Professional Documents

Culture Documents

Nitoflor Anti-Slip Grans

Nitoflor Anti-Slip Grans

Uploaded by

Balasubramanian AnanthCopyright:

Available Formats

You might also like

- 3 STOREY Commercial Building Phase 2Document21 pages3 STOREY Commercial Building Phase 2Vic NairaNo ratings yet

- Site Master FileDocument51 pagesSite Master FileMilonhg100% (2)

- Sds - Bengalac Gloss - English (Uk) - DubaiDocument5 pagesSds - Bengalac Gloss - English (Uk) - DubaiBalasubramanian Ananth0% (1)

- Sds - Bengalac Gloss - English (Uk) - DubaiDocument5 pagesSds - Bengalac Gloss - English (Uk) - DubaiBalasubramanian Ananth0% (1)

- Rigidrain RigisewerDocument84 pagesRigidrain Rigiseweralberto5791No ratings yet

- 1.0 Objectives of Covered LinkwaysDocument4 pages1.0 Objectives of Covered LinkwaysDavid WangNo ratings yet

- Hydraulic Computation For Depressed Sewer (Inverted Syphon) : 1. Velocity Calculation For Supernatant PipeDocument2 pagesHydraulic Computation For Depressed Sewer (Inverted Syphon) : 1. Velocity Calculation For Supernatant PipeJennifer PearsonNo ratings yet

- Stucco PDFDocument3 pagesStucco PDFBalasubramanian AnanthNo ratings yet

- Sds - Bengalac Woodprimer - English (Uk) - DubaiDocument5 pagesSds - Bengalac Woodprimer - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- Liquid Penetrant Method - Level II - A QuestionDocument16 pagesLiquid Penetrant Method - Level II - A Questionmahmoud_allam375% (4)

- Product Development & Design PACKAGING Design & Labelling: March 31, 2017Document88 pagesProduct Development & Design PACKAGING Design & Labelling: March 31, 2017Nhizza Dawn Aleria-Daligdig TuburanNo ratings yet

- Semi-Automatic Blowing Machine B-IDocument5 pagesSemi-Automatic Blowing Machine B-IHitendra Nath BarmmaNo ratings yet

- Inner Scraper Self-Cleaning FiltersDocument1 pageInner Scraper Self-Cleaning FiltersCarlos BarriosNo ratings yet

- FFS-579 OutDocument134 pagesFFS-579 OutAwanNo ratings yet

- 2924-A110-13C67-DWG-0004 - R0.1 - Electrical Cable Routing and Tray Routing Layout AdsorberDocument7 pages2924-A110-13C67-DWG-0004 - R0.1 - Electrical Cable Routing and Tray Routing Layout AdsorberRonti ChanyangNo ratings yet

- Volkmann Technical Exclusive Vacuum ConveyingDocument3 pagesVolkmann Technical Exclusive Vacuum ConveyingMarkNo ratings yet

- GondolaDocument1 pageGondolascax25No ratings yet

- Rescue and Ventilation Plan Template (Vent Plan)Document1 pageRescue and Ventilation Plan Template (Vent Plan)Denn HairlyNo ratings yet

- Filter Press QuestionnaireDocument3 pagesFilter Press QuestionnaireRakhee SinhaNo ratings yet

- Ce - 02aDocument1 pageCe - 02aArnulfo Jose Pi DiNo ratings yet

- 036909C 2bae05 Iso SCS 23500 01 1S3Document4 pages036909C 2bae05 Iso SCS 23500 01 1S3NguyenCanhBaoNo ratings yet

- 2 1 PDFDocument162 pages2 1 PDFyvanmmuNo ratings yet

- Plate & Frame Filter Press: Filter Plates Filter ClothsDocument1 pagePlate & Frame Filter Press: Filter Plates Filter ClothsinstrutechNo ratings yet

- Series 500 Mk3 General Arrangement Rev 3 RNE PUMP PARTSDocument1 pageSeries 500 Mk3 General Arrangement Rev 3 RNE PUMP PARTSZaen SalimNo ratings yet

- Punj LloydDocument21 pagesPunj LloydGaurav Kumar100% (1)

- 042 OSHA Stairways LaddersDocument45 pages042 OSHA Stairways LaddersAMITNo ratings yet

- Dosing Unit Modifications FinalDocument11 pagesDosing Unit Modifications FinalMrNo ratings yet

- 2006 Spiral CatalogDocument52 pages2006 Spiral CatalogalemilioNo ratings yet

- Clearwater Self-Cleaning Suction Screen BrochureDocument2 pagesClearwater Self-Cleaning Suction Screen BrochureIonut SomneaNo ratings yet

- Roto Pump VLCA-571 General ArrangeDocument1 pageRoto Pump VLCA-571 General ArrangeEdinsonUribeTorresNo ratings yet

- Aqua SilencerDocument14 pagesAqua Silencermd inam ul hasan safwan100% (1)

