Professional Documents

Culture Documents

Sine Wave Tracking: Getting The Most From Your Surge Proctective Devices (SPDS)

Sine Wave Tracking: Getting The Most From Your Surge Proctective Devices (SPDS)

Uploaded by

Alejandro Romero SepulvedaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sine Wave Tracking: Getting The Most From Your Surge Proctective Devices (SPDS)

Sine Wave Tracking: Getting The Most From Your Surge Proctective Devices (SPDS)

Uploaded by

Alejandro Romero SepulvedaCopyright:

Available Formats

Sine Wave Tracking

Getting the Most From Your Surge Proctective Devices (SPDs)

August 2012 / 9910-0005A

Sine wave tracking is a term that has been used

throughout the surge industry for many years. In

the early 1990s it was Schneider ElectricTM who

first introduced the sine wave tracking concept in

their surge protection plug-strips with their Sine

Wave Tracker technology. Since then many

Surge Protective Device (SPD) manufacturers have

followed with their own versions and trade marked

names.

Over the years sine wave tracking has been

misinterpreted and incorrectly specified. Many

perceive sine wave tracking to relate to the noise

attenuation and filtering characteristics of an

SPD which is not correct. The purpose of this

document is to provide a clear understanding

of what sine wave tracking is, the benefits it

can provide, and where these SPDs should be

installed.

Not all SPDs provide this technology. SPDs

that DO NOT incorporate sine wave tracking are

referred to as threshold clamping SPDs.

Threshold clamping SPDs establish their clamping

voltage irrespective of the instantaneous sine

wave. Depending on the phase angle in which

the transient is induced, the overall clamping or letthrough voltage level will vary as the voltage must

reach the set threshold before it starts to respond.

The threshold is determined by the ratings of

the Metal Oxide Varistors (MOVs) or other surge

components that are utilized. Typically that

threshold is set 15-25% above the nominal system

voltage and is represented as the Maximum

Continuous Operating Voltage (MCOV) of the

device. (Figure 1)

Figure 1: Threshold Clamping

Threshold Clamping (+)

What is sine wave tracking?

Sine wave tracking is a descriptive term

commonly used by manufacturers to express a

principle of operation. Sine wave tracking itself

is not a recognized attribute of an SPD within

the industry standards committees. Unlike other

SPD performance values such as MCOV, VPR,

In or SCCR which are clearly defined, there are

no industry approved standard definitions or test

procedures found within UL, IEEE, NEMA, IEC or

other standards bodies for sine wave tracking and

its performance characteristics.

Let-through

voltage

90

Let-through

voltage

180

Let-through

voltage

270

Threshold Clamping (-)

Schneider Electric, who first introduced the Sine

Wave Tracker technology to the SPD industry,

defines sine wave tracking as:

With a threshold clamping SPD a transient voltage

must reach a pre-defined level before the SPD will

react and start to suppress the transient.

Sine wave tracking The ability of an SPD

to suppress high frequency, low-energy

ring wave transients, providing uniform

suppression around the fundamental

voltage waveform regardless of the phase

angle at which a surge is induced.

Sine wave tracking SPDs incorporate hybrid

circuitry to effectively suppress high frequency, low

energy ring wave transients, at whatever phase

angle they occur. Because of this, they provide

better (lower) clamping or let-through levels than

threshold clamping devices and create uniform

protection levels, regardless of the phase angle of

the transient. (Figure 2)

Sine Wave Tracking

Getting the Most From Your Surge Protective Devices (SPDs)

Figure 2: Sine Wave Tracking

that are generated outside a facility. Lightning,

utility switching, and other unexpected electrical

events are some examples that may cause these

impulse transients.

Let-through

voltage

90

Ring wave transients are found internal to a facility.

As loads are constantly being switched on and off

many smaller transients are being induced into the

distribution system. The inductance, capacitance,

and resistance of the overall distribution systems

cause these transients to take on a ringing shape.

Let-through

voltage

180

Sine wave tracking

window of suppression

Let-through

voltage

270

Laboratory testing on both threshold clamping,

and sine wave tracking SPDs clearly show the

benefits of the hybrid circuitry found within sine

wave tracking SPDs.

Studies show that the majority of all transients

(80%) are generated inside a facility while only 20%

come externally from the utility side. However, as

the impulse type transients progress through the

distribution system they too will slowly take on ring

wave characteristics.

Let-through voltage is measured from the point of

insertion (i.e. 90, 180, 270) to the peak of the

suppressed surge voltage.

Sine wave tracking SPDs are designed to respond

to these high frequency, low energy ring wave

transients. The hybrid technology used in sine

wave tracking enabled SPDs is capable of sensing

a sudden change of voltage (dv/dt) and will react

to it immediately. By doing so it provides much

better clamping performance over the threshold

clamping SPDs. Lower clamping at the SPD

level directly relates to lower surge voltages down

stream at the sensitive equipment.

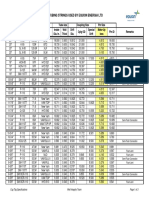

Table 1: Let-through Voltage 2

Getting the most out of your SPD

When subjected to a Category A ring wave as

defined in ANSI/IEEE C62.41-2002 1, the letthrough voltage is measured at varying phase

angles and compared against each other. (Table 1)

Phase Angle

Threshold

Sine wave

clamping SPD

tracking SPD

90

194v

78v

180

362v

78v

270

524v

78v

As shown by the testing, the let-through voltages

of the threshold clamping SPD range from 2.5

times up to 6.5 times the let-through voltage of

the sine wave tracking SPD, depending on the

induced phase angle. Sine wave tracking SPDs

certainly provides the better and more uniform

suppression against ring wave transients.

Ring Wave Transients are they real?

There are two types of transients that have been

described in ANSI/IEEE C62.41.2-2002: the

impulse type transient and the ring wave type

transient.

Impulse transients are typical of those transients

Threshold clamping SPDs do have their place

and provide great surge suppression for electrical

distribution systems. As with many products you

buy today, there are optional features that can be

added making a good thing even better. And,

as with other products additional options and

features, such as sine wave tracking, will typically

increase the cost of an SPD.

When placing any SPD into service there are

a number of factors that one should take into

consideration. One of the most critical factors is

location. At which locations should sine wave

tracking SPDs be utilized?

As the hybrid technology is designed for ring wave

type transients, it makes the most sense to place

these SPDs within the distribution system where

ring waves are being generated. One will get the

most benefit from sine wave tracking SPDs when

placed at the sub-panel levels of the distribution

system, where they are more likely be exposed to

ring wave transients.

Schneider Electric USA, Inc. 1751 S. 4800 W., Salt Lake City, UT 84104, USA

Document Number 9910-0005A

Telephone: (801)-977-9009

Fax: (801)-977-0200

www.surgelogic.com

August 2012

bw

Choosing the Right Level of Protection

Specifying sine wave tracking

When specifying, referencing, or comparing

performance criteria around sine wave tracking,

the best way to evaluate its effectiveness is to

measure the let through voltage at a number

of phase angles such as 90, 180 and 270.

These are good references and commonly used

measurement points.

As described by NEMASurge.com in the FAQ

section All SPDs with capacitive RFI/EMI filtering

exhibit sine wave tracking abilities 3. So specifying

sine wave tracking simply means that an SPD

contains hybrid circuitry in addition to threshold

components.

However, a simple Yes to the question, Does

the SPD have sine wave tracking? does not tell

the full story. Two SPDs that both have sine wave

tracking characteristics may have very different

performance values when subjected to transients

at various phase angles.

The let-through voltage of a sine wave tracking

SPD is not a set value. The type, size, design,

number of components, and actual current effects

how tight the clamping window is around the

sine wave. It is up to the end user to determine

what is sufficient for the application. The lower

the let-through voltage, the better suppression the

SPD is providing.

Many manufacturers describe their sine wave

tracking performance in dB of attenuation. This

is a unit of measure used to characterize the

performance of EMI/RFI filters. Circuitry used

in providing sine wave tracking typically also

provides EMI/RFI filtering. Typically, an SPD that

has enhanced EMI/RFI filtering will also provide

an increased level of sine wave tracking and vice

versa. While the dB of attenuation gives some

indication of the filtering capability of the SPD,

dB of attenuation should not be used to indicate

the level of sine wave tracking. The best way to

quantify the sine wave tracking capability of the

SPD is the measurement of let-through voltages at

various points of the sine wave.

Conclusion

Surge Protective Devices are installed into

electrical distribution systems for one reason: to

shunt and suppress the transient surge voltages

that are being induced from both internal and

external sources.

Many manufacturers have followed Schneider

Electric by incorporating sine wave tracking

technology into their SPDs to provide an added

level of suppression against ring wave transients.

This added level of suppression helps safeguard

the electronics found deep inside a distribution

system that could be sensitive to ringing or

oscillations.

Things to remember:

Sine wave tracking is most effective against

ring wave transients.

Sine wave tracking SPDs are most effective

when placed at the sub-panel level of the

distribution system where ring wave transients

are being generated.

Sine wave tracking SPDs provide uniform

suppression against ring wave transients.

Quantifying sine wave tracking capabilities of

an SPD is the measurement of let-through

voltages when the SPD is surged at various

points of the sine wave. dB of attenuation

should not be used to indicate the level of sine

wave tracking.

Having the proper understanding of what sine

wave tracking truly is, will help you identify those

applications where the technology should be used.

Implementing sine wave tracking correctly will

ensure you are getting the most from your SPD.

References

1. ANSI/IEEE C62.41.2-2002, Section 6.1.1

2. Table 1. Test results reflect 120v Schneider electric

product when subjected to the Category A ring wave

with a peak voltage of 2kV and a peak current of

67A.

3. nemasurge.com - Permission to reprint granted by

NEMA.

Schneider Electric USA, Inc. 1751 S. 4800 W., Salt Lake City, UT 84104, USA

Document Number 9910-0005A

2012 Schneider Electric. All rights reserved.

Schneider Electric and Sine Wave Tracker are trademarks owned by Schneider Electric Industries SAS or its affiliated companies. All other trademarks are the property of their respective owners.

IEEE category C locations, typically service

entrance and outdoor locations, are most often

subjected to impulse transients. Sine wave

tracking provides little benefit with large impulse

transients. If an SPD is intended only to mitigate

large impulse transients, sine wave tracking may

not provide much benefit. However, if switching

components are located near a category C

location, sine wave tracking can provide some

benefit.

Telephone: (801)-977-9009

Fax: (801)-977-0200

www.surgelogic.com

August 2012

bw

You might also like

- Toyota Sienta 2017 Owner's Manual-2Document212 pagesToyota Sienta 2017 Owner's Manual-2F R0% (1)

- Borri Ups b9000 Ups Service ManualDocument199 pagesBorri Ups b9000 Ups Service ManualKhalid MehmoodNo ratings yet

- Detector de Humo Fotoelectrico CONV 71 - 55Document4 pagesDetector de Humo Fotoelectrico CONV 71 - 55heberthNo ratings yet

- Catalog SurgelogicDocument14 pagesCatalog SurgelogicLuizNo ratings yet

- Shadow AlarmDocument36 pagesShadow Alarmanuvaishnavi60% (5)

- YD13 YD133 YL13 Transmission Service Manual PDFDocument100 pagesYD13 YD133 YL13 Transmission Service Manual PDFadelmomoura100% (3)

- Rca TV 19la30rq ManualDocument46 pagesRca TV 19la30rq ManualiskibanoydNo ratings yet

- PDA100A ManualDocument17 pagesPDA100A ManualMahmoud AllawiNo ratings yet

- Rudolf - Surge Protective DeviceDocument7 pagesRudolf - Surge Protective DevicesanankhanNo ratings yet

- Frequently Asked Questions: NEMA Surge Protection InstituteDocument11 pagesFrequently Asked Questions: NEMA Surge Protection InstituteDeep ManNo ratings yet

- Surge Protection Catalogue of AustraliaDocument44 pagesSurge Protection Catalogue of AustraliaSrikanth NakkaNo ratings yet

- Surge Protection Device (SPD) Faqs & DefinitionsDocument8 pagesSurge Protection Device (SPD) Faqs & DefinitionsAlexander RemachaNo ratings yet

- Report - Phase ShifterDocument8 pagesReport - Phase ShifterAmeer AliNo ratings yet

- E1289B-WWEN - SRF N Series - NventDocument16 pagesE1289B-WWEN - SRF N Series - NventmaungmaunglattNo ratings yet

- Arc Flash Analysis: Electrical SafetyDocument16 pagesArc Flash Analysis: Electrical SafetyOsha InstructorsNo ratings yet

- Stahl 9000Document3 pagesStahl 9000Leonardo De La ViaNo ratings yet

- T2 - Proximity Transducer System OperationDocument34 pagesT2 - Proximity Transducer System OperationarijitnagNo ratings yet

- Study of Micro Wave Components-1Document6 pagesStudy of Micro Wave Components-1narasimhaNo ratings yet

- Laser Intruder AlarmDocument16 pagesLaser Intruder AlarmSohail G BittuNo ratings yet

- PA Probe Catalog en 201304Document24 pagesPA Probe Catalog en 201304Durgamadhaba Mishra100% (2)

- To Protection: Surge A PathDocument4 pagesTo Protection: Surge A PathLuis RomeroNo ratings yet

- Product Data Sheet: Tesys K - Differential Thermal Overload Relays - 3.7... 5.5 A - Class 10ADocument3 pagesProduct Data Sheet: Tesys K - Differential Thermal Overload Relays - 3.7... 5.5 A - Class 10Aakbar55555No ratings yet

- 9.ESD SuppressionDocument62 pages9.ESD Suppressionmuvin236100% (1)

- Fault LocatorDocument4 pagesFault LocatorRobert MihayoNo ratings yet

- Microwave ExperimentDocument37 pagesMicrowave Experimentsufiyan aliNo ratings yet

- GFL 1000newDocument3 pagesGFL 1000newElvio MNo ratings yet

- Suppliers of Ese Lightning Conductor Kalre Lightning ArresterDocument2 pagesSuppliers of Ese Lightning Conductor Kalre Lightning ArresterRemedies EarthingNo ratings yet

- MX Series Pulser Options: Instruction ManualDocument16 pagesMX Series Pulser Options: Instruction ManualRómulo Zevallos GutiérrezNo ratings yet

- Data Sheet R-SeriesV RM5 Analog 552114 ENDocument12 pagesData Sheet R-SeriesV RM5 Analog 552114 ENdylancottrill.the84groupNo ratings yet

- Analog Sensors AssignmentDocument7 pagesAnalog Sensors AssignmentPathum SudasingheNo ratings yet

- PA Probe Catalog en 201308Document24 pagesPA Probe Catalog en 201308Alvaro Alexis Mendoza PradaNo ratings yet

- Protech Technologies SDI-76M-HS1 Instruction ManualDocument4 pagesProtech Technologies SDI-76M-HS1 Instruction ManualJMAC SupplyNo ratings yet

- Spec Sheet: S322C Thermal Power HeadDocument4 pagesSpec Sheet: S322C Thermal Power HeadHP ghnNo ratings yet

- Magnetic Polarity Detector Circuit Using Hall Effect SensorDocument11 pagesMagnetic Polarity Detector Circuit Using Hall Effect SensorKoushik MaityNo ratings yet

- Wireless Object LocatorDocument37 pagesWireless Object Locatorbalu540% (1)

- Data Sheet E-Series ER Analog 551246 ENDocument7 pagesData Sheet E-Series ER Analog 551246 ENShanks DiexNo ratings yet

- RM st60Document2 pagesRM st60Hồ ThànhNo ratings yet

- 300 Series: 330/320 Surge Protective DeviceDocument8 pages300 Series: 330/320 Surge Protective DeviceComspec MarketingNo ratings yet

- Using Surge Suppressor With VAMP Protection Relays: Application NoteDocument3 pagesUsing Surge Suppressor With VAMP Protection Relays: Application NoteUdit SharmaNo ratings yet

- Installation of Vibration SensorsDocument8 pagesInstallation of Vibration SensorsnmguravNo ratings yet

- Cable Fault Locators Surge Wave Generators An OverviewDocument4 pagesCable Fault Locators Surge Wave Generators An OverviewSMART REFILLNo ratings yet

- Protect Your Investment, Reduce Your System DowntimeDocument4 pagesProtect Your Investment, Reduce Your System DowntimeJuan Esteban Benjumea BenjumeaNo ratings yet

- SF810INTDocument15 pagesSF810INTarhamsg001No ratings yet

- Light Emitting Diode ColourDocument9 pagesLight Emitting Diode Colourmariamamr28624No ratings yet

- Wurth The Protection of USB 20 ApplicationsDocument9 pagesWurth The Protection of USB 20 ApplicationsRaul ArenasNo ratings yet

- Alineamiento Antena ALUDocument4 pagesAlineamiento Antena ALUmaximusandNo ratings yet

- Arc Flash Analysis: Electrical SafetyDocument16 pagesArc Flash Analysis: Electrical SafetyChaitanya MajalukodiNo ratings yet

- Spectrum Analyzer: Operation ManualDocument39 pagesSpectrum Analyzer: Operation ManualNeljan Agad CuñadoNo ratings yet

- Micrometer: ProbeDocument27 pagesMicrometer: ProbeJêmš NavikNo ratings yet

- RS Calibration Isotech-3610DDocument23 pagesRS Calibration Isotech-3610DMe MeNo ratings yet

- Sensore - SS443RDocument11 pagesSensore - SS443RPAOLONo ratings yet

- Si Instruction-Digital 202205 ENDocument4 pagesSi Instruction-Digital 202205 ENaripmujitoNo ratings yet

- Page 1 of 6: Effective Date 7/2007 PS01005002EDocument4 pagesPage 1 of 6: Effective Date 7/2007 PS01005002EkrcdewanewNo ratings yet

- SMA Grid Guard 2 Certified in Accordance With VDE 0126 - 1-1: Background, Development and Requirements of The New StandardDocument9 pagesSMA Grid Guard 2 Certified in Accordance With VDE 0126 - 1-1: Background, Development and Requirements of The New StandardkotiniNo ratings yet

- AND9009/D Types of Electrical Overstress Protection: Application NoteDocument13 pagesAND9009/D Types of Electrical Overstress Protection: Application Notev2304451No ratings yet

- 938 Aurora Boulevard, Cubao, Quezon City: Technological Institute of The PhilippinesDocument10 pages938 Aurora Boulevard, Cubao, Quezon City: Technological Institute of The PhilippinesMikko OmanaNo ratings yet

- Dat SWG en 160729Document4 pagesDat SWG en 160729SMART REFILLNo ratings yet

- Surge Protection Technical TrainingDocument52 pagesSurge Protection Technical TrainingAndrewcaesarNo ratings yet

- TDR RI-407 User Manual ENG v3Document69 pagesTDR RI-407 User Manual ENG v3Phong DuongNo ratings yet

- ABB Low Voltage Surge Arrester PDFDocument8 pagesABB Low Voltage Surge Arrester PDFrajpre1213No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Catalogue 2008Document29 pagesCatalogue 2008cpan67No ratings yet

- Crimp Tool For King InstallsDocument6 pagesCrimp Tool For King InstallssafariNo ratings yet

- WEEK 3 Summer PDFDocument19 pagesWEEK 3 Summer PDFRandall Lyn BlascoNo ratings yet

- MX2300 2700G N SM Installation Manual GBDocument88 pagesMX2300 2700G N SM Installation Manual GBsebulba1234No ratings yet

- Lecture-5 Auto-Transformer, Harmonics and Energy ConversionDocument44 pagesLecture-5 Auto-Transformer, Harmonics and Energy ConversionRohit SenNo ratings yet

- Carlos Gavazzi RVCF Drive Advanced User ManualDocument122 pagesCarlos Gavazzi RVCF Drive Advanced User ManualCarlos P100% (1)

- LED Series Parallel Array Wizardled 3mmDocument4 pagesLED Series Parallel Array Wizardled 3mmalbertanton99No ratings yet

- Tank MagnetsDocument2 pagesTank MagnetsAlexisAlejandroSandovalFloresNo ratings yet

- AHU, MAU Preventive Maintenance RoasterDocument30 pagesAHU, MAU Preventive Maintenance RoasternizamNo ratings yet

- Spare Parts List Cab ExteriorDocument5 pagesSpare Parts List Cab ExteriorApexiNo ratings yet

- Case VAIDocument99 pagesCase VAITractorDiéselNo ratings yet

- WC 52xx & 53xxDocument5 pagesWC 52xx & 53xxVj PatelNo ratings yet

- 8253Document17 pages8253Parv SharmaNo ratings yet

- Fa5500ap FujiDocument26 pagesFa5500ap FujiAlooomNo ratings yet

- Project Report 1Document20 pagesProject Report 1ernestoNo ratings yet

- Day Work Road Maintenance IPDSDocument3 pagesDay Work Road Maintenance IPDSazwar arsyadNo ratings yet

- Design Considerations To Optimize Stator Manufacturing: Outside Diameter ShapeDocument8 pagesDesign Considerations To Optimize Stator Manufacturing: Outside Diameter ShapeCarlosNo ratings yet

- OKI Printer Error CodesDocument4 pagesOKI Printer Error CodesReginaldo BandeiraNo ratings yet

- KSB RioRioZDocument32 pagesKSB RioRioZSrdjanNo ratings yet

- Electrical Solutions For The Oil and Gas IndustryDocument32 pagesElectrical Solutions For The Oil and Gas IndustrycubarturNo ratings yet

- Genie S-40 S045 Manual PDFDocument325 pagesGenie S-40 S045 Manual PDFstephen prosserNo ratings yet

- Camshaft Position Sensor ADocument4 pagesCamshaft Position Sensor ADannyDDannyDNo ratings yet

- Symbol SNI Elektronik Dan ListrikDocument7 pagesSymbol SNI Elektronik Dan ListrikInyomanKrishnaNo ratings yet

- Instrumentation 3e Level 3 Courseplanning PDFDocument44 pagesInstrumentation 3e Level 3 Courseplanning PDFSameer PawarNo ratings yet

- Class - 10 - LN - 12 - Class TestDocument8 pagesClass - 10 - LN - 12 - Class TestSrivatsan BalajiNo ratings yet

- CSG TBG Dimensions PDFDocument3 pagesCSG TBG Dimensions PDFElisa Maria Angulo VanegasNo ratings yet