Professional Documents

Culture Documents

60 Series Tube Fitting 150123

60 Series Tube Fitting 150123

Uploaded by

Nilesh MistryOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

60 Series Tube Fitting 150123

60 Series Tube Fitting 150123

Uploaded by

Nilesh MistryCopyright:

Available Formats

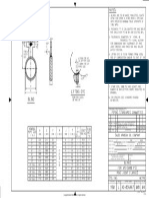

60 Series Tube Fittings

60,000 psi (4137 bar)

Instrumentation Solutions

1540 Clinton Square

Rochester

New York

USA 14604

Tel. : 1-855-693-4638

Fax: 1-877-297-4661

E-mail: info@finelok.com

Instrumentation Solutions

www.finelok.com

60 Series Tube Fitting 1

Contents

Features

Glands - G

Coned-and-Threaded Connection.

Metal-to-metal seal provides perfect leak-tight service from critical vacuum to high pressure.

Anti-vibration connection components available.

Fittings are easy to disconnect and retighten.

Material is high tensile 316 stainless steel.

Every fitting is stamped with size, material and heat code.

Crosses - C

3

Collars - CO

8

3

Anti-Vibration Gland Assemblies - AVGA

Composition

Plugs - TP

9

3

Coned and Threaded Nipples - CTN

Male Connectors - CM

9

4

60 Series Tubing

10

Female Connectors - CF

Tubing

Gland

Collar

5

Union Couplings - U

Working Pressure

5

Reducing Union Couplings - U

Working pressure are dependent on the end connection with the lowest working pressures. Working pressure for the

end connections used in this catalog are identified below.

60 Series Tube Ends

6

Union Couplings (Slip Type) - SU

Tube

O.D.

in.

Bulkhead Couplings - BU

7

Caps - TC

Working Pressure, psig (bar)

-423 to 100F

200F

400F

600F

800F

(-252 to 37.8C)

(93C)

(204C)

(316C)

(427C)

1/4

60000 (4137)

60000 (4137)

57750 (3982)

54250 (3740)

50700 (3496)

3/8

60000 (4137)

60000 (4137)

57750 (3982)

54250 (3740)

50700 (3496)

9/16

60000 (4137)

60000 (4137)

57750 (3982)

54250 (3740)

50700 (3496)

Date in this table is applied only to the working temperature below 800F (427C), For the working temperature

above 800F (427C) please consult FINELOK, and then we will provide you relative solutions.

7

Elbows - LU

7

Tees - TTT

Instrumentation Solutions

2 60 Series Tube Fitting

60 Series Tube Fitting 3

Dimensions

NPT Pipe Thread Ends

Tube

Glands

T - Tube

O.D.

in.

G - Hex

1/16

1/8

Working Pressure, psig (bar)

NPT Size

15000 (1034)

1/4

3/8

Dimensions, in. (mm)

Ordering Number

G

1/4

SS-G-60S4

0.63 (15.9)

0.82 (20.8)

3/8

SS-G-60S6

0.81 (20.6)

1.13 (28.7)

9/16

SS-G-60S9

1.19 (30.2)

1.50 (38.1)

1/2

3/4

10000 (689)

Collars

Tube

T - Tube

O.D.

in.

No allowance is made for corrosion or erosion.

Working Temperature

1/4

SS-CO-60S4

0.38 (9.6)

0.38 (9.6)

3/8

SS-CO-60S6

0.50 (12.7)

0.54 (13.7)

9/16

SS-CO-60S9

0.81 (20.6)

0.62 (15.8)

Temperature Rating

-423F(-252C) to 1200F(649C)

NPT Pipe Thread Ends

-325F(-198C) to 400F(204C)

Plugs

Tube

60 Series Tube Ends

Connection

Dimensions, in. (mm)

Ordering Number

Installation Instructions

T - Tube

O.D.

in.

Ordering Number

1/4

SS-TP-60S4

0.38 (9.6)

1.04 (26.4)

3/8

SS-TP-60S6

0.50 (12.7)

1.35 (34.3)

9/16

SS-TP-60S9

0.81 (20.6)

1.89 (48.0)

Refer to the Tools & Installation Instructions.

Dimensions, in. (mm)

Cautions:

Dimensions are for reference only, subject to change.

Do not loosen or tighten fittings when system is pressurized.