- SNO M BBB FD 80 204 - Rev - A1Document2 pagesSNO M BBB FD 80 204 - Rev - A1Anonymous p0iwBoNo ratings yet

- Vacuum Conveying: C Series Conveyor Troubleshooting GuideDocument60 pagesVacuum Conveying: C Series Conveyor Troubleshooting Guidesafe150_239331910No ratings yet

- 2924-G000-13517-DWG-0008 - 0.0 - Standard Drawing For Floor and JoistDocument3 pages2924-G000-13517-DWG-0008 - 0.0 - Standard Drawing For Floor and JoistGeta Oisis Arya PutraNo ratings yet

- GB Prorox-Product CatalogDocument19 pagesGB Prorox-Product CatalogGozuengineer GozuNo ratings yet

- OxfordFiltration SelfCleaningFiltersDocument2 pagesOxfordFiltration SelfCleaningFiltersgui51comlimaoNo ratings yet

- SPE-177914-MS Successful Chemical Water Shut-Off Treatment in An Omani Field Heavy-Oil WellDocument19 pagesSPE-177914-MS Successful Chemical Water Shut-Off Treatment in An Omani Field Heavy-Oil Wellnia setya budiningtyasNo ratings yet

- Ventilation For Confined SpacesDocument17 pagesVentilation For Confined SpacesahmadhatakeNo ratings yet

- Type 1 Structural DrawingDocument23 pagesType 1 Structural Drawingmyoaung.clickNo ratings yet

- Confined Space-Purging and VentilationDocument13 pagesConfined Space-Purging and VentilationFernando De FerrarisNo ratings yet

- High Speed DoorsDocument64 pagesHigh Speed DoorsTgNo ratings yet

- M14-Oil & Water StrainerDocument31 pagesM14-Oil & Water StrainerAlexNo ratings yet

- Lateral DimensionsDocument1 pageLateral DimensionsaravindhcamNo ratings yet

- Florida Guard Rail SystemDocument26 pagesFlorida Guard Rail SystemZaher Mhd SharafNo ratings yet

- Anti Slip Coatingp 63 FinalDocument50 pagesAnti Slip Coatingp 63 Finalaripramono100% (1)

- On-Site Electrolytic Chlorination Skid-Mounted OSEC B-Pak SystemDocument4 pagesOn-Site Electrolytic Chlorination Skid-Mounted OSEC B-Pak SystemgohviccNo ratings yet

- Settling Tank DecantDocument23 pagesSettling Tank Decantjvan migvelNo ratings yet

- Repair or Alteration of Pressure VesselsDocument4 pagesRepair or Alteration of Pressure VesselsMSNo ratings yet

- QueenstownDocument9 pagesQueenstownYap Juin ShiongNo ratings yet

- Technical Guidelines 2013WEB PDFDocument116 pagesTechnical Guidelines 2013WEB PDFTien Hong DoNo ratings yet

- Data Sheet, GAD and QAP of Y StrainerDocument13 pagesData Sheet, GAD and QAP of Y StrainerSHABAHATNo ratings yet

- Absorptive SilencersDocument5 pagesAbsorptive SilencersDaniel SmsNo ratings yet

- Meiser GratingDocument62 pagesMeiser GratingDushan RomicNo ratings yet

- Column Footing ScheduleDocument1 pageColumn Footing ScheduleCMM INFRAPROJECTS LTDNo ratings yet

- Bell Mouth PDFDocument3 pagesBell Mouth PDFSubramanian SaravananNo ratings yet

- Air Con LouvresDocument1 pageAir Con LouvresChung May LynnNo ratings yet

- SCOMET Declaration FormatDocument1 pageSCOMET Declaration FormatChirag Sankaranarayanan VaitheeswaranNo ratings yet

- Gas Flotation Package (Asbea-A-2703) 32294 Ponticelli - Al Shaheen PWTDocument54 pagesGas Flotation Package (Asbea-A-2703) 32294 Ponticelli - Al Shaheen PWTTĩnh Hồ TrungNo ratings yet

- FQP For Chimney 3 MechanicalDocument4 pagesFQP For Chimney 3 MechanicalKuldeep ChakerwartiNo ratings yet

- Plant Location and LayoutDocument36 pagesPlant Location and LayoutNishaThakuriNo ratings yet

- Warning and Safety Reminders For Screw, Drag, and Bucket Elevator ConveyorsDocument2 pagesWarning and Safety Reminders For Screw, Drag, and Bucket Elevator ConveyorsAndreLeandro10No ratings yet

- EMCO Floating Suctions enDocument2 pagesEMCO Floating Suctions enAnonymous yQ7SQrNo ratings yet

- Type AB Air Gaps - Practical ExamplesDocument3 pagesType AB Air Gaps - Practical ExamplesZack ZakariaNo ratings yet

- 20ft Skid ISO FrameDocument1 page20ft Skid ISO FrameThanhdong DoNo ratings yet

- Confined Space VentilationDocument31 pagesConfined Space VentilationX100% (1)

