Professional Documents

Culture Documents

DLFU Tech

DLFU Tech

Uploaded by

Sujanto WidjajaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DLFU Tech

DLFU Tech

Uploaded by

Sujanto WidjajaCopyright:

Available Formats

DLFU

EBARA Submersible Sewage Pumps

Contents

Project:

Model:

Model DLFU

50DLFU61.5

80DLFU61.5

80DLMFU61.5

80DLFU62.2

80DLMFU62.2

80DLFU63.7

80DLMFU63.7

80DLFU65.5

80DLMFU65.5

80DLFU67.5

80DLCMFU67.5

80DLFU611

80DLCMFU611

80DLFU615

80DLFU618

80DLFU622

100DLFU61.5

100DLFU62.2

100DLMFU62.2

100DLFU63.7

100DLMFU63.7

100DLFU65.5

100DLMFU65.5

100DLFU67.5

100DLMFU67.5

100DLFU611

100DLMFU611

100DLFU615

100DLMFU615

100DLFU618

100DLMFU618

100DLFU622

100DLMFU622

100DLFU630

Section

Specifications

Selection Chart

Performance Curves

Outline Drawings

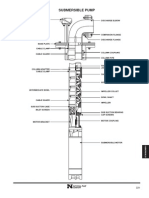

Sectional View

QDC Information

Technical Information

100DLFU637

100DLFU645

150DLFU67.5

150DLFU611

150DLFU615

150DLFU618

150DLFU622

150DLFU630

150DLFU637

150DLFU645

200DLFU67.5

200DLFU611

200DLFU615

200DLFU618

200DLFU622

200DLFU630

200DLFU637

200DLFU645

Chkd:

Date:

250DLFU611

250DLBFU615

250DLCFU615

250DLFU618

250DLFU622

250DLFU630

250DLFU637

250DLFU645

300DLFU618

300DLFU622

300DLFU630

300DLFU637

300DLFU645

Page

2-158

2-165

2-166

2-191

2-210

2-278

2-289.1

material specification

impeller description

motor protection

cable entry

paint specifications

mechanical seal

general

Motor Data

2-315.1

motor electrical specifications

cable data

wiring diagrams

motor electrical data

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-155

rev. 11/02

DLFU

EBARA Submersible Sewage Pumps

Contents

Project:

Model:

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

Chkd:

Date:

2-156

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Model Designation

Project:

Model:

Chkd:

100

DLF/

DLMF

Date:

1.5

DISCHARGESIZE mm

50mm 2"

200mm 8"

80mm 3"

250mm 10"

100mm 4"

300mm 12"

150mm 6"

MODELTYPE

DLF/DLMF submersible sewage pump

DLFM/DLMFM FM explosion proof designation

GEOGRAPHICDESIGNATION

U U.S.A. market

HERTZ

6 - 60

RATEDKW

1.5 2HP

2.2 3HP

3.7 5HP

5.5 71/2HP

7.5 10HP

11 15HP

15 20HP

18 25HP

22

30

37

45

30HP

40HP

50HP

60HP

PHASE

none three phase

VOLTAGE

2 - 208/230

4 - 460

5 - 575

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-157

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Specifications

Project:

Model:

Chkd:

Date:

Model DLFU

Specifications

Standard

Size

2, 3, 4, 6, 8, 10, 12 inch

Range of HP

Range of Performance

2 to 60 HP

Capacity 13 to 4000 GPM

Head 7 to 243 feet

Limitation

Maximum Water Temperature

Synchronous Speed

Materials

Casing

Impeller

Shaft

Motor Frame

Fastener

Mechanical Seal

Material Upper Side

Material Lower Side

Impeller Type

Bearing

Motor

Three Phase

Service Factor

Motor Protection

Submersible cable

Optional

104F ( 40C)

1800 RPM

Cast Iron

Cast Iron (2 to 60HP)

Ductile Iron (150-300 DLFU 40 to 60 HP)

403 Stainless Steel (2 to 5HP)

420 Stainless Steel (71/2 to 60HP)

Cast Iron

304 Stainless Steel

Double Mechanical Seal

Carbon/Ceramic (2 to 60HP)

Silicon Carbide/Silicon Carbide (2 to 60HP)

Tungsten Carbide/Tungsten Carbide (150-300 DLFU

50 and 60HP only)

Semi-open (2 to 30HP)

Enclosed (40 to 60HP)

Prelubricated Ball Bearing

Insulation Class F (2-5HP), H (71/2 to 60HP)

208/230/460V

1.15

Thermal Detector Klixons

Mechanical Seal Leakage Detector Float Switch

33 ft. (2 to 5HP)

50 ft. (71/2 to 60HP)

Accessories

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

Tungsten Carbide/Tungsten Carbide

Tungsten Carbide/Tungsten Carbide

FM Explosion Proof, Class 1,

Division 1, Group C, D

____ ft. (customer specified)

QDC System

2-158

rev. 02/13

DLFU

EBARA Submersible Sewage Pumps

Specifications

Project:

Model:

Chkd:

Date:

A. General:

Provide submersible sewage pumps suitable for continuous duty operation underwater without loss of watertight

integrity to a depth of 65 feet. Pump system design shall include a guide rail system be such that the pump will be

automatically connected to the discharge piping when lowered into place on the discharge connection. The pump

shall be easily removable for inspection or service, requiring no bolts, nuts, or other fasteners to be disconnected, or

the need for personnel to enter the wet well. The motor and pump shall be designed, manufactured, and assembled

by the same manufacturer.

B. Manufacturer:

EBARA International Corporation

C. Pump Characteristics:

Pumps shall conform to the following requirements:

Number of units

Design flow (gpm)

Design TDH (ft)

Minimum shut off head (ft)

RPM

Maximum HP

Minimum efficiency at design (%)

Minimum power factor at design (%)

Voltage/HZ

Phase

1800

208/230V, 460V / 60

3

D. Pump Construction:

All major parts of the pumping unit(s) including casing, impeller, suction cover, wear rings, motor frame and discharge

elbow shall be manufactured from gray cast iron, ASTM A-48 Class 30. Castings shall have smooth surfaces devoid

of blow holes or other casting irregularities. Casing design shall be centerline discharge with a large radius on the

cut water to prevent clogging. Units shall be furnished with a discharge elbow and 125 lb. flat face ANSI flange. All

exposed bolts and nuts shall be 304 stainless steel. All mating surfaces of major components shall be machined and

fitted with NBR o-rings where watertight sealing is required. Machining and fitting shall be such that sealing is

accomplished by automatic compression of o-rings in two planes and o-ring contact is made on four surfaces without

the requirement of specific torque limits. Internal and external surfaces are prepared to SPPC-VISI-SP-3-63 then

coated with a zinc-chromate primer. The external surfaces are then coated with a H.B. Teneme-Tar 46H-413 Polyamide

Epoxy - Coal Tar paint

1. Impellers:

a. For units 2 to 5 HP, the impeller shall be radial single or multi-vane, semi-open design. It shall be dynamically

balanced and shall be designed for solids handling with a long thrulet without acute turns. The inlet edge of the

impeller vanes shall be angled toward the impeller periphery so as to facilitate the release of objects that might

otherwise clog the pump. The 2 to 5 HP impeller design shall also include back pump out vanes to reduce the

pressure and entry of foreign materials into the mechanical seal area. In addition, a lip seal shall be located

behind the impeller hub to further reduce the entry of foreign materials into the seal area. Impellers shall be direct

connected to the motor shaft with a slip fit, key driven, and secured with an impeller bolt. The design shall include

a replaceable cast iron suction cover. The suction cover shall be designed such that it may be adjusted to maintain

working clearances and hydraulic efficiencies.

b. For units 71/2 to 30 HP, the impeller shall be a mixed flow multi-vane semi-open design. It shall be dynamically

balanced and shall be designed for solids handling with a long thrulet without acute turns. The inlet edge of the

impeller vanes shall be angled toward the impeller periphery so as to facilitate the release of objects that might

otherwise clog the pump. The 71/2 to 30 HP impeller design shall also include back pump out vanes to reduce the

pressure and entry of foreign materials into the mechanical seal area. In addition, a lip seal shall be located

behind the impeller hub to further reduce the entry of foreign materials into the seal area. Impellers shall be direct

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-159

rev. 10/11

DLFU

EBARA Submersible Sewage Pumps

Specifications

Project:

Model:

Chkd:

Date:

connected to the motor shaft with a slip fit, key driven, and secured with an impeller bolt. The design shall include

a replaceable cast iron suction cover. The suction cover shall be designed such that it may be adjusted to maintain

working clearances and hydraulic efficiencies.

c. For high head units with 4'' discharge, 40 to 60 HP shall have a radial multi-vane, enclosed impeller design. It

shall be dynamically balanced and shall be designed for solids handling with a long thrulet without acute turns.

