Professional Documents

Culture Documents

Column Wall Design

Column Wall Design

Uploaded by

Civilax.comCopyright:

Available Formats

You might also like

- Foundation Dynamic AnalysisDocument27 pagesFoundation Dynamic AnalysisCatherine Mohanji GeraNo ratings yet

- Sub 01 012Document21 pagesSub 01 012ARYA JENA100% (1)

- Prestressed-Precast Design SpreadsheetDocument6 pagesPrestressed-Precast Design SpreadsheetCivilax.com100% (3)

- Box Culvert Calculation As Per BD3101Document21 pagesBox Culvert Calculation As Per BD3101Pilippenge Asanka Iraj LaknathaNo ratings yet

- Design of Sanitary Wastewater ManholesDocument4 pagesDesign of Sanitary Wastewater Manholessajeerala0% (1)

- Appendix: Appendix A1: Example PSSR Completion FormDocument5 pagesAppendix: Appendix A1: Example PSSR Completion FormSumantrra ChattopadhyayNo ratings yet

- Project No. Date - Sheet No. Computed by 1 of 9 - Subject - Checked by Approved byDocument9 pagesProject No. Date - Sheet No. Computed by 1 of 9 - Subject - Checked by Approved bysaravananNo ratings yet

- Al Tala'A: TECHINAL Industries (L.L.C)Document1 pageAl Tala'A: TECHINAL Industries (L.L.C)premNo ratings yet

- Stability CheckDocument2 pagesStability ChecksaravananNo ratings yet

- POLEFDNDocument10 pagesPOLEFDNcoolkaisyNo ratings yet

- PT Foundation ApprovedDocument6 pagesPT Foundation ApprovedSujit RasailyNo ratings yet

- Foundation F1 Design CalculationDocument30 pagesFoundation F1 Design CalculationvasudhaNo ratings yet

- WallDocument44 pagesWallUmesh ChamaraNo ratings yet

- Design of Gantry GirderDocument9 pagesDesign of Gantry GirderAzim KadriNo ratings yet

- Slab Manual DesignDocument1 pageSlab Manual DesignAtul ShrivastavaNo ratings yet

- Gutter DesignDocument6 pagesGutter Designtawas200% (1)

- Isolated Footing (ACI)Document4 pagesIsolated Footing (ACI)Boubakeur FerkousNo ratings yet

- Wind CalculationDocument6 pagesWind CalculationKhairul JaggerNo ratings yet

- Base Plate Design BS CodeDocument3 pagesBase Plate Design BS CodeFodor ZoltanNo ratings yet

- 00calculation Sheet For MMII Compressor Shed1Document31 pages00calculation Sheet For MMII Compressor Shed1clarkgaguiNo ratings yet

- Combined Footing Design1Document39 pagesCombined Footing Design1John Carlo Amodia0% (2)

- STAAD - PRO - Single PoleDocument2 pagesSTAAD - PRO - Single PoleAmol GoleNo ratings yet

- BoxDocument8 pagesBoxJack Danielz LubisNo ratings yet

- Pad Foundation DesignDocument4 pagesPad Foundation Designg4goharNo ratings yet

- Isolated FootingDocument289 pagesIsolated FootingjoanreyNo ratings yet

- Precast Column - Stability CalculationDocument1 pagePrecast Column - Stability Calculationarif_rubinNo ratings yet

- Combined Footing Design - UjjwalDocument25 pagesCombined Footing Design - UjjwalUjjwal MondolNo ratings yet

- BS 8110:part 1: 1985, Section Three, Table 3.9: C S V 1/3 1/4 MDocument7 pagesBS 8110:part 1: 1985, Section Three, Table 3.9: C S V 1/3 1/4 MnaconnetNo ratings yet

- RCC94 Two-Way Slabs (Tables) GGGDocument3 pagesRCC94 Two-Way Slabs (Tables) GGGThomas OluwafemiNo ratings yet

- Reference Calculations Output: N/A Project CalculationDocument2 pagesReference Calculations Output: N/A Project CalculationRyan De LeonNo ratings yet

- Anchor Bolt Design For Portal and Connecting BridgeDocument2 pagesAnchor Bolt Design For Portal and Connecting BridgeAbhinav YadavNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument103 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectToy GamesNo ratings yet

- Foundation Design For 66kV Steel Poles Bo-Kenema-SOIL CLASS 2A-08-11-21Document22 pagesFoundation Design For 66kV Steel Poles Bo-Kenema-SOIL CLASS 2A-08-11-21BAWA ALEXNo ratings yet

- Load Combination For Steel Design Per BS en 1990 EditionDocument2 pagesLoad Combination For Steel Design Per BS en 1990 EditionAsaru Deen100% (2)

- General Purpose Worksheet: Wind LoadingDocument11 pagesGeneral Purpose Worksheet: Wind LoadingabuzahrauNo ratings yet

- Grating1 2Document17 pagesGrating1 2Dhanraj VasanthNo ratings yet

- BeamDocument7 pagesBeamsomumallidiNo ratings yet

- Slab Design-@ Design OfficeDocument40 pagesSlab Design-@ Design OfficeShamen AmarasekaraNo ratings yet

- Ledge Design HCSDocument3 pagesLedge Design HCSsidiq7No ratings yet

- Design of Base PlateDocument4 pagesDesign of Base PlatesanggythaNo ratings yet

- WALLPRES ExcavationDocument11 pagesWALLPRES ExcavationShekh Muhsen Uddin AhmedNo ratings yet

- M3D - SampleProblemSet ACI PDFDocument6 pagesM3D - SampleProblemSet ACI PDFasaisenthilNo ratings yet

- ACI BendDocument3 pagesACI Bendمصطفى عبدالرحيمNo ratings yet

- DESIGN OF SLAB - ContdDocument4 pagesDESIGN OF SLAB - ContdmeenuNo ratings yet

- Wind Load CalculationDocument2 pagesWind Load CalculationWangTFNo ratings yet

- Rean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionDocument11 pagesRean'S Building 5/24/2002 Angle Plate Design: Framed Beam Connectionmhel_almoNo ratings yet

- Load Combination - Various CodesDocument6 pagesLoad Combination - Various CodesAlex ImmanuelNo ratings yet

- Design Isolated FootingDocument4 pagesDesign Isolated FootingMaheshreddyNo ratings yet

- Client Comment Response - DG FoundationDocument7 pagesClient Comment Response - DG FoundationAnnelzNo ratings yet

- Minaret EQDocument4 pagesMinaret EQGandhi HammoudNo ratings yet

- VMS Gantry DesignDocument14 pagesVMS Gantry DesignNIRMAN INFRASTRUCTURESNo ratings yet

- Security Tower Analysis ReportDocument30 pagesSecurity Tower Analysis ReportdovermanNo ratings yet

- Structural Design Calculations Precast Boundary WallDocument35 pagesStructural Design Calculations Precast Boundary WallrenishkavukattNo ratings yet

- Beam - Deflection CheckDocument8 pagesBeam - Deflection CheckEko Bayu AjiNo ratings yet

- Pad Foundation Example TeddsDocument7 pagesPad Foundation Example TeddsWei Hong TehNo ratings yet

- Entrance B: 1008 72 CHS 559x25 (S355) 80.64 1314 72 CHS 610x28 (S355) 105.12Document2 pagesEntrance B: 1008 72 CHS 559x25 (S355) 80.64 1314 72 CHS 610x28 (S355) 105.12suman_civilNo ratings yet

- Design of Purlin: 1.15 M 4.2 M UPN120 1 5.71 Loads 13.3 KG/M 10 100 115 Bending Moment Loads Major Axis Minor Axis UnitDocument3 pagesDesign of Purlin: 1.15 M 4.2 M UPN120 1 5.71 Loads 13.3 KG/M 10 100 115 Bending Moment Loads Major Axis Minor Axis UnitSudhakar KrishnamurthyNo ratings yet

- Load Combinations and Snow Load According To NBC 2015Document16 pagesLoad Combinations and Snow Load According To NBC 2015MartialNo ratings yet

- Lashing Lug Round Bar Design: 1. GeneralDocument3 pagesLashing Lug Round Bar Design: 1. GeneralinnovativekarthiNo ratings yet

- Raft DesignDocument8 pagesRaft Designramesh_madkatte1082No ratings yet

- RCC Bund Wall Without Shear KeyDocument21 pagesRCC Bund Wall Without Shear Keynhulugalla100% (1)

- RCC Bund Wall With Shear KeyDocument27 pagesRCC Bund Wall With Shear Keynhulugalla100% (1)

- Test Tank TK 1527 Equal DepthDocument20 pagesTest Tank TK 1527 Equal DepthnhulugallaNo ratings yet

- Tank Sample 최종Document34 pagesTank Sample 최종anon_548256226No ratings yet

- Pile Design SheetDocument14 pagesPile Design SheetKhader Abu-dagga75% (8)

