Professional Documents

Culture Documents

BHEL Specification Sheet TDC.0.304 Rev01

BHEL Specification Sheet TDC.0.304 Rev01

Uploaded by

Naresh GoudOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BHEL Specification Sheet TDC.0.304 Rev01

BHEL Specification Sheet TDC.0.304 Rev01

Uploaded by

Naresh GoudCopyright:

Available Formats

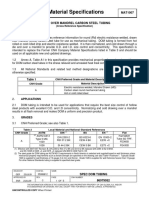

Technical Delivery Condition (TDC)

For

Cold Drawn coiled sheets to specification

ASTM B575 UNS N 10276

Ranipet

Doc Ref:

TDC: O : 304

Rev.No.

01

Date:

08 06 2010

Page No

Page 1 of 2

1.0 Scope

1.1

This TDC specifies the additional requirements for the delivery of cold drawn sheets

conforming to ASTM B 575 UNS N10276 to the latest edition.

1.2

The size and Quantity shall be as specified in the Enquiry / purchase order.

2.0 Chemical composition and process

2.1

The material shall be made by any one of the process allowed in the specification

and chemical composition shall comply with the specification requirements.

2.2

Final sheet thickness shall be made by cold drawing with minimum reduction of

thickness of about 20% for getting required stiffness.

3.0 Dimensional tolerances

3.1

The supply of sheets is in coil form, the following tolerance shall apply.

a) Thickness

As per Enquiry / PO

b) Thickness tolerance

As per ASTM B 906 Table I

c) Width

Plus 0.5mm , minus 0 mm

d) Flatness

1mm /Meter (Max) ,when uncoiled and stretched

e) No. of waves

3 per meter (max)

f) Camber

Maximum 3mm for

g) Coil ID

200mm (minimum) to 250 mm (maximum)

h) Coil OD

400mm maximum

i)

50 KGs, +/- 5 KGs

Coil weight

2 meter length

4.0

Heat treatment

4.1

The sheets will be supplied in cold drawn condition without any heat treatment

5.0

Mechanical Test

5.1

Testing shall be done for each melt as per ASTM E8 and

given below

acceptance norms are

a) Ultimate tensile strength

182000Psi/1255 Mpa (Max)

b) Hardness on finished sheet

330 to 380VHN

6.0

Freedom from defects

6.1

All sheets shall be free from harmful defective like cracks, lamination, Scarabs, Etc

The surface shall be free from scales , rust, pitting, wrinkles

6.2

Repair on finished coil is prohibited.

7.0

Finish

7.1

The edges of coils shall be slit without fish tails and kinks. The coils should

contain any weld seam

Record of

revision

not

Rev 00/ DTD 01 04 94

Original Issue

Rev 01 /08 06 2010

TDC requirements are reviewed fully in consultation with

Engineering ,MPL , purchase, QA and QC (proc.). correction in

Clause 3.1, 5.1, 8.1 and in other clauses

minor editorial

correction done .

Technical Delivery Condition (TDC)

For

Cold Drawn coiled sheets to specification

ASTM B575 UNS N 10276

Ranipet

Doc Ref:

TDC: O : 304

Rev.No.

01

Date:

08 06 2010

Page No

Page 2 of 2

8.0

Marking

8.1

Each coil shall be identified by Tag and also permanent stickers at ID and OD of the

coil .The details shall be as given below

a) Coil number

b) Specification

c) Size (Thickness x Width )

d) Heat number

e) Weight of coil in KGs

f) Length of coil in Meter

g) PO Number

h) Manufacturers identification.

9.0

Packing and Dispatch

9.1

It is the responsibility

transit

9.2

Each coil shall be rigidly wrapped with gum tape so as to cover the entire coil and

packed in polythene cover.

9.3

Coils shall be packed in a wooden box as per ASTM A700 Fig. No 78 .

10.0

Inspection and certification

10.1

All tests shall be complied as per the specification for each heat and the same shall

be submitted along with supply.

10.2

The test certificates shall be furnish the following details legibly in English language

only

a) BHEL Purchase order number

b) Test certificate number

of the supplier

to ensure that no damage

occurs during

c) Specification and Grade with applicable year of code

d) PO Quantity and size

e)

f)

g)

h)

i)

Melt number

Chemistry (Melt wise)

Mechanical test results UTS and Hardness

Coil number and weight

Process of manufacturing with amount of cold reduction

12.0

End use

12.1

The coils are intended for manufacturing flexible seals for Gates and Dampers for

the purpose of isolation of Hot/Cold Air / flue gas.

Prepared by

Reviewed by

Engineering (GD)

Purchase

MPL

QC/proc.