The inlet edge of the impeller vanes shall be angled toward the impeller periphery so as to facilitate the release

of objects that might otherwise clog the pump. A lip seal shall be located behind the impeller hub to reduce the

entry of foreign materials into the mechanical seal area. Impellers shall be direct connected to the motor shaft

with a slip fit, key driven, and secured with an impeller bolt. The design shall include a replaceable casing wear

ring at the pump suction to maintain working clearances and hydraulic efficiencies.

d. For units 6'' to 12'' discharge sizes, 40 to 60 HP, the impeller shall be a mixed flow multi-vane enclosed design. It

shall be dynamically balanced and shall be designed for solids handling with a long thrulet without acute turns.

The inlet edge of the impeller vanes shall be angled toward the impeller periphery so as to facilitate the release

of objects that might otherwise clog the pump. A lip seal shall be located behind the impeller hub to reduce the

entry of foreign materials into the seal area. Impellers shall be direct connected to the motor shaft with a slip fit,

key driven, and secured with an impeller bolt. The design shall include a replaceable casing wear ring at the

pump suction to maintain working clearances and hydraulic efficiencies.

optional K-series design:

e. For units 2 to 5 HP, the impeller shall be radial single or multi-vane, semi-open design. It shall be dynamically

balanced and shall be designed for solids handling with a long thrulet without acute turns. The inlet edge of the

impeller vanes shall be angled toward the impeller periphery so as to facilitate the release of objects that might

otherwise clog the pump. The 2 to 5 HP impeller design shall also include back pump out vanes to reduce the

pressure and entry of foreign materials into the mechanical seal area. In addition, a lip seal shall be located behind

the impeller hub to further reduce the entry of foreign materials into the seal area. Impellers shall be direct connected

to the motor shaft with a slip fit, key driven, and secured with an impeller bolt. The design shall include a replaceable

cast iron suction cover. The suction cover shall contain a groove(s) perpendicular to the suction opening to disrupt

fibrous solids that may otherwise become lodged between the impeller and suction cover. The suction cover shall

be designed such that it may be adjusted to maintain working clearances and hydraulic efficiencies.

f. For units 71/2 to 30 HP, the impeller shall be a mixed flow multi-vane semi-open design. It shall be dynamically

balanced and shall be designed for solids handling with a long thrulet without acute turns. The inlet edge of the

impeller vanes shall be angled toward the impeller periphery so as to facilitate the release of objects that might

otherwise clog the pump. The 71/2 to 30 HP impeller design shall also include back pump out vanes to reduce the

pressure and entry of foreign materials into the mechanical seal area. In addition, a lip seal shall be located

behind the impeller hub to further reduce the entry of foreign materials into the seal area. Impellers shall be direct

connected to the motor shaft with a slip fit, key driven, and secured with an impeller bolt. The design shall include

a replaceable cast iron suction cover. The suction cover shall contain a groove(s) perpendicular to the suction opening

to disrupt fibrous solids that may otherwise become lodged between the impeller and suction cover.The suction

cover shall be designed such that it may be adjusted to maintain working clearances and hydraulic efficiencies.

2. Mechanical Seals

a. For units 2 to 5 HP, double mechanical seals operating in an oil bath shall be provided on all units. The oil filled

seal chamber shall be designed to prevent over-filling and include an anti-vortexing vane to insure proper lubrication

of both seal faces. Lower face materials shall be silicon carbide, upper faces carbon vs. ceramic, NBR elastomers,

and 304SS hardware. Seal system shall not rely on pumping medium for lubrication.

b. Units 71/2 to 60 HP shall be designed to include a double mechanical seal in a tandem arrangement. Each seal

shall be positively driven and act independently with its own spring system. The upper seal operates in an oil

bath, while the lower seal is lubricated by the oil from between the shaft and the seal faces, and in contact with

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-160

rev. 10/11

DLFU

EBARA Submersible Sewage Pumps

Specifications

Project:

Model:

Chkd:

Date:

the pumpage. The oil filled seal chamber shall be designed to prevent over-filling and include an anti-vortexing

vane to insure proper lubrication of both seal faces. Lower face materials shall be silicon carbide (tungsten carbide

for 150-300 DLF 50 & 60 HP only), upper faces carbon vs. ceramic, NBR elastomers, and 304SS hardware. Seal

system shall not rely on pumping medium for lubrication.

E. Motor Construction:

The pump motor shall be an air filled induction type with a squirrel cage rotor, shell type design, built to NEMA MG-1,

Design B specifications. Stator windings shall be copper, insulated with moisture resistant Class H insulation, rated

for 356F. The stator shall be dipped and baked three times in Class H varnish and heat shrunk fitted into the stator

housing. Rotor bars and short circuit rings shall be manufactured of cast aluminum. Motor shaft shall be one piece

AISI403 for 2 to 5 HP, AISI420 for 71/2 to 60 HP, rotating on two permanently lubricated ball bearings designed for a

minimum B-10 life of 60,000 hours. Motor service factor shall be 1.15 and capable of up to 20 starts per hour. The

motor shall be designed for continuous duty pumping at a maximum sump temperature of 104F. Voltage and

frequency tolerances shall be a maximum 10 / 5% respectively. Motor over temperature protection shall be provided

by miniature thermal protectors embedded in the windings. Mechanical seal failure protection shall be provided by a

mechanical float switch located in a chamber above the seal. This switch shall be comprised of a magnetic float that

actuates a dry reed switch encapsulated within the stem. Should the mechanical seal fail, liquid shall be directed

into the float chamber, in which the rising liquid activates the switch opening the normally closed circuit. For units 2

to 30 HP the float body and float shall be a polypropylene material with a 316SS stopper. Units 40 HP and greater,

the float switch components shall be 304SS. The motor shall be non-overloading over the entire specified range of

operation and be able to operate at full load intermittently while unsubmerged without damage to the unit.

Power cable jacket shall be manufactured of an oil resistant chloroprene rubber material, designed for submerged

applications. Cable shall be watertight to a depth of a least 65'. The cable entry system shall comprise of primary,

secondary, and tertiary sealing methods. The primary seal shall be achieved by a cylindrical elastomeric grommet

compressed between the motor cover and a 304SS washer. Secondary sealing is accomplished with a compressed

o-ring made of NBR material. Compression and subsequent sealing shall preclude specific torque requirements. The

system shall also include tertiary sealing to prevent leakage into the motor housing due to capillary action through the

insulation if the cable is damaged or cut. The cable wires shall be cut, stripped, re-connected with a copper butt end

connector, and embedded in epoxy within the cable gland. This provides a dead end for leakage through the cable

insulation into the motor junction area. The cable entry system shall be the same for both the power and control cables.

F. Guide Rail system:

Design shall include two (2) 304SS schedule 40 guide rails sized to mount directly to the quick discharge connector,

QDC, at the floor of the wetwell and to a guide rail bracket at the top of the wetwell below the hatch opening, (refer

to project drawings). Intermediate guide brackets are recommended for rail lengths over 15 feet.

