Professional Documents

Culture Documents

Level Sensors 101

Level Sensors 101

Uploaded by

Rishal AliCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Level Sensors 101

Level Sensors 101

Uploaded by

Rishal AliCopyright:

Available Formats

2007-Chem-101

Level Sensors

Assignment Report

Report Title: Level Sensors

Subject: Industrial Instrumentation

Submitted By:

2007-Chem-101

Submitted To:

Dr. Naveed Ramzan

University of Engineering & Technology,

Lahore

Page | 1

www.engineering-resource.com

2007-Chem-101

Level Sensors

Abstract

A wide variety of level measurement systems are available to address the broad spectrum of

applications, accuracy needs, installation requirements, and practices. Measurement

technologies are made available in different versions to address a wide range of

measurement needs or sometimes to address just one specific application. This subsection

will attempt to define some of the general selection considerations of many available

technologies, the general forms of these technologies, and some of their general

advantages and disadvantages. As always, one must consult the specifications from the

various manufacturers for specific products and users experiences in different installations

to truly determine their applicability to measurement situations.

The family of level measurement systems can be divided into many categories: liquids or

solids level measurement, point or continuous level measurement, electromechanical or

electrical/electromagnetic level measurement, or contacting or noncontacting /nonintrusive

level measurement.

Page | 2

www.engineering-resource.com

2007-Chem-101

Level Sensors

Table of Contents

Introduction ............................................................................................................................................ 4

Classification ........................................................................................................................................... 4

Types of Sensors ..................................................................................................................................... 5

Differential Pressure ........................................................................................................................... 5

Displacement ...................................................................................................................................... 6

Float Level Sensors.............................................................................................................................. 7

Ultrasonic / Sonic ................................................................................................................................ 8

Weight and Cable ................................................................................................................................ 9

Sight Glass ........................................................................................................................................... 9

Radioactive (Nuclear) ........................................................................................................................ 10

Bubbler .............................................................................................................................................. 11

Vibration ........................................................................................................................................... 12

Rotating Paddle Level Sensors .......................................................................................................... 13

Diaphragm......................................................................................................................................... 13

Resistance Tape ................................................................................................................................ 14

Hook- Type Level Sensor ................................................................................................................... 16

Level Measurement Sensor Selection................................................................................................... 16

References ............................................................................................................................................ 17

Page | 3

www.engineering-resource.com

2007-Chem-101

Level Sensors

Introduction

Level measurement is defined as the measurement of the position of an interface between

two media. These media are typically gas and liquid, but they also could be two liquids.

Level sensors detect the level of substances that flow, including liquids, slurries, granular

materials, and powders. All such substances flow to become essentially level in their

containers (or other physical boundaries) because of gravity. The substance to be measured

can be inside a container or can be in its natural form (e.g. a river or a lake). The level

measurement can be either continuous or point values. Continuous level sensors measure

level within a specified range and determine the exact amount of substance in a certain

place, while point-level sensors only indicate whether the substance is above or below the

sensing point. Generally the latter detect levels that are excessively high or low.

There are many physical and application variables that affect the selection of the optimal

level monitoring method for industrial and commercial processes. The selection criteria

include the physical: phase (liquid, solid or slurry), temperature, pressure or vacuum,

chemistry, dielectric constant of medium, density (specific gravity) of medium, agitation,

acoustical or electrical noise, vibration, mechanical shock, tank or bin size and shape. Also

important are the application constraints: price, accuracy, appearance, response rate, ease

of calibration or programming, physical size and mounting of the instrument, monitoring or

control of continuous or discrete (point) levels.

Classification

Level devices operate under different principles. They can be classified into three main

categories

that measure

the position (height) of the surface.

the pressure head.

the weight of the material through load cells.

