Professional Documents

Culture Documents

Chin Et Al-1992-International Journal For Numerical Methods in Engineering

Chin Et Al-1992-International Journal For Numerical Methods in Engineering

Uploaded by

SPCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- DLP For Cot 1Document5 pagesDLP For Cot 1Maricel Guevarra90% (10)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cycle Counting in Fatigue Analysis: Standard Practices ForDocument10 pagesCycle Counting in Fatigue Analysis: Standard Practices ForSPNo ratings yet

- Form Factors Grey Bodies and Radks Course PDFDocument179 pagesForm Factors Grey Bodies and Radks Course PDFSPNo ratings yet

- Thermoelastic Damping in Micro-Beam Resonators: Yuxin Sun, Daining Fang, Ai Kah SohDocument17 pagesThermoelastic Damping in Micro-Beam Resonators: Yuxin Sun, Daining Fang, Ai Kah SohSPNo ratings yet

- Towards Automated Determination of USERMAT For The Nonlinear Constitutive Behavior of CompositesDocument19 pagesTowards Automated Determination of USERMAT For The Nonlinear Constitutive Behavior of CompositesSPNo ratings yet

- Mapping 1mmDocument1,810 pagesMapping 1mmSPNo ratings yet

- IntegrationToolkitProgrammerGuide V10Document434 pagesIntegrationToolkitProgrammerGuide V10velkshanmuga100% (2)

- Automated Crack Extension Fracture SeminarDocument23 pagesAutomated Crack Extension Fracture SeminarSPNo ratings yet

- SessionPlans Db99dMAT101 Syllabus & QBDocument14 pagesSessionPlans Db99dMAT101 Syllabus & QBNaitik TiwariNo ratings yet

- Sister Nivedita University Syllabus FOR Three Years Bachelor Degree Course IN Computer Application (Bca) Under Ugc-Cbcs SystemDocument72 pagesSister Nivedita University Syllabus FOR Three Years Bachelor Degree Course IN Computer Application (Bca) Under Ugc-Cbcs Systemsuyashsahu2505No ratings yet

- BEGEOINFODocument90 pagesBEGEOINFOShebinNo ratings yet

- TTK - S AP Calculus ABDocument36 pagesTTK - S AP Calculus ABIan CausseauxNo ratings yet

- Dy DX Ax: Calculus Made EasyDocument6 pagesDy DX Ax: Calculus Made EasyIkhda Wardhani NstNo ratings yet

- SusicDocument19 pagesSusicALVARO DIEGO MACHACA CONDORINo ratings yet

- All India Test Series LeafletDocument8 pagesAll India Test Series LeafletResonance Kota100% (1)

- DPT Syllabus II IV SemDocument26 pagesDPT Syllabus II IV SemxxxpressionNo ratings yet

- Cap 4Document90 pagesCap 4Andreu Nieto MarinNo ratings yet

- Class 12 - Maths Subject - CH 7 - Integrals - Formulas by SP GuptaDocument10 pagesClass 12 - Maths Subject - CH 7 - Integrals - Formulas by SP Gupta12B-E1 PRANAV B.No ratings yet

- U Zaw Zaw AungDocument9 pagesU Zaw Zaw AungPrince JacintoNo ratings yet

- Numerical Analysis I (MATH 573)Document3 pagesNumerical Analysis I (MATH 573)Zerihun IbrahimNo ratings yet

- Mpae PDFDocument70 pagesMpae PDFKABADDI RISINGNo ratings yet

- J C Burkill Theory of Ordinary Differential EquationsDocument125 pagesJ C Burkill Theory of Ordinary Differential EquationsPawan Mishra100% (1)

- JEE MAIN and ADVANCED Chapterwise PYQ Mathematics Prabhat PublicationDocument445 pagesJEE MAIN and ADVANCED Chapterwise PYQ Mathematics Prabhat PublicationNguyen Van Justonly Chi100% (4)

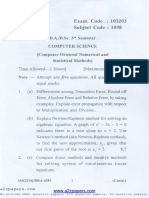

- Cs Ba-Bsc 3rd Sem 2016Document4 pagesCs Ba-Bsc 3rd Sem 2016So RvNo ratings yet

- CH 16Document106 pagesCH 16Ignacio MagañaNo ratings yet

- BSC MathematicsDocument13 pagesBSC MathematicsGanesh TiwariNo ratings yet

- MATH 141 Final Exam Sample CDocument5 pagesMATH 141 Final Exam Sample CRAJESH KUMARNo ratings yet

- Sách bài tập Giải tích Demidovich-trang-18-43Document26 pagesSách bài tập Giải tích Demidovich-trang-18-43xuansangtruongthi2201No ratings yet

- MATH 31B - Week 2 Integrals Involving Logarithms and L'Hopital RuleDocument3 pagesMATH 31B - Week 2 Integrals Involving Logarithms and L'Hopital RuleAgus LeonardiNo ratings yet

- The Poincare Lemma and de Rham CohomologyDocument14 pagesThe Poincare Lemma and de Rham CohomologyAlex YuNo ratings yet

- Complex Analysis Paper-II Segment Wise Questions From 1983 To 2011 Civil ServiceDocument7 pagesComplex Analysis Paper-II Segment Wise Questions From 1983 To 2011 Civil ServiceNagendran KrishnamoorthiNo ratings yet

- Mathematics: Paper 9709/11 Paper 11 Key MessagesDocument59 pagesMathematics: Paper 9709/11 Paper 11 Key MessagesAditiNo ratings yet

- Piskunov - Differential and Integral Calculus - Volume 2 - MirDocument589 pagesPiskunov - Differential and Integral Calculus - Volume 2 - MirMarcos NahuelNo ratings yet

- GATE Engineering Mathematics MaterialDocument17 pagesGATE Engineering Mathematics Materialmanoj kaushikNo ratings yet

- B.tech+ +Civil+Engg.+ + (C) + +Applicable+to+All+BatchDocument158 pagesB.tech+ +Civil+Engg.+ + (C) + +Applicable+to+All+BatchShruti YadavNo ratings yet

- Discretization NotesDocument19 pagesDiscretization NotesmasterrkNo ratings yet

- Jam BooksDocument2 pagesJam BooksSavi Randhawa100% (2)

Chin Et Al-1992-International Journal For Numerical Methods in Engineering

Chin Et Al-1992-International Journal For Numerical Methods in Engineering

Uploaded by

SPOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chin Et Al-1992-International Journal For Numerical Methods in Engineering

Chin Et Al-1992-International Journal For Numerical Methods in Engineering

Uploaded by

SPCopyright:

Available Formats

INTERNATIONALJOURNAL FOR NUMERICAL METHODS I N ENGINEERING, VOL.

