

52

of the lower end of the mast section distribute the forces

between the sections to relatively large areas of the

1/ 1976 Ebersold ..

1/ 1977 Brady ---

4,004,695 V1977 Hockensmlth

''

4,168,008

9/1979

Granryd

..'. u

aluminum sheet which forms the mast sections.

.... .. 52/118

4,171,598 10/1979 Holmes ............................... .. 52/ 118

7 Claims, 6 Drawing Figures

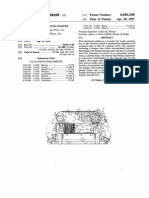

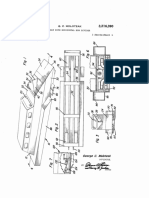

US. Patent' Apr. 14,1987 _

Sheet1of4

4,657,112

FIGURE 2

~6

HI.

QL:

8 .

"'l l

PF(5%?

3

= \

E, I

U. S. Patent Apr. 14,1987

ii

ShetZ of4

4,657,112

FIGURE 3

29

240

\ A

I

\

\ \(Q

33

"V

28

32

2?

[/7

'f

//7

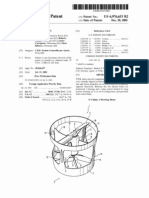

I U. S. Patent

Apr. 14,1987

FIGURE 6

Sheet4 0f4

I60

I61:

4,657,112

I60

16d

'

4,657,112

MAST CONSTRUCTION FOR PEDESTAL

SCAFFOLD

raising and lowering of the mast sections.

Other aspects and advantages of the invention will be

set forth in the course of the following detailed descrip

tion.

. TECHNICAL FIELD

This invention relates to movable pedestal type scaf

fold units such as shown in U.S. Pat. No. 4,397,373,

BRIEF DESCRIPTION OF THE DRAWINGS

In the drawings which form a part of the application,

and in which like parts are designated by like reference

numerals throughout the same.

issued Aug. 9, 1983, and application Ser. No. 781,221,

?led Sept. 27, 1985, and now U.S. Pat. No. 4,592,447,

issued June 3, 1986.

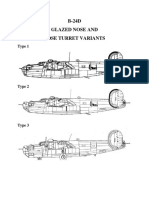

FIG. 1 is a perspective view of a personnel lift with a

BACKGROUND ART

telescopic mast constructed in accordance with the

present invention, the mast shown in retracted position.

Personnel lifts of the pedestal type exempli?ed by the

above patents typically have an upright mast mounted

FIG. 2 is a view as in FIG. 1 with the mast of FIG. 1

shown in an extended position.

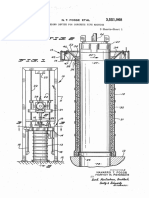

FIG. 3 is a simpli?ed cross-sectional view of the mast

on a relatively small base member, and a work cage

mounted on the mast for vertical movement.

The present invention is particularly directed to an

improved construction of the vertically extendible mast

of such scaffold units. For example, the mast of the U.S.

Pat. No. 4,397,373 comprises a plurality of side-by-side

parallel frame sections arranged to extend vertically

relative to each other. Typically, these mast sections

comprise opposed vertical extruded aluminum channels

connected together by a plurality of cross pieces. With

In a further aspect of the invention, chains and straps

?t into the narrow spaces between the mast sections for

of FIG. 1, showing the various stages thereof and the

apparatus for extending the mast.

20

FIG. 4 is a perspective view of one of the stages of

the mast of FIG. 1.

FIG. 5 is a vertical sectional view through portions of

the three innermost stages of the mast of FIG. 1.

FIG. 6 is a sectional view of the mast of FIG. 1.

DESCRIPTION OF THE PREFERRED

EMBODIMENTS

heavy and relatively expensive to manufacture. The

Referring now to the drawings, wherein is illustrated

weight of a scaffold unit of this type is an important

a preferred embodiment of the invention, FIG. 1 shows

consideration since these units must be moved from

place to place and loaded onto and off of trucks by the 30 a movable pedestal scaffold 10 having a base member 11

with wheels 12 at either end of the base member. As is

workmen using the scaffolds. The cost of construction

such construction, the mast sections are relatively

fold units to be sold at a price that can be afforded by

conventional in these type units, outriggers 13, each

with a vertically adjustable ground engaging member

purchasers. The weight of the mast sections is, of

14, are attachable to the base member 11 to provide an

expensive to manufacture. In particular, aluminum ex

trusions require costly dies for the extrusion process and

in the drawings, the work cage is spaced horizontally

is also an important consideration in enabling the scaf

course, also related to the cost of manufacture in that 35 extended area of support for the unit.