Instrumentation Solutions

Instrumentation Solutions

4 60 Series Tube Fitting

60 Series Tube Fitting 5

Female Connectors

Male Connectors

F - Hex

G - Hex

NPT Thread

Tube

T - Tube

O.D.

in.

1/4

P - NPT

Size

in.

Ordering

Number

1/8

SS-CM-60S4-NT2

1.25 (31.8)

0.50 (12.7)

0.09 (2.3)

0.63 (15.9)

0.75 (19.1)

T - Tube

O.D.

in.

1/4

1/4

1/4

SS-CM-60S4-NT4

1.38 (34.9)

0.50 (12.7)

0.09 (2.3)

0.63 (15.9)

0.75 (19.1)

1/4

3/8

SS-CM-60S4-NT6

1.38 (34.9)

0.50 (12.7)

0.09 (2.3)

0.63 (15.9)

1/4

1/2

SS-CM-60S4-NT8

1.50 (38.1)

0.50 (12.7)

0.09 (2.3)

1/4

3/4

SS-CM-60S4-NT12

1.75 (44.5)

0.50 (12.7)

3/8

1/8

SS-CM-60S6-NT2

1.50 (38.1)

3/8

1/4

SS-CM-60S6-NT4

3/8

3/8

3/8

NPT Thread

Tube

Dimensions, in. (mm)

F

P - NPT

Size

in.

Ordering

Number

Dimensions, in. (mm)

L

1/8

SS-CF-60S4-NT2

1.38 (34.9)

0.50 (12.7)

0.09 (2.3)

0.63 (15.9)

0.75 (19.1)

1/4

1/4

SS-CF-60S4-NT4

1.63 (41.3)

0.50 (12.7)

0.09 (2.3)

0.63 (15.9)

0.94 (23.8)

0.75 (19.1)

1/4

3/8

SS-CF-60S4-NT6

1.63 (41.3)

0.50 (12.7)

0.09 (2.3)

0.63 (15.9)

1.13 (28.6)

0.63 (15.9)

0.88 (22.2)

1/4

1/2

SS-CF-60S4-NT8

2.00 (50.8)

0.50 (12.7)

0.09 (2.3)

0.63 (15.9)

1.38 (34.9)

0.09 (2.3)

0.63 (15.9)

1.06 (27.0)

1/4

3/4

SS-CF-60S4-NT12

2.00 (50.8)

0.50 (12.7)

0.09 (2.3)

0.63 (15.9)

1.50 (38.1)

0.53 (13.5)

0.13 (3.3)

0.81 (20.6)

1.00 (25.4)

1/4

SS-CF-60S4-NT16

2.38 (60.3)

0.50 (12.7)

0.09 (2.3)

0.63 (15.9)

1.75 (44.5)

1.63 (41.3)

0.53 (13.5)

0.13 (3.3)

0.81 (20.6)

1.00 (25.4)

3/8

1/8

SS-CF-60S6-NT2

1.63 (41.3)

0.53 (13.5)

0.13 (3.3)

0.81 (20.6)

1.00 (25.4)

SS-CM-60S6-NT6

1.63 (41.3)

0.53 (13.5)

0.13 (3.3)

0.81 (20.6)

1.00 (25.4)

3/8

1/4

SS-CF-60S6-NT4

1.88 (47.6)

0.53 (13.5)

0.13 (3.3)

0.81 (20.6)

1.00 (25.4)

1/2

SS-CM-60S6-NT8

1.75 (44.5)

0.53 (13.5)

0.13 (3.3)

0.81 (20.6)

1.00 (25.4)

3/8

3/8

SS-CF-60S6-NT6

1.88 (47.6)

0.53 (13.5)

0.13 (3.3)

0.81 (20.6)

1.13 (28.6)

3/8

3/4

SS-CM-60S6-NT12

2.00 (50.8)

0.53 (13.5)

0.13 (3.3)

0.81 (20.6)

1.06 (27.0)

3/8

1/2

SS-CF-60S6-NT8

2.13 (54.0)

0.53 (13.5)

0.13 (3.3)

0.81 (20.6)

1.38 (34.9)

3/8

SS-CM-60S6-NT16

2.00 (50.8)

0.53 (13.5)

0.13 (3.3)

0.81 (20.6)

1.38 (34.9)

3/8

3/4

SS-CF-60S6-NT12

2.00 (50.8)

0.53 (13.5)

0.13 (3.3)

0.81 (20.6)

