Professional Documents

Culture Documents

Mm'mon FOR MAKIN: Filed Aug. 8, 1925

Mm'mon FOR MAKIN: Filed Aug. 8, 1925

Uploaded by

arufatoCopyright:

Available Formats

You might also like

- The Preparation of Methylamine Hydrochloride From Acetamide by Means of Calcium HypochloriteDocument3 pagesThe Preparation of Methylamine Hydrochloride From Acetamide by Means of Calcium Hypochloritegeovani2100% (1)

- Nalco New Approach For MacrofoulingDocument73 pagesNalco New Approach For Macrofoulingarufato100% (2)

- J. N. CarothersDocument4 pagesJ. N. CarothershaviedNo ratings yet

- United States Patent Office: Patented Jan. I9, 1954Document2 pagesUnited States Patent Office: Patented Jan. I9, 1954JavierNo ratings yet

- UNITED Starts: Patented Apr. 16, 1935Document2 pagesUNITED Starts: Patented Apr. 16, 1935shalsinia chantalNo ratings yet

- Translate Paten US5976485Document24 pagesTranslate Paten US5976485Lenywulandari AyundaNo ratings yet

- Us 2021699Document5 pagesUs 2021699haviedNo ratings yet

- United States Patent Office: Production of Disopum PhosphateDocument2 pagesUnited States Patent Office: Production of Disopum PhosphatefredyNo ratings yet

- United States: Patent OfficeDocument3 pagesUnited States: Patent OfficefredyNo ratings yet

- United States Patent 0: '3, l50, l74 ICCDocument2 pagesUnited States Patent 0: '3, l50, l74 ICCMuhammadAmdadulHoqueNo ratings yet

- Patent Office: 5 Claims. (CL 260-69)Document2 pagesPatent Office: 5 Claims. (CL 260-69)Teleson MarquesNo ratings yet

- Storage: o - InzoDocument4 pagesStorage: o - InzoOscar SobradosNo ratings yet

- US3689216Document5 pagesUS3689216PABLO URIZ CEREZONo ratings yet

- A Safe Method For Preparation of Uncontaminated Hydrazoic AcidDocument1 pageA Safe Method For Preparation of Uncontaminated Hydrazoic Acidgeovani2No ratings yet

- Facturing Fertilizer Containing Potassium, Nitrogen, and Phosphorous CompoundsDocument1 pageFacturing Fertilizer Containing Potassium, Nitrogen, and Phosphorous CompoundsBharat A. KaduNo ratings yet

- A To The OF A Preliminary Study of Hitherto AND: ProcedureDocument11 pagesA To The OF A Preliminary Study of Hitherto AND: ProcedureMariaNo ratings yet

- United States Patent 0 "Ice: Patented May 9, 1972Document4 pagesUnited States Patent 0 "Ice: Patented May 9, 1972Nguyễn Thanh TùngNo ratings yet

- US3347627Document3 pagesUS3347627Nuttapong JongjitsatitmunNo ratings yet

- United States Patent (191: Inoue Et A) - (11) Patent Number: (45) Date of PatentDocument4 pagesUnited States Patent (191: Inoue Et A) - (11) Patent Number: (45) Date of PatentShrutiNo ratings yet

- US2321218Document3 pagesUS2321218shirazizadehsinaNo ratings yet

- Us 744128Document2 pagesUs 744128haviedNo ratings yet

- United States Patent (191: GermanyDocument5 pagesUnited States Patent (191: GermanyChem2014EngNo ratings yet

- United States Patent PO: Patented Nov. 20, 1956Document2 pagesUnited States Patent PO: Patented Nov. 20, 1956shenn0No ratings yet

- Unite Sites Fret (19) : DahlinDocument3 pagesUnite Sites Fret (19) : Dahlintrinh xuan hiepNo ratings yet

- Preparation and Assay of Acetyl PhosphateDocument4 pagesPreparation and Assay of Acetyl PhosphatecataawwwNo ratings yet

- United States Patent 0 ": Patented Dec. 15, 1959Document2 pagesUnited States Patent 0 ": Patented Dec. 15, 1959Aaron CurrieNo ratings yet

- United States Patent (191: Macdonald 145) Feb. 25, 1975Document4 pagesUnited States Patent (191: Macdonald 145) Feb. 25, 1975Javier Alejandro Rodriguez MelgozaNo ratings yet

- Pentaeritritol 2Document6 pagesPentaeritritol 2Ibnul BaasithNo ratings yet

- US3014784Document2 pagesUS3014784SatyamSahuNo ratings yet

- Us 2375054Document3 pagesUs 2375054haviedNo ratings yet

- Matrix Acidizing of Sandstone4Document5 pagesMatrix Acidizing of Sandstone4HelyaNo ratings yet

- Arsenal Philadelphia, Pa. 19137: FrankfordDocument23 pagesArsenal Philadelphia, Pa. 19137: FrankfordPutri PramodyaNo ratings yet