At one end of the base member 11, a vertical mast 16

the more the weight, the more the material that is used

extends upwardly. As seen in FIG. 2, the mast 16 com

in the mast.

prises six telescoped mast sections 16a-f the outermost

The mast of the Ser. No. 781,221 application com

mast section 16a being mounted on the base member 11.

prises a plurality of telescopically arranged aluminum

A

work cage 17 is mounted, by cantilever arm 18, to the

extrusions. Again, such a mast is relatively heavy and

the wall thickness of an extruded column must inher

ently be relatively great. The outermost mast sections in

particular will have considerable weight and be quite

high in manufacturing cost.

The main object of the present invention is to provide

upper end of the innermost mast section 16f As shown

from the innermost mast section 16f and extends down

wardly from the upper end of the mast section 16f and

along one side of the mast.

A ladder 19 on the base member 11 enables a work

man to climb up to the work cage when the cage is at its

downwardly retracted position of FIG. 1. Also carried

a pedestal type scaffold with a extendable mast which is

in the base member 11, as generally indicated at 20, is

much lighter in weight and more economical in manu 50 apparatus for powering the elevation of the telescopic

facture than those of the prior art.

mast 16 and work cage 17. Typically, such apparatus 20

will

include a hydraulic reservoir, a ?uid pump and

DISCLOSURE OF THE INVENTION

batteries for driving the pump.

The present invention is directed overcoming the

FIG. 3 shows in simpli?ed form the apparatus for

problems set forth above and towards ful?lling the 55 vertical extension of the sections 16b-f of mast 16. A

above object.

extensible ?uidoperated ram 21 is vertically disposed

In general, the present invention provides a pedestal

centrally of the mast 16, with its piston member 22

scaffold having a base member, a mast mounted on the

secured to the lower end of the outermost mast section

base member, and a work cage carried by the upper end

16a and with its cylinder member 23 secured to the

of the mast, the mast including a plurality of nested 60 lower end of the next innermost mast section 16b. A

tubular mast sections in which the majority of the mast

sprocket 24 is mounted on the upper end of ram 21 and

sections are made of thin-walled sheet aluminum, with

chain 26 extends around sprocket 24 with one end of the

rounded corners and vertical stiffening ribs on each side

chain 26 being connected to the lower end of the outer

of the section. Plastic slide blocks at the upper and

most mast section 160 and with the other end of the

lower ends of the mast sections and at the four corners 65 chain being connected to the lower end of mast section

of the mast sections have mast engaging surfaces com

16c.

plimentary in shape to the rounded corners of the mast

Additional sprockets 27, 28 and 29 are mounted on

the upper ends of mast sections 16c, 16d and 16e, respec

sections.

4,657,112

tively. Chain 31 extends from the upper end of mast

section 16b up over sprocket 27 and then down to the

lower end of mast section 16d. Likewise, chain 32 runs

from the upper end of mast section 160 upward over

sprocket 28 and down to the lower end of mast section

16e, while chain 33 runs from the upper end of mast

section 16d up over sprocket 29 and down to the lower

end of the innermost mast section 16}:

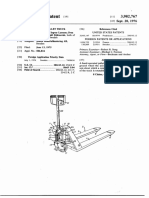

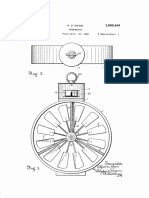

FIGS. 4-6 illustrate the details of the sections of the

mast 12. FIG. 4 illustrates, in perspective, mast section

16c. As is shown, mast section 160 is made from two

identical U-shaped channels 41 and 42 formed from

In operation, vertical extension of ram 21 will di

rectly move mast section 16b upwardly from mast sec

thin-walled sheet aluminum. By way of example, per

sonnel lifts have been built in accordance with the pres

tion 160. This relative movement will in cause chain 26

to pull mast section 160 upwardly relative to mast sec

tion 16b. In turn, this relative upward movement will

cause chain 31 to pull mast section 16d upwardly rela

tive to mast section 16c. Likewise, chain 32 will pull

mast section 162 upwardly relative to section 16]: and

ent invention with a 38 foot maximum platform height

chain 33 will pull the innermost mast section 16f up

wardly relative to section l6e.

