Professional Documents

Culture Documents

Note 27 Tuning of Individual Inlet and Exhaust Systems: Car Engine Tuning - The 1922 Miller 183

Note 27 Tuning of Individual Inlet and Exhaust Systems: Car Engine Tuning - The 1922 Miller 183

Uploaded by

Nurul FuadiahCopyright:

Available Formats

You might also like

- 2015 N13 Engine Engine Service ManualDocument1,259 pages2015 N13 Engine Engine Service ManualJonathan Luiz Poleza67% (3)

- Mtu Series 60 MarineDocument5 pagesMtu Series 60 MarineMuhammad rizki0% (1)

- Mercury Four & Six Cylinder (1955-1965) Old Outboard MotorDocument14 pagesMercury Four & Six Cylinder (1955-1965) Old Outboard MotorLinus0% (1)

- TD27 EngineDocument67 pagesTD27 EngineПетр83% (6)

- 11570-Navistar MaxxForce DT-9 DT-10 2014Document577 pages11570-Navistar MaxxForce DT-9 DT-10 2014Lester Noel100% (4)

- Kohler Carburetor Reference Manual TP-2377-EDocument60 pagesKohler Carburetor Reference Manual TP-2377-EChevronelle100% (1)

- Ford PushrodDocument7 pagesFord PushrodLouise Ellis-Rix50% (2)

- Matchless MotorcyclesDocument44 pagesMatchless Motorcyclesisland14No ratings yet

- A Brief History of Aircraft Carburetors and Fuel SystemsDocument13 pagesA Brief History of Aircraft Carburetors and Fuel SystemsbnolascoNo ratings yet

- Ford Kent CrossflowDocument6 pagesFord Kent CrossflowSean OsborneNo ratings yet

- Allison v-1710 Aircraft EngineDocument10 pagesAllison v-1710 Aircraft EngineWilliamNo ratings yet

- Type - 9 - Gearbox To Essex v6Document11 pagesType - 9 - Gearbox To Essex v6aakk75No ratings yet

- Matchless 1939 1955 Manual de Reparatie WWW - Manualedereparatie.info NoRestrictionDocument60 pagesMatchless 1939 1955 Manual de Reparatie WWW - Manualedereparatie.info NoRestrictionBhavesh Hathiwala67% (3)

- Technical Data: @perkinsDocument6 pagesTechnical Data: @perkinsHendra SyalalaNo ratings yet

- CAT 3412 Air Inlet and Exhaust SystemDocument8 pagesCAT 3412 Air Inlet and Exhaust SystemCEVegaO100% (2)

- Diesel Engine and Components: Series Paragraphs 51-53Document9 pagesDiesel Engine and Components: Series Paragraphs 51-53Branko MikulinjakNo ratings yet

- TOYOTA Technical Training - Exhaust Gas Recirculation (EGR) System DiagnosisDocument12 pagesTOYOTA Technical Training - Exhaust Gas Recirculation (EGR) System DiagnosisEbag333100% (2)

- Dodge A500 Transmission HistoryDocument7 pagesDodge A500 Transmission Historymobile_filesNo ratings yet

- Later Single-Cylinder EnginesDocument14 pagesLater Single-Cylinder EnginesImade EmadeNo ratings yet

- Cosworth StoryDocument32 pagesCosworth StoryTanoV12-Formula1AmarcordNo ratings yet

- Engine TypesDocument4 pagesEngine TypesRoss GrimmettNo ratings yet

- Formula One Grand Prix Motor Racing Fédération Internationale de L'automobile Formula One RegulationsDocument5 pagesFormula One Grand Prix Motor Racing Fédération Internationale de L'automobile Formula One RegulationsAmitkumar VermaNo ratings yet

- Mec 523Document88 pagesMec 523Saman BrookhimNo ratings yet

- The Deltic EngineDocument15 pagesThe Deltic Enginedshmkh_prynk100% (1)

