Professional Documents

Culture Documents

Properties of Chitosanase From Bacillus Cereus S1

Properties of Chitosanase From Bacillus Cereus S1

Uploaded by

vignesh9489Copyright:

Available Formats

You might also like

- DNA Extraction and CharacterizationDocument4 pagesDNA Extraction and CharacterizationEricka Galang100% (1)

- Purification and Properties Ofa Xylanase Frombacillussubtilis GiDocument7 pagesPurification and Properties Ofa Xylanase Frombacillussubtilis Githaibinh90No ratings yet

- Isolation and partial characterisation of α-amylase components evolved during early wheat germinationDocument13 pagesIsolation and partial characterisation of α-amylase components evolved during early wheat germinationDwi Surya AtmajaNo ratings yet

- To Whom Reprint Requests Should Be AddressedDocument11 pagesTo Whom Reprint Requests Should Be AddressedAracely FloresNo ratings yet

- Xylanase and Beta-Xylosidase Produced by A Purification and Properties of ThermostableDocument5 pagesXylanase and Beta-Xylosidase Produced by A Purification and Properties of Thermostableaditi_joshee419No ratings yet

- Liquid Chromatographic Determination of Biogenic Amines in A Meat Product During Fermentation and Long-Term StorageDocument9 pagesLiquid Chromatographic Determination of Biogenic Amines in A Meat Product During Fermentation and Long-Term Storagemelimeli106No ratings yet

- Artigo GioDocument8 pagesArtigo GioPuji LestariNo ratings yet

- FulltextDocument5 pagesFulltextAmeba OioNo ratings yet

- Biochemical Properties of A B-Xylosidase From: Clostridium CellulolyticumDocument4 pagesBiochemical Properties of A B-Xylosidase From: Clostridium CellulolyticumPedro HamannNo ratings yet

- AcetobacterDocument11 pagesAcetobacterdiantinurwindaNo ratings yet

- 1981 Hizukuri, Takjzda, Yasuda 1981Document9 pages1981 Hizukuri, Takjzda, Yasuda 1981Łukasz GraczykNo ratings yet

- Purification and Characterization of Proteases From Clinical Isolate of Kums 3958Document8 pagesPurification and Characterization of Proteases From Clinical Isolate of Kums 3958Etna VeraguasNo ratings yet

- Erwinia Carotovora: Research ArticleDocument10 pagesErwinia Carotovora: Research Articlesrinu_aerrowNo ratings yet

- Mutanolisina EnglishDocument10 pagesMutanolisina EnglishCristobal Hernandez ToledoNo ratings yet

- Pmecx 4 - Marcado TotalDocument7 pagesPmecx 4 - Marcado TotalVictor RoticivNo ratings yet

- Isolation and Purification of CellulaseDocument6 pagesIsolation and Purification of CellulaseMeshal NoorNo ratings yet

- Vries Mann 2009Document6 pagesVries Mann 2009Roberto Tello UrreloNo ratings yet

- Zhang 1999Document4 pagesZhang 1999Alexsandro Nicolay PontoanNo ratings yet

- As - Fisiol.Veg. 7 - 1 - 15-19 - 1995Document5 pagesAs - Fisiol.Veg. 7 - 1 - 15-19 - 1995evilbioNo ratings yet

- Cellulase Enzyme Production by Streptomyces SP Using Fruit Waste As SubstrateDocument5 pagesCellulase Enzyme Production by Streptomyces SP Using Fruit Waste As SubstrateHamka NurkayaNo ratings yet

- Purification and Characterization of A Monoacylglycerol Lipase From The Moderately Thermophilic Bacillus Sp. H-257Document7 pagesPurification and Characterization of A Monoacylglycerol Lipase From The Moderately Thermophilic Bacillus Sp. H-257ayauNo ratings yet

- Enzym ProteazaDocument16 pagesEnzym Proteazavithuat1No ratings yet

- Canilha, L. Et AlDocument9 pagesCanilha, L. Et AlragndsNo ratings yet

- Aquino Et Al 2003Document6 pagesAquino Et Al 2003Karen AlagunaNo ratings yet

- Chin 1991Document5 pagesChin 1991Pedro RetamalNo ratings yet

- Journal of Bacteriology-1991-Kordel-4836.fullDocument6 pagesJournal of Bacteriology-1991-Kordel-4836.fullMuhammad Abdullah HanifNo ratings yet

- Downstreaming and Purification of Lovastatin From Monascus Purpureus CultureDocument8 pagesDownstreaming and Purification of Lovastatin From Monascus Purpureus CultureHrithik BaradiaNo ratings yet

- Estrogens, ConjugatedDocument10 pagesEstrogens, ConjugatedJuan PerezNo ratings yet

- Acido Pectico MucilagoDocument8 pagesAcido Pectico MucilagoPilar Salazar GallegoNo ratings yet

- Sugar Oxidizing Respiratory Chain of Gluconobacter Suboxydans Evidence For A Branched Respiratory Chain and Characterization of Respiratory ChainDocument9 pagesSugar Oxidizing Respiratory Chain of Gluconobacter Suboxydans Evidence For A Branched Respiratory Chain and Characterization of Respiratory ChainArbe BelcenaNo ratings yet

- Esterification of Fatty Acids Using Partially Purified Dvl-2 LipaseDocument44 pagesEsterification of Fatty Acids Using Partially Purified Dvl-2 Lipaseakashgoyal1992100% (1)

- Tyrosine Decarboxylase Activity of Lactobacillus Brevis IOEB 9809 Isolated From Wine and L. Brevis ATCC 367Document6 pagesTyrosine Decarboxylase Activity of Lactobacillus Brevis IOEB 9809 Isolated From Wine and L. Brevis ATCC 367api-3743140No ratings yet

- Lacfis: Improvement of Diacetyl Production by Ssp. CNRZ Through Oxygen ControlDocument7 pagesLacfis: Improvement of Diacetyl Production by Ssp. CNRZ Through Oxygen ControlsantiNo ratings yet

- 00 - Gavilanes (1982) Int J Peptide Protein Res - Pigeon Egg White LysozymeDocument8 pages00 - Gavilanes (1982) Int J Peptide Protein Res - Pigeon Egg White Lysozyme1810mNo ratings yet

- Isolation, Fractionation, and Characterization of Xanthine Oxidase From Goat's MilkDocument6 pagesIsolation, Fractionation, and Characterization of Xanthine Oxidase From Goat's Milkfatimah arifNo ratings yet