Page | 4

www.engineering-resource.com

2007-Chem-101

Level Sensors

Types of Sensors

Electromechanical level measurement and detection systems

Floats for level detection and measurement of liquids

Displacers for level detection and measurement of liquids

Level detection of solids using rotating paddles

Level measurement of liquids and solids using plumb bob

Electronic/electromagnetic energy level measurement and detection systems

Level detection of liquids by use of conductivity

Level detection of liquids by use of vibrating forks resonance or rod attenuation

Level detection of solids by use of vibrating fork or rod attenuation

Level detection of liquids by use of ultrasonic gap

Level detection of liquids by use of thermodispersion

Level measurement of liquids by use of bubblers

Level measurement of liquids by use of hydrostatic pressure

Ultrasonic level detection and measurement of liquids and solids

Capacitance level detection and measurement of liquids and solids

Radar level detection and measurement of liquids and solids

Level detection and measurement of liquids and solids by use of time-domain reflectometry

Level measurement of liquids by use of magnetostrictive

Level measurement of liquids by use of laser

Level detection and measurement of liquids and solids by use of radiometric

Level measurement of liquids and solids by use of weighing

Level detection by use of optics

Level detection in liquids by use of ultrasonic tank resonance [7]

Differential Pressure

Differential-pressure level measurement, also known as hydrostatic, is based on the

height of the liquid head. Level measurement in open tanks is based on the formula that the

pressure head is equal to the liquid height above the tap multiplied by the specific gravity of

the fluid being measured. In closed tanks, the true level is equal to the pressure measured

at the tank bottom minus the static pressure above the liquid surface. To compensate for

that static pressure, a leg is connected from the tank top to the low side of the differential

pressure transmitter . Two options are available: dry leg and wet leg. In dry leg applications,

it is expected that the low side will remain empty (i.e., no condensation). [1]

If condensation takes place, an error will occur because a pressure head will be created on

the low side. This error is avoided by intentionally filling the low side with a liquidhence

the term wet leg. Where filled systems (with diaphragm seals) are used between the

transmitter and the tank, calibration of the transmitter should allow for the specific gravity

of the fill fluid. The user should refer to the vendors instructions when setting the zero and

span values. [1]

Advantages/Disadvantages

Differential-pressure level measuring devices are easy to install and have a wide range of

applications. With proper modifications, such as extended diaphragm seals and flange

connections, these instruments will handle hard-to-measure fluids (e.g., viscous, slurries,

corrosive, hot). They are simple and accurate. Calibration of differential-pressure measuring

Page | 5

www.engineering-resource.com

2007-Chem-101

Level Sensors

devices is simple. Adjustments to zero, elevation/suppression, and span are easy, and no

special tools are required.

Differential-pressure measuring devices are affected by changes in density. They can only be

used for liquids with fixed specific gravity. Changes in liquid density due to changes in

temperature will introduce errors. Differential-pressure devices are susceptible to dirt or

scale entering the tubing (in small process connections), which can easily plug them. Parts of

the instrument are exposed to the process fluid, while the outside leg is susceptible to

freezing. [1]

Figure 1: Differential Pressure

Displacement

A displacer , which can be either partially or totally immersed, is restricted from moving

freely with the liquid level. It transmits its change in buoyancy (mechanical force) to a

transducer through a torque-tube unit. Sometimes the term float is used instead of

displacer. [1]

Advantages/Disadvantages

Displacers are simple, dependable, and accurate. They may be mounted internally or

externally. These level measurement can only be used for liquids with fixed specific gravity,

where accuracy is not required. A suitable drain is provided at the low point and a vent valve

at the highest point.

Displacers are difficult to calibrate and have many mechanical components. Therefore,

displacer, linkages, or levers should be free to move. Boiling liquid may cause violent

agitation at the liquid surface, so stilling wells

may be required where turbulence exists. the accuracy is also affected by coating, buildup,

or dirt. [1]

Page | 6

www.engineering-resource.com

2007-Chem-101

Level Sensors

Figure 2: Displacer

Float Level Sensors

The principle behind magnetic, mechanical, cable, and other float level sensors involves the

opening or closing of a mechanical switch, either through direct contact with the switch, or

magnetic operation of a reed. With magnetically actuated float sensors, switching occurs

when a permanent magnet sealed inside a float rises or falls to the actuation level. With a

mechanically actuated float, switching occurs as a result of the movement of a float against

a miniature (micro) switch. For both magnetic and mechanical float level sensors, chemical

compatibility, temperature, specific gravity (density), buoyancy, and viscosity affect the

selection of the stem and the float. For example, larger floats may be used with liquids with

specific gravities as low as 0.5 while still maintaining buoyancy. The choice of float material

is also influenced by temperature-induced changes in specific gravity and viscosity - changes

that directly affect buoyancy. [2]

Float-type sensors can be designed so that a shield protects the float itself from turbulence

and wave motion. Float sensors operate well in a wide variety of liquids, including corrosives.