- Formula One Engines WikipediaDocument14 pagesFormula One Engines Wikipediaantoniocdof1No ratings yet

- Engine HistoryDocument9 pagesEngine HistorycowpunchrNo ratings yet

- America's First OSCA'sDocument17 pagesAmerica's First OSCA'sSteveNo ratings yet

- Cosworthstory PDFDocument25 pagesCosworthstory PDFmicheleNo ratings yet

- EPA HQ OAR 2015 0827 0548 - ContentDocument16 pagesEPA HQ OAR 2015 0827 0548 - ContentStephen RivettNo ratings yet

- AMC Straight-4 Engine - WikipediaDocument5 pagesAMC Straight-4 Engine - WikipediaJordan4444409No ratings yet

- The Simson Story and The Simson Awo 425 97-2003 Version 2Document48 pagesThe Simson Story and The Simson Awo 425 97-2003 Version 2hellenaSRNo ratings yet

- ST TA2 1 Experimental V4x Stirling EngineDocument12 pagesST TA2 1 Experimental V4x Stirling EnginesynkanNo ratings yet

- Turbo ChargersDocument16 pagesTurbo ChargersNaishadh J Desai AnD's100% (1)

- Hyper EngineDocument3 pagesHyper EnginetorrefacaomerendaNo ratings yet

- CH 1 Engine Types and Operating Parameter - 1Document79 pagesCH 1 Engine Types and Operating Parameter - 1Dhamarjati Riyan SufajarNo ratings yet

- Fundamentals of CarburetorDocument12 pagesFundamentals of Carburetorecasayang0% (1)

- NEVA93011FUDocument21 pagesNEVA93011FUvictor.ansartNo ratings yet

- Land Speed Record Norman SuperchargersDocument5 pagesLand Speed Record Norman Superchargersandrew_harveNo ratings yet

- Grand Prix Motorcycle Engine Development Over Last 60 YearsDocument35 pagesGrand Prix Motorcycle Engine Development Over Last 60 YearsShaswata Panja100% (1)

- List of Perkins Engines - Wikipedia PDFDocument33 pagesList of Perkins Engines - Wikipedia PDFLAli0% (1)

- History of Racing CarsDocument17 pagesHistory of Racing CarsPrajith Kumar KpNo ratings yet

- BMW Motorcycle InformationDocument45 pagesBMW Motorcycle Informationtradern100% (1)

- History of LanchesterDocument11 pagesHistory of LanchesterRajanikantJadhavNo ratings yet

- Straight-Eight Engine: Early Period (1903-1918) Inter-War Period (1919-1941)Document6 pagesStraight-Eight Engine: Early Period (1903-1918) Inter-War Period (1919-1941)MARCELA LA QUE SE MEANo ratings yet

- General Electric Military Jet EnginesDocument7 pagesGeneral Electric Military Jet EnginesMarica RazvanNo ratings yet

- The Design of Competition EnginesDocument546 pagesThe Design of Competition EnginesJoão Victor Paschoal PoletiNo ratings yet

- Engine: Metric HP PS Maybach HL 230 P30Document4 pagesEngine: Metric HP PS Maybach HL 230 P30Austin LeeNo ratings yet

- Turbo-Liner: Development of The Allison T-38 Engine in A Convair 240Document1 pageTurbo-Liner: Development of The Allison T-38 Engine in A Convair 240Floyd PriceNo ratings yet

- Air Filter BasicDocument24 pagesAir Filter BasicapwaniNo ratings yet

- M 572 ContentDocument1,501 pagesM 572 ContentNilson SenaNo ratings yet

- Etymology: Carby in AustraliaDocument14 pagesEtymology: Carby in Australiayustina hasibuanNo ratings yet

- 2010 Opposed Piston RenaissanceDocument17 pages2010 Opposed Piston RenaissanceEric ZachowNo ratings yet