QA

Issued by

QUALITY ASSURANCE

Signature

Approved by

(DGM/QA)

You might also like

- Astm F 30 - 96 R02 - RJMWDocument5 pagesAstm F 30 - 96 R02 - RJMWphaindikaNo ratings yet

- Astm B 33Document6 pagesAstm B 33Kamer Bibuçukvolt SemerciogluNo ratings yet

- Astm D3261 (1997)Document6 pagesAstm D3261 (1997)anish_am2005No ratings yet

- Din & IsoDocument94 pagesDin & IsoZeinHarisHasibuan100% (5)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Distortion Mechanisms Due To The Cooling Process in Aluminum ExtrusionDocument16 pagesDistortion Mechanisms Due To The Cooling Process in Aluminum ExtrusionСтанислав Подольский100% (1)

- TCVN 2622-1995 Fire Prevention Standards - enDocument49 pagesTCVN 2622-1995 Fire Prevention Standards - enCity Boy100% (3)

- B932-2004 (2010)Document3 pagesB932-2004 (2010)Srinivasan KrishnamoorthyNo ratings yet

- B520-12 Standard Specification For Tin-Coated, Copper-Clad Steel Wire For Electronic ApplicationDocument6 pagesB520-12 Standard Specification For Tin-Coated, Copper-Clad Steel Wire For Electronic ApplicationmithileshNo ratings yet

- B424 05Document4 pagesB424 05Srinivasan KrishnamoorthyNo ratings yet

- Instrumentation-Cables 1.5SQMM 6P 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDSDocument2 pagesInstrumentation-Cables 1.5SQMM 6P 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDShydrothermsNo ratings yet

- Is 2041Document8 pagesIs 2041hhr2412No ratings yet

- Circuit PlateDocument8 pagesCircuit PlateMosa Elnaid ElnaidNo ratings yet

- Tanks CP System CalculationDocument1 pageTanks CP System CalculationkakoullisgNo ratings yet

- B 19 95 PDFDocument5 pagesB 19 95 PDFluis_may22No ratings yet

- IGS-M-TP-014-2-C (2) Sep. 2008: 3 Ply Co-Extruded Plastic Tape For Field Joint and Rehabilitation of Steel PipelineDocument13 pagesIGS-M-TP-014-2-C (2) Sep. 2008: 3 Ply Co-Extruded Plastic Tape For Field Joint and Rehabilitation of Steel PipelineTa GiNo ratings yet

- Cartridge Brass Sheet, Strip, Plate, Bar, and Disks (Blanks)Document5 pagesCartridge Brass Sheet, Strip, Plate, Bar, and Disks (Blanks)LUISALBERTO06011985No ratings yet

- Nickel-Iron-Chromium-Molybdenum-Copper Alloy (UNS N08825 and N08221) Seamless Pipe and TubeDocument4 pagesNickel-Iron-Chromium-Molybdenum-Copper Alloy (UNS N08825 and N08221) Seamless Pipe and TubePrasan SJNo ratings yet

- Design of Shell and Tube Heat Exchanger: NPTEL - Chemical Engineering - Chemical Engineering Design - IIDocument40 pagesDesign of Shell and Tube Heat Exchanger: NPTEL - Chemical Engineering - Chemical Engineering Design - IIPranav Mishra0% (1)

- Tin-Coated, Copper-Clad Steel Wire For Electronic ApplicationDocument6 pagesTin-Coated, Copper-Clad Steel Wire For Electronic ApplicationRed RedNo ratings yet

- 0 75px1tscnarmdDocument2 pages0 75px1tscnarmdnmpkumarNo ratings yet

- Astm B 101Document5 pagesAstm B 101naina ka madhavNo ratings yet

- Cartridge Brass Sheet, Strip, Plate, Bar, and Disks (Blanks)Document10 pagesCartridge Brass Sheet, Strip, Plate, Bar, and Disks (Blanks)luis_may22No ratings yet

- Procurement Specification For Centrifugal Basket Cover Plates (1.4362) SPEC NO.: 4005-S-00033 Revision: 0 Date: 17.03.2016Document1 pageProcurement Specification For Centrifugal Basket Cover Plates (1.4362) SPEC NO.: 4005-S-00033 Revision: 0 Date: 17.03.2016sagarNo ratings yet

- JPKT 00 P 1 012 Rev 0 Specification For Field Joint CoatingDocument11 pagesJPKT 00 P 1 012 Rev 0 Specification For Field Joint Coatingrohitbhat2345No ratings yet

- Asme Ccase - 2058Document2 pagesAsme Ccase - 2058ADAMJSRAONo ratings yet

- L&T Bhilai Gtp-01 Dated 24-04-12Document3 pagesL&T Bhilai Gtp-01 Dated 24-04-12ashokbathwalNo ratings yet