- Footing Upon Pile DesignDocument5 pagesFooting Upon Pile DesignCivilax.comNo ratings yet

- (Bore Hole No. 2) : Calculation Spec.: NO. Soil Bearing & Pile Capacity REV. No.: 0Document26 pages(Bore Hole No. 2) : Calculation Spec.: NO. Soil Bearing & Pile Capacity REV. No.: 0mayureshNo ratings yet

- Shear Design SpreadsheetDocument15 pagesShear Design SpreadsheetCivilax.com0% (1)

- Pile Length CalculationDocument3 pagesPile Length CalculationCivilax.comNo ratings yet

- LdgPiles PILE DESIGN SPREADSHEETDocument7 pagesLdgPiles PILE DESIGN SPREADSHEETCivilax.comNo ratings yet

- Lateral Capacity of Pile (FEM)Document26 pagesLateral Capacity of Pile (FEM)Civilax.comNo ratings yet

- Test Pile Loading RecordDocument14 pagesTest Pile Loading RecordCivilax.com100% (1)

- Pile Geotechnical &structural Design Using SPT ValuesDocument12 pagesPile Geotechnical &structural Design Using SPT ValuesCivilax.comNo ratings yet

- AASHTO GeoTechnical Design of PileDocument6 pagesAASHTO GeoTechnical Design of PileCivilax.comNo ratings yet

- Road Development Authority: Verification Year 2016 Physical Mesurment SheetDocument86 pagesRoad Development Authority: Verification Year 2016 Physical Mesurment SheetCivilax.comNo ratings yet

- Bearing Capacity All MethodsDocument2 pagesBearing Capacity All MethodsJayChristian QuimsonNo ratings yet

- Reasons of Premature Cracking Pavement Deterioration - A Case StudyDocument11 pagesReasons of Premature Cracking Pavement Deterioration - A Case StudyCivilax.comNo ratings yet

- SPTDocument3 pagesSPTCivilax.comNo ratings yet

- All SSTDocument14 pagesAll SSTCivilax.com100% (1)

- CH Existing Level ABC Finish LevelDocument3 pagesCH Existing Level ABC Finish LevelCivilax.comNo ratings yet

- Pile Capacity in Khulna Sub-SoilDocument2 pagesPile Capacity in Khulna Sub-SoilCivilax.comNo ratings yet

- Rcc95 Continuous Beams (Tables)Document7 pagesRcc95 Continuous Beams (Tables)Eric Villenas100% (1)

- STUDY ON THE SALINITY AND PH AND ITS EFFECT ON GEOTECHNICAL PROPERTIES OF SOIL IN SOUTH-WEST REGION OF BANGLADESHDocument2 pagesSTUDY ON THE SALINITY AND PH AND ITS EFFECT ON GEOTECHNICAL PROPERTIES OF SOIL IN SOUTH-WEST REGION OF BANGLADESHCivilax.com100% (2)

- Calculo de Poligonal Base y Radiaciones TaquimetriaDocument3 pagesCalculo de Poligonal Base y Radiaciones Taquimetrianilton54321No ratings yet

- Asphalt PresentationDocument48 pagesAsphalt PresentationCivilax.comNo ratings yet

- ACI Method of Mix DesignDocument11 pagesACI Method of Mix DesignCivilax.comNo ratings yet

- Crack Width BS 8110Document2 pagesCrack Width BS 8110nhulugallaNo ratings yet

- 4 Pile Cap Design (Civilax - Com)Document33 pages4 Pile Cap Design (Civilax - Com)Civilax.comNo ratings yet

- Specification For Design and Construction of Mine RoadsDocument32 pagesSpecification For Design and Construction of Mine RoadsNamme KyarakhahaiNo ratings yet

- SIKADocument32 pagesSIKAwaleedroomyNo ratings yet

- (BP Process Safety Series) - Hazards of Trapped Pressure and Vacuum-Institution of Chemical Engineers (2009)Document100 pages(BP Process Safety Series) - Hazards of Trapped Pressure and Vacuum-Institution of Chemical Engineers (2009)DanielNo ratings yet

- ABB Construction MS 020 Pump InstallationDocument5 pagesABB Construction MS 020 Pump InstallationMike MatshonaNo ratings yet

- 60-0000-L-SPE-0001 Rev 2 - Spec For Plant and Piping Layout PDFDocument48 pages60-0000-L-SPE-0001 Rev 2 - Spec For Plant and Piping Layout PDFNatthasart MuangsuankwanNo ratings yet

- Ofs Light PavingDocument14 pagesOfs Light PavingMorgan SidesoNo ratings yet

- Report For Extensive SurveyDocument104 pagesReport For Extensive SurveyBalakrishna SNo ratings yet

- Evidence Portfolio Sanjaya1 - MergedDocument46 pagesEvidence Portfolio Sanjaya1 - MergedJanaka SenanayakaNo ratings yet

- Mogsl EmsDocument23 pagesMogsl EmsMUKODWA NAJIBNo ratings yet

- F&GS LeakDetection SIL PDFDocument44 pagesF&GS LeakDetection SIL PDFAlvaro José Rodríguez Talavera100% (1)

- Noc 21052011 0012Document13 pagesNoc 21052011 0012Jake MontalbanNo ratings yet

- Risk Assessment For Offshore Refuelling Rev 0Document9 pagesRisk Assessment For Offshore Refuelling Rev 0ringbolt100% (1)

- Sop CNT 45 Waste Management Procedure For Contractors: Revision ListDocument15 pagesSop CNT 45 Waste Management Procedure For Contractors: Revision Listchaitra rNo ratings yet

- Effluent Discharge Mock Emergency and Evalaution ReportDocument3 pagesEffluent Discharge Mock Emergency and Evalaution Reportremember0% (1)

- HSE HSG 244 (Ed 1 2004) - Remotely Operated Shutoff ValvesDocument37 pagesHSE HSG 244 (Ed 1 2004) - Remotely Operated Shutoff Valvesrees1098No ratings yet

- 1 - Old TankDocument49 pages1 - Old Tanknaveen75% (4)

- New Tank ProjectDocument6 pagesNew Tank Projectlaxmanrokz100% (7)

- Markout Guidelines Registers & Records To Be Maintained On Works & at Section LevelDocument34 pagesMarkout Guidelines Registers & Records To Be Maintained On Works & at Section LevelsandhyaNo ratings yet

- Fire and Explosion Assessment On Oil and Gas Oating Production Storage of Oading (FPSO) : An Effective Screening and Comparison ToolDocument14 pagesFire and Explosion Assessment On Oil and Gas Oating Production Storage of Oading (FPSO) : An Effective Screening and Comparison ToolKonstantinKotNo ratings yet

- Used Oil Storage and DisposalDocument4 pagesUsed Oil Storage and DisposalGrace PassiniNo ratings yet

- Ssdx12-25 Handbook Dse702 & Esr3.1 Issue 3Document29 pagesSsdx12-25 Handbook Dse702 & Esr3.1 Issue 3azry_alqadryNo ratings yet

- ERMCO 2006 - Environmental Checklist For Concrete PlantDocument12 pagesERMCO 2006 - Environmental Checklist For Concrete PlantFadhiel MuhammadNo ratings yet

- Pompa SelwoodDocument4 pagesPompa SelwoodakkilluaNo ratings yet

- VesselsDocument16 pagesVesselsRonald TysonNo ratings yet

- The Storage of Flammable Liquids in TanksDocument64 pagesThe Storage of Flammable Liquids in Tanksaugur886No ratings yet

- The Hydraquip WayDocument192 pagesThe Hydraquip WayAnna Lachner100% (1)

- Risk Assessment Data Directory - Ignition Probabilities 434-06Document48 pagesRisk Assessment Data Directory - Ignition Probabilities 434-06Deepak RajoriaNo ratings yet

- Liquid Storage and Handling GuidelinesDocument52 pagesLiquid Storage and Handling GuidelinesAvyan KelanNo ratings yet

Column Wall Design

Column Wall Design

Uploaded by

Civilax.comOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Column Wall Design

Column Wall Design

Uploaded by

Civilax.comCopyright:

Available Formats

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : Design of Column Bund Wall

Rev No

:

for Main Crude Oil Tank TK - 1526 &

Prep. By :

Test Tank Tk - 1527

Checkd. By :

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

4.7 Design of Concrete Column Bund Wall for

Main Crude Oil Tank TK - 1526 &

Test Tank Tk - 1527.