- 44.al Si MG Pin FinDocument73 pages44.al Si MG Pin FineshuNo ratings yet

- The Evolution of Cars 1Document32 pagesThe Evolution of Cars 1freddieestillore104No ratings yet

- Mechanical Radial EngineDocument11 pagesMechanical Radial EngineAnindam Deb100% (1)

- Four Stroke Engines: ItalaDocument2 pagesFour Stroke Engines: Italapratik dhuriNo ratings yet

- (Rolls Royce Griffon) AIMDocument5 pages(Rolls Royce Griffon) AIMDaniel ArmstrongNo ratings yet

- The History of The Diesel EngineDocument5 pagesThe History of The Diesel EngineDelmar Giltendez NangcasNo ratings yet

- Combustionchambersinsiengines 170803232402 PDFDocument11 pagesCombustionchambersinsiengines 170803232402 PDFSiva Kumar SNo ratings yet

- Ford FDocument33 pagesFord FJuan Martin PuigNo ratings yet

- Seminar FormatDocument25 pagesSeminar Formatstan leeNo ratings yet

- Engine HistoryDocument10 pagesEngine HistoryFelipe SierraNo ratings yet

- Aerodynamics in Formula 1 Racing 2 2Document6 pagesAerodynamics in Formula 1 Racing 2 2api-390681562No ratings yet

- From Wikipedia, The Free EncyclopediaDocument13 pagesFrom Wikipedia, The Free Encyclopediaharish321No ratings yet

- Volvo FH12 With Engine D12A Fault Codes PDFDocument4 pagesVolvo FH12 With Engine D12A Fault Codes PDFShadreck Takudzwa Ngwerume100% (1)

- 4 V158 TIhhDocument1 page4 V158 TIhhramizbd5No ratings yet

- Using A Volumetric Efficiency CalculatorDocument1 pageUsing A Volumetric Efficiency CalculatorWilliam KibbeNo ratings yet

- Experiment No. - 3: B.S.A. College of Engg. & Technology MathuraDocument3 pagesExperiment No. - 3: B.S.A. College of Engg. & Technology MathuraROHIT SRIVASTAVNo ratings yet

- VW Golf Engine RattleDocument2 pagesVW Golf Engine RattleArtin HykoNo ratings yet

- New Dealer Package Kit 2007 HarleyDocument9 pagesNew Dealer Package Kit 2007 HarleyCleveston MoraisNo ratings yet

- N60 Ent M40 DS P3d04n004e PDFDocument4 pagesN60 Ent M40 DS P3d04n004e PDFPablo BurgosNo ratings yet

- k21.k25 Engine Parts PDFDocument10 pagesk21.k25 Engine Parts PDFВиталий Чернов100% (1)

- PR754 LiebherrDocument651 pagesPR754 LiebherrRene Ramos Meneses75% (4)

- Fifth Semester B.Tech Degree Examination: 08.504 Auto Electrical and Electronics (U)Document2 pagesFifth Semester B.Tech Degree Examination: 08.504 Auto Electrical and Electronics (U)Rinu SathyanNo ratings yet

- Nissan S13 SR20DET To Wolf V500 Pinouts With LinkDocument1 pageNissan S13 SR20DET To Wolf V500 Pinouts With Linkwolfems88% (8)

- 32 - 44 CRDocument12 pages32 - 44 CRMunteanu Sylvèr RobèrtNo ratings yet

- 400 Series ManualDocument108 pages400 Series Manualsfe100% (1)

- Direct Injection: o o o oDocument7 pagesDirect Injection: o o o opardeep4372No ratings yet

- Brosur Genset Perkins 200 Kva SilentDocument2 pagesBrosur Genset Perkins 200 Kva Silentbagus saputraNo ratings yet

- Intervalo de ManutençãoDocument3 pagesIntervalo de Manutençãowagner_guimarães_1No ratings yet