such a hang up, the operator can then cause the mast to

extend upwardly so that the obstruction can be re

moved. After that, retraction can take place in a normal

manner.

and using 5052 H32 sheet aluminum with a 0.060 inch

wall thickness for the sheet aluminum mast sections.

Each U-shaped channel 41 and 42 is formed will

substantially rounded corners 43 and is deformed from

the plane of the base side 44 of the channel to provide a

stiffening rib 46 extending the full height of the channel.

The legs 47 of the channel are also deformed from the

The lift forces exerted by the chains on the mast

planes of the legs to provide offset end portions 48

sections are necessarily offset from the central axis of 20 parallel to the planes of the legs. The two channel sec

the mast. However, the offset forces are balanced to a

tions 41 and 42 are placed with the offset portions 48

considerable degree by the weight of the work cage and

adjacent to each other and are joined together by rivets

its occupant which are also offset from the central axis

49 along the height of the mast section. The offset por

of the mast, but on the side of the mast opposite from

tions thus form a stiffening rib.

the chain mechanism.

25

An upper collar 51, preferably of cast aluminum,

The chains and sprockets described above are prefer

surrounds the upper end of the joined together sheet

ably doubled for the stages to equalize loading forces

aluminum channels 41 and 42, the collar 51 having ver

and to provide backup support in the event of a chain

tical ?anges 52, to which the channels 41 and 42 are

failure.

secured by rivets 53, and an outwardly projecting hori

Still with reference to FIG. 3, a plurality of fabric 30 zontal flange 54. The collar 51 protects the upper edges

straps 36, 37, 38 and 39, made for example of nylon

of the sheet aluminum channels and maintains the rect

material, interconnect the mast sections on the side of

angularity of the mast section. In addition, the collar 51

the mast opposite to the chains described above, with

supports sprocket 27 and provides a rigid member to

each strap being secured to the upper end of a mast

which chains 32 are secured. Likewise, the collar 51

section and extending down to and around the lower

provides a rigid member for attachment of strap 38.

end of the next innermost mast section and then being

A similar, but inverted, lower collar 56, also prefera

secured to the lower end of the then next innermost

bly of cast aluminum, extends around the inside of the

mast section. For example, strap 36 is secured to mast

joined together sheet aluminum channels and is secured

section 16a, extends down around the lower end of mast

thereto by rivets 57. This collar likewise protects the

section 1611 and is secured to the lower end of mast 40 lower edges of the channels 41 and 42, maintains the

section 160.

rectangularity of the mast section, and provides a rigid

In normal operation, the mast 16 will retract down

member for attachment to the strap 36 (not shown in

wardly with release of hydraulic ?uid from the ram 21

FIG. 4) secured thereto. For other mast sections, the

causing mast secsection 16b to move downwardly. The

lower collar 51 also provides a rigid member to which

weight of the work cage will cause the other mast sec 45 chains 31, 32 and 33 may be secured.

tions to lower as the various sprockets 24, 27, 28 and 29

Each of the aluminum sheet mast sections 16b~e has

move downwardly. During such operation, the straps

an upper and lower collar 51, 56 generally as described

36-39 merely follow the downward movement of the

in connection with mast section 16c. The outermost

mast sections and bear no stress.

mast section 160 has an upper collar 51 thereon, but no

If however one of the mast sections should hang up 50 lower collar 56 is needed since the attachment of the

during retraction then the straps 36-39 will serve to

mast section 160 to the frame member 11 serves the

prevent retraction of lower mast sections. For example,

purpose.

suppose mast section 16d were to hang up on some

The preferred embodiment shown herein has an ex

obstruction as it was moving downwardly. The lower

truded aluminum tube as the innermost mast section 16f

end of mast section 16d would then be ?xed against 55 Because of the relatively small cross-sectional modulus

further downward movement. Since the upper end of

of this innermost mast section, a thicker walled alumi

the outermost mast section 160 is likewise ?xed against

num sheet would be necessary to withstand the high

vertical movement, straps 36 and 37 will support mast

bending stresses. Further, the mast was designed so that

sections 16b and 16c and prevent them from moving

the innermost mast section has a 4X4 inch size which is

downwardly. Chains 32 and 33 will likewise prevent 60 a standard, commercially available aluminum extrusion,

with a % inch wall thickness.