- Ingles CDocument8 pagesIngles Coscar rodriguezNo ratings yet

- US2301231Document2 pagesUS2301231Abu Mejza'atNo ratings yet

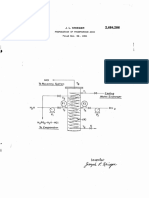

- July 20, 1954 J. L. Krieger 2,684,286: InventorDocument4 pagesJuly 20, 1954 J. L. Krieger 2,684,286: InventorNurhafizah Abd JabarNo ratings yet

- US1960211 (Sudah)Document3 pagesUS1960211 (Sudah)aris_nurhidayatNo ratings yet

- Filed June l5, 1935Document6 pagesFiled June l5, 1935Yustinus Selis ToronNo ratings yet

- This Invention Relates To A Process For Making A Stable CopperDocument3 pagesThis Invention Relates To A Process For Making A Stable CopperAngel BuenoNo ratings yet

- US3718545 (1) PatenteDocument8 pagesUS3718545 (1) PatenteAndrés BelloniNo ratings yet

- Launcelot: Massachusetts Health, Analysis, BostonDocument6 pagesLauncelot: Massachusetts Health, Analysis, BostonMaxi GonzalezNo ratings yet

- Patent Nines,: Nited StatesDocument2 pagesPatent Nines,: Nited Statesjeque661No ratings yet

- Arease: Nov. 8, 1966 W. Wogt Et Al 3,284,495 Process For The Continuous Manufacture, Purification andDocument3 pagesArease: Nov. 8, 1966 W. Wogt Et Al 3,284,495 Process For The Continuous Manufacture, Purification andRachmad HermawanNo ratings yet

- Us 3229777Document4 pagesUs 3229777Parth AggarwalNo ratings yet

- Us1951789 PDFDocument5 pagesUs1951789 PDFJames EdwardsNo ratings yet

- United States Patent Office: Patented Sept. 1, 1959Document4 pagesUnited States Patent Office: Patented Sept. 1, 1959هیمن مNo ratings yet

- Per Acetic AcidDocument5 pagesPer Acetic AcidMaruthi KNo ratings yet

- US3416887Document6 pagesUS3416887khairulNo ratings yet

- Patente 2Document3 pagesPatente 2Saul MamaniNo ratings yet

- AAS Methods 2520of 2520 ProductionDocument4 pagesAAS Methods 2520of 2520 Productionapi-3714811No ratings yet

- Copie de US2899444-1Document4 pagesCopie de US2899444-1KHALED KHALEDNo ratings yet

- Indigo Prodn. From Phenyl-Glycine Carboxylic Acid Salt - by Fusion in Mixed Potassium Hydroxide and Sodium Hydroxide Melt, Then OxidnDocument4 pagesIndigo Prodn. From Phenyl-Glycine Carboxylic Acid Salt - by Fusion in Mixed Potassium Hydroxide and Sodium Hydroxide Melt, Then OxidnCillian CreedonNo ratings yet

- Us2094573-Production of Potassumsulphate Ammonium Sulphate Double SaltDocument2 pagesUs2094573-Production of Potassumsulphate Ammonium Sulphate Double Saltkvsj2001No ratings yet

- Removal of Fluorine From Wet Process Phosphoric AcidDocument2 pagesRemoval of Fluorine From Wet Process Phosphoric AcidAdios ANo ratings yet

- Benzoic Acid To Benzaldehyde, P-Nitrobenzoic Acid To Nitrobenzene and More.Document3 pagesBenzoic Acid To Benzaldehyde, P-Nitrobenzoic Acid To Nitrobenzene and More.banjo010% (1)

- Rile From NH4Document10 pagesRile From NH4rrivera7396No ratings yet

- United States: Patent Office. VDocument2 pagesUnited States: Patent Office. VAmir HamzahNo ratings yet

- United States Patent (191: MercadeDocument4 pagesUnited States Patent (191: MercadeSoufi BadrNo ratings yet

- Determination of Gamma No and TSDocument3 pagesDetermination of Gamma No and TSAditya ShrivastavaNo ratings yet

- United States Patent Office: Patented Mar. 13, 1951 ... ."Document2 pagesUnited States Patent Office: Patented Mar. 13, 1951 ... ."Ruchita PoilkarNo ratings yet

- United States Patent (191: Wu Et Al. (451 Nov. 6, 1979Document6 pagesUnited States Patent (191: Wu Et Al. (451 Nov. 6, 1979FatonaRifkyPNo ratings yet

- 5991-6846EN BrosurDocument8 pages5991-6846EN BrosurarufatoNo ratings yet

- Tolerance Chart: (Maximum Permissible Error)Document3 pagesTolerance Chart: (Maximum Permissible Error)arufatoNo ratings yet

- Catalog KaoDocument1 pageCatalog KaoarufatoNo ratings yet

- Effects of Temperature On PH v4 - TSP-01-2Document7 pagesEffects of Temperature On PH v4 - TSP-01-2Aridita AnggrainiNo ratings yet

- 14.12 Kulcsar U PDFDocument6 pages14.12 Kulcsar U PDFarufatoNo ratings yet

- ASTM D7740 Optimizing AASDocument9 pagesASTM D7740 Optimizing AASarufatoNo ratings yet

- Doc316 53 01486 PDFDocument6 pagesDoc316 53 01486 PDFarufatoNo ratings yet

- Effects of Temperature On PH v4 - TSP-01-2 PDFDocument7 pagesEffects of Temperature On PH v4 - TSP-01-2 PDFarufatoNo ratings yet