35,

641-653 (1992)

SPACECRAFT THERMAL MODELLING

J. H. CHIN, T. D. PANCZAK AND L. FRIED

Lockheed Missiles and Space Co., Inc., Sunnyvale, California. U.S.A.

SUMMARY

Thermal modelling of spacecraft requires approaches which can handle dominant radiative heat transfers

and many special thermal control components. Present network-type thermal analysers allow simulation,

especially for components with rectangular geometries, but at the expense of considerable awkwardness and

much error-prone manual input. The user interfaces for pre- and postprocessing for these analysers are also

very deficient. Finite element thermal analysers solve some of the analytical difficulties, but are not widely

used because they lack the flexibility to simulate special operations. The Galerkin finite element method

(GFEM) distributes the contributions within an element to the element nodal points. The assembly of the

contributions from all elements yields a system of energy balance equations for the nodal points of the

system. Monte Carlo raytracing, in conjunction with a GFEM energy distribution to element nodal points,

yields a procedure of consistent nowisothermal surface radiation exchange. This procedure reduces a source

of simulation error caused by non-uniform element illumination and shading. Orbital heating, fluid flow and

special analysis features are discussed. The main analysis program is interfaced to the preprocessing and

postprocessing modules. Example results are given.

1 . INTRODUCTION

Historically, approaches to thermal modelling of spacecraft have been driven by the capabilities

of computer hardware, by the domination of radiative heat transfer and by the need for flexibility

in analysis. Two types of analysis software evolved. The first is an equation solver (e.g.

SINDA85') which requires hand input of the R-C thermal network components. Initially, no

formalized scheme was available t o calculate the conduction resistors and thus the quality of the

conduction network depended upon the skill of the engineer building it. The availability of

preprocessors such as Thermal Model Generator (TMG)' eased the problem somewhat. However, T M G s algorithm is only approximate and may yield unreliable results for irregular

geometries and anisotropic material properties.

The second type calculates radiative exchanges between various surfaces, as well as the

environmental heating or cooling for the external surfaces. The very earliest software could not

handle the effects of intervening bodies on the heat flow between surfaces. This problem was

finally solved3 and most subsequent software (e.g. TRASYS4) incorporates the original basic

algorithm.

Computer hardware capabilities also dictated the design of software, as for instance, the

radiation algorithm of TRASYS. Because of the slow speed of the available computers, schemes

such as double area integration were used, despite their known theoretical limitations and their

inability to handle specular surfaces. Properly designed ray-tracing schemes together with

modern computer hardware eliminate these restriction^.^

Although the finite element method (FEM) has become more accepted in thermal analysis in

recent years, its use in spacecraft thermal analysis is relatively infrequent. The major reason is that

0029-598 1/92/170641-13$11 S O

0 1992 by John Wiley & Sons, Ltd.

Received 3 February 1992

Revised 8 May 1992

642

J. H. CHIN, T. D. PANCZAK AND L. FRIED

most finite element codes do not provide the flexibility to incorporate special logic to simulate the

operation of heat transfer components such as heaters or heat pipes.

Complex geometry, large size and enhanced mission timelines of modern-day spacecraft

dictated the need for more advanced methods than existing analysis tools can provide. The

advances in modern computer aided engineering (CAE), powerful computer graphics and work

stations, and parallel and distributed processing have paved the way for the development of the

next generation integrated thermal analysis system, such as the Thermal Synthesizer System

(TSS).6*7An alternative is to use available commercial software for preprocessing and postprocessing. Interface programs are then developed to communicate between the commercial package

and the main analyser program.8

Section 2 reviews the main analysis components. Preprocessing and postprocessing are

discussed in Section 3. Example results are given in Section 4.

2. ANALYSIS COMPONENTS AND APPROACHES

This section reviews the analysis components: conduction, radiation, orbital heating, fluid flow

analysis and special analysis features.

2.1. Conduction analysis

The network method (NWM) and finite element method (FEM) are discussed and the FEM

algorithm for conductance and capacitance is described.

2.1.1. NWM versus FEM. As already mentioned, the commonly used equation solver for

spacecraft thermal analysis requires user calculation and input of the values of R-C network

components, computation and output controls. The capacitance of a node, in energy per degree

units, is specified with its index and initial temperature. The conductance of a conductor in energy

per unit time per degree, is input with its index and the indexes of its adjoining nodes. The

conductor may be a conduction conductor or radiation conductor. N o geometry information is

utilized by the equation solver. Computational controls include, for instance, the selection of the

finite differencing technique for time integration.

Because of the lack of geometry descriptions in the equation solver, a significant of amount of

engineering time is required to accommodate design changes and parametric designs. The user

must build new models repeatedly. The inadequate geometry description also results in unsatisfactory postprocessing. Good graphical representation of the analysis results speeds up the

design acceptance process.

The geometry description is generally prepared by the user or by a preprocessor. A controlvolume is drawn around a node. The bounding volume and bounding surface areas to the

adjacent nodes are computed. The capacitance of the node equals the product of its volume,

density and specific heat. Its conductance equals the product of the material conductivity and

cross-sectional area of the flow path, divided by the length of the path (i.e. from the node centroid

to the center of bounding area). For simple and regular configurations such as rectangles, this

conductance algorithm yields good analytical results. However, if the geometry is very irregular

or skewed, for instance a node having a skewed parallelogram boundary, this algorithm produces

poor analysis results. Therefore, with this conductance algorithm, it is important to avoid skewed

nodal shapes.

In other words, in the preprocess, the geometry region of interest is first divided into subregions

or control-volumes (elements). The capacitance of each element is lumped to its centroid. The

SPACECRAFT-THERMAL MODELLING

643

conductance of the subregion from the centroid to the boundary is computed to provide the

calculation of the centroid-to-centroid conductance values. The element is assumed to be at a

uniform temperature. This assumption coincides with the fact that radiation exchange is also

traditionally modelled by energy balance between finite isothermal elemental surfaces. With

coarse meshes, the isothermal assumption tends to under-predict the temperature gradients.