SR NO

TABLE OF CONTENTS

1.0

Design Data

2.0

Design Philosophy

3.0

Design of Wall

4.0

Design of Column

5.0

Design of Footing

APPENDIX - I

Typical GA & RC Details of Column Wall

PAGE NO

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : Design of Column Bund Wall

Rev No

:

for Main Crude Oil Tank TK - 1526 &

Prep. By :

Test Tank Tk - 1527

Checkd. By :

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for Main Crude Oil Tank TK - 1526 &

Test Tank Tk - 1527

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

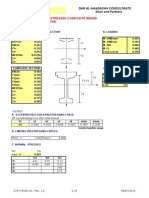

1.0 DESIGN DATA :

Lc

Wc

Tw

Ht3

Lw

Ww

Tank side

Out Side

H1

H

Ht2

Ho2

Ht1

Ho1

Tf

Tf

Wf

Lf

Elevation

Section A - A

1.1 Geometrical Data :

Length of footing ( Lf )

4.7

Width of footing ( W f )

2.7

Thickness of footing ( Tf )

0.6

Width of column ( W c )

0.4

Length of column ( Lc )

0.6

Length of Wall ( Lw )

3.6

m, ( Max wall Length has been Considered )

Width of wall ( W w )

4.4

Thickness of wall ( Tw )

0.3

Top of footing from tank side GL ( Ht1 )

1.6

Height of liquid from GL ( Ht2 )

2.7

Free board ( Ht3 )

0.3

Top of footing from out side GL ( Ho1 )

1.6

Height of wall from outside GL ( Ho2 )

Height of wall from top of footing ( H1 )

=

=

4.6

5.2

m

m

18

150

kN/m3

KN/m2

Top of wall from bottom of footing ( H )

1.2 Soil Data : ( As Per JI-180-000-ECV-SPE-001 )

Unit weight of soil,( )

=

Bearing capacity of soil

Coefficient of soil pressure at rest ( Ko )

Angle of internal friction, (

Coefficient of active earth pre. ( Ka )

0.5

32

( 1-SIN ) / ( 1+SIN )

Coefficient of passive earth pre. ( Kp )

=

=

=

( 1+SIN ) / ( 1-SIN )

1.75

1.75

Factor of safety against sliding

Factor of safety against overturning

=

=

1.3 Material Data: ( As Per JI-180-000-ECV-SPE-001 )

Grade of Concrete ( Fcu )

=

30

88

N/mm2

Width of wall insufficient

0.31

3.25

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : Design of Column Bund Wall

Rev No

:

for Main Crude Oil Tank TK - 1526 &

Prep. By :

Test Tank Tk - 1527

Checkd. By :

2

Yield Strength of reinforcement ( Fy )

N/mm

=

414

89

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : Design of Column Bund Wall

Rev No

:

for Main Crude Oil Tank TK - 1526 &

Prep. By :

Test Tank Tk - 1527

Checkd. By :

Clear Cover to Reinforcement ( c )

=

75

mm

Unit Weight of Concrete ( c )

KN/m3

=

24

Density of retained liquid, ( w )

KN/m3

=

8.77

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

2.0 DESIGN PHILOSOPHY :

Here, wall has been designed for two condition,

a ) Tank side empty and Other side earth + wind pressure, &

b ) Tank side with liquid & Submerged soil pressure & Other side with soil pressure only.

In both of the cases whatever pressure will comes over the wall will be transferred through the one way

load distribution pattern to column and then will ultimately go to ground. So in this case design formula as

per Clause 3.4.4.2 of BS : 8110 ( Part I ) has been used.

3.0 DESIGN OF WALL :

3.1 BM Calculation For Case ( a ) :

a)

Active earth pressure ( Pa )

Moment at base of wall due to

active earth Pressure ( Ma )

b)

Wind pressure, ( Qw )

Moment at base of wall due to

wind pressure ( Mw )

c)

Passive earth pressure ( Pp )

=

=

=

=

=

=

*Ka* Ho1

8.8704 KN/m2

1/6 * Pa * Ho12

3.785

kNm

KN/m2, For the top height of (Ho2) =

0.76

Qw * Ho2 * ( Ho1 + Ho2 /2 )

7.068

=

=

*Kp*Ht1

3.00m

kNm

( Passive pressure for moment

Moment at base of wall due to

passive earth Pressure ( Mp )

Total Moment at the base ( M1 )

=

=

0.00

KN/m2

1/6 * Pp * Ht12

0.00

calculation has been ignored so

as to be on conservative side )

kNm

Ma + M w - M p

10.853

kNm

Converting to eq triangle of same ht which will prodcue the same moment at the base.

0.76

1/2 x Peq x 4.40 x 4.40/3

Peq

=

=

10.853

3.363441 KN/m2

0.76

2

Dividing plate into 3 equal part, and designing for the same.

Effective Length of each plate ( Lweff )

Lw + W c

=

=

Width of each plate ( W e )

=

=

4

Ww / 3

4.82

3

1.466667 m

Calculating moment and shear for each panel using coefficient of BS : 8110 (Part I ) : Table 3.5

90

8.87

8.8704

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : Design of Column Bund Wall

Rev No

:

for Main Crude Oil Tank TK - 1526 &

Prep. By :

Test Tank Tk - 1527

Checkd. By :

Moment coefficient for middle of interior span ( Mcoeffspan )

=

0.07

91

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : Design of Column Bund Wall

Rev No

:

for Main Crude Oil Tank TK - 1526 &

Prep. By :

Test Tank Tk - 1527

Checkd. By :

Moment coefficient for interior supports ( Mcoeffsupport )

=

0.08

Shear coefficient at interior supports ( Scoeffsupport )

Shear at interior supports

0

Dipak

Mr. Girish Kurnool

0.55

( Load factor for soil pressure is 1.4, as per BS:8110-Part I )

1.4 * Mcoeffspan * W * W e * Lweff 2

Moment at middle of interior span

=

Moment at interior supports

JI-180-000-ECV-CAL-050

kNm

1.4 * Mcoeffsupport * W * W e * Lweff 2

kNm

1.4 * Scoeffsupport * W * W e * Lw 2

kNm

Table 5.1 Design Moment And Shear For Case ( a )

Panel

1

2

3

Span Moment

1.748 kNm

11.074 kNm

20.400 kNm

Support Moment

1.997 kNm

12.656 kNm

23.314 kNm

Design Moment

1.997 kNm

12.656 kNm

23.314 kNm

Support Shear

3.090 kN

19.577 kN

36.063 kN

3.2 BM Calculation For Case ( b ) :

a)

Liquid pressure ( Pl )

Moment at base of wall due to

liquid pressure ( Ml )

b)

Active earth pressure ( Pa )

Moment at base of wall due to

active earth Pressure ( Ma )

c)

Passive earth pressure ( Pp )

Moment at base of wall due to

passive earth Pressure ( Mp )

d)

Wind pressure, ( Qw )

=

=

w * H 1

40.342 KN/m2

Pl * H 1 2 / 6

142.273 kNm

=

=

=

Ka*Ht1

4.549 KN/m2

Ka*Ht13 /6

1.941

=

=

*Kp*Ho1

=

=

0

KN/m2

1/6 * Pp * Ho12

0

( Passive pressure for moment

calculation has been ignored so

as to be on conservative side )

kNm

KN/m2, For the top height of (Ho2) =

0.76

Qw * Ht3 * ( H1 - Ht3 /2 )

Moment at base of wall due to

wind pressure ( Mw )

=

=

1.0146

Moment at base ( M2 )

Ml

kNm

kNm

145.228 kNm

+

Mp

Ma

1

15.00

30.01

3

45.01

92

Mw

Converting to eq triangle of same ht,

which will prodcue the same moment at the base.

3.00m

0.76

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : Design of Column Bund Wall

Rev No

:

for Main Crude Oil Tank TK - 1526 &

Prep. By :

Test Tank Tk - 1527

Checkd. By :

1/2 x Peq x 4.40 x 4.40/3

=

145.2281

Peq

=

45.00871 KN/m2

93

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

4.55

40.34

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for Main Crude Oil Tank TK - 1526 &

Test Tank Tk - 1527

Dividing plate into 3 equal part, and designing for the same.

