Professional Documents

Culture Documents

Ijri MT 01 003

Ijri MT 01 003

Uploaded by

ijripublishersCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MC Case PDFDocument20 pagesMC Case PDFShivani KarkeraNo ratings yet

- Leg Support Calculation PDFDocument2 pagesLeg Support Calculation PDFSanjay MoreNo ratings yet

- CFD Analysis On Pulsating Heat Pipe To Improve Heat TransferDocument5 pagesCFD Analysis On Pulsating Heat Pipe To Improve Heat TransferijripublishersNo ratings yet

- Ijri Cce 01 010Document22 pagesIjri Cce 01 010ijripublishersNo ratings yet

- Structural and Modal Analysis of An Engine Block by Varying MaterialsDocument4 pagesStructural and Modal Analysis of An Engine Block by Varying MaterialsijripublishersNo ratings yet

- Modeling and Thermal Analysis of Air-Conditioner EvaporatorDocument6 pagesModeling and Thermal Analysis of Air-Conditioner Evaporatorijripublishers100% (1)

- Ijri Cce 01 008Document16 pagesIjri Cce 01 008ijripublishersNo ratings yet

- International Journal of Research and Innovation : Model On Carpooling Technique To Reduce Congestion 1401-1402Document7 pagesInternational Journal of Research and Innovation : Model On Carpooling Technique To Reduce Congestion 1401-1402ijripublishersNo ratings yet

- Ijri Cce 02 004Document7 pagesIjri Cce 02 004ijripublishersNo ratings yet

- CFD Analysis On Ejector Cooling System With Variable Throat GeometryDocument6 pagesCFD Analysis On Ejector Cooling System With Variable Throat GeometryijripublishersNo ratings yet

- Ijri Cce 01 012Document9 pagesIjri Cce 01 012ijripublishersNo ratings yet

- International Journal of Research and Innovation : Strengthening of RC Beams Using FRP Sheet 1401-1402Document13 pagesInternational Journal of Research and Innovation : Strengthening of RC Beams Using FRP Sheet 1401-1402ijripublishersNo ratings yet

- Ijri Cce 01 006Document13 pagesIjri Cce 01 006ijripublishersNo ratings yet

- Ijri Cce 02 007Document8 pagesIjri Cce 02 007ijripublishersNo ratings yet

- Ijri Cce 02 006Document9 pagesIjri Cce 02 006ijripublishersNo ratings yet

- Ijri Cce 01 005Document4 pagesIjri Cce 01 005ijripublishersNo ratings yet

- Ijri Cce 02 005Document7 pagesIjri Cce 02 005ijripublishersNo ratings yet

- Ijri Cce 01 009Document9 pagesIjri Cce 01 009ijripublishersNo ratings yet

- Ijri Cce 02 008Document8 pagesIjri Cce 02 008ijripublishersNo ratings yet

- Ijri Cce 01 011Document6 pagesIjri Cce 01 011ijripublishersNo ratings yet

- Ijri Cce 01 002Document7 pagesIjri Cce 01 002ijripublishersNo ratings yet

- Ijri Cce 01 003Document12 pagesIjri Cce 01 003ijripublishersNo ratings yet

- Problem: Determine The Total Volume of Earth To Be Excavated Up To Elevation 0Document17 pagesProblem: Determine The Total Volume of Earth To Be Excavated Up To Elevation 0gtech00100% (1)

- Palliative Ultrasound-Guided Endoscopic Diode Laser Ablation of Transitional Cell Carcinomas of The Lower Urinary Tract in Dogs.Document10 pagesPalliative Ultrasound-Guided Endoscopic Diode Laser Ablation of Transitional Cell Carcinomas of The Lower Urinary Tract in Dogs.Dante Nathaniel FajardoNo ratings yet

- English Final Test Grade XiiDocument9 pagesEnglish Final Test Grade XiiLiza RahmawatiNo ratings yet

- ManvantaraDocument3 pagesManvantaraafterragnarokNo ratings yet

- CSC 2701 - CalculusDocument5 pagesCSC 2701 - CalculusMd Rubaiyat BhuiyanNo ratings yet

- Material Balance PDFDocument31 pagesMaterial Balance PDFApril Joy HaroNo ratings yet

- ProductSheet Iq200 Rackmount SatelliteModemDocument2 pagesProductSheet Iq200 Rackmount SatelliteModemAsim Penkar PenkarNo ratings yet

- TSB-1139 8SC Wiring DiagramDocument2 pagesTSB-1139 8SC Wiring Diagramxavier marsNo ratings yet

- Hilton Chapter 5 Adobe Connect Activity-Based Costing and ManagementDocument11 pagesHilton Chapter 5 Adobe Connect Activity-Based Costing and ManagementyosepjoltNo ratings yet

- He Is A Chocolate Lover: Kamaladevi RengasamyDocument4 pagesHe Is A Chocolate Lover: Kamaladevi RengasamyKamala DeviNo ratings yet

- Plant Hormones PDFDocument5 pagesPlant Hormones PDFYASHNo ratings yet

- HPB21-0457 FINAL Submittal 09-07-2021 - Ritz Sagamore LOIDocument13 pagesHPB21-0457 FINAL Submittal 09-07-2021 - Ritz Sagamore LOIthe next miamiNo ratings yet

- Biology Investigatory Project: Malaria: Its Effects and CausesDocument17 pagesBiology Investigatory Project: Malaria: Its Effects and CausesRishi KeshavNo ratings yet

- Free Download All Aeronautical Engg Books: AERO 3-1 BOOKSDocument11 pagesFree Download All Aeronautical Engg Books: AERO 3-1 BOOKSMacen SnoodleNo ratings yet

- A Clinical Audit Into The Success Rate of Inferior Alveolar Nerve Block Analgesia in General Dental PracticeDocument4 pagesA Clinical Audit Into The Success Rate of Inferior Alveolar Nerve Block Analgesia in General Dental PracticeGina CastilloNo ratings yet

- SONTU Flat Panel Dectector CatalogDocument6 pagesSONTU Flat Panel Dectector CatalogWajahat SheikhNo ratings yet

- Ignatian SpiritualityDocument16 pagesIgnatian SpiritualityMihai Frentz100% (2)

- Petroleum Engineering Lab 1 (PGE313) Experiment 2 Determination of PorosityDocument13 pagesPetroleum Engineering Lab 1 (PGE313) Experiment 2 Determination of PorosityAli AbubakarNo ratings yet

- Cefixime and Palpitations - From FDA ReportsDocument3 pagesCefixime and Palpitations - From FDA ReportsMuhammad UbaidNo ratings yet

- Asme A13.1 - 1996Document27 pagesAsme A13.1 - 1996lohv100% (1)

- Allotrope Partners Indonesia Renewable Energy Project AssociateDocument2 pagesAllotrope Partners Indonesia Renewable Energy Project AssociateRizal ZulkarnaenNo ratings yet

- Transport Phenomena: τ =μ dv dyDocument2 pagesTransport Phenomena: τ =μ dv dySYED ASGHAR ALI SULTANNo ratings yet

- Ipc DRM 18FDocument34 pagesIpc DRM 18FThamilvaanan.sNo ratings yet

- NASA NOAA Earth Sciences Letter To TrumpDocument6 pagesNASA NOAA Earth Sciences Letter To TrumpMelissa Meehan BaldwinNo ratings yet

- Pablocastillo PDFDocument44 pagesPablocastillo PDFPabloNo ratings yet

- NEW Sales Tax Invoice - 2023-07-27T164634.549Document1 pageNEW Sales Tax Invoice - 2023-07-27T164634.549Saadat IrfanNo ratings yet

- MATH 4 PPT Q3 W4 - Lesson 52 - Quadrilateral 1Document17 pagesMATH 4 PPT Q3 W4 - Lesson 52 - Quadrilateral 1Erika Mae TupagNo ratings yet

- Behaviour of Hollow Core Slabs Under Point LoadsDocument17 pagesBehaviour of Hollow Core Slabs Under Point LoadsVálter LúcioNo ratings yet

Ijri MT 01 003

Ijri MT 01 003

Uploaded by

ijripublishersOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ijri MT 01 003

Ijri MT 01 003

Uploaded by

ijripublishersCopyright:

Available Formats

International Journal of Research and Innovation (IJRI)

International Journal of Research and Innovation

(IJRI)

DESIGN OF MOULD TOOL & COOLING CHANNEL OPTIMIZATION OF REMOTE

CONTROL TOP PANEL

Peer Review- 1401-1402

V.Venkata Krishna Mohan, D.Gopichand

Mother Theresa Institute of Technology(mist) Sanketika Nagar Sathupally Khammam,India

Abstract

A plastic material is any of a wide range of synthetic or semi-synthetic organic solids that are moldable. Plastics are

typically organic polymers of high molecular mass, but they often contain other substances. They are usually synthetic,

most commonly derived from petrochemicals, but many are partially natural.

Molding is the process of manufacturing by shaping liquid or pliable raw material using a rigid frame called a mold or

matrix. This itself may have been made using a pattern or model of the final object.

Cooling channels are used in mold tool to reduce the temperature of the object to help molten material to solidify quickly

before the ejection. It is quite useful to increase the production rate.

The aim of this project work is to design mold structure and optimize cooling channel system to reduce effect of warpage

of remote control top panel.

Literature survey and data collection will be done to understand working process of cooling channels, effects of warpage

on plastic parts, mold optimization.

3D model of remote control top panel will be prepared and die design calculations will be done to model the entire mold

step.

Assembly of complete mold will be prepared for further process.

Analysis will be carried out on mold cooling channels for evaluation and Analysis will be done on different models to

obtain optimum structure and cooling channel system.

Conclusion will be mode according to the obtained results

*Corresponding Author:

V.Venkata Krishna Mohan,

Mother Theresa Institute of Technology(mist) Sanketika Nagar

Sathupally Khammam,India

Published: Sep 22, 2014

Volume No: I

Issue No. : III

Citation:V.Venkata Krishna Mohan, D.Gopichand (2014) DESIGN OF MOULD TOOL & COOLING CHANNEL OPTIMIZATION OF REMOTE CONTROL TOP PANEL

Problem Description

UN proper cooling effects on surface finish of the

component and warpage may occur, due to that

part dimensions may get deformed than generic/

modeld part.

Generally different types of cooling channels are

used in the field of plastic part manufacturing, it

directly effects on surface finish and warpage of the

component, even material properties also effect on

the same.

Methodology

The following methods are followed to rectify the

above problem

Plastic flow analysis will be done using various plastic materials.

Thermal analysis will be done on different types of

cooling channel systems, to suggest the optimum to

ensure sufficient cooling and fill quality.

Introduction To Cad

Computer Aided Design (CAD) is a technique in

which problem solving will be done in the combination of man and machine for high precision work

flow.

1

International Journal of Research and Innovation (IJRI)

Computer Aided Design is an interactive process,

where the exchange of information between the

designer and the computer is made as simple and

effective as possible. Computer aided design encompasses a wide variety of computer based methodologies and tools for engineering activity planning, analysis, detailing, drafting, construction,

manufacturing, monitoring, management, process

control and maintenance. CAD is more concerned

with the use of computer-based tools to support the

entire life cycle of engineering system.

Introduction To Creo Parametric 2.0 (Creo 2.0)

CREO PARAMETRIC is one of the most popular PLM

software founded by Parametric Technology Corporation which consists of CAD/CAM/CAE. So that

designer can easily check their part/product design

compatibility with FEM and CAM segments and

also they can check plastic flow for injection moldings parts to reduce production/component errors.

CREO PARAMETRIC is completely feature based

modeling tool with ribbon mode which is very easy

to understand by the users.

Summary of capabilities

Like any software it is continually being developed

to include new functionality. The details below aim

to outline the scope of capabilities to give an over-

view rather than giving specific details on the individual functionality of the product.

Engineering Design

Creo parametric 2.0 offers a range of tools to enable

the generation of a complete digital representation

of the product being designed. In addition to the

general geometry tools there is also the ability to

generate geometry of other integrated design disciplines such as industrial and standard pipe work

and complete wiring definitions. Tools are also

available to support collaborative development.

A number of concept design tools that provide upfront Industrial Design concepts can then be used

in the downstream process of engineering the product. These range from conceptual Industrial design

sketches, reverse engineering with point cloud data

and comprehensive freeform surface tools.

Manufacturing

By using the fundamental abilities of the software

with regards to the single data source principle, it

provides a rich set of tools in the manufacturing environment in the form of tooling design and simulated CNC machining and output.

Tooling options cover specialty tools for molding,

die-casting and progressive tooling design.

Modeling of remote

The above image shows the 2d sketch of remote using trimmed circles and arcs

International Journal of Research and Innovation (IJRI)

The above image shows the fillets using round option

The above image shows the completed image of remote

The above image shows 2d drafting of remote

International Journal of Research and Innovation (IJRI)

Injection Moulding

In manufacturing processes Injection moulding

plays a crucial role for producing plastic components by using thermo plastic and thermo setting.

After completion of product design as per client requirement done by an engineer, molds are prepared

by tool maker. For less number of components Aluminum is the better option. For large production

better to use steel alloys to maintain good surface

finish, dimensional stability. Maximum of components are made by thermo plastic which are recycled (or) reusable.

plasticsMaterial is fed into a heated barrel, mixed,

and forced into a mold cavity where it cools and

hardens to the configuration of the mold cavity

Commonly open top components are produced in

injection molding which is having minimum thickness of 0.5mm, for good quality of product the wall

thickness should be more than 2mm.

For remote control panel better to use recycled polypropelene due to good impact resistence, low cost

and eco-friendly and it has good structural stability.

Process Characteristics

Utilizes a ram or screw-type plunger to force

molten plastic material into a mold cavity

Produces a solid or open-ended shape which has

conformed to the contour of the mold

Uses thermoplastic or thermoset materials

Produces a parting line, sprue, and gate marks

Ejector pin marks are usually present

Injection molding is used to create many things

such as wire spools, packaging, bottle caps, automotive dashboards, pocket combs, and most other

plastic products available today. Injection molding

is the most common method of part manufacturing.

It is ideal for producing high volumes of the same

object. Some advantages of injection molding are

high production rates, repeatable high tolerances,

and the ability to use a wide range of materials, low

labour cost, minimal scrap losses, and little need to

finish parts after molding. Some disadvantages of

this process are expensive equipment investment,

potentially high running costs, and the need to design moldable parts.

Design

Molds separate into two sides at a parting line, the

A side, and the B side, to permit the part to be extracted. Plastic resin enters the mold through

a sprue in the A plate, branches out between

the two sides through channels called runners, and

enters each part cavitythrough one or more specialized gates. Inside each cavity, the resin flows

around cores and conforms to the cavity geometry to form the desired part. The amount of

resin required to fill the sprue, runner and cavities

of a mold is a shot. When a core shuts offagainst

an opposing mold cavity or core, a hole results in

the part. Air in the cavities when the mold closes

escapes through very slight gaps between the

plates and pins, into shallow plenums called

vents. To permit removal of the part, its features

must not overhang one another in the direction

that the mold opens, unless parts of the mold are

designed to move from between such overhangs

when the mold opens. Sides of the part that appear

parallel with the direction of draw are typically draft

with to ease release of the part from the mold, and

examination of most plastic household objects will

reveal this. Parts with bucket-like features tend to

shrink onto the cores that form them while cooling, and cling to those cores when the cavity is

pulled away. The mold is usually designed so that

the molded part reliably remains on the ejector side

of the mold when it opens, and draws the runner

and the sprue out of the side along with the parts.

The part then falls freely when ejected from the side.

Tunnel gatestunnel sharply below the parting surface of the B side at the tip of each runner so that

the gate is sheared off of the part when both are

ejected. Ejector pins are the most popular method

for removing the part from the side core, but air

ejection, and stripper plates can also be used depending on the application. Most ejector plates are

found on the moving half of the tool, but they can

be placed on the fixed half if spring loaded. For

thermoplastics, coolant, usually water with corrosion inhibitors, circulates throughpassageways

bored through the main plates on both sides of the

mold to enable temperature control and rapid part

solidification.

Plastic Advisor In Creo Parametric

Problems found after tooling development are always expensive and frustrating. For plastic part

design and manufacture, there is a better way. By

simulating the plastic-filling process for injectionmolded parts, Pro/ENGINEER Plastic Advisor enables engineers to design for manufacturability, uncover problems, and propose remedies, reducing

development time and expense.

CREO Plastic Advisor simulates mold filling for injection molded plastic parts. Advanced features

provide valuable manufacturability insight - insight that can significantly reduce late-cycle design

changes and mold reengineering costs.

CREO Plastic Advisor simulates mold filling for injection molded plastic parts. Advanced features

provide valuable manufacturability insight - insight that can significantly reduce late-cycle design

changes and mold reengineering costs.

Features & Benefits

Animates plastic injection fill process and automatically creates Web reports within Pro/ENGINEER browser

4

International Journal of Research and Innovation (IJRI)

Access library of common plastic materials and

automatically select from typical injection-molding

machine parameters

Identify optimal injection locations to reduce cycle

time and improve product appearance

Identify potential mold-filling problems such as

short shots, air traps, and weld lines

Improve design quality and reduces manufacturing cycle times and rework of molds

Materials

Polypropylene (pp)

Acrylonitrile Butadiene System (ABS)

High Density Polyethylene (HDPE)

Polyvinyl Chloride (PVC)

Polybutylene terepthalate (PBT)

Plastic Flow analysis of remote control panel using polypropylene (pp)

The above image shows fill time

The above image shows confidence of fill

International Journal of Research and Innovation (IJRI)

The above image shows injection pressure

The above image shows pressure drop

The above image shows flow front temp

International Journal of Research and Innovation (IJRI)

The above image shows quality prediction

The above image shows surface temp variance

Plastic Flow analysis of remote control panel using Acrylonitrile Butadiene System (ABS)

The above image shows fill time

International Journal of Research and Innovation (IJRI)

The above image shows injection pressure

The above image shows pressure drop

The above image shows surface temp variance

8

International Journal of Research and Innovation (IJRI)

Plastic Flow analysis of remote control panel using High Density Polyethylene (HDPE)

The above image shows fill time

The above image shows injection pressure

The above image shows pressure drop

International Journal of Research and Innovation (IJRI)

The above image shows surface temp variance

Plastic Flow analysis of remote control panel using Polyvinyl Chloride (PVC)

The above image shows fill time

The above image shows injection pressure

10

International Journal of Research and Innovation (IJRI)

The above image shows pressure drop

The above image shows surface temp variance

Plastic Flow analysis of remote control panel using polybutylene terepthalate (PBT)

The above image shows fill time

11

International Journal of Research and Innovation (IJRI)

The above image shows injection pressure

The above image shows pressure drop

The above image shows surface temp variance

12

International Journal of Research and Innovation (IJRI)

MOULD EXTRACTION

A die is usually made in two halves and when closed

it forms a cavity similar to the casting desired. One

half of the die that remains stationary is known as

cover die and the other movable half is called

ejector die.

The die casting method is used for castings of nonferrous metals of comparatively Low fusion tem-

perature. This process is cheaper and quicker than

permanent or sand mould casting. Most of the automobile parts like fuel pump, carburetor bodies,

Horn heater, wipers, brackets, steering wheels,

hubs and crank cases are made with this process.

Core: The core which is the male portion of the mold

forms the internal shape of the molding.

Cavity: The cavity which is the female portion of the

mold, gives the molding its external form.

Parting Line Creation

The above image shows the parting surface

Core and cavity preparation

The above image shows the work piece creation

13

International Journal of Research and Innovation (IJRI)

The above image shows the cavity part

The above image shows the core part

Mold Tool Design For Remote Control Top Panel

The above image shows cavity

14

International Journal of Research and Innovation (IJRI)

The above image shows core

The above image shows mould assembly

The above image shows exploded view

15

International Journal of Research and Innovation (IJRI)

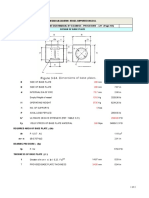

2D Drafting For Mold Tool Design

BILL OF MATERIALS

16

International Journal of Research and Innovation (IJRI)

Optimized Cooling Channels For Remote Control Top Panel

The above image shows linear

The above image shows horizontal

The above image shows vertical

17

International Journal of Research and Innovation (IJRI)

The above image shows spiral

Introduction To Ansys

ANSYS is general-purpose finite element analysis

(FEA) software package. Finite Element Analysis

is a numerical method of deconstructing a complex

system into very small pieces (of user-designated

size) called elements. The software implements

equations that govern the behaviour of these elements and solves them all; creating a comprehensive explanation of how the system acts as a whole.

These results then can be presented in tabulated,

or graphical forms. This type of analysis is typically

used for the design and optimization of a system far

too complex to analyze by hand. Systems that may

fit into this category are too complex due to their

geometry, scale, or governing equations.

ANSYS is the standard FEA teaching tool within

the Mechanical Engineering Department at many

colleges. ANSYS is also used in Civil and Electrical

Engineering, as well as the Physics and Chemistry

departments.

Warpage Analysis Of Remote Control Top Panel Using Coupled Field Analysis

Linear type cooling system

The above image shows imported model of remote control top panel with linear cooling system

18

International Journal of Research and Innovation (IJRI)

The above image shows meshed model

The above image shows total deformation

The above image shows temperature

19

International Journal of Research and Innovation (IJRI)

The above image shows total heat flux

The above image shows thermal error

Spiral type cooling system

The above image shows total deformation

20

International Journal of Research and Innovation (IJRI)

The above image shows temperature

The above image shows total heat flux

The above image shows thermal error

21

International Journal of Research and Innovation (IJRI)

Zigzag horizontal type cooling system

The above image shows total deformation

The above image shows temperature

The above image shows total heat flux

22

International Journal of Research and Innovation (IJRI)

The above image shows thermal error

Zigzag vertical type cooling system

The above image shows total deformation

The above image shows temperature

23

International Journal of Research and Innovation (IJRI)

The above image shows total heat flux

The above image shows thermal error

Results

Result table for plastic flow analysis

PP

ABS

HDPE

PVC

PbT

Fill time

0.96

1.38

1.19

2.57

1.50

Injection pressure

19.30

36.31

34.31

65.43

61.24

Pressure drop

19.30

36.31

34.31

65.43

61.24

Flow front

temperature

240.01

230.04

210.07

170.15

247.18

Surface temperature variance

4.98

4.98

4.98

4.98

4.98

24

International Journal of Research and Innovation (IJRI)

Result table for optimized cooling channels

Linear

Spiral

Zigzag horizontal

Zigzag vertical

Total deforma- 0.019266

tion

0.0096524

0.019223

0.019331

Temperature

200

200

200

200

Total heat flux

8.2928e-12

8.3161e-12

9.6433e-12

9.7462e-12

Thermal error

1.3267e-18

1.3616e-18

3.7358e-18

3.7255e-18

Conclusion

This project work deals with design of mold tool

and cooling channel optimization of remote control

top panel to suggest optimum material and cooling

channel system to reduce warpage of the product.

Initially literature survey and data collection was

done to understand the methodology and material

selection.

Remote control top panel was modeled and designed

mold tool for the same using parametric software

creo-2.0 (pro-engineer).

Mold flow analysis was conducted on part by varying plastic materials.

tronic version) ISSN 1503-8181 Doctoral theses at

NTNU, 2008:113

4]. B. Sidda Reddy 1,*, J. Suresh Kumar2, Vijaya

Kumar Reddy2 and G. Padmanabhan3 1 Department of Mechanical Engineering, R. G. M. College

of Engineering & Technology, Nandyal, Kurnool

(Dt), A.P-518 501, India. 2 Mechanical Engineering,

J.N.T University, Hyderabad, India. 3 Mechanical

Engineering, S.V. University College of Engineering,

S.V. University, Tirupati, A.P. India

5]. Omar A. Mohamed, S.H. Masood, AbulSaifullah

Faculty of Engineering and Industrial Science, Swinburne University of Technology, Hawthorn, Melbourne, Australia Corresponding Email: smasood@

swin.edu.au

As per flow analysis P.P (polypropylene) is showing

good characteristics in confidence of fill and quality

with in low pressure and less drop, but it requires

little bit high temperature than other materials.

6]. Mohammad Aashiq M1, Arun A.P1, Parthiban

M2 1 PGD IN TOOL & DIE DESIGN ENGINEERINGPSG IAS 2 ASST.PROFESSOR DEPARTMENT OF

MECHANICAL ENGINEERING-PSG CT Coimbatore

641004, India

Thermal analysis is done in ansys work bench by

varying cooling channel systems to analyze thermal

behavior.

7]. JiajunShen An Engineering Project Submitted

to the Graduate Faculty of Rensselaer Polytechnic

Institute

As per thermal analysis spiral system is showing

good quality in providing sufficient cooling effect to

the part.

Authors

As per above analysis results this project work concludes that remote control with P.P (polypropylene)

material along with spiral cooling channel system

gives good quality product due to its quality of filling

and sufficient cooling effect.

References

1]. P. Postawa*, D. Kwiatkowski, E. Bociaga Institute of Polymer Processing and Production Management, Czestochowa University of Technology, al.

ArmiiKrajowej 19c, 42-200 Czstochowa, PolandCorresponding author: E-mail address: postawa@

kpts.pcz.czest.pl

2]. Hong-Seok Park and Xuan-Phuong Dang University of Ulsan South Korea Z. Shayfull*1, M.F.

Ghazali1, M. Azaman1, S.M. Nasir1, N.A. Faris2

1School of Manufacturing Engineering, Universiti

Malaysia Perlis, Malaysia 2Politeknik Sultan Abdul

HalimMuadzam Shah (POLIMAS), Malaysia shayfull@unimap.edu.my

3].Lars-Erik Rnnar ISBN 978-82-471-8270-3

(printed version) ISBN 978-82-471-8284-0 (elec-

vadlamannati venkata krishna mohan

25 Years Teching Experience In Govt Polytechnic

College

D.Gopichand

Qualification: m.tech

Designation: assistant profressor

Experience :4 yr in teaching & 2 yr experience in

InfoTech as design engineer

25

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MC Case PDFDocument20 pagesMC Case PDFShivani KarkeraNo ratings yet

- Leg Support Calculation PDFDocument2 pagesLeg Support Calculation PDFSanjay MoreNo ratings yet

- CFD Analysis On Pulsating Heat Pipe To Improve Heat TransferDocument5 pagesCFD Analysis On Pulsating Heat Pipe To Improve Heat TransferijripublishersNo ratings yet

- Ijri Cce 01 010Document22 pagesIjri Cce 01 010ijripublishersNo ratings yet

- Structural and Modal Analysis of An Engine Block by Varying MaterialsDocument4 pagesStructural and Modal Analysis of An Engine Block by Varying MaterialsijripublishersNo ratings yet

- Modeling and Thermal Analysis of Air-Conditioner EvaporatorDocument6 pagesModeling and Thermal Analysis of Air-Conditioner Evaporatorijripublishers100% (1)

- Ijri Cce 01 008Document16 pagesIjri Cce 01 008ijripublishersNo ratings yet

- International Journal of Research and Innovation : Model On Carpooling Technique To Reduce Congestion 1401-1402Document7 pagesInternational Journal of Research and Innovation : Model On Carpooling Technique To Reduce Congestion 1401-1402ijripublishersNo ratings yet

- Ijri Cce 02 004Document7 pagesIjri Cce 02 004ijripublishersNo ratings yet

- CFD Analysis On Ejector Cooling System With Variable Throat GeometryDocument6 pagesCFD Analysis On Ejector Cooling System With Variable Throat GeometryijripublishersNo ratings yet

- Ijri Cce 01 012Document9 pagesIjri Cce 01 012ijripublishersNo ratings yet

- International Journal of Research and Innovation : Strengthening of RC Beams Using FRP Sheet 1401-1402Document13 pagesInternational Journal of Research and Innovation : Strengthening of RC Beams Using FRP Sheet 1401-1402ijripublishersNo ratings yet

- Ijri Cce 01 006Document13 pagesIjri Cce 01 006ijripublishersNo ratings yet

- Ijri Cce 02 007Document8 pagesIjri Cce 02 007ijripublishersNo ratings yet

- Ijri Cce 02 006Document9 pagesIjri Cce 02 006ijripublishersNo ratings yet

- Ijri Cce 01 005Document4 pagesIjri Cce 01 005ijripublishersNo ratings yet

- Ijri Cce 02 005Document7 pagesIjri Cce 02 005ijripublishersNo ratings yet

- Ijri Cce 01 009Document9 pagesIjri Cce 01 009ijripublishersNo ratings yet

- Ijri Cce 02 008Document8 pagesIjri Cce 02 008ijripublishersNo ratings yet

- Ijri Cce 01 011Document6 pagesIjri Cce 01 011ijripublishersNo ratings yet

- Ijri Cce 01 002Document7 pagesIjri Cce 01 002ijripublishersNo ratings yet

- Ijri Cce 01 003Document12 pagesIjri Cce 01 003ijripublishersNo ratings yet

- Problem: Determine The Total Volume of Earth To Be Excavated Up To Elevation 0Document17 pagesProblem: Determine The Total Volume of Earth To Be Excavated Up To Elevation 0gtech00100% (1)

- Palliative Ultrasound-Guided Endoscopic Diode Laser Ablation of Transitional Cell Carcinomas of The Lower Urinary Tract in Dogs.Document10 pagesPalliative Ultrasound-Guided Endoscopic Diode Laser Ablation of Transitional Cell Carcinomas of The Lower Urinary Tract in Dogs.Dante Nathaniel FajardoNo ratings yet

- English Final Test Grade XiiDocument9 pagesEnglish Final Test Grade XiiLiza RahmawatiNo ratings yet

- ManvantaraDocument3 pagesManvantaraafterragnarokNo ratings yet

- CSC 2701 - CalculusDocument5 pagesCSC 2701 - CalculusMd Rubaiyat BhuiyanNo ratings yet

- Material Balance PDFDocument31 pagesMaterial Balance PDFApril Joy HaroNo ratings yet

- ProductSheet Iq200 Rackmount SatelliteModemDocument2 pagesProductSheet Iq200 Rackmount SatelliteModemAsim Penkar PenkarNo ratings yet

- TSB-1139 8SC Wiring DiagramDocument2 pagesTSB-1139 8SC Wiring Diagramxavier marsNo ratings yet

- Hilton Chapter 5 Adobe Connect Activity-Based Costing and ManagementDocument11 pagesHilton Chapter 5 Adobe Connect Activity-Based Costing and ManagementyosepjoltNo ratings yet

- He Is A Chocolate Lover: Kamaladevi RengasamyDocument4 pagesHe Is A Chocolate Lover: Kamaladevi RengasamyKamala DeviNo ratings yet

- Plant Hormones PDFDocument5 pagesPlant Hormones PDFYASHNo ratings yet

- HPB21-0457 FINAL Submittal 09-07-2021 - Ritz Sagamore LOIDocument13 pagesHPB21-0457 FINAL Submittal 09-07-2021 - Ritz Sagamore LOIthe next miamiNo ratings yet

- Biology Investigatory Project: Malaria: Its Effects and CausesDocument17 pagesBiology Investigatory Project: Malaria: Its Effects and CausesRishi KeshavNo ratings yet

- Free Download All Aeronautical Engg Books: AERO 3-1 BOOKSDocument11 pagesFree Download All Aeronautical Engg Books: AERO 3-1 BOOKSMacen SnoodleNo ratings yet

- A Clinical Audit Into The Success Rate of Inferior Alveolar Nerve Block Analgesia in General Dental PracticeDocument4 pagesA Clinical Audit Into The Success Rate of Inferior Alveolar Nerve Block Analgesia in General Dental PracticeGina CastilloNo ratings yet

- SONTU Flat Panel Dectector CatalogDocument6 pagesSONTU Flat Panel Dectector CatalogWajahat SheikhNo ratings yet

- Ignatian SpiritualityDocument16 pagesIgnatian SpiritualityMihai Frentz100% (2)

- Petroleum Engineering Lab 1 (PGE313) Experiment 2 Determination of PorosityDocument13 pagesPetroleum Engineering Lab 1 (PGE313) Experiment 2 Determination of PorosityAli AbubakarNo ratings yet

- Cefixime and Palpitations - From FDA ReportsDocument3 pagesCefixime and Palpitations - From FDA ReportsMuhammad UbaidNo ratings yet

- Asme A13.1 - 1996Document27 pagesAsme A13.1 - 1996lohv100% (1)

- Allotrope Partners Indonesia Renewable Energy Project AssociateDocument2 pagesAllotrope Partners Indonesia Renewable Energy Project AssociateRizal ZulkarnaenNo ratings yet

- Transport Phenomena: τ =μ dv dyDocument2 pagesTransport Phenomena: τ =μ dv dySYED ASGHAR ALI SULTANNo ratings yet

- Ipc DRM 18FDocument34 pagesIpc DRM 18FThamilvaanan.sNo ratings yet

- NASA NOAA Earth Sciences Letter To TrumpDocument6 pagesNASA NOAA Earth Sciences Letter To TrumpMelissa Meehan BaldwinNo ratings yet

- Pablocastillo PDFDocument44 pagesPablocastillo PDFPabloNo ratings yet

- NEW Sales Tax Invoice - 2023-07-27T164634.549Document1 pageNEW Sales Tax Invoice - 2023-07-27T164634.549Saadat IrfanNo ratings yet

- MATH 4 PPT Q3 W4 - Lesson 52 - Quadrilateral 1Document17 pagesMATH 4 PPT Q3 W4 - Lesson 52 - Quadrilateral 1Erika Mae TupagNo ratings yet

- Behaviour of Hollow Core Slabs Under Point LoadsDocument17 pagesBehaviour of Hollow Core Slabs Under Point LoadsVálter LúcioNo ratings yet