- Analysis Strength of Scaffolding Structure On Stack HRSG For Cable TightDocument5 pagesAnalysis Strength of Scaffolding Structure On Stack HRSG For Cable TighthendraNo ratings yet

- Pipe RacksDocument1 pagePipe RacksBryan AyalaNo ratings yet

- Nitoflor Anti-Slip GransDocument2 pagesNitoflor Anti-Slip GranstalatzahoorNo ratings yet

- TDS - STUCCO - English - Issued.18.11.2002Document3 pagesTDS - STUCCO - English - Issued.18.11.2002Balasubramanian AnanthNo ratings yet

- SDS - Texo Compound - English (Uk) - DubaiDocument4 pagesSDS - Texo Compound - English (Uk) - DubaiBalasubramanian Ananth100% (3)

- SDS - Acrylic Emulsion Primer - English (Uk) - DubaiDocument4 pagesSDS - Acrylic Emulsion Primer - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- SDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiDocument5 pagesSDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- SDS - Fenomastic Emulsion Matt - English (Uk) - DubaiDocument5 pagesSDS - Fenomastic Emulsion Matt - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- Penguard HB - Comp ADocument5 pagesPenguard HB - Comp ABalasubramanian AnanthNo ratings yet

- SDS - Fenomastic Enamel Matt - English (Uk) - DubaiDocument5 pagesSDS - Fenomastic Enamel Matt - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- SDS - Bengalac Matt - English (Uk) - DubaiDocument5 pagesSDS - Bengalac Matt - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- SDS - Durosan - English (Uk) - DubaiDocument5 pagesSDS - Durosan - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- SDS - Fenomastic Emulsion Semigloss - English (Uk) - DubaiDocument5 pagesSDS - Fenomastic Emulsion Semigloss - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- SDS - Bengalac Red Oxide Primer - English (Uk) - DubaiDocument5 pagesSDS - Bengalac Red Oxide Primer - English (Uk) - DubaiBalasubramanian Ananth100% (1)

- SDS - Bengalac Semigloss - English (Uk) - DubaiDocument5 pagesSDS - Bengalac Semigloss - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- Penguard HB - Comp B-ScribdDocument5 pagesPenguard HB - Comp B-ScribdBalasubramanian AnanthNo ratings yet

- SDS - Acrylic Emulsion Primer - English (Uk) - DubaiDocument4 pagesSDS - Acrylic Emulsion Primer - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- SDS - Bengalac Aluminium - English (Uk) - Dubai-Start ScribdDocument5 pagesSDS - Bengalac Aluminium - English (Uk) - Dubai-Start ScribdBalasubramanian AnanthNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthNo ratings yet

- Safety Data Sheet: Identification of The Substance/preparation and of The Company/undertakingDocument4 pagesSafety Data Sheet: Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian Ananth100% (1)

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument3 pagesSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthNo ratings yet

- Durathane Matt - Comp ADocument4 pagesDurathane Matt - Comp ABalasubramanian AnanthNo ratings yet

- Safety Data Sheet: Identification of The Substance/preparation and of The Company/undertakingDocument5 pagesSafety Data Sheet: Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthNo ratings yet

- Class I - 2L - Class I - 2011-2012Document4 pagesClass I - 2L - Class I - 2011-2012Balasubramanian AnanthNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthNo ratings yet

- RBC FGDocument18 pagesRBC FGdragon_ecuNo ratings yet

- Trane Rental Service BrochureDocument4 pagesTrane Rental Service BrochureNoe AriasNo ratings yet

- StenterDocument2 pagesStenterMusa Eltayeb100% (2)

- Alpha Design Presentation.Document35 pagesAlpha Design Presentation.vasucristalNo ratings yet

- Production Planning and Control: Introductio NDocument29 pagesProduction Planning and Control: Introductio NPankaj MishraNo ratings yet

- Plastic TechnologyDocument171 pagesPlastic Technologyeitan-dalia4971No ratings yet

- Drum Screen SDocument2 pagesDrum Screen SMariusCapraNo ratings yet

- Display Merchandising Pop Promotion CatalogueDocument20 pagesDisplay Merchandising Pop Promotion CataloguePrinceIposNo ratings yet

- Website Design of Job Description Based On Isco-08 and Calculation of Employee Total Needs Based On Work LoadDocument10 pagesWebsite Design of Job Description Based On Isco-08 and Calculation of Employee Total Needs Based On Work LoadAgra AdiyasaNo ratings yet

- Pil 01 PilcDocument6 pagesPil 01 Pilcpingu 132435No ratings yet

- MS494: Total Quality Management: Course Instructor: DR Noor Muhammad Teaching Assistant: Ms MamoonaDocument36 pagesMS494: Total Quality Management: Course Instructor: DR Noor Muhammad Teaching Assistant: Ms MamoonaFurqan YousafzaiNo ratings yet