Effective Length of each plate ( Lweff )

=

4

Width of each plate ( W e )

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

1.466667 m

Calculating moment and shear for each panel using coefficient of BS : 8110 (Part I ) : Table 3.5

Moment coefficient for middle of interior span ( Mcoeffspan )

=

0.07

Moment coefficient for interior supports ( Mcoeffsupport )

0.08

Shear coefficient at interior supports ( Scoeffsupport )

0.55

( Load factor for soil pressure is 1.4, as per BS:8110-Part I )

1.4 * Mcoeffspan * W * W e * Lweff 2

Moment at middle of interior span

=

Moment at interior supports

Shear at interior supports

kNm

1.4 * Mcoeffsupport * W * W e * Lweff 2

kNm

1.4 * Scoeffsupport * W * W e * Lw 2

kNm

Table 5.2 Design Moment And Shear For Case ( b )

Panel

1

2

3

Span Moment

34.503 kNm

69.005 kNm

103.508 kNm

Support Moment

39.432 kNm

78.863 kNm

118.295 kNm

Design Moment

39.432 kNm

78.863 kNm

118.295 kNm

Support Shear

60.996 kNm

121.992 kNm

182.987 kNm

Table 5.3 Maximum Design Moment And Shear

Panel

1

2

3

Tank Side

39.432 kNm

78.863 kNm

118.295 kNm

Out Side

34.503 kNm

69.005 kNm

103.508 kNm

Support Shear

60.996 kNm

121.992 kNm

182.987 kNm

3.3 Rebar Calculation :

( Sample calculation for panel 3 )

Design factored bending

moment ( Mu )

Assumed main dia of wall ( dmain )

Effective thickness of wall ( Tweff )

=

=

118.29

kNm

20

kNm

( Tw * 1000 ) - (dmainl / 2) - c

215

mm

Now as per clause 3.4.4.4 of BS 8110 ( Part - I )

k

=

=

=

Mu / fcu bd2

30

0.058

118.29

x 1467

<

x 106

x 215

0.156

=

=

=

d* [ 0.5 + sqrt ( 0.25 - k/0.9 )]

215 x [ 0.5 + sqrt( 0.25 200.07 mm

&

0.95 x d

94

x 215

0.058

/0.9)]

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for Main Crude Oil Tank TK - 1526 &

Test Tank Tk - 1527

=

204.25 mm

95

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for Main Crude Oil Tank TK - 1526 &

Test Tank Tk - 1527

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

Take z

=

=

Minimum of above two values

200.07 mm

Required Ast1

=

=

M / [0.95*fy*z]

1503.36 mm2/m

=

=

=

0.13 % of Area of concrete

0.130

x 1467

x 300

572.00 mm2/m

As per table 3.25 of BS : 8110 ( Part - I )

Min reinforcement for flexure ten Ast2

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

/ 100

As per table 3.25 of BS : 8110 ( Part - I ) clause 3.9.4.19

Min reinforcement for crack control Ast3

=

0.25 % of Area of concrete

=

=

=

From the above required Astreq1

Required 20 mm bar at a spacing of 306 mm c/c

Provide 20 mm bar at a spacing of

200

Area of steel provided Astprov1

=

ptprovided

0.250

1100

550

x 1467

mm2

mm2

1503.36 mm2/m

x 300 / 100

on both face

on each face

Max of Ast1, Ast2 & Ast3

mm c/c

2303

mm2

0.52 %

Table 5.4 Steel Provided On The Tank Side Face

Panel

1

2

3

Ast Required

501 mm2

1002 mm2

1503 mm2

Rebar Dia Spacing

12 mm

200 mm

16 mm

150 mm

20 mm

200 mm

Ast Provided

829 mm2

1965 mm2

2303 mm2

OK

OK

OK

Table 5.5 Steel Provided On The Other Side Face

Panel

1

2

3

Ast Required

438 mm2

877 mm2

1315 mm2

Rebar Dia Spacing

12 mm

200 mm

16 mm

150 mm

20 mm

200 mm

Ast Provided

829 mm2

1965 mm2

2303 mm2

OK

OK

OK

3.4 Distribution Steel :

Provide Min Reinforcement As Dist. Steel, As per table 3.25 of BS : 8110 ( Part - I )

Distribution steel, Adist

=

0.13 % of Area of concrete

=

0.13

x 1000

x 300

=

390

mm2/m

Dia of distribution rebar

Provide 12 mm bar at a spacing of

Area of steel provided Astprov1

=

200

=

12

mm c/c

565

96

mm

mm2

/ 100

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for Main Crude Oil Tank TK - 1526 &

Test Tank Tk - 1527

3.5 Check For Shear :

( Sample calculation for panel 3 )

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

Shear V at face of the column

183 kN

Shear stress at face of support, ( v )

Maximum allowed Max( 0.8fck , 5 )

0.580

N/mm

4.382

N/mm2

100 Ast / bd

0.73

From BS 8110, Part 1 Table 3.8, ( vc )

Revise value of ( vc )

=

=

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

or 5 N/mm2

O.K. (Clause 3.7.7.2)

For fcu = 25 N/mm2

0.61

N/mm

1/3

vc * ( fcu /25 )

For fcu = 30 N/mm2

0.648

N/mm

Since vc > v Hence Section Is SAFE In Shear

Table 5.6 Shear Check At Face Of Column For Each Panel

Panel

Shear

Stress

(

v N/mm2 )

1

2

3

0.193

0.387

0.580

100 Ast / bd

0.26

0.62

0.73

Permissible Shear

Stress

( vc N/mm2 )

0.430 N/mm2

0.540 N/mm2

0.610 N/mm2

Revised

Shear

Stress ( vc )

0.457

0.573

0.648

v < vc, Ok

v < vc, Ok

v < vc, Ok

3.6 Calculation Of Crack Width

Maximum allowable crack width

0.3

mm (Per BS 8110-2 : 1985 clause 3.2.4)

1 ) Crack width for drying shrinkage / thermal movement :

fcu

fy

=

=

=

=

Thermal strain r

R

=

=

=

=

=

Thermal strain r

Characteristic strength of reinforced concrete

30

N/mm2

Characteristic strength of reinforcing steel as per table 3.1 of BS 8110

( As per design philosophy 0.9fy )

414

N/mm2

=

0.6

( Per Table 3.3 of BS 8110-2)

Coefficient of thermal expansion of mature concrete

0.000012

Table 7.3 of BS 8110 ( Part 2 )

Fall in temperatue between hydration peak and ambient

20

( per Table 3.2 of BS 8110-2)

=

Design surface crack width, W 1

Where,

acr

0.8*t**R ( Refer equation 14 of clause 3.8.4.2 of BS 8110-2)

=

=

0.0001152

=

3*acr*r/(1+2*((acr-cmin)/(h-x)))

Dist from point considered to the surface of the nearest long bar

Sqrt( S/22+ (c+/2)2 ) - (/2)

97

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for Main Crude Oil Tank TK - 1526 &

Test Tank Tk - 1527

=

131.21 mm

=

=

Size of each reinforcing bar

20

=

=

Depth of wall = B

300

=

=

Spacing of reinforcement

200

As

=

=

Area of steel

2303

mm2

W1

0.03

mm

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

acr

<

0.30

mm

OK

2 ) Crack width in flexure :

Crack width, ( W 2 )

Where,

3*acr*m/(1+2*(acr - cmin)/(h-x))

acr

=

=

=

=

=

=

=

average strain at the level where the cracking is being considered

1 -2

=

=

=

84.50

kNm

M/(As*(d-S'/2))

190.91582 N/mm2

=

=

=

=

=

=

=

Overall depth of member

= D

300

mm

Width of section at the centroid of tensile steel

1466.67 mm

Modulus of elasticity of reinforcement

200000.00 N/mm2

Distance from the compression face to the point at which the

crack width is being calculated

effective depth ( d )

215

mm

Effective depth

D - cmin - /2

2

1

Moment in section, M

Stress in steel, fs

h

bt

Es

a

d

cmin

k

z

=

=

=

=

=

=

=

=

=

=

131.21

mm

0.001

bt*(h-x)*(a'-x)/3*Es*As*(d-x)

for crack width of 0.3mm

0.0003

fs/Es*((h-x)/(d-x))

0.001

( Unfactored moment)

OK

215

mm

Minimum cover to tensile steel

75.00

mm

Mu / fcu bd2

0.085

<

0.156

d* [ 0.5 + sqrt ( 0.25 - k/0.9 )]

98

&

0.95 x d

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for Main Crude Oil Tank TK - 1526 &

Test Tank Tk - 1527

=

192.21 mm

&

z

=

192.21 mm

S'

x

W2

=

=

=

=

=

Depth of stress block

45.589754 mm

depth of neutral axis

(d-z)/0.45

50.655282 mm

=

=

3*acr*m/(1+2*(acr - cmin)/(h-x))

0.32

mm

99

>

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

204.25

0.30

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

mm

mm

NOT OK

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for Main Crude Oil Tank TK - 1526 &

Test Tank Tk - 1527

100

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for

Wet

Main

Crude

Crude

Oil Oil

Tank-21-TK-001

Tank TK - 1526 &

Test Tank Tk - 1527

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

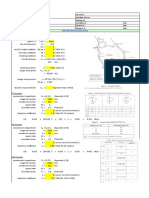

6.0 DESIGN OF COLUMN :

A

Lw

Lc

Tw

Tank Side

Ht3

Lc

Tank side

Lf

Out Side

H1

Out Side

Ht2

Ho2

Ht1

Ho1

Wc

x

z

Wf

Tf

Lf

Plan

Section A - A

Here,

Length of footing ( Lf )

4.70

Width of footing ( W f )

2.70

Width of column ( W c )

0.40

Length of column ( Lc )

0.60

Width of wall ( W w )

4.40

Length of Wall ( Lw )

3.60

m, ( Max wall Length has been Considered )

Top of footing from tank side GL ( Ht1 )

1.60

Height of liquid from GL ( Ht2 )

2.70

Free board ( Ht3 )

0.30

Top of footing from out side GL ( Ho1 )

1.60

Height of wall from outside GL ( Ho2 )

3.00

Thickness of footing ( Tf )

0.60

Height of wall from top of footing ( H1 )

=

=

4.60

5.20

m

m

0.30

Top of wall from bottom of footing ( H )

Thickness of wall ( Tw )

6.1 BM Calculation :

Case ( a ) :

> Here, column is subjected to uniaxial bending moment due to earth

and wind pressure & compressive load due to self wt as well as weight of wall.