- Ion Exchange Design ProcedDocument30 pagesIon Exchange Design ProcedFajar IndrawanNo ratings yet

- Simulation Mixed BedDocument13 pagesSimulation Mixed BedarufatoNo ratings yet

- 30265527A V03.16 KarlFischer Titrators Broch EN LR PDFDocument16 pages30265527A V03.16 KarlFischer Titrators Broch EN LR PDFarufatoNo ratings yet

- 2015 11 06 - Cetamine Technology in Power Plants - Swedish Conference 2015Document42 pages2015 11 06 - Cetamine Technology in Power Plants - Swedish Conference 2015arufatoNo ratings yet

- Gfps Chemicals PowerPlantsDocument2 pagesGfps Chemicals PowerPlantsarufatoNo ratings yet

- History of Fluorine Recovery ProcessesDocument21 pagesHistory of Fluorine Recovery ProcessesmahaNo ratings yet

- Phosphoric Acid Fuel Cell (Pafc)Document10 pagesPhosphoric Acid Fuel Cell (Pafc)Else Feba Paul0% (1)

- Phosphoric Acid - MSDSDocument3 pagesPhosphoric Acid - MSDSSathish KumarNo ratings yet

- 1 s2.0 S2213343722017419 MainDocument21 pages1 s2.0 S2213343722017419 MainIkram ADNANENo ratings yet

- PiperacilinDocument2 pagesPiperacilinivaNo ratings yet

- Buffer SolutionsDocument6 pagesBuffer SolutionsIrmey Hamidi100% (1)

- 900 Inorganic Questions For IIT JEE ADVANCEDDocument64 pages900 Inorganic Questions For IIT JEE ADVANCEDSourabh Dhavala95% (19)

- Naval JellyDocument4 pagesNaval JellyjohnsopranaNo ratings yet

- GST Food Item ListDocument88 pagesGST Food Item ListgeorgiinaNo ratings yet

- 1 s2.0 S1877705812045341 MainDocument11 pages1 s2.0 S1877705812045341 MainJavier Alejandro RodriguezNo ratings yet

- Solubility and Complex-Ion Equilibria: Practice ExamplesDocument33 pagesSolubility and Complex-Ion Equilibria: Practice Exampleskennethleo69No ratings yet

- Uses of Phosphoric AcidDocument3 pagesUses of Phosphoric AcidMarnel Roy MayorNo ratings yet

- Di-Calcium Phosphate by Direct Acidulation of Phosphate RockDocument111 pagesDi-Calcium Phosphate by Direct Acidulation of Phosphate RockAshutosh GuptaNo ratings yet

- Sciencedirect: The Use of Advanced Process Controls in A Phosphoric Acid ReactorDocument7 pagesSciencedirect: The Use of Advanced Process Controls in A Phosphoric Acid ReactorJavier Alejandro RodriguezNo ratings yet

- Fundamentals of The Wet Process Phosphor PDFDocument8 pagesFundamentals of The Wet Process Phosphor PDFVandenberg Soares de AndradeNo ratings yet

- EtanolDocument57 pagesEtanolexe241293No ratings yet

- History of Phosphoric Acid Technology (Evolution and Future Perspectives)Document7 pagesHistory of Phosphoric Acid Technology (Evolution and Future Perspectives)Fajar Zona67% (3)

- P-Block 15 To 16 GroupDocument38 pagesP-Block 15 To 16 GroupBharti GoelNo ratings yet

- Fertilizer Technology Section 1Document14 pagesFertilizer Technology Section 1Roed Alejandro LlagaNo ratings yet

- LiteraturDocument94 pagesLiteraturMuhammad Iqbal MaulanaNo ratings yet

- Che 329 - Lectre - 2Document95 pagesChe 329 - Lectre - 2anandseshadri901No ratings yet

- June 2018 QP - Paper 1 OCR (A) Chemistry AS-LevelDocument24 pagesJune 2018 QP - Paper 1 OCR (A) Chemistry AS-LevelRunNo ratings yet

- Panamax Cargo Hold Cleaning Manual Rev00Document36 pagesPanamax Cargo Hold Cleaning Manual Rev00Cenk ÇobanNo ratings yet

- Cleaning & Sanitising - Food Processing IndustryDocument21 pagesCleaning & Sanitising - Food Processing Industrydrmarvin2k5100% (1)

- Lecture 21 PhosphorousDocument53 pagesLecture 21 PhosphorousAnilKumar100% (2)

- L Uk SulphDocument24 pagesL Uk SulphypyeeNo ratings yet

- Calcium Sulfate Crystallization in Phosphoric Acid PDFDocument133 pagesCalcium Sulfate Crystallization in Phosphoric Acid PDFabderrahimnNo ratings yet

- TSP Tour ReportDocument16 pagesTSP Tour ReportArefin ShahriarNo ratings yet

- Chemicalcleaning For BoilerDocument16 pagesChemicalcleaning For Boilerak_thimiriNo ratings yet

Mm'mon FOR MAKIN: Filed Aug. 8, 1925

Mm'mon FOR MAKIN: Filed Aug. 8, 1925

Uploaded by

arufatoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mm'mon FOR MAKIN: Filed Aug. 8, 1925

Mm'mon FOR MAKIN: Filed Aug. 8, 1925

Uploaded by

arufatoCopyright:

Available Formats

0a. so, 1928.