Since the nodes are at the centroid of a control-volume, zero-capacitance nodes are introduced

at the boundary in order to apply the boundary conditions there. Alternately, the node may be

placed on the boundary of the control-volume instead of at its centroid.

In FEM, the analysis domain is divided into a number of finite elements (areas in 2-D and

volumes in 3-D). A preprocessor (mesh generation) yields the global co-ordinates of the nodal

(corner) points and the element connectivity (nodal point indexes for each element). The common

nodal points are shared by adjacent elements; thus the continuity of the primitive variables from

element to element is established. Further information required for analysis consists of material

properties, boundary conditions, various types of loading including internal and external sources,

and computational controls (e.g. iteration or time integration schemes).

Many thermal engineers, who use the network and control-volume approaches to derive the

heat balance equations, do not feel comfortable with the finite element approach that minimizes

the residual using Galerkin weighting functions. However, the Galerkin approach may also be

described in terms of energy balance. Consider a four-node quadrilateral as shown in Figure l(a).

This quadrilateral may be mapped into a square in natural co-ordinates 5 and q, with corner coordinates as indicated in Figure l(b). The temperature at any point (5, q ) inside the square may be

interpolated in terms of the temperature at the four nodal points:

where p refers to node p, No(&q ) is the element shape function (interpolation function) for node p

evaluated at location (5, q) and N , is the number of nodes of the element. For a linear, four-node

isoparametric element, the element shape functions are, written in a 1 x 4 matrix form

4 1

5 ) (1 - 111, (1 + 5) (1 - rl), (1 + 5 ) (1 + rl), (1 - 5) (1 + r1)l

(2)

Now consider a point source Q situated at (x,, yo) within an element. The energy of this point

source may be distributed to the nodal points of the element by using the unit Dirac impulse

function:

Q, =

Joe

QW - xo, Y - Y~)N,(X,

y)dx dy

yo), (a = 1, NP)

(3)

Thus the energy of the point source is simply distributed to the element nodal points according to

its shape functions at the location of the point source.

Since the sum of the element shape functions equals unity, the energy of the point source is

conserved. If the location of the point source coincides with node a, the total point source energy

is deposited to this node, according to equation (3).

If point sources of different magnitudes are distributed throughout the element, integration

over the element then yields the total power (in energy per unit time) deposited to each of the

element nodal points.

Consider replacing the element shape function in equation (3) by a different weighting function

w,(x, y). The point source energy will be distributed to the nodes in a different proportion, which

= QN,(xo,

644

J. H. CHIN, T. D. PANCZAK AND L. FRIED

(a)

(-l>-l)

(l,-l)

(b)

Figure 1. Finite element geometry: (a) global co-ordinates; (b) natural co-ordinates

may not be natural. One weighting function orthogonal to the shape function (which yields a

diagonal mass matrix), for an element (0 < < 1, 0 < 1 < l), is

<

cwi = 2

3 0 (2 - 311, - (1

3 0 (2 - 31), (1 - 3 0 (1 - 31),

(2 - 35) (1

- 3111

(4)

instead of the shape function

C(1 - 0(1 - 11,4(1 - r), 5% (1 - 011

(5)

With this weighting function, if the point source coincides with the node at (0,0), the distribution

of the point source energy to the four nodes will be [4, - 2, 1, - 21, which is not natural,

although the energy to the element is conserved (summed to unity).

If the weighting functions are the same as the element shape functions, the method is the

Galerkin method. For the point source, the Galerkin method is thus more natural than the use

of other weighting functions. The algorithm of consistent non-isothermal surface radiation

exchange to be discussed later also evolves naturally from the Galerkin method.

The above consideration may be extended to the diffusion (heat conduction) and heat

capacitance terms of the heat equation. Different considerations apply to the convection term and

will not be discussed in this article.

The Galerkin finite element method (GFEM) thus provides a method of distributing the

various contributions within the element to the element nodal points. Energy is conserved

because summation of the element shape functions equals unity. Summation of the contributions

from all elements surrounding a nodal point yields in essence an energy balance equation for this

nodal point. The assembly of the contributions from all elements then yields a system of energy

balance equations for the nodal points of the system. Note no control boundary surrounding a

nodal point is required in the Galerkin approach.

Further discussion of conduction FEM follows.

2.1.2. Conductamelcapacitance by F E M . With the centroidal approach, the difficulty of

computing the conductor values, particularly for irregular geometries and anisotropic material

properties, may be circumvented by first creating a finite element mesh, computing the element

conductivity matrix K,,, and setting the value of the conductor between two nodes i and j to

minus the off-diagonal i, j terms of K , : G i j = - K i j (cf. Reference 11). As already mentioned, the

GFEM distributes the heat capacitance within an element to the element nodal points. The

network prepared in this manner is consistent with the FEM space discretization.

SPACECRAFT THERMAL MODELLING

645

2.1.3. Flux and control-volume FEM. The heat equation may be written in a conservative form

instead of in terms of temperature:

in terms of enthalpy and heat

The same isoparametric element shape functions are used to interpolate the temperature,

enthalpy and heat fluxes:

T = I I N ( x ) I ( T ) , H = i I N ( x ) I ( H } , qi = CN(x)I(qi)

(7)

where { } represents a vector of quantities at the element nodal points.

Application of the Galerkin procedure to the conservative form of the heat equation will yield

element integrals independent of the material properties. Further, these integrals may be

evaluated in closed form. Some results indicate that the flux formulation reduces significantly the

computational time compared to numerical integration.13

The control-volume finite element method (CVFEM)14 is an alternate to the GFEM. In the

CVFEM, we first divide the element into subvolumes, one for each nodal point. For the twodimensional, four-noded quadrilateral element, the internal boundaries of the sub-controlvolumes (SCV1 to SCV4) are shown in Figures 2(a) and 2(b). The internal line segments are

termed subsurfaces (SS1 to SS4). The midpoints of the subsurfaces are the integration points

(ipl to ip4). For SCVI, the integral of the heat flux across subsurface SSI is approximated by the

midpoint value at integration point ipl multiplied by the surface area of SS1. In a similar manner,

the heat flux integral across SS4 for this element is calculated. If node 1 is an interior node, the

sum of the contributions from the four sub-control-volumes surrounding node 1 will yield an

energy balance equation for this node. As in the Galerkin method, the isoparametric element

shape functions and their derivatives are used to provide the interpolations needed, for CVFEM,

to obtain the thermal conductivities, surface normal and area, temperature and temperature

gradients at the points of integration of the subsurfaces.