> It is assumed that column is monolithically constructured to both side with

same span, height and thick wall, So it is subjected to uniaxial moment only.

Wt of column ( W c )

=

=

c x L c x W c x H 1

26.496

kN

Wt of wall ( W w )

=

=

c x L w x W w x T w

114.048

96

kN

Kp = 0

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for

Wet

Main

Crude

Crude

Oil Oil

Tank-21-TK-001

Tank TK - 1526 &

Test Tank Tk - 1527

Axial Force in column ( W )

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

Wc + Ww

97

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for

Wet

Main

Crude

Crude

Oil Oil

Tank-21-TK-001

Tank TK - 1526 &

Test Tank Tk - 1527

=

Eccentricity of Wall ( ewall )

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

140.544

kN

0.15

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

... ( 1 )

( Weight of platform

has been neglected )

Active

a)

Calculation of Moment & Shear due to wind and active earth pressure about the base of column.

Wind pressure ( Qw )

KN/m2, For the top ht of ( Ho2 ) = 3m

=

0.76

Wind & Active earth pressure ( Pia )

=

=

Shear at base of column due to wind &

active earth pressure ( Via )

Moment at base of column due to wind

& active earth pressure ( Mia )

b)

Moment due to wall eccentricity ( Mwa )

(*Ka*Ho1 + Qw ) x ( Lw + W c )

38.5216 kN/m2

( 1/2**Ka*Ho12 + Qw * Ho2 ) ( Lw+W c )

37.505

kN

( 1/6**Ka*Ho13 +

43.411

=

=

W w ewall

Qw * Ho2 * (Ho2 / 2 + Ho1)) *( Lw+W c)

kNm

17.1072

kNm

Passive

c)

Calculation of Moment & Shear due to 2/3 height of passive earth pressure about the base of column.

( Passive pressure has been ignored so as to be on conservative side )

Passive earth pressure ( Pip )

=

=

*Kp*(2/3*Ht1 - Tf/3) * ( Lw + W c )

0.000

kN/m2

1/2**Kp*(2/3*Ht1 - Tf/3)2 * ( Lw + W c )

Shear at base of column due to

passive earth pressure ( Vip )

Moment at base of column due to

passive earth pressure ( Mip )

=

=

0.000

Shear at the base of column ( V )

=

=

Via - Vip

37.505

=

=

Mia + Mwa - Mip

60.518

kNm

Moment at the base of column ( M )

0.000

kN

1/6**Kp*(2/3*Ht1 - Tf/3)3 * ( Lw + W c )

kNm

kN

... ( 2 )

... ( 3 )

Case ( b ) :

> Here, column is subjected to uniaxial bending moment due to submerged earth

and liquid pressure & compressive load due to self wt as well as weight of wall.

> It is assumed that column is monolithically constructured to both side with

same span, height and thick wall, So it is subjected to uniaxial moment only.

Axial Force in column ( W )

Wc + Ww

140.544

Active

98

Kp = 0

kN

... ( 4 )

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

: JI-180-000-ECV-CAL-050

Subject : Design of Column Bund Wall

Rev No

: 0

for

Wet

Main

Crude

Crude

Oil Oil

Tank-21-TK-001

Tank TK - 1526 &

Prep. By : Dipak

Test Tank Tk - 1527

Checkd. By : Mr. Girish Kurnool

a)

Calculation of Moment & Shear due to wind, liquid and submerged active earth pre about the base of column.

99

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for

Wet

Main

Crude

Crude

Oil Oil

Tank-21-TK-001

Tank TK - 1526 &

Test Tank Tk - 1527

Wind pressure, ( Qw )

=

0.76

Doc No

: JI-180-000-ECV-CAL-050

Rev No

: 0

Prep. By : Dipak

Checkd. By : Mr. Girish Kurnool

2

kN/m , For the top ht of ( Ho2 ) = 3m

Pressure due to wind, liquid &

submerged active earth pressure ( Pia )

(*(H1 - Ht3)+ Ka*(-w)*Ht1 + Qw) x (Lw + W c)

Shear due to wind, liquid & submerged

active earth pressure ( Via )

172.08

kN/m2

2

(w*( H1 - Ht3) /2 + Ka*Ht12/2 + Qw*Ht3)x(Lw + W c)

Moment due to wind, liquid &

submerged active earth pressure ( Mia )

339.78

kN

( Ka*Ht13/6 + Qw*Ht3*(Ht3/2+Ht2+Ht1) +

w*(H1 - Ht3)3/6) x (Lw + W c)

476.67

kNm

Passive

b)

Calculation of Moment & Shear due passive earth pressure abou the base of column.

Passive earth pressure ( Pip )

=

=

Shear due to passive earth

pressure ( Vip )

Moment due to passive

earth pressure ( Mip )

=

=

c)

Moment due to wall eccentricity ( Mwp )

=

=

Shear at the base of column ( V )

=

=

Moment at the base of column ( M )

=

=

*Kp*(2/3*Ho1 - Tf/3) * ( Lw + W c )

202.99

kN/m2

1/2**Kp*(2/3*Ho1 - Tf/3)2 * ( Lw + W c )

87.96

kN

1/6**Kp*(2/3*Ho1 - Tf/3)3 * ( Lw + W c )

25.41

kNm

W w ewall

17.1072

kNm

Via - Vip

251.82

kN

Mia - Mip - Mwp

434.15

... ( 5 )

kNm

... ( 6 )

( Load factor for soil pressure is 1.4, as per BS:8110-Part I )

Maximum Axial Force, Moment & Shear From Case I & II :

Fy

=

=

1.4*Max of ( 1 ) & ( 4 )

196.76

kNm

Fx

=

=

1.4*Max of ( 2 ) & ( 5 )

352.55

kNm

Mz

=

=

1.4*Max of ( 3 ) & ( 6 )

607.82

kNm

Table 6.1 Ultimate Load For Column Design.

FY

197

Fx

353

dtendia

25

mm

dstirr

mm

MAX

Fz

0

6.2 Rebar Caculation :

100

Mx

0

Mz

608

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for

Wet

Main

Crude

Crude

Oil Oil

Tank-21-TK-001

Tank TK - 1526 &

Test Tank Tk - 1527

Assumed pt%

=

2

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

%

101

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for

Wet

Main

Crude

Crude

Oil Oil

Tank-21-TK-001

Tank TK - 1526 &

Test Tank Tk - 1527

Width of column ( W c )

b

=

=

h

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

0.40

m

Length of column ( Lc )

=

=

0.60

Effective width b'

=

=

Effective length h'

=

=

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

b - c - dstirrups - dtendia/2

0.305

m

h - c - dstirrups - dtendia/2

0.505

Here, As per BS 8110 : Cl 3.8.1, h / b

1.50

if h/b < 4, Design it as a column

a)

Axial Force & Moment From Case I & II :

N = Maximum Design Axial load ( W u )

196.76

kN

... ( 7 )

Mz = Maximum Design Moment ( Mu )

607.82

kNm

... ( 8 )

Mx = Maximum Design Moment ( Mu )

kNm

... ( 9 )

b)

Moment due to mnimum eccentricity :

Minimum Eccentricity ( emin ) as per BS : 8110 Cl 3.8.2.4

In X direction ( ex )

20

mm

In Z direction ( ez )

20

mm

Moment due to minimum eccentricity ( Me = W u x emin )

In X direction (Mez = ex W u)

3.935

kNm

... ( 10 )

In Z direction (Mex = ez W u)

3.935

kNm

... ( 11 )

=

=

2.2

0.75

Un braced

Braced

in X direction ( Lox )

H1

4.60 m < 60 x Minimum Dim

in Y direction ( Loz )

H1

4.60 m < 60 x Minimum Dim

c)

Moment due to slenderness :

Restrain factor ( ),

in X direction

in Z direction

Clear height between end restrain ( Lo )

Effective length ( Le )

x Lo

in X direction ( Lex = x Lox)

10.12

Un braced

<

10

Short Column

in Z direction ( Ley = x Loz)

3.45

Braced

<

15

Short Column

Moment due slenderness ( Madd )

In X direction (Mzadd )

In Z direction (Mxadd )

=

=

=

=

W u x (1/2000)(lex/h)2 x K x h

... ( 12 )