- Is 5522 1992Document6 pagesIs 5522 1992psewagNo ratings yet

- D.T.D.5014A: Ministry of Defence Defence Procurement Agency, ADRP2 Abbey Wood Bristol BS34 8JHDocument3 pagesD.T.D.5014A: Ministry of Defence Defence Procurement Agency, ADRP2 Abbey Wood Bristol BS34 8JHBobby ChippingNo ratings yet

- Astm B 473-07Document7 pagesAstm B 473-07Ramsi Ankzi100% (1)

- Compliance Statement - Steel StructureDocument1 pageCompliance Statement - Steel StructureMariam Mousa100% (1)

- Required Thicknesses of Pipe or Tube Per ASME B31.3 - 2012 Process Piping CodeDocument3 pagesRequired Thicknesses of Pipe or Tube Per ASME B31.3 - 2012 Process Piping CodeAlex Javier Garzon OrduñaNo ratings yet

- Astm b127 (Monel 400)Document10 pagesAstm b127 (Monel 400)Jarbas MoraesNo ratings yet

- Baosteel CRGO StandardDocument12 pagesBaosteel CRGO Standarddarkonikolic78No ratings yet

- Soft or Annealed Copper Wire: Standard Specification ForDocument5 pagesSoft or Annealed Copper Wire: Standard Specification Fororlando acevedoNo ratings yet

- Instrumentation-Cables 1.5SQMM 4 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDSDocument2 pagesInstrumentation-Cables 1.5SQMM 4 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDShydrothermsNo ratings yet

- A308Document4 pagesA308alirioNo ratings yet

- A1014Document3 pagesA1014malika_00No ratings yet

- Alfanar Building Cables Wires CatalogDocument12 pagesAlfanar Building Cables Wires CatalogAdel KlkNo ratings yet

- BS 1722 Part 4 (Chestnut Pale Fences)Document16 pagesBS 1722 Part 4 (Chestnut Pale Fences)nandi_scrNo ratings yet

- F 364 - 96 - RJM2NC05NGDocument3 pagesF 364 - 96 - RJM2NC05NGjamaljamal20No ratings yet

- CNH Mat 1007 - 07-2009Document5 pagesCNH Mat 1007 - 07-2009rgi178No ratings yet

- Technical Data - CABLE 2P X 1 SQMMDocument1 pageTechnical Data - CABLE 2P X 1 SQMMManoj AgarwalNo ratings yet

- Pipeline Cathodic Protection DesignDocument20 pagesPipeline Cathodic Protection DesignNguyen Thi Thu Huong80% (5)

- Omn WL 900 Ins Ds 2017 Is Cable DatasheetDocument5 pagesOmn WL 900 Ins Ds 2017 Is Cable DatasheetPranav DubeyNo ratings yet

- ITP Structural SteelDocument14 pagesITP Structural SteelNavneet SinghNo ratings yet

- C 1032 - 96 r02 QzewmzitukveDocument5 pagesC 1032 - 96 r02 QzewmzitukveHumberto GutierrezNo ratings yet

- Un 2004-03 - Ud-Au-000-Eb-00009 PDFDocument3 pagesUn 2004-03 - Ud-Au-000-Eb-00009 PDFManjeet SainiNo ratings yet

- Astm B370 22Document7 pagesAstm B370 22Anang PrasetyoNo ratings yet

- Airex C51: Industrial Processing FoamDocument3 pagesAirex C51: Industrial Processing FoamCrizzti Nuara PbNo ratings yet

- 1PX12PSCNARMDDocument1 page1PX12PSCNARMDJainam ShahNo ratings yet

- B 3 - 95 - Qjmtotu - PDFDocument5 pagesB 3 - 95 - Qjmtotu - PDFAifam RawNo ratings yet

- Asme CCase 2029-2Document2 pagesAsme CCase 2029-2ADAMJSRAONo ratings yet

- Mil-T-10727c (1) TinDocument12 pagesMil-T-10727c (1) Tingfourn1_896133160No ratings yet

- Technical Data - 2019EBDocument4 pagesTechnical Data - 2019EBManoj AgarwalNo ratings yet

- 8677 - TDC - INCOLOY 825 Rev 1Document1 page8677 - TDC - INCOLOY 825 Rev 1kannanNo ratings yet

- ASTM B33-2010 (2014) - 3022 StandardDocument3 pagesASTM B33-2010 (2014) - 3022 StandardPrakash RanjanNo ratings yet

- Tin-Coated Soft or Annealed Copper Wire For Electrical PurposesDocument6 pagesTin-Coated Soft or Annealed Copper Wire For Electrical PurposesAhmed BilalNo ratings yet