In CVFEM, the energy of a point source within an element will be deposited to only the subcontrol-volume (SCV) in which it is located. The method of allocation of the energy from point

sources is thus of lower order for CVFEM than for GFEM.

2.1.4. Consistent boundary flux evaluation. For external boundaries with applied temperatures, the usual method of evaluating the boundary fluxes is first to compute the temperature

gradients by numerical differentiation. This procedure requires fine meshes near the boundary.

Another procedure evaluates the boundary flux more consistently; that is, when the computed

fluxes are imposed as a Neumann boundary condition, the same temperatures are obtained as

from the original Dirichlet problem.'

2.2. Radiation analysis

Radiation is a dominant mode of heat transfer for spacecraft. Infrared radiation interchange

factor calculation and the calculation of orbital heating rates from the sun, planetary albedo and

planetary infrared emission are central to the analysis of spacecraft and consume the majority of

computer resources used in the thermal analysis.

2.2.1. Radiation exchange factor evaluation. Two basic methods are available for determining

radiation interchange factors: the Gebhart methodi6 and the Monte Carlo method.17 The

Gebhart method requires the calculation of form factors from which the radiation interchange

646

J. H. CHIN. T. D. PANCZAK AND L. FRIED

Figure 2. Control-volume finite element geometry: (a) sub-control-volumes; (b) subsurfaces and integration points

factors are derived. The Monte Carlo method (MCM) performs radiation interchange calculations by directly simulating the process of emission, reflection, transmission and absorption.

The advantages of analysing radiation interchange with the MCM have long been known.

Since the emission and reflection processes are simulated directly, directional and spectral surface

property variations may be modelled at the same cost as modelling diffuse surfaces. The

requirements of the Gebhart method are not only that the surfaces emit diffusely and uniformly

but also that the surfaces are illuminated uniformly and diffusely, a requirement that is often

overlooked.

Despite the inherent advantages, the MCM is not widely used because of the extensive

computational resources required by the algorithm. The time required to perform an analysis is

proportional to the square of the number of surfaces in the model, which makes large models

intractable.

2.2.2. M C M with adaptive spatially coherent subdivision. The calculation of radiation interchange factors using the MCM involves the following steps.I7

1. Generate a ray from the emitting surface (using a random number generator"). Tally the

energy for the emitting node.

2. Find the intersection point of the closest surface along the ray direction.

3. Tally the absorbed energy from the ray. Reflect the ray from the new surface.

After the ray is reflected, the next closest surface is determined. This process repeats until the

energy in the ray has been exhausted. The closest surface is determined by performing a ray

intersection test with all of the surfaces in the model. Since each ray undergoes many reflections,

the vast majority of CPU time is spent performing ray/surface intersection calculations. Studies

have shown that up to 95 per cent of the CPU time is used to calculate ray/surface intersections

for large models.

Efficiency is greatest by incorporating a way to reduce the number of ray/surface intersections.

The most popular schemes in the graphics and aerospace industries include: direct view method,

hierarchical bounding volumes, regular spatially coherent subdivision, and adaptive spatially

coherent subdivision.' The last scheme 'is judged most efficient' and is described below.

SPACECRAFT THERMAL MODELLING

647

The geometric space is divided into subregions of varying sizes by balancing the number of

surfaces per subregion. An oct-cell datastructure accomplishes this goal, while maintaining

spatial coherency.

The oct-cell datastructure is a three-dimensional variation of the two-dimensional quad-tree,

Figure 3, used for image compaction of bit mapped images. The box in the upper left of Figure 3

shows a conventional representation of an image. The image is represented by a square array of

cells, each of which is either on or OK The middle box shows the same image represented by a

quad-tree. The quad-tree eliminates the storage of empty regions by successively dividing the

image into four smaller, hierarchically organized subregions.

The quad-tree is built by starting with a rectangle that encloses the entire image. This rectangle

is called the root of the quad-tree. The root node is subdivided into four equal size rectangles.

Each of the child rectangles is examined to see if it is full, empty, or partially full. If a subregion is

partially full, it is subdivided. This process continues until all leaf nodes of the tree are either full,

empty, or at the maximum number of allowed subdivisions. The image shown is subdivided a

maximum of four levels. A portion of the quad-tree is shown at the right of the figure using the

child cell numbering and node type identification convention indicated.

The three-dimensional analogue of the quad-tree is referred to as an oct-tree. A large box is

placed around the geometric model. This box, called the master box, or universe box, can be

subdivided into eight smaller boxes. Each subregion is subdivided until it is either completely full,

completely empty, or is at the maximum number of subdivisions (called the resolution of the tree).

The oct-tree contains the complete geometrical information of the model and may be used as the

fundamental geometric primitive. The complete kinematic history of a solid geometric model may

be maintained by a hex-tree,* a tree consisting of nodes each of which has sixteen children, by

applying the binary partitioning scheme to the time domain. The hex-tree can be thought of as

two oct-trees occupying the same region, one for past and one for future.

The oct-tree could also be used to represent a surface model; however, all of the nodes would be

at the limit of precision. The leaf nodes could contain a small planar approximating patch of the

nodal surface in order to generate a surface normal for ray reflection. The closest surface would

be determined as soon as the ray encountered a partially full leaf node during its traversal of the

oct-tree, eliminating the need for explicit ray/surface intersection tests. The major drawback to

the method is that a very large amount of memory would be required to subdivide the tree to a

resolution that accurately approximates the geometric model.

The oct-cell method uses adaptive spatial subdivision as in the oct-tree, but maintains a list of

surfaces in each partially full leaf node, as in the regular subdivision techniques. The generation of

the tree starts with a box enclosing the geometric model. This box is subdivided into eight smaller

boxes, each of which contains a list of surfaces that lie in its region. If the box contains more than

a prescribed number of surfaces, it is further subdivided. Subregions are subdivided until the cell

contains less than a given number of surfaces or until the limit of precision is reached.