- Residential Steel Frame Building Case StudyDocument29 pagesResidential Steel Frame Building Case Studyprajoshi62No ratings yet

- European Standards For Metallic MaterialsDocument16 pagesEuropean Standards For Metallic MaterialsClaudia Mms0% (1)

- Sohrab ProjectDocument8 pagesSohrab ProjectZarak MirNo ratings yet

- Rigid Pavement DistressesDocument26 pagesRigid Pavement Distressesசுப. ஸ்ரீதர்100% (1)

- Product Design & DevelopmentDocument50 pagesProduct Design & DevelopmentAshok Dargar100% (1)

- Harsh Iit Kanpur CVDocument3 pagesHarsh Iit Kanpur CVapi-293629330No ratings yet

- K Thermostats Brochure 5lDocument2 pagesK Thermostats Brochure 5laldariz201181No ratings yet

- ShearingDocument3 pagesShearingSuraj Singh100% (1)

- Reliability Centered MaintenanceDocument116 pagesReliability Centered MaintenanceantonNo ratings yet

- Design HandbookDocument49 pagesDesign HandbookStas Zabarsky100% (1)

- Qualice Solutions - BrochureDocument18 pagesQualice Solutions - Brochurejamil voraNo ratings yet

- P250 Ceramic TilesDocument4 pagesP250 Ceramic TilesabbNo ratings yet

- TR4 - Listing of HDB-PDB-MRS For Thermoplastic Piping MaterialsDocument66 pagesTR4 - Listing of HDB-PDB-MRS For Thermoplastic Piping MaterialsRyan Carter100% (1)

- Production Analysis Short Run and Long Run Costs, Economies of ScaleDocument69 pagesProduction Analysis Short Run and Long Run Costs, Economies of ScaleDr. Rakesh BhatiNo ratings yet

- LFS Report 2010Document268 pagesLFS Report 2010Sohel RanaNo ratings yet

Nitoflor Anti-Slip Grans

Nitoflor Anti-Slip Grans

Uploaded by

Balasubramanian AnanthOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nitoflor Anti-Slip Grans

Nitoflor Anti-Slip Grans

Uploaded by

Balasubramanian AnanthCopyright:

Available Formats

Nitoflor Anti-Slip Grains

constructive solutions

Non-slip flooring aggregates

Uses

Application instructions

Nitoflor anti-slip grains are designed for use with Nitoflor

resin products to produce non-slip industrial floors. Ideally

suite for wet work areas in abattoirs, breweries, dairies,

chemical industries, food processing areas, loading bays,

ramps and walkways.

Advantages

Range of products to suit most applications.

Special grading to suit Nitoflor products.

All Nitoflor anti-slip grains should be clean and dry prior to

application.

Nitoflor anti-slip grains No. 1, No. 2 and No. 3 are designed

for use with Nitoflor FC150, solvent free, resin based, roller

applied floor coating, and Nitoflor SL2000, Nitoflor SL3000

and Nitoflor SL4000 self-smoothing, solvent free epoxy floor

toppings. In the case of application onto the SL products, a

final coat of Nitoflor FC150 is applied.

Nitoflor anti-slip grain No. 4 is used in conjunction with

Nitoflor FC130 and Nitoflor FC140 floor coatings. When

using anti-slip grain No. 4, the resultant floor finish will be of

a fine texture the thickness of which will range from 0.3 to

0.6 mm.

Pre-packed ready for immediate site use.

Description

Nitoflor anti-slip grains are available in four grades to suit

most site requirements, they are identified as follows:

Nitoflor anti-slip grain No. 1

Specially selected, hard wearing, chemically inert aggregate

of road stone quality for use with the Nitoflor SL range to

provide a coarse textured, non-slip floor topping.

Nitoflor anti-slip grain No. 2

Chemically inert, graded, hard wearing aggregate for use

with Nitoflor FC150 and the SL range to produce a medium

coarse textured floor finish.

Nitoflor anti-slip grain No. 3

Finely graded, chemically inert aggregate for use with

Nitoflor FC150 and the LS range to produce a non-slip floor

with a fine textured finish.

Application

The specially graded aggregates are scattered on to the

first rolled coat of Nitoflor resin flooring whilst it is still wet.

Sufficient Nitoflor anti-slip gains should be applied to

completely cover or blind the surface.

The selected anti-slip grain should be allowed to fall

vertically onto the resin coating rather than be thrown across

the surface as this may cause ridges or scour the coating,

and damage the continuous film of the resin flooring.

When the first coat has dried, the excess aggregate can be

brushed or vacuumed off the substrate and provided it is still

clean and dry can be re-used.

The final roller coat of Nitoflor FC can then be applied to

produce a hard wearing, chemically resistant non-slip floor.

The texture and thickness of the floor is determined by the

choice of the Nitoflor anti-slip grain.