0.000

kNm

W u x (1/2000)(lez/b)2 x K x b

0.000

kNm

... ( 13 )

Maximum design moment for column as per BS : 8110

For braced column

maximum of

M

Mi + Madd

emin N

M + Madd

For unbraced

e N

column maximum of min

102

Here, Mi = 0.4M1 + 0.6M2 > 0.4M2

M1 = 0 ;

M2 = M ;

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for

Wet

Main

Crude

Crude

Oil Oil

Tank-21-TK-001

Tank TK - 1526 &

Test Tank Tk - 1527

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

103

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for

Wet

Main

Crude

Crude

Oil Oil

Tank-21-TK-001

Tank TK - 1526 &

Test Tank Tk - 1527

Design Moment :

In X direction ( Mz )

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

Maximum

Of

607.82

Maximum

Of

3.94

kNm

=

=

0.85

0.82

N/mm2

4.22

N/mm2

30

N/mm2

Fy

d/h

N / bh

Mz / bh2

=

=

=

460

0.85

0.82

N/mm2

from chart No 28 to 50, for

N/mm2

4.22

N/mm2

100 Asc / bh

2.50 %

6000

In Z direction ( Mx )

607.82

3.94

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

For Un braced condition

kNm

0.00

0.00

3.94

... ( 14 )

For Braced

... ( 15 )

Here, Mx << Mz

d/h

N / bh

Mz / bh2

Refering corresponding chart for

Fcu

0.85

We have,

Asc

Provide T25 of 12 No bars, &

Provide stirrups T8 of 150 mm c/c

mm2

( Stirrups calculation formula not added )

6.3 Loading Data For Stability Check :

Resisting Moment & Axial Force Calculation :

Case ( a )

Wt of column ( W c )

=

=

Wt of wall ( W w )

=

=

Soil Cushion ( W s1 )

Soil Cushion ( W s2 )

Eccentricity of W s2 in x

direction ( es2 )

c x L c x W c x H 1

26.496

kN

c x L w x W w x T w

114.048 kN

x Ht1xW f x Lh

272.16

kN

x Ho1 x [(W f - W c)*(Lc - Tw) + W f*Lt]

66.53

kN

[(W f - W c)*(Lc - Tw)*(Lt+(Lc-Tw)/2) + W f*Lt*Lt/2]

[(W f - W c)*(Lc - Tw) + W f*Lt]

104

condition

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for

Wet

Main

Crude

Crude

Oil Oil

Tank-21-TK-001

Tank TK - 1526 &

Test Tank Tk - 1527

=

Weight of Footing ( W fo )

=

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

0.434

c*W f*Lf*Tf

105

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for

Wet

Main

Crude

Crude

Oil Oil

Tank-21-TK-001

Tank TK - 1526 &

Test Tank Tk - 1527

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

182.74

Fy

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

kN

W c + W w + W s1 + W s2 + W fo

=

=

661.97 kN

... ( 16 )

Resisting Moment ( Mrz )

Moment @ heel

Mrz

W c*(Lc/2+Lh) + W w*(Lh+Tw/2) + W s1*(Lh/2) +

W s2*( Lf-es2 ) + W fo*Lf/2

=

1706.48

kNm

... ( 17 )

Resisting Moment ( Mrx )

Mrx

=

=

( W c + W w + W s1 + W s2 + W fo ) * W f/2

893.66

kNm

=

=

w x Ht2 x (W f*Lh)

... ( 18 )

Case ( b )

Weight of liquid ( W l )

Fy

223.77

kN

W c + W w + W s1 + W s2 + W fo + W l

=

=

885.73 kN

... ( 19 )

Resisting Moment ( Mrz )

Moment @ toe

Mrz

W c*(Lc/2+Lt) + W w*(Lt+Lc-Tw/2) + W s1*(Lh/2+Lc+Lt) +

W s2*es2 + W fo*Lf/2 + W l*(Lh/2+Lc+Lt)

=

2064.88

kNm

... ( 20 )

Resisting Moment ( Mrx )

Mrx

=

=

( W c + W w + W s1 + W s2 + W fo + W l ) * W f/2

1195.74 kNm

Wl

Ww

... ( 21 )

Here,

Ws1

Ws2

Y

W fo

Heel

X

Lh

Toe

Lc

Lt

Lf

Axial Force From Case I & II :

Fy

Resisting moment From Case I & II :

Mzr

=

=

Max of ( 16 ) & ( 19 )

885.73

kN

=

=

Max of ( 17 ) & ( 20 )

2064.88 kNm

106

Lt

0.6

Lh

3.50

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for

Wet

Main

Crude

Crude

Oil Oil

Tank-21-TK-001

Tank TK - 1526 &

Test Tank Tk - 1527

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

Resisting moment From Case I & II :

107

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for

Wet

Main

Crude

Crude

Oil Oil

Tank-21-TK-001

Tank TK - 1526 &

Test Tank Tk - 1527

Mxr

=

=

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

Max of ( 18 ) & ( 21 )

1195.74 kNm

Over turning Moment ( Mz ) & Shear ( Fx ) Calculation :

Case ( a ) :

Active

a)

Calculation of Moment & Shear due to wind and active earth pressure about the base of footing.

Wind pressure ( Qw )

kN/m2, For the top ht of ( Ho2 )

=

0.76

Pressure due to wind & earth ( Pia )

=

=

Shear at base of footing due to wind

& active earth pressure ( Via )

Moment at base of footing due to Wind

& active earth pressure ( Mia )

= 3m

(*Ka*(Ho1+Tf )+ Qw ) x ( Lw + W c )

51.827

kN/m2

( 1/2**Ka*(Ho1+Tf )2 + Qw * Ho2 ) ( Lw+W c )

62.786

kN

( 1/6**Ka*(Ho1+Tf)3 +

Qw * Ho2 * (Ho2 / 2 + Ho1 + Tf )) *( Lw+W c)

73.099

kNm

Passive

b)

Calculation of Moment & Shear due to 2/3 height of passive earth pressure about the base of footing.

Passive earth pressure ( Pip )

=

=

*Kp*2/3*(Ht1 + Tf) * ( Lw + W c )

Shear due to earth pressure ( Vip )

=

=

Moment due to earth pressure ( Mip )

=

=

0.000

kN/m2

2/9**Kp*(Ht1 + Tf)2 * ( Lw + W c )

0.000

kN

4/81**Kp*(Ht1 + Tf)3 *( Lw + W c )

0.000

kNm

Shear at the base of footing ( Vs )

=

=

Via - Vip

62.786

=

=

Mia + Msa - Mip - Msp

Moment at the base of footing ( Mo )

73.099

kN

kNm

... ( 22 )

... ( 23 )

Case ( b ) :

Active

a)

Calculation of Moment & Shear due to wind, liquid and active earth pressure about the base of footing.

Wind pressure, ( Qw )

kN/m2, For the top ht of ( Ho2 ) = 3m

=

0.76

Pressure due to wind, liquid &

submerged earth ( Pia )

(*(H - Ht3)+ Ka*(-w)*(Ht1+Tf )+ Qw) x (Lw + W c)

Shear due to wind, liquid & submerged

active ( Via )

196.91

kN/m2

2

(w*( H - Ht3) /2 + Ka*(Ht1+Tf)2/2 + Qw*Ht3)x(Lw+W c)

Moment due to wind, liquid &

submerged earth ( Mia )

449.57

kN

(Ka*(Ht1+Tf)3/6 + Qw*Ht3*(H - Ht3/2) +

w*(H - Ht3)3/6*) x (Lw + W c)

712.64

108

kNm

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for

Wet

Main

Crude

Crude

Oil Oil

Tank-21-TK-001

Tank TK - 1526 &

Test Tank Tk - 1527

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

109

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

: JI-180-000-ECV-CAL-050

Subject : Design of Column Bund Wall

Rev No

: 0

for

Wet

Main

Crude

Crude

Oil Oil

Tank-21-TK-001

Tank TK - 1526 &

Prep. By : Dipak

Test Tank Tk - 1527

Checkd. By : Mr. Girish Kurnool

Passive

b)

Calculation of Moment & Shear due to 2/3 height of passive earth pressure about the base of footing.