Guide rails are not part of the pump package and shall be supplied by others.

The QDC shall be manufactured of cast iron, ASTM A48 Class 30. It shall be designed to adequately support the

guide rails, discharge piping, and pumping unit under both static and dynamic loading conditions with support legs

that are suitable for anchoring it to the wetwell floor. The face of the inlet QDC flange shall be perpendicular to the

floor of the wetwell. The discharge flange of the QDC shall conform to ANSI B16.1 Class 125.

The pump design shall include an integral self-aligning sliding bracket. Sealing of the pumping unit to the QDC shall

be accomplished by a single, linear, downward motion of the pump. The entire weight of the pump unit shall be guided

to and wedged tightly against the inlet flange of the QDC, making metal to metal contact with the pump discharge

forming a seal without the use of bolts, gaskets or o-rings.

A stainless steel lifting chain of adequate length for removing and installing the pump unit is recommended. The chain

shall have a round link with a 2-1/4'' inside diameter every two feet. This link will allow for a sliding pinch bar through

the link to pick the chain, more than once if necessary, at multiple intervals during pump removal and installation.

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-161

rev. 10/11

DLFMUExplosion Proof Non-clog

EBARA Submersible Sewage Pumps

Specifications

Project:

Model:

Chkd:

Date:

A. General:

Provide FM explosion proof submersible non clog sewage pumps suitable for continuous duty operation underwater

without loss of watertight integrity to a depth of 65 feet. Pump system design shall include a guide rail system be

such that the pump will be automatically connected to the discharge piping when lowered into place on the discharge connection. The pump shall be easily removable for inspection or service, requiring no bolts, nuts, or other

fasteners to be disconnected, or the need for personnel to enter the wet well. The motor and pump shall be

designed, manufactured, and assembled by the same manufacturer.

B. Manufacturer:

EBARA International Corporation

C. Pump Characteristics:

Pumps shall conform to the following requirements:

Number of units

Design flow (gpm)

Design TDH (ft)

Minimum shut off head (ft)

RPM

Maximum HP

Minimum efficiency at design (%)

Minimum power factor at design (%)

Voltage/HZ

Phase

1800

208/230V, 460V / 60

3

D. Pump Construction:

All major parts of the pumping unit(s) including casing, impeller, suction cover, wear rings, motor frame and discharge

elbow shall be manufactured from gray cast iron, ASTM A-48 Class 30. Castings shall have smooth surfaces devoid

of blow holes or other casting irregularities. Casing design shall be centerline discharge with a large radius on the

cut water to prevent clogging. Units shall be furnished with a discharge elbow and 125 lb. flat face ANSI flange. All

exposed bolts and nuts shall be 304 stainless steel. All mating surfaces of major components shall be machined and

fitted with NBR o-rings where watertight sealing is required. Machining and fitting shall be such that sealing is

accomplished by automatic compression of o-rings in two planes and o-ring contact is made on four surfaces without

the requirement of specific torque limits. Internal and external surfaces are prepared to SPPC-VISI-SP-3-63 then coated

with a zinc-chromate primer. The external surfaces are then coated with a H.B. Teneme-Tar 46H-413 Polyamide

Epoxy - Coal Tar paint.

1. Impellers:

a. For units 2 to 5HP, the impeller shall be single or radial multi-vane, semi-open design. It shall be dynamically balanced

and shall be designed for solids handling with a long thrulet without acute turns. The inlet edge of the impeller

vanes shall be angled toward the impeller periphery so as to facilitate the release of objects that might otherwise

clog the pump. The 2 to 5 HP impeller design shall also include back pump out vanes to reduce the pressure and

entry of foreign materials into the mechanical seal area. In addition, a lip seal shall be located behind the impeller

hub to further reduce the entry of foreign materials into the seal area. Impellers shall be direct connected to the

motor shaft with a slip fit, key driven, and secured with an impeller bolt. The design shall include a replaceable

cast iron suction cover. The suction cover shall be designed such that it may be adjusted to maintain working

clearances and hydraulic efficiencies.

b. For units 71/2 to 30 HP, the impeller shall be a mixed flow multi-vane semi-open design. It shall be dynamically

balanced and shall be designed for solids handling with a long thrulet without acute turns. The inlet edge of the

impeller vanes shall be angled toward the impeller periphery so as to facilitate the release of objects that might

otherwise clog the pump. The 71/2 to 30 HP impeller design shall also include back pump out vanes to reduce the

pressure and entry of foreign materials into the mechanical seal area. In addition, a lip seal shall be located

behind the impeller hub to further reduce the entry of foreign materials into the seal area. Impellers shall be direct

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-162

rev. 10/11

DLFMUExplosion Proof Non-clog

EBARA Submersible Sewage Pumps

Specifications

Project:

Model:

Chkd:

Date:

connected to the motor shaft with a slip fit, key driven, and secured with an impeller bolt. The design shall include

a replaceable cast iron suction cover. The suction cover shall be designed such that it may be adjusted to maintain

working clearances and hydraulic efficiencies.

c. For high head units, 4'' discharge, 40 to 60 HP shall have a radial multi-vane, enclosed impeller design. It shall

be dynamically balanced and shall be designed for solids handling with a long thrulet without acute turns. The

inlet edge of the impeller vanes shall be angled toward the impeller periphery so as to facilitate the release of

objects that might otherwise clog the pump. A lip seal shall be located behind the impeller hub to reduce the entry

of foreign materials into the mechanical seal area. Impellers shall be direct connected to the motor shaft with a

slip fit, key driven, and secured with an impeller bolt. The design shall include a replaceable casing wear ring at

the pump suction to maintain working clearances and hydraulic efficiencies.

d. For units 6'' to 12'' discharge sizes, 40 to 60 HP, the impeller shall be a mixed flow multi-vane enclosed design. It

shall be dynamically balanced and shall be designed for solids handling with a long thrulet without acute turns.

The inlet edge of the impeller vanes shall be angled toward the impeller periphery so as to facilitate the release

of objects that might otherwise clog the pump. A lip seal shall be located behind the impeller hub to reduce the

entry of foreign materials into the seal area. Impellers shall be direct connected to the motor shaft with a slip fit,

key driven, and secured with an impeller bolt. The design shall include a replaceable casing wear ring at

the pump suction to maintain working clearances and hydraulic efficiencies.

optional K-series design:

e. For units 2 to 5HP, the impeller shall be single or radial multi-vane, semi-open design. It shall be dynamically balanced

and shall be designed for solids handling with a long thrulet without acute turns. The inlet edge of the impeller

vanes shall be angled toward the impeller periphery so as to facilitate the release of objects that might otherwise

clog the pump. The 2 to 5 HP impeller design shall also include back pump out vanes to reduce the pressure and

entry of foreign materials into the mechanical seal area. In addition, a lip seal shall be located behind the impeller

hub to further reduce the entry of foreign materials into the seal area. Impellers shall be direct connected to the

motor shaft with a slip fit, key driven, and secured with an impeller bolt. The design shall include a replaceable

cast iron suction cover. The suction cover shall contain a groove(s) perpendicular to the suction opening to disrupt

fibrous solids that may otherwise become lodged between the impeller and suction cover. The suction cover shall

be designed such that it may be adjusted to maintain working clearances and hydraulic efficiencies.

f. For units 71/2 to 30 HP, the impeller shall be a mixed flow multi-vane semi-open design. It shall be dynamically

balanced and shall be designed for solids handling with a long thrulet without acute turns. The inlet edge of the

impeller vanes shall be angled toward the impeller periphery so as to facilitate the release of objects that might

otherwise clog the pump. The 71/2 to 30 HP impeller design shall also include back pump out vanes to reduce the

pressure and entry of foreign materials into the mechanical seal area. In addition, a lip seal shall be located

behind the impeller hub to further reduce the entry of foreign materials into the seal area. Impellers shall be direct

connected to the motor shaft with a slip fit, key driven, and secured with an impeller bolt. The design shall include

a replaceable cast iron suction cover. The suction cover shall contain a groove(s) perpendicular to the suction opening

to disrupt fibrous solids that may otherwise become lodged between the impeller and suction cover. The suction

cover shall be designed such that it may be adjusted to maintain working clearances and hydraulic efficiencies.