V "

v , _

I J. .N. CAROTHERS

,

_

mm'mon FOR MAKIN G

1,689,547.

TRI'-SODIUM PHOSPHATE.

Filed Aug. 8, 1925

J. . QRROTHER":

55a:

@2192:

'

1,689,547

Patented Oct. 30, 1928.

UNITED STATES PATENT OFFICE. ,

JOHN R. CABOTHEBS, 0F ANNISTON, ALABAMA, ASSIGLIOB TO FEDERAL PHOSPHOBUS

COMPANY, OF BIRMINGHAM, ALABAMA, A COBIOP'ATION OF ALABAMA.

METHOD FOR MAKING TERI-SODIUM PHOSPHATE.

Application ?led August a, 1925. Serial m3. mass.

This invention relates to a method for by the chemical formula Na,PO.12H,O,

from which an inspection shows there is

making tri-sodium-phosphate, especially present

approximatel 57% water of crystaladapted to the use of concentrated phos

phoric acid.

5

I ,

lization. I proceed by adding sodium car

strong phosphoric acid simul

The object is td provide a method which bonate and

in a mixingtank, where vdi-sodium

requires less e uipment and is therefore less taneously

phosphate is formed. By strong phos

costly, and w ich at the same time, has

acid I mean an acid of such concen

greater e?iciency than existing methods phoric

tration

that it will not be necessary to em~

which are adapted to the use, of dilute phos

ploy any evaporation step in my process,

the water with the phosphoricacid, the

With these and other objects in view, the but

di-sodium

phosphate ?lter press water, and

invention consists in the novel details of a

that necessary to dissolve the caustic soda"

method embodying features of construcw will

provide enough to supply the water of

tion and combination of equipment consti

16 tuting my invention, more fully disclosed crystallization in the product. This acid 70

and particularly set forth in the appended may range from 50% to 75% HsPO? de

pendiInIg on operatingconditions, and while

,PO, may be continuously used pro

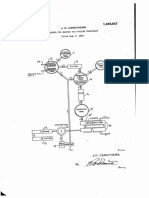

Referring to the accompanying drawing, 50%

vided

the

di-sodiuin ?lter press water be re

forming part of this speci cation, the appas

20 ratus comprises an acid tank 1 containing duced in proportion to the additional water

strong phosphoric acid, which is neutralized added by such acid, it is preferable to employ

by the addition of sodium carbonate to di acid of higher concentrations. The phos

sodium phosphate solution in mixing tank phoric acid and sodium carbonate are added

2, from which the solution passes through until di-sodium phosphate is formed, having,

10 phoric acid.

claims.

25 ?lter 3 into the receiving and mixing tank 4, in case iron tanks are used, a slight excess of

where caustic soda solution is added from sodium carbonate. Where acid resistant

dissolving tank 5.' After thoroughly mix-' tanks are used no excess of sodium carbonate

ing the resultant tri-sodium phosphate solu is needed. The chemical reaction is repre

tion in tank 4 it is assed through ?lter 6 and sented by the following equation:

30-,into receiving ta ,7, from which it ?ows

through crystallizers 8 which may have arti

?cial coolers 81 if desired. From the crystal-

lizers the crystals and a portion of the mother The solution is heated approximately 100

liquor pass into the centrifuge 9 where the ' C. by a heating coil 14 to expel all dissolved

35 crystals are de-watered. The mother liquor carbonic acid (00,) and to coagulate the

passes from the centrifuge 9 into the sump precipitate of iron, aluminum, calcium or

tank 10 and thence is returned by pump 11 magnesium phosphates, which will form if

to mixing tank 2 or'4, according to opera these impurities be present. In case this so

tion requirements, while the crystals pass lution is higher than 1.30-1.36 speci?c grav

40 ?rst through dryer 12" and then through ity at 85 0., wash water or mother liquor 95

be added to reduce the speci?c grav

cooler 13, after which they may be shipped should

as dried or screened crystals in any well ity to that mentioned. From the mixing

known manner. The elements of the, fore tank 2 the di-sodium phosphate solution

going apparatus are conveniently illus-\ passes through a ?lter of any standard type

45 trated as they constitute severally standard to remove the precipitate from the solution. 100

The clear solution of di-sodium phosphate

equipment.