- Ana Blanco 1995Document3 pagesAna Blanco 1995divyeshbhagat007No ratings yet

- Cheng Et Al., 2005Document6 pagesCheng Et Al., 2005Guillermo Gallardo VásquezNo ratings yet

- Amylaseactivity Gluco2Document10 pagesAmylaseactivity Gluco2DilaksNo ratings yet

- Impact of Methyl Jasmonate On Squalene Bio Synthesis in MicroalgaDocument5 pagesImpact of Methyl Jasmonate On Squalene Bio Synthesis in MicroalgaGerman ColqueNo ratings yet

- Profiling of Methyltransferases and Other S-Adenosyl - Homocysteine-Binding Proteins by Capture Compound Mass Spectrometry (CCMS)Document7 pagesProfiling of Methyltransferases and Other S-Adenosyl - Homocysteine-Binding Proteins by Capture Compound Mass Spectrometry (CCMS)Anh TranNo ratings yet

- Abu-Khudir Et Al, 2019Document16 pagesAbu-Khudir Et Al, 2019pavimathuNo ratings yet

- N-Acyl Homoserine Lactone Analog Modulators of The Pseudomonas Aeruginosa RhII Quorum Signal Synthase, Shin Et Al.Document77 pagesN-Acyl Homoserine Lactone Analog Modulators of The Pseudomonas Aeruginosa RhII Quorum Signal Synthase, Shin Et Al.deryhermawanNo ratings yet

- Biochemical Changes in Experimental Soy Sauce KojiDocument13 pagesBiochemical Changes in Experimental Soy Sauce KojiTâm Dương ĐứcNo ratings yet

- 7484 PDFDocument13 pages7484 PDFRifkarosita PutriNo ratings yet

- Characterization AcetylDocument14 pagesCharacterization AcetylhtersadrNo ratings yet

- 1971 - Cold Osmotic Shock in Saccharomyces CerevisiaeDocument8 pages1971 - Cold Osmotic Shock in Saccharomyces CerevisiaeGiancarlo GHNo ratings yet

- Silver Recovery From Waste Photographic Films by AnDocument2 pagesSilver Recovery From Waste Photographic Films by AnMuhammad Adnan LaghariNo ratings yet

- Study On The Substrate Specificity of That Contribute To Soil Removal in DetergentsDocument2 pagesStudy On The Substrate Specificity of That Contribute To Soil Removal in DetergentsmariNo ratings yet

- Or-Amylase Production in Aqueous Two-Phase Systems With: Bacillus SubtilisDocument6 pagesOr-Amylase Production in Aqueous Two-Phase Systems With: Bacillus SubtilisHong HanhNo ratings yet

- Plntphys00211 0097Document7 pagesPlntphys00211 0097yasmineat29No ratings yet

- Cristalización CuajoDocument9 pagesCristalización CuajoPablo GarcíaNo ratings yet

- Partial Characterization of Lipase From Cocoa BeanDocument6 pagesPartial Characterization of Lipase From Cocoa BeannubnubNo ratings yet

- Sterol Carrier Protein and Fatty Acid-Binding ProteinDocument7 pagesSterol Carrier Protein and Fatty Acid-Binding ProteinMartin OreNo ratings yet

- Antibacterial and Antioxidant ActivitiesDocument7 pagesAntibacterial and Antioxidant ActivitiesAshwinee KadelNo ratings yet

- Damian L 1994Document6 pagesDamian L 1994yosyNo ratings yet

- Sporo Genes'Document4 pagesSporo Genes'millodoriaNo ratings yet

- Gao Et Al. - 2008 - Purification and Characterization of Chitosanase From Bacillus Cereus D-11Document8 pagesGao Et Al. - 2008 - Purification and Characterization of Chitosanase From Bacillus Cereus D-11José Matías ZapiolaNo ratings yet

- 03 CPEnzDocument5 pages03 CPEnzPuji LestariNo ratings yet

- WINSEM2020-21 BIT3012 ELA VL2020210501829 Reference Material I 25-Mar-2021 Amylase Enzyme KineticsDocument8 pagesWINSEM2020-21 BIT3012 ELA VL2020210501829 Reference Material I 25-Mar-2021 Amylase Enzyme KineticsVijayasarathy Sampath KumarNo ratings yet

- Jurnal InternasionalDocument7 pagesJurnal InternasionalSunflowerNo ratings yet

- Plant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterFrom EverandPlant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterNo ratings yet

- Enterotoxin-Producing Staphylococcus AureusDocument17 pagesEnterotoxin-Producing Staphylococcus Aureusvignesh9489No ratings yet

- Haemophilus InfluenzaeDocument20 pagesHaemophilus Influenzaevignesh9489No ratings yet

- Erysipelothrix Rhusiopathiae: Molecular Medical Microbiology. DOI: © 2015 Elsevier Ltd. All Rights ReservedDocument14 pagesErysipelothrix Rhusiopathiae: Molecular Medical Microbiology. DOI: © 2015 Elsevier Ltd. All Rights Reservedvignesh9489No ratings yet

- Entrance Test For M.Sc. (Biotechnology) I May 2L, 2oll IDocument41 pagesEntrance Test For M.Sc. (Biotechnology) I May 2L, 2oll Ivignesh9489No ratings yet

- 4 261650026147611555 PDFDocument9 pages4 261650026147611555 PDFvignesh9489No ratings yet

- 4 261650026147611533 PDFDocument15 pages4 261650026147611533 PDFvignesh9489No ratings yet

- School RepresentativesDocument4 pagesSchool Representativesvignesh9489No ratings yet

- RDNA Technology Workshop - 28th - 30th Aug2019Document1 pageRDNA Technology Workshop - 28th - 30th Aug2019vignesh9489No ratings yet

- Integrated Pest ManagementDocument3 pagesIntegrated Pest Managementvignesh9489No ratings yet

- Rotating Biological ContactorDocument6 pagesRotating Biological Contactorvignesh9489No ratings yet

- Integrated Pest Management PDFDocument3 pagesIntegrated Pest Management PDFvignesh9489No ratings yet

- SDS-Polyacrylamide Gel Electrophoresis of ProteinsDocument9 pagesSDS-Polyacrylamide Gel Electrophoresis of ProteinsYoung LoveNo ratings yet

- 2009 ChanoseyelidDocument14 pages2009 ChanoseyelidAnne CurrayNo ratings yet

- The Isolation and Characterisation of Jacalin Artocarpus Heterophyllus Jackfruit Lectin Based On Its Charge Properties 1995 The International JournalDocument10 pagesThe Isolation and Characterisation of Jacalin Artocarpus Heterophyllus Jackfruit Lectin Based On Its Charge Properties 1995 The International JournalsfsmNo ratings yet