16f above the hung-up mast section 16d.

For a six stage mast as illustrated herein, with a maxi

Thus, if any mast section is externally prevented from

mum platform height of 38 feet, the mast sections will

retracting downwardly, the straps and chains will pre

range in height from about 7 feet for mast section 16a to

vent all of the other mast sections from retracting. The 65 about 5% feet for the innermost mast section 16f. The

any downward movement of the mast sections 16e and

use of straps as disclosed is very advantageous since

they are strong, ?exible and can fit easily into the very

restricted spaces between the mast sections. In case of

cross-sectional area of the mast sections ranges from

about 9X12 inches for mast section 16a to 4X4 inches

for the mast section 16f

4,657,112

With further reference to FIG. 4, the mast section 16c

has a set of four plastic slide blocks 61 mounted on the

upper end of the mast section, with one of the slide

blocks being mounted at each of the four inside corners

of the mast section and secured thereto, as by screws 62,

the slide blocks being approximately 6 inches in height.

Each slide block has an outer surface 63 of a shape

complementary to the shape of the inside comer of the

mast section to which it is secured and an inner surface

64 of a shape complementary to the shape of the outside

comer of the next inner mast section 16d adjacent

thereto. Preferably, the slide blocks are made of

UHMW (ultra high molecular weight) high density

polyethylene. The slide blocks are placed at the corners

of the mast sections where the mast sections are stron

gest and where the least amount of deformation will

occur when the mast is under'load. The rounded cor

ners of the mast sections and the complementary shaped

slide blocks serve to distribute the bearing pressure on

the slide blocks and to distribute the force from the slide

blocks onto a relatively large area of the thin-walled

aluminum sheet mast sections.

In like manner, mast section 16c has a set of four slide

blocks 66 mounted on the lower end of the mast section

at the outside of each of the four corners. Slide blocks

66 each have an inner surface 67 of a shape complemen

tary to the shape of the outside corner of mast section

.160 to which it is mounted and an outer surface 68 of a

shape complementary to the shape of the inner corner

of the next mast section adjacent thereto. Again, the

shape of the slide blocks spreads the forces over a sub

stantial area of the aluminum sheet instead of concen

trating them at a sharp corner.

As may be seen from the foregoing, the present in 35

vention provides a mast that is relatively light in weight

and relatively inexpensive to manufacture because it is

largely made out of thin walled aluminum sheet rather

than thicker and considerably more expensive alumi

num extrusions. The relatively large rectangular cross

section of the mast section provides for a very ef?cient

distribution of material while providing a very rigid

6

and a vertical stiffening rib formed on each side and

extending the height thereof,

(c) a ?rst set of four plastic slide blocks mounted on

the upper end of each mast section except the in

nermost section, each of the four slide blocks in a

set being mounted at a different one of the inside

corners of a mast section, each slide block having

an outer surface of a shape complementary to the

shape of the inside corner of the mast section to

which it is mounted and having an inner surface of

a shape complementary to the shape of the outside

corner of the next inner mast section adjacent

thereto,

(d) a second set of four plastic slide blocks mounted

on the lower end of each mast section except the

outermost section, each of the four slide blocks of a

set being mounted at a different one of the outside

comers of a mast section, each slide block having

an inner surface of 'a shape complementary to the

shape of the outside comer to which it is mounted

and an outer surface of a shape complementary to

the shape of the inner corner of the next outer mast

section adjacent thereto,

(e) a work cage mounted on the upper end of the

innermost of said mast sections, said work cage

being spaced horizontally from said innermost mast

section,

(i) an extensible ram vertically disposed in said mast

and having a piston member and a housing mem

ber, one of which members is secured to the lower

end of the outermost of said mast sections and the

other of which members is secured to the lower

end of the next innermost mast section,

(g) extending means for upwardly extending all of

said mast sections which are inwardly of the next to

outermost mast sections in response to upward

movement of said next to outermost mast section

relative the outermost mast section, said means

including a plurality of chains interconnecting said

mast sections and located on the side of said mast '

sections opposite to said work cage.