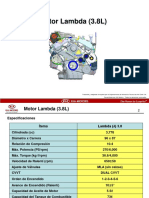

- 1.HM Lambda Engine CompletedDocument10 pages1.HM Lambda Engine CompletedAlex GarciaNo ratings yet

- ZAMA Kits Price ListDocument14 pagesZAMA Kits Price ListHugoNo ratings yet

- Kta50 G9Document2 pagesKta50 G9Paul TriumfanteNo ratings yet

- Double Drum Bomag BW 202 AD-4Document3 pagesDouble Drum Bomag BW 202 AD-4Mohamed SaiedNo ratings yet

Note 27 Tuning of Individual Inlet and Exhaust Systems: Car Engine Tuning - The 1922 Miller 183

Note 27 Tuning of Individual Inlet and Exhaust Systems: Car Engine Tuning - The 1922 Miller 183

Uploaded by

Nurul FuadiahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Note 27 Tuning of Individual Inlet and Exhaust Systems: Car Engine Tuning - The 1922 Miller 183

Note 27 Tuning of Individual Inlet and Exhaust Systems: Car Engine Tuning - The 1922 Miller 183

Uploaded by

Nurul FuadiahCopyright:

Available Formats

Note 27

Tuning of individual inlet and exhaust systems

Naturally, single-cylinder engine makers were those who developed most intensively the art

and science of tuning individual inlet and exhaust tracts for frequency and inertia effects in

the air/mixture/gas flows so as to create a higher-than-normal density in a Naturally Aspirated

(NA) piston engine cylinder at the moment the inlet valve closed, so raising Volumetric

Efficiency (EV) and therefore BMEP. This was not actually 'free supercharge' because the

gain at the tuned RPM had to be 'paid for' in a loss of EV at some other speeds - until

variable length or variable capacity systems were introduced when the 'payment' was in

terms of extra complexity and weight.

Pre-WW2 the British motor-cycle racing singles, especially Norton and Velocette, were the

beneficiaries of the art, carried to the 'super tuning' level with diffusers ('megaphones ') on

the exhaust to lower the pressure at the valve and help induce more charge. The 1938 Senior

TT -winning Norton had an area ratio of about 8 from exhaust port to megaphone exit and the

latter had an included cone angle of 13. In this way Joe Craig, Norton's engineering/racing

manager, obtained BMPP = 13 Bar at R = 11 on 50/50 petrol/Benzole fuel at MPSP = 21.2

m/s ((12B) and SO12). For comparison, the 1938 Delahaye GP Type 145 60V12 4.5L had

BMPP = 9.4 Bar at R = 8.5, probably on similar fuel with three two-choke carburettors, at

MPSP = 14.1 m/s (485). However, the Norton would not run smoothly below 60% of peak

speed and the clutch had to be slipped at the start and on hairpin corners.

Continental motor-cycle racers in the mid '30s had gone instead of super-tuning for the

allowed option of mechanical supercharging but Moto-Guzzi and Benelli had developed the

NA tuning method.

Car engine tuning - the 1922 Miller 183

In car engines, inlet tuning had been pioneered by Harry Miller who, in 1922, had fitted his

183 cu. inch (3L) IL8 with individual tracts breathing through four two-choke own-design

up draught carburettors. However, this engine was very limited in RPM, short of power peak,

by having only a three-bearing crank. Its BMEP = 9.4 Bar on R = 8, probably petrol, at

MPS = 13.6 m/s ((6) and S07))*. It is speculated by Griffith Borgeson that Eduardo Weber

was inspired to produce his later famous two-choke carburettors by seeing the Miller units

(on a 2L car) at Monza in 1923 (6).

As Miller, in company with all other front-rank car racing engine makers, moved on to

mechanical supercharging in 1924, his NA work came to a halt. Later NA engines from the

Offenhauser/Meyer-Drake successors to Miller did not resume individual and tuned inlets

until the development of Hilborn indirect fuel injection in 1950.