Pressure due to earth ( Pip )

=

=

Shear due to earth pressure ( Vip )

Moment due to earth pressure ( Mip )

=

=

=

=

Shear at the base of footing ( Vs )

=

=

Moment at the base of footing ( Mo )

=

=

Maximum Moment & Shear From Case I & II :

Mz

=

Fx

*Kp*2/3*(Ho1 + Tf) * ( Lw + W c )

343.52

kN/m2

2/9**Kp*(Ho1 + Tf)2 * ( Lw + W c )

251.91

kN

4/81**Kp*(Ho1 + Tf)3 * ( Lw + W c )

123.16

Via - Vip

197.65

Mia - Mip

589.48

kNm

kN

... ( 24 )

kNm

... ( 25 )

Max of ( 23 ) & ( 25 )

589.48

kNm

=

=

Max of ( 22 ) & ( 24 )

197.65

kNm

Table 6.2 Load for Stability & Bearing Pressure Check

MAX

FY

886

FX

198

110

FZ

0

MX

0

MZ

589

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for

Wet

Main

Crude

Crude

Oil Oil

Tank-21-TK-001

Tank TK - 1526 &

Test Tank Tk - 1527

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

111

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for Main Crude Oil Tank TK - 1526 &

Test Tank Tk - 1527

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

7.0 DESIGN OF FOUNDATION:

y

z

x

Wc Wf

H1

z

Water Table

Lc

Tf

Lf

Lf

7.1 Geometrical Data :

Width of footing ( W f )

2.7

Length of footing ( Lf )

4.7

Depth of Footing ( Tf )

0.6

Width of column ( W c )

0.4

Length of column ( Lc )

0.6

Height of column ( H1 )

=

=

4.6

3.00

m

m

Projection of column above ground

7.2 Soil Data :

Unit weight of soil,( s )

Net allowable bearing pressure

Angle of internal friction, (

Factor of safety against overturning

Factor of safety against sliding

Coefficient of active earth pre. ( Ka )

Coefficient of passive earth pre. ( Kp )

Depth of Water table from Ground

7.3 Material Data :

Grade of Concrete ( Fcu )

=

=

=

=

=

=

18

KN/m3

150

KN/m2

O

32

1.75

1.75

( 1-SIN ) / ( 1+SIN )

=

=

( 1+SIN ) / ( 1-SIN )

10

m

0.31

3.25

30

N/mm2

Yield strength of rebar ( Fy )

414

N/mm2

Unit Weight of Concrete ( c )

Dia of Reinforcement in direction of Lf

Dia of Reinforcement in direction of Wf

Clear Cover to Reinforcement ( c )

Factor for the moment calculation ( f )

=

=

=

=

=

24

16

16

75

1.4

KN/m3

mm

mm

mm

FX

198

FZ

0

MX

0

MZ

589

FX

277

FZ

0

MX

0

MZ

825

FX

198

FZ

0

MX

0

MZ

589

7.4 Load Data For Stability Check :

(a) Load for Stability

JOINT

FY

MAX

886

(b) Ultimate load combination for concrete design.

JOINT

FY

MAX

1240

(c) Load combination for bearing pressure check:.

JOINT

FY

MAX

1

886

18

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for Main Crude Oil Tank TK - 1526 &

Test Tank Tk - 1527

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

19

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for Main Crude Oil Tank TK - 1526 &

Test Tank Tk - 1527

Uplift Force Due to Water Table ( Bf )

Total Weight ( Fy )

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

=

=

=

0

Fy + Bf

886

kN

198

KN

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

kN

7.5 Check For Stability :

Check For Sliding :

In X direction:

Sliding force in X direction ( Fx )

FY

Resisting frictional force ( Rx )

=

=

F.O.S. against sliding in X direction

=

=

In Z direction:

Net Sliding force in Z direction ( Fz )

FY

Resisting frictional force ( Rz )

Check For Overturning :

In X direction:

Forces acting at bottom of footing about Z

FY

Rx / F x

1.75

O.K. as value greater than permissible value

KN

886

KN

=

=

=

=

F.O.S. against sliding in Z direction

886

kN

Fy tan(2/3*)

345.93 KN

Fy tan(2/3*)

345.9272 KN

Rz / F z

NA

O.K. as value greater than permissible value

( Mzo )

Restoring Moment ( Mr )

=

=

=

886

Mz

589

BF*Lf/2

KN

KNm

+ Mzr

From Case I & II

2064.883 KN-m

Factor of safity against overturning = Mr / Mzo

=

3.50

1.4

2.35

O.K. , As value is greater than 1.75

BF

In Z direction:

Forces acting at bottom of footing about X

FY

Total overturning moment

( Mxo )

=

=

=

20

885.7346 KN

Mx

0

kNm

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for Main Crude Oil Tank TK - 1526 &

Test Tank Tk - 1527

Restoring Moment ( Mr )

=

=

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

BF*Lf/2

+ Mxr

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

From Case I & II

1195.742 kNm

Mr / Mxo

Factor of safity against overturning =

= N.A.

1.4

O.K. , As value is greater than 1.75

p

1.35

BF

7.5 Check For Bearing Pressure:

Gross vertical load ( PY )

886

Mxo

Mxr

Mx

Net Moment

Moment about X

Mzo

Mzr

Mz

KN

Moment about Z

Net Moment

kNm

1196

kNm

Mxo - Mxr

=

589

1195.7

kNm

1475.4

kNm

kNm

2065

kNm

Mzo - Mzr

=

( Mzo - Mzr ) / PY

1.67

m

( Mxo - Mxr ) / PY

1.35

m

=

=

ex

Lf/2 - x

0.684

e<L/6, No Tension in footing.

ez

W f/2 - z

0.00

e<B/6, No Tension in Footing.

Gross pressure under footing ( p )

=

=

P Y ( 1 6 e x 6 eZ )

Lf W f

Lf

Wf

p1

130.77

kN/m2

p3

130.77

kN/m2

p2

8.83

kN/m2

p4

8.83

kN/m2

Here, Contact Area

p4

100.000%

p3

+Mx

Maximum Gross Pressure

Mx

=

=

2P/ 3W f(0.5Lf - ex)

130.77

<

KN/m2

189.60

p2

KN/m

p1

Mz

Sign Convention

O.K. Less than allowable bearing pressure

4.7

4.7

7.6 Check For Moment And Shear

Pressure intensities at the base of footing:

p1u =

p3ut =

130.77

kN/m2

p2u =

8.83

kN/m

p4u =

130.77

kN/m2

8.83

kN/m2

21

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for Main Crude Oil Tank TK - 1526 &

Test Tank Tk - 1527

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

Downward pressure intensities due to selfweight of footing & earth cushion:

p1d =

p3d = 36.00 kN/m2

36.00

kN/m2

p2d =

36.00

p4d =

kN/m2

36.00

kN/m2

(a) Check for Moment and One way Shear in X direction

1

1 2

36.00

36.00

P2

P1

8.83

77.58

104.41

90.99

( d = D - 75 - 8

130.77

Factored Pressure Distribution At Salient points

Moment at the Critical section 1:

Shear at critical section 1:

d

= 517 mm )

Critical Sections For Moment & Shear

=

=

22

161.8788 KNm/m Width of Footing.

139.7583 KN

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for Main Crude Oil Tank TK - 1526 &

Test Tank Tk - 1527

Shear at critical section 2:

Shear at critical section 3:

=

=

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

114.7934 KN

103.9843 KN

=

=

=

=

=

=

=

Mu / fcubd2 Factore Moment

0.028263 < 0.156

d[0.5+(0.25-k/0.9)]

500.22 mm

&

0.95*d

491.15 mm

491.15 mm

M/0.95fyz

Reqd. Spacing of 16 mm dia bar

Provided Spacing of 16 mm dia bar

Ast,provided

=

=

=

=

=

=

=

Design Concrete shear stress c

0.389

Ultimate shear stress v1

0.100121 N/mm2

Maximum allowed 0.8fcu

4.38178 N/mm2

Ultimate shear stress v2

0.082236 N/mm2

Maximum allowed 1.5c

0.583631 N/mm2

Ultimate shear stress v3

0.074493 N/mm2

Maximum allowed c

0.389087 N/mm2

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

Tensile Reinforcement:

K

Z

Hence z

Ast

Amin

Section 1

Section 2

Section 3

838.0151 mm2/m

0.13% of Area of concrete

mm2/m

780

240

mm

mm

200

mm2/m

1005.31

N/mm2

O.K. (Clause 3.7.7.2)

O.K. (Clause 3.7.7.4)

O.K.

(b) Check for Moment and One way Shear in Z direction

1 2 3

36.00

36.00

1

P3

P1

130.77

130.77

130.77

130.77

( d= D-75-16-8

130.77

Factored Pressure Distribution At Salient points

Moment at the Critical section 1:

Shear at critical section 1:

Shear at critical section 2:

Shear at critical section 3:

= 501 mm )

Critical Sections For Moment & Shear

=

=

=

=

23

62.67

108.984

61.505

37.765

KNm/m Width of Footing.