Nitoflor anti-slip grain No. 4

Nitoflor anti-slip

grain

Extra fine, chemically inert aggregate for use only with

Nitoflor FC130 or Nitoflor FC140 to provide a fine textured

non-slip finish with thin floor coatings.

Technical support

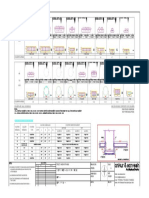

No. 1

No. 2

No. 3

Finished floor

texture

Coarse

Medium

Fine

Finished floor

thickness for

Nitoflor FC150

2.00 - 2.5 mm

1.50 - 2.0 mm

0.75 - 1.5 mm

Estimating

Fosroc offers a comprehensive range of high performance,

high quality repair, maintenance and construction products.

In addition, Fosroc offers a technical support package to

specifiers, end-users and contractors, as well as on-site

technical assistance in locations all over the world.

Supply

Nitoflor anti-slip grains:

Page 1

25 kg bags

Nitoflor Anti-Slip Grains

Approximate usage

Gross:

Nett:

kg/m2

4 - 12

2-4

m2/25 kg bags

2-6

8 - 16

Storage

Storage conditions

Store in dry conditions in the original, unopened bags or

packs.

Precautions

Health and safety

Nitoflor anti-slip grains are non-hazardous.

Fire

Nitoflor anti-slip grains are non-flammable.

Additional information

Nitoflor anti-slip grains are part of a range of Fosroc

specialised flooring materials.

In addition, Fosroc

manufactures a range of complementary products which

includes waterproofing membranes, joint sealants, grouting

and anchoring. Additionally, a wide range of products

specifically designed for the repair and refurbishment of

damaged reinforced concrete is available.

Important note:

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions for the

Supply of Goods and Services, copies of which may be obtained on request. Whilst Fosroc endeavours to ensure that any advice,

recommendation, specification of information it may give is accurate and correct, it cannot, because it has no direct or continuous

control over where or how its products are applied, accept any liability either directly or indirectly arising from the use of its products,

whether or not in accordance with any advice, specification, recommendation of information given by it.

Fosam Company Limited

Head Office

Post Box 11081

Jeddah 21453

Saudi Arabia

www.fosroc.com

Telephone: +966 2 637 5345

Fax: +966 2 637 5891

email: fosam@fosroc.com

Regional Offices

Jeddah Sales Office

Jeddah Showroom

Riyadh

Dammam

Khamis Mushayt

Tel: (02) 608 0999

Tel: (02) 665 0187

Tel: (01) 482 9303

Tel: (03) 814 1282

Tel: (07) 250 0469

Fax: (02) 635 3330

Fax: (02) 667 4844

Fax: (01) 482 7562

Fax: (03) 814 1581

Fax: (07) 250 0469

Yanbu

Makkah

Medinah

Jubail

CSD

Tel: (04) 322 4280

Tel: (02) 542 0869

Tel: (04) 845 1767

Tel: (03) 362 3904

Tel: (02) 608 0999

Fax: (04) 391 2980

Fax: (02) 542 0869

Fax: (04) 846 3195

Fax: (03) 362 3875

Fax: (02) 635 3330

Registered Office: Industrial Area, Phase 4, Road No. 414, Street No. 407

Page 2

FO SA/NTIOFLOR ANTI-SLIP GRAINS/05/A

You might also like

- 3 STOREY Commercial Building Phase 2Document21 pages3 STOREY Commercial Building Phase 2Vic NairaNo ratings yet

- Site Master FileDocument51 pagesSite Master FileMilonhg100% (2)

- Sds - Bengalac Gloss - English (Uk) - DubaiDocument5 pagesSds - Bengalac Gloss - English (Uk) - DubaiBalasubramanian Ananth0% (1)

- Sds - Bengalac Gloss - English (Uk) - DubaiDocument5 pagesSds - Bengalac Gloss - English (Uk) - DubaiBalasubramanian Ananth0% (1)

- Rigidrain RigisewerDocument84 pagesRigidrain Rigiseweralberto5791No ratings yet

- 1.0 Objectives of Covered LinkwaysDocument4 pages1.0 Objectives of Covered LinkwaysDavid WangNo ratings yet

- Hydraulic Computation For Depressed Sewer (Inverted Syphon) : 1. Velocity Calculation For Supernatant PipeDocument2 pagesHydraulic Computation For Depressed Sewer (Inverted Syphon) : 1. Velocity Calculation For Supernatant PipeJennifer PearsonNo ratings yet

- Stucco PDFDocument3 pagesStucco PDFBalasubramanian AnanthNo ratings yet

- Sds - Bengalac Woodprimer - English (Uk) - DubaiDocument5 pagesSds - Bengalac Woodprimer - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- Liquid Penetrant Method - Level II - A QuestionDocument16 pagesLiquid Penetrant Method - Level II - A Questionmahmoud_allam375% (4)

- Product Development & Design PACKAGING Design & Labelling: March 31, 2017Document88 pagesProduct Development & Design PACKAGING Design & Labelling: March 31, 2017Nhizza Dawn Aleria-Daligdig TuburanNo ratings yet