- SDS Page ExerciseDocument10 pagesSDS Page ExerciseJasminSutkovicNo ratings yet

- Lab Report Exp 4Document4 pagesLab Report Exp 4Brilliant SiemaNo ratings yet

- 2 MercaptoethanolDocument3 pages2 Mercaptoethanoldorelia_simonaNo ratings yet

- Agerose Gel ElectrophoresisDocument6 pagesAgerose Gel ElectrophoresisAnura BandaraNo ratings yet

- 9 DNA TroubleshootingDocument6 pages9 DNA TroubleshootingRicha AroraNo ratings yet

- Lysis Protocol With Tritonx-100Document2 pagesLysis Protocol With Tritonx-100ishfillup50No ratings yet

- Fosforo Disponible Metodo de OlsenDocument8 pagesFosforo Disponible Metodo de OlsenJose MartinezNo ratings yet

- Lecture 6 DP Protein SeperationDocument23 pagesLecture 6 DP Protein SeperationAkshayaaRaveeNo ratings yet

- Chapter 3-EnZYME Production and PURIFICATION 20141009Document58 pagesChapter 3-EnZYME Production and PURIFICATION 20141009Minh Tiến TrầnNo ratings yet

- Vol 3 Issue 7 PDFDocument114 pagesVol 3 Issue 7 PDFDwi WulandariNo ratings yet

- SDS-PAGE Gradient Gel 3-15%Document2 pagesSDS-PAGE Gradient Gel 3-15%Camha NguyenNo ratings yet

- Protein Purification TechniquesDocument102 pagesProtein Purification TechniquesDawlat SlamaNo ratings yet

- Electrophoresis 1Document8 pagesElectrophoresis 1AshpokemonNo ratings yet

- Protein PurificationDocument33 pagesProtein PurificationAaditya Vignyan VellalaNo ratings yet

- Miracle Fruit ResearchDocument9 pagesMiracle Fruit ResearchKyla de SilvaNo ratings yet

- Measuring Traction Forces in Long-Term Cell Cultures: C M and D LDocument10 pagesMeasuring Traction Forces in Long-Term Cell Cultures: C M and D Lnestor_bouNo ratings yet

- Food Chemistry 298 (2019) 125081Document11 pagesFood Chemistry 298 (2019) 125081trinh phamNo ratings yet

- Soy Proteins A Review On Composition, Aggregation and EmulsificationDocument18 pagesSoy Proteins A Review On Composition, Aggregation and EmulsificationkesdamileNo ratings yet

- Lab Long Test 1: Exercise 1: Microscopy: Cell Size Measurements and Counting CellsDocument3 pagesLab Long Test 1: Exercise 1: Microscopy: Cell Size Measurements and Counting CellsAlisha ChuganiNo ratings yet

- Clinical Applications of Capillary Electrophoresis: Methods and ProtocolsDocument270 pagesClinical Applications of Capillary Electrophoresis: Methods and Protocolshesicos100% (1)

- Mini-PROTEAN 3 Multi-Casting Chamber Instruction Manual: Catalog Number 165-4110Document10 pagesMini-PROTEAN 3 Multi-Casting Chamber Instruction Manual: Catalog Number 165-4110Mauricio GoldfederNo ratings yet

- Troubleshooting TableDocument2 pagesTroubleshooting Tableapi-3799757No ratings yet

- Erythropoietin Concentrated SolutionDocument5 pagesErythropoietin Concentrated SolutionMAHESH100% (1)

- Biochemistry 09 - Class Notes - Shodh 2.0 Batch For CSIR NET - GATE Life SciencesDocument33 pagesBiochemistry 09 - Class Notes - Shodh 2.0 Batch For CSIR NET - GATE Life SciencesSanjay Kumar RaoNo ratings yet

- Biological Techniques TechniquesDocument13 pagesBiological Techniques TechniquesDr. Dhondiba VishwanathNo ratings yet

- 1774392.PDF DanieletalDocument10 pages1774392.PDF DanieletalRegiane PinheiroNo ratings yet

Properties of Chitosanase From Bacillus Cereus S1

Properties of Chitosanase From Bacillus Cereus S1

Uploaded by

vignesh9489Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Properties of Chitosanase From Bacillus Cereus S1

Properties of Chitosanase From Bacillus Cereus S1

Uploaded by

vignesh9489Copyright:

Available Formats

CURRENT MICROBIOLOGY Vol. 40 (2000), pp.

69

DOI: 10.1007/s002849910002

An International Journal

R Springer-Verlag New York Inc. 2000

Properties of Chitosanase from Bacillus cereus S1

Masahiro Kurakake, Shou Yo-u, Kiyomi Nakagawa, Minako Sugihara, Toshiaki Komaki

Department of Food Science & Technology, Fukuyama University, Sanzou, Gakuenchou 1 banchi, Fukuyama, Hiroshima 729-0292, Japan

Received: 8 June 1999 / Accepted: 20 July 1999

Abstract. Chitosanase from Bacillus cereus S1 was purified, and the enzymatic properties were

investigated. The molecular weight was estimated to 45,000 on SDS-PAGE. Optimum pH was about 6,

and stable pH in the incubation at 40C for 60 min was 611. This chitosanase was stable in alkaline side.

Optimum temperature was around 60C, and enzyme activity was relatively stable below 60C. The

degradations of colloidal chitosan and carboxymethyl cellulose (CMC) were about 30 and 20% relative to

the value of soluble chitosan, respectively, but colloidal chitin and crystalline cellulose were not almost

hydrolyzed. On the other hand, S1 chitosanase adsorbed on colloidal chitin completely and by about 50%

also on crystalline cellulose, in contrast to colloidal chitosan, which it did not adsorb. S1 chitosanase

finally hydrolyzed 100% N-deacetylated chitosan (soluble state) to chitobiose (27.2%), chitotriose

(40.6%), and chitotetraose (32.2%). In the hydrolysis of various chitooligosaccharides, chitobiose and

chitotriose were not hydrolyzed, and chitotetraose was hydrolyzed to chitobiose. Chitobiose and

chitotriose were released from chitopentaose and chitohexaose. From this specificity, it was hypothesized

that the active site of S1 chitosanase recognized more than two glucosamine residues posited in both sides

against splitting point for glucosamine polymer.