- Polytetrafluoroethylene (PTFE) Resin Cast Film: Standard Specification ForDocument3 pagesPolytetrafluoroethylene (PTFE) Resin Cast Film: Standard Specification ForWilsondjustNo ratings yet

- FLOWTRON Glass Tube Rotameters Rotameters GC-TECHNOTRADINGDocument6 pagesFLOWTRON Glass Tube Rotameters Rotameters GC-TECHNOTRADINGDaniel Sandoval RodriguezNo ratings yet

- Celpure®: High Purity Diatomite Filter MediaDocument2 pagesCelpure®: High Purity Diatomite Filter MediaMeira FontalvoNo ratings yet

- Me-662 Convective Heat and Mass TransferDocument16 pagesMe-662 Convective Heat and Mass TransferhsemargNo ratings yet

- Brochure - Highly Insulated Pipe-In PipeDocument2 pagesBrochure - Highly Insulated Pipe-In PipefralgiugiaNo ratings yet

- understandingNFPA654 2006 EditionDocument2 pagesunderstandingNFPA654 2006 EditionCarlos JiménezNo ratings yet

- Msds N ButaneDocument6 pagesMsds N Butanenirmal_subudhiNo ratings yet

- 2 Slip+Twin1Document364 pages2 Slip+Twin1نيزو اسوNo ratings yet

- Basf Ucrete hf100rt TdsDocument4 pagesBasf Ucrete hf100rt TdsRana Ahmad AamirNo ratings yet

- Brix CurveDocument4 pagesBrix CurveKemoy Johnson100% (8)

- Chemistry Practical 2015-1 PDFDocument227 pagesChemistry Practical 2015-1 PDFSourav SamaddarNo ratings yet

- Simulation of Perovskite Based Solar Cell and Photodetector UsingDocument9 pagesSimulation of Perovskite Based Solar Cell and Photodetector UsingeniNo ratings yet

- Uji Kadar Air (Jurin)Document11 pagesUji Kadar Air (Jurin)HANIP GALIH PAMBUDINo ratings yet

- CAC-Hyperfluid R150: Superplasticiser For High Performance Concrete Based On Poly-Carboxylic EtherDocument2 pagesCAC-Hyperfluid R150: Superplasticiser For High Performance Concrete Based On Poly-Carboxylic Ethermohsin shaikh100% (1)

- Essential Features of Combustion ProcessDocument6 pagesEssential Features of Combustion Processbaraulia substationNo ratings yet

- Printing of 100% Polyester With Disperses Dye by Block Method.Document4 pagesPrinting of 100% Polyester With Disperses Dye by Block Method.Naimul HasanNo ratings yet

- S5MT Ia B 1.1 - USEFULANDHARMFULMATERIALSDocument5 pagesS5MT Ia B 1.1 - USEFULANDHARMFULMATERIALSMa Marisa Arbalate100% (1)

- PH20 Value PH Tester Kit User Manual: Apera Instruments, LLCDocument8 pagesPH20 Value PH Tester Kit User Manual: Apera Instruments, LLCGerman Arrieta ZapaNo ratings yet

- CB - Building Material PDFDocument17 pagesCB - Building Material PDFMariwan MirNo ratings yet

- Energetic Materials - Physics and Chemistry of The Inorganic AzidesDocument8 pagesEnergetic Materials - Physics and Chemistry of The Inorganic AzidesangelofgloryNo ratings yet

- PracticleDocument15 pagesPracticleMr. Parmar Himanshu ManojNo ratings yet

- Rubio Monocoat Oil2c Data SheetDocument1 pageRubio Monocoat Oil2c Data SheetJosh PiersmaNo ratings yet

- Fundamental PV Tech-Mod 02 Sunlight Solar Cell BasicsDocument53 pagesFundamental PV Tech-Mod 02 Sunlight Solar Cell BasicsSultan ZahidNo ratings yet

- Chap7 Entropy HandoutDocument22 pagesChap7 Entropy HandoutSyahrul AminNo ratings yet

- Stainless Steel Pipes - Dimensions and Weights ANSI - ASME 36Document2 pagesStainless Steel Pipes - Dimensions and Weights ANSI - ASME 36Abhijit DekaNo ratings yet

- Chem 4Document17 pagesChem 4zaeemhussain665No ratings yet

- P-N JunctionDocument6 pagesP-N JunctionMuhamad Hanif RidhaNo ratings yet

- E P H V S C G T C: Mohd Warid Hussin, Lim Siong Kang, Fadhadli ZakariaDocument13 pagesE P H V S C G T C: Mohd Warid Hussin, Lim Siong Kang, Fadhadli ZakariamajedsalehNo ratings yet

- Lecture 7Document17 pagesLecture 7Farahin BurhanNo ratings yet