2. Mechanical Seals

a. For units 2 to 5 HP, double mechanical seals operating in an oil bath shall be provided on all units. The oil filled

seal chamber shall be designed to prevent over-filling and include an anti-vortexing vane to insure proper lubrication

of both seal faces. Lower face materials shall be silicon carbide, upper faces carbon vs. ceramic, NBR elastomers,

and 304SS hardware. Seal system shall not rely on pumping medium for lubrication.

b. Units 71/2 to 60 HP shall be designed to include a double mechanical seal in a tandem arrangement. Each seal

shall be positively driven and act independently with its own spring system. The upper seal operates in an oil

bath, while the lower seal is lubricated by the oil from between the shaft and the seal faces, and in contact with

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-163

rev. 10/11

DLFMUExplosion Proof Non-clog

EBARA Submersible Sewage Pumps

Specifications

Project:

Model:

Chkd:

Date:

the pumpage. The oil filled seal chamber shall be designed to prevent over-filling and include an anti-vortexing

vane to insure proper lubrication of both seal faces. Lower face materials shall be silicon carbide (tungsten carbide

for 150-300 DLFU 50 & 60 HP only), upper faces carbon vs. ceramic, NBR elastomers, and 304SS hardware.

Seal system shall not rely on pumping medium for lubrication.

E. Motor Construction:

The pump motor shall be FM Explosion Proof, Class 1, Division 1, Groups C, D. The design shall be an air filled

induction type with a squirrel cage rotor, shell type design, built to NEMA MG-1, Design B specifications. Stator

windings shall be copper, insulated with moisture resistant Class H insulation, rated for 356F. The stator shall be

dipped and baked three times in Class H varnish and heat shrunk fitted into the stator housing. Rotor bars and short

circuit rings shall be manufactured of cast aluminum. Motor shaft shall be one piece AISI403 material for 2 to 5 HP,

AISI420 for 71/2 to 60 HP material, rotating on two permanently lubricated ball bearings designed for a minimum B-10

life of 60,000 hours. Motor service factor shall be 1.15 and capable of up to 20 starts per hour. The motor shall be

designed for continuous duty pumping at a maximum sump temperature of 104F. Voltage and frequency tolerances

shall be a maximum 10 / 5% respectively. Motor over temperature protection shall be provided by miniature thermal

protectors embedded in the windings. Mechanical seal failure protection shall be provided by a mechanical float

switch located in a chamber above the seal. This switch shall be comprised of a magnetic float that actuates a dry

reed switch encapsulated within the stem. Should the mechanical seal fail, liquid shall be directed into the float

chamber, in which the rising liquid activates the switch opening the normally closed circuit. For units 2 to 10 HP the

float body and float shall be a polypropylene material with a 316SS stopper. Units 15 HP and greater, the float switch

components shall be 304SS. The motor shall be non-overloading over the entire specified range of operation and be

able to operate at full load intermittently while unsubmerged without damage to the unit.

Power cable jacket shall be manufactured of an oil resistant chloroprene rubber material, designed for submerged

applications. Cable shall be watertight to a depth of a least 65'. The cable entry system shall comprise of primary,

secondary, and tertiary sealing methods. The primary seal shall be achieved by a cylindrical elastomeric grommet

compressed between the motor cover and a 304SS washer. Secondary sealing is accomplished with a compressed

o-ring made of NBR material. Compression and subsequent sealing shall preclude specific torque requirements. The

system shall also include tertiary sealing to prevent leakage into the motor housing due to capillary action through

the insulation if the cable is damaged or cut. The cable wires shall be cut, stripped, re-connected with a copper butt

end connector, and embedded in epoxy within the cable gland. This provides a dead end for leakage through the cable

insulation into the motor junction area. The cable entry system shall be the same for both the power and control cables.

F. Guide Rail system:

Design shall include two (2) 304SS schedule 40 guide rails sized to mount directly to the quick discharge connector,

QDC, at the floor of the wetwell and to a guide rail bracket at the top of the wetwell below the hatch opening, (refer

to project drawings). Intermediate guide brackets are recommended for rail lengths over 15 feet.

Guide rails are not part of the pump package and shall be supplied by others.

The QDC shall be manufactured of cast iron, ASTM A48 Class 30. It shall be designed to adequately support the

guide rails, discharge piping, and pumping unit under both static and dynamic loading conditions with support legs

that are suitable for anchoring it to the wetwell floor. The face of the inlet QDC flange shall be perpendicular to the

floor of the wetwell. The discharge flange of the QDC shall conform to ANSI B16.1 Class 125.

The pump design shall include an integral self-aligning sliding bracket. Sealing of the pumping unit to the QDC shall

be accomplished by a single, linear, downward motion of the pump. The entire weight of the pump unit shall be guided

to and wedged tightly against the inlet flange of the QDC, making metal to metal contact with the pump discharge

forming a seal without the use of bolts, gaskets or o-rings.

A stainless steel lifting chain of adequate length for removing and installing the pump unit is recommended. The chain

shall have a round link with a 2-1/4'' inside diameter every two feet. This link will allow for a sliding pinch bar through

the link to pick the chain, more than once if necessary, at multiple intervals during pump removal and installation.

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-164

rev. 04/11

DLFU

EBARA Submersible Sewage Pumps

Selection Chart

Project: DLFU

Model

Three Phase 60Hz

Model:

Chkd:

m ft

300

80

60Hz (Synchronous Speed 1800 RPM)

TOTAL HEAD

60 200

50

150

40

28

40

25 / 26

23 / 24

7

6

5

4

39

21 / 22

38

48

47

37

19 / 20

36

17 / 18

35

13 / 14

33

2

9 / 10

11 / 12

31

45

44

52

42

59

66

58

65

57

50

64

41

30

63

49

15

15

20

30

40 50 60

0.1

0.2

80 100

150 200

0.3 0.4 0.5 0.6

54

62

55

10

10

53

51

32

20

60

43

34

3

61

46

15 / 16

4

3

29

27

30 100

80

20

60

15 50

40

10

30

8

6

5

Date:

300 400 500 600 800 1000

0.8 1.0

1.5 2.0

56

1500 2000 3000 4000 USGPM

3.0 4.0 5.0 6.0

8.0 10

15 m3/min

CAPACITY

Please note: Overlap in coverage is designated by the two numbers; for example "9 / 10". Refer to the legend

below for the specific model numbers.