When used for organic solvents, however, one will need to verify that these liquids are

chemically compatible with the materials used to construct the sensor. Float-style sensors

should not be used with high viscosity (thick) liquids, sludge or liquids that adhere to the

stem or floats, or materials that contain contaminants such as metal chips; other sensing

technologies are better suited for these applications. [2]

A special application of float type sensors is the determination of interface level in oil-water

separation systems. Two floats can be used with each float sized to match the specific

gravity of the oil on one hand, and the water on the other. Another special application of a

stem type float switch is the installation of temperature or pressure sensors to create a

multi-parameter sensor. Magnetic float switches are popular for simplicity, dependability

and low cost. [2]

Advantages/Disadvantages

Floats work well with clean liquids and are accurate and adaptable to wide variations in fluid

densities. Once commissioned, however, the process fluid measured must maintain its

density if repeatability is required. Float Switches are available and are capable of fail safe

operation in extreme process conditions. [2]

Page | 7

www.engineering-resource.com

2007-Chem-101

Level Sensors

Floats are affected by changes in product density since the displacement of the body is

equal to the weight of the fluid displaced. If the specific gravity changes, then the weight of

the displaced material changes, thus changing the calibration. This is especially problematic

in interface measurements, where both liquids increase or decrease density, while the signal

is proportional to the density difference.[2]

Figure 3: Float

Ultrasonic / Sonic

Ultrasonic transmitters work on the principle of sending a sound wave from a peizo electric

transducer to the contents of the vessel. The device measures the length of time it takes for

the reflected sound wave to return to the transducer. A successful measurement depends

on reflection from the process material in a straight line back to the transducer. [3]

Advantages/ Disadvantages

The main advantages of ultrasonic level instrumentation are that the transducer does not

come into contact with the process material, they have no moving parts and a single top of

vessel entry makes leaks less probable than fully wetted techniques.[3]

There are various influences that affect the return signal. Things such as powders, heavy

vapors, surface turbulence, foam and even ambient noise can affect the returning signal.

Temperature can also be a limiting factor in many process applications. Ultrasonic devices

will not operate on vacuum or high pressure applications. [3]

Figure 4 Sonic/Ultrasonic

Page | 8

www.engineering-resource.com

2007-Chem-101

Level Sensors

Weight and Cable

With the weight and cable device , a cable or tape is attached to a weight that descends into

the tank. This motion is activated by a timer. When the weight makes contact with the

surface of the material, the motor automatically reverses direction and retrieves the weight

at about 1 ft/s (0.3 m/s). During descent, pulses are generated and displayed on a counting

unit, which indicates either material stored or available filling capacity. [1]

Advantages/Disadvantages

Weight and cables are accurate devices, and they are only momentarily in contact with the

process material prevents product from building up on the weight. They can have

mechanical problems, such as hang-up and friction. They must be activated in order to

measure, and they have no signal transmission capability.

In outdoor use, measures should be taken to protect the mechanical parts of the level

measuring instruments from possible weather interference. Stilling wells are often used if

the vessel is agitated. [1]

Figure 5: Weight and Cable

Sight Glass

A sight glass or water gauge is a transparent tube through which the operator of a tank or

boiler can observe the level of liquid contained within. Simple sight glasses may be just a

plastic or glass tube connected to the bottom of the tank at one end and the top of the tank

at the other. The level of liquid in the sight glass will be the same as the level of liquid in the

tank. Today, however, sophisticated float switches have replaced sight glasses in many such

applications.[4]

Advantages/Disadvantages

Gages are used as a local indicator for open or pressurized vessels. They must be accessible

and located within visual range. Gages are cheap and provide direct-reading measurement.