The method is relatively insensitive to the geometric configuration and the only parameters

required of the user are the resolution of the oct-cell tree and the maximum number of surfaces

per cell. The time required to generate the tree is minimal, so that it can be generated

transparently before the raytracing process begins. In practice, levels between five and seven have

produced the best results.

2.2.3. Consistent non-isothermal surface radiation exchange. In traditional radiation exchange

calculations, the emitting ray would carry an average energy of the emitter element. The energy of

the hitting ray is then distributed uniformly over the receiver element, regardless of whether this

648

J. H. CHIN, T. D. PANCZAK AND L. FRIED

Figure 3. Conventional and quad-tree representation of 2-D image

element is shaded by intervening surfaces or not. This is equivalent to an isothermal or averaging

approximation, which becomes inaccurate when shading effects are dominant.

Figure 4(a) shows a ray of radiation leaving an emitter element 1. Assuming uniform radiative

properties over the element, the emitter ray energy is calculated by interpolation of the energies at

the element nodal points.'O

Qf,

= A'E'E~N i ( t i , q i )

(8)

where N i ( ( f , , q f ) is the element shape function for nodal point fi evaluated at element natural

co-ordinates ((fi, q i ) for the nth ray, A , is the surface area, is the emissivity and E i is the blackbody emissive power at nodal point fi of element 1. For a non-isothermal element, Qf, varies over

'the element, dependent upon the origin of the emitting ray. This ray may hit element J directly, or

it may undergo one or more reflections, partial absorptions (and refractions) before hitting J . This

ray may also hit element J multiple times by virtue of multiple, diffuse and specular reflections.

Let

be the transport fraction for ray n due to the intermediate surface k with absorptivity a. For a

direct hit, Tf = 1. After the Tfn attenuation of energy, ray n hits element J , Figure 4(b), at its

natural co-ordinates (ti, 1;). Multiplying the hitting energy by aJ then yields a point source

deposition of energy to element J .

As discussed earlier with equation (3), the energy of a point source Q situated at (xo, yo) within

an element is distributed to the element nodal points according to its shape functions at the point

source location. Sum over times hit for ray n and then sum over Nray rays yield the expression for

energy from node a of element I to node fi of element J :

(a' = 1, N,; fiJ = 1, N,)

(10)

where i(a') is the global node index corresponding to local node index a for emitter element 1 and

j ( p J ) is the global node index for local node fl for receiver element J .

SPACECRAFT THERMAL MODELLING

649

Figure 4. Finite element raytracing geometry: (a) emitting ray energy from interpolation of energy of corner nodes;

(b) energy of hitting ray distributed to corner nodes according to hit location

In equation (lo), E' and clJ are assumed to be independent of direction and location; otherwise

they are put behind the appropriate summation sign. The fact that subscript i ( d ) appears in

Q&$i,Jl,jcsJ,

means that for each ray from an emitter element, four energy buckets, one for each of the

N , = 4 nodal points (a' = 1, 4), are maintained. Similarly, for each hitting ray to an element .I,

four energy buckets, one for each of the nodal points (/IJ = 1, 4), are kept.

Summing over the elements sharing global emitter node i and then summing over the elements

sharing global receiver node j yields the energy interchange between globar nodes i and j .

where Bijis the radiation exchange factor between global nodes i and j . The above summation is

performed in the regular, finite element assembly process. The raytracing equations described

above provide a consistent procedure of computing the radiation exchange factors between

nodal points rather than between elements. This procedure yields more accurate results than the

application of traditional isothermal radiation exchange factors, by accounting for both the nonisothermal nature of surfaces and the partial blockage (shading) conditions.

2.3. Orbital heating calculation

The function of the Orbit application' is to specify an orbit for input into HEATRATE, a

Monte Carlo raytracing program that computes orbital heating of a spacecraft due to direct solar

illumination, albedo and infrared emission from the planet. The application also contains many

useful features for conceptual design and mission planning. The main screen of the application is

shown in Plate 1. The planet, orbit, calculation positions, solar cone and other viewing items may

be toggled on or off to aid in visualization of the orbit. The view may be rotated as desired, or

standard viewing positions such as the North Pole, Vernal Equinox, or the Sun may be selected.

650

J. H. CHIN, T. D. PANCZAK AND L. FRIED

2.4. Fluid flow analysis

Fluid flow problems in spacecraft may be put into two types: problems which may be simulated

using a one-dimensional (1-D) fluid network (cf. Reference 1) and problems which must be

considered three dimensional (3-D) or may be approximated by two-dimensional (2-D) or

axisymmetric approaches. The 1-D approaches are used to analyse the performance of cooling

circuits for heat generating payloads. The 2-D or 3-D methods are used to predict the flow fields

over spacecraft with sensitive thermal-optical systems on board. Approximate solutions may be

obtained for the 2-D or 3-D flow fields using engineering approaches. However, during the past

several years, considerable work has been devoted to develop computational fluid dynamic

(CFD) techniques to solve the 2-D or 3-D Navier-Stokes equations. Example results of CFD

approaches for spacecraft flow analysis are given in Section 4.

2.5. Special analysis features

The engineer building thermal mathematical models must be provided considerable flexibility

because of the need to account for specialized type of operations. Frequently operations cannot

be preprogrammed, but rather depend upon the dynamics of spacecraft operation. A simple

example is the on/off heater with or without deadband. More complicated heater controls include

proportional control and operation that may depend on a combination of conditions such as the

temperature and temperature gradients, or available power which may be a function of solar

array and battery temperatures or some other complex control laws. In addition to heaters,

thermal control components such as simple and variable conductance heat pipes must also be

represented in a thermal math model of a spacecraft.

To allow the simulation of these special model components, entry points or modes are placed

in the driver program. The user must write subroutines for these modes to be compiled and linked

with the standard routines. This approach provides the flexibility needed. However, it requires

more user understanding of not only the physical problems but also the necessary programming

skills. It also promotes the proliferation of user-written codes of diverse styles and readability and

consequently the problem of program maintenance and control.

In the context of finite element procedures, the heaters may be simulated by volumetric or

environmental sources, which may be functions of time or temperatures of specified nodal points.