Chitosan is one of the abundant resources, preparing from

chitin (crab or shrimp shell origin) through the chemical

N-deacetylation, and its biological properties like biocompatibility and antimicrobial activity are remarked. Actually, chitosan is applied widely to medical and food

materials. Especially, the chitooligosaccharides depolymerized from chitosan are also demanded because of the

high solubility in which the application is widened and

the absorption in vivo is improved. Enzymatic hydrolysis

by chitosanase is very useful for producing di-, tri-, and

tetra-chitooligosaccharides mainly. Some chitosanaseproducing microorganisms were separated from nature,

but all the action patterns to chitosan were almost the

same endo-type [13, 510].

Previously, we separated Bacillus cereus S1 from

soil in the screening with 0.2% colloidal chitosan plate

culture. However, chitosan was not an inducer for the

expression of chitosanase because the enzyme was also

intensely produced in a medium with glucose as a carbon

source. This chitosanase from B. cereus has been not

reported over the world, though the strain is well known

Correspondence to: M. Kurakake

in food poisoning. In this study, B. cereus S1 chitosanase

was purified, and the enzymatic properties were investigated.

Materials and Methods

Materials. Commercial chitosan (Kimitsuchitosan LLWP [7585%

N-deacetylated]; Kimitsu Chemical Industries Ltd., Tokyo) was used

for the culture medium and the measurement of chitosanase activity.

Perfectly N-deacetylated chitosan was supplied from Katakura Chikkarin Ltd., Tokyo. All other chemicals were of reagent grade.

Production of chitosanase by liquid culture. B. cereus S1 was

cultivated by 5 ml liquid medium containing 1% glucose, 0.5% yeast

extract, and 0.2% Na2HPO4 12H2O in 18 180 mm test tube at 30C

for 2024 h. Three milliliters of the precultured broth was inoculated

into 100 ml same liquid medium in a 500-ml flask and cultivated at

30C and 220 rpm for 48 h. The cultured broth of the seven duplications

were collected and centrifuged at 3,000 rpm for 10 min. The chitosanase

containing in the supernatant was salted out by adding ammonium

sulfate to make 90% saturation. The precipitated protein separated by

centrifugation was dissolved with 100 ml water and precipitated again

by adding cold acetone to be 70% v/v. The occurring precipitate was

separated by centrifugation, dissolving with water. The crude enzyme

solution was applied to column chromatography for the purification of

chitosanase.

Determination of chitosanase activity. One gram of chitosan (LLWP)

was dissolved in 80 ml water by adding 0.57 ml acetic acid and volume

M. Kurakake et al.: Chitosanase from Bacillus cereus

up to 100 ml after adjusting pH to 6 (1% chitosan, 0.1 M acetic acid).

This chitosan solution (0.91%) was incubated with enzyme sample at

pH 6 and 40C for 10 min. The reaction was stopped by adding 0.2 ml of

1 M NaOH and the mixture was centrifuged at 3,000 rpm for 10 min.

The concentration of reducing sugar of the supernatant was determined

by 3,5-dinitrosalicylic acid method [4]. One unit was defined as the

amount of enzyme that could produce 1 mol reducing sugar (glucose

base) for 1 min.

Purification of chitosanase. Chitosanase was purified by the following

chromatography steps, which were done at 4C. Step 1: Crude enzyme

solution was applied to gel filtration on Sephadex G-25 column

(2.5 50 cm; Pharmacia Ltd., Uppsala) preequilibrated with 10 mM

sodium acetate buffer (pH 5). Proteins were eluted with the same buffer

at a flow rate of 1.3 ml/min. Fractions were collected every 3 min. Step

2: Fractions with chitosanase activity were pooled and applied to

anion-exchange chromatography on Super Q Toyopearl column

(1.0 50 cm; Toso Ltd., Tokyo) preequilibrated with 10 mM sodium

acetate buffer (pH 5). Proteins were eluted with a linear gradient of 0 to

0.6 M NaCl at a flow rate of 0.2 ml/min.

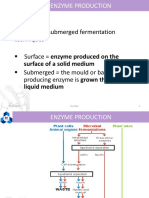

Fig. 1. Separation of chitosanase on gel chromatography on Sephadex

G-25 column. , chitosanase activity, solid line; absorbance at 280 nm.

Adsorption of chitosanase. S1 chitosanase (3.44 U/ml) was mixed

with 0.5% solid carbohydrates, colloidal chitosan, colloidal chitin, and

crystalline cellulose (Funacel; Funakoshi Ltd., Tokyo) and incubated at

40C for 20 min with stirring. After centrifuging (3,000 rpm, 10 min),

the chitosanase activity in the supernatant (unadsorbed enzyme) was

measured. Adsorbed enzyme (Eads) was calculated by the subtraction of

activity in supernatant from total activity (Et).

Analysis of sugars. Chitooligosaccharides were analyzed by highperformance liquid chromatography (HPLC) under the following

conditions: column, Amido 80 (Toso Ltd.); mobile phase, acetonitrile:

20 mM phosphate (45:55 v/v); flow rate, 1.0 ml/min; and detector,

Hitachi (Tokyo) model L-3300 differential refractive index monitor.

SDS-Polyacrylamide gel electrophoresis (SDS-PAGE). It was done

with Atto (Tokyo) model AE-6400 using 7.5% polyacrylamide gel (pH

8.8). SDS molecular weight marker (Sigma, Ltd., St. Louis, MO)

consisting of carbonic anhydrase (29,000), egg albumin (45,000),

bovine albumin (66,000), phosphorylase b (97,400), and -galactosidase (116,000) were used as standard proteins.

Amino acid sequencing. The N-terminal amino acid sequence of

chitosanase was analyzed by automatic Edman degradation using 491

protein sequencing system (Applied Biosystems Ltd., Foster City, CA)

Results

Purification of chitosanase. Crude enzyme solution

prepared by salting out with ammonium sulfate and

precipitating with acetone was applied to gel chromatography on Sephadex G-25 column. As shown in Fig. 1, two

chitosanase peaks of F1 (major fraction) and F2 (minor

fraction) were separated. F1 was applied to anionexchange chromatography on Toyopearl Super Q column, but the enzyme was not adsorbed on the resin and

passed out. Chitosanase of the eluted active fraction was

almost homogeneous on SDS-PAGE (see Fig. 2), as other

proteins adsorbed on the anion-exchange resin. The

molecular weight was estimated to 45,000. These purification steps from culture broth were summarized as

shown in Table 1. The N-terminal amino acid sequence of

Fig. 2. SDS-PAGE of purified S1 chitosanase. a: standard, b: purified S1

chitosanase.