1.50 (38.1)

9/16

1/8

SS-CM-60S9-NT2

1.63 (41.3)

0.81 (20.6)

0.19 (4.8)

1.19 (30.2)

1.38 (34.9)

3/8

SS-CF-60S6-NT16

2.25 (57.2)

0.53 (13.5)

0.13 (3.3)

0.81 (20.6)

1.75 (44.5)

9/16

1/4

SS-CM-60S9-NT4

1.75 (44.5)

0.81 (20.6)

0.19 (4.8)

1.19 (30.2)

1.38 (34.9)

9/16

1/8

SS-CF-60S9-NT2

1.81 (46.0)

0.81 (20.6)

0.19 (4.8)

1.19 (30.2)

1.38 (34.9)

9/16

3/8

SS-CM-60S9-NT6

1.75 (44.5)

0.81 (20.6)

0.19 (4.8)

1.19 (30.2)

1.38 (34.9)

9/16

1/4

SS-CF-60S9-NT4

2.00 (50.8)

0.81 (20.6)

0.19 (4.8)

1.19 (30.2)

1.38 (34.9)

9/16

1/2

SS-CM-60S9-NT8

1.88 (47.6)

0.81 (20.6)

0.19 (4.8)

1.19 (30.2)

1.38 (34.9)

9/16

3/8

SS-CF-60S9-NT6

2.00 (50.8)

0.81 (20.6)

0.19 (4.8)

1.19 (30.2)

1.38 (34.9)

9/16

3/4

SS-CM-60S9-NT12

2.13 (54.0)

0.81 (20.6)

0.19 (4.8)

1.19 (30.2)

1.38 (34.9)

9/16

1/2

SS-CF-60S9-NT8

2.38 (60.3)

0.81 (20.6)

0.19 (4.8)

1.19 (30.2)

1.38 (34.9)

9/16

SS-CM-60S9-NT16

2.25 (57.2)

0.81 (20.6)

0.19 (4.8)

1.19 (30.2)

1.38 (34.9)

9/16

3/4

SS-CF-60S9-NT12

2.38 (60.3)

0.81 (20.6)

0.19 (4.8)

1.19 (30.2)

1.50 (38.1)

9/16

SS-CF-60S9-NT16

2.50 (63.5)

0.81 (20.6)

0.19 (4.8)

1.19 (30.2)

1.75 (44.5)

Union Couplings

F - Hex

G - Hex

T

G - Hex

F - Hex

Tube

T - Tube

O.D.

in.

Instrumentation Solutions

Ordering

Number

Dimensions, in. (mm)

L

1/4

SS-U-60S4

1.38 (34.9)

0.50 (12.7)

0.09 (2.3)

0.63 (15.9)

0.75 (19.1)

3/8

SS-U-60S6

1.75 (44.5)

0.53 (13.5)

0.13 (3.3)

0.81 (20.6)

1.00 (25.4)

9/16

SS-U-60S9

2.19 (55.6)

0.81 (20.6)

0.19 (4.8)

1.19 (30.2)

1.38 (34.9)

Instrumentation Solutions

6 60 Series Tube Fitting

60 Series Tube Fitting 7

Bulkhead Couplings

F - Hex

F - Hex

G - Hex

G - Hex

T

Tx

Gx - Hex

Reducing Union Couplings

Cx

Tube

T - Tube Tx - Tube

O.D.

O.D.

in.

in.

Ordering

Number

Dimensions, in. (mm)

L

Cx

Gx

Tube

Dimensions, in. (mm)

1.38 (34.9)

T - Tube

O.D.

in.

Ordering

Number

1.38 (34.9)

1/4

SS-BU-60S4

1.88 (47.8)

0.50 (12.7)

0.09 (2.3)

0.63 (15.9)

3/8

SS-BU-60S6

2.38 (60.5)

0.53 (13.5)

0.13 (3.3)

9/16

SS-BU-60S9

2.75 (69.9)

0.81 (20.6)

0.19 (4.8)

3/8

1/4

SS-U-60S6-60S4

1.63 (41.3)

0.53 (13.5)

0.50 (12.7)

0.09 (2.3)

0.81 (20.6)

0.63 (15.9)

1.00 (25.4)

9/16

1/4

SS-U-60S9-60S4

1.75 (44.5)

0.81 (20.6)

0.50 (12.7)

0.09 (2.3)