1

In order that the operation of my method is then mixed with a caustic soda solution to

carried out in my apparatus may be clearly form tri-sodium phosphate. This reaction

understood and practiced by those skilled in is represented by the following equation:

50 the art, I will outline the procedure in NaJIPO, 121L120 +NaOH=

volved. In the production of tri-sodium phos

phate a large percentage of the compound

'

106

Na3PO,,.12H2O+H,O

is water which is present as water of crystals Caustic soda solution may be prepared by

lization. The compound is represented dissolving solid caustic, or commercial caus

1,689,547

tie solution may be used. The strength of

the solution may be varied, but if made from

solid caustic a solution containing approxi

mately 70-72% NaOH is preferred. Since

Having thus described my invention, what

claim as new and desire to secure by Let

ters Patent, is :

_

rocess for the

_ l. The hereindescribed

commercial caustic soda solution contains production of tri-sodium p osphate, whlch 70"

only approximately 50% NaOH, this may consists in subjecting sodium carbonate to

not be used exclusively; however, a mixture the action of phosphoric acid having more

of solid caustic dissolved in the commercial, than 50% HsPO4 to form di-sodium phos

solution may be' satisfactorily used. The phate, then adding su?icient caustic soda to

10 tri-sodium phos hate solution is then ?ltered

convert said dil-sodium phosphate into tri .75

in any standar ?lter to remove solid mat

ter introduced b the caustic, as well as an

precipitate whic

'ay result from the addi

tion of caustic so a to the di-sodium phos

phate solution. In the addition of caustic

soda, su?lcient is added until titration with

half normal acid of a sample of the solution

being causticized, shows a relation of the

end point of phenolphthalein and the end

points of phenolphthalein and methyl or

20

an e

sodium phosphate, substantially as de

scribed.

2. The hereindescribed process for the

production of tri-sodium' phosphate, which

consists in subjecting sodium carbonate to

the action of stron phosphoric acid havingv

more than 50% ,PO, to form .di-sodium

phosphate, then removing all solid matter,

then adding caustic soda to convert said d1

sodium phosphate to tri-sodium phosphate,

varying between 0.53 and 0.56, arrived substantially as described.

. at by dividin the reading from the phenol

phthalein en point, by t e sum of the phe

3. The hereindescribed

rocess for the

production of tri-sodium osphate, which

nolphthalein and methyl orange end points. consists in subjecting sodlum carbonate in

This relation of titrations is a simple and

to the action of strong ghosphoric

quick means of controlling the addition of solution,

acid having more than 50% HSP ,, to form

caustic. After causticizing, the solution. di-sodium phosphate, then remov'

all

should have a speci?c gravity from 1.36'to solid matter, then adding caustic so a so

1.40 at 85 C. for best operation. After ?l lution to convert said di-sodium phosphate

tration, the solution is run into any suitable into tri-sodium phosphate, then cooling said

crystallizing uipment. The use of a con tri-sodium- phosphate solution until crystals

tinuous. 'crysta izer is referred, as thereb of tri-sodium phosphate form, substantially

30

a continuous feed and 'scharge is obtaine . as described.

It is desirable to add a certain percentage of

mother liquor, from

4. The hereindescribed

revious crystalliza production

of tri-sodium

rocess for the

osphate, which

100

tions, to aid in suspen in the crystals and consists in subjecting a sodium carbonate so

to facilitate han/dling. g.lhe quantity of - lution

to the action of stron phosphoric

mother liquor added Wlll vary depending on acid to ,form a di-sodium phospiate

solution

operating conditions at the time, .andsthe

approximately 1.33 speci?c gravity at 85

only means of judging is the fact that crys- - of

(1., t en'removing all so id matter, then add

tals produced are of the size desired, and in? caustic soda solution to convert said di

hand e readily in the crystallizer. From the so ium phosphate into tri-sodium phos

(0

crystallizer, the crystals pass into a centri

_fuge where they are d'e-watered before pass

15 mg to the dryer. '

. "

ince the I melting point of tri-sodium

phate, then cooling said tri-s'odium phos

phosphate form, thenseparatin said crys

105

phate solution until crystals of tri-sodium

'110

tals from the accompanying s?ution', sub

phos hate is very' ow, it is necessary to stantially

as described.

avoiw overheating and either melting or

5. The hereindescribed rocess for the ,

partly de-hydrating the crystals. _ In order

of tri-sodium osphate, which

that the dried crystals may be .in the best production

consists in subjecting SOdluIII carbonate to 115

physical condition, it is preferable that they the action of stron phosphoric acid to form

passed through a cooler aftenthe dryer, 1a di-sodium phosg ate solution of approxi~ I

that they may be at atmospheric tempera mately 1.33 speci c gravity at 85 0., then

ture when stored or packed.

55

The solution, elimlnated from the. crys removing all solid matter therefrom, then

" tals in the centrifu e, ?ows to a sump tank adding caustic soda solution to convert said

di-sodium phosphate into tri-sodium phos

from w ere it may

e returned by pump 11, phate in a solution of ap roximately 1.38

4 as conditions of pper speci?c gravity at 85 _C., t en cooling said

[nation require._

'~ $By the use of strong phosphoric acid and tri~sodium phosphate solution until crystals

the apparatus as described, I am enabled to of tri-sodium (phosphate are formed, then

separatingso1sai

"cr?stals from the accom

roduce .tri-sodium phosphate more ef panying

ution, t on d in said 0 stals

- to mixing tank 2 or

.cientlyv and less expensively than otherwise, substantially as described.y g

ry

,

"smce the expensive evaporation step em

6.