Table 1. Purification of chitosanase from S1 strain

Purification steps

Culture filtrate

90% (NH3 )2SO4

70% acetone

Sephadex G-25

Super Q Toyopearl

Total

activity (U)

Yield (%)

Specific

activity (U/mg)

319.5

251.0

179.9

77.0

54.9

100

78.5

71.7

24.1

17.2

53

66

85

145

196

S1 chitosanase was GEKEMKPFPQQVNYA. Incidentally, F2 (minor fraction) had the same molecular weight

and reactivity for substrate as F1 (data not shown), except

for the adsorption on dextran of Sephadex G-25 resin.

Effect of pH and temperature on chitosanase. Chitosanase activity was measured at various pHs under the

stated condition, using phosphate-citrate (pH 2.28) and

glycine-NaCl-NaOH (pH 910) buffers. Figure 3A shows

the effects of pH on S1 chitosanase. Optimum pH was

CURRENT MICROBIOLOGY Vol. 40 (2000)

Table 2. Degradation of some carbohydrates by S1 chitosanase

Relative

degradation (%)

Carbohydrates

Soluble chitosan

Colloidal chitosan

Colloidal chitin

Carboxymethyl cellulose (CMC)

Crystalline cellulose (Funacel)

100

31.8

7.0

21.6

0.9

Each sample (0.5%) was incubated with chitosanase (0.108 U/ml) at pH

6 and 40C for 24 h.

Table 3. Adsorption of S1 chitosanase on some carbohydrates

Carbohydrates

Colloidal chitosan

Colloidal chitin

Crystalline cellulose

Eads /Et (%)

Eads (U/g)

0.0

100

46.4

0.0

688.2

319.4

Each sample (1%) was incubated with chitosanase (3.44 U/ml) at pH 6

and 40C for 20 min.

Table 4. Hydrolysis of chitooligosaccharides by S1 chitosanase

Fig. 3. Effects of pH (A) and temperature (B) on chitosanase activity.

Stability for pH was examined at 40C and at various pHs for 60 min,

and that for temperature was done at pH 5 and at various temperatures

for 30 min. , , pH and , , temperature for relative, residual

activities.

about 6, and stable pH in the incubation at 40C for 60

min was 611. This chitosanase was stable in alkaline

side. As shown in Fig. 3B, optimum temperature was

around 60C and enzyme activity was relatively stable

below 60C in the incubation at pH 5 for 30 min.

Reactivity for substrate. Purified chitosanase (0.12

U/ml) was incubated with various substrates (0.5%), such

as soluble chitosan, colloidal chitosan, colloidal chitin,

carboxymethyl cellulose (CMC), and crystalline cellulose (Funacel; Funakoshi Ltd.) at pH 6 and 40C for 24 h.

As shown in Table 2, the degradation of colloidal

chitosan was about 30% relative to the value of soluble

chitosan. In other carbohydrates with different structure

from chitosan, the relative degradation for CMC was

about 20%, but colloidal chitin and crystalline cellulose

were not almost hydrolyzed by S1 chitosanase.

Table 3 shows the adsorption of chitosanase on three

solid carbohydrates. Chitosanase adsorbed on colloidal

Substrates

Sugars after hydrolysis

Relative initial

rate (%)

(GlcN)2

(GlcN)3

(GlcN)4

(GlcN)5

(GlcN)6

(GlcN)2

(GlcN)3

(GlcN)2

(GlcN)2 , (GlcN)3

(GlcN)2 , (GlcN)3 , 5(GlcN)4 )6

0

0

1.95

44.4

100

Each chitooligosaccharide (0.45%) was incubated with chitosanase

(0.25 U/ml) at pH 6 and 40C for 22 h.

chitin completely and by about 50% also on crystalline

cellulose. However, the adsorption on colloidal chitosan

was not observed at all, in contrast to that on colloidal

chitin.

S1 chitosanase finally hydrolyzed 100% N-deacetylated chitosan (soluble state) to chitobiose (27.2%),

chitotriose (40.6%), and chitotetraose (32.2%) in the

reaction for 24 h. Chitotetraose and chitopentaose were

released at an early reaction period, hydrolyzing to lower

molecular sugars during the reaction. In the hydrolysis of

7585% deacetylated chitosan, the products were three

chitooligosaccharides as well as in that of 100% deacetylated chitosan. Table 4 show hydrolyzing action for

various chitooligosaccharides. Chitobiose and chitotriose

were not hydrolyzed by S1 chitosanase, and chitotetraose

was hydrolyzed to chitobiose. Chitobiose and chitotriose

were released from chitopentaose and chitohexaose,

where small amount of chitotetraose was residual in the

M. Kurakake et al.: Chitosanase from Bacillus cereus

hydrolysis of chitohexaose. The larger the molecular

weight among tetra-, penta-, and hexa-saccharides, the

larger the reactivity for S1 chitosanase.

Discussion

Chitosanase from B. cereus S1 was more stable under the

alkaline condition, than that from Bacillus P1-7S (pH

3.37.4) and Bacillus circulans MH-K1 (pH 49) [6, 10].

The N-terminal amino acid sequence was different from

those of other chitosanases according to DAD and

SWISS-PROT databases. There was a feature also in the

reactivity for CMC. S1 chitosanase hydrolyzed CMC by

about 20% relative to chitosan, though most chitosanases

do not show the reactivity for CMC [2, 5, 6, 10]. It seems

that the enzyme does not recognized so severely amino

group of C2 position in glucosamine residue when

enzyme-substrate complex was formed. This finding

could be associated with the property that some cellulase

can hydrolyze chitosan.

From the finding in Table 3, the adsorption of S1

chitosanase depends on the type of functional group of

C2 position in the glycoside residue. The degree of

adsorption for enzyme was larger for acetoamido

(-NHCOCH3), hydroxyl (OH), and amino group

(NH2) in turn. It seems that the colloidal chitin binds

with chitosanase as a competitive inhibitor because of the

similar structure. On the other hand, in the adsorption on

colloidal chitosan, the adsorption site would be decreased

because of the following hydrolysis process. Anyway, it

was found that S1 chitosanase had specificity on the

adsorption.