2. A pedestal scaffold as set forth in claim 1 wherein

mast which will resist bending forces from the cantile

at least one of said sheet aluminum mast sections com

ver mounted work cage and torsional forces impared by

prises two identical U-shaped channels formed from

reaction forces by a workman working to his side while 45 sheet aluminum, with each leg of the channel having a

in the cage.

parallel offset end portion, the two U-shaped channels

The foregoing description of a preferred embodiment

being disposed with the offset portion adjacent to and

of the invention has been presented for purposes of

illustration and description. It is not intended to be

riveted to each other.

3. A pedestal scaffold as set forth in claim 2 wherein

exhaustive or to limit the invention to the precise form 50 each of said sheet aluminum mast sections inwardly of

disclosed, and obviously many modi?cations and varia

the outermost mast section and outwardly of the inner

tions are possible in light of the above teaching. The

most mast section includes an upper collar around and

embodiment was chosen and described in order to best

secured to the outside of the upper end of the mast

explain the principles of the invention and its practical

section and a lower collar around and secured to the

application to thereby enable others in the art to best 55 inside of the mast section.

utilize the invention in various embodiments and with

4. A pedestal scaffold as set forth in claim 3 wherein

various modi?cations as are suited to the particular use

said extending means includes a sprocket mounted on

contemplated. It is intended that the scope of the inven

the upper collar of one of said mast sections and a chain

tion be de?ned by the claims appended hereto.

We claim:

1. A pedestal scaffold comprising:

(a) a base member having ground engageable sup

ports,

trained around said sprocket, said chain being secured

to the upper collar of the next outermost mast section

and to the lower collar of the next innermost mast sec

tion.

5. A pedestal scaffold as set forth in claim 4, and

(b) a vertical mast mounted on said base member, said

further including a plurality of fabric strap members, on

mast having a plurality of telescopically nested 65 the side of said mast sections opposite to said chains,

each strap being secured to the upper end of a mast

tubular mast sections of rectangular cross-section,

the majority of which mast sections are made from

section and extending down to and around the lower

end of the next innermost mast section and being se

thin-walled sheet aluminum with rounded corners

4,657,112

cured to the lower end of the then next innermost mast

7. A pedestal scaffold as set forth in claim 6, and

section.

6. A pedestal scaffold as set forth in claim 4 wherein

said extending means includes a sprocket mounted on

the upper end of the ram member which is secured to

further including a plurality of fabric strap members, on

the side of said mast sections opposite to said chains,

each strap being secured to the upper end of a mast

section and extending down to and around the lower

said next innermost mast section and a chain trained

around said sprocket, said chain being secured at one

end to the outermost mast section and being secured at

end of the next innermost mast section and being se

cured to the lower end of the then next innermost mast

section.

t

the other end to the then next innermost mast section.

15

20

25

35

45

55

65

You might also like

- ProtoDocument456 pagesProtoissloNo ratings yet

- Faa Form 5100 1 Airport Pavement DesignDocument4 pagesFaa Form 5100 1 Airport Pavement DesignElyas TawerghiNo ratings yet

- FVSysID ShortCourse 1 Introduction1Document28 pagesFVSysID ShortCourse 1 Introduction1Nuta ConstantinNo ratings yet

- Air Regulations CPL Level QuestionsDocument80 pagesAir Regulations CPL Level QuestionsprachatNo ratings yet

- Life Cycle Assessment of Offshore and Onshore Sited Wind Farms.Document68 pagesLife Cycle Assessment of Offshore and Onshore Sited Wind Farms.K.RamachandranNo ratings yet

- Us 2912244Document9 pagesUs 2912244alexhkiNo ratings yet

- Jurnal Bubut FixsafasfasfDocument6 pagesJurnal Bubut FixsafasfasfAdiBimaSanjaya100% (1)