- Semi-Automatic Blowing Machine B-IDocument5 pagesSemi-Automatic Blowing Machine B-IHitendra Nath BarmmaNo ratings yet

- Inner Scraper Self-Cleaning FiltersDocument1 pageInner Scraper Self-Cleaning FiltersCarlos BarriosNo ratings yet

- FFS-579 OutDocument134 pagesFFS-579 OutAwanNo ratings yet

- 2924-A110-13C67-DWG-0004 - R0.1 - Electrical Cable Routing and Tray Routing Layout AdsorberDocument7 pages2924-A110-13C67-DWG-0004 - R0.1 - Electrical Cable Routing and Tray Routing Layout AdsorberRonti ChanyangNo ratings yet

- Volkmann Technical Exclusive Vacuum ConveyingDocument3 pagesVolkmann Technical Exclusive Vacuum ConveyingMarkNo ratings yet

- GondolaDocument1 pageGondolascax25No ratings yet

- Rescue and Ventilation Plan Template (Vent Plan)Document1 pageRescue and Ventilation Plan Template (Vent Plan)Denn HairlyNo ratings yet

- Filter Press QuestionnaireDocument3 pagesFilter Press QuestionnaireRakhee SinhaNo ratings yet

- Ce - 02aDocument1 pageCe - 02aArnulfo Jose Pi DiNo ratings yet

- 036909C 2bae05 Iso SCS 23500 01 1S3Document4 pages036909C 2bae05 Iso SCS 23500 01 1S3NguyenCanhBaoNo ratings yet

- 2 1 PDFDocument162 pages2 1 PDFyvanmmuNo ratings yet

- Plate & Frame Filter Press: Filter Plates Filter ClothsDocument1 pagePlate & Frame Filter Press: Filter Plates Filter ClothsinstrutechNo ratings yet

- Series 500 Mk3 General Arrangement Rev 3 RNE PUMP PARTSDocument1 pageSeries 500 Mk3 General Arrangement Rev 3 RNE PUMP PARTSZaen SalimNo ratings yet

- Punj LloydDocument21 pagesPunj LloydGaurav Kumar100% (1)

- 042 OSHA Stairways LaddersDocument45 pages042 OSHA Stairways LaddersAMITNo ratings yet

- Dosing Unit Modifications FinalDocument11 pagesDosing Unit Modifications FinalMrNo ratings yet

- 2006 Spiral CatalogDocument52 pages2006 Spiral CatalogalemilioNo ratings yet

- Clearwater Self-Cleaning Suction Screen BrochureDocument2 pagesClearwater Self-Cleaning Suction Screen BrochureIonut SomneaNo ratings yet

- Roto Pump VLCA-571 General ArrangeDocument1 pageRoto Pump VLCA-571 General ArrangeEdinsonUribeTorresNo ratings yet

- Aqua SilencerDocument14 pagesAqua Silencermd inam ul hasan safwan100% (1)

- SNO M BBB FD 80 204 - Rev - A1Document2 pagesSNO M BBB FD 80 204 - Rev - A1Anonymous p0iwBoNo ratings yet

- Vacuum Conveying: C Series Conveyor Troubleshooting GuideDocument60 pagesVacuum Conveying: C Series Conveyor Troubleshooting Guidesafe150_239331910No ratings yet

- 2924-G000-13517-DWG-0008 - 0.0 - Standard Drawing For Floor and JoistDocument3 pages2924-G000-13517-DWG-0008 - 0.0 - Standard Drawing For Floor and JoistGeta Oisis Arya PutraNo ratings yet

- GB Prorox-Product CatalogDocument19 pagesGB Prorox-Product CatalogGozuengineer GozuNo ratings yet

- OxfordFiltration SelfCleaningFiltersDocument2 pagesOxfordFiltration SelfCleaningFiltersgui51comlimaoNo ratings yet

- SPE-177914-MS Successful Chemical Water Shut-Off Treatment in An Omani Field Heavy-Oil WellDocument19 pagesSPE-177914-MS Successful Chemical Water Shut-Off Treatment in An Omani Field Heavy-Oil Wellnia setya budiningtyasNo ratings yet

- Ventilation For Confined SpacesDocument17 pagesVentilation For Confined SpacesahmadhatakeNo ratings yet

- Type 1 Structural DrawingDocument23 pagesType 1 Structural Drawingmyoaung.clickNo ratings yet

- Confined Space-Purging and VentilationDocument13 pagesConfined Space-Purging and VentilationFernando De FerrarisNo ratings yet

- High Speed DoorsDocument64 pagesHigh Speed DoorsTgNo ratings yet

- M14-Oil & Water StrainerDocument31 pagesM14-Oil & Water StrainerAlexNo ratings yet