1.19 (30.2)

0.63 (15.9)

9/16

3/8

SS-U-60S9-60S6

2.00 (50.8)

0.81 (20.6)

0.53 (13.5)

0.13 (3.3)

1.19 (30.2)

0.81 (20.6)

Panel Hole

Size

Max. Panel

Thickness

1.06 (27.0)

0.94 (23.8)

0.38 (9.7)

0.81 (20.6)

1.38 (34.9)

1.13 (28.6)

0.38 (9.7)

1.19 (30.2)

1.88 (47.6)

1.69 (42.9)

0.38 (9.7)

Union Couplings (Slip Type)

F - Hex

G - Hex

T

Caps

F - Hex

G - Hex

T

Tube

Tube

T - Tube

O.D.

in.

Ordering

Number

1/4

SS-SU-60S4

1.38 (34.9)

0.50 (12.7)

0.09 (2.3)

0.63 (15.9)

0.75 (19.1)

3/8

SS-SU-60S6

1.75 (44.5)

0.53 (13.5)

0.13 (3.3)

0.81 (20.6)

1.00 (25.4)

9/16

SS-SU-60S9

2.19 (55.6)

0.81 (20.6)

0.19 (4.8)

1.19 (30.2)

1.38 (34.9)

1/4

SS-TC-60S4

0.75 (19.1)

0.50 (12.7)

0.63 (15.9)

0.75 (19.1)

3/8

SS-TC-60S6

1.13 (28.6)

0.53 (13.5)

0.81 (20.6)

1.00 (25.4)

9/16

SS-TC-60S9

1.38 (34.9)

0.81 (20.6)

1.19 (30.2)

1.38 (34.9)

Dimensions, in. (mm)

L

Elbows

L

E

E1

L1

G - Hex

Ordering

Number

Dimensions, in. (mm)

C

T - Tube

O.D.

in.

Tube

T - Tube

O.D.

in.

Instrumentation Solutions

Ordering

Number

Dimensions, in. (mm)

C

L1

E1

Thickness

1/4

SS-LU-60S4

0.50 (12.7)

0.09 (2.3)

0.63 (15.9)

1.50 (38.1)

0.88 (22.4)

1.00 (25.4)

0.62 (15.7)

0.75 (19.1)

3/8

SS-LU-60S6

0.53 (13.5)

0.13 (3.3)

0.81 (20.6)

2.00 (50.8)

1.25 (31.8)

1.50 (38.1)

1.00 (25.4)

1.00 (25.4)

9/16

SS-LU-60S9

0.81 (20.6)

0.19 (4.8)

1.19 (30.2)

2.62(66.5)

1.88 (47.8)

1.88 (47.8)

1.12 (28.4)

1.50 (38.1)

Instrumentation Solutions

8 60 Series Tube Fitting

60 Series Tube Fitting 9

Tees

Anti-Vibration Gland Assemblies

G - Hex

T

L1

The extreme vibration or shock, such as mobile pressure systems or long tubing runs culminating at a compressor that the tubing

systems are subjected to, will be prevented by using Finelok Anti-Vibration Gland Assemblies. These assemblies use the same

reliable connection geometries as the standard Finelok fittings, with the added advantage of essentially unlimited vibrational

fatigue life.

A coned and threaded tube, when subjected to unusual or excessive vibration, may fail prematurely and break at the last thread.

Finelok Anti-Vibration Gland Assembly acts to move the fulcrum of vibration away from the threaded part of the tube and onto

the strong, solid wall of the tubing. A wedge-like collet firmly holds the assembly in place, virtually eliminating premature tubing

failure while reliably maintaining a leakage-free connection between the tube and the connection seat.

Tube

F - Hex

Tube

Dimensions, in. (mm)

Ordering

Number

L1

T - Tube

O.D.

in.

Thickness

1/4

SS-TTT-60S4

0.50 (12.7)

0.09 (2.3)

0.63 (15.9)

2.00 (50.8)

1.25 (31.8)

0.88 (22.4)

0.75 (19.1)

3/8

SS-TTT-60S6

0.53 (13.5)

0.13 (3.3)

0.81 (20.6)

2.00 (50.8)

1.56 (39.6)

1.06 (26.9)

1.00 (25.4)

9/16

SS-TTT-60S9

0.81 (20.6)

0.19 (4.8)

1.19 (30.2)

2.62 (66.5)

2.12 (53.8)

1.38 (35.0)

1.50 (38.1)

T - Tube

O.D.

in.