- Patente Rotative Winged Aircraft Larsen 1938 Us2111975Document8 pagesPatente Rotative Winged Aircraft Larsen 1938 Us2111975Mariela TisseraNo ratings yet

- Unlted States Patent (19) (11) Patent Number: 4,660,248: IllllllDocument15 pagesUnlted States Patent (19) (11) Patent Number: 4,660,248: Illllll113314No ratings yet

- Us 4207797Document7 pagesUs 4207797fghdfjerNo ratings yet

- @et E7, 96? J. P. Yates: Filed March l2, 1965Document3 pages@et E7, 96? J. P. Yates: Filed March l2, 1965Ye PhoneNo ratings yet

- Patented May 27, 1919.: S. H. GarstDocument4 pagesPatented May 27, 1919.: S. H. GarstKrozeNo ratings yet

- April 2, 1968.: Filed Sept 26, 1966Document7 pagesApril 2, 1968.: Filed Sept 26, 1966Pedja Bekic100% (1)

- United States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDocument7 pagesUnited States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDanister GladwinNo ratings yet

- United States Patent: (12) (10) Patent N0.: US 7,377,754 B2Document23 pagesUnited States Patent: (12) (10) Patent N0.: US 7,377,754 B2Selvaraji MuthuNo ratings yet

- United States Patent: SimpsonDocument5 pagesUnited States Patent: Simpsonاحمد عبدالكريمNo ratings yet

- Day v. Fair Haven & Westville R. Co., 132 U.S. 98 (1889)Document4 pagesDay v. Fair Haven & Westville R. Co., 132 U.S. 98 (1889)Scribd Government DocsNo ratings yet

- Braiding MachineDocument7 pagesBraiding Machinejojaberi100% (1)

- Us 6131519Document4 pagesUs 6131519dgfhjsdg hfsdhyjNo ratings yet

- United States Patent 1191Document13 pagesUnited States Patent 1191ddeeff715No ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2014/0021016 A1Document14 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2014/0021016 A1Kalai SelvanNo ratings yet

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANDocument6 pagesWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaNo ratings yet

- US1685447Document5 pagesUS1685447Redirecting DecoyNo ratings yet

- Dec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetDocument6 pagesDec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetEstebanPortilloNo ratings yet

- European Patent Specification F01D 11/00: Printed by Jouve, 75001 PARIS (FR)Document10 pagesEuropean Patent Specification F01D 11/00: Printed by Jouve, 75001 PARIS (FR)shamsNo ratings yet

- Us1434007 PDFDocument5 pagesUs1434007 PDFsebastian escobarNo ratings yet

- United States Patent: BauvinDocument3 pagesUnited States Patent: Bauvingibson_sx87No ratings yet

- ?T T T - FT ?: April 9, 1968Document6 pages?T T T - FT ?: April 9, 1968Pooria1989No ratings yet

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Document13 pages(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuNo ratings yet

- Get. 15, 1968 J. A. Gregoire 3,405,901: Filed July 5, 1966 3 Sheets-Sheet LDocument6 pagesGet. 15, 1968 J. A. Gregoire 3,405,901: Filed July 5, 1966 3 Sheets-Sheet LFercon DocenciaNo ratings yet

- Us 3026089Document4 pagesUs 3026089takanobu ouraNo ratings yet

- Fieie) : ' Jan. 5, 1971 N. T. Fosse Etal 3,551,958Document6 pagesFieie) : ' Jan. 5, 1971 N. T. Fosse Etal 3,551,958adrianomc25No ratings yet

- Vernier DesignDocument9 pagesVernier DesignRakeshNo ratings yet

- Copy No, 3: Aircraft Circltars::Ati0Ral Avisory Colaiittee Fot AeronauticsDocument10 pagesCopy No, 3: Aircraft Circltars::Ati0Ral Avisory Colaiittee Fot Aeronauticsrritter78No ratings yet

- M © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815Document3 pagesM © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815James LindonNo ratings yet

- Tank ErectionDocument20 pagesTank ErectionPlok Caca piiii100% (5)

- US3982767Document6 pagesUS3982767takanobu ouraNo ratings yet

- Berthier Us1366863Document9 pagesBerthier Us1366863cll1968No ratings yet

- European Patent Application F04B 27/10: Rotor For Variable Displacement Swash Plate CompressorDocument16 pagesEuropean Patent Application F04B 27/10: Rotor For Variable Displacement Swash Plate CompressorSelvaraji MuthuNo ratings yet