1 50DLFU61.5 2HP

19

2 80DLMFU61.5 2HP

37 100DLFU622 30HP

55 250DLBFU615 20HP

20 100DLMFU611 15HP

38 150DLFU630 40HP

56 250DLCFU615 20HP

3 80DLMFU62.2 3HP

21

39 150DLFU637 50HP

57 250DLFU618

25HP

4 80DLMFU63.7 5HP

22 100DLMFU615 20HP

40 150DLFU645 60HP

58 250DLFU622

30HP

5 80DLMFU65.5 7HP

23

41 150DLFU67.5 10HP

59 250DLFU630

40HP

6 80DLCMFU67.5 10HP

24 100DLMFU618 25HP

42 150DLFU611 15HP

60 250DLFU637

50HP

7 80DLCMFU611 15HP

25

43 150DLFU615 20HP

61 250DLFU645

60HP

8 100DLFU61.5 2HP

26 100DLMFU622 30HP

44 150DLFU618 25HP

62 300DLFU618

25HP

9 80DLFU61.5 2HP

27 100DLFU630 40HP

45 150DLFU622 30HP

63 300DLFU622

30HP

10 100DLMFU61.5 2HP

28 100DLFU637 50HP

46 200DLFU630 40HP

64 300DLFU630

40HP

11

29 100DLFU645 60HP

47 200DLFU637 50HP

65 300DLFU637

50HP

12 100DLMFU62.2 3HP

30 100DLFU62.2 3HP

48 200DLFU645 60HP

66 300DLFU645

60HP

13

31 100DLFU63.7 5HP

49 200DLFU67.5 10HP

14 100DLMFU63.7 5HP

32 100DLFU65.5 7HP

50 200DLFU611 15HP

15

33 100DLFU67.5 10HP

51 200DLFU615 20HP

16 100DLMFU65.5 7HP

34 100DLFU611 15HP

52 200DLFU618 25HP

17

35 100DLFU615 20HP

53 200DLFU622 30HP

36 100DLFU618 25HP

54 250DLFU611 15HP

80DLFU62.2 3HP

80DLFU63.7 5HP

80DLFU65.5 7HP

80DLFU67.5 10HP

18 100DLMFU67.5 10HP

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

80DLFU611 15HP

80DLFU615 20HP

80DLFU618 25HP

80DLFU622 30HP

2-165

rev. 03/03

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

50DLF61.5 (2HP) Synchronous Speed: 1800 RPM

Chkd:

Date:

2, 3 inch Discharge

60

Curve No: DL-C603-9203

Solid Dia 1 1/2"

LM65

Max. Dia. 182mm-No Trim

60

50

Total Head (Ft)

Efficiency (%)

50

40

30

EFFICIENCY

20

30

BHP

20

10

10

0

0

20

40

60

80

100

120

Brake Horsepower (BHP)

40

140

Capacity USGPM

80DLF61.5 (2HP) Synchronous Speed: 1800 RPM

100

3, 4 inch Discharge

50

Curve No: DL-C604-9203

Solid Dia: 2 1/2"

LM80

90

6.0

5.5

5.0

80

40

4.5

70

50

40

4.0

30

3.5

3.0

EFFICIENCY

2.5

20

2.0

BHP

30

1.5

20

10

1.0

10

0

0.5

0

0

20

40

60

80

100

120

140

160

180

200

220

240

Brake Horsepower (BHP)

60

Total Head (Ft)

Efficiency (%)

Max. Dia. 170mm - No Trim

0.0

260

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-166

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

80DLMF61.5 (2HP) Synchronous Speed: 1800 RPM

Chkd:

Date:

3, 4 inch Discharge

50

Curve No: DLM-C601-9203

Solid Dia 3"

LM80

Max. Dia. 170mm-No Trim

50

40

30

EFFICIENCY

20

30

20

BHP

10

10

Brake Horsepower (BHP)

60

Total Head (Ft)

Efficiency (%)

40

0

0

20

40

60

80

100

120

140

160

180

200

220

240

260

Capacity USGPM

80DLF62.2 (3HP) Synchronous Speed: 1800 RPM

3, 4 inch Discharge

40

Curve No: DL-C605-9203

Solid Dia 2 1/2"

LL100

Max. Dia. 160mm

30

50

Min. Dia. 145mm

EFFICIENCY

20

40

30

10

20

BHP

10

2

1

Brake Horsepower (BHP)

60

Total Head (Ft)

Efficiency (%)

70

0

0

40

80

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

120

160

200

240

Capacity USGPM

280

320

360

400

2-167

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

Chkd:

80DLMF62.2 (3HP) Synchronous Speed: 1800 RPM

Date:

3, 4 inch Discharge

60

Curve No: DLM-C602-9203

Solid Dia 3"

LM80

Max. Dia. 188mm - No Trim

50

Efficiency (%)

Total Head (Ft)

40

30

EFFICIENCY

40

20

BHP

30

20

10

10

Brake Horsepower (BHP)

50

0

0

20

40

60

80

100

120

140

160

180

200

220

240

260

Capacity USGPM

80DLF63.7 (5HP) Synchronous Speed: 1800 RPM

3, 4 inch Discharge

60

Curve No: DLM-C607-9203

Solid Dia 3"

LL100

Max. Dia. 189mm

40

60

50

40

Min. Dia. 171mm

30

EFFICIENCY

20

30

20

BHP

10

10

0

Brake Horsepower (BHP)

70

Total Head (Ft)

EFFICIENCY (%)

50

0

0

100

200

300

400

500

600

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-168

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

Chkd:

80DLMF63.7 (5HP) Synchronous Speed: 1800 RPM

Date:

3, 4 inch Discharge

70

Curve No: DLM-C603-9203

Solid Dia 3"

LM80

Max. Dia. 208mm

60

60

Min. Dia. 188mm

40

30

EFFICIENCY

50

40

20

30

BHP

20

10

10

0

Brake Horsepower (BHP)

70

Total Head (Ft)

Efficiency (%)

50

0

0

40

80

120

160

200

240

280

320

Capacity USGPM

80DLF65.5 (71/2HP) Synchronous Speed: 1800 RPM

3, 4 inch Discharge

70

Curve No: DLM-C608-9203

Solid Dia 3"

LL100

60

50

50

30

20

EFFICIENCY

Min. Dia. 186mm

40

30

20

BHP

6

10

10

4

2

0

0

100

200

300

400

500

Brake Horsepower (BHP)

40

Total Head (Ft)

EFFICIENCY (%)

Max. Dia. 207mm

60

600

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-169

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

80DLMF65.5 (71/2HP) Synchronous Speed: 1800 RPM

Chkd:

Date:

3, 4 inch Discharge

90

Curve No: DLM-C604-9203

Solid Dia: 3"

LM80

Max. Dia. 225mm

80

50

40

60

Min. Dia. 203mm

EFFICIENCY

50

40

30

30

20

20

10

10

BHP

6

4

2

Brake Horsepower (BHP)

Efficiency (%)

60

Total Head (Ft)

70

0

0

50

100

150

200

250

300

350

400

Capacity USGPM

80DLF67.5 (10HP) Synchronous Speed: 1800 RPM

3, 4 inch Discharge

80

70

70

60

60

Curve No: DLM-C609-9203

Solid Dia 3"

LL100

Max. Dia. 151.9/249mm

40

50

Min. Dia. 122.9/220mm

40

30

30

20

20

10

10

BHP

10

Brake Horsepower (BHP)

50

Total Head (Ft)

EFFICIENCY (%)

EFFICIENCY

0

0

100

200

300

400

500

600

700

800

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-170

rev. 02/09

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

Chkd:

80DLCMF67.5 (10HP) Synchronous Speed: 1800 RPM

100

3, 4 inch Discharge

100

50

Curve No: DLM-C605-9203

Solid Dia: 3"

LL80

Max. Dia. 187.5/259mm T.D.H.

90

90

80

80

70

70

Date:

45

40

Min. Dia. 165.5/237mm T.D.H.