However, they are not suitable for dark liquids and dirty fluids will prevent the liquid level

from being viewed. They can be easily damaged or broken.

Glass gages should not be used to measure hazardous liquids. Reflex gages are used for lowand medium-pressure applications. For high-pressure applications, or where the fluid is

toxic, magnetic-type armored gages are used. When installing such devices, good lighting is

Page | 9

www.engineering-resource.com

2007-Chem-101

Level Sensors

required. In installations where the gage is at a lower temperature than the process,

condensation may occur on the walls, making the reading difficult. [1]

Figure 6: Sight Glass

Radioactive (Nuclear)

With the radioactive (nuclear) device , a radioactive source radiates through the vessel. The

gamma quantum is seen by the radiation detector (such as a Geiger counter) and is

transformed into a signal. When the vessel is empty, the count rate is high. The radioactive

source holder is designed to direct a collimated beam of radiation toward the tank and to be

shielded in all other directions so as to reduce the radiation levels to below the legal limit.

The strength of the sensed radiation depends on the thickness of the vessel wall, the

distance between the source and detector, and the density and thickness of the measured

material. The radiation source generally has a half-life of 30 years; therefore, corrections for

source decay are rarely required. [1]

Advantages/Disadvantages

Radioactive level measurement is external device. It can be added or removed without

disturbing the process. Radioactive (nuclear) devices are highly reliable, non-contacting

devices with no moving parts. They are unaffected by temperature, pressure, and corrosion,

and their mode of failure is limited and predictable.

Radioactive (nuclear) devices require special engineering and licensing for the application

they are used with, and extreme care is required when locating and installing the

radioactive source. Operator exposure to radiation must be minimized, and therefore,

plants may need shielding lead plates at the source or detector. Radioactive (nuclear) units

are expensive to install. They are expensive and they are difficult to calibrate. On vessels

larger than 30 ft (10 m) in diameter or on vessels with extremely thick walls, the source may

have to be suspended vertically inside the vessel. [1]

Page | 10

www.engineering-resource.com

2007-Chem-101

Level Sensors

Figure 7: Radioactive

Bubbler

In a bubbler , a small amount of air (or inert gas) purge flows through a dip tube in the

vessel. Sometimes, to provide rigidity, a stand pipe is used instead of a dip tube. The dip

tube (or pipe) generally extends to about 3 inches (75 mm) from the bottom of the tank and

is notched to keep the size of the air bubble small. The pressure that is required to force air

bubbles from the bottom of the tube is the liquid head above the end of the tube. A purge

meter, which consists of a rota meter with a needle valve, is required to provide a constant

airflow of about 0.2 to 2.0 scfh (0.005 to 0.05 m3/hr). A pressure regulator located upstream

of the purge meter provides a smooth operation. In plants where remote level indication is

required, the high-pressure side of the differential-pressure transmitter measures the tube

pressure, and the low side measures the vessels top pressure, if it is not vented to the

atmosphere. [1]

Advantages/Disadvantages

The bubbler offers low cost and easy maintenance. It can be operate without electrical

power. It can be used on pressurized or unpressurized vessels. Variations in density will

affect the bubblers reading. Bubblers can become coated or plugged by process fluid

residue or dirt. The cost of purging fluid is ongoing, and the purge gas can introduce

unwanted components into the process. The materials

of construction for the bubbler must be compatible with the process it is used in, and the

bubblers dip tube installation must be capable of withstanding the maximum air pressure

that blockage causes. A tee piece at the top of the dip tube (or pipe) may be required to

enable rodding. [1]

Page | 11

www.engineering-resource.com

2007-Chem-101

Level Sensors

Figure 8: Bubbler

Vibration

Vibration devices consist of a tuning fork that vibrates at its natural resonant frequency by a

piezoelectric crystal, which is located at the base of the probe. When the vibrating fork

contacts a material, either dry or in suspension (20% minimum), the vibration frequency is

altered, which switches a relay. The material needs to have a bulk density of 0.9 lb/ft (12.8

kg/m) or greater. When the level drops below the fork, the vibrating frequency is again in

effect, and the relay is reversed. [1]

Advantages/Disadvantages

Vibration units have no moving parts, are rugged and reliable, are good for low-density

materials, and require little maintenance. They cannot be used in vibrating bins, especially if

the two frequencies are close. Product buildup will affect the performance of vibration units,

the switch setting cannot be readily changed, and vibration units typically require protection

from materials that are charged from the top. [1]

Figure 9: Vibration

Page | 12

www.engineering-resource.com

2007-Chem-101

Level Sensors

Rotating Paddle Level Sensors

Rotating paddle level sensors are a very old and established technique for bulk solid point

level indication. The technique requires a low speed gear motor that rotates a paddle wheel.