- US2427676Document4 pagesUS2427676udrogono2No ratings yet

- Illlllllllllilllllllllilllllllllli: United States Patent (191Document3 pagesIlllllllllllilllllllllilllllllllli: United States Patent (191dgfsduuwioNo ratings yet

- US1302577Document4 pagesUS1302577dfsdfsdfsdfNo ratings yet

- Nov. 9, 1965 G. C. Molotzak 3,216,390Document5 pagesNov. 9, 1965 G. C. Molotzak 3,216,390احمد عبدالكريمNo ratings yet

- Us 2345069Document4 pagesUs 234506916f628aNo ratings yet

- Dec. 10, 1940. E. N. Necke 2,224,606Document4 pagesDec. 10, 1940. E. N. Necke 2,224,606Mary HullNo ratings yet

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- Balança 4182-A (Mecanica) - Revisão 02.08.2007 PDFDocument12 pagesBalança 4182-A (Mecanica) - Revisão 02.08.2007 PDFKadson AmaralNo ratings yet

- Mannlicher Us1008162Document6 pagesMannlicher Us1008162cll1968No ratings yet

- 6ave. E: Sept. 13, 1966 F. Rompelen Etal 3,273,061Document4 pages6ave. E: Sept. 13, 1966 F. Rompelen Etal 3,273,061mohamed hemdanNo ratings yet

- RR PatentsDocument7 pagesRR PatentsAlan SmartNo ratings yet

- US3173686 (Coin-Op Kiddie Ride)Document8 pagesUS3173686 (Coin-Op Kiddie Ride)ENo ratings yet

- Pantente Primer DollyDocument6 pagesPantente Primer DollyJorge SotoNo ratings yet

- Umted States Patent (191 (11) 4,173,936: Secord Et Al. (45) Nov. 13, 1979Document8 pagesUmted States Patent (191 (11) 4,173,936: Secord Et Al. (45) Nov. 13, 1979venkatrangan2003No ratings yet

- Anemometer - US1905444Document4 pagesAnemometer - US1905444Aaron Choco De GuzmanNo ratings yet

- United States Patent: Perlo Et Al. (45) Date of Patent: Dec. 20, 2005Document10 pagesUnited States Patent: Perlo Et Al. (45) Date of Patent: Dec. 20, 2005tristanNo ratings yet

- Rig-E???': Gill!Document6 pagesRig-E???': Gill!luiscremaschiNo ratings yet

- BYY "So: June 7, 1966 M, A Brown 3,254,776Document7 pagesBYY "So: June 7, 1966 M, A Brown 3,254,776Yu YangNo ratings yet

- Sept. 24, 1929. W. Siders: Filed Nov. 5. 1925Document3 pagesSept. 24, 1929. W. Siders: Filed Nov. 5. 1925monem2014No ratings yet

- United States Patent (191: Lown (45) Nov. 11, 1980Document4 pagesUnited States Patent (191: Lown (45) Nov. 11, 1980HamedJamshidiNo ratings yet

- US2228469Document4 pagesUS2228469George AcostaNo ratings yet

- LLL Billion" .Vizíaßllllla: July 14, 1959 F.V F. EhrlchDocument6 pagesLLL Billion" .Vizíaßllllla: July 14, 1959 F.V F. EhrlchDouglas SanchezNo ratings yet

- O/ie/7 Covaz: Nov. 4, 1941. O. H. Cottingham 2,261,231Document5 pagesO/ie/7 Covaz: Nov. 4, 1941. O. H. Cottingham 2,261,231VyacheslavNo ratings yet

- 1001-Experimental Evaluation of A Digital Hydraulic Power Management SystemDocument15 pages1001-Experimental Evaluation of A Digital Hydraulic Power Management SystemPhanHathamNo ratings yet

- De Chinh Thuc N3 PDFDocument95 pagesDe Chinh Thuc N3 PDFPhanHatham100% (1)

- 10 5445ir1000070929 PDFDocument239 pages10 5445ir1000070929 PDFPhanHathamNo ratings yet