The

hereindescribed

continuous

.proc

ployed in\ common practice is eliminated.

ess of 'producing tri-sodium phosphate crys

120

meme-7v

3'

talsg which consists in producing a. tri- and returning the mother liquor to the tri

sodium phosphate solution from strong acid, sodium phosphate solution, substantially as

continuously feeding" such tri-sodium phos- described.

phete solution having an approximate spe~

In testimony whereof I al?x my signa

ci?o gravity of 1.36 to 1.410v at 85 vG. to a ture.

crystallizer, and continuously Withdrawing

crystals of tri-sodium phosphate therefrom,

JOHN N. CAROTHERS.

You might also like

- The Preparation of Methylamine Hydrochloride From Acetamide by Means of Calcium HypochloriteDocument3 pagesThe Preparation of Methylamine Hydrochloride From Acetamide by Means of Calcium Hypochloritegeovani2100% (1)

- Nalco New Approach For MacrofoulingDocument73 pagesNalco New Approach For Macrofoulingarufato100% (2)

- J. N. CarothersDocument4 pagesJ. N. CarothershaviedNo ratings yet

- United States Patent Office: Patented Jan. I9, 1954Document2 pagesUnited States Patent Office: Patented Jan. I9, 1954JavierNo ratings yet

- UNITED Starts: Patented Apr. 16, 1935Document2 pagesUNITED Starts: Patented Apr. 16, 1935shalsinia chantalNo ratings yet

- Translate Paten US5976485Document24 pagesTranslate Paten US5976485Lenywulandari AyundaNo ratings yet

- Us 2021699Document5 pagesUs 2021699haviedNo ratings yet

- United States Patent Office: Production of Disopum PhosphateDocument2 pagesUnited States Patent Office: Production of Disopum PhosphatefredyNo ratings yet

- United States: Patent OfficeDocument3 pagesUnited States: Patent OfficefredyNo ratings yet

- United States Patent 0: '3, l50, l74 ICCDocument2 pagesUnited States Patent 0: '3, l50, l74 ICCMuhammadAmdadulHoqueNo ratings yet

- Patent Office: 5 Claims. (CL 260-69)Document2 pagesPatent Office: 5 Claims. (CL 260-69)Teleson MarquesNo ratings yet

- Storage: o - InzoDocument4 pagesStorage: o - InzoOscar SobradosNo ratings yet

- US3689216Document5 pagesUS3689216PABLO URIZ CEREZONo ratings yet

- A Safe Method For Preparation of Uncontaminated Hydrazoic AcidDocument1 pageA Safe Method For Preparation of Uncontaminated Hydrazoic Acidgeovani2No ratings yet

- Facturing Fertilizer Containing Potassium, Nitrogen, and Phosphorous CompoundsDocument1 pageFacturing Fertilizer Containing Potassium, Nitrogen, and Phosphorous CompoundsBharat A. KaduNo ratings yet

- A To The OF A Preliminary Study of Hitherto AND: ProcedureDocument11 pagesA To The OF A Preliminary Study of Hitherto AND: ProcedureMariaNo ratings yet

- United States Patent 0 "Ice: Patented May 9, 1972Document4 pagesUnited States Patent 0 "Ice: Patented May 9, 1972Nguyễn Thanh TùngNo ratings yet

- US3347627Document3 pagesUS3347627Nuttapong JongjitsatitmunNo ratings yet

- United States Patent (191: Inoue Et A) - (11) Patent Number: (45) Date of PatentDocument4 pagesUnited States Patent (191: Inoue Et A) - (11) Patent Number: (45) Date of PatentShrutiNo ratings yet

- US2321218Document3 pagesUS2321218shirazizadehsinaNo ratings yet

- Us 744128Document2 pagesUs 744128haviedNo ratings yet

- United States Patent (191: GermanyDocument5 pagesUnited States Patent (191: GermanyChem2014EngNo ratings yet

- United States Patent PO: Patented Nov. 20, 1956Document2 pagesUnited States Patent PO: Patented Nov. 20, 1956shenn0No ratings yet

- Unite Sites Fret (19) : DahlinDocument3 pagesUnite Sites Fret (19) : Dahlintrinh xuan hiepNo ratings yet

- Preparation and Assay of Acetyl PhosphateDocument4 pagesPreparation and Assay of Acetyl PhosphatecataawwwNo ratings yet

- United States Patent 0 ": Patented Dec. 15, 1959Document2 pagesUnited States Patent 0 ": Patented Dec. 15, 1959Aaron CurrieNo ratings yet

- United States Patent (191: Macdonald 145) Feb. 25, 1975Document4 pagesUnited States Patent (191: Macdonald 145) Feb. 25, 1975Javier Alejandro Rodriguez MelgozaNo ratings yet

- Pentaeritritol 2Document6 pagesPentaeritritol 2Ibnul BaasithNo ratings yet

- US3014784Document2 pagesUS3014784SatyamSahuNo ratings yet

- Us 2375054Document3 pagesUs 2375054haviedNo ratings yet

- Matrix Acidizing of Sandstone4Document5 pagesMatrix Acidizing of Sandstone4HelyaNo ratings yet

- Arsenal Philadelphia, Pa. 19137: FrankfordDocument23 pagesArsenal Philadelphia, Pa. 19137: FrankfordPutri PramodyaNo ratings yet