KN

KN

KN

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for Main Crude Oil Tank TK - 1526 &

Test Tank Tk - 1527

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

24

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for Main Crude Oil Tank TK - 1526 &

Test Tank Tk - 1527

Tensile Reinforcement:

Mu / fcubd2

Reqd. Spacing of 16 mm dia bar

Provided Spacing of 16 mm dia bar

Ast,provided

=

=

=

=

=

=

=

=

=

=

=

=

=

=

Design Concrete shear stress c

0.370

N/mm2

Ultimate shear stress v1

0.046

N/mm2

Maximum allowed 0.8fcu

4.38

N/mm2

Ultimate shear stress v2

0.03

N/mm2

Maximum allowed 1.5c

0.555003 N/mm2

Ultimate shear stress v3

0.016038 N/mm2

Maximum allowed c

K

Z

Hence z

Ast

Amin

Section 1

Section 2

Section 3

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

Factore Moment

0.011651 < 0.156

d[0.5+(0.25-k/0.9)]

494.43 mm

0.95*d

475.95 mm

475.95 mm

M/0.95fyz

&

334.77 mm2/m

0.13% of Area of concrete

mm2/m

780

258

mm

mm

200

1005.31 mm2/m

0.37

N/mm2

O.K. (Clause 3.7.7.2)

O.K. (Clause 3.7.7.4)

Hence O.K.

(c) Check for Punching Shear

UO

1.5d

U1

1.5d

Average of effective depth in two directions ( d )

Uo = 2 (W c+Lc)

=

2000 mm

U1 = U0 +12d

=

8108 mm

509

Maximum ultimate Vertical load on column FY

1240

KN

Ultimate shear stress for Uo

1.218

N/mm2

Maximum allowed 0.8fcu

4.382

N/mm2

Ultimate shear stress for U1 =

0.300

N/mm

Maximum allowed c =

0.370

N/mm2

25

mm

O.K.

O.K.

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for Main Crude Oil Tank TK - 1526 &

Test Tank Tk - 1527

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

26

JI-180-000-ECV-CAL-050

0

Dipak

Mr. Girish Kurnool

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of Column Bund Wall

for Main Crude Oil Tank TK - 1526 &

Test Tank Tk - 1527

Doc No

: JI-180-000-ECV-CAL-050

Rev No

: 0

Prep. By : Dipak

Checkd. By :Mr. Girish Kurnool

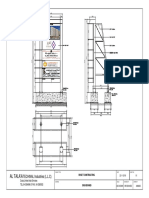

Appendix - I

A

EL 100.50

400

EL 100.50

3600

400

600

300

3000

4400

2700

300

1600

1600

600

600

3.5

2700

0.6

4700

GA Details Of Wall & Column

Section A-A

** All Dimensions Are In MM

** All Dimensions Are In MM

B

T 12 @ 200 mm c/c

Tt

To

Sectional Plan Of Wall

x

z

( RC Detail Only )

Panel

Tankside Face ( Tt )

Otherside Face ( To )

Top - 1

T 12 @ 200 mm c/c

T 12 @ 200 mm c/c

Mid - 2

T 16 @ 150 mm c/c

T 16 @ 150 mm c/c

Bottom -3

T 20 @ 200 mm c/c

T 20 @ 200 mm c/c

T 8 @ 150 mm c/c

T 25 @ 12 Nos

T 16 @ 200 mm c/c

T 16 @ 200 mm c/c

Section B-B

24

( RC Detail Only )

25

You might also like

- Foundation Dynamic AnalysisDocument27 pagesFoundation Dynamic AnalysisCatherine Mohanji GeraNo ratings yet

- Sub 01 012Document21 pagesSub 01 012ARYA JENA100% (1)

- Prestressed-Precast Design SpreadsheetDocument6 pagesPrestressed-Precast Design SpreadsheetCivilax.com100% (3)

- Box Culvert Calculation As Per BD3101Document21 pagesBox Culvert Calculation As Per BD3101Pilippenge Asanka Iraj LaknathaNo ratings yet

- Design of Sanitary Wastewater ManholesDocument4 pagesDesign of Sanitary Wastewater Manholessajeerala0% (1)

- Appendix: Appendix A1: Example PSSR Completion FormDocument5 pagesAppendix: Appendix A1: Example PSSR Completion FormSumantrra ChattopadhyayNo ratings yet

- Project No. Date - Sheet No. Computed by 1 of 9 - Subject - Checked by Approved byDocument9 pagesProject No. Date - Sheet No. Computed by 1 of 9 - Subject - Checked by Approved bysaravananNo ratings yet

- Al Tala'A: TECHINAL Industries (L.L.C)Document1 pageAl Tala'A: TECHINAL Industries (L.L.C)premNo ratings yet

- Stability CheckDocument2 pagesStability ChecksaravananNo ratings yet

- POLEFDNDocument10 pagesPOLEFDNcoolkaisyNo ratings yet

- PT Foundation ApprovedDocument6 pagesPT Foundation ApprovedSujit RasailyNo ratings yet

- Foundation F1 Design CalculationDocument30 pagesFoundation F1 Design CalculationvasudhaNo ratings yet

- WallDocument44 pagesWallUmesh ChamaraNo ratings yet

- Design of Gantry GirderDocument9 pagesDesign of Gantry GirderAzim KadriNo ratings yet

- Slab Manual DesignDocument1 pageSlab Manual DesignAtul ShrivastavaNo ratings yet

- Gutter DesignDocument6 pagesGutter Designtawas200% (1)

- Isolated Footing (ACI)Document4 pagesIsolated Footing (ACI)Boubakeur FerkousNo ratings yet

- Wind CalculationDocument6 pagesWind CalculationKhairul JaggerNo ratings yet

- Base Plate Design BS CodeDocument3 pagesBase Plate Design BS CodeFodor ZoltanNo ratings yet

- 00calculation Sheet For MMII Compressor Shed1Document31 pages00calculation Sheet For MMII Compressor Shed1clarkgaguiNo ratings yet

- Combined Footing Design1Document39 pagesCombined Footing Design1John Carlo Amodia0% (2)

- STAAD - PRO - Single PoleDocument2 pagesSTAAD - PRO - Single PoleAmol GoleNo ratings yet

- BoxDocument8 pagesBoxJack Danielz LubisNo ratings yet

- Pad Foundation DesignDocument4 pagesPad Foundation Designg4goharNo ratings yet

- Isolated FootingDocument289 pagesIsolated FootingjoanreyNo ratings yet

- Precast Column - Stability CalculationDocument1 pagePrecast Column - Stability Calculationarif_rubinNo ratings yet

- Combined Footing Design - UjjwalDocument25 pagesCombined Footing Design - UjjwalUjjwal MondolNo ratings yet

- BS 8110:part 1: 1985, Section Three, Table 3.9: C S V 1/3 1/4 MDocument7 pagesBS 8110:part 1: 1985, Section Three, Table 3.9: C S V 1/3 1/4 MnaconnetNo ratings yet

- RCC94 Two-Way Slabs (Tables) GGGDocument3 pagesRCC94 Two-Way Slabs (Tables) GGGThomas OluwafemiNo ratings yet

- Reference Calculations Output: N/A Project CalculationDocument2 pagesReference Calculations Output: N/A Project CalculationRyan De LeonNo ratings yet

- Anchor Bolt Design For Portal and Connecting BridgeDocument2 pagesAnchor Bolt Design For Portal and Connecting BridgeAbhinav YadavNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument103 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectToy GamesNo ratings yet

- Foundation Design For 66kV Steel Poles Bo-Kenema-SOIL CLASS 2A-08-11-21Document22 pagesFoundation Design For 66kV Steel Poles Bo-Kenema-SOIL CLASS 2A-08-11-21BAWA ALEXNo ratings yet

- Load Combination For Steel Design Per BS en 1990 EditionDocument2 pagesLoad Combination For Steel Design Per BS en 1990 EditionAsaru Deen100% (2)

- General Purpose Worksheet: Wind LoadingDocument11 pagesGeneral Purpose Worksheet: Wind LoadingabuzahrauNo ratings yet

- Grating1 2Document17 pagesGrating1 2Dhanraj VasanthNo ratings yet

- BeamDocument7 pagesBeamsomumallidiNo ratings yet

- Slab Design-@ Design OfficeDocument40 pagesSlab Design-@ Design OfficeShamen AmarasekaraNo ratings yet

- Ledge Design HCSDocument3 pagesLedge Design HCSsidiq7No ratings yet

- Design of Base PlateDocument4 pagesDesign of Base PlatesanggythaNo ratings yet

- WALLPRES ExcavationDocument11 pagesWALLPRES ExcavationShekh Muhsen Uddin AhmedNo ratings yet

- M3D - SampleProblemSet ACI PDFDocument6 pagesM3D - SampleProblemSet ACI PDFasaisenthilNo ratings yet

- ACI BendDocument3 pagesACI Bendمصطفى عبدالرحيمNo ratings yet

- DESIGN OF SLAB - ContdDocument4 pagesDESIGN OF SLAB - ContdmeenuNo ratings yet

- Wind Load CalculationDocument2 pagesWind Load CalculationWangTFNo ratings yet

- Rean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionDocument11 pagesRean'S Building 5/24/2002 Angle Plate Design: Framed Beam Connectionmhel_almoNo ratings yet