When the paddle is stalled by solid materials, the motor is rotated on its shaft by its own

torque until a flange mounted on the motor contacts a mechanical switch. The paddle can

be constructed from a variety of materials, but tacky material must not be allowed to build

up on the paddle. Build up may occur if the process material becomes tacky because of high

moisture levels or high ambient humidity in the hopper. For materials with very low bulk

densities (very low weight per unit volume) such as Pearlite, Bentonite or fly ash, the weight

of the material is insufficient to stop the paddle. For such difficult applications, special

paddle designs and the use of lower-torque motors can be employed. Fine particles or dust

must be prevented from penetrating the shaft bearings and motor by proper placement of

the paddle in the hopper or bin and using appropriate sealing technology.[3]

Advantages/Disadvantages

A paddle wheel is inexpensive, simple, and reliable. It is susceptible to shock, vibration, and

damage by falling material. Paddle wheels generally require some protection(e.g., a

protective baffle) from material charging from the top. Hang-ups or material buildup on the

paddle will affect the device performance.

Figure 10: Paddle Wheel

Diaphragm

The diaphragm is a point measurement device. The process materials (or hydrostatic

pressure) apply pressure on a diaphragm, which in turn actuates a switch. [1]

Advantages/Disadvantages

The diaphragm is reliable, easy to maintain. Coating may affect the flexing of the diaphragm,

and abrasive material may affect its performance. The accuracy of the unit is affected by

changes in specific gravity.

The diaphragm must be in contact with the material. It should be at least 2 to 3 in. (50 to

75mm.) above any sediment in the vessel bottom to prevent dirt from building up at the

diaphragm. [1]

Page | 13

www.engineering-resource.com

2007-Chem-101

Level Sensors

Figure 11: Diaphragm

Resistance Tape

The resistance-tape material level sensor with which the invention is employed is sold

commercially and is known as a "Metritape" sensor,

The Metritape sensor comprises an elongated metallic base strip having electrical insulation

on the edges and back of the strip to define an un-insulated zone along the length of the

base strip, and a resistance wire or ribbon helically wound around the insulated base strip,

with the helical turns bridging the insulated edge portions being spaced from the underlying

un-insulated zone of the base strip. This sensor structure is enclosed within a continuous

polymeric or other protective sleeve to provide a clean and dry inner chamber for the

sensor. The sensor is disposed within a tank or vessel containing the liquid or fluent material,

the level of which is to be monitored. The pressure of the material surrounding the

immersed sensor causes the deflection of the enclosing sleeve and helical turns in the

immersed portion of the sensor into engagement and electrical contact with the underlying

base strip, such that an electrical resistance proportional to material level is provided.[5]

Advantages/Disadvantages

A resistance tape will handle corrosive liquids and slurries. It must contact the material and

is susceptible to moisture getting inside the tape. Resistance tape devices are affected by

changes in specific gravity, are not suitable for flammable atmospheres, and are neither

accurate nor rugged. They require careful engineering and careful installation. Plants may

need to use stilling if turbulence exists. [1]

Page | 14

www.engineering-resource.com

2007-Chem-101

Level Sensors

Figure 12: Resistance tape

Laser

There are two types of laser measurement pulsed and continuous wave (frequency

modulated). In industrial applications, the pulsed-type is the most common because of its

range and ability to penetrate through vapors and dust.

The pulsed-type laser operates as follows: its transmitter emits a continuous series of pulses

at a target. The time taken by each pulse to travel from the transmitter to the target (e.g.,

the liquid surface) and back is measured and converted into distance.