- Lateral DimensionsDocument1 pageLateral DimensionsaravindhcamNo ratings yet

- Florida Guard Rail SystemDocument26 pagesFlorida Guard Rail SystemZaher Mhd SharafNo ratings yet

- Anti Slip Coatingp 63 FinalDocument50 pagesAnti Slip Coatingp 63 Finalaripramono100% (1)

- On-Site Electrolytic Chlorination Skid-Mounted OSEC B-Pak SystemDocument4 pagesOn-Site Electrolytic Chlorination Skid-Mounted OSEC B-Pak SystemgohviccNo ratings yet

- Settling Tank DecantDocument23 pagesSettling Tank Decantjvan migvelNo ratings yet

- Repair or Alteration of Pressure VesselsDocument4 pagesRepair or Alteration of Pressure VesselsMSNo ratings yet

- QueenstownDocument9 pagesQueenstownYap Juin ShiongNo ratings yet

- Technical Guidelines 2013WEB PDFDocument116 pagesTechnical Guidelines 2013WEB PDFTien Hong DoNo ratings yet

- Data Sheet, GAD and QAP of Y StrainerDocument13 pagesData Sheet, GAD and QAP of Y StrainerSHABAHATNo ratings yet

- Absorptive SilencersDocument5 pagesAbsorptive SilencersDaniel SmsNo ratings yet

- Meiser GratingDocument62 pagesMeiser GratingDushan RomicNo ratings yet

- Column Footing ScheduleDocument1 pageColumn Footing ScheduleCMM INFRAPROJECTS LTDNo ratings yet

- Bell Mouth PDFDocument3 pagesBell Mouth PDFSubramanian SaravananNo ratings yet

- Air Con LouvresDocument1 pageAir Con LouvresChung May LynnNo ratings yet

- SCOMET Declaration FormatDocument1 pageSCOMET Declaration FormatChirag Sankaranarayanan VaitheeswaranNo ratings yet

- Gas Flotation Package (Asbea-A-2703) 32294 Ponticelli - Al Shaheen PWTDocument54 pagesGas Flotation Package (Asbea-A-2703) 32294 Ponticelli - Al Shaheen PWTTĩnh Hồ TrungNo ratings yet

- FQP For Chimney 3 MechanicalDocument4 pagesFQP For Chimney 3 MechanicalKuldeep ChakerwartiNo ratings yet

- Plant Location and LayoutDocument36 pagesPlant Location and LayoutNishaThakuriNo ratings yet

- Warning and Safety Reminders For Screw, Drag, and Bucket Elevator ConveyorsDocument2 pagesWarning and Safety Reminders For Screw, Drag, and Bucket Elevator ConveyorsAndreLeandro10No ratings yet

- EMCO Floating Suctions enDocument2 pagesEMCO Floating Suctions enAnonymous yQ7SQrNo ratings yet

- Type AB Air Gaps - Practical ExamplesDocument3 pagesType AB Air Gaps - Practical ExamplesZack ZakariaNo ratings yet

- 20ft Skid ISO FrameDocument1 page20ft Skid ISO FrameThanhdong DoNo ratings yet

- Confined Space VentilationDocument31 pagesConfined Space VentilationX100% (1)

- Analysis Strength of Scaffolding Structure On Stack HRSG For Cable TightDocument5 pagesAnalysis Strength of Scaffolding Structure On Stack HRSG For Cable TighthendraNo ratings yet

- Pipe RacksDocument1 pagePipe RacksBryan AyalaNo ratings yet

- Nitoflor Anti-Slip GransDocument2 pagesNitoflor Anti-Slip GranstalatzahoorNo ratings yet

- TDS - STUCCO - English - Issued.18.11.2002Document3 pagesTDS - STUCCO - English - Issued.18.11.2002Balasubramanian AnanthNo ratings yet

- SDS - Texo Compound - English (Uk) - DubaiDocument4 pagesSDS - Texo Compound - English (Uk) - DubaiBalasubramanian Ananth100% (3)

- SDS - Acrylic Emulsion Primer - English (Uk) - DubaiDocument4 pagesSDS - Acrylic Emulsion Primer - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- SDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiDocument5 pagesSDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- SDS - Fenomastic Emulsion Matt - English (Uk) - DubaiDocument5 pagesSDS - Fenomastic Emulsion Matt - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- Penguard HB - Comp ADocument5 pagesPenguard HB - Comp ABalasubramanian AnanthNo ratings yet

- SDS - Fenomastic Enamel Matt - English (Uk) - DubaiDocument5 pagesSDS - Fenomastic Enamel Matt - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- SDS - Bengalac Matt - English (Uk) - DubaiDocument5 pagesSDS - Bengalac Matt - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- SDS - Durosan - English (Uk) - DubaiDocument5 pagesSDS - Durosan - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- SDS - Fenomastic Emulsion Semigloss - English (Uk) - DubaiDocument5 pagesSDS - Fenomastic Emulsion Semigloss - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- SDS - Bengalac Red Oxide Primer - English (Uk) - DubaiDocument5 pagesSDS - Bengalac Red Oxide Primer - English (Uk) - DubaiBalasubramanian Ananth100% (1)