The detailed design and analysis of various types of heat pipes (e.g. Reference 22) are beyond the

scope of this paper. One example of a simple approach is described in the next paragraph.

The heat transfer characteristics of a heat pipe/honeycomb radiation panel were successfully

modelled using a finite element technique.23 The tube and fluid elements were modelled using

PTUBE and PFTUBE elements of the NASTRAN thermal analyser program.24 (The ROD and

FLUID ROD elements of the

code may also be used.) Each pipe was treated as an

evaporator tube element, three condenser tube element, and one vapour node (may be simulated

by the ENCLOSURE ROD element of CAFE) represented isothermal vapour along the entire

length. An over-all effective conductance [based on test data] was used between the vapour and

the wall.

We can also consider the coupling of the general conduction and the heat pipe solution

through interface boundary conditions:

0

Assume a heat pipe solution procedure is available

a Given:

Heat flux distribution to evaporator

Sink temperature for condenser

SPACECRAFT THERMAL MODELLING

65 1

Effective conductance or effective radiation exchange factor from condenser to sink

0

Compute:

Heat pipe wall temperatures

Use calculated heat pipe wall temperatures as the boundary conditions for the general

conduction problem

Evaluate the boundary heat flux input to the heat pipe wall, using a consistent boundary flux

algorithm

Cycle between heat pipe and general conduction solutions to obtain the coupled solution

The above procedure can be applied to the coupling of the general conduction and the fluid

network (single or two phase) solution.

3. PREPROCESSING AND POSTPROCESSING

Before the analyses discussed in Section 2 can be carried out, a proper mesh must be generated for

the problem. Output from the mesh generator is then translated, if required, into the input format

for the main analysis program. Results from the main analysis program are then translated and

transferred, if required, to a graphics program for display. For complex configurations, pre- and

postprocessing are very important components of the analysis chain.

3.1. Preprocessing

For complex configurations, geometry generation is a pace-setting item of preprocessing. Two

approaches may be used to create the required mesh for analysis: extraction and synthesis.

Generally simplications are introduced to the mechanical design such that the resulting geometry

is more amenable for thermal analysis. The key geometry parameters are extracted from CAE

drawings, for instance, by removal of fillets. Alternately, the analysis geometry is synthesized by

combining geometry primitives such as rectangles, bricks, cylinders, cones and spheres. Commercial solid modellers (e.g. IDEAS2) are general preprocessors, whereas the Geometry Module

of TSS7 is a special preprocessor to create analysis geometry for spacecraft.

There are pros and cons of using a general or special preprocessor. The complete design

of a spacecraft requires the coordination of many analysis components: mechanical, thermal,

dynamic, structural, environmental and cost. Therefore, the interface problems between different

analysis components must be worked out in order to reduce the project time and cost. It may be

easier to construct interface codings with general preprocessors. On the other hand, specialized

analysis modules tend to be more efficient than general analysis packages.

Plate 2 shows an example of the main screen of the geometry application of a specialized

preprocessor of TSS. This application is used to build a combined solid and surface model for

both conduction and radiation.

3.2. Postprocessing

As with preprocessing, there are general postprocessors (e.g. IDEASz7) and specialized

postprocessors (e.g. TSS7).Postprocessor output includes X Y plots, contour plots and animation

videos. Sophisticated raytracing techniques are used to generate photo-realistic images showing

detailed shadow patterns and the effects of specularity and transparency.j Special translators, if

required, convert the output from the main analysis program to input for the postprocessor.

652

J. H. CHIN, T. D. PANCZAK AND L. FRIED

4. EXAMPLE RESULTS

Results of three example problems will be given. The first two examples were analysed by the

specialized TSS7 system. Plate 3 shows the magnitudes of radiation form factors to space for the

Space Shuttle surface model. Plate 4 displays a spacecraft concept using a photo-realistic

raytracing algorithm.

The third example represents a spacecraft internal flow problem. The commercial package

IDEASz7 is used as a pre- and postprocessor. The internal flow field is solved using a

compressible Navier-Stokes code ENSA3D.* Plate 5 shows the surface grids for one half of the

configuration: a brick obstacle inside a circular cylinder. Air enters a circular hole in front and

exits from an opening on the side of the cylinder. The cylinder and obstacle walls are maintained

at a hotter, uniform temperature than the entering fluid. The velocity vectors on the plane of

symmetry and from the exit are indicated. Plate 6 shows a cut-away view of the temperature field

on all surfaces, including the plane of symmetry.

These examples illustrate the fact that all components of the analysis: preprocessing, main

analysis algorithm and postprocessing contribute to the final results.

5. CONCLUSIONS

Both current network and finite element methods have drawbacks. Intelligent use of FEM,

including the use of Monte Carlo raytracing from non-isothermal surfaces and flexible pre- and

postprocessing modules, can overcome most of these. Additional flexibilities such as options for

the FFEM and CVFEM, and procedures for simulation of special thermal control components

such as heat pipes should be included.

REFERENCES

1. B. A. Cullimore, R. G. Goble, C. L. Jensen and S. G. Ring, SINDA 85/FLUINT, Systems Improved Numerical

Diflerencing Analyzer and Fluid Integrator, Users Manual, Version 2.0, MCR-85-644 (Revision l), Contract NAS

9-17053, Martin Marietta Corp., Denver Aerospace, U.S.A., Aug. 1986.

2. MAYA Heat Transfer Technologies Ltd., TMG Thermal Model Generator, a thermal analysis computer program,

MAYA Heat Transfer Technologies Ltd., Suite 380, 5180 Queen Mary Rd, Montreal, Quebec, Canada H3W 3E7,

Sept. 1, 1987.

3. T. S. Newby, R. G. Eurich and D. Ow, Heat flux study, M-16-64-1, Lockheed Missiles & Space Company, Inc.,

Sunnyvale, California, U.S.A., 15 July 1964.

4. Lockheed Engineering and Management Services Company, Thermal Radiation Analyzer System (TRAS YS) Users

Manual, LEMSCO-22641, Contract NAS 9-17900, Lockheed Engineering and Management Services Company,

Houston, Texas, U.S.A., Apr. 1988.