The continuous wave laser consists of a transmitter that emits a continuous laser beam at

the target. When the beam hits the target, phase-shifting occurs. Based on the degree of

phase shift and on other constant parameters such as wave frequency, the device

determines the distance of the target and therefore level. [1]

Advantages/Disadvantages

Laser transducers mounted outside a metal vessel can measure level through a processrated sight glass. This means the laser unit can be accessed without having to interrupt the

process. Laser-type level measurement uses an extremely short wavelength and produces a

very narrow beam. These features provide very good accuracy and non-contact

measurement for difficult applications.

Lasers are relatively expensive, though still better then radioactive (nuclear) types.[1]

Figure 13: Laser

Page | 15

www.engineering-resource.com

2007-Chem-101

Level Sensors

Hook- Type Level Sensor

Hook- Type level Indicator consists of a wire of corrosion resistance alloy bent into U-shaped

with one arm longer than the other. The shorter arm is pointed with 60 degrees while the

longer is attached to a slider on a Vernier scale, which moves over the main scale and shows

the reading. [6]

In this type of sensor the hook is pushed below the surface of the liquid whose level is to be

measured and gradually raised until the point is just about to break through the surface.

This principle is also utilized in measuring point manometer in which measuring point

consists of a steel point fixed with the point upward underneath the water surface. [6]

Level Measurement Sensor Selection

General considerations in level measurement technology selection

Density and viscosity

Chemical composition

Ambient temperature

Process temperature

Process pressure

Regulated environments

Process agitation

Vapor, mist, and dust

Interfaces and gradients

Process conductivity and dielectric constants

Vibration

Material buildup or stickiness

Static charge

Humidity/moisture

Repeatability, stability and accuracy requirements

Page | 16

www.engineering-resource.com

2007-Chem-101

Level Sensors

References

1. Battikha, N. E., The Condensed Handbook of Measurement and Control; Publisher

ISA: The Instrumentation, Systems, and Automation Society (2006); 3rd Ed., pg. 99121

2. http://www.iceweb.com.au/technical.html (retrieved on 05-11-2010)

3. http://www.iceweb.com.au/Level/LevelWeb.htm (retrieved on 05-11-2010)

4. http://en.wikipedia.org/wiki/Sight_glass#cite_note-bell (retrieved on 06-11-2010)

5. Edwin P. Dews, N.H. William.E.Pierce, D. Ehrenfried, (1990), United States Patent, p

6

6. Singh, S. K., Industrial Instrumentation and Control; McGraw Hill Publishing

Company Limited; 2nd edition, pg. 225; 226

7. McMillan, Gregory K. , Process/Industrial Instruments and Controls Handbook;

McGraw Hill Publishing Company Ltd; 5th Ed. , pg. 155 Section 4

Page | 17

www.engineering-resource.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- THM 200 4RDocument96 pagesTHM 200 4Rerick alexander hernandez100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- My Atlas: Mount Guide International SchoolDocument1 pageMy Atlas: Mount Guide International SchoolRishal AliNo ratings yet

- Avts Biodata FormDocument1 pageAvts Biodata FormRishal AliNo ratings yet

- Study On Downhole Multi-Sensor Monitoring and Data Transmission of Electric Submersible PumpDocument4 pagesStudy On Downhole Multi-Sensor Monitoring and Data Transmission of Electric Submersible PumpRishal AliNo ratings yet

- Butterfly Valve SpecificationDocument6 pagesButterfly Valve SpecificationRishal AliNo ratings yet

- Media Studies Notes-Class: Co-Owner of A Lonely Heart and DR Who: An Unearthly ChildDocument3 pagesMedia Studies Notes-Class: Co-Owner of A Lonely Heart and DR Who: An Unearthly ChildAksharaNo ratings yet

- Manual Inglés APM - V3.6Document73 pagesManual Inglés APM - V3.6Implementación OLCNo ratings yet

- Negotiating Mobile Identity in The Global Nightscape: Krzysztof Z. JankowskiDocument9 pagesNegotiating Mobile Identity in The Global Nightscape: Krzysztof Z. JankowskiAlex YiuNo ratings yet