Main products from chitosan by many chitosanase

were di-, tri-, and tetra-chitooligosaccharides. However

their action patterns to chitosan were different on the

origin. Although Bacillus P1-7S chitosanase hydrolyze

chitotetraose to glucosamine and chitotriose, and chitotriose to chitobiose and glucosamine [6], S1 chitosanase

does not hydrolyze chitotriose and hydrolyze chitotetraose to chitobiose as well as those from Bacillus

licheniformis UTK, Amycolatopsis CsO-2, and B. circulans MH-K1 [5, 9, 10]. As shown in Table 4, a glu-

cosamine monomer was not released from chitopentaose

and chitohexaose. This means that the active site of S1

chitosanase recognizes more than two glucosamine residues posited in both sides against a splitting point for the

glucosamine polymer. The subsites for four glucosamine

residues in all were not satisfied with chitobiose and

chitotriose (two and three glucosamine residues). Chitotetraose was just fitted to the subsites and split in the

middle glycosidic bond. In the same manner, two sugars

of chitobiose and chitotriose were released from chitopentaose, and three sugars of chitobiose, chitotriose, and

chitotetraose were released from chitohexaose, where

chitotetraose was successively hydrolyzed to chitobiose.

Literature Cited

1. Alfonos C, Martines MJ, Reyes F (1992) Purification and properties of two endochitosanases from Mucor rouxii implicated in its

cell wall degradation. FEMS Microbiol Lett 95:187194

2. Fenton DM, Eveleigh DE (1981) Purification and mode of action of

a chitosanase from Penicillium islandicum. J Gen Microbiol

126:151165

3. Izume M, Ohtakara A (1987) Preparation of D-glucosamine

oligosaccharides by the enzymatic hydrolysis of chitosan. Agric

Biol Chem 51(4):11891191

4. Miller GL (1959) Use of dinitrosalicilic acid reagent for determination of reducing sugar. Anal Chem 31:426428

5. Okajima S, Ando A, Shinoyama H, Fujii T (1994) Purification and

characterization of an extracellular chitosanase produced by Amycolatopsis sp. CsO-2. J Ferment Bioeng 77(6):617620

6. Seino H, Tsukada K, Shimasue Y (1991) Properties and action

pattern of a chitosanase from Bacillus sp. PI-7S. Agric Biol Chem

55(9):24212423

7. Shimosaka M, Nogawa M, Ohno Y, Okazaki M (1993) Chitosanase

from the plant pathogenic fungus, Fusarium solanif sp. phaseoli

purification and some properties. Biosci Biotech Biochem 57(2):

231235

8. Shimosaka M, Nogawa M, Wand XY, Kumehara M, Okazaki M

(1995) Production of two chitosanases from a chitosan-assimilating

bacterium, Acinetobacter sp. strain CHB101. Appl Environ Microbiol 61(2):438442

9. Uchida Y, Tateishi K, Yamaguchi K, Takeda H (1994) Purification

and characterization of chitosanases produced by Bacillus licheniformis UTK. Bull Fac Agr Saga Univ 77:5363

10. Yabuki M, Uchiyama A, Suzuki K, Ando A, Fujii T (1988)

Purification and properties of chitosanase from Bacillus circulans

MH-K1. L. Gen Appl Microbiol 34:255270

You might also like

- DNA Extraction and CharacterizationDocument4 pagesDNA Extraction and CharacterizationEricka Galang100% (1)

- Purification and Properties Ofa Xylanase Frombacillussubtilis GiDocument7 pagesPurification and Properties Ofa Xylanase Frombacillussubtilis Githaibinh90No ratings yet

- Isolation and partial characterisation of α-amylase components evolved during early wheat germinationDocument13 pagesIsolation and partial characterisation of α-amylase components evolved during early wheat germinationDwi Surya AtmajaNo ratings yet

- To Whom Reprint Requests Should Be AddressedDocument11 pagesTo Whom Reprint Requests Should Be AddressedAracely FloresNo ratings yet

- Xylanase and Beta-Xylosidase Produced by A Purification and Properties of ThermostableDocument5 pagesXylanase and Beta-Xylosidase Produced by A Purification and Properties of Thermostableaditi_joshee419No ratings yet

- Liquid Chromatographic Determination of Biogenic Amines in A Meat Product During Fermentation and Long-Term StorageDocument9 pagesLiquid Chromatographic Determination of Biogenic Amines in A Meat Product During Fermentation and Long-Term Storagemelimeli106No ratings yet

- Artigo GioDocument8 pagesArtigo GioPuji LestariNo ratings yet

- FulltextDocument5 pagesFulltextAmeba OioNo ratings yet

- Biochemical Properties of A B-Xylosidase From: Clostridium CellulolyticumDocument4 pagesBiochemical Properties of A B-Xylosidase From: Clostridium CellulolyticumPedro HamannNo ratings yet

- AcetobacterDocument11 pagesAcetobacterdiantinurwindaNo ratings yet

- 1981 Hizukuri, Takjzda, Yasuda 1981Document9 pages1981 Hizukuri, Takjzda, Yasuda 1981Łukasz GraczykNo ratings yet

- Purification and Characterization of Proteases From Clinical Isolate of Kums 3958Document8 pagesPurification and Characterization of Proteases From Clinical Isolate of Kums 3958Etna VeraguasNo ratings yet

- Erwinia Carotovora: Research ArticleDocument10 pagesErwinia Carotovora: Research Articlesrinu_aerrowNo ratings yet

- Mutanolisina EnglishDocument10 pagesMutanolisina EnglishCristobal Hernandez ToledoNo ratings yet

- Pmecx 4 - Marcado TotalDocument7 pagesPmecx 4 - Marcado TotalVictor RoticivNo ratings yet

- Isolation and Purification of CellulaseDocument6 pagesIsolation and Purification of CellulaseMeshal NoorNo ratings yet

- Vries Mann 2009Document6 pagesVries Mann 2009Roberto Tello UrreloNo ratings yet

- Zhang 1999Document4 pagesZhang 1999Alexsandro Nicolay PontoanNo ratings yet

- As - Fisiol.Veg. 7 - 1 - 15-19 - 1995Document5 pagesAs - Fisiol.Veg. 7 - 1 - 15-19 - 1995evilbioNo ratings yet

- Cellulase Enzyme Production by Streptomyces SP Using Fruit Waste As SubstrateDocument5 pagesCellulase Enzyme Production by Streptomyces SP Using Fruit Waste As SubstrateHamka NurkayaNo ratings yet

- Purification and Characterization of A Monoacylglycerol Lipase From The Moderately Thermophilic Bacillus Sp. H-257Document7 pagesPurification and Characterization of A Monoacylglycerol Lipase From The Moderately Thermophilic Bacillus Sp. H-257ayauNo ratings yet

- Enzym ProteazaDocument16 pagesEnzym Proteazavithuat1No ratings yet

- Canilha, L. Et AlDocument9 pagesCanilha, L. Et AlragndsNo ratings yet

- Aquino Et Al 2003Document6 pagesAquino Et Al 2003Karen AlagunaNo ratings yet

- Chin 1991Document5 pagesChin 1991Pedro RetamalNo ratings yet

- Journal of Bacteriology-1991-Kordel-4836.fullDocument6 pagesJournal of Bacteriology-1991-Kordel-4836.fullMuhammad Abdullah HanifNo ratings yet