C

L

Dimensions, in. (mm)

Ordering

Number

1/4

SS-AVGA-60S4

0.81 (20.6)

0.50 (12.7)

0.63 (15.9)

3/8

SS-AVGA-60S6

1.12 (28.4)

0.62 (15.7)

0.81 (20.6)

9/16

SS-AVGA-60S9

1.50 (38.1)

1.00 (25.4)

1.19 (30.2)

Crosses

Coned and Threaded Nipples

L1

G - Hex

Tx

Tube

T - Tube

O.D.

in.

Instrumentation Solutions

Ordering

Number

Tx - Tube

I.D.

in.

Ordering

Number

L

in. (mm)

1/4

0.083

SS-CTN-60S4-2.75

1/4

0.083

SS-CTN-60S4-3

3 (76.2)

1/4

0.083

SS-CTN-60S4-4

4 (101.6)

1/4

0.083

SS-CTN-60S4-6

6 (152.4)

1/4

0.083

SS-CTN-60S4-8

8 (203.2)

1/4

0.083

SS-CTN-60S4-10

10 (254.0)

1/4

0.083

SS-CTN-60S4-12

12 (304.8)

3/8

0.125

SS-CTN-60S6-3

3 (76.2)

3/8

0.125

SS-CTN-60S6-4

4 (101.6)

3/8

0.125

SS-CTN-60S6-6

6 (152.4)

8 (203.2)

2.75 (69.9)

T - Tube

O.D.

in.

Dimensions, in. (mm)

C

L1

Thickness

1/4

SS-C-60S4

0.50 (12.7)

0.09 (2.3)

0.63 (15.9)

2.00 (50.8)

1.25 (31.8)

0.75 (19.1)

3/8

0.125

SS-CTN-60S6-8

3/8

SS-C-60S6

0.53 (13.5)

0.13 (3.3)

0.81 (20.6)

2.00 (50.8)

2.12 (53.8)

1.00 (25.4)

3/8

0.125

SS-CTN-60S6-10

10 (254.0)

9/16

SS-C-60S9

0.81 (20.6)

0.19 (4.8)

1.19 (30.2)

2.62 (66.5)

2.75 (69.9)

1.50 (38.1)

3/8

0.125

SS-CTN-60S6-12

12 (304.8)

9/16

0.188

SS-CTN-60S9-4

4 (101.6)

9/16

0.188

SS-CTN-60S9-6

6 (152.4)

9/16

0.188

SS-CTN-60S9-8

8 (203.2)

9/16

0.188

SS-CTN-60S9-10

10 (254.0)

9/16

0.188

SS-CTN-60S9-12

12 (304.8)

Instrumentation Solutions

10 60 Series Tube Fitting

60 Series Tubing

Working pressure: 60000 psig (4137 bar).

316 and 304 stainless steel are standard material. Other materials are available upon request.

Material, size, and heat code are indicated on the tubing surface.

T - Tube

O.D.

in.

1/4

Tx - Tube

I.D.

in.

0.083

1/4

Material

Basic Ordering

Number

Tolerance O.D.

in. (mm)

316 SS

SS-HT-60S4-

0.248/0.243(6.30/6.17)

0.083

304 SS

S4-HT-60S4-

0.248/0.243(6.30/6.17)

3/8

0.125

316 SS

SS-HT-60S6-

0.370/0.365(9.40/9.27)

3/8

0.125

304 SS

S4-HT-60S6-

0.370/0.365(9.40/9.27)

9/16

0.188

316 SS

SS-HT-60S9-

0.557/0.552(14.15/14.02)

9/16

0.188

304 SS

S4-HT-60S9-

0.557/0.552(14.15/14.02)

Add the actual foot (feet)/meter (meters) as a suffix to the basic ordering number

to get the complete ordering number.

For example:

1. 10 feet length, O.D. is 1/4", I.D. is 0.083", 316 SS 60 Series tube, the complete

ordering number is: SS-HT-60S4-10.

2. 3 meters length, O.D. is 9/16", I.D. is 0.188", 304 SS 60 Series tube, the complete

ordering number is: S4-HT-60S9-3M.