- Ingles CDocument8 pagesIngles Coscar rodriguezNo ratings yet

- US2301231Document2 pagesUS2301231Abu Mejza'atNo ratings yet

- July 20, 1954 J. L. Krieger 2,684,286: InventorDocument4 pagesJuly 20, 1954 J. L. Krieger 2,684,286: InventorNurhafizah Abd JabarNo ratings yet

- US1960211 (Sudah)Document3 pagesUS1960211 (Sudah)aris_nurhidayatNo ratings yet

- Filed June l5, 1935Document6 pagesFiled June l5, 1935Yustinus Selis ToronNo ratings yet

- This Invention Relates To A Process For Making A Stable CopperDocument3 pagesThis Invention Relates To A Process For Making A Stable CopperAngel BuenoNo ratings yet

- US3718545 (1) PatenteDocument8 pagesUS3718545 (1) PatenteAndrés BelloniNo ratings yet

- Launcelot: Massachusetts Health, Analysis, BostonDocument6 pagesLauncelot: Massachusetts Health, Analysis, BostonMaxi GonzalezNo ratings yet

- Patent Nines,: Nited StatesDocument2 pagesPatent Nines,: Nited Statesjeque661No ratings yet

- Arease: Nov. 8, 1966 W. Wogt Et Al 3,284,495 Process For The Continuous Manufacture, Purification andDocument3 pagesArease: Nov. 8, 1966 W. Wogt Et Al 3,284,495 Process For The Continuous Manufacture, Purification andRachmad HermawanNo ratings yet

- Us 3229777Document4 pagesUs 3229777Parth AggarwalNo ratings yet

- Us1951789 PDFDocument5 pagesUs1951789 PDFJames EdwardsNo ratings yet

- United States Patent Office: Patented Sept. 1, 1959Document4 pagesUnited States Patent Office: Patented Sept. 1, 1959هیمن مNo ratings yet

- Per Acetic AcidDocument5 pagesPer Acetic AcidMaruthi KNo ratings yet

- US3416887Document6 pagesUS3416887khairulNo ratings yet

- Patente 2Document3 pagesPatente 2Saul MamaniNo ratings yet

- AAS Methods 2520of 2520 ProductionDocument4 pagesAAS Methods 2520of 2520 Productionapi-3714811No ratings yet

- Copie de US2899444-1Document4 pagesCopie de US2899444-1KHALED KHALEDNo ratings yet

- Indigo Prodn. From Phenyl-Glycine Carboxylic Acid Salt - by Fusion in Mixed Potassium Hydroxide and Sodium Hydroxide Melt, Then OxidnDocument4 pagesIndigo Prodn. From Phenyl-Glycine Carboxylic Acid Salt - by Fusion in Mixed Potassium Hydroxide and Sodium Hydroxide Melt, Then OxidnCillian CreedonNo ratings yet

- Us2094573-Production of Potassumsulphate Ammonium Sulphate Double SaltDocument2 pagesUs2094573-Production of Potassumsulphate Ammonium Sulphate Double Saltkvsj2001No ratings yet

- Removal of Fluorine From Wet Process Phosphoric AcidDocument2 pagesRemoval of Fluorine From Wet Process Phosphoric AcidAdios ANo ratings yet

- Benzoic Acid To Benzaldehyde, P-Nitrobenzoic Acid To Nitrobenzene and More.Document3 pagesBenzoic Acid To Benzaldehyde, P-Nitrobenzoic Acid To Nitrobenzene and More.banjo010% (1)

- Rile From NH4Document10 pagesRile From NH4rrivera7396No ratings yet

- United States: Patent Office. VDocument2 pagesUnited States: Patent Office. VAmir HamzahNo ratings yet

- United States Patent (191: MercadeDocument4 pagesUnited States Patent (191: MercadeSoufi BadrNo ratings yet

- Determination of Gamma No and TSDocument3 pagesDetermination of Gamma No and TSAditya ShrivastavaNo ratings yet

- United States Patent Office: Patented Mar. 13, 1951 ... ."Document2 pagesUnited States Patent Office: Patented Mar. 13, 1951 ... ."Ruchita PoilkarNo ratings yet

- United States Patent (191: Wu Et Al. (451 Nov. 6, 1979Document6 pagesUnited States Patent (191: Wu Et Al. (451 Nov. 6, 1979FatonaRifkyPNo ratings yet

- 5991-6846EN BrosurDocument8 pages5991-6846EN BrosurarufatoNo ratings yet

- Tolerance Chart: (Maximum Permissible Error)Document3 pagesTolerance Chart: (Maximum Permissible Error)arufatoNo ratings yet

- Catalog KaoDocument1 pageCatalog KaoarufatoNo ratings yet

- Effects of Temperature On PH v4 - TSP-01-2Document7 pagesEffects of Temperature On PH v4 - TSP-01-2Aridita AnggrainiNo ratings yet

- 14.12 Kulcsar U PDFDocument6 pages14.12 Kulcsar U PDFarufatoNo ratings yet

- ASTM D7740 Optimizing AASDocument9 pagesASTM D7740 Optimizing AASarufatoNo ratings yet