35

60

30

50

25

40

40

20

30

30

15

20

20

10

10

10

50

BHP

100

200

300

400

Brake Horsepower (BHP)

60

Total Head (Ft)

Efficiency (%)

EFFICIENCY

0

600

500

Capacity USGPM

80DLF611 (15HP) Synchronous Speed: 1800 RPM

100

90

90

Max. Dia. 172.4/263mm

70

Min. Dia. 151.4/242mm

60

50

EFFICIENCY

40

40

30

30

20

10

20

BHP

15

10

10

5

0

Brake Horsepower (BHP)

Total Head (Ft)

Efficiency(%)

70

50

Curve No: DLM-C610-9203

Solid Dia 3"

LL100

80

80

60

3, 4 inch Discharge

0

0

100

200

300

400

500

600

700

800

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-171

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

Chkd:

80DLCMF611 (15HP) Synchronous Speed: 1800 RPM

100

90

Date:

3, 4 inch Discharge

120

Curve No: DLM-C606-9203

Solid Dia 3"

LL80

110

Max. Dia. 215/281mm

100

80

90

80

50

40

70

60

50

40

30

30

15

BHP

20

10

20

10

10

0

0

100

200

300

400

500

Brake Horsepower (BHP)

60

EFFICIENCY

Min. Dia. 191/257mm

Total Head (Ft)

Efficiency (%)

70

600

Capacity USGPM

80DLF615 (20HP) Synchronous Speed: 1800 RPM

3, 4 inch Discharge

120

Curve No: DLM-C611-9203

Solid Dia 3"

LL100

Max. Dia. 196.4/287mm

110

100

90

Min. Dia. 172.4/263mm

60

70

60

50

50

40

40

30

30

20

20

10

10

EFFICIENCY

BHP

100

200

300

400

20

15

10

5

0

500

600

700

Brake Horsepower (BHP)

70

Total Head (Ft)

Efficiency (%)

80

800

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-172

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

80DLF618 (25HP) Synchronous Speed: 1800 RPM

Chkd:

Date:

3, 4 inch Discharge

140

Curve No: DLM-C612-9203

Solid Dia 3"

LL100

Max. Dia. 225/307mm

120

100

60

80

60

EFFICIENCY

50

25

BHP

40

40

20

30

15

20

20

10

10

0

0

100

200

300

400

500

600

700

Brake Horsepower (BHP)

70

Total Head (Ft)

Efficiency (%)

Min. Dia. 199/281mm

800

Capacity USGPM

80DLF622 (30HP) Synchronous Speed: 1800 RPM

3, 4 inch Discharge

160

Curve No: DLM-C613-9203

Solid Dia 3"

LL100

Max. Dia. 238/320mm

140

Min. Dia. 211/293mm

100

70

60

80

EFFICIENCY

60

50

40

40

30

20

30

BHP

20

20

10

0

10

0

Brake Horsepower (BHP)

Total Head (Ft)

Efficiency (%)

120

0

0

100

200

300

400

500

600

700

800

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-173

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

100DLF61.5 (2HP) Synchronous Speed: 1800 RPM

Chkd:

Date:

3, 4 inch Discharge

30

Curve No: DL-C613-9203

Solid Dia 3"

LM80

Max. Dia. 138mm

60

EFFICIENCY

Min. Dia. 125mm

30

10

20

3

BHP

10

2

1

Brake Horsepower (BHP)

40

20

Total Head (Ft)

Efficiency (%)

50

0

0

50

100

150

200

250

300

350

Capacity USGPM

100DLF62.2 (3HP) Synchronous Speed: 1800 RPM

3, 4 inch Discharge

40

Curve No: DL-C614-9203

Solid Dia 3"

LM80

Max. Dia. 160mm

50

EFFICIENCY

Min. Dia. 145mm

20

40

30

10

20

BHP

3

2

10

1

0

Brake Horsepower (BHP)

60

Total Head (Ft)

Efficiency (%)

30

0

0

100

200

300

400

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-174

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

100DLMF62.2 (3HP) Synchronous Speed: 1800 RPM

Chkd:

Date:

3, 4 inch Discharge

40

Curve No: DL-C605-9203

Solid Dia 2 1/2"

LL100

Max. Dia. 160mm

30

Total Head (Ft)

Efficiency (%)

70

60

50

Min. Dia. 145mm

EFFICIENCY

20

Brake Horsepower (BHP)

40

30

10

20

BHP

3

10

2

1

0

0

40

80

120

160

200

240

Capacity USGPM

280

320

100DLF63.7 (5HP) Synchronous Speed: 1800 RPM

360

400

3, 4 inch Discharge

50

Curve No: DL-C615-9203

Solid Dia 3"

LM80

40

50

40

30

EFFICIENCY

Min. Dia. 156mm

20

30

20

BHP

10

0

5

4

3

2

1

0

10

0

0

50

100

150

200

250

300

350

400

450

500

550

Brake Horsepower (BHP)

60

Total Head (Ft)

Efficiency (%)

Max. Dia. 172mm

600

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-175

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

Chkd:

100DLMF63.7 (5HP) Synchronous Speed: 1800 RPM

Date:

3, 4 inch Discharge

60

Curve No: DLM-C607-9203

Solid Dia 3"

LL100

50

Max. Dia. 189mm

60

50

40

Min. Dia. 171mm

EFFICIENCY

30

Brake Horsepower (BHP)

70

Total Head (Ft)

Efficiency (%)

40

20

30

20

10

5

BHP

10

0

0

0

100

200

300

400

500

600

Capacity USGPM

100DLF65.5 (71/2HP) Synchronous Speed: 1800 RPM

100

4, 6 inch Discharge

45

90

Curve No: DLM-C614-9203

Solid Dia 3"

LL125

40

Max. Dia. 102.8/217mm

80

35

30

60

50

Total Head (Ft)

Efficiency (%)

70

Min. Dia. 89.8/204mm

25

EFFICIENCY

20

15

30

20

10

10

BHP

10

Brake Horsepower (BHP)

40

0

0

100

200

300

400

500

600

700

800

900

1000

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-176

rev. 03/07

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

Chkd:

100DLMF65.5 (71/2HP) Synchronous Speed: 1800 RPM

Date:

3, 4 inch Discharge

70

Curve No: DLM-C608-9203

Solid Dia 3"

LL100

Max. Dia. 207mm

60

60

50

50

40

30

20

Min. Dia. 186mm

40

30

20

Brake Horsepower (BHP)

Total Head (Ft)

Efficiency (%)

EFFICIENCY

BHP

6

10

10

4

2

0

0

100

200

300

400

500

600

Capacity USGPM

100DLF67.5 (10HP) Synchronous Speed: 1800 RPM

4, 6 inch Discharge

60

Curve No: DLM-C615-9203

Solid Dia 3"

LL125

100

Max. Dia. 120.8/235mm

50

90

60

50

40

Min. Dia. 103.8/218mm

EFFICIENCY

30

20

30

20

BHP

10

10

10

0

5

0

0

0

100

200

300

400

500

600

700

800

900

1000

Brake Horsepower (BHP)

70

40

Total Head (Ft)

Efficiency (%)

80

1100

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

2-176.1

(t) 803 327 5005 (f) 803 327 5097

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

Chkd:

100DLMF67.5 (10HP) Synchronous Speed: 1800 RPM

100

80

70

70

60

Efficiency (%)

60

50

3, 4 inch Discharge

Curve No: DLM-C609-9203

Solid Dia. 3"

LL100

Max. Dia. 151.9/249mm.