Instrumentation Solutions

You might also like

- ASME B31 4 Calculator V1 1Document11 pagesASME B31 4 Calculator V1 1vazzoleralex6884100% (1)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Multi-Storey Concrete Car Parks: A Guide To Design and ConstructionDocument20 pagesMulti-Storey Concrete Car Parks: A Guide To Design and ConstructionipostkastNo ratings yet

- A11Document1 pageA11liviu_dovaNo ratings yet

- Threaded Weld-In Socket Weld and Limited Space ThermowellsDocument2 pagesThreaded Weld-In Socket Weld and Limited Space ThermowellsRajadurai SinghNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Estimate For Grouted RiprapDocument6 pagesEstimate For Grouted RiprapTing Pipx80% (5)

- 60 Series Tube Fittings and TubingDocument5 pages60 Series Tube Fittings and TubingNilesh MistryNo ratings yet

- Catalago Swagelok Suportes PDFDocument8 pagesCatalago Swagelok Suportes PDFvitorpoNo ratings yet

- Tube SupportsDocument8 pagesTube SupportsSyahirul AlimNo ratings yet

- A02Document1 pageA02liviu_dovaNo ratings yet

- MS 01 34Document8 pagesMS 01 34Agustin CesanNo ratings yet

- PL 008748Document10 pagesPL 008748ronaldxmenNo ratings yet

- Valvulas de Bola - JAMESBURYDocument4 pagesValvulas de Bola - JAMESBURYcasv9No ratings yet

- Agip STD - Piping Project SpecificationDocument1 pageAgip STD - Piping Project Specificationhalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- Metering Valves (MS-01-142)Document9 pagesMetering Valves (MS-01-142)HashemAliHashemNo ratings yet

- FT MedPress AutoclaveDocument12 pagesFT MedPress AutoclaveAymeeenNo ratings yet

- Calculator ASME B31 4Document11 pagesCalculator ASME B31 4Denstar Ricardo Silalahi50% (2)

- Actuador NeumaticoDocument12 pagesActuador NeumaticoJose Alfredo Rojas UribeNo ratings yet

- Rociadores STD TycoDocument86 pagesRociadores STD TycoIvAldreteNo ratings yet

- Grease Nipples From UMETA Catalogue GK84-E 04-2012-2Document46 pagesGrease Nipples From UMETA Catalogue GK84-E 04-2012-2FranzKafkaNo ratings yet

- Modular Dual Line SystemDocument6 pagesModular Dual Line Systemangela_draguNo ratings yet

- Clampco CatalogueDocument39 pagesClampco CatalogueMisaghNo ratings yet

- Swagelok High Pressure FittingsDocument8 pagesSwagelok High Pressure FittingsSyahirul AlimNo ratings yet

- Thread o Ring - Fittings (T O R)Document2 pagesThread o Ring - Fittings (T O R)Jimmy ChanNo ratings yet

- RUELCO - Diff Pressure SwitchDocument2 pagesRUELCO - Diff Pressure SwitchAiman Hilmi Aiman HilmiNo ratings yet

- A17Document1 pageA17liviu_dovaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- STD PipingDocument51 pagesSTD PipingRodrigo Iván Latorre AlmirallNo ratings yet

- Bulletin B150-5 - Ball Valve For H2O2Document0 pagesBulletin B150-5 - Ball Valve For H2O2pdaga19691383No ratings yet

- GI - Thermowell CatalogueDocument18 pagesGI - Thermowell CatalogueMahdy MazinyNo ratings yet

- Series 406NRSRW Specification SheetDocument2 pagesSeries 406NRSRW Specification SheetWattsNo ratings yet

- High Pressure Needle ValvesDocument11 pagesHigh Pressure Needle ValvesNilesh MistryNo ratings yet

- 6 Series Pipe FittingsDocument18 pages6 Series Pipe FittingsNilesh MistryNo ratings yet

- MasterSeries 850 Specification SheetDocument2 pagesMasterSeries 850 Specification SheetFEBCONo ratings yet

- 61502YDocument9 pages61502YbalajivangaruNo ratings yet

- 6 Series Tube Fittings 131119Document46 pages6 Series Tube Fittings 131119Brunno Vasques100% (1)

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- Grease Nipples From UMETA Catalogue GK84-E 04-2012-2Document46 pagesGrease Nipples From UMETA Catalogue GK84-E 04-2012-2Vishwambhar Shirodkar100% (1)