- Doc316 53 01486 PDFDocument6 pagesDoc316 53 01486 PDFarufatoNo ratings yet

- Effects of Temperature On PH v4 - TSP-01-2 PDFDocument7 pagesEffects of Temperature On PH v4 - TSP-01-2 PDFarufatoNo ratings yet

- Ion Exchange Design ProcedDocument30 pagesIon Exchange Design ProcedFajar IndrawanNo ratings yet

- Simulation Mixed BedDocument13 pagesSimulation Mixed BedarufatoNo ratings yet

- 30265527A V03.16 KarlFischer Titrators Broch EN LR PDFDocument16 pages30265527A V03.16 KarlFischer Titrators Broch EN LR PDFarufatoNo ratings yet

- 2015 11 06 - Cetamine Technology in Power Plants - Swedish Conference 2015Document42 pages2015 11 06 - Cetamine Technology in Power Plants - Swedish Conference 2015arufatoNo ratings yet

- Gfps Chemicals PowerPlantsDocument2 pagesGfps Chemicals PowerPlantsarufatoNo ratings yet

- History of Fluorine Recovery ProcessesDocument21 pagesHistory of Fluorine Recovery ProcessesmahaNo ratings yet

- Phosphoric Acid Fuel Cell (Pafc)Document10 pagesPhosphoric Acid Fuel Cell (Pafc)Else Feba Paul0% (1)

- Phosphoric Acid - MSDSDocument3 pagesPhosphoric Acid - MSDSSathish KumarNo ratings yet

- 1 s2.0 S2213343722017419 MainDocument21 pages1 s2.0 S2213343722017419 MainIkram ADNANENo ratings yet

- PiperacilinDocument2 pagesPiperacilinivaNo ratings yet

- Buffer SolutionsDocument6 pagesBuffer SolutionsIrmey Hamidi100% (1)

- 900 Inorganic Questions For IIT JEE ADVANCEDDocument64 pages900 Inorganic Questions For IIT JEE ADVANCEDSourabh Dhavala95% (19)

- Naval JellyDocument4 pagesNaval JellyjohnsopranaNo ratings yet

- GST Food Item ListDocument88 pagesGST Food Item ListgeorgiinaNo ratings yet

- 1 s2.0 S1877705812045341 MainDocument11 pages1 s2.0 S1877705812045341 MainJavier Alejandro RodriguezNo ratings yet

- Solubility and Complex-Ion Equilibria: Practice ExamplesDocument33 pagesSolubility and Complex-Ion Equilibria: Practice Exampleskennethleo69No ratings yet

- Uses of Phosphoric AcidDocument3 pagesUses of Phosphoric AcidMarnel Roy MayorNo ratings yet

- Di-Calcium Phosphate by Direct Acidulation of Phosphate RockDocument111 pagesDi-Calcium Phosphate by Direct Acidulation of Phosphate RockAshutosh GuptaNo ratings yet

- Sciencedirect: The Use of Advanced Process Controls in A Phosphoric Acid ReactorDocument7 pagesSciencedirect: The Use of Advanced Process Controls in A Phosphoric Acid ReactorJavier Alejandro RodriguezNo ratings yet

- Fundamentals of The Wet Process Phosphor PDFDocument8 pagesFundamentals of The Wet Process Phosphor PDFVandenberg Soares de AndradeNo ratings yet

- EtanolDocument57 pagesEtanolexe241293No ratings yet

- History of Phosphoric Acid Technology (Evolution and Future Perspectives)Document7 pagesHistory of Phosphoric Acid Technology (Evolution and Future Perspectives)Fajar Zona67% (3)

- P-Block 15 To 16 GroupDocument38 pagesP-Block 15 To 16 GroupBharti GoelNo ratings yet

- Fertilizer Technology Section 1Document14 pagesFertilizer Technology Section 1Roed Alejandro LlagaNo ratings yet

- LiteraturDocument94 pagesLiteraturMuhammad Iqbal MaulanaNo ratings yet

- Che 329 - Lectre - 2Document95 pagesChe 329 - Lectre - 2anandseshadri901No ratings yet

- June 2018 QP - Paper 1 OCR (A) Chemistry AS-LevelDocument24 pagesJune 2018 QP - Paper 1 OCR (A) Chemistry AS-LevelRunNo ratings yet

- Panamax Cargo Hold Cleaning Manual Rev00Document36 pagesPanamax Cargo Hold Cleaning Manual Rev00Cenk ÇobanNo ratings yet

- Cleaning & Sanitising - Food Processing IndustryDocument21 pagesCleaning & Sanitising - Food Processing Industrydrmarvin2k5100% (1)

- Lecture 21 PhosphorousDocument53 pagesLecture 21 PhosphorousAnilKumar100% (2)

- L Uk SulphDocument24 pagesL Uk SulphypyeeNo ratings yet

- Calcium Sulfate Crystallization in Phosphoric Acid PDFDocument133 pagesCalcium Sulfate Crystallization in Phosphoric Acid PDFabderrahimnNo ratings yet

- TSP Tour ReportDocument16 pagesTSP Tour ReportArefin ShahriarNo ratings yet

- Chemicalcleaning For BoilerDocument16 pagesChemicalcleaning For Boilerak_thimiriNo ratings yet