20

80

70

Min. Dia. 122.9/220mm

EFFICIENCY

60

50

50

40

40

30

30

20

20

40

30

90

10

10

BHP

100

200

300

400

Brake Horsepower (BHP)

80

Total Head (Ft)

90

Date:

10

500

600

700

800

Capacity USGPM

100DLF611 (15HP) Synchronous Speed: 1800 RPM

4, 6 inch Discharge

90

70

70

60

60

40

Max. Dia. 139.7/254mm

EFFICIENCY

Min. Dia. 120.7/235mm

50

40

30

30

20

20

10

10

BHP

15

10

5

0

0

100

200

300

400

500

600

700

800

900

1000

Brake Horsepower (BHP)

50

Total Head (Ft)

Efficiency (%)

80

Curve No: DLM-C616-9203

Solid Dia 3"

LL125

1100

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-177

rev. 02/13

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

Chkd:

100DLMF611 (15HP) Synchronous Speed: 1800 RPM

3, 4 inch Discharge

90

100

90

90

70

Curve No: DLM-C610-9203

Solid Dia 3"

LL100

Max. Dia. 172.4/263mm

80

80

Date:

Min. Dia. 151.4/242mm

80

70

50

60

EFFICIENCY

50

50

40

40

30

30

40

30

20

20

20

BHP

10

10

0

0

0

10

Brake Horsepower (BHP)

60

60

Total Head (Ft)

Efficiency (%)

70

0

100

200

300

400

500

600

700

800

Capacity USGPM

100DLF615 (20HP) Synchronous Speed: 1800 RPM

4, 6 inch Discharge

110

Curve No: DLM-C617-9203

Solid Dia 3"

LL125

Max. Dia. 173.1/278mm

100

90

60

50

EFFICIENCY

70

Min. Dia. 151.1/256mm

60

50

40

40

30

30

20

20

10

10

BHP

200

400

600

20

15

10

5

0

800

1000

Brake Horsepower (BHP)

Efficiency (%)

70

Total Head (Ft)

80

1200

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-178

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

100DLMF615 (20HP) Synchronous Speed: 1800 RPM

Chkd:

Date:

3, 4 inch Discharge

120

Curve No: DLM-C611-9203

Solid Dia 3"

LL100

Max. Dia. 196.4/287mm

110

100

90

Min. Dia. 172.4/263mm

60

70

60

50

50

40

40

30

30

20

20

10

10

EFFICIENCY

BHP

100

200

300

20

15

10

5

0

400

500

600

700

Brake Horsepower (BHP)

70

Total Head (Ft)

Efficiency (%)

80

800

Capacity USGPM

100DLMF618 (25HP) Synchronous Speed: 1800 RPM

3, 4 inch Discharge

140

Curve No: DLM-C612-9203

Solid Dia 3"

LL100

Max. Dia. 225/307mm

120

100

60

80

60

EFFICIENCY

50

40

25

40

20

BHP

30

20

15

20

10

10

0

5

0

0

0

100

200

300

400

500

600

700

Brake Horsepower (BHP)

70

Total Head (Ft)

Efficiency (%)

Min. Dia. 199/281mm

800

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-179

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

100DLF618 (25HP) Synchronous Speed: 1800 RPM

Chkd:

Date:

4, 6 inch Discharge

120

100

100

90

90

80

80

60

Curve No: DLM-C618-9203

Solid Dia 3"

LL125

Max. Dia. 192/288mm

Min. Dia. 168/264mm

70

60

50

50

40

40

30

30

20

20

10

10

EFFICIENCY

25

20

15

10

5

0

BHP

100

200

300

400

500

600

700

800

900

Brake Horsepower (BHP)

70

Total Head (Ft)

Efficiency (%)

110

1000 1100 1200

Capacity USGPM

100DLMF622 (30HP) Synchronous Speed: 1800 RPM

3, 4 inch Discharge

160

Curve No: DLM-C613-9203

Solid Dia 3"

LL100

Max. Dia. 238/320mm

140

Min. Dia. 211/293mm

100

70

60

80

EFFICIENCY

60

50

40

40

30

20

30

BHP

20

20

10

0

10

0

Brake Horsepower (BHP)

Total Head (Ft)

Efficiency (%)

120

0

0

100

200

300

400

500

600

700

800

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-180

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

Chkd:

100DLF622 (30HP) Synchronous Speed: 1800 RPM

Date:

4, 6 inch Discharge

140

Curve No: DLM-C619-9203

Solid Dia 3"

LL125

Max. Dia. 208/304mm

120

100

100

80

70

60

Min. Dia. 183/279mm

80

60

50

EFFICIENCY

40

40

30

30

20

BHP

20

20

10

10

Brake Horsepower (BHP)

Total Head (Ft)

Efficiency (%)

90

0

0

100

200

300

400

500

600

700

800

900

1000 1100 1200

Capacity USGPM

100DLF630 to 645 (40-60HP) Synchronous Speed: 1800 RPM

260

D = 360mm

240

D = 345mm

220

3, 4 inch Discharge

Curve No: DL-C601-9608

Solid Dia 3"

LL100

50

60

65

D = 330mm

68

200

D = 315mm

Total Head (Ft)

70

180

D = 300mm

160

70

140

120

40 HP

100

60 HP

80

50 HP

60

40

0

200

400

600

800

1000

1200

1400

1600

1800

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

2-180.1

(t) 803 327 5005 (f) 803 327 5097

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

150DLF67.5 200DLF67.5 (10HP) Synchronous Speed: 1800 RPM

Chkd:

Date:

6, 8 inch Discharge

60

Curve No: DL-C622-9203

Solid Dia 3"

LL150

50

Max. Dia. 124.6/225mm

60

50

Total Head (Ft)

Efficiency (%)

70

40

EFFICIENCY

Min. Dia. 107.6/208mm

30

20

30

BHP

20

10

10

10

Brake Horsepower (BHP)

40

0

0

200

400

600

800

1000

1200

1400

Capacity USGPM

150DLF611 200DLF611 (15HP) Synchronous Speed: 1800 RPM

6, 8 inch Discharge

80

70

Curve No: DL-C623-9203

Solid Dia 3"

LL150

70

Max. Dia. 143.6/244mm

EFFICIENCY

40

50

40

Min. Dia. 125.6/226mm

30

30

20

20

BHP

15

10

10

10

5

0

0

200

400

600

800

1000

1200

1400

Brake Horsepower (BHP)

50

60

Total Head (Ft)

Efficiency (%)

60

0

1600

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-181

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

150DLF615 200DLF615 (20HP) Synchronous Speed: 1800 RPM

Chkd:

Date:

6, 8 inch Discharge

100

Curve No: DL-C624-9203

Solid Dia 3"

LL150

Max. Dia. 180/268mm

90

80

50

EFFICIENCY

60

Min. Dia. 152/240mm

50

40

40

30

30

20

20

10

10

BHP

20

10

200

400

600

800

1000

1200

1400

Brake Horsepower (BHP)

60

70

Total Head (Ft)

Efficiency (%)

70

0

1600

Capacity USGPM

150DLF618 200DLF618 (25HP) Synchronous Speed: 1800 RPM

110

100

6, 8 inch Discharge

Curve No: DL-C625-9203

Solid Dia 3"

LL150

Max. Dia. 186/274mm

90

60

50

EFFICIENCY

70

Min. Dia. 163/251mm

60

50

40

40

30

30

20

20

10

10

BHP

25

20

15

10

5

0

0

200

400

600

800

1000

1200

1400

Brake Horsepower (BHP)

Efficiency (%)

70

Total Head (Ft)

80

1600

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

2-181.1

(t) 803 327 5005 (f) 803 327 5097

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

150DLF622 200DLF622 (30HP) Synchronous Speed: 1800 RPM

Chkd:

Date:

6,8 inch Discharge

110

Curve No: DL-C626-9203

Solid Dia 3"

LL150

100

Max. Dia. 192/296mm

90

80

50

Min. Dia. 168/272mm

60

50

40

40

30

30

20

20

20

10

10

10

BHP

30

0

0

200

400

600

800

1000

1200

1400

Brake Horsepower (BHP)

60

EFFICIENCY

70

Total Head (Ft)

Efficiency (%)

70

1600

Capacity USGPM

150DLF630 (40HP) Synchronous Speed: 1800 RPM

6 inch Discharge

140

Curve No: DLY-C601-9203

Solid Dia 3"

LL150Y

Max. Dia. 213/319mm

120

70

60

Min. Dia. 186/292mm

80

EFFICIENCY

60

50

40

40

40

BHP

30

20

30

20

20

10

0

10

0

0

200

400

600

800

1000

1200

1400

1600

1800

0

2000

Brake Horsepower (BHP)

80

Total Head (Ft)

Efficiency (%)

100

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-182

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

150DLF637 (50HP) Synchronous Speed: 1800 RPM

Chkd:

Date:

6 inch Discharge

160

Curve No: DLY-C602-9203

Solid Dia 3"