- Downstreaming and Purification of Lovastatin From Monascus Purpureus CultureDocument8 pagesDownstreaming and Purification of Lovastatin From Monascus Purpureus CultureHrithik BaradiaNo ratings yet

- Estrogens, ConjugatedDocument10 pagesEstrogens, ConjugatedJuan PerezNo ratings yet

- Acido Pectico MucilagoDocument8 pagesAcido Pectico MucilagoPilar Salazar GallegoNo ratings yet

- Sugar Oxidizing Respiratory Chain of Gluconobacter Suboxydans Evidence For A Branched Respiratory Chain and Characterization of Respiratory ChainDocument9 pagesSugar Oxidizing Respiratory Chain of Gluconobacter Suboxydans Evidence For A Branched Respiratory Chain and Characterization of Respiratory ChainArbe BelcenaNo ratings yet

- Esterification of Fatty Acids Using Partially Purified Dvl-2 LipaseDocument44 pagesEsterification of Fatty Acids Using Partially Purified Dvl-2 Lipaseakashgoyal1992100% (1)

- Tyrosine Decarboxylase Activity of Lactobacillus Brevis IOEB 9809 Isolated From Wine and L. Brevis ATCC 367Document6 pagesTyrosine Decarboxylase Activity of Lactobacillus Brevis IOEB 9809 Isolated From Wine and L. Brevis ATCC 367api-3743140No ratings yet

- Lacfis: Improvement of Diacetyl Production by Ssp. CNRZ Through Oxygen ControlDocument7 pagesLacfis: Improvement of Diacetyl Production by Ssp. CNRZ Through Oxygen ControlsantiNo ratings yet

- 00 - Gavilanes (1982) Int J Peptide Protein Res - Pigeon Egg White LysozymeDocument8 pages00 - Gavilanes (1982) Int J Peptide Protein Res - Pigeon Egg White Lysozyme1810mNo ratings yet

- Isolation, Fractionation, and Characterization of Xanthine Oxidase From Goat's MilkDocument6 pagesIsolation, Fractionation, and Characterization of Xanthine Oxidase From Goat's Milkfatimah arifNo ratings yet

- Ana Blanco 1995Document3 pagesAna Blanco 1995divyeshbhagat007No ratings yet

- Cheng Et Al., 2005Document6 pagesCheng Et Al., 2005Guillermo Gallardo VásquezNo ratings yet

- Amylaseactivity Gluco2Document10 pagesAmylaseactivity Gluco2DilaksNo ratings yet

- Impact of Methyl Jasmonate On Squalene Bio Synthesis in MicroalgaDocument5 pagesImpact of Methyl Jasmonate On Squalene Bio Synthesis in MicroalgaGerman ColqueNo ratings yet

- Profiling of Methyltransferases and Other S-Adenosyl - Homocysteine-Binding Proteins by Capture Compound Mass Spectrometry (CCMS)Document7 pagesProfiling of Methyltransferases and Other S-Adenosyl - Homocysteine-Binding Proteins by Capture Compound Mass Spectrometry (CCMS)Anh TranNo ratings yet

- Abu-Khudir Et Al, 2019Document16 pagesAbu-Khudir Et Al, 2019pavimathuNo ratings yet

- N-Acyl Homoserine Lactone Analog Modulators of The Pseudomonas Aeruginosa RhII Quorum Signal Synthase, Shin Et Al.Document77 pagesN-Acyl Homoserine Lactone Analog Modulators of The Pseudomonas Aeruginosa RhII Quorum Signal Synthase, Shin Et Al.deryhermawanNo ratings yet

- Biochemical Changes in Experimental Soy Sauce KojiDocument13 pagesBiochemical Changes in Experimental Soy Sauce KojiTâm Dương ĐứcNo ratings yet

- 7484 PDFDocument13 pages7484 PDFRifkarosita PutriNo ratings yet

- Characterization AcetylDocument14 pagesCharacterization AcetylhtersadrNo ratings yet

- 1971 - Cold Osmotic Shock in Saccharomyces CerevisiaeDocument8 pages1971 - Cold Osmotic Shock in Saccharomyces CerevisiaeGiancarlo GHNo ratings yet

- Silver Recovery From Waste Photographic Films by AnDocument2 pagesSilver Recovery From Waste Photographic Films by AnMuhammad Adnan LaghariNo ratings yet

- Study On The Substrate Specificity of That Contribute To Soil Removal in DetergentsDocument2 pagesStudy On The Substrate Specificity of That Contribute To Soil Removal in DetergentsmariNo ratings yet

- Or-Amylase Production in Aqueous Two-Phase Systems With: Bacillus SubtilisDocument6 pagesOr-Amylase Production in Aqueous Two-Phase Systems With: Bacillus SubtilisHong HanhNo ratings yet

- Plntphys00211 0097Document7 pagesPlntphys00211 0097yasmineat29No ratings yet

- Cristalización CuajoDocument9 pagesCristalización CuajoPablo GarcíaNo ratings yet

- Partial Characterization of Lipase From Cocoa BeanDocument6 pagesPartial Characterization of Lipase From Cocoa BeannubnubNo ratings yet

- Sterol Carrier Protein and Fatty Acid-Binding ProteinDocument7 pagesSterol Carrier Protein and Fatty Acid-Binding ProteinMartin OreNo ratings yet

- Antibacterial and Antioxidant ActivitiesDocument7 pagesAntibacterial and Antioxidant ActivitiesAshwinee KadelNo ratings yet

- Damian L 1994Document6 pagesDamian L 1994yosyNo ratings yet

- Sporo Genes'Document4 pagesSporo Genes'millodoriaNo ratings yet

- Gao Et Al. - 2008 - Purification and Characterization of Chitosanase From Bacillus Cereus D-11Document8 pagesGao Et Al. - 2008 - Purification and Characterization of Chitosanase From Bacillus Cereus D-11José Matías ZapiolaNo ratings yet

- 03 CPEnzDocument5 pages03 CPEnzPuji LestariNo ratings yet

- WINSEM2020-21 BIT3012 ELA VL2020210501829 Reference Material I 25-Mar-2021 Amylase Enzyme KineticsDocument8 pagesWINSEM2020-21 BIT3012 ELA VL2020210501829 Reference Material I 25-Mar-2021 Amylase Enzyme KineticsVijayasarathy Sampath KumarNo ratings yet