- Rank Name Net Worth Billones AgeDocument79 pagesRank Name Net Worth Billones AgeANGIE KATHERINE MU�OZ TORRESNo ratings yet

- C FB BrochureDocument20 pagesC FB BrochureböhmitNo ratings yet

- Material Safety Data Sheet: Poly Aluminium ChlorideDocument4 pagesMaterial Safety Data Sheet: Poly Aluminium Chloridehinur awaNo ratings yet

- Brann, Kalkavage, Salem - Plato's Sophist or The Professor of WisdomDocument102 pagesBrann, Kalkavage, Salem - Plato's Sophist or The Professor of WisdomMichael Wiitala100% (1)

- Safety Data Sheet: Musol SolventDocument15 pagesSafety Data Sheet: Musol SolventHưng Lê TrungNo ratings yet

- Android-Based Classroom Monitoring System For Teacher Using QR Code TechnologyDocument12 pagesAndroid-Based Classroom Monitoring System For Teacher Using QR Code TechnologyAkmad Ali AbdulNo ratings yet

- Research Proposal FinalDocument53 pagesResearch Proposal FinalKamira Sulait Kyepa100% (1)

- Jetjat Live-W: Owner's ManualDocument34 pagesJetjat Live-W: Owner's ManualEdison BonillaNo ratings yet

- HVAC Value EngineeringDocument2 pagesHVAC Value EngineeringamarandmoazNo ratings yet

- 5 AM Club SummaryDocument2 pages5 AM Club SummaryShaher Yar Ahmad75% (4)

- Importance of Training and DevelopmentDocument4 pagesImportance of Training and DevelopmentAnnaIzzatNo ratings yet

- Database Programming With SQL 2-3: Limit Rows Selected Practice ActivitiesDocument2 pagesDatabase Programming With SQL 2-3: Limit Rows Selected Practice ActivitiesIrfan J SaputraNo ratings yet

- Leadership AssignmentDocument3 pagesLeadership AssignmentDavidNo ratings yet

- Project Management: by Jagmohan BhatiaDocument16 pagesProject Management: by Jagmohan BhatiaAkashdeep SinghNo ratings yet

- Systematic and Random ErrorsDocument19 pagesSystematic and Random ErrorsБейбарыс КиякбаевNo ratings yet

- Kent Scientific Catalog 2009Document68 pagesKent Scientific Catalog 2009Syah MiNo ratings yet

- Scheduling: Organization. It Relates To The Use of Equipment, Facilities, and Human ActivitiesDocument8 pagesScheduling: Organization. It Relates To The Use of Equipment, Facilities, and Human ActivitiesRafiaNo ratings yet

- Saarthi - Excel AssignmentDocument17 pagesSaarthi - Excel AssignmentBHUMIT KATARIANo ratings yet

- LyserDocument3 pagesLyserRosemarie EustaquioNo ratings yet

- Chirana CheeseDocument2 pagesChirana CheeseElena HalmaghiNo ratings yet

- Building Thinking Classrooms: Conditions For Problem SolvingDocument27 pagesBuilding Thinking Classrooms: Conditions For Problem SolvingmattroihuongdongNo ratings yet

- High Speed Centrifugal Spray DryerDocument8 pagesHigh Speed Centrifugal Spray DryerHilyaNo ratings yet

- Work Experience: Birth Date: Birth Place: Age: Civil Status: Nationality: Height: Language SpokenDocument2 pagesWork Experience: Birth Date: Birth Place: Age: Civil Status: Nationality: Height: Language SpokenJohn De LeonNo ratings yet

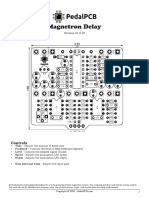

- Magnetron Delay: Revision 10.13.20Document5 pagesMagnetron Delay: Revision 10.13.20manecolooperNo ratings yet

- Unequal EnglishesDocument279 pagesUnequal EnglishesDr-Hasan AbbasNo ratings yet

- Parts Catalog: 25 HP (521cc) 2 Stroke ModelsDocument32 pagesParts Catalog: 25 HP (521cc) 2 Stroke ModelsRonei MartinsNo ratings yet