- General Brochure HESS Group EnglishDocument19 pagesGeneral Brochure HESS Group EnglishPhanHathamNo ratings yet

- IndexDocument197 pagesIndexPhanHathamNo ratings yet

- 0-Development of New Hybrid ExcavatorDocument9 pages0-Development of New Hybrid ExcavatorPhanHathamNo ratings yet

- ZKL Brno Katalog 2007 enDocument74 pagesZKL Brno Katalog 2007 enPhanHathamNo ratings yet

- English Rhetoric PDFDocument1 pageEnglish Rhetoric PDFPhanHathamNo ratings yet

- PDF Manuel ERREM Coupler 2012 1 UK PDFDocument7 pagesPDF Manuel ERREM Coupler 2012 1 UK PDFPhanHathamNo ratings yet

- TG17 - 15 Identification of EN74-1 CouplersDocument2 pagesTG17 - 15 Identification of EN74-1 CouplersPhanHathamNo ratings yet

- General KnowledgeDocument25 pagesGeneral KnowledgeShakil KhanNo ratings yet

- Solid Propulsion GoDocument5 pagesSolid Propulsion GorichiNo ratings yet

- IGBT As A SwitchDocument4 pagesIGBT As A SwitchTharanga M PremathilakeNo ratings yet

- Gujarat Technological University: Subject Name: Semester - VIIDocument4 pagesGujarat Technological University: Subject Name: Semester - VIIKSghNo ratings yet

- TCAR 1 - Part 66 AMC - GM - VER 04 - VER FINALDocument208 pagesTCAR 1 - Part 66 AMC - GM - VER 04 - VER FINALjakara tongchimNo ratings yet

- Growth and Evolution of Civil Aviation Industry in IndiaDocument26 pagesGrowth and Evolution of Civil Aviation Industry in Indiakrupa290490No ratings yet

- Unit 2 ExercisesDocument10 pagesUnit 2 ExercisesAlberto Rivas CidNo ratings yet

- Eddy Current TestingDocument48 pagesEddy Current TestingBhuvanesh Ponnan88% (8)

- Fuel PenaltiesDocument5 pagesFuel PenaltiesAndrey DanilchenkoNo ratings yet

- Ballistic CoefficientDocument6 pagesBallistic CoefficientMB-RPNo ratings yet

- Paper Helicopter: Time: 15 Minutes Difficulty: HintDocument3 pagesPaper Helicopter: Time: 15 Minutes Difficulty: HintPowerhouse MuseumNo ratings yet

- Familiarization Bridge and EquipmentDocument30 pagesFamiliarization Bridge and Equipmentsimon_midjaja100% (1)

- Aircraft Fleet Serviceability StatusDocument2 pagesAircraft Fleet Serviceability Statusinghar lalNo ratings yet

- Aeromag Asia-March April 2020Document64 pagesAeromag Asia-March April 2020Vlad AlexandruNo ratings yet

- Aircraft D TypesDocument34 pagesAircraft D TypesEdgar Zacapa100% (3)

- Piston Ring ApplicationDocument6 pagesPiston Ring ApplicationMoaed KanbarNo ratings yet

- IQOQ ProtocolDocument4 pagesIQOQ ProtocolVijay RajaindranNo ratings yet

- 05 Structural LoadingsDocument9 pages05 Structural LoadingsMUHAMMAD ILHAM DIRGANTARANo ratings yet

- Dynamics Solns Ch05Document191 pagesDynamics Solns Ch05jbeaubrun93100% (2)

- Ac 120-76aDocument32 pagesAc 120-76aAndrewNo ratings yet

- Bombardier: BD-700-1A10 Global Express XRSDocument4 pagesBombardier: BD-700-1A10 Global Express XRSHog FliesNo ratings yet

- Friction Loss in PipesDocument12 pagesFriction Loss in Pipesannussciah suppiah100% (3)

- Natural Ventilation - Wikipedia, The Free EncyclopediaDocument7 pagesNatural Ventilation - Wikipedia, The Free EncyclopediadasaNo ratings yet

- MCQ 2Document5 pagesMCQ 2gaya8404No ratings yet

- MIGDocument7 pagesMIGMuhammad RedzuanNo ratings yet