- SDS - Bengalac Semigloss - English (Uk) - DubaiDocument5 pagesSDS - Bengalac Semigloss - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- Penguard HB - Comp B-ScribdDocument5 pagesPenguard HB - Comp B-ScribdBalasubramanian AnanthNo ratings yet

- SDS - Acrylic Emulsion Primer - English (Uk) - DubaiDocument4 pagesSDS - Acrylic Emulsion Primer - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- SDS - Bengalac Aluminium - English (Uk) - Dubai-Start ScribdDocument5 pagesSDS - Bengalac Aluminium - English (Uk) - Dubai-Start ScribdBalasubramanian AnanthNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthNo ratings yet

- Safety Data Sheet: Identification of The Substance/preparation and of The Company/undertakingDocument4 pagesSafety Data Sheet: Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian Ananth100% (1)

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument3 pagesSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthNo ratings yet

- Durathane Matt - Comp ADocument4 pagesDurathane Matt - Comp ABalasubramanian AnanthNo ratings yet

- Safety Data Sheet: Identification of The Substance/preparation and of The Company/undertakingDocument5 pagesSafety Data Sheet: Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthNo ratings yet

- Class I - 2L - Class I - 2011-2012Document4 pagesClass I - 2L - Class I - 2011-2012Balasubramanian AnanthNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthNo ratings yet

- RBC FGDocument18 pagesRBC FGdragon_ecuNo ratings yet

- Trane Rental Service BrochureDocument4 pagesTrane Rental Service BrochureNoe AriasNo ratings yet

- StenterDocument2 pagesStenterMusa Eltayeb100% (2)

- Alpha Design Presentation.Document35 pagesAlpha Design Presentation.vasucristalNo ratings yet

- Production Planning and Control: Introductio NDocument29 pagesProduction Planning and Control: Introductio NPankaj MishraNo ratings yet

- Plastic TechnologyDocument171 pagesPlastic Technologyeitan-dalia4971No ratings yet

- Drum Screen SDocument2 pagesDrum Screen SMariusCapraNo ratings yet

- Display Merchandising Pop Promotion CatalogueDocument20 pagesDisplay Merchandising Pop Promotion CataloguePrinceIposNo ratings yet

- Website Design of Job Description Based On Isco-08 and Calculation of Employee Total Needs Based On Work LoadDocument10 pagesWebsite Design of Job Description Based On Isco-08 and Calculation of Employee Total Needs Based On Work LoadAgra AdiyasaNo ratings yet

- Pil 01 PilcDocument6 pagesPil 01 Pilcpingu 132435No ratings yet

- MS494: Total Quality Management: Course Instructor: DR Noor Muhammad Teaching Assistant: Ms MamoonaDocument36 pagesMS494: Total Quality Management: Course Instructor: DR Noor Muhammad Teaching Assistant: Ms MamoonaFurqan YousafzaiNo ratings yet

- Residential Steel Frame Building Case StudyDocument29 pagesResidential Steel Frame Building Case Studyprajoshi62No ratings yet

- European Standards For Metallic MaterialsDocument16 pagesEuropean Standards For Metallic MaterialsClaudia Mms0% (1)

- Sohrab ProjectDocument8 pagesSohrab ProjectZarak MirNo ratings yet

- Rigid Pavement DistressesDocument26 pagesRigid Pavement Distressesசுப. ஸ்ரீதர்100% (1)

- Product Design & DevelopmentDocument50 pagesProduct Design & DevelopmentAshok Dargar100% (1)

- Harsh Iit Kanpur CVDocument3 pagesHarsh Iit Kanpur CVapi-293629330No ratings yet

- K Thermostats Brochure 5lDocument2 pagesK Thermostats Brochure 5laldariz201181No ratings yet

- ShearingDocument3 pagesShearingSuraj Singh100% (1)

- Reliability Centered MaintenanceDocument116 pagesReliability Centered MaintenanceantonNo ratings yet

- Design HandbookDocument49 pagesDesign HandbookStas Zabarsky100% (1)

- Qualice Solutions - BrochureDocument18 pagesQualice Solutions - Brochurejamil voraNo ratings yet

- P250 Ceramic TilesDocument4 pagesP250 Ceramic TilesabbNo ratings yet

- TR4 - Listing of HDB-PDB-MRS For Thermoplastic Piping MaterialsDocument66 pagesTR4 - Listing of HDB-PDB-MRS For Thermoplastic Piping MaterialsRyan Carter100% (1)

- Production Analysis Short Run and Long Run Costs, Economies of ScaleDocument69 pagesProduction Analysis Short Run and Long Run Costs, Economies of ScaleDr. Rakesh BhatiNo ratings yet

- LFS Report 2010Document268 pagesLFS Report 2010Sohel RanaNo ratings yet