5. T. D. Panczak, A fast, linear time, Monte Carlo radiation interchange program utilizing adaptive spatially coherent

subdivision, in R. W. Lewis and K. Morgan (eds.), Numerical Methods in Thermal Problems, Vol. VI, Proceedings of

the Sixth International Conference, Swansea, U.K., July 3-7, 1989, Pineridge Press, Swansea, U.K., 1989, pp. 702-712.

6. B. de Graff. J. Kukla and T. Panczak, Thermal Synthesizer System (TSS) annual report: 1986, NASA Contract NAS

9-17474, DRD MA-968T, Lockheed Missiles & Space Co., Inc., Sunnyvale, California, U.S.A., 1986, Section 3.3.1.1.

7. T. Panczak, S. Rickman, M. Welch and L. Fried, An overview of the Thermal Synthesizer System: A system for

spacecraft thermal analysis, in R. W. Lewis et al. (eds.), Numerical Methods in Thermal Problems, Vol. VII,

Proceedings of the Seventh International Conference, Stanford, U.S.A., July 8-12, 1991, Pineridge Press, Swansea,

U.K., 1991, pp. 1367-1377.

8. J. H. Chin and M. C. Fong, Flow modeling techniques for spacecraft,in C. Taylor et al. (eds.), Numerical Methods in

Laminar and Turbulent Flow, Vol. VII, Proceedings of the Seventh International Conference, Stanford, U.S.A., July

15-19, 1991, Pineridge Press, Swansea, U.K., 1991, pp. 841-851.

9. Huntsville Research & Engineering Center, The general interpolands method (The GIM code), LMSC-HREC TB

0784120-8, Lockheed Missiles & Space Company, Inc., Huntsville, Alabama, U.S.A., Mar. 1981.

10. J. H. Chin, T. D. Panczak and L. Fried, Finite element and raytracing in coupled thermal problems, in R. W. Lewis

and K. Morgan (eds.), Numerical Methods in Thermal problems, Vol. VI, Proceedings of the Sixth International

Conference, Swansea, U.K., July 3-7, 1989, Pineridge Press, Swansea, U.K., 1989, pp. 683-701.

Plate 1 . View of orbit plane for a low earth orbit

Plate 2. TSS geometry application main screen

Plate 3. Form factors to space, Space Shuttle surface model

Plate 4. Photo-realistic raytracing display of spacecraft concept

Plate 6. Temperature field on all surfaces, cut-away view

SPACECRAFT THERMAL MODELLING

653

11. T. Anderson, F. Baum and P. R. Zarda, Thermal analysis with Supertab and FEMJSINDA, SDRC I-DEASTM/

CAEDR, Users Conference Series, International Proceedings, Cincinnati, Ohio, U.S.A., Oct. 1988, pp. 125-1 37.

12. E. A. Thornton and N. Balakrishnan, A finite element solution algorithm for nonlinear thermal problems with severe

gradients, 27th Aerospace Sciences Meeting, Jan. 9-12, 1989, Reno, Nevada, U.S.A., AIAA Paper 89-0520.

13. A. K. Pandey, P. Dechaumphai and A. R. Wieting, Thermal-structural finite element analysis using linear flux

formulation, AIAAIASMEJASCEIAHSIASC 30th Structural, Structural Dynamics and Materials Conference, Apr.

3-5, 1989, Mobile, Alabama, U.S.A., AIAA Paper 89-1224-CP.

14. G . E. Schneider, Elliptic systems: Finite-element methods 1,Chapter 10 in W. J. Minkowycz et al. (eds.), Handbook of

Numerical Heat Transfer, Wiley, New York, 1988, pp, 379-420.

15. P. M. Gresho and R. L. Lee, The consistent method for compnting derived boundary quantities when the Galerkin

FEM is used to solve thermal and/or fluid problems, in R. W. Lewis et al. (eds.), Numerical Methods in Thermal

Problems, Vol. ZI, Proceedings of the Second International Conference, Venice, Italy, July 7-10, 198 I , Pineridge Press,

Swansea, U.K., 1981, pp. 663-675.

16. B. Gebhart, Unified treatment for thermal radiation transfer processes-Gray, diffuse radiators and absorbers, Dec.

1957, ASME Paper No. 57-A-34.

17. R. Seigel and J. R. Howell, Thermal Radiation Heat Transfer, McGraw-Hill, New York, 1981.

18. J. L. Potter, Using hextrees to model 4 space, Topical Meeting on Machine Vision, Mar. 20-22, 1985, pp. FC2-1FC2-4.

19. I. Carbom, 1. Chakravarty and D. Vanderschel, A hierarchical data structure for representing the spatial decomposition of 3-D objects, IEEE Comp. Gruphics Applic., Apr. (1985), pp. 24-31.

20. A. S. Glassner, Space subdivision for fast ray tracing, I E E E Comp. Graphics Applic., Oct. (1984), pp. 15-22.

21. J. A. Melton, T. S. Newby and S. Kay, Therm manual spacecraft thermodynamics, LMSC-D711792, Lockheed

Missiles & Space Co., Inc., Sunnyvale, California, U.S.A., July 1981.

22. P. Dunn and D. A. Reay, Heat Pipes, 3 edn, Pergamon Press, 1982.

23. R. D. Karam and H. Hwangbo, Thermal interaction between a heat pipe radiator and a coolant fluid header, in

D. A. Reay (ed.), Proceedings of the ZVth International Heat Pipe Conference, 7-10 Sept. 1981, Pergamon Press,

Oxford, 1981, pp. 359-372.

24. The MacNeal-Schwendler Corporation, M S C I N A S T R A N Users Manual, The MacNeal-Schwendler Corporation,

815 Colorado Blvd., Los Angeles, CA 90041, U.S.A.

25. J. H. Chin, Charring ablation by finite element, in R. W. Lewis et al. (eds.), Numerical Methods in Thermal Problems,

Vol. 11, Proceedings o f t h e Second International Conference, Venice, Italy, July 7-10, 1981, Pineridge Press, Swansea,

U.K., 1981, pp. 672-682.

26. J. H. Chin and D. R. Frank, Engineering finite element analysis of conduction, convection and radiation, Chapter 10

in R. W. Lewis and K. Morgan (eds.), Numerical Methods in Heat Transfer, Vol. I l l , Wiley, New York, 1985,

pp. 215-229.