- Jurnal InternasionalDocument7 pagesJurnal InternasionalSunflowerNo ratings yet

- Plant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterFrom EverandPlant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterNo ratings yet

- Enterotoxin-Producing Staphylococcus AureusDocument17 pagesEnterotoxin-Producing Staphylococcus Aureusvignesh9489No ratings yet

- Haemophilus InfluenzaeDocument20 pagesHaemophilus Influenzaevignesh9489No ratings yet

- Erysipelothrix Rhusiopathiae: Molecular Medical Microbiology. DOI: © 2015 Elsevier Ltd. All Rights ReservedDocument14 pagesErysipelothrix Rhusiopathiae: Molecular Medical Microbiology. DOI: © 2015 Elsevier Ltd. All Rights Reservedvignesh9489No ratings yet

- Entrance Test For M.Sc. (Biotechnology) I May 2L, 2oll IDocument41 pagesEntrance Test For M.Sc. (Biotechnology) I May 2L, 2oll Ivignesh9489No ratings yet

- 4 261650026147611555 PDFDocument9 pages4 261650026147611555 PDFvignesh9489No ratings yet

- 4 261650026147611533 PDFDocument15 pages4 261650026147611533 PDFvignesh9489No ratings yet

- School RepresentativesDocument4 pagesSchool Representativesvignesh9489No ratings yet

- RDNA Technology Workshop - 28th - 30th Aug2019Document1 pageRDNA Technology Workshop - 28th - 30th Aug2019vignesh9489No ratings yet

- Integrated Pest ManagementDocument3 pagesIntegrated Pest Managementvignesh9489No ratings yet

- Rotating Biological ContactorDocument6 pagesRotating Biological Contactorvignesh9489No ratings yet

- Integrated Pest Management PDFDocument3 pagesIntegrated Pest Management PDFvignesh9489No ratings yet

- SDS-Polyacrylamide Gel Electrophoresis of ProteinsDocument9 pagesSDS-Polyacrylamide Gel Electrophoresis of ProteinsYoung LoveNo ratings yet

- 2009 ChanoseyelidDocument14 pages2009 ChanoseyelidAnne CurrayNo ratings yet

- The Isolation and Characterisation of Jacalin Artocarpus Heterophyllus Jackfruit Lectin Based On Its Charge Properties 1995 The International JournalDocument10 pagesThe Isolation and Characterisation of Jacalin Artocarpus Heterophyllus Jackfruit Lectin Based On Its Charge Properties 1995 The International JournalsfsmNo ratings yet

- SDS Page ExerciseDocument10 pagesSDS Page ExerciseJasminSutkovicNo ratings yet

- Lab Report Exp 4Document4 pagesLab Report Exp 4Brilliant SiemaNo ratings yet

- 2 MercaptoethanolDocument3 pages2 Mercaptoethanoldorelia_simonaNo ratings yet

- Agerose Gel ElectrophoresisDocument6 pagesAgerose Gel ElectrophoresisAnura BandaraNo ratings yet

- 9 DNA TroubleshootingDocument6 pages9 DNA TroubleshootingRicha AroraNo ratings yet

- Lysis Protocol With Tritonx-100Document2 pagesLysis Protocol With Tritonx-100ishfillup50No ratings yet

- Fosforo Disponible Metodo de OlsenDocument8 pagesFosforo Disponible Metodo de OlsenJose MartinezNo ratings yet

- Lecture 6 DP Protein SeperationDocument23 pagesLecture 6 DP Protein SeperationAkshayaaRaveeNo ratings yet

- Chapter 3-EnZYME Production and PURIFICATION 20141009Document58 pagesChapter 3-EnZYME Production and PURIFICATION 20141009Minh Tiến TrầnNo ratings yet

- Vol 3 Issue 7 PDFDocument114 pagesVol 3 Issue 7 PDFDwi WulandariNo ratings yet

- SDS-PAGE Gradient Gel 3-15%Document2 pagesSDS-PAGE Gradient Gel 3-15%Camha NguyenNo ratings yet

- Protein Purification TechniquesDocument102 pagesProtein Purification TechniquesDawlat SlamaNo ratings yet

- Electrophoresis 1Document8 pagesElectrophoresis 1AshpokemonNo ratings yet

- Protein PurificationDocument33 pagesProtein PurificationAaditya Vignyan VellalaNo ratings yet

- Miracle Fruit ResearchDocument9 pagesMiracle Fruit ResearchKyla de SilvaNo ratings yet

- Measuring Traction Forces in Long-Term Cell Cultures: C M and D LDocument10 pagesMeasuring Traction Forces in Long-Term Cell Cultures: C M and D Lnestor_bouNo ratings yet

- Food Chemistry 298 (2019) 125081Document11 pagesFood Chemistry 298 (2019) 125081trinh phamNo ratings yet

- Soy Proteins A Review On Composition, Aggregation and EmulsificationDocument18 pagesSoy Proteins A Review On Composition, Aggregation and EmulsificationkesdamileNo ratings yet

- Lab Long Test 1: Exercise 1: Microscopy: Cell Size Measurements and Counting CellsDocument3 pagesLab Long Test 1: Exercise 1: Microscopy: Cell Size Measurements and Counting CellsAlisha ChuganiNo ratings yet

- Clinical Applications of Capillary Electrophoresis: Methods and ProtocolsDocument270 pagesClinical Applications of Capillary Electrophoresis: Methods and Protocolshesicos100% (1)

- Mini-PROTEAN 3 Multi-Casting Chamber Instruction Manual: Catalog Number 165-4110Document10 pagesMini-PROTEAN 3 Multi-Casting Chamber Instruction Manual: Catalog Number 165-4110Mauricio GoldfederNo ratings yet

- Troubleshooting TableDocument2 pagesTroubleshooting Tableapi-3799757No ratings yet

- Erythropoietin Concentrated SolutionDocument5 pagesErythropoietin Concentrated SolutionMAHESH100% (1)

- Biochemistry 09 - Class Notes - Shodh 2.0 Batch For CSIR NET - GATE Life SciencesDocument33 pagesBiochemistry 09 - Class Notes - Shodh 2.0 Batch For CSIR NET - GATE Life SciencesSanjay Kumar RaoNo ratings yet

- Biological Techniques TechniquesDocument13 pagesBiological Techniques TechniquesDr. Dhondiba VishwanathNo ratings yet

- 1774392.PDF DanieletalDocument10 pages1774392.PDF DanieletalRegiane PinheiroNo ratings yet