Professional Documents

Culture Documents

04 Pneumatic Testing Procedure Shell OK

04 Pneumatic Testing Procedure Shell OK

Uploaded by

Eduardo GarciaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 Pneumatic Testing Procedure Shell OK

04 Pneumatic Testing Procedure Shell OK

Uploaded by

Eduardo GarciaCopyright:

Available Formats

CROMANZA S.A.

Industrial Service and

DE C.V.

Maintenance

Pneumatic Test on Reinforcing

Pads

Procedure

Rev.

Date

Page

Index

CONTENTS

SHEET

1. Purpose.

2. Scope

3. Applicable Documents.

4. Responsibilities

.

5. Definitions

6. Procedure

7. Acceptance

Criteria

8. Records

.

8.1.

Forms: .

04

0

06/12/2015

1 of 6

CROMANZA S.A.

Industrial Service and

DE C.V.

Maintenance

Pneumatic Test on Reinforcing

Pads

Procedure

Rev.

Date

Page

04

0

06/12/2015

2 of 6

1. PURPOSE

The purpose of this document is to reinforcing the activities that will be carried out

for the performance of the pneumatic tests that are required on reinforcement pads

of nozzles, saddles, attachments etc.

2. SCOPE

This procedure applies in all pneumatic test performed on reinforcement pads by

Cromanza, S.A. de C.V.., at shop and field site, in accordance with ASME Section

VIII Div. 1 and purchaser specifications.

3. APPLICABLE DOCUMENTS

- Chapter 4, 9, and 10, of the Quality Control System Manual

- Section VIII Division 1, of the ASME Code, for Boiler and Pressure Vessels 2013

Edition

4. RESPONSIBILITIES

-

Quality Control Manager shall be responsible the revision and approval, and

updating of this procedure and approval of test certificates, witnessing of test by

himself or his designee.

Coordinate all activities related to the verification and record of pneumatic tests,

preparation and preservation of calibrated gages in accordance with this

procedure. Also, review of test certificates their filling and preservation.

Engineering Manager shall establish fabrication drawings, the test pressure

rate and special instructions when applicable, to which the equipment or

component will be tested, in accordance to applicable Customer and Code

requirements.

Construction Manager shall be responsible for the preparation of pads to be

tested, installation of test gages and/or recorders.

CROMANZA S.A.

Industrial Service and

DE C.V.

Maintenance

Pneumatic Test on Reinforcing

Pads

Procedure

Rev.

Date

Page

04

0

06/12/2015

3 of 6

5. DEFINITIONS

The following definitions are applicable to this document:

LEAK: Is the evidence that a fluid is passing from on side to another in a closed

vessel, independent the amount of fluid.

6. PROCEDURE

The inspection area shall be clean and free of dirt, oxidation, scale, slag, splatters,

oil or other foreigner materials that can hide weld defects.

The reinforcement pad shall have one threaded hole of NPT in that which shall

be applied the air at least to 15 psi for a sufficient time to permit inspection of the

welds.

The examination shall be made using soaps suds looking for any leakage inside

and outside of the nozzle and on the pipe neck to reinforcement pad weld, and the

reinforcement pad to vessel weld.

7. ACCEPTANCE CRITERIAL

No leaks are permitted. In the case that is detected any leak, this one has to be

repaired using approved welding procedure, and retested using the procedure

described above.

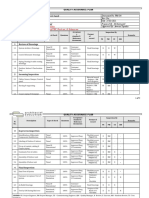

8. RECORDS

All the records and other documents originated by the activities described in this

procedure shall be maintained by the Quality Control Manager on Job File and shall

be properly filled.

8.1.

FORMS

The Pneumatic Test results shall be recorder in the Traveler Sheet; acceptance

of the test is obtained by signature and dated in the document

CROMANZA S.A.

Industrial Service and

DE C.V.

Maintenance

Pneumatic Test on Reinforcing

Pads

Procedure

Rev.

Date

Page

04

0

06/12/2015

4 of 6

CROMANZA S.A.

Industrial Service and

DE C.V.

Maintenance

Pneumatic Test on Reinforcing

Pads

Procedure

Rev.

Date

Page

04

0

06/12/2015

5 of 6

CROMANZA S.A.

Industrial Service and

DE C.V.

Maintenance

Pneumatic Test on Reinforcing

Pads

Approved By

Quality Control Manager

Authorized Inspector

Sign

Date

Rev

.