- Ss 01059 eDocument8 pagesSs 01059 eDavid LapacaNo ratings yet

- STAS Steel Liquid and Suction Line Filter DrierDocument2 pagesSTAS Steel Liquid and Suction Line Filter DrierVeve MariusNo ratings yet

- A2 1 16junDocument2 pagesA2 1 16junamitrai86No ratings yet

- Low Pressure SW Series Compression FittingsDocument20 pagesLow Pressure SW Series Compression FittingsShankar RajNo ratings yet

- rc33026 D12-UscDocument7 pagesrc33026 D12-Usceww08No ratings yet

- 6 Series Weld FittingsDocument10 pages6 Series Weld FittingsNilesh MistryNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- Spirax Sarco Commissioning Strainer 1Document3 pagesSpirax Sarco Commissioning Strainer 1swaraj4uNo ratings yet

- Bleed&Purge ValveDocument2 pagesBleed&Purge ValveNilesh MistryNo ratings yet

- HeliCoil Tangless InsertsDocument6 pagesHeliCoil Tangless InsertsAce Industrial SuppliesNo ratings yet

- KITZ DJ Series Ductile Iron Butterfly Valves E-231-06 PDFDocument16 pagesKITZ DJ Series Ductile Iron Butterfly Valves E-231-06 PDFYulita Ika PawestriNo ratings yet

- Lifting Eye Blind: NotesDocument1 pageLifting Eye Blind: Notesnarutothunderjet216No ratings yet

- 2011628233138490Document14 pages2011628233138490adventure11111No ratings yet

- Metric Section BDocument26 pagesMetric Section BniladriprasadrNo ratings yet

- Ball ValveDocument12 pagesBall ValveIdabaNo ratings yet

- Pipeline StrainersDocument6 pagesPipeline Strainerssairam2234No ratings yet

- 200 Series Check ValvesDocument2 pages200 Series Check ValvesMoanquileNo ratings yet

- 13 BushingsDocument25 pages13 BushingsRolffoTelloNo ratings yet

- Ari Checko V Pn63 - 160Document8 pagesAri Checko V Pn63 - 160Josue MorenoNo ratings yet

- Bifold UpdatedDocument8 pagesBifold UpdatedGopinath GunasekaranNo ratings yet

- 2015 Q1 - Intertek - MalaysiaDocument1 page2015 Q1 - Intertek - MalaysiaNilesh MistryNo ratings yet

- Resources Industrial Thomson ValveLineCard OnlineversionDocument4 pagesResources Industrial Thomson ValveLineCard OnlineversionNilesh MistryNo ratings yet

- Cat Acvbr9000Document16 pagesCat Acvbr9000Nilesh MistryNo ratings yet

- Supplier Quality Assurance ManualDocument29 pagesSupplier Quality Assurance ManualNilesh Mistry0% (1)

- WWW - Ventile.cz 7. Instrument Manifold Amp Gauge ValvesDocument10 pagesWWW - Ventile.cz 7. Instrument Manifold Amp Gauge ValvesNilesh MistryNo ratings yet

- L&T Gate Globe Check Valves API 602Document12 pagesL&T Gate Globe Check Valves API 602Nilesh MistryNo ratings yet

- Valve Con STR FeaturesDocument1 pageValve Con STR FeaturesNilesh MistryNo ratings yet

- VS3 VS6 Instrumentation ValvesDocument2 pagesVS3 VS6 Instrumentation ValvesNilesh MistryNo ratings yet

- Tech Ascend CNC Student ManualDocument42 pagesTech Ascend CNC Student ManualabyzenNo ratings yet

- 08 Push in Fittings For PneumaticDocument20 pages08 Push in Fittings For PneumaticNilesh MistryNo ratings yet

- Instrumentation Tube: Tube and Tube AccessoriesDocument4 pagesInstrumentation Tube: Tube and Tube AccessoriesNilesh MistryNo ratings yet

- Quick Release Coupling: CouplingsDocument3 pagesQuick Release Coupling: CouplingsNilesh MistryNo ratings yet

- 02 Precision Pipe FittingsDocument28 pages02 Precision Pipe FittingsNilesh MistryNo ratings yet

- L&T Globe Control ValvesDocument4 pagesL&T Globe Control ValvesNilesh MistryNo ratings yet

- 04 Two Three Way Ball Valves For CNG ApplicationsDocument4 pages04 Two Three Way Ball Valves For CNG ApplicationsNilesh MistryNo ratings yet