Car engine tuning - the Dixon Rileys 1930-1935

Freddy Dixon, a very experienced and successful motor-cycle racer, following up a works

Riley initiative in fitting four Amal motor-cycle carburettors to an IL4 1100cc sports car

engine in 1930, became the great exponent in the mid '30s of individual tuned inlet and

exhaust systems on NA Rileys from the 1l00cc to the lL6 2L. With the latter in a low

nominal- two-seater, long-tail chassis he achieved a lap of the Brooklands Outer Circuit

(BOC) banked track at 134.4 mph (216.3 kph) in 1935. This may be compared with the alltime BOC record of 143.4 mph made by a 500 HP machine and is believed to represent a

genuine 150 HP from 2L NA (BMPP = 11.3 Bar at R = 10.8 on alcohol/toluol fuel, MPSP

about 21 m/s) (141) (Dixon never bench-tested his engines). Percy Maclure and Hector Dobbs

built similar Riley-based engines.

*See the note at the end concerning the tuning of the Miller 183.

Page 1 of 2

1950 developments, British and Italian

Ferrari, racing V12 F2 2L NA engines in 1950, was impressed by the performance on twisty

circuits of the IL4 cars of Amadee Gordini and John Heath, the latter named HWM and fitted

with Geoffrey Taylor-built Alta engines. Both raced with only two carburettors. The Alta was

tested originally with four Amal carburettors and four individual, tuned-length exhaust pipes

and as such carried on and improved upon the pre- WW2 Dixon layout - but the Amals did

not give adequate starting or acceleration characteristics and were not raced, while breakages

of the long separate exhausts soon forced a change to a manifold and single pipe; power

dropped 13% after these two alterations (147).

Connaught at the end of 1950 had introduced an F2 car with four tuned inlets using Amals

applied to an IL4 1.8L modified Lea-Francis engine (originally aimed at US Midget racing)

very similar in head design to Dixon's Rileys. The exhaust system had cylinders 1,4 and 2,3

flowing into a separate pair of tail pipes. This car had not raced abroad.

When Aurelio Lampredi designed the Ferrari Type 500 IL4 F2 2L NA engine in late 1950, as

his response to the Gordini and HWM performances, it is considered that, because of the time,

space and culture gaps from the earlier work on tuned, individual inlet and exhaust systems,

he made his own decisions in the matter of such tuning. Weber apparently produced a suitable

two-choke/one-float-chamber horizontal carburettor (Type DCO) especially for the new

Ferrari engine at the appropriate bore (50mm) and port spacing.

With a bore of 38mm the DCO was sold simultaneously to HWM for their 1951 singleseaters. On their 2L Alta engine these Weber units became part of a tuned individual inlet and

stub-exhaust system which was actually the first to race internationally post-WW2, 29 years

after Miller's pioneering engine (it recovered the 13% lost from the early 1950 tests, back to

130 HP) (147). The Ferrari IL4 engine, in 2.5L form, first raced in early September 1951.

Simple inlet-tuning theory

In the simple organ-pipe theory, as given in (282), the Mean Piston Speed (MPS) at which

resonance occurs can be estimated from.MPS = 88.25 x (S/LIN) m/s

where LIN = Inlet system length to back of valve, in same units as S = Stroke.

Consequently, the following

applies:

LIN/S

Resonant MPS m/s

3

29.4

3.53

25

4

22.1

5

17.7

6

14.7

7

12.6

The Ferrari Type 500 in 1953 (Eg 31) had LIN/S = 330/78 = 4.23 and would have resonated

theoretically at 20.9 m/s; the peak speed was actually 19.5 m/s.

Miller 183

Ref (6) shows that this engine had LIN/S = 600/101.6 = 5.9 and the simple formula gives

resonant MPS = about 15 m/s, versus the rated maximum of 13.6 m/s. The optimum

length was found by varying the pipe lengths and timing the car round the Beverly Hills

banked board track.