1

0

Date

Approve

d

Reviewe

d

Remarks

06/012/20

15

S.G.P.

S.A.R.

Initial Emission

Procedure

Rev.

Date

Page

04

0

06/12/2015

6 of 6

You might also like

- RA 024 Risk Assessment - Precast Concrete WorksDocument14 pagesRA 024 Risk Assessment - Precast Concrete Worksthomson80% (10)

- Inspection Checklist For Concrete Placement Pre & Post PlacementDocument4 pagesInspection Checklist For Concrete Placement Pre & Post PlacementUsman ShahidNo ratings yet

- Procedure For Magnetic Particle Examination 1.0 SCOPEDocument3 pagesProcedure For Magnetic Particle Examination 1.0 SCOPEpmkar100% (1)

- Blasting and Painting Procedure CompleteDocument128 pagesBlasting and Painting Procedure CompletenuntaricherdchaiNo ratings yet

- Updated QAQC FormatDocument16 pagesUpdated QAQC FormatAkash Singh TomarNo ratings yet

- Arita Katalog Building - SmallDocument16 pagesArita Katalog Building - SmallAlamsyah PutraNo ratings yet

- Hydrotest QI304-sampleDocument3 pagesHydrotest QI304-sampleHanuman Rao100% (1)

- Katalog ARITA 20199Document68 pagesKatalog ARITA 20199Fresly JayaNo ratings yet

- Test Certificate 01Document1 pageTest Certificate 01Anoop RaghuNo ratings yet

- Client: Job No.: Job Title: Client's Job No.:: Company NameDocument13 pagesClient: Job No.: Job Title: Client's Job No.:: Company NamejorgekarlosprNo ratings yet

- Lot Inspection Report For LPG New CylindersDocument3 pagesLot Inspection Report For LPG New CylindersJagannath MajhiNo ratings yet

- Fit Up ReportDocument76 pagesFit Up Reportvinas kusdinarNo ratings yet

- Prefabricacion y Montaje de Tuberias HDPE Por Electrofusion (Ingles)Document10 pagesPrefabricacion y Montaje de Tuberias HDPE Por Electrofusion (Ingles)Kike BúNo ratings yet

- MSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryDocument1 pageMSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryMohd SaffririzalNo ratings yet

- Oil Penetrant Test ProcedureDocument4 pagesOil Penetrant Test Procedurehasan_676489616No ratings yet

- ITP For Ball Valves - (ON-OFF) - 32 Inch NGL Pipeline PDFDocument3 pagesITP For Ball Valves - (ON-OFF) - 32 Inch NGL Pipeline PDFGordon LongforganNo ratings yet

- Sa01 Genxxx SDGG PRTS 0107 V00Document7 pagesSa01 Genxxx SDGG PRTS 0107 V00amini_mohiNo ratings yet

- Made in Italy - EuropeDocument8 pagesMade in Italy - EuropeenenickNo ratings yet

- Project GuidelineDocument7 pagesProject GuidelineNg Kee NainNo ratings yet

- WOPQ Form English1Document2 pagesWOPQ Form English1oaperuchenaNo ratings yet

- Daftar Harga Fire Hydrant AppronDocument2 pagesDaftar Harga Fire Hydrant AppronWeri IsvebriantiNo ratings yet

- Weld RepairDocument2 pagesWeld RepairAnurag YadavNo ratings yet

- Project Report On Threading Drill PipesDocument34 pagesProject Report On Threading Drill PipesVamshi KrishnaNo ratings yet

- WI-08 - Work Instruction For Use of UTM 18.03.2021Document1 pageWI-08 - Work Instruction For Use of UTM 18.03.2021Saurav KumarNo ratings yet

- Original: Mill Test CertificateDocument3 pagesOriginal: Mill Test CertificateAhmad NafilulhudaNo ratings yet

- 8-Piping Final InspectionDocument1 page8-Piping Final InspectionM.A.NNo ratings yet

- RF Pad Test ReportDocument1 pageRF Pad Test ReportKarthik100% (1)

- Drawing Pressure Vessel 1 PDFDocument8 pagesDrawing Pressure Vessel 1 PDFMonica R ZelaNo ratings yet

- Sample WPS 1Document13 pagesSample WPS 1waqas pirachaNo ratings yet

- List Certificates of Werder QualificationDocument2 pagesList Certificates of Werder QualificationMuhammad FajarNo ratings yet

- Receiving Material Procedure CoverDocument1 pageReceiving Material Procedure Covergst ajahNo ratings yet

- Risks in Facility Build Quality and Project Handover: What Happened?Document3 pagesRisks in Facility Build Quality and Project Handover: What Happened?musaismail8863No ratings yet

- Tie in MosDocument2 pagesTie in MosAAISATNo ratings yet

- Test Pack Clearance FormatDocument2 pagesTest Pack Clearance FormatKarthikNo ratings yet

- Soal CswipDocument1 pageSoal Cswipakun jeparaNo ratings yet

- Shop ItpDocument4 pagesShop ItpRanu JanuarNo ratings yet

- GSB-Form-246 Dimension Inspection Report (Circum)Document1 pageGSB-Form-246 Dimension Inspection Report (Circum)Made GileeNo ratings yet

- Inspectation Test PlanDocument1 pageInspectation Test Planazimr157No ratings yet

- Itp PWHTDocument1 pageItp PWHTTridib DeyNo ratings yet

- BMID Hydrant Test FormDocument2 pagesBMID Hydrant Test FormSheikh Faiz RockerNo ratings yet

- Hydrostatic Test Report: Project Description Job Order No. Test Date Qty EquipmentDocument1 pageHydrostatic Test Report: Project Description Job Order No. Test Date Qty EquipmentgjoeNo ratings yet

- ITP-format For VesselsDocument5 pagesITP-format For VesselsHanuman RaoNo ratings yet

- FInal QAP HDPE WeldingDocument2 pagesFInal QAP HDPE Weldingkannagi198No ratings yet

- Docslide - Us - Itp Structural WorkDocument4 pagesDocslide - Us - Itp Structural Workomda4wadyNo ratings yet

- Welcome To: Training Program On GUIDED TOUR OF Asme CodesDocument120 pagesWelcome To: Training Program On GUIDED TOUR OF Asme CodesDiego HenriqueNo ratings yet

- Katalog Aksesoris HydrantDocument21 pagesKatalog Aksesoris HydrantPratikno SajaNo ratings yet

- Inspection & Test Plan: Dangote Oil Refinery CompanyDocument7 pagesInspection & Test Plan: Dangote Oil Refinery CompanyGowtham VenkatNo ratings yet

- Re-Welding, Expansion & HT ProcedureDocument6 pagesRe-Welding, Expansion & HT Proceduresuria qaqcNo ratings yet

- Basics - Dew Point Measurement - P60 P63 PDFDocument4 pagesBasics - Dew Point Measurement - P60 P63 PDFAnonymous o38k1iEKFNo ratings yet

- Quality Plan and Checklist (HVAC) - Sandvik G BlockDocument3 pagesQuality Plan and Checklist (HVAC) - Sandvik G BlockParasNo ratings yet

- Sprinkler System - General InformationDocument5 pagesSprinkler System - General InformationshahidenterNo ratings yet

- Fire Hydrant SpecsDocument7 pagesFire Hydrant SpecsMajuraNo ratings yet

- Fire Hydrantl Inspection ChecklistDocument1 pageFire Hydrantl Inspection ChecklistKurt StanburyNo ratings yet

- Hydrotest Presentation REV1Document21 pagesHydrotest Presentation REV1Marsya MasyitaNo ratings yet

- Ug PipingDocument1 pageUg PipingVinoth KumarNo ratings yet

- ContractorsAbovegroundPiping PDFDocument2 pagesContractorsAbovegroundPiping PDFIvan SFNo ratings yet

- Minimum Number of Thermocouples-Local PWHTDocument5 pagesMinimum Number of Thermocouples-Local PWHTPradip Goswami100% (1)

- Request For NDT Test FormDocument1 pageRequest For NDT Test FormJohn OliverNo ratings yet

- Handover To QAQC-Anand KumarDocument6 pagesHandover To QAQC-Anand KumarAnonymous fBkcEze1No ratings yet

- HDPE Butt Fusion Weld Inspection and Imaging PDFDocument19 pagesHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdNo ratings yet

- PDF 04 Pneumatic Testing Procedure Shell Ok 4 DLDocument6 pagesPDF 04 Pneumatic Testing Procedure Shell Ok 4 DLAmin ThabetNo ratings yet

- Method Statemant HydroDocument8 pagesMethod Statemant Hydrojay_rajeshirkeNo ratings yet

- TRIBOX Thermoplastic Enclosure - 2021Document16 pagesTRIBOX Thermoplastic Enclosure - 2021VBANo ratings yet

- Asme B36.10M-2018Document36 pagesAsme B36.10M-2018امينNo ratings yet

- The Book of Stone: Stancliffe Stone Company LTDDocument13 pagesThe Book of Stone: Stancliffe Stone Company LTDrizone83No ratings yet

- Tipolo WH Gantt ChartDocument15 pagesTipolo WH Gantt ChartMayeterisk RNo ratings yet

- Gaqe of Angle-StandardDocument1 pageGaqe of Angle-StandardjcNo ratings yet

- Pressure Regulators: Gas Ounces Back Pressure To Atmosphere W/Outside SupplyDocument7 pagesPressure Regulators: Gas Ounces Back Pressure To Atmosphere W/Outside SupplySantiago Mateo Enciso AvilaNo ratings yet

- A 416 A416-M - 99Document5 pagesA 416 A416-M - 99Tan Tanju100% (1)

- Concrete Cube Testing & NDT: Ravi RanadeDocument18 pagesConcrete Cube Testing & NDT: Ravi RanadeShashi KumarNo ratings yet

- CE LawsDocument2 pagesCE LawsMichael Christian MercadoNo ratings yet

- P CSL Datasheet Factory Splicing JointingDocument2 pagesP CSL Datasheet Factory Splicing Jointingzym3344No ratings yet

- Property Name: Die Casting Centrifugal Casting Investment CastingDocument11 pagesProperty Name: Die Casting Centrifugal Casting Investment CastingjohnblackburnNo ratings yet

- Shaft Footing ExampleDocument10 pagesShaft Footing Exampleอภิรักษ์ มานะกิจศิริสุทธิNo ratings yet

- Curriculum Vitae: Michael H. ScottDocument8 pagesCurriculum Vitae: Michael H. ScottAngga Fajar SetiawanNo ratings yet

- RC Design U 2017 v13.2Document74 pagesRC Design U 2017 v13.2MazenMowafyNo ratings yet

- Assignment No.3Document17 pagesAssignment No.3simon maaaklaNo ratings yet

- Ballastless TrackDocument190 pagesBallastless TrackADEN BANDEL100% (1)

- CGBM Revised NoteDocument10 pagesCGBM Revised NoteSunil Bose100% (2)

- JINGONA CE168P-2 A3 WBS-Chart PDFDocument1 pageJINGONA CE168P-2 A3 WBS-Chart PDFFatimah Rahima JingonaNo ratings yet

- IS800 - 2007 - Tube - Detailed Calculation PDFDocument4 pagesIS800 - 2007 - Tube - Detailed Calculation PDFLandon MitchellNo ratings yet

- Classified2020 3 14476666.Document1 pageClassified2020 3 14476666.udmanNo ratings yet

- Important Open Book Quiz API 650 653Document2 pagesImportant Open Book Quiz API 650 653Basel MohammadNo ratings yet

- RC BeamDocument5 pagesRC BeamvikasNo ratings yet

- 101 College Street CD CommitteeDocument18 pages101 College Street CD CommitteeHelen BennettNo ratings yet

- Performance of Partially Replaced Plastic Bottoles (Pet) As Coarse Aggregate in Producing ConcreteDocument10 pagesPerformance of Partially Replaced Plastic Bottoles (Pet) As Coarse Aggregate in Producing ConcreteShakil Bin AzizNo ratings yet

- Alarm Valve: Model: Sdh-AvaDocument14 pagesAlarm Valve: Model: Sdh-AvaRolandNo ratings yet

- Anchoring Conditions: Non-Cracked Concrete 25 6 900 115 100 10 190 40 31.66667 6.666667 150 Hilti HIT-RE 500-SDDocument11 pagesAnchoring Conditions: Non-Cracked Concrete 25 6 900 115 100 10 190 40 31.66667 6.666667 150 Hilti HIT-RE 500-SDTimothy PinchinNo ratings yet

- Instruction Manual (Centrifugal Pump-E)Document16 pagesInstruction Manual (Centrifugal Pump-E)Naman BajpaiNo ratings yet

- Architecture in Cambridge - Examples of Architectural Styles From Saxon To Modern TimesDocument139 pagesArchitecture in Cambridge - Examples of Architectural Styles From Saxon To Modern TimesArnav DasaurNo ratings yet