- ValvesDocument13 pagesValvesNilesh MistryNo ratings yet

- Selection of Roofing and Wall MaterialsDocument3 pagesSelection of Roofing and Wall MaterialsSaket Pandey100% (1)

- Plastic Identification CodesDocument1 pagePlastic Identification CodesMuhammad Adnan HafeezNo ratings yet

- جهات تقويم المطابقة المقبولة لدى الهيئة على النظام الجديد 1 11 1438Document13 pagesجهات تقويم المطابقة المقبولة لدى الهيئة على النظام الجديد 1 11 1438Wajid KNo ratings yet

- Detail Tulangan Spun-PileDocument1 pageDetail Tulangan Spun-PileAlanNo ratings yet

- Main Stone MarinerDocument4 pagesMain Stone Marinercidinha lellisNo ratings yet

- Gs Graphite Specialties Solutions Metallurgy - 0 - MERSENDocument12 pagesGs Graphite Specialties Solutions Metallurgy - 0 - MERSENlucia.calvoNo ratings yet

- 5 - 11KV-Composite - Polymer - Pin-Insulator - Specifications - GTP PDFDocument18 pages5 - 11KV-Composite - Polymer - Pin-Insulator - Specifications - GTP PDFGrbo PlavsicNo ratings yet

- Aluminium in ShipbuildingDocument2 pagesAluminium in ShipbuildingPhung Tuan Anh100% (1)

- BHEL SPEC Section D2 PDFDocument249 pagesBHEL SPEC Section D2 PDFelangorengaNo ratings yet

- Zincoseal 605 MWL PDFDocument3 pagesZincoseal 605 MWL PDFPrince NaswaNo ratings yet

- Concrete Soctety - Construction JointsDocument11 pagesConcrete Soctety - Construction Jointswaynectw100% (1)

- Kingspan PIR Datasheet King Zip Roof July 2020Document10 pagesKingspan PIR Datasheet King Zip Roof July 2020Georgios PNo ratings yet

- Flat Head Rivets - IS2998Document7 pagesFlat Head Rivets - IS2998Rajasekaran MuruganNo ratings yet

- Final Exam: Technical Proposal Retrofitting MethodDocument5 pagesFinal Exam: Technical Proposal Retrofitting Methodjucar fernandezNo ratings yet

- D. V. Bompa and A. Y. Elghazouli, 2020. Experimental and Numerical Assessment of The Shear Behaviour of Lime Mortar Clay Brick Masonry TripletsDocument17 pagesD. V. Bompa and A. Y. Elghazouli, 2020. Experimental and Numerical Assessment of The Shear Behaviour of Lime Mortar Clay Brick Masonry TripletsMichael PisfilNo ratings yet

- POLYMERS - ApplicationDocument54 pagesPOLYMERS - ApplicationkavineshpraneetaNo ratings yet

- Catalogo General Eldon EnglishDocument317 pagesCatalogo General Eldon EnglishsandeshNo ratings yet

- Lav 1 Faucet Kohler K 73168 4Document2 pagesLav 1 Faucet Kohler K 73168 4Enak CenirNo ratings yet

- Basement ConstructionDocument5 pagesBasement ConstructionWayne BurgessNo ratings yet

- Steelwise Welds Web r1Document4 pagesSteelwise Welds Web r1alberto rosadoNo ratings yet

- Microstructure and Mechanical Properties of AustenDocument7 pagesMicrostructure and Mechanical Properties of AustenkarahandevrimNo ratings yet

- Quality Assurance Manual: Check List For Projects ActivityDocument31 pagesQuality Assurance Manual: Check List For Projects ActivityPetals ParadiseNo ratings yet

- 1 - Bricks - DocxconstructionDocument14 pages1 - Bricks - DocxconstructionMuhammad Irfan KhanNo ratings yet

- Eurogypsum Finshing Uk02Document12 pagesEurogypsum Finshing Uk02Chan Yong HongNo ratings yet

- PVC Water Stops - Kanta Rubber Pvt. LTDDocument2 pagesPVC Water Stops - Kanta Rubber Pvt. LTDabdul khaderNo ratings yet

- NOLMURI FWC (Ok)Document427 pagesNOLMURI FWC (Ok)emrubelNo ratings yet

- Nas1352 Rev 11Document6 pagesNas1352 Rev 11staedtlerpNo ratings yet