27. Structural Dynamics Research Corporation, I-DEAS Finite Element Modeling Users Guide, Structural Dynamics

Research Corporation, 2000 Eastman Drive, Milford, Ohio 45150, U.S.A., 1990.

28. F. Shakib, Finite element analysis of the compressible Euler and Navier-Stokes equations, Ph.D. Dissertation,

Department of Mechanical Engineering, Stanford University, Stanford, Calif., U.S.A., Nov 1988.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- DLP For Cot 1Document5 pagesDLP For Cot 1Maricel Guevarra90% (10)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cycle Counting in Fatigue Analysis: Standard Practices ForDocument10 pagesCycle Counting in Fatigue Analysis: Standard Practices ForSPNo ratings yet

- Form Factors Grey Bodies and Radks Course PDFDocument179 pagesForm Factors Grey Bodies and Radks Course PDFSPNo ratings yet

- Thermoelastic Damping in Micro-Beam Resonators: Yuxin Sun, Daining Fang, Ai Kah SohDocument17 pagesThermoelastic Damping in Micro-Beam Resonators: Yuxin Sun, Daining Fang, Ai Kah SohSPNo ratings yet

- Towards Automated Determination of USERMAT For The Nonlinear Constitutive Behavior of CompositesDocument19 pagesTowards Automated Determination of USERMAT For The Nonlinear Constitutive Behavior of CompositesSPNo ratings yet

- Mapping 1mmDocument1,810 pagesMapping 1mmSPNo ratings yet

- IntegrationToolkitProgrammerGuide V10Document434 pagesIntegrationToolkitProgrammerGuide V10velkshanmuga100% (2)

- Automated Crack Extension Fracture SeminarDocument23 pagesAutomated Crack Extension Fracture SeminarSPNo ratings yet

- SessionPlans Db99dMAT101 Syllabus & QBDocument14 pagesSessionPlans Db99dMAT101 Syllabus & QBNaitik TiwariNo ratings yet

- Sister Nivedita University Syllabus FOR Three Years Bachelor Degree Course IN Computer Application (Bca) Under Ugc-Cbcs SystemDocument72 pagesSister Nivedita University Syllabus FOR Three Years Bachelor Degree Course IN Computer Application (Bca) Under Ugc-Cbcs Systemsuyashsahu2505No ratings yet

- BEGEOINFODocument90 pagesBEGEOINFOShebinNo ratings yet

- TTK - S AP Calculus ABDocument36 pagesTTK - S AP Calculus ABIan CausseauxNo ratings yet

- Dy DX Ax: Calculus Made EasyDocument6 pagesDy DX Ax: Calculus Made EasyIkhda Wardhani NstNo ratings yet

- SusicDocument19 pagesSusicALVARO DIEGO MACHACA CONDORINo ratings yet

- All India Test Series LeafletDocument8 pagesAll India Test Series LeafletResonance Kota100% (1)

- DPT Syllabus II IV SemDocument26 pagesDPT Syllabus II IV SemxxxpressionNo ratings yet

- Cap 4Document90 pagesCap 4Andreu Nieto MarinNo ratings yet

- Class 12 - Maths Subject - CH 7 - Integrals - Formulas by SP GuptaDocument10 pagesClass 12 - Maths Subject - CH 7 - Integrals - Formulas by SP Gupta12B-E1 PRANAV B.No ratings yet

- U Zaw Zaw AungDocument9 pagesU Zaw Zaw AungPrince JacintoNo ratings yet

- Numerical Analysis I (MATH 573)Document3 pagesNumerical Analysis I (MATH 573)Zerihun IbrahimNo ratings yet

- Mpae PDFDocument70 pagesMpae PDFKABADDI RISINGNo ratings yet

- J C Burkill Theory of Ordinary Differential EquationsDocument125 pagesJ C Burkill Theory of Ordinary Differential EquationsPawan Mishra100% (1)

- JEE MAIN and ADVANCED Chapterwise PYQ Mathematics Prabhat PublicationDocument445 pagesJEE MAIN and ADVANCED Chapterwise PYQ Mathematics Prabhat PublicationNguyen Van Justonly Chi100% (4)

- Cs Ba-Bsc 3rd Sem 2016Document4 pagesCs Ba-Bsc 3rd Sem 2016So RvNo ratings yet

- CH 16Document106 pagesCH 16Ignacio MagañaNo ratings yet

- BSC MathematicsDocument13 pagesBSC MathematicsGanesh TiwariNo ratings yet

- MATH 141 Final Exam Sample CDocument5 pagesMATH 141 Final Exam Sample CRAJESH KUMARNo ratings yet

- Sách bài tập Giải tích Demidovich-trang-18-43Document26 pagesSách bài tập Giải tích Demidovich-trang-18-43xuansangtruongthi2201No ratings yet

- MATH 31B - Week 2 Integrals Involving Logarithms and L'Hopital RuleDocument3 pagesMATH 31B - Week 2 Integrals Involving Logarithms and L'Hopital RuleAgus LeonardiNo ratings yet

- The Poincare Lemma and de Rham CohomologyDocument14 pagesThe Poincare Lemma and de Rham CohomologyAlex YuNo ratings yet

- Complex Analysis Paper-II Segment Wise Questions From 1983 To 2011 Civil ServiceDocument7 pagesComplex Analysis Paper-II Segment Wise Questions From 1983 To 2011 Civil ServiceNagendran KrishnamoorthiNo ratings yet

- Mathematics: Paper 9709/11 Paper 11 Key MessagesDocument59 pagesMathematics: Paper 9709/11 Paper 11 Key MessagesAditiNo ratings yet

- Piskunov - Differential and Integral Calculus - Volume 2 - MirDocument589 pagesPiskunov - Differential and Integral Calculus - Volume 2 - MirMarcos NahuelNo ratings yet

- GATE Engineering Mathematics MaterialDocument17 pagesGATE Engineering Mathematics Materialmanoj kaushikNo ratings yet

- B.tech+ +Civil+Engg.+ + (C) + +Applicable+to+All+BatchDocument158 pagesB.tech+ +Civil+Engg.+ + (C) + +Applicable+to+All+BatchShruti YadavNo ratings yet

- Discretization NotesDocument19 pagesDiscretization NotesmasterrkNo ratings yet

- Jam BooksDocument2 pagesJam BooksSavi Randhawa100% (2)