LL150Y

Max. Dia. 226/324mm

140

120

Min. Dia. 199/297mm

60

80

EFFICIENCY

60

50

50

BHP

40

40

40

30

30

20

20

20

10

10

0

0

200

400

600

800

1000

1200

1400

1600

1800

0

2000

Brake Horsepower (BHP)

70

Total Head (Ft)

Efficiency (%)

100

Capacity USGPM

150DLF645 (60HP) Synchronous Speed: 1800 RPM

6 inch Discharge

200

180

80

160

70

140

Curve No: DLY-C603-9203

Solid Dia 3"

LL150Y

Max. Dia. 255/353mm

50

120

Min. Dia. 225/323mm

100

40

80

30

60

20

40

10

20

60

BHP

50

40

30

20

0

200

400

600

800

1000

1200

1400

1600

Brake Horsepower (BHP)

60

Total Head (Ft)

Efficiency (%)

EFFICIENCY

1800

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-183

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

Chkd:

200DLF630 (40HP) Synchronous Speed: 1800 RPM

Date:

8 inch Discharge

120

110

Curve No: DLY-C604-9203

Solid Dia 3"

LL200Y

Max. Dia. 220/307mm

100

80

60

70

60

50

50

40

40

30

30

20

20

10

10

EFFICIENCY

BHP

40

30

20

10

0

0

200

400

600

800

1000

1200

1400

1600

1800

2000

Brake Horsepower (BHP)

70

Min. Dia. 194/281mm

Total Head (Ft)

Efficiency (%)

90

2200

Capacity USGPM

200DLF637 (50HP) Synchronous Speed: 1800 RPM

8 inch Discharge

160

Curve No: DLY-C605-9203

Solid Dia 3"

LL200Y

140

Max. Dia. 246/333mm

Total Head (Ft)

120

70

60

Min. Dia. 217/304mm

80

EFFICIENCY

60

50

40

BHP

50

40

30

20

40

30

20

10

0

20

Brake Horsepower (BHP)

Efficiency (%)

100

10

0

0

200

400

600

800

1000

1200

1400

1600

1800

2000

2200

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-184

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

Chkd:

200DLF645 (60HP) Synchronous Speed: 1800 RPM

Date:

8 inch Discharge

180

Curve No: DLY-C606-9203

Solid Dia 3"

LL200Y

160

Max. Dia. 263/350mm

60

EFFICIENCY

120

Min. Dia. 232/319mm

100

50

80

40

60

60

BHP

50

30

40

40

30

20

20

20

0

200

400

600

800

Brake Horsepower (BHP)

70

140

Total Head (Ft)

Efficiency (%)

80

1000 1200 1400 1600 1800 2000 2200 2400

Capacity USGPM

250DLF611 (15HP) Synchronous Speed: 1800 RPM

100

10 inch Discharge

60

Curve No: DL-C627-9203

Solid Dia 3 1/4"

LL250

90

Max. Dia. 143.1/243mm

50

80

60

50

Total Head (Ft)

EFFICIENCY (%)

70

EFFICIENCY

40

Min. Dia. 130.1/230mm

30

20

30

BHP

15

20

10

10

10

0

5

0

0

0

200

400

600

800

1000

1200

1400

1600

1800

Brake Horsepower (BHP)

40

2000

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-185

rev. 03/07

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

Chkd:

250DLBF615 (20HP) Synchronous Speed: 1800 RPM

Date:

10 inch Discharge

70

Curve No: DL-C628-9203

Solid Dia 3 1/4"

LL250

60

Max. Dia. 158.1/258mm

60

40

EFFICIENCY

Min. Dia. 138.1/238mm

30

50

40

20

30

BHP

20

20

10

10

10

0

0

200

400

600

800

1000

1200

1400

1600

1800

2000

Brake Horsepower (BHP)

70

Total Head (Ft)

EFFICIENCY (%)

50

2200

Capacity USGPM

250DLCF615 (20HP) Synchronous Speed: 1800 RPM

10 inch Discharge

80

Curve No: DL-C629-9203

Solid Dia 3 1/4"

LL250

70

Max. Dia. 168/262mm

60

50

Min. Dia. 148/242mm

40

EFFICIENCY

30

50

40

20

30

20

25

BHP

20

10

10

0

15

Brake Horsepower (BHP)

70

Total Head (Ft)

EFFICIENCY (%)

60

10

0

0

200

400

600

800

1000

1200

1400

1600

1800

2000

2200

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-186

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

Chkd:

250DLF618 (25HP) Synchronous Speed: 1800 RPM

Date:

10 inch Discharge

90

70

70

60

60

40

Max. Dia. 179/273mm

EFFICIENCY

50

Min. Dia. 157/251mm

40

30

30

20

20

10

10

BHP

25

20

15

10

5

400

800

1200

1600

Brake Horsepower (BHP)

50

Total Head (Ft)

EFFICIENCY (%)

80

Curve No: DL-C630-9203

Solid Dia 3 1/4"

LL250

0

2400

2000

Capacity USGPM

250DLF622 (30HP) Synchronous Speed: 1800 RPM

10 inch Discharge

100

80

80

70

70

Curve No: DL-C631-9203

Solid Dia 3 1/4"

LL250

Max. Dia. 193/287mm

90

50

60

Min. Dia. 169/263mm

50

40

40

30

30

20

20

20

10

10

10

BHP

30

Brake Horsepower (BHP)

60

Total Head (Ft)

EFFICIENCY (%)

EFFICIENCY

0

0

400

800

1200

1600

2000

2400

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-187

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

Chkd:

250DLF630 (40HP) Synchronous Speed: 1800 RPM

Date:

10 inch Discharge

100

Max. Dia. 209/299mm

Curve No: DLY-C607-9203

Solid Dia 3"

LL250Y

80

80

70

70

50

EFFICIENCY

Min. Dia. 184/274mm

60

50

40

40

30

30

20

20

10

10

BHP

40

30

20

10

300

600

900

1200

1500

1800

2100

2400

2700

Brake Horsepower (BHP)

60

Total Head (Ft)

EFFICIENCY (%)

90

0

3000

Capacity USGPM

250DLF637 (50HP) Synchronous Speed: 1800 RPM

10 inch Discharge

140

Max. Dia. 231/321mm

Curve No: DLY-C608-9203

Solid Dia 3"

LL250Y

120

60

Min. Dia. 203/293mm

80

EFFICIENCY

60

BHP

50

40

50

40

40

30

20

30

20

20

10

0

10

0

0

0

500

1000

1500

2000

2500

Brake Horsepower (BHP)

70

Total Head (Ft)

EFFICIENCY (%)

100

3000

Capacity USGPM

EBARA Fluid Handling

www.pumpsebara.com

(t) 803 327 5005 (f) 803 327 5097

2-188

rev. 01/02

DLFU

EBARA Submersible Sewage Pumps

Performance Curves

Project:

GPM:

TDH:

EFF:

HP:

250DLF645 (60HP) Synchronous Speed: 1800 RPM

Chkd:

Date:

10 inch Discharge

140

Curve No: DLY-C609-9203

Solid Dia 3"

LL250Y

Max. Dia. 248/338mm

120

70

60

Min. Dia. 219/309mm

80

EFFICIENCY

60

50

40

40

BHP

30

20

60

40

20

10

20

0

0

500

1000

1500

2000

2500

3000

Brake Horsepower (BHP)

80

Total Head (Ft)

EFFICIENCY (%)

100

3500

Capacity USGPM

300DLF618 (25HP) Synchronous Speed: 1800 RPM

12 inch Discharge

50

Curve No: DL-C632-9203

Solid Dia 3 1/2"

LL300

Max. Dia. 137.1/237mm

50

40

30

EFFICIENCY

Min. Dia. 120.1/220mm

20

30

20

BHP

25

20

10