Page 2 of 2

You might also like

- 2015 N13 Engine Engine Service ManualDocument1,259 pages2015 N13 Engine Engine Service ManualJonathan Luiz Poleza67% (3)

- Mtu Series 60 MarineDocument5 pagesMtu Series 60 MarineMuhammad rizki0% (1)

- Mercury Four & Six Cylinder (1955-1965) Old Outboard MotorDocument14 pagesMercury Four & Six Cylinder (1955-1965) Old Outboard MotorLinus0% (1)

- TD27 EngineDocument67 pagesTD27 EngineПетр83% (6)

- 11570-Navistar MaxxForce DT-9 DT-10 2014Document577 pages11570-Navistar MaxxForce DT-9 DT-10 2014Lester Noel100% (4)

- Kohler Carburetor Reference Manual TP-2377-EDocument60 pagesKohler Carburetor Reference Manual TP-2377-EChevronelle100% (1)

- Ford PushrodDocument7 pagesFord PushrodLouise Ellis-Rix50% (2)

- Matchless MotorcyclesDocument44 pagesMatchless Motorcyclesisland14No ratings yet

- A Brief History of Aircraft Carburetors and Fuel SystemsDocument13 pagesA Brief History of Aircraft Carburetors and Fuel SystemsbnolascoNo ratings yet

- Ford Kent CrossflowDocument6 pagesFord Kent CrossflowSean OsborneNo ratings yet

- Allison v-1710 Aircraft EngineDocument10 pagesAllison v-1710 Aircraft EngineWilliamNo ratings yet

- Type - 9 - Gearbox To Essex v6Document11 pagesType - 9 - Gearbox To Essex v6aakk75No ratings yet

- Matchless 1939 1955 Manual de Reparatie WWW - Manualedereparatie.info NoRestrictionDocument60 pagesMatchless 1939 1955 Manual de Reparatie WWW - Manualedereparatie.info NoRestrictionBhavesh Hathiwala67% (3)

- Technical Data: @perkinsDocument6 pagesTechnical Data: @perkinsHendra SyalalaNo ratings yet

- CAT 3412 Air Inlet and Exhaust SystemDocument8 pagesCAT 3412 Air Inlet and Exhaust SystemCEVegaO100% (2)

- Diesel Engine and Components: Series Paragraphs 51-53Document9 pagesDiesel Engine and Components: Series Paragraphs 51-53Branko MikulinjakNo ratings yet

- TOYOTA Technical Training - Exhaust Gas Recirculation (EGR) System DiagnosisDocument12 pagesTOYOTA Technical Training - Exhaust Gas Recirculation (EGR) System DiagnosisEbag333100% (2)

- Dodge A500 Transmission HistoryDocument7 pagesDodge A500 Transmission Historymobile_filesNo ratings yet

- Later Single-Cylinder EnginesDocument14 pagesLater Single-Cylinder EnginesImade EmadeNo ratings yet

- Cosworth StoryDocument32 pagesCosworth StoryTanoV12-Formula1AmarcordNo ratings yet

- Engine TypesDocument4 pagesEngine TypesRoss GrimmettNo ratings yet

- Formula One Grand Prix Motor Racing Fédération Internationale de L'automobile Formula One RegulationsDocument5 pagesFormula One Grand Prix Motor Racing Fédération Internationale de L'automobile Formula One RegulationsAmitkumar VermaNo ratings yet

- Mec 523Document88 pagesMec 523Saman BrookhimNo ratings yet

- The Deltic EngineDocument15 pagesThe Deltic Enginedshmkh_prynk100% (1)

- Formula One Engines WikipediaDocument14 pagesFormula One Engines Wikipediaantoniocdof1No ratings yet

- Engine HistoryDocument9 pagesEngine HistorycowpunchrNo ratings yet

- America's First OSCA'sDocument17 pagesAmerica's First OSCA'sSteveNo ratings yet

- Cosworthstory PDFDocument25 pagesCosworthstory PDFmicheleNo ratings yet

- EPA HQ OAR 2015 0827 0548 - ContentDocument16 pagesEPA HQ OAR 2015 0827 0548 - ContentStephen RivettNo ratings yet

- AMC Straight-4 Engine - WikipediaDocument5 pagesAMC Straight-4 Engine - WikipediaJordan4444409No ratings yet

- The Simson Story and The Simson Awo 425 97-2003 Version 2Document48 pagesThe Simson Story and The Simson Awo 425 97-2003 Version 2hellenaSRNo ratings yet

- ST TA2 1 Experimental V4x Stirling EngineDocument12 pagesST TA2 1 Experimental V4x Stirling EnginesynkanNo ratings yet

- Turbo ChargersDocument16 pagesTurbo ChargersNaishadh J Desai AnD's100% (1)

- Hyper EngineDocument3 pagesHyper EnginetorrefacaomerendaNo ratings yet

- CH 1 Engine Types and Operating Parameter - 1Document79 pagesCH 1 Engine Types and Operating Parameter - 1Dhamarjati Riyan SufajarNo ratings yet

- Fundamentals of CarburetorDocument12 pagesFundamentals of Carburetorecasayang0% (1)

- NEVA93011FUDocument21 pagesNEVA93011FUvictor.ansartNo ratings yet

- Land Speed Record Norman SuperchargersDocument5 pagesLand Speed Record Norman Superchargersandrew_harveNo ratings yet

- Grand Prix Motorcycle Engine Development Over Last 60 YearsDocument35 pagesGrand Prix Motorcycle Engine Development Over Last 60 YearsShaswata Panja100% (1)

- List of Perkins Engines - Wikipedia PDFDocument33 pagesList of Perkins Engines - Wikipedia PDFLAli0% (1)

- History of Racing CarsDocument17 pagesHistory of Racing CarsPrajith Kumar KpNo ratings yet

- BMW Motorcycle InformationDocument45 pagesBMW Motorcycle Informationtradern100% (1)

- History of LanchesterDocument11 pagesHistory of LanchesterRajanikantJadhavNo ratings yet

- Straight-Eight Engine: Early Period (1903-1918) Inter-War Period (1919-1941)Document6 pagesStraight-Eight Engine: Early Period (1903-1918) Inter-War Period (1919-1941)MARCELA LA QUE SE MEANo ratings yet

- General Electric Military Jet EnginesDocument7 pagesGeneral Electric Military Jet EnginesMarica RazvanNo ratings yet

- The Design of Competition EnginesDocument546 pagesThe Design of Competition EnginesJoão Victor Paschoal PoletiNo ratings yet

- Engine: Metric HP PS Maybach HL 230 P30Document4 pagesEngine: Metric HP PS Maybach HL 230 P30Austin LeeNo ratings yet

- Turbo-Liner: Development of The Allison T-38 Engine in A Convair 240Document1 pageTurbo-Liner: Development of The Allison T-38 Engine in A Convair 240Floyd PriceNo ratings yet

- Air Filter BasicDocument24 pagesAir Filter BasicapwaniNo ratings yet

- M 572 ContentDocument1,501 pagesM 572 ContentNilson SenaNo ratings yet

- Etymology: Carby in AustraliaDocument14 pagesEtymology: Carby in Australiayustina hasibuanNo ratings yet

- 2010 Opposed Piston RenaissanceDocument17 pages2010 Opposed Piston RenaissanceEric ZachowNo ratings yet

- 44.al Si MG Pin FinDocument73 pages44.al Si MG Pin FineshuNo ratings yet

- The Evolution of Cars 1Document32 pagesThe Evolution of Cars 1freddieestillore104No ratings yet

- Mechanical Radial EngineDocument11 pagesMechanical Radial EngineAnindam Deb100% (1)

- Four Stroke Engines: ItalaDocument2 pagesFour Stroke Engines: Italapratik dhuriNo ratings yet

- (Rolls Royce Griffon) AIMDocument5 pages(Rolls Royce Griffon) AIMDaniel ArmstrongNo ratings yet

- The History of The Diesel EngineDocument5 pagesThe History of The Diesel EngineDelmar Giltendez NangcasNo ratings yet

- Combustionchambersinsiengines 170803232402 PDFDocument11 pagesCombustionchambersinsiengines 170803232402 PDFSiva Kumar SNo ratings yet

- Ford FDocument33 pagesFord FJuan Martin PuigNo ratings yet

- Seminar FormatDocument25 pagesSeminar Formatstan leeNo ratings yet

- Engine HistoryDocument10 pagesEngine HistoryFelipe SierraNo ratings yet

- Aerodynamics in Formula 1 Racing 2 2Document6 pagesAerodynamics in Formula 1 Racing 2 2api-390681562No ratings yet

- From Wikipedia, The Free EncyclopediaDocument13 pagesFrom Wikipedia, The Free Encyclopediaharish321No ratings yet

- Volvo FH12 With Engine D12A Fault Codes PDFDocument4 pagesVolvo FH12 With Engine D12A Fault Codes PDFShadreck Takudzwa Ngwerume100% (1)

- 4 V158 TIhhDocument1 page4 V158 TIhhramizbd5No ratings yet

- Using A Volumetric Efficiency CalculatorDocument1 pageUsing A Volumetric Efficiency CalculatorWilliam KibbeNo ratings yet

- Experiment No. - 3: B.S.A. College of Engg. & Technology MathuraDocument3 pagesExperiment No. - 3: B.S.A. College of Engg. & Technology MathuraROHIT SRIVASTAVNo ratings yet

- VW Golf Engine RattleDocument2 pagesVW Golf Engine RattleArtin HykoNo ratings yet

- New Dealer Package Kit 2007 HarleyDocument9 pagesNew Dealer Package Kit 2007 HarleyCleveston MoraisNo ratings yet

- N60 Ent M40 DS P3d04n004e PDFDocument4 pagesN60 Ent M40 DS P3d04n004e PDFPablo BurgosNo ratings yet

- k21.k25 Engine Parts PDFDocument10 pagesk21.k25 Engine Parts PDFВиталий Чернов100% (1)

- PR754 LiebherrDocument651 pagesPR754 LiebherrRene Ramos Meneses75% (4)

- Fifth Semester B.Tech Degree Examination: 08.504 Auto Electrical and Electronics (U)Document2 pagesFifth Semester B.Tech Degree Examination: 08.504 Auto Electrical and Electronics (U)Rinu SathyanNo ratings yet

- Nissan S13 SR20DET To Wolf V500 Pinouts With LinkDocument1 pageNissan S13 SR20DET To Wolf V500 Pinouts With Linkwolfems88% (8)

- 32 - 44 CRDocument12 pages32 - 44 CRMunteanu Sylvèr RobèrtNo ratings yet

- 400 Series ManualDocument108 pages400 Series Manualsfe100% (1)

- Direct Injection: o o o oDocument7 pagesDirect Injection: o o o opardeep4372No ratings yet

- Brosur Genset Perkins 200 Kva SilentDocument2 pagesBrosur Genset Perkins 200 Kva Silentbagus saputraNo ratings yet

- Intervalo de ManutençãoDocument3 pagesIntervalo de Manutençãowagner_guimarães_1No ratings yet

- 1.HM Lambda Engine CompletedDocument10 pages1.HM Lambda Engine CompletedAlex GarciaNo ratings yet

- ZAMA Kits Price ListDocument14 pagesZAMA Kits Price ListHugoNo ratings yet

- Kta50 G9Document2 pagesKta50 G9Paul TriumfanteNo ratings yet

- Double Drum Bomag BW 202 AD-4Document3 pagesDouble Drum Bomag BW 202 AD-4Mohamed